DODGE RAM 2001 Service Service Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 41 of 2889

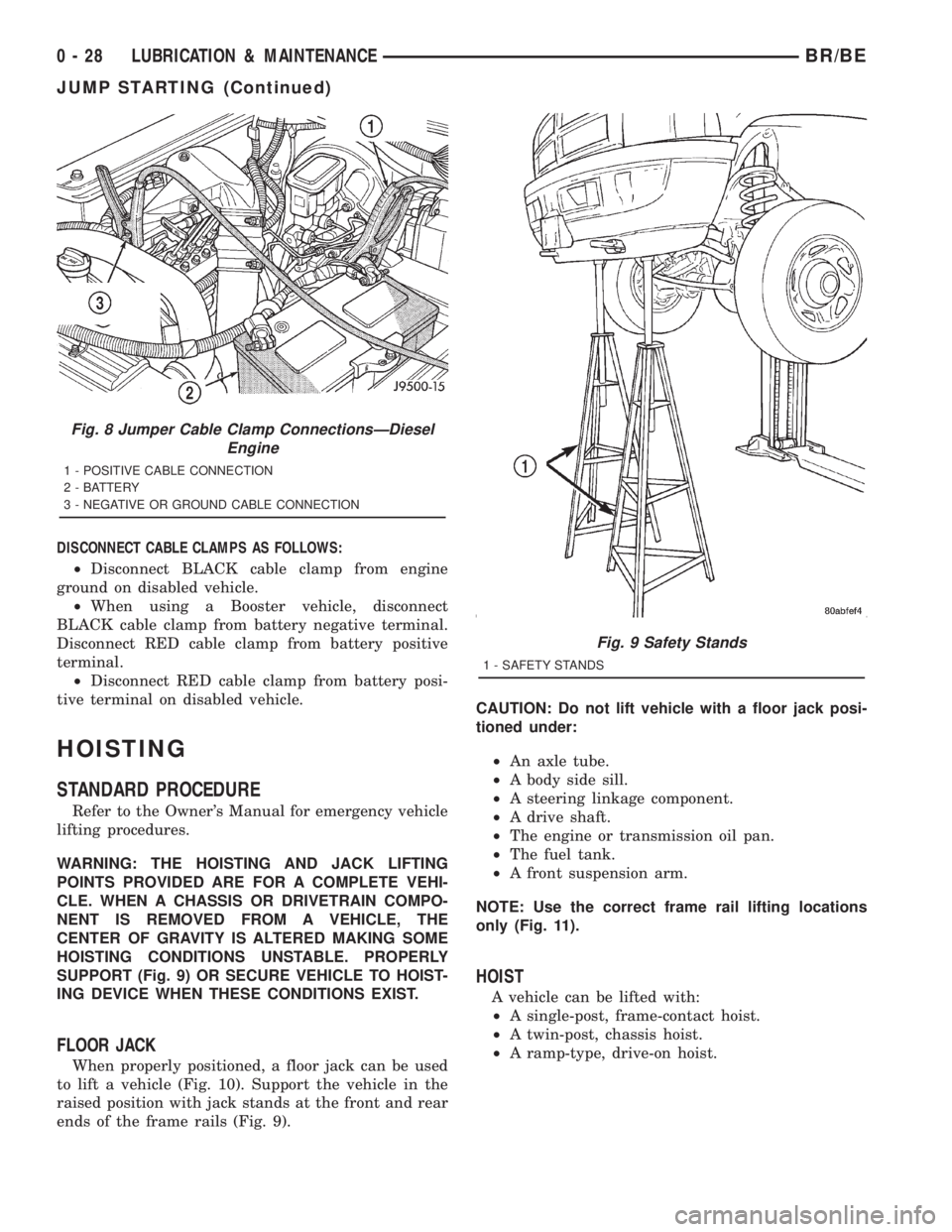

DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

HOISTING

STANDARD PROCEDURE

Refer to the Owner's Manual for emergency vehicle

lifting procedures.

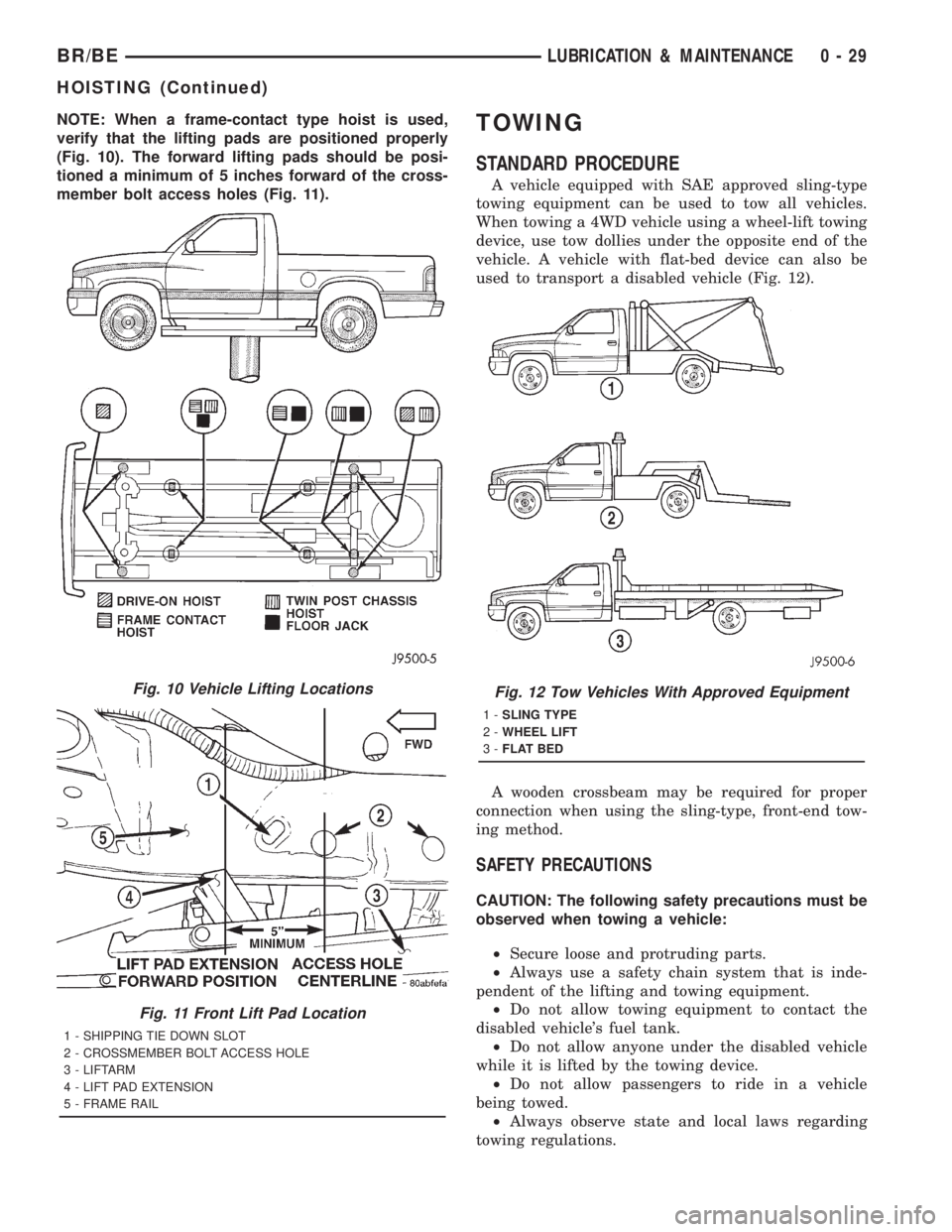

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN A CHASSIS OR DRIVETRAIN COMPO-

NENT IS REMOVED FROM A VEHICLE, THE

CENTER OF GRAVITY IS ALTERED MAKING SOME

HOISTING CONDITIONS UNSTABLE. PROPERLY

SUPPORT (Fig. 9) OR SECURE VEHICLE TO HOIST-

ING DEVICE WHEN THESE CONDITIONS EXIST.

