AC Wiring DODGE RAM 1500 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 573 of 2627

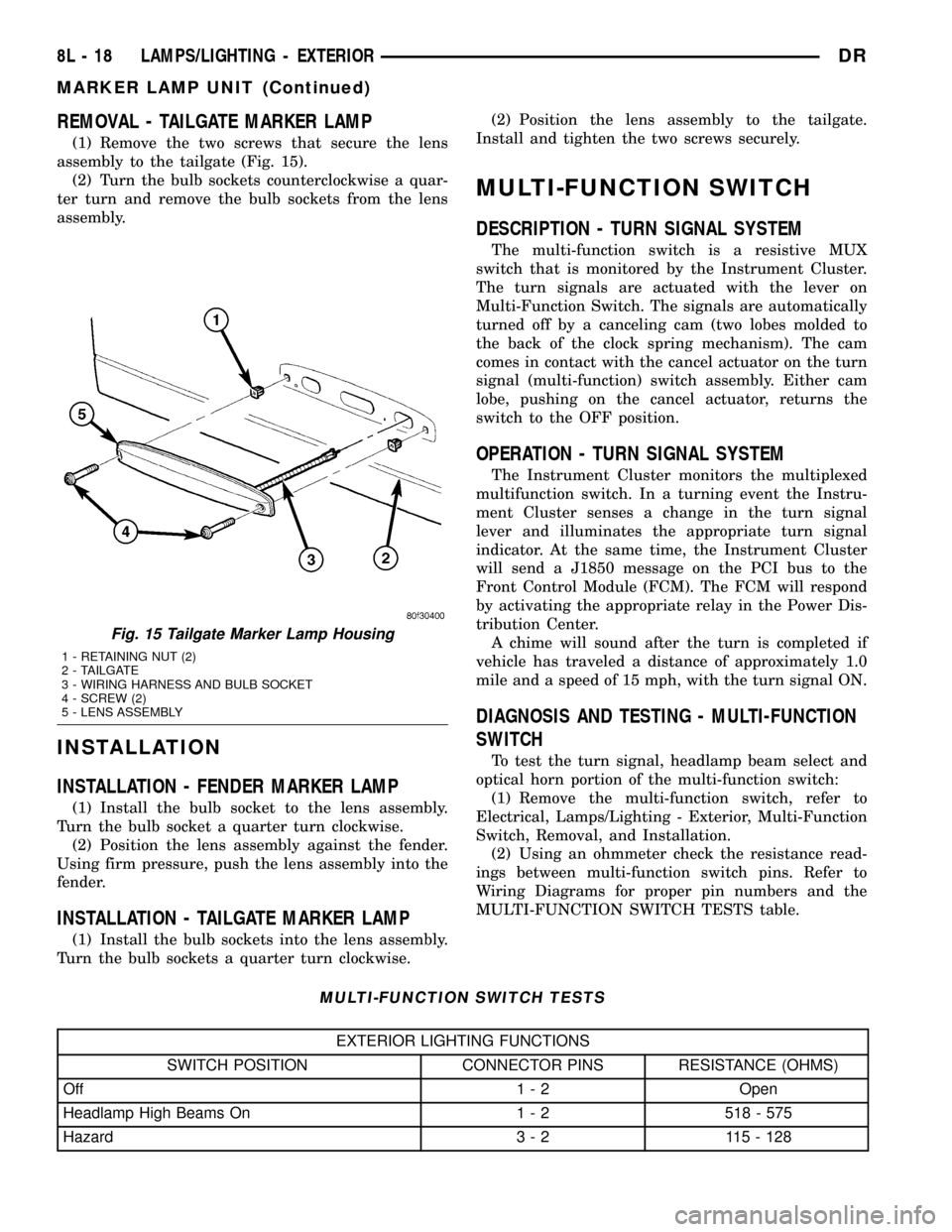

REMOVAL - TAILGATE MARKER LAMP

(1) Remove the two screws that secure the lens

assembly to the tailgate (Fig. 15).

(2) Turn the bulb sockets counterclockwise a quar-

ter turn and remove the bulb sockets from the lens

assembly.

INSTALLATION

INSTALLATION - FENDER MARKER LAMP

(1) Install the bulb socket to the lens assembly.

Turn the bulb socket a quarter turn clockwise.

(2) Position the lens assembly against the fender.

Using firm pressure, push the lens assembly into the

fender.

INSTALLATION - TAILGATE MARKER LAMP

(1) Install the bulb sockets into the lens assembly.

Turn the bulb sockets a quarter turn clockwise.(2) Position the lens assembly to the tailgate.

Install and tighten the two screws securely.

MULTI-FUNCTION SWITCH

DESCRIPTION - TURN SIGNAL SYSTEM

The multi-function switch is a resistive MUX

switch that is monitored by the Instrument Cluster.

The turn signals are actuated with the lever on

Multi-Function Switch. The signals are automatically

turned off by a canceling cam (two lobes molded to

the back of the clock spring mechanism). The cam

comes in contact with the cancel actuator on the turn

signal (multi-function) switch assembly. Either cam

lobe, pushing on the cancel actuator, returns the

switch to the OFF position.

OPERATION - TURN SIGNAL SYSTEM

The Instrument Cluster monitors the multiplexed

multifunction switch. In a turning event the Instru-

ment Cluster senses a change in the turn signal

lever and illuminates the appropriate turn signal

indicator. At the same time, the Instrument Cluster

will send a J1850 message on the PCI bus to the

Front Control Module (FCM). The FCM will respond

by activating the appropriate relay in the Power Dis-

tribution Center.

A chime will sound after the turn is completed if

vehicle has traveled a distance of approximately 1.0

mile and a speed of 15 mph, with the turn signal ON.

DIAGNOSIS AND TESTING - MULTI-FUNCTION

SWITCH

To test the turn signal, headlamp beam select and

optical horn portion of the multi-function switch:

(1) Remove the multi-function switch, refer to

Electrical, Lamps/Lighting - Exterior, Multi-Function

Switch, Removal, and Installation.

(2) Using an ohmmeter check the resistance read-

ings between multi-function switch pins. Refer to

Wiring Diagrams for proper pin numbers and the

MULTI-FUNCTION SWITCH TESTS table.

MULTI-FUNCTION SWITCH TESTS

EXTERIOR LIGHTING FUNCTIONS

SWITCH POSITION CONNECTOR PINS RESISTANCE (OHMS)

Off 1 - 2 Open

Headlamp High Beams On 1 - 2 518 - 575

Hazard 3 - 2 115 - 128

Fig. 15 Tailgate Marker Lamp Housing

1 - RETAINING NUT (2)

2 - TAILGATE

3 - WIRING HARNESS AND BULB SOCKET

4 - SCREW (2)

5 - LENS ASSEMBLY

8L - 18 LAMPS/LIGHTING - EXTERIORDR

MARKER LAMP UNIT (Continued)

