hood release DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 546 of 2255

TURN SIGNAL CANCEL CAM

DESCRIPTION

The turn signal cancel cam is concealed within the

steering column below the steering wheel. The turn

signal cancel cam consists of two lobes that are inte-

gral to the lower surface of the clockspring rotor. The

clockspring mechanism provides turn signal cancella-

tion as well as a constant electrical connection

between the horn switch, driver airbag, speed control

switches, and remote radio switches on the steering

wheel and the instrument panel wire harness on the

steering column. The housing of the clockspring is

secured to the steering column and remains station-

ary. The rotor of the clockspring, including the turn

signal cancel cam lobes rotate with the steering

wheel.

The turn signal cancel cam is serviced as a unit

with the clockspring and cannot be repaired. If faulty

or damaged, the entire clockspring unit must be

replaced. (Refer to 8 - ELECTRICAL/RESTRAINTS/

CLOCKSPRING - REMOVAL).

OPERATION

The turn signal cancel cam has two lobes molded

into the lower surface of the clockspring rotor. When

the turn signals are activated by moving the multi-

function switch control stalk to a detent position, a

turn signal cancel actuator is extended from the

inside surface of the multi-function switch housing

toward the center of the steering column and the

turn signal cancel cam. When the steering wheel is

rotated during a turning maneuver, one of the two

turn signal cancel cam lobes will contact the turn sig-

nal cancel actuator. The cancel actuator latches

against the cancel cam rotation in the direction oppo-

site that which is signaled. In other words, if the left

turn signal detent is selected, the lobes of the cancel

cam will ratchet past the cancel actuator when the

steering wheel is rotated to the left, but will unlatch

the cancel actuator as the steering wheel rotates to

the right and returns to center, which will cancel the

turn signal event and release the control stalk from

the detent so it returns to the neutral Off position.