FLOOR JACK

When properly positioned, a floor jack can be used

to lift a vehicle (Fig. 10). Support the vehicle in the

raised position with jack stands at the front and rear

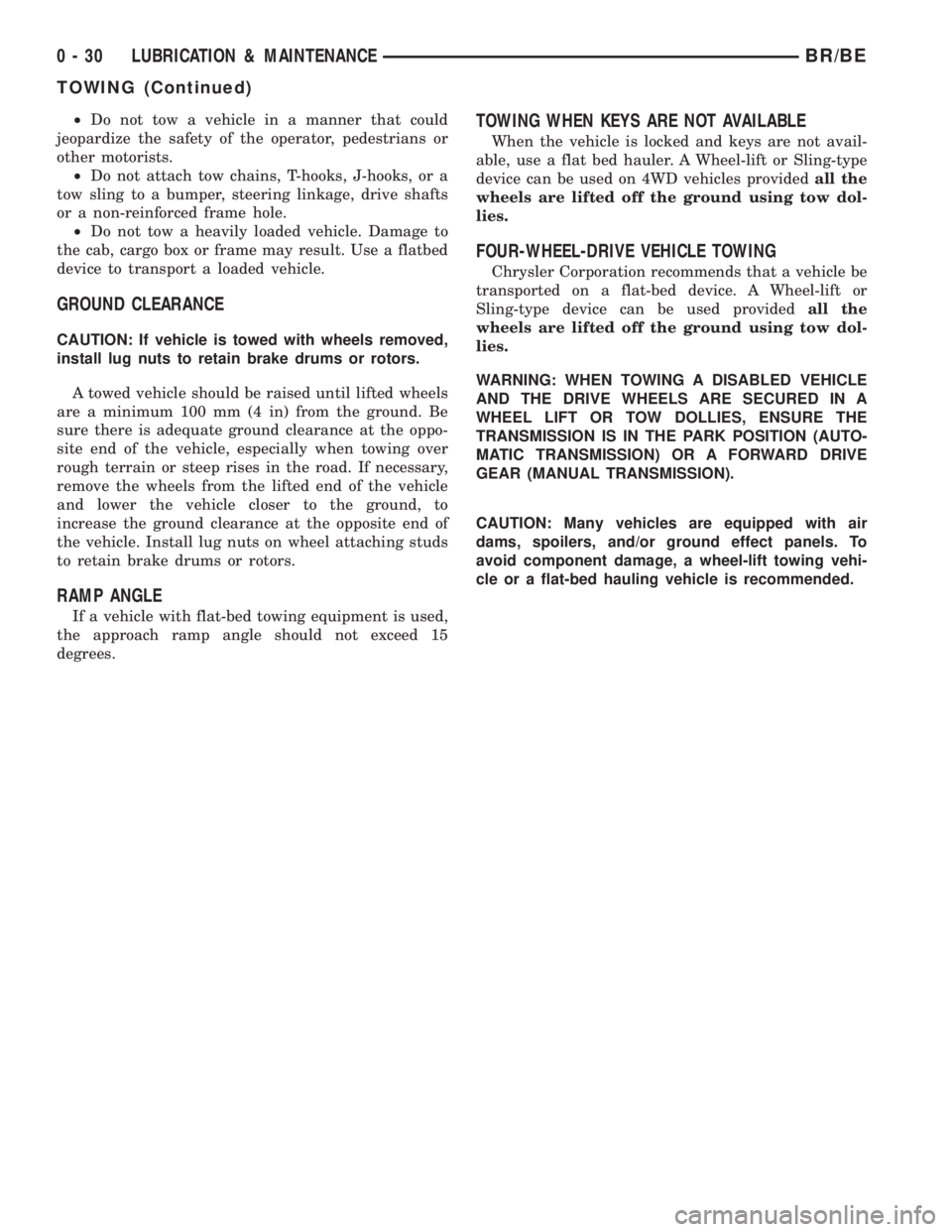

ends of the frame rails (Fig. 9).CAUTION: Do not lift vehicle with a floor jack posi-

tioned under:

²An axle tube.

²A body side sill.

²A steering linkage component.

²A drive shaft.

²The engine or transmission oil pan.

²The fuel tank.

²A front suspension arm.

NOTE: Use the correct frame rail lifting locations

only (Fig. 11).

HOIST

A vehicle can be lifted with:

²A single-post, frame-contact hoist.

²A twin-post, chassis hoist.

²A ramp-type, drive-on hoist.

Fig. 8 Jumper Cable Clamp ConnectionsÐDiesel

Engine

1 - POSITIVE CABLE CONNECTION

2 - BATTERY

3 - NEGATIVE OR GROUND CABLE CONNECTION

Fig. 9 Safety Stands

1 - SAFETY STANDS

0 - 28 LUBRICATION & MAINTENANCEBR/BE

JUMP STARTING (Continued)

Page 42 of 2889

NOTE: When a frame-contact type hoist is used,

verify that the lifting pads are positioned properly

(Fig. 10). The forward lifting pads should be posi-

tioned a minimum of 5 inches forward of the cross-

member bolt access holes (Fig. 11).TOWING

STANDARD PROCEDURE

A vehicle equipped with SAE approved sling-type

towing equipment can be used to tow all vehicles.

When towing a 4WD vehicle using a wheel-lift towing

device, use tow dollies under the opposite end of the

vehicle. A vehicle with flat-bed device can also be

used to transport a disabled vehicle (Fig. 12).

A wooden crossbeam may be required for proper

connection when using the sling-type, front-end tow-

ing method.

SAFETY PRECAUTIONS

CAUTION: The following safety precautions must be

observed when towing a vehicle:

²Secure loose and protruding parts.

²Always use a safety chain system that is inde-

pendent of the lifting and towing equipment.

²Do not allow towing equipment to contact the

disabled vehicle's fuel tank.

²Do not allow anyone under the disabled vehicle

while it is lifted by the towing device.

²Do not allow passengers to ride in a vehicle

being towed.

²Always observe state and local laws regarding

towing regulations.