Page 575 of 2627

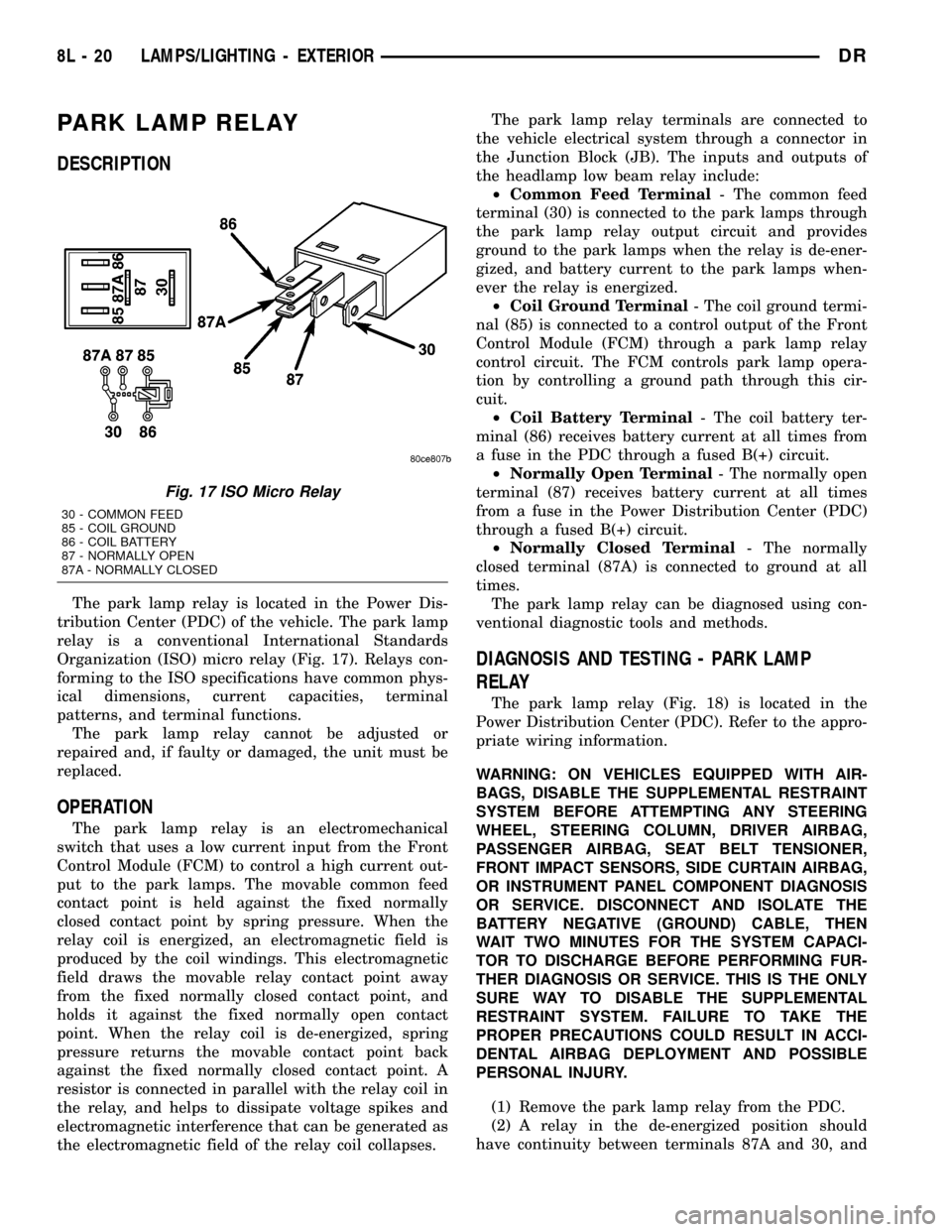

PARK LAMP RELAY

DESCRIPTION

The park lamp relay is located in the Power Dis-

tribution Center (PDC) of the vehicle. The park lamp

relay is a conventional International Standards

Organization (ISO) micro relay (Fig. 17). Relays con-

forming to the ISO specifications have common phys-

ical dimensions, current capacities, terminal

patterns, and terminal functions.

The park lamp relay cannot be adjusted or

repaired and, if faulty or damaged, the unit must be

replaced.

OPERATION

The park lamp relay is an electromechanical

switch that uses a low current input from the Front

Control Module (FCM) to control a high current out-

put to the park lamps. The movable common feed

contact point is held against the fixed normally

closed contact point by spring pressure. When the

relay coil is energized, an electromagnetic field is

produced by the coil windings. This electromagnetic

field draws the movable relay contact point away

from the fixed normally closed contact point, and

holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.The park lamp relay terminals are connected to

the vehicle electrical system through a connector in

the Junction Block (JB). The inputs and outputs of

the headlamp low beam relay include:

²Common Feed Terminal- The common feed

terminal (30) is connected to the park lamps through

the park lamp relay output circuit and provides

ground to the park lamps when the relay is de-ener-

gized, and battery current to the park lamps when-

ever the relay is energized.

²Coil Ground Terminal- The coil ground termi-

nal (85) is connected to a control output of the Front

Control Module (FCM) through a park lamp relay

control circuit. The FCM controls park lamp opera-

tion by controlling a ground path through this cir-

cuit.

²Coil Battery Terminal- The coil battery ter-

minal (86) receives battery current at all times from

a fuse in the PDC through a fused B(+) circuit.

²Normally Open Terminal- The normally open

terminal (87) receives battery current at all times

from a fuse in the Power Distribution Center (PDC)

through a fused B(+) circuit.

²Normally Closed Terminal- The normally

closed terminal (87A) is connected to ground at all

times.

The park lamp relay can be diagnosed using con-

ventional diagnostic tools and methods.

DIAGNOSIS AND TESTING - PARK LAMP

RELAY

The park lamp relay (Fig. 18) is located in the

Power Distribution Center (PDC). Refer to the appro-

priate wiring information.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Remove the park lamp relay from the PDC.

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

Fig. 17 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

8L - 20 LAMPS/LIGHTING - EXTERIORDR

Page 579 of 2627

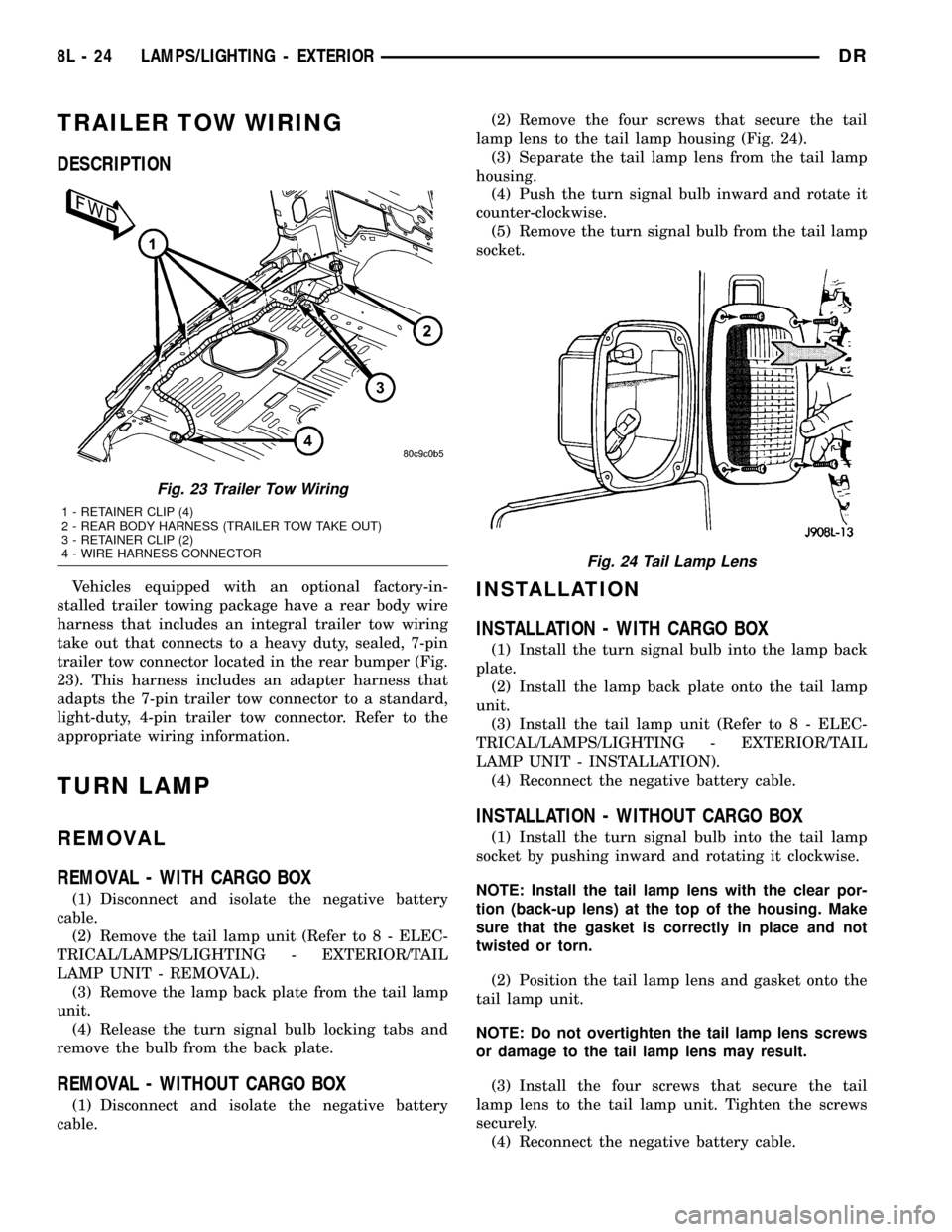

TRAILER TOW WIRING

DESCRIPTION

Vehicles equipped with an optional factory-in-

stalled trailer towing package have a rear body wire

harness that includes an integral trailer tow wiring

take out that connects to a heavy duty, sealed, 7-pin

trailer tow connector located in the rear bumper (Fig.