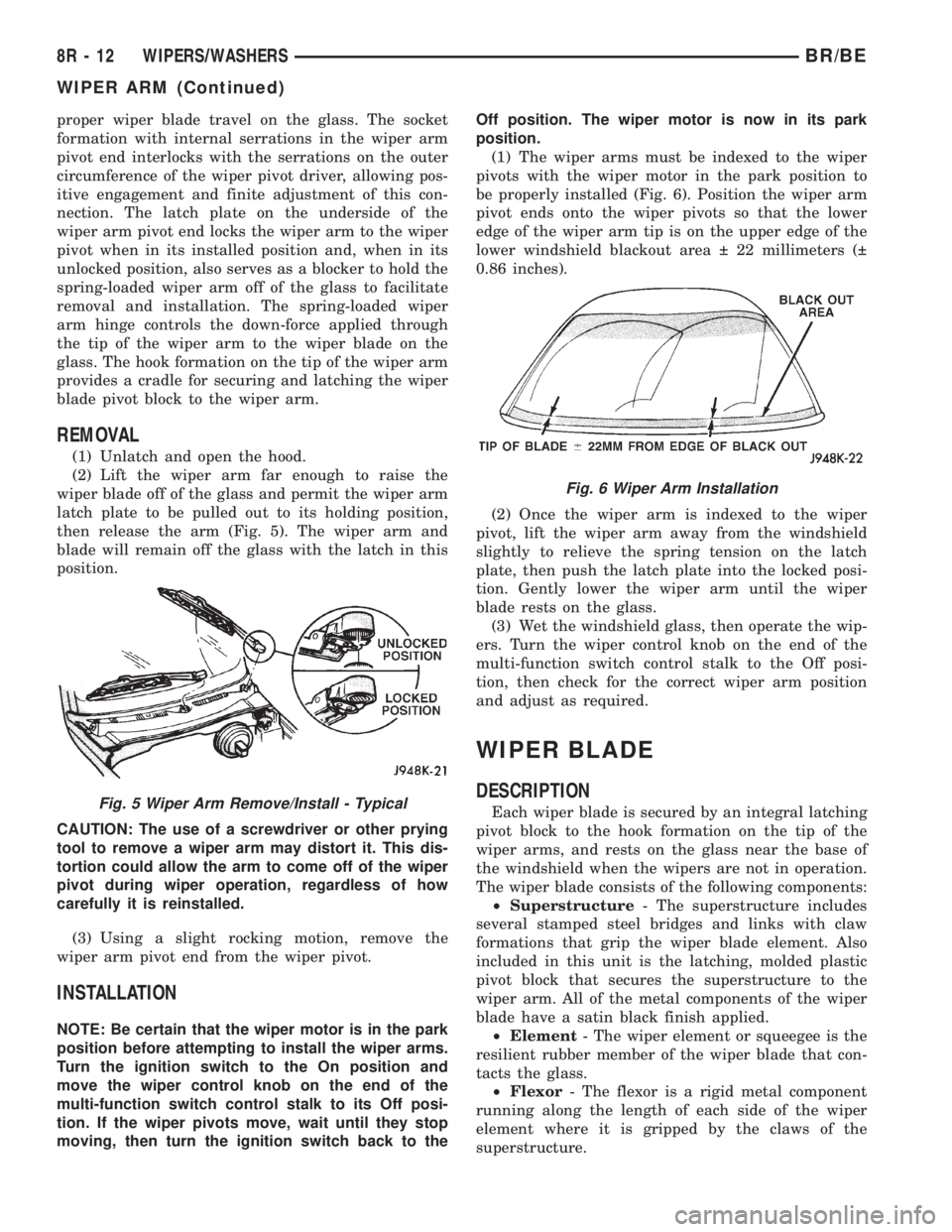

UNDERHOOD LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Insert a small flat blade in the access slot

between the lamp base and lamp lens.

(3) Pry the lamp lens upward and remove the

lamp lens (Fig. 31).

(4) Depress the bulb terminal inward (Fig. 32) to

release the bulb.