Fig. 10 Vehicle Lifting Locations

Fig. 11 Front Lift Pad Location

1 - SHIPPING TIE DOWN SLOT

2 - CROSSMEMBER BOLT ACCESS HOLE

3 - LIFTARM

4 - LIFT PAD EXTENSION

5 - FRAME RAIL

Fig. 12 Tow Vehicles With Approved Equipment

1-SLING TYPE

2-WHEEL LIFT

3-FLAT BED

BR/BELUBRICATION & MAINTENANCE 0 - 29

HOISTING (Continued)

Page 43 of 2889

²Do not tow a vehicle in a manner that could

jeopardize the safety of the operator, pedestrians or

other motorists.

²Do not attach tow chains, T-hooks, J-hooks, or a

tow sling to a bumper, steering linkage, drive shafts

or a non-reinforced frame hole.

²Do not tow a heavily loaded vehicle. Damage to

the cab, cargo box or frame may result. Use a flatbed

device to transport a loaded vehicle.

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels removed,

install lug nuts to retain brake drums or rotors.

A towed vehicle should be raised until lifted wheels

are a minimum 100 mm (4 in) from the ground. Be

sure there is adequate ground clearance at the oppo-

site end of the vehicle, especially when towing over

rough terrain or steep rises in the road. If necessary,

remove the wheels from the lifted end of the vehicle

and lower the vehicle closer to the ground, to

increase the ground clearance at the opposite end of

the vehicle. Install lug nuts on wheel attaching studs

to retain brake drums or rotors.

RAMP ANGLE

If a vehicle with flat-bed towing equipment is used,

the approach ramp angle should not exceed 15

degrees.

TOWING WHEN KEYS ARE NOT AVAILABLE

When the vehicle is locked and keys are not avail-

able, use a flat bed hauler. A Wheel-lift or Sling-type

device can be used on 4WD vehicles providedall the

wheels are lifted off the ground using tow dol-

lies.

FOUR-WHEEL-DRIVE VEHICLE TOWING

Chrysler Corporation recommends that a vehicle be

transported on a flat-bed device. A Wheel-lift or

Sling-type device can be used providedall the

wheels are lifted off the ground using tow dol-

lies.

WARNING: WHEN TOWING A DISABLED VEHICLE

AND THE DRIVE WHEELS ARE SECURED IN A

WHEEL LIFT OR TOW DOLLIES, ENSURE THE

TRANSMISSION IS IN THE PARK POSITION (AUTO-

MATIC TRANSMISSION) OR A FORWARD DRIVE

GEAR (MANUAL TRANSMISSION).

CAUTION: Many vehicles are equipped with air

dams, spoilers, and/or ground effect panels. To

avoid component damage, a wheel-lift towing vehi-

cle or a flat-bed hauling vehicle is recommended.

0 - 30 LUBRICATION & MAINTENANCEBR/BE

TOWING (Continued)