23). This harness includes an adapter harness that

adapts the 7-pin trailer tow connector to a standard,

light-duty, 4-pin trailer tow connector. Refer to the

appropriate wiring information.

TURN LAMP

REMOVAL

REMOVAL - WITH CARGO BOX

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the tail lamp unit (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/TAIL

LAMP UNIT - REMOVAL).

(3) Remove the lamp back plate from the tail lamp

unit.

(4) Release the turn signal bulb locking tabs and

remove the bulb from the back plate.

REMOVAL - WITHOUT CARGO BOX

(1) Disconnect and isolate the negative battery

cable.(2) Remove the four screws that secure the tail

lamp lens to the tail lamp housing (Fig. 24).

(3) Separate the tail lamp lens from the tail lamp

housing.

(4) Push the turn signal bulb inward and rotate it

counter-clockwise.

(5) Remove the turn signal bulb from the tail lamp

socket.

INSTALLATION

INSTALLATION - WITH CARGO BOX

(1) Install the turn signal bulb into the lamp back

plate.

(2) Install the lamp back plate onto the tail lamp

unit.

(3) Install the tail lamp unit (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/TAIL

LAMP UNIT - INSTALLATION).

(4) Reconnect the negative battery cable.

INSTALLATION - WITHOUT CARGO BOX

(1) Install the turn signal bulb into the tail lamp

socket by pushing inward and rotating it clockwise.

NOTE: Install the tail lamp lens with the clear por-

tion (back-up lens) at the top of the housing. Make

sure that the gasket is correctly in place and not

twisted or torn.

(2) Position the tail lamp lens and gasket onto the

tail lamp unit.

NOTE: Do not overtighten the tail lamp lens screws

or damage to the tail lamp lens may result.

(3) Install the four screws that secure the tail

lamp lens to the tail lamp unit. Tighten the screws

securely.

(4) Reconnect the negative battery cable.

Fig. 23 Trailer Tow Wiring

1 - RETAINER CLIP (4)

2 - REAR BODY HARNESS (TRAILER TOW TAKE OUT)

3 - RETAINER CLIP (2)

4 - WIRE HARNESS CONNECTOR

Fig. 24 Tail Lamp Lens

8L - 24 LAMPS/LIGHTING - EXTERIORDR

Page 581 of 2627

LAMPS/LIGHTING - INTERIOR

TABLE OF CONTENTS

page page

DOME LAMP

DESCRIPTION.........................26

OPERATION...........................26

REMOVAL.............................26

INSTALLATION.........................26

DOOR AJAR SWITCH

DESCRIPTION.........................27

OPERATION...........................27GLOVE BOX LAMP/SWITCH

REMOVAL.............................27

INSTALLATION.........................28

READING LAMP

DESCRIPTION.........................28

OPERATION...........................28

REMOVAL.............................28

INSTALLATION.........................29

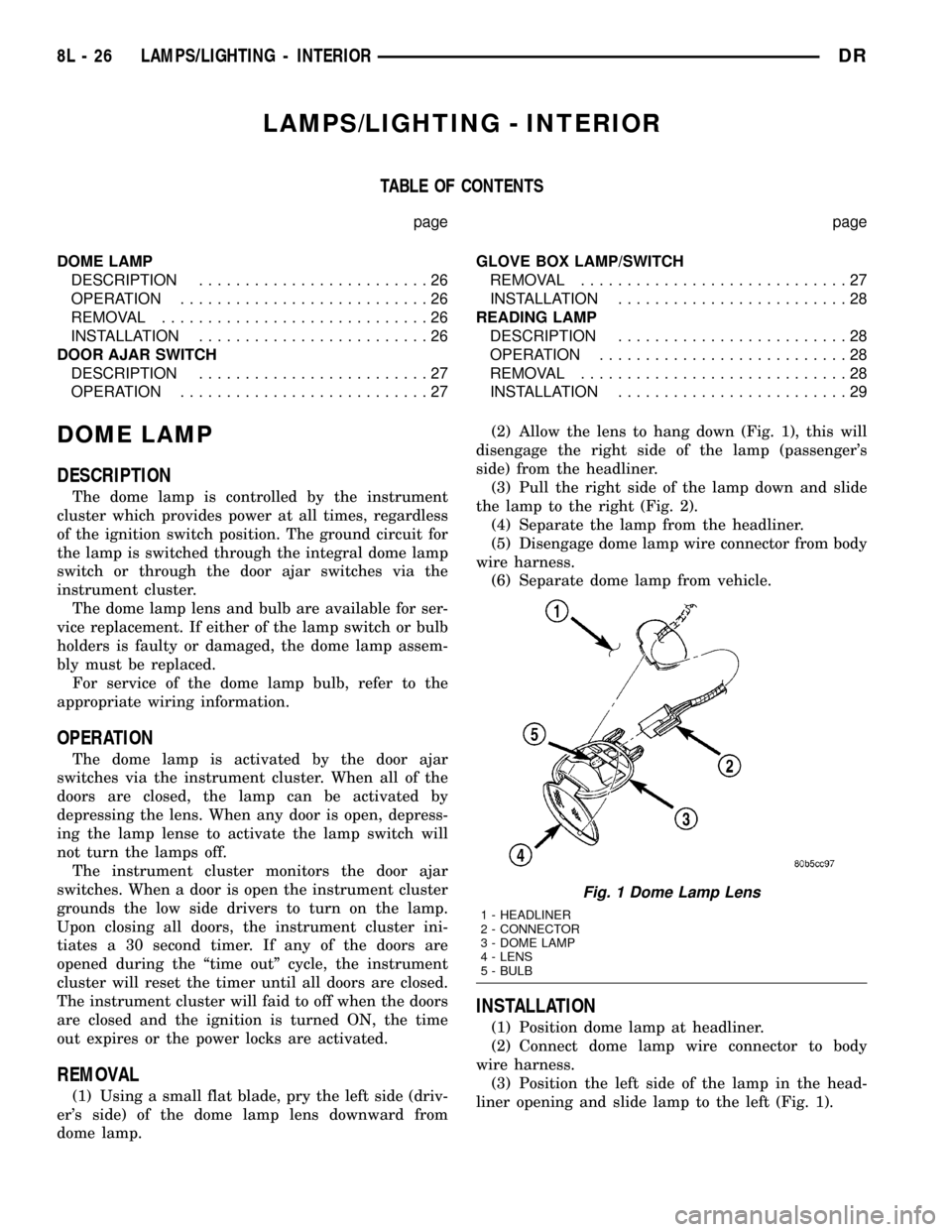

DOME LAMP

DESCRIPTION

The dome lamp is controlled by the instrument

cluster which provides power at all times, regardless

of the ignition switch position. The ground circuit for

the lamp is switched through the integral dome lamp

switch or through the door ajar switches via the

instrument cluster.

The dome lamp lens and bulb are available for ser-

vice replacement. If either of the lamp switch or bulb

holders is faulty or damaged, the dome lamp assem-

bly must be replaced.

For service of the dome lamp bulb, refer to the

appropriate wiring information.

OPERATION

The dome lamp is activated by the door ajar

switches via the instrument cluster. When all of the

doors are closed, the lamp can be activated by

depressing the lens. When any door is open, depress-

ing the lamp lense to activate the lamp switch will

not turn the lamps off.

The instrument cluster monitors the door ajar

switches. When a door is open the instrument cluster

grounds the low side drivers to turn on the lamp.

Upon closing all doors, the instrument cluster ini-

tiates a 30 second timer. If any of the doors are

opened during the ªtime outº cycle, the instrument

cluster will reset the timer until all doors are closed.

The instrument cluster will faid to off when the doors

are closed and the ignition is turned ON, the time

out expires or the power locks are activated.

REMOVAL

(1) Using a small flat blade, pry the left side (driv-

er's side) of the dome lamp lens downward from

dome lamp.(2) Allow the lens to hang down (Fig. 1), this will

disengage the right side of the lamp (passenger's

side) from the headliner.