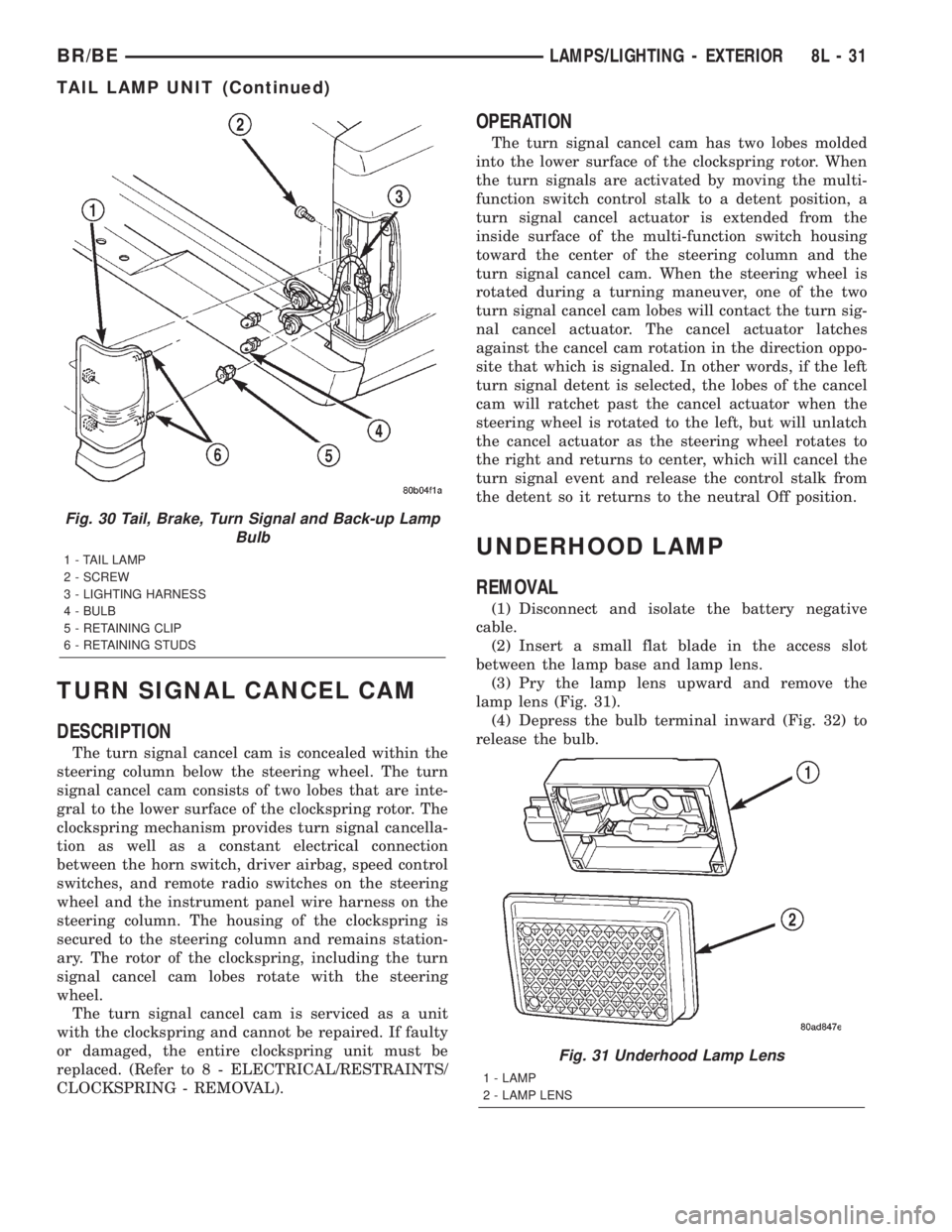

Fig. 30 Tail, Brake, Turn Signal and Back-up Lamp

Bulb

1 - TAIL LAMP

2 - SCREW

3 - LIGHTING HARNESS

4 - BULB

5 - RETAINING CLIP

6 - RETAINING STUDS

Fig. 31 Underhood Lamp Lens

1 - LAMP

2 - LAMP LENS

BR/BELAMPS/LIGHTING - EXTERIOR 8L - 31

TAIL LAMP UNIT (Continued)

Page 655 of 2255

proper wiper blade travel on the glass. The socket

formation with internal serrations in the wiper arm

pivot end interlocks with the serrations on the outer

circumference of the wiper pivot driver, allowing pos-

itive engagement and finite adjustment of this con-

nection. The latch plate on the underside of the

wiper arm pivot end locks the wiper arm to the wiper

pivot when in its installed position and, when in its

unlocked position, also serves as a blocker to hold the

spring-loaded wiper arm off of the glass to facilitate

removal and installation. The spring-loaded wiper

arm hinge controls the down-force applied through

the tip of the wiper arm to the wiper blade on the

glass. The hook formation on the tip of the wiper arm

provides a cradle for securing and latching the wiper

blade pivot block to the wiper arm.

REMOVAL

(1) Unlatch and open the hood.

(2) Lift the wiper arm far enough to raise the

wiper blade off of the glass and permit the wiper arm

latch plate to be pulled out to its holding position,

then release the arm (Fig. 5). The wiper arm and

blade will remain off the glass with the latch in this

position.

CAUTION: The use of a screwdriver or other prying

tool to remove a wiper arm may distort it. This dis-

tortion could allow the arm to come off of the wiper

pivot during wiper operation, regardless of how

carefully it is reinstalled.

(3) Using a slight rocking motion, remove the

wiper arm pivot end from the wiper pivot.

INSTALLATION

NOTE: Be certain that the wiper motor is in the park

position before attempting to install the wiper arms.

Turn the ignition switch to the On position and

move the wiper control knob on the end of the

multi-function switch control stalk to its Off posi-

tion. If the wiper pivots move, wait until they stop

moving, then turn the ignition switch back to theOff position. The wiper motor is now in its park

position.