Page 44 of 2889

SUSPENSION

TABLE OF CONTENTS

page page

WHEEL ALIGNMENT.......................1

FRONT - 2WD............................7FRONT - 4WD...........................14

REAR..................................26

WHEEL ALIGNMENT

TABLE OF CONTENTS

page page

WHEEL ALIGNMENT

DESCRIPTION............................1

OPERATION.............................2

DIAGNOSIS AND TESTING..................2

PRE-ALIGNMENT........................2

STANDARD PROCEDURE...................2ALIGNMENT INDEPENDENT FRONT

SUSPENSION...........................2

CASTER CORRECTION MEASUREMENT.....3

ALIGNMENT LINK/COIL SUSPENSION........5

SPECIFICATIONS.........................6

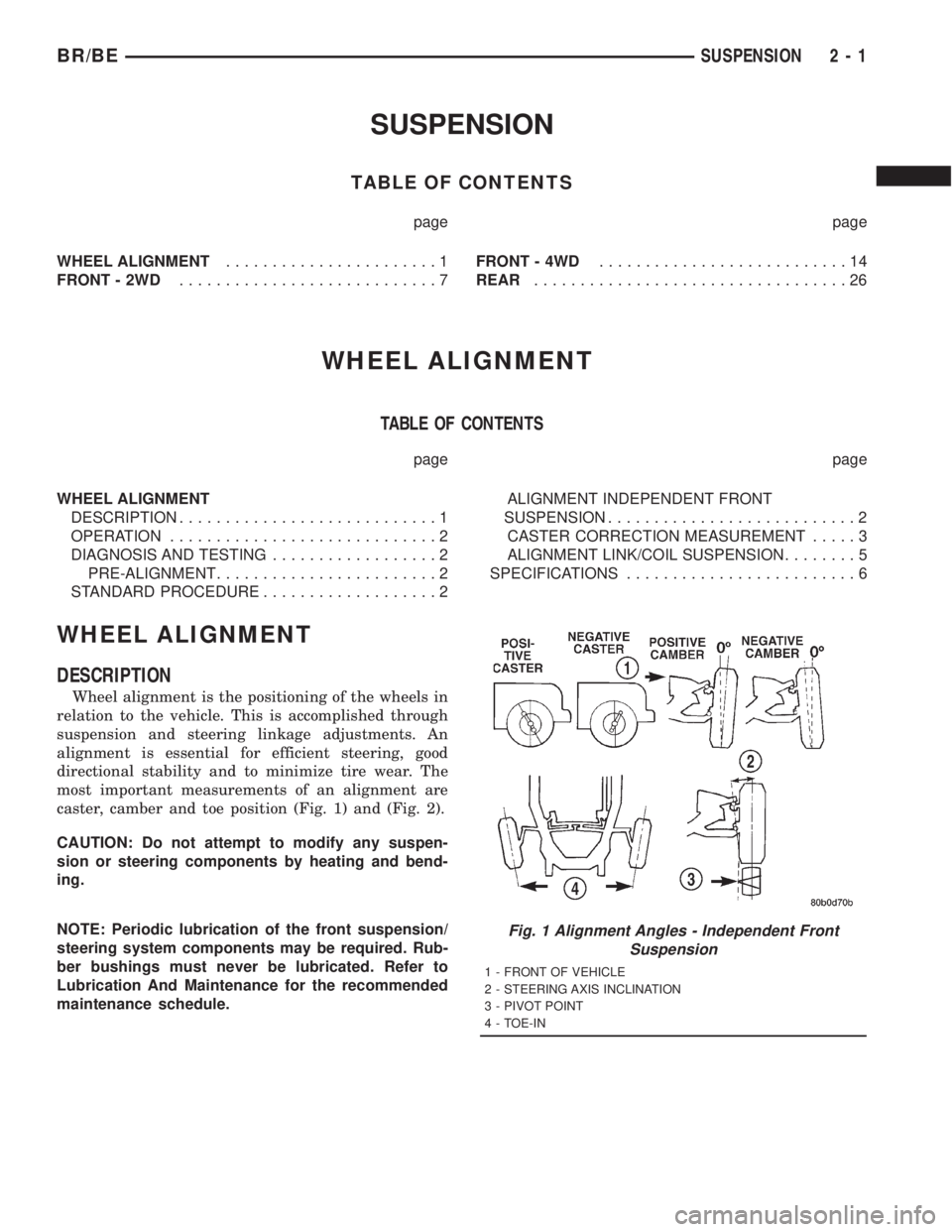

WHEEL ALIGNMENT

DESCRIPTION

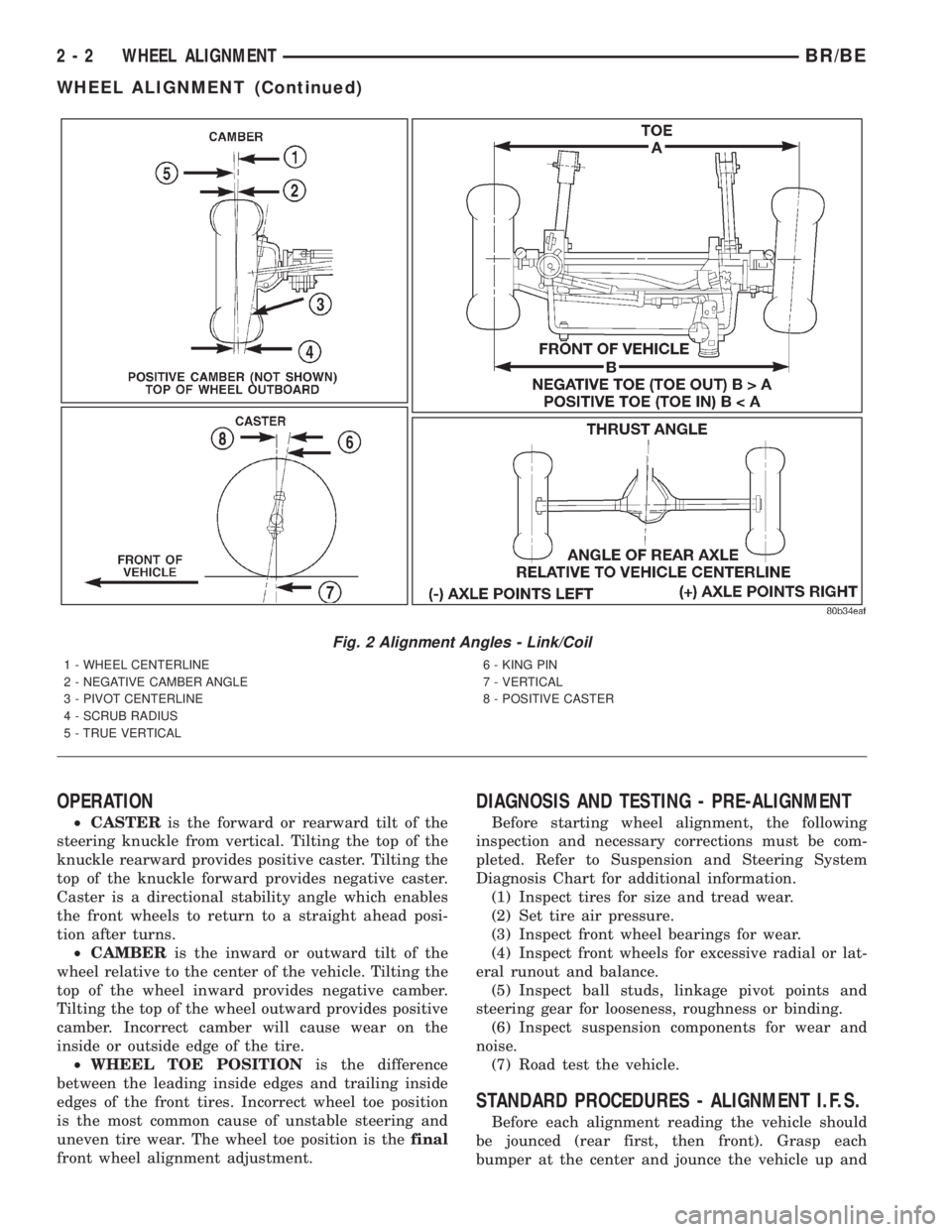

Wheel alignment is the positioning of the wheels in

relation to the vehicle. This is accomplished through

suspension and steering linkage adjustments. An

alignment is essential for efficient steering, good

directional stability and to minimize tire wear. The

most important measurements of an alignment are

caster, camber and toe position (Fig. 1) and (Fig. 2).

CAUTION: Do not attempt to modify any suspen-

sion or steering components by heating and bend-

ing.

NOTE: Periodic lubrication of the front suspension/

steering system components may be required. Rub-

ber bushings must never be lubricated. Refer to

Lubrication And Maintenance for the recommended

maintenance schedule.

Fig. 1 Alignment Angles - Independent Front

Suspension

1 - FRONT OF VEHICLE

2 - STEERING AXIS INCLINATION

3 - PIVOT POINT

4 - TOE-IN

BR/BESUSPENSION 2 - 1

Page 45 of 2889

OPERATION

²CASTERis the forward or rearward tilt of the

steering knuckle from vertical. Tilting the top of the

knuckle rearward provides positive caster. Tilting the

top of the knuckle forward provides negative caster.

Caster is a directional stability angle which enables

the front wheels to return to a straight ahead posi-

tion after turns.

²CAMBERis the inward or outward tilt of the

wheel relative to the center of the vehicle. Tilting the

top of the wheel inward provides negative camber.

Tilting the top of the wheel outward provides positive

camber. Incorrect camber will cause wear on the

inside or outside edge of the tire.

²WHEEL TOE POSITIONis the difference

between the leading inside edges and trailing inside

edges of the front tires. Incorrect wheel toe position

is the most common cause of unstable steering and

uneven tire wear. The wheel toe position is thefinal

front wheel alignment adjustment.

DIAGNOSIS AND TESTING - PRE-ALIGNMENT

Before starting wheel alignment, the following

inspection and necessary corrections must be com-

pleted. Refer to Suspension and Steering System

Diagnosis Chart for additional information.

(1) Inspect tires for size and tread wear.

(2) Set tire air pressure.

(3) Inspect front wheel bearings for wear.

(4) Inspect front wheels for excessive radial or lat-

eral runout and balance.

(5) Inspect ball studs, linkage pivot points and

steering gear for looseness, roughness or binding.

(6) Inspect suspension components for wear and

noise.

(7) Road test the vehicle.

STANDARD PROCEDURES - ALIGNMENT I.F.S.

Before each alignment reading the vehicle should

be jounced (rear first, then front). Grasp each

bumper at the center and jounce the vehicle up and

Fig. 2 Alignment Angles - Link/Coil

1 - WHEEL CENTERLINE

2 - NEGATIVE CAMBER ANGLE

3 - PIVOT CENTERLINE

4 - SCRUB RADIUS

5 - TRUE VERTICAL6 - KING PIN

7 - VERTICAL

8 - POSITIVE CASTER

2 - 2 WHEEL ALIGNMENTBR/BE

WHEEL ALIGNMENT (Continued)

Page 46 of 2889

down several times. Always release the bumper in

the down position.Set the front end alignment to

specifications while the vehicle is in its NOR-

MALLY LOADED CONDITION.