(3) Pull the right side of the lamp down and slide

the lamp to the right (Fig. 2).

(4) Separate the lamp from the headliner.

(5) Disengage dome lamp wire connector from body

wire harness.

(6) Separate dome lamp from vehicle.

INSTALLATION

(1) Position dome lamp at headliner.

(2) Connect dome lamp wire connector to body

wire harness.

(3) Position the left side of the lamp in the head-

liner opening and slide lamp to the left (Fig. 1).

Fig. 1 Dome Lamp Lens

1 - HEADLINER

2 - CONNECTOR

3 - DOME LAMP

4 - LENS

5 - BULB

8L - 26 LAMPS/LIGHTING - INTERIORDR

Page 583 of 2627

INSTALLATION

(1) Reach through the glove box opening and

behind the glove box lamp and switch mounting

bracket to feed the instrument panel wire harness

connectors out through the hole in the glove box

lamp and switch housing mounting bracket.

(2) Position the glove box lamp and switch unit to

the instrument panel.

(3) Reconnect the instrument panel wire harness

connector to the connector receptacle on the back of

the glove box lamp and switch unit.

(4) Push the glove box lamp and switch unit into

the hole in the mounting bracket on the instrument

panel glove box opening upper reinforcement.

(5) Install the glove box onto the instrument panel.

(Refer to 23 - BODY/INSTRUMENT PANEL/GLOVE

BOX - INSTALLATION) for the procedures.

(6) Close the glove box.

(7) Reconnect the battery negative cable.

READING LAMP

DESCRIPTION

The overhead console in this vehicle is equipped

with two individual reading and courtesy lamps. The

lamp lenses are the only visible components of these

lamps. Each lamp has its own switch, bulb, reflector

and lens within the overhead console.

The overhead console reading and courtesy lamps

are controlled by the instrument cluster which pro-

vides power at all times, regardless of the ignition

switch position. The ground circuit for the lamps is

switched through the integral reading and courtesy

lamp switches or through the door ajar switches.

Each lamp is designed and aimed to provide illumi-

nation that will be directed only to that side of the

vehicle on which the lamp is located.

The reading and courtesy lamp lenses and bulbs

are available for service replacement. The reading

and courtesy lamp switches, bulb holders and wiring

are only available as part of the overhead console

wire harness. If either of the lamp switches or bulb

holders is faulty or damaged, the entire overhead

console wire harness assembly must be replaced.

For service of the reading and courtesy lamp bulbs,

refer to the appropriate wiring information.

OPERATION

All reading and courtesy lamps located in the over-

head console are activated by the door ajar switches

via the instrument cluster. When all of the doors are

closed, these lamps can be individually activated by

depressing the corresponding lens. When any door is

open, depressing the lamp lenses to activate the lamp

switches will not turn the lamps off.The instrument cluster monitors the door ajar

switches. When a door is open the instrument cluster

grounds the low side drivers to turn on the lamps.

Upon closing all doors, the instrument cluster ini-

tiates a 30 second timer. If any of the doors are

opened during the ªtime outº cycle, the instrument

cluster will reset the timer until all doors are closed.

The instrument cluster will faid to off when the doors

are closed and the ignition is turned ON, the time

out expires or the power locks are activated.

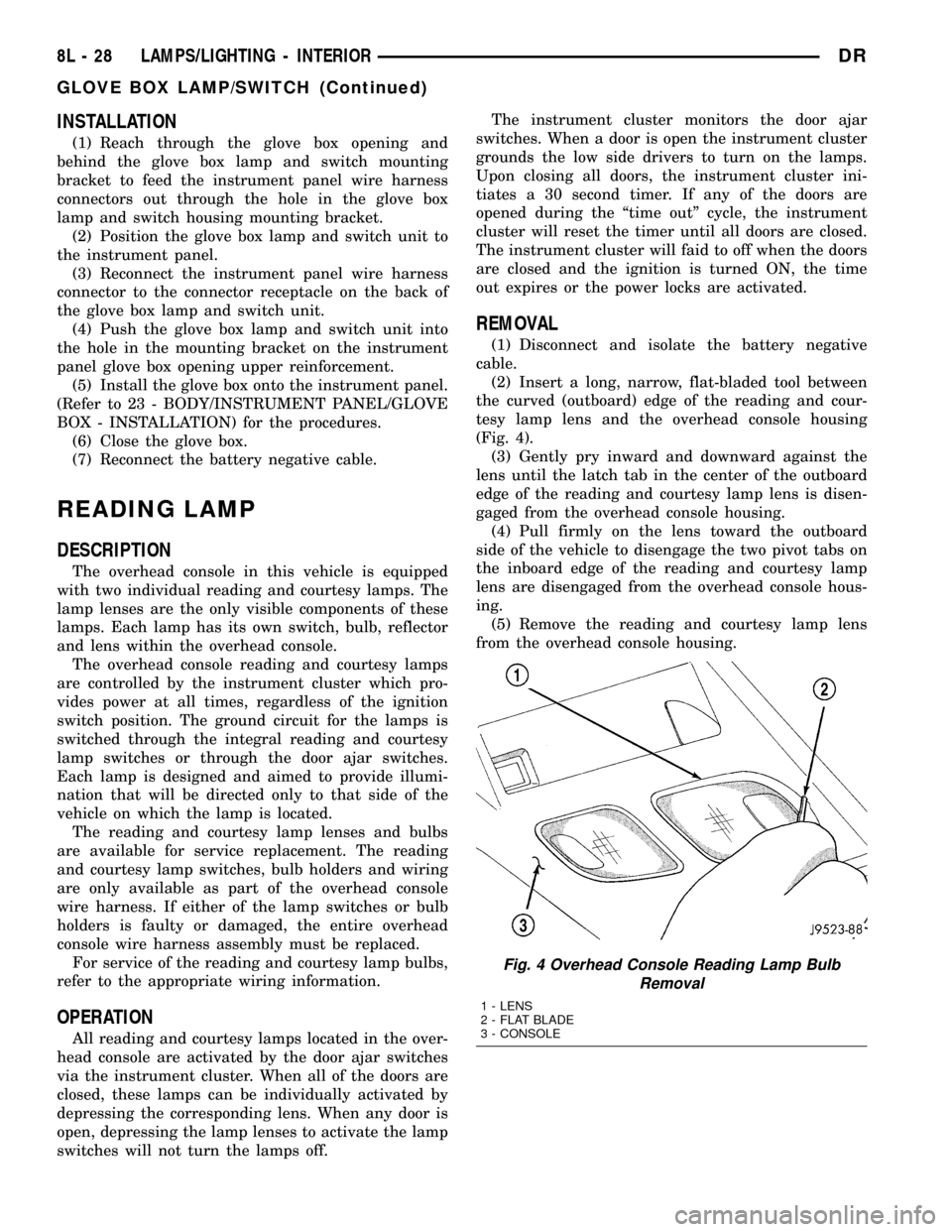

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Insert a long, narrow, flat-bladed tool between

the curved (outboard) edge of the reading and cour-

tesy lamp lens and the overhead console housing

(Fig. 4).

(3) Gently pry inward and downward against the

lens until the latch tab in the center of the outboard

edge of the reading and courtesy lamp lens is disen-

gaged from the overhead console housing.

(4) Pull firmly on the lens toward the outboard

side of the vehicle to disengage the two pivot tabs on

the inboard edge of the reading and courtesy lamp

lens are disengaged from the overhead console hous-

ing.

(5) Remove the reading and courtesy lamp lens

from the overhead console housing.

Fig. 4 Overhead Console Reading Lamp Bulb

Removal

1 - LENS

2 - FLAT BLADE

3 - CONSOLE

8L - 28 LAMPS/LIGHTING - INTERIORDR

GLOVE BOX LAMP/SWITCH (Continued)

Page 587 of 2627

The compass unit also will compensate for magne-

tism the body of the vehicle may acquire during nor-

mal use. However, avoid placing anything magnetic

directly on the roof of the vehicle. Magnetic mounts

for an antenna, a repair order hat, or a funeral pro-

cession flag can exceed the compensating ability of

the compass unit if placed on the roof panel. Mag-

netic bit drivers used on the fasteners that hold the

overhead console assembly to the roof header can

also affect compass operation. If the vehicle roof

should become magnetized, the demagnetizing and

calibration procedures found in this section may be

required to restore proper compass operation.

TEMPERATURE DISPLAY

All the available overhead consoles on this model

include Temperature information. The temperature

displays the outside ambient temperature in whole

degrees. The temperature display can be toggled

from Fahrenheit to Celsius by selecting the desired

U.S./Metric option from the customer programmable

features. The displayed temperature is not an instant

reading of conditions, but an average temperature. It

may take the temperature display several minutes to

respond to a major temperature change, such as driv-

ing out of a heated garage into winter temperatures.

When the ignition switch is turned to the Off posi-

tion, the last displayed temperature reading stays in

the electronic control modules, (CMTC, EVIC) mem-

ory. When the ignition switch is turned to the On

position again, the electronic module will display the

memory temperature for one minute; then update the

display to the current average temperature reading

within five minutes.The temperature function is supported by an ambi-

ent temperature sensor. This sensor is mounted out-

side the passenger compartment near the front and

center of the vehicle, and is hard wired to the Front

Control Module (FCM). The FCM sends temperature

status messages to the module over the J1850 PCI

data bus circuit. For more information on the ambi-

ent temperature sensor, refer to Ambient Tempera-

ture Sensor later in this section.

Following are general descriptions of the major

components used in the overhead console. Refer to

Wiring Diagrams for complete circuit schematics.

OPERATION

Refer to the vehicle Owner's Manual for specific

operation of each overhead console and its systems.

DIAGNOSIS AND TESTING - OVERHEAD

CONSOLE

If the problem with the overhead console is an

inaccurate or scrambled display, refer toSELF-DI-

AGNOSTIC TESTlater in this text. If the problem

with the overhead console is incorrect Vacuum Fluo-

rescent Display (VFD) dimming levels, use a DRB

IIItscan tool and the proper Diagnostic Procedures

manual to test for the correct dimming message

inputs being received from the Body Control Module

(BCM) or Front Control Module (FCM) over the

J1850 Programmable Communications Interface

(PCI) data bus circuit. If the problem is a no-display

condition, use the following procedure. For complete

circuit diagrams, refer toOverhead Consolein the

Wiring Diagrams section of the service manual.

(1) Remove the overhead console from the head-

liner (Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE - REMOVAL).

(2) Check for battery voltage at the overhead con-

sole electrical connector. Refer to Wiring for connec-

tor information. If OK, go to Step 3. If not OK, Check

for battery voltage at the appropriate B(+) fuse in the

integrated power module, repair the open fused B(+)

circuit as required.

(3) Turn the ignition switch to the On position.

Check the fused ignition switch output circuit(s) at

the overhead console electrical connector. If OK, go to

Step 4. If not OK, repair the open or shorted circuit

as required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Check for continuity between the ground circuit cav-

ity of the overhead console electrical connector and a

good ground. There should be continuity. If OK, refer

toSELF-DIAGNOSTIC TESTbelow for further

diagnosis of the electronics module and the J1850

PCI data bus circuit. If not OK, repair the open

ground circuit as required.

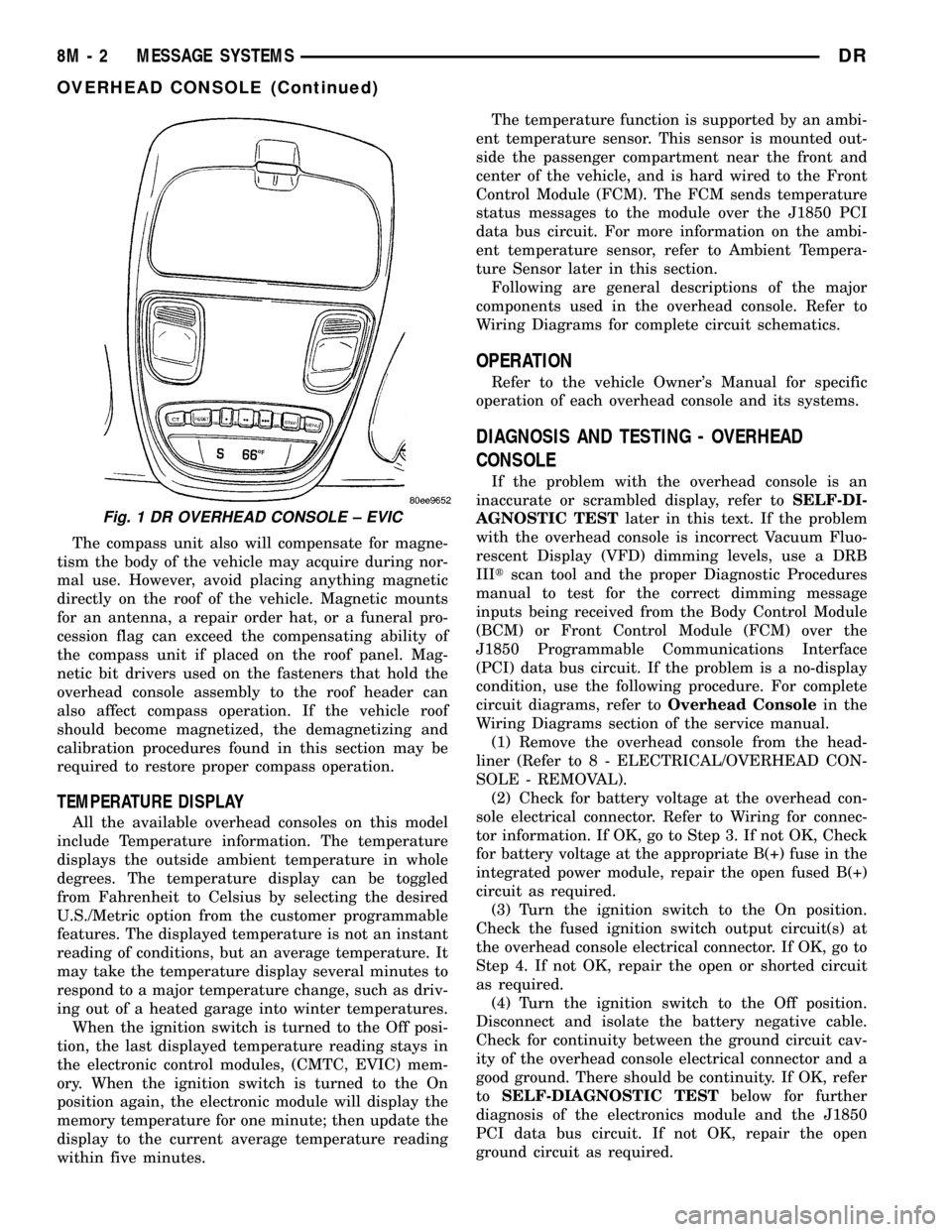

Fig. 1 DR OVERHEAD CONSOLE ± EVIC

8M - 2 MESSAGE SYSTEMSDR

OVERHEAD CONSOLE (Continued)

Page 595 of 2627

(2) Install the screws holding the EVIC module in

the overhead console.

(3) Connect the EVIC module electrical connector.

(4) Install the overhead console on the headlin-

er(Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE - INSTALLATION).

(5) Connect the battery negative cable.

(6) Check EVIC module function.

NOTE: If a new EVIC module has been installed, the

compass will have to be calibrated and the variance

set. Refer to Compass Variation Adjustment and

Compass Calibration in the Standard Procedures

section of this group for the procedures.