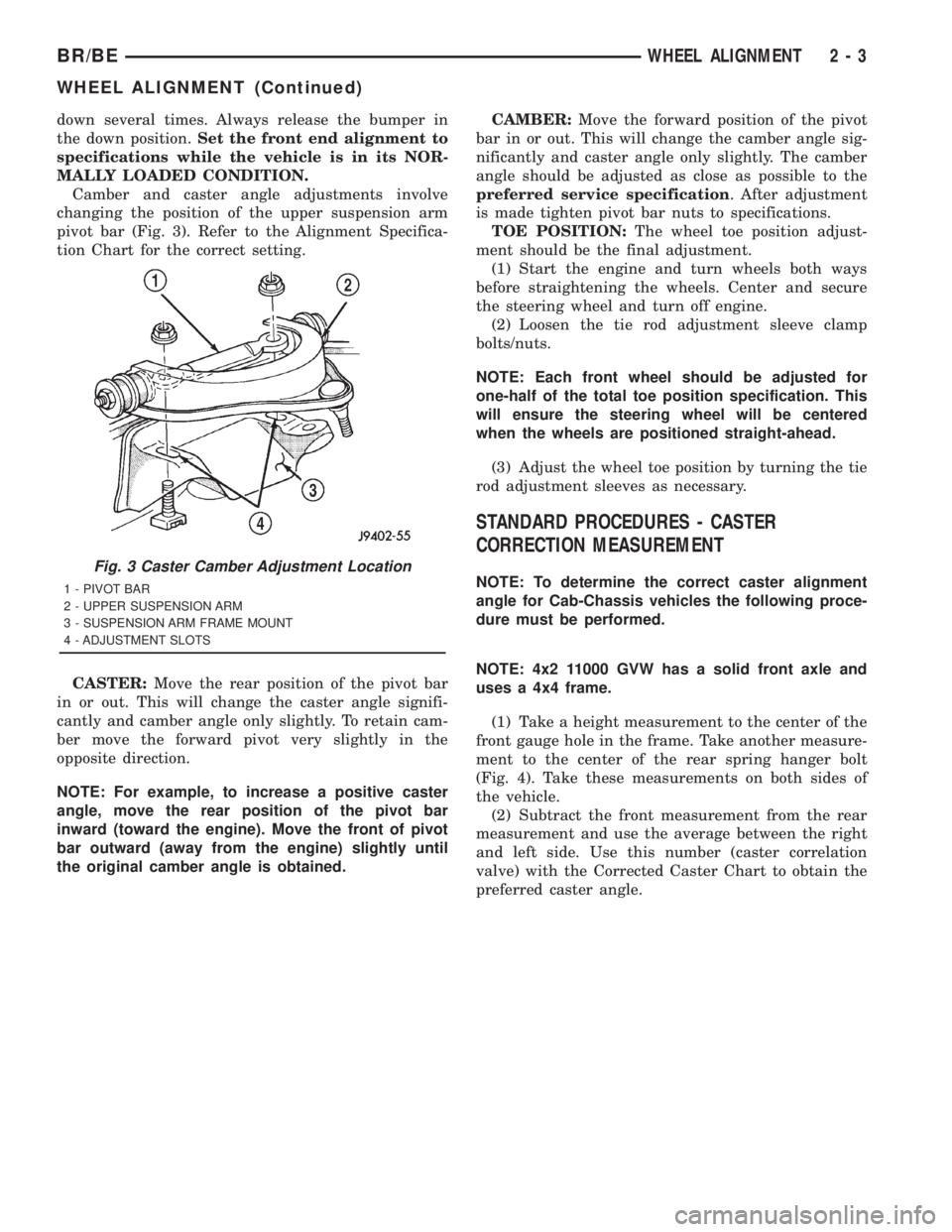

Camber and caster angle adjustments involve

changing the position of the upper suspension arm

pivot bar (Fig. 3). Refer to the Alignment Specifica-

tion Chart for the correct setting.

CASTER:Move the rear position of the pivot bar

in or out. This will change the caster angle signifi-

cantly and camber angle only slightly. To retain cam-

ber move the forward pivot very slightly in the

opposite direction.

NOTE: For example, to increase a positive caster

angle, move the rear position of the pivot bar

inward (toward the engine). Move the front of pivot

bar outward (away from the engine) slightly until

the original camber angle is obtained.CAMBER:Move the forward position of the pivot

bar in or out. This will change the camber angle sig-

nificantly and caster angle only slightly. The camber

angle should be adjusted as close as possible to the

preferred service specification. After adjustment

is made tighten pivot bar nuts to specifications.

TOE POSITION:The wheel toe position adjust-

ment should be the final adjustment.

(1) Start the engine and turn wheels both ways

before straightening the wheels. Center and secure

the steering wheel and turn off engine.

(2) Loosen the tie rod adjustment sleeve clamp

bolts/nuts.

NOTE: Each front wheel should be adjusted for

one-half of the total toe position specification. This

will ensure the steering wheel will be centered

when the wheels are positioned straight-ahead.

(3) Adjust the wheel toe position by turning the tie

rod adjustment sleeves as necessary.