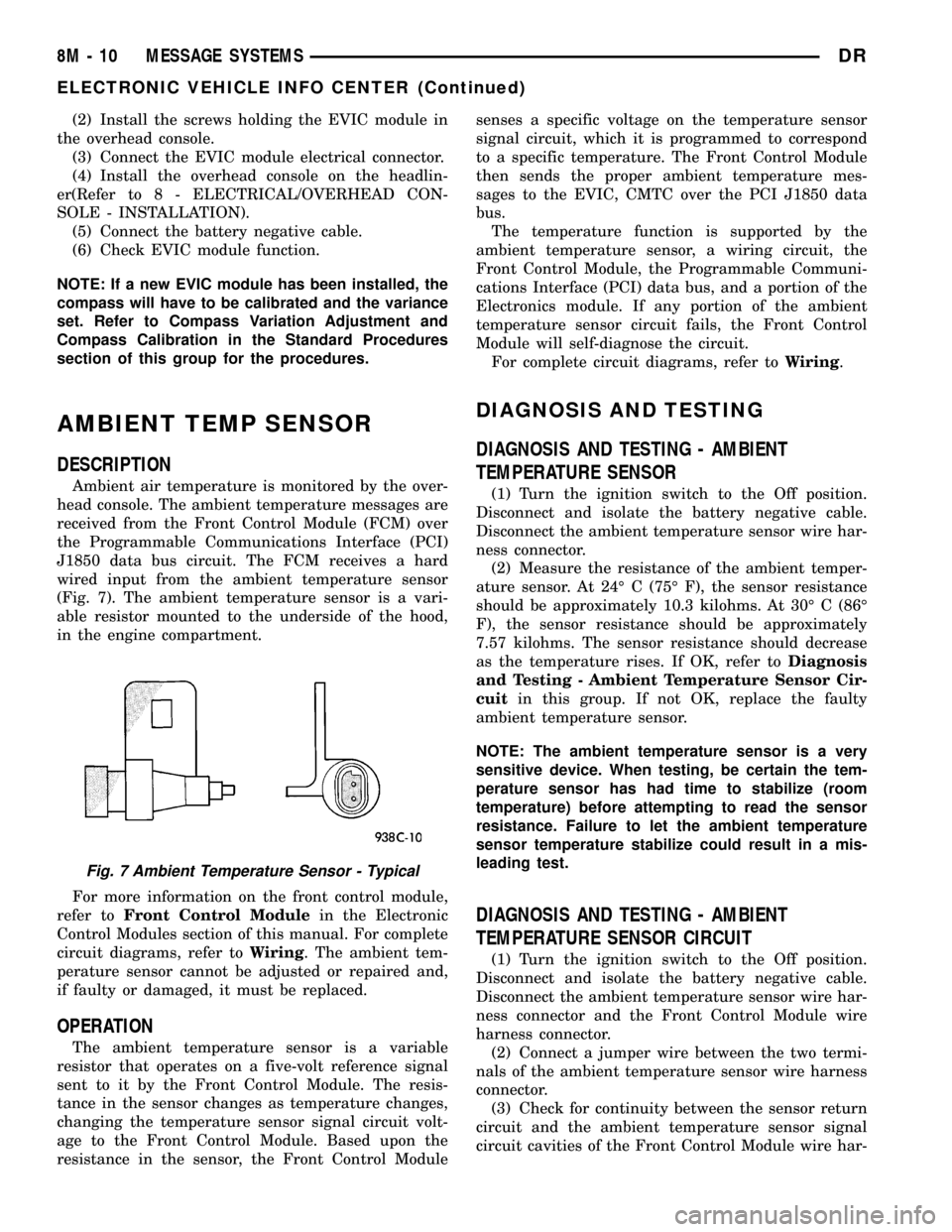

AMBIENT TEMP SENSOR

DESCRIPTION

Ambient air temperature is monitored by the over-

head console. The ambient temperature messages are

received from the Front Control Module (FCM) over

the Programmable Communications Interface (PCI)

J1850 data bus circuit. The FCM receives a hard

wired input from the ambient temperature sensor

(Fig. 7). The ambient temperature sensor is a vari-

able resistor mounted to the underside of the hood,

in the engine compartment.

For more information on the front control module,

refer toFront Control Modulein the Electronic

Control Modules section of this manual. For complete

circuit diagrams, refer toWiring. The ambient tem-

perature sensor cannot be adjusted or repaired and,

if faulty or damaged, it must be replaced.

OPERATION

The ambient temperature sensor is a variable

resistor that operates on a five-volt reference signal

sent to it by the Front Control Module. The resis-

tance in the sensor changes as temperature changes,

changing the temperature sensor signal circuit volt-

age to the Front Control Module. Based upon the

resistance in the sensor, the Front Control Modulesenses a specific voltage on the temperature sensor

signal circuit, which it is programmed to correspond

to a specific temperature. The Front Control Module

then sends the proper ambient temperature mes-

sages to the EVIC, CMTC over the PCI J1850 data

bus.

The temperature function is supported by the

ambient temperature sensor, a wiring circuit, the

Front Control Module, the Programmable Communi-

cations Interface (PCI) data bus, and a portion of the

Electronics module. If any portion of the ambient

temperature sensor circuit fails, the Front Control

Module will self-diagnose the circuit.

For complete circuit diagrams, refer toWiring.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire har-

ness connector.

(2) Measure the resistance of the ambient temper-

ature sensor. At 24É C (75É F), the sensor resistance

should be approximately 10.3 kilohms. At 30É C (86É

F), the sensor resistance should be approximately

7.57 kilohms. The sensor resistance should decrease

as the temperature rises. If OK, refer toDiagnosis

and Testing - Ambient Temperature Sensor Cir-

cuitin this group. If not OK, replace the faulty

ambient temperature sensor.

NOTE: The ambient temperature sensor is a very

sensitive device. When testing, be certain the tem-

perature sensor has had time to stabilize (room

temperature) before attempting to read the sensor

resistance. Failure to let the ambient temperature

sensor temperature stabilize could result in a mis-

leading test.

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR CIRCUIT

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire har-

ness connector and the Front Control Module wire

harness connector.

(2) Connect a jumper wire between the two termi-

nals of the ambient temperature sensor wire harness

connector.

(3) Check for continuity between the sensor return

circuit and the ambient temperature sensor signal

circuit cavities of the Front Control Module wire har-

Fig. 7 Ambient Temperature Sensor - Typical

8M - 10 MESSAGE SYSTEMSDR

ELECTRONIC VEHICLE INFO CENTER (Continued)

Page 596 of 2627

ness connector. There should be continuity. If OK, go

to Step 4. If not OK, repair the open sensor return or

signal circuit as required.

(4) Remove the jumper wire from the ambient tem-

perature sensor wire harness connector. Check for

continuity between the sensor return circuit cavity of

the Front Control Module wire harness connector

and a good ground. There should be no continuity. If

OK, go to Step 5. If not OK, repair the shorted sen-

sor return circuit as required.

(5) Check for continuity between the ambient tem-

perature sensor signal circuit cavity of the Front

Control Module wire harness connector and a good

ground. There should be no continuity. If OK, refer to

Diagnosis and Testing - Overhead Consolein

this group. If not OK, repair the shorted ambient

temperature sensor signal circuit as required.

REMOVAL

(1) Open the hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Working on the underside of the hood, remove

screw holding sensor to hood panel.

(4) Disconnect the sensor electrical connector and

remove sensor from vehicle.

INSTALLATION

(1) Connect the sensor electrical connector.

(2) Working on the underside of the hood, install

screw holding sensor to hood panel.

(3) Connect the battery negative cable.

(4) Close the hood.

UNIVERSAL TRANSMITTER

DESCRIPTION

Some DR models are equipped with a universal

transmitter transceiver. The universal transmitter is

integral to the Electronic Vehicle Information Center

(EVIC) and the Compass Mini-Trip Computer

(CMTC), which is located in the overhead console.

The only visible component of the universal transmit-

ter are the three transmitter push buttons centered

between the modules push buttons located just rear-

ward of the display screen in the overhead console.

The three universal transmitter push buttons are

identified with one, two or three light indicators so

that they be easily identified.

Each of the three universal transmitter push but-

tons control an independent radio transmitter chan-

nel. Each of these three channels can be trained to

transmit a different radio frequency signal for the

remote operation of garage door openers, motorized

gate openers, home or office lighting, security sys-tems or just about any other device that can be

equipped with a radio receiver in the 286 to 399

MegaHertz (MHz) frequency range for remote opera-

tion. The universal transmitter is capable of operat-

ing systems using either rolling code or non-rolling

code technology.

The electronics module displays messages and a

small house-shaped icon with one, two or three dots

corresponding to the three transmitter buttons to

indicate the status of the universal transmitter. The

EVIC messages are:

²Clearing Channels- Indicates that all of the

transmitter codes stored in the universal transmitter

have been successfully cleared.

²Channel ªXº Training- Indicates that the uni-

versal transmitter is in its transmitter learning

mode.

²Channel ªXº Trained- Indicates that the uni-

versal transmitter has successfully acquired a new

transmitter code.

²Channel ªXº Transmitting- Indicates that a

trained universal transmitter button has been

depressed and that the universal transmitter is

transmitting.

The universal transmitter cannot be repaired, and

is available for service only as a unit with the EVIC

or CMTC modules. If any part of the universal trans-

mitter is faulty or damaged, the complete EVIC or

CMTC module must be replaced.

OPERATION

The universal transmitter operates on a non-

switched source of battery current so the unit will

remain functional, regardless of the ignition switch

position. For more information on the features, pro-

gramming procedures and operation of the universal

transmitter, see the owner's manual in the vehicle

glove box.

DIAGNOSIS AND TESTING - UNIVERSAL

TRANSMITTER

If the Universal Transmitter is inoperative, but the

Electronic Vehicle Information Center (EVIC) is oper-

ating normally, see the owner's manual in the vehicle

glove box for instructions on training the Transmit-

ter. Retrain the Transmitter with a known good

transmitter as instructed in the owner's manual and

test the Transmitter operation again. If the unit is

still inoperative, test the universal transmitter with

Radio Frequency Detector special tool. If both the

Transmitter and the EVIC module are inoperative,

refer toElectronic Vehicle Information Center

Diagnosis and Testingin this group for further

diagnosis. For complete circuit diagrams, refer to

Wiring Diagrams. (Fig. 8) as described below:

DRMESSAGE SYSTEMS 8M - 11

AMBIENT TEMP SENSOR (Continued)

Page 600 of 2627

AUTOMATIC DOOR LOCKS

When the automatic door locks are ENABLED the

door locks will lock when the vehicle is moving at

about 25.7 Km/h (15 mph), all doors are closed and

the accelerator pedal is depressed. This feature can

be switched ON or OFF as desired. When the system

is DISABLED the door locks will operate normally,

but will not lock automatically when the vehicle is

rolling. Once the automatic door locks have been

actuated, they will not try to lock the doors again

until a door is opened.

DOOR LOCK INHIBIT

If the key is in the ignition, in any position, and

either front door is ajar, the doors can not be locked,

but the unlock function still operates. Pressing the

RKE lock/unlock button under these conditions will

result in a normal lock/unlock activation.

After the key is removed from the ignition switch,

or the doors are closed, the power door locks will

operate normally.

DOOR LOCK CIRCUIT PROTECTION

If the door lock switch is actuated continuously for

more than five seconds the instrument cluster will

turn the output driver OFF (the instrument cluster

would consider the switch stuck). Each lock motor is

protected with a Positive Temperature Coefficient

device that prevents motor burn out.

REMOTE KEYLESS ENTRY

²LOCK: Pressing the LOCK button locks all

doors, sounds horn (chirp) once if enabled, flashes the

park lamps once if enabled, and arms the Vehicle

Theft Security System (VTSS), if enabled. The chirp

verifies that the RKE module has sent a message to

the instrument cluster for door lock operation. If a

door has not been closed before pressing the LOCK

button, the vehicle may not be secured and the VTSS

(if equipped) will not arm until the door is closed.

²UNLOCK: Pressing the UNLOCK button once

will unlock the driver's door first if enabled, flashes

the park lamps twice if enabled, activates the illumi-

nated entry system, and disarms the Vehicle Theft

Security System (VTSS), if equipped. Pressing the

UNLOCK button twice within five seconds will

unlock all doors, if driver's door first is enabled.

²PANIC:

Pressing the PANIC button sounds the

horns at half second intervals, flashes the exterior

lamps, and turns ON the interior lamps. The panic

alarm will remain on for three minutes, or until the

PANIC button is actuated again or the vehicle speed

exceeds 25.7 Km/h (15 mph) will cancel the panic event.

The Remote Keyless Entry Module is capable of

retaining the transmitter Vehicle Access Code(s) in its

memory even after vehicle power has been interrupted.

DIAGNOSIS AND TESTING - POWER LOCKS

The most reliable, efficient, and accurate

means to diagnose the power lock system

requires the use of a DRBIIItscan tool and the

proper Diagnostic Procedures manual.

Following are tests that will help to diagnose the

hard wired components and circuits of the power lock

system. However, these tests may not prove conclu-

sive in the diagnosis of this system. In order to

obtain conclusive testing of the power lock system,

the Programmable Communications Interface (PCI)

data bus network and all of the electronic modules

that provide inputs to, or receive outputs from the

power lock system components must be checked.

The instrument cluster will set Diagnostic Trouble

Codes (DTC) for the power lock system.

Refer to the appropriate wiring information.

PRELIMINARY DIAGNOSIS

As a preliminary diagnosis for the power lock sys-

tem, note the system operation while you actuate

both the Lock and Unlock functions with the power

lock switches and with the Remote Keyless Entry

(RKE) transmitter. Then, proceed as follows:

²If the entire power lock system fails to function

with either the power lock switches or the RKE

transmitter, check the fused B(+) fuse in the Inte-

grated Power Module (IPM).

²If the power lock system functions with both

power lock switches, but not with the RKE transmit-

ter, proceed to diagnosis of the Remote Keyless Entry

(RKE) system. (Refer to 8 - ELECTRICAL/POWER

LOCKS/KEYLESS ENTRY TRANSMITTER - DIAG-

NOSIS AND TESTING) or (Refer to 8 - ELECTRI-

CAL/POWER LOCKS/REMOTE KEYLESS ENTRY

MODULE - DIAGNOSIS AND TESTING).

²If the power lock system functions with the RKE

transmitter, but not with one or both power lock

switches, proceed to diagnosis of the door lock

switches. (Refer to 8 - ELECTRICAL/POWER

LOCKS/POWER LOCK SWITCH - DIAGNOSIS AND

TESTING).

²If the driver side power lock switch operates

only the driver side front door power lock motor, but

all other power lock motors operate with the passen-

ger side power lock switch or the RKE transmitter,

use a DRBIIItscan tool and the appropriate diagnos-

tic information to diagnose the Programmable Com-

munications Interface (PCI) data bus.

²If only one power lock motor fails to operate

with both power lock switches and the RKE trans-

mitter, proceed to diagnosis of the power lock motor.

(Refer to 8 - ELECTRICAL/POWER LOCKS/POWER

LOCK MOTOR - DIAGNOSIS AND TESTING).

DRPOWER LOCKS 8N - 3

POWER LOCKS (Continued)

Page 601 of 2627

POWER LOCK SWITCH

DIAGNOSIS AND TESTING - POWER LOCK

SWITCH

The Light-Emitting Diode (LED) illumination lamp

of the power lock switch receives battery current

through a fuse in the Integrated Power Module (IPM)

on a fused ignition switch output (run) circuit. The

power lock switch on the driver side front door trim

panel is integral to the driver door module. (Refer to

8 - ELECTRICAL/POWER LOCKS/DOOR MODULE

- DIAGNOSIS AND TESTING). If the power lock

switch operates, but the LED is inoperative, check

for battery current at the switch with the ignition

switch in the On position. If OK, replace the faulty

switch. Refer to the appropriate wiring information.

(1) Disconnect and isolate the battery negative

cable. Remove the power lock switch from the door

trim panel. Disconnect the door wire harness connec-

tor for the power lock switch from the switch connec-

tor receptacle.