STANDARD PROCEDURES - CASTER

CORRECTION MEASUREMENT

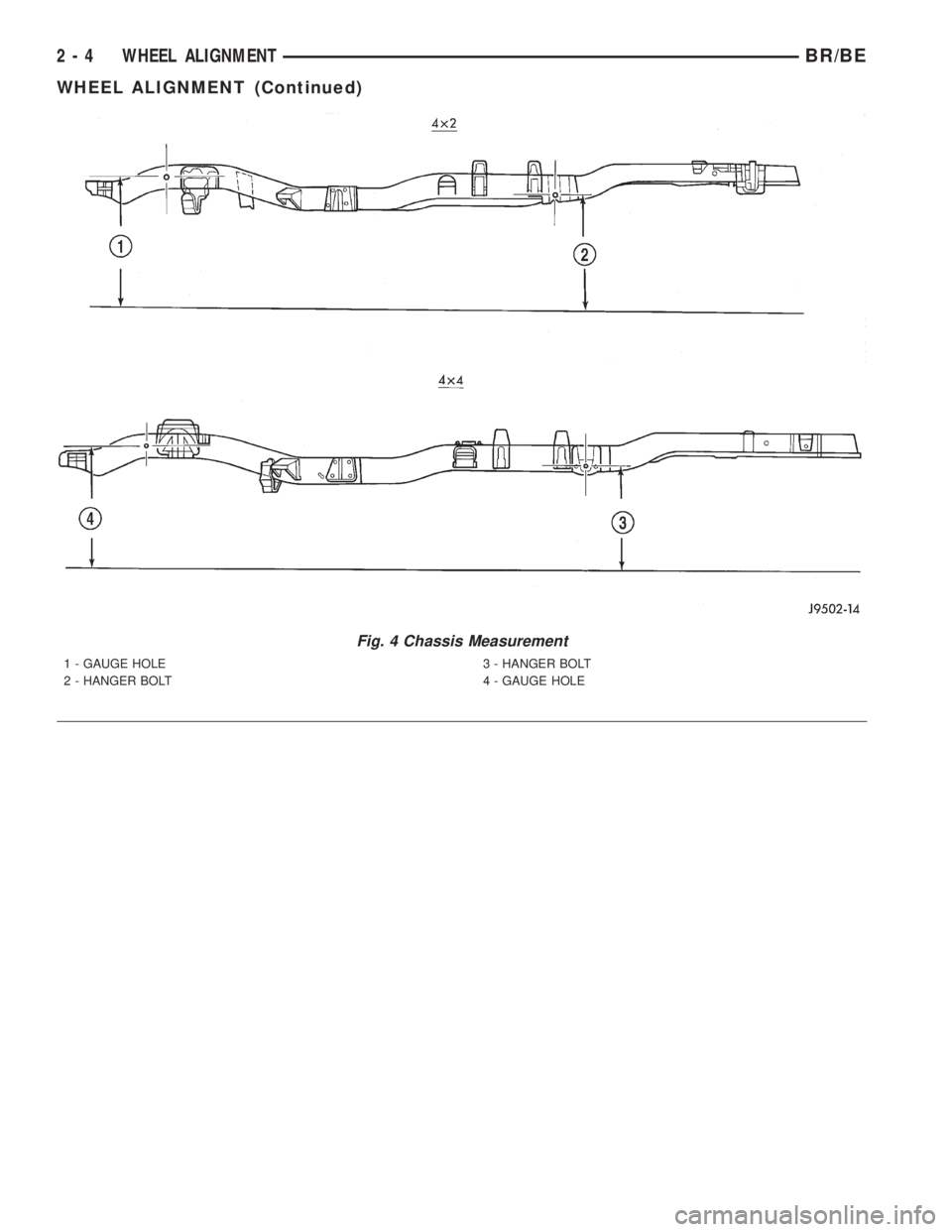

NOTE: To determine the correct caster alignment

angle for Cab-Chassis vehicles the following proce-

dure must be performed.

NOTE: 4x2 11000 GVW has a solid front axle and

uses a 4x4 frame.

(1) Take a height measurement to the center of the

front gauge hole in the frame. Take another measure-

ment to the center of the rear spring hanger bolt

(Fig. 4). Take these measurements on both sides of

the vehicle.

(2) Subtract the front measurement from the rear

measurement and use the average between the right

and left side. Use this number (caster correlation

valve) with the Corrected Caster Chart to obtain the

preferred caster angle.

Fig. 3 Caster Camber Adjustment Location

1 - PIVOT BAR

2 - UPPER SUSPENSION ARM

3 - SUSPENSION ARM FRAME MOUNT

4 - ADJUSTMENT SLOTS

BR/BEWHEEL ALIGNMENT 2 - 3

WHEEL ALIGNMENT (Continued)

Page 47 of 2889

Fig. 4 Chassis Measurement

1 - GAUGE HOLE

2 - HANGER BOLT3 - HANGER BOLT

4 - GAUGE HOLE

2 - 4 WHEEL ALIGNMENTBR/BE

WHEEL ALIGNMENT (Continued)

Page 48 of 2889

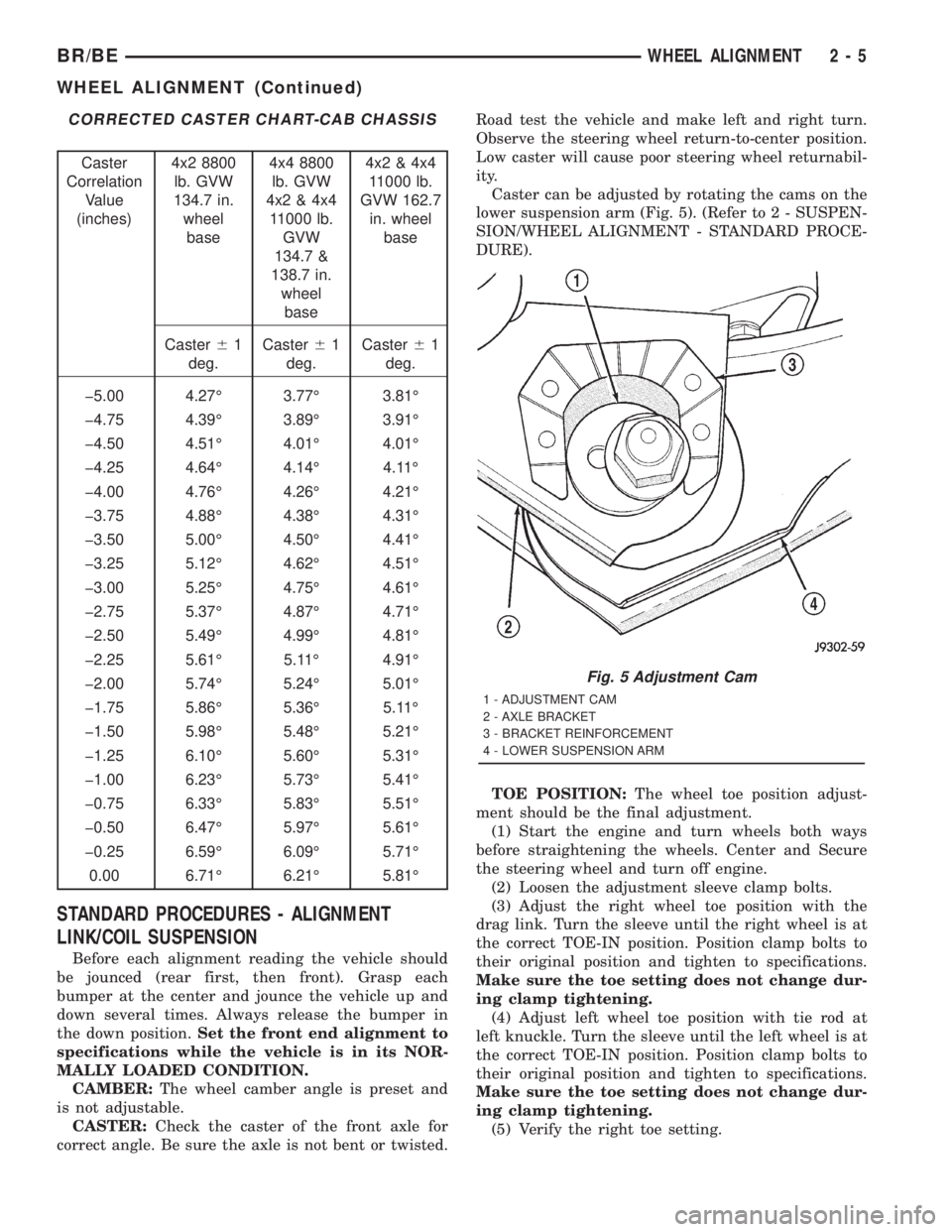

CORRECTED CASTER CHART-CAB CHASSIS

Caster

Correlation

Value

(inches)4x2 8800

lb. GVW

134.7 in.

wheel

base4x4 8800

lb. GVW

4x2 & 4x4

11000 lb.

GVW

134.7 &

138.7 in.

wheel

base4x2 & 4x4

11000 lb.

GVW 162.7

in. wheel

base

Caster61

deg.Caster61

deg.Caster61

deg.