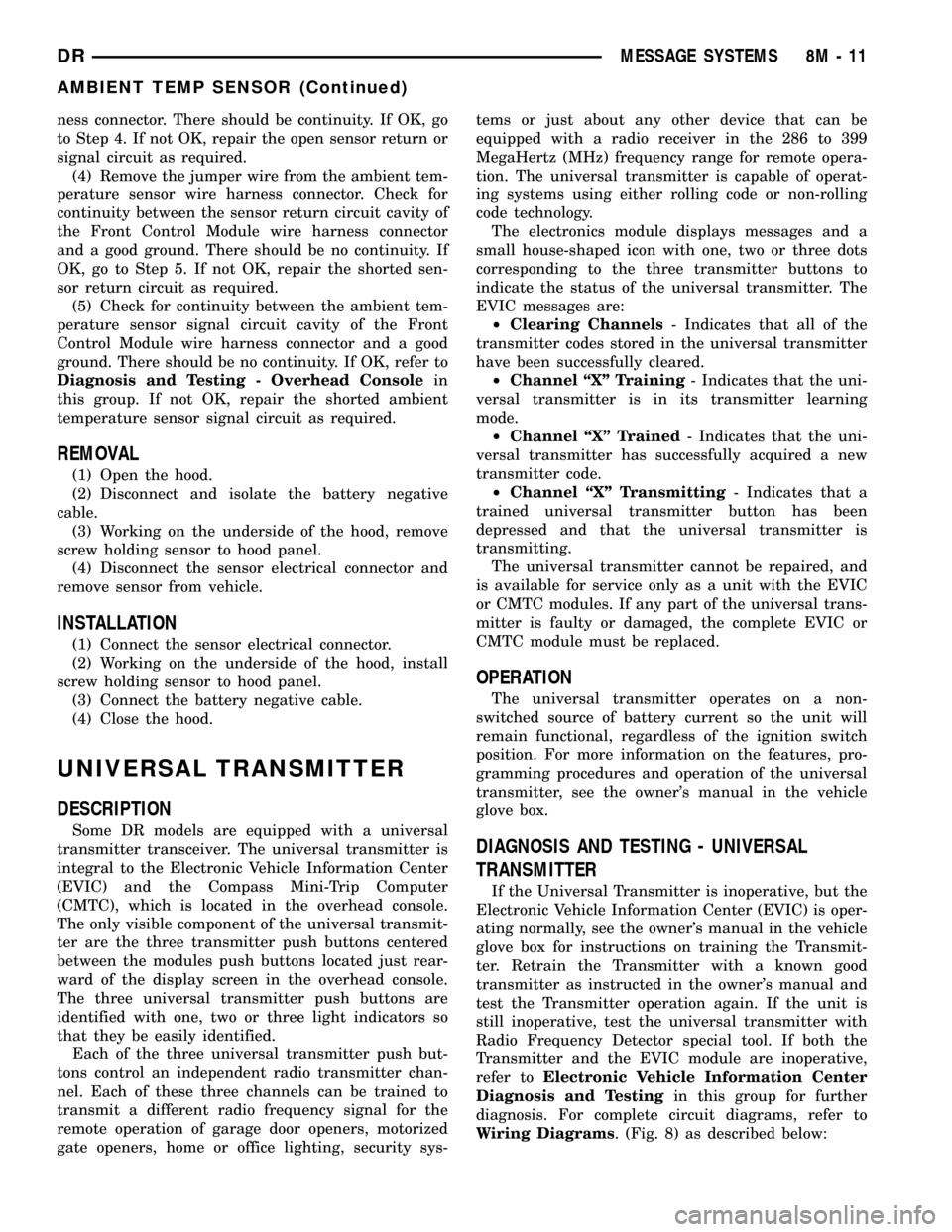

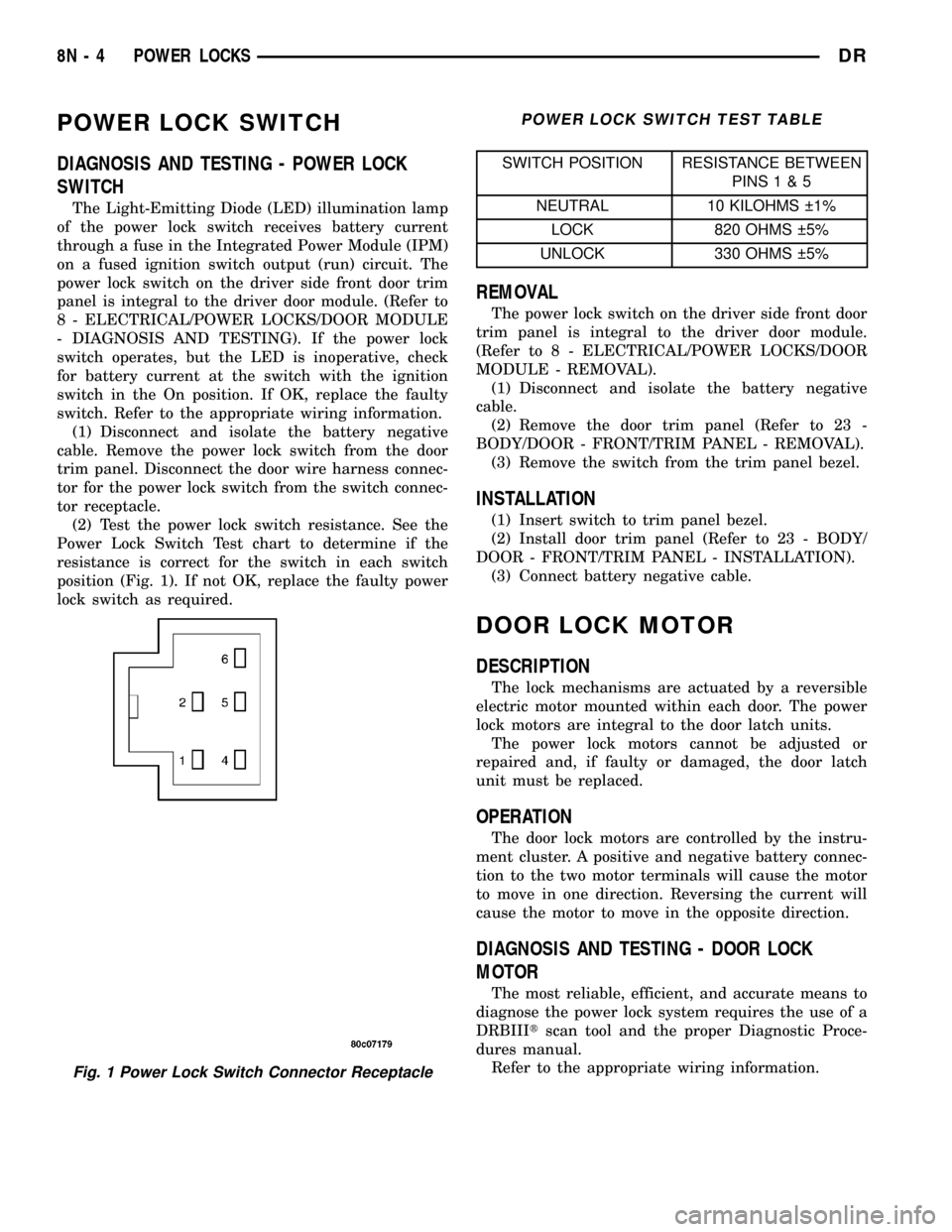

(2) Test the power lock switch resistance. See the

Power Lock Switch Test chart to determine if the

resistance is correct for the switch in each switch

position (Fig. 1). If not OK, replace the faulty power

lock switch as required.

POWER LOCK SWITCH TEST TABLE

SWITCH POSITION RESISTANCE BETWEEN

PINS1&5

NEUTRAL 10 KILOHMS 1%

LOCK 820 OHMS 5%

UNLOCK 330 OHMS 5%

REMOVAL

The power lock switch on the driver side front door

trim panel is integral to the driver door module.

(Refer to 8 - ELECTRICAL/POWER LOCKS/DOOR

MODULE - REMOVAL).

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the door trim panel (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - REMOVAL).

(3) Remove the switch from the trim panel bezel.

INSTALLATION

(1) Insert switch to trim panel bezel.

(2) Install door trim panel (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - INSTALLATION).

(3) Connect battery negative cable.

DOOR LOCK MOTOR

DESCRIPTION

The lock mechanisms are actuated by a reversible

electric motor mounted within each door. The power

lock motors are integral to the door latch units.

The power lock motors cannot be adjusted or

repaired and, if faulty or damaged, the door latch

unit must be replaced.

OPERATION

The door lock motors are controlled by the instru-

ment cluster. A positive and negative battery connec-

tion to the two motor terminals will cause the motor

to move in one direction. Reversing the current will

cause the motor to move in the opposite direction.

DIAGNOSIS AND TESTING - DOOR LOCK

MOTOR

The most reliable, efficient, and accurate means to

diagnose the power lock system requires the use of a

DRBIIItscan tool and the proper Diagnostic Proce-

dures manual.

Refer to the appropriate wiring information.

Fig. 1 Power Lock Switch Connector Receptacle

8N - 4 POWER LOCKSDR