þ5.00 4.27É 3.77É 3.81É

þ4.75 4.39É 3.89É 3.91É

þ4.50 4.51É 4.01É 4.01É

þ4.25 4.64É 4.14É 4.11É

þ4.00 4.76É 4.26É 4.21É

þ3.75 4.88É 4.38É 4.31É

þ3.50 5.00É 4.50É 4.41É

þ3.25 5.12É 4.62É 4.51É

þ3.00 5.25É 4.75É 4.61É

þ2.75 5.37É 4.87É 4.71É

þ2.50 5.49É 4.99É 4.81É

þ2.25 5.61É 5.11É 4.91É

þ2.00 5.74É 5.24É 5.01É

þ1.75 5.86É 5.36É 5.11É

þ1.50 5.98É 5.48É 5.21É

þ1.25 6.10É 5.60É 5.31É

þ1.00 6.23É 5.73É 5.41É

þ0.75 6.33É 5.83É 5.51É

þ0.50 6.47É 5.97É 5.61É

þ0.25 6.59É 6.09É 5.71É

0.00 6.71É 6.21É 5.81É

STANDARD PROCEDURES - ALIGNMENT

LINK/COIL SUSPENSION

Before each alignment reading the vehicle should

be jounced (rear first, then front). Grasp each

bumper at the center and jounce the vehicle up and

down several times. Always release the bumper in

the down position.Set the front end alignment to

specifications while the vehicle is in its NOR-

MALLY LOADED CONDITION.

CAMBER:The wheel camber angle is preset and

is not adjustable.

CASTER:Check the caster of the front axle for

correct angle. Be sure the axle is not bent or twisted.Road test the vehicle and make left and right turn.

Observe the steering wheel return-to-center position.

Low caster will cause poor steering wheel returnabil-

ity.

Caster can be adjusted by rotating the cams on the

lower suspension arm (Fig. 5). (Refer to 2 - SUSPEN-

SION/WHEEL ALIGNMENT - STANDARD PROCE-

DURE).

TOE POSITION:The wheel toe position adjust-

ment should be the final adjustment.

(1) Start the engine and turn wheels both ways

before straightening the wheels. Center and Secure

the steering wheel and turn off engine.

(2) Loosen the adjustment sleeve clamp bolts.

(3) Adjust the right wheel toe position with the

drag link. Turn the sleeve until the right wheel is at

the correct TOE-IN position. Position clamp bolts to

their original position and tighten to specifications.

Make sure the toe setting does not change dur-

ing clamp tightening.

(4) Adjust left wheel toe position with tie rod at

left knuckle. Turn the sleeve until the left wheel is at

the correct TOE-IN position. Position clamp bolts to

their original position and tighten to specifications.

Make sure the toe setting does not change dur-

ing clamp tightening.

(5) Verify the right toe setting.

Fig. 5 Adjustment Cam

1 - ADJUSTMENT CAM

2 - AXLE BRACKET

3 - BRACKET REINFORCEMENT

4 - LOWER SUSPENSION ARM

BR/BEWHEEL ALIGNMENT 2 - 5

WHEEL ALIGNMENT (Continued)

Page 49 of 2889

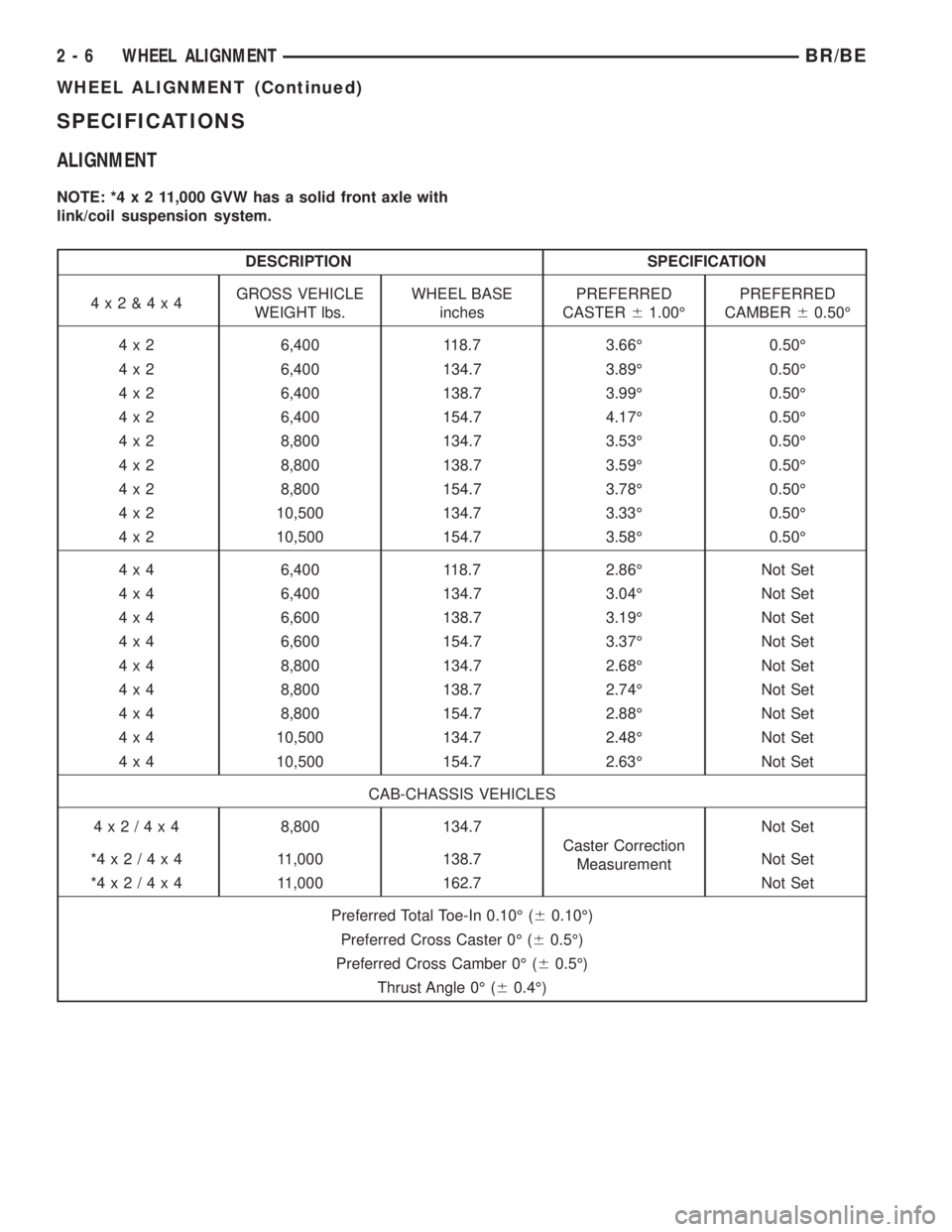

SPECIFICATIONS

ALIGNMENT

NOTE: *4x211,000 GVW has a solid front axle with

link/coil suspension system.

DESCRIPTION SPECIFICATION

4x2&4x4GROSS VEHICLE

WEIGHT lbs.WHEEL BASE

inchesPREFERRED

CASTER61.00ÉPREFERRED

CAMBER60.50É

4 x 2 6,400 118.7 3.66É 0.50É

4 x 2 6,400 134.7 3.89É 0.50É

4 x 2 6,400 138.7 3.99É 0.50É

4 x 2 6,400 154.7 4.17É 0.50É

4 x 2 8,800 134.7 3.53É 0.50É

4 x 2 8,800 138.7 3.59É 0.50É

4 x 2 8,800 154.7 3.78É 0.50É

4 x 2 10,500 134.7 3.33É 0.50É

4 x 2 10,500 154.7 3.58É 0.50É

4 x 4 6,400 118.7 2.86É Not Set

4 x 4 6,400 134.7 3.04É Not Set

4 x 4 6,600 138.7 3.19É Not Set

4 x 4 6,600 154.7 3.37É Not Set

4 x 4 8,800 134.7 2.68É Not Set

4 x 4 8,800 138.7 2.74É Not Set

4 x 4 8,800 154.7 2.88É Not Set

4 x 4 10,500 134.7 2.48É Not Set

4 x 4 10,500 154.7 2.63É Not Set

CAB-CHASSIS VEHICLES

4x2/4x48,800 134.7

Caster Correction

MeasurementNot Set

*4x2/4x4 11,000 138.7 Not Set

*4x2/4x4 11,000 162.7 Not Set

Preferred Total Toe-In 0.10É (60.10É)

Preferred Cross Caster 0É (60.5É)

Preferred Cross Camber 0É (60.5É)

Thrust Angle 0É (60.4É)

2 - 6 WHEEL ALIGNMENTBR/BE

WHEEL ALIGNMENT (Continued)

Page 50 of 2889

FRONT - 2WD

TABLE OF CONTENTS

page page

FRONT - 2WD

DESCRIPTION............................7

SPECIFICATIONS.........................8

SPECIAL TOOLS..........................9

HUB / BEARING

REMOVAL...............................9

INSTALLATION............................9

JOUNCE BUMPER

DESCRIPTION............................9

OPERATION.............................9

KNUCKLE

DESCRIPTION............................9

OPERATION.............................10

REMOVAL..............................10

INSTALLATION...........................10

LOWER BALL JOINT

DIAGNOSIS AND TESTING.................10

LOWER BALL JOINT....................10

LOWER CONTROL ARM

REMOVAL..............................10

INSTALLATION...........................10

SHOCK

DESCRIPTION...........................11OPERATION.............................11

DIAGNOSIS AND TESTING.................11

SHOCK...............................11

REMOVAL..............................11

INSTALLATION...........................11

SPRING

DESCRIPTION...........................11

OPERATION.............................11

REMOVAL..............................11

INSTALLATION...........................12

STABILIZER BAR

DESCRIPTION...........................12

OPERATION.............................12

REMOVAL..............................12

INSTALLATION...........................12

UPPER BALL JOINT

DIAGNOSIS AND TESTING.................12

UPPER BALL JOINT.....................12

UPPER CONTROL ARM

REMOVAL..............................13

INSTALLATION...........................13

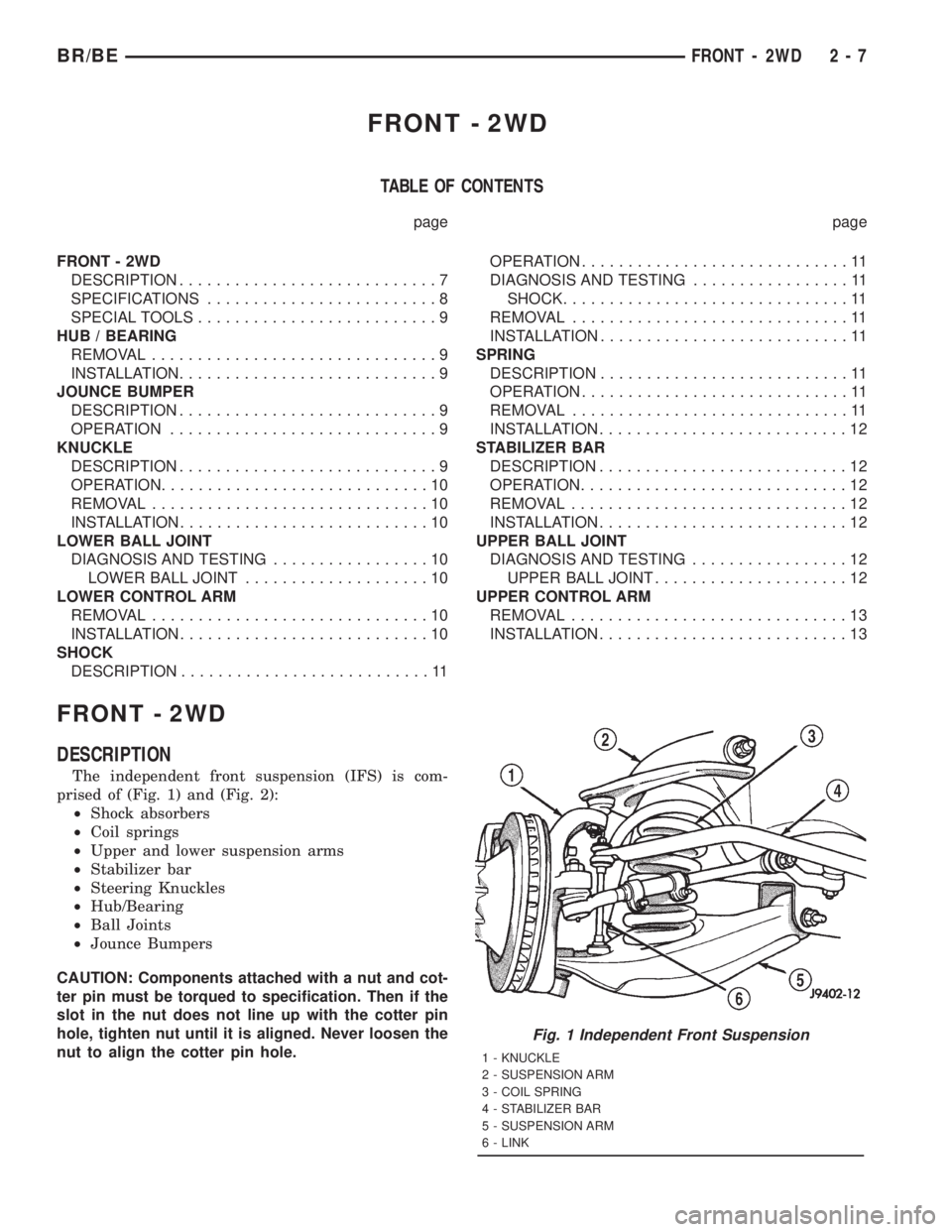

FRONT - 2WD

DESCRIPTION

The independent front suspension (IFS) is com-

prised of (Fig. 1) and (Fig. 2):

²Shock absorbers

²Coil springs

²Upper and lower suspension arms

²Stabilizer bar

²Steering Knuckles

²Hub/Bearing

²Ball Joints

²Jounce Bumpers

CAUTION: Components attached with a nut and cot-

ter pin must be torqued to specification. Then if the

slot in the nut does not line up with the cotter pin

hole, tighten nut until it is aligned. Never loosen the

nut to align the cotter pin hole.

Fig. 1 Independent Front Suspension

1 - KNUCKLE

2 - SUSPENSION ARM

3 - COIL SPRING

4 - STABILIZER BAR

5 - SUSPENSION ARM

6 - LINK

BR/BEFRONT - 2WD 2 - 7