(1) The wiper arms must be indexed to the wiper

pivots with the wiper motor in the park position to

be properly installed (Fig. 6). Position the wiper arm

pivot ends onto the wiper pivots so that the lower

edge of the wiper arm tip is on the upper edge of the

lower windshield blackout area 22 millimeters (

0.86 inches).

(2) Once the wiper arm is indexed to the wiper

pivot, lift the wiper arm away from the windshield

slightly to relieve the spring tension on the latch

plate, then push the latch plate into the locked posi-

tion. Gently lower the wiper arm until the wiper

blade rests on the glass.

(3) Wet the windshield glass, then operate the wip-

ers. Turn the wiper control knob on the end of the

multi-function switch control stalk to the Off posi-

tion, then check for the correct wiper arm position

and adjust as required.

WIPER BLADE

DESCRIPTION

Each wiper blade is secured by an integral latching

pivot block to the hook formation on the tip of the

wiper arms, and rests on the glass near the base of

the windshield when the wipers are not in operation.

The wiper blade consists of the following components:

²Superstructure- The superstructure includes

several stamped steel bridges and links with claw

formations that grip the wiper blade element. Also

included in this unit is the latching, molded plastic

pivot block that secures the superstructure to the

wiper arm. All of the metal components of the wiper

blade have a satin black finish applied.

²Element- The wiper element or squeegee is the

resilient rubber member of the wiper blade that con-

tacts the glass.

²Flexor- The flexor is a rigid metal component

running along the length of each side of the wiper

element where it is gripped by the claws of the

superstructure.Fig. 5 Wiper Arm Remove/Install - Typical

Fig. 6 Wiper Arm Installation

8R - 12 WIPERS/WASHERSBR/BE

WIPER ARM (Continued)

Page 1066 of 2255

tor between many of the engine compartment, instru-

ment panel, and body wire harnesses. The JB houses

up to nineteen blade-type fuses (two standard-type

and seventeen mini-type), up to two blade-type auto-

matic resetting circuit breakers, the electronic combi-

nation turn signal and hazard warning flasher, and

one International Standards Organization (ISO)

micro-relay.

The molded plastic JB housing has integral mount-

ing brackets that are secured with two screws to the

left instrument panel end bracket. The left end of the

instrument panel cover has a snap-fit fuse access

panel that can be removed for service of the JB. A

fuse puller and spare fuse holders are located on the

back of the fuse access cover, as well as an adhesive-

backed fuse layout map to ensure proper fuse identi-

fication.

The JB unit cannot be repaired and is only ser-

viced as an assembly. If any internal circuit or the JB

housing is faulty or damaged, the entire JB unit

must be replaced.

OPERATION

All of the circuits entering and leaving the JB do

so through up to nine wire harness connectors, which

are connected to the JB through integral connector

receptacles molded into the JB housing. Internal con-

nection of all of the JB circuits is accomplished by an

intricate combination of hard wiring and bus bars.

Refer toWiring Diagramsfor the location of com-

plete JB circuit diagrams.

DIAGNOSIS AND TESTING - JUNCTION BLOCK

The junction block does not incorporate any self

diagnostic capability. Most of the electrical circuits

incorporated into the vehicle must pass through the

junction block at one point or another. The most effi-

cient means of diagnosing a suspected junction block

problem involves a simple continuity tester or ohm

meter. Using the Wiring Diagrams as a guide trace

the problem circuit to the proper junction block cav-

ity and test all circuits in the effected circuit for

proper continuity. A open or high resistance circuit is

a sign of a problem. Some other possible junction

block problems to look for are:

²Loose fuse receptacle terminals.

²Loose relay / circuit breaker receptacle termi-

nals.

²Bent or distorted electrical circuit pins.

²Incorrect size fuse installed in junction block

fuse cavity.

²Dark areas identifying a source of excess heat.

²Defective fuse, relay or circuit breaker installed

in junction block cavity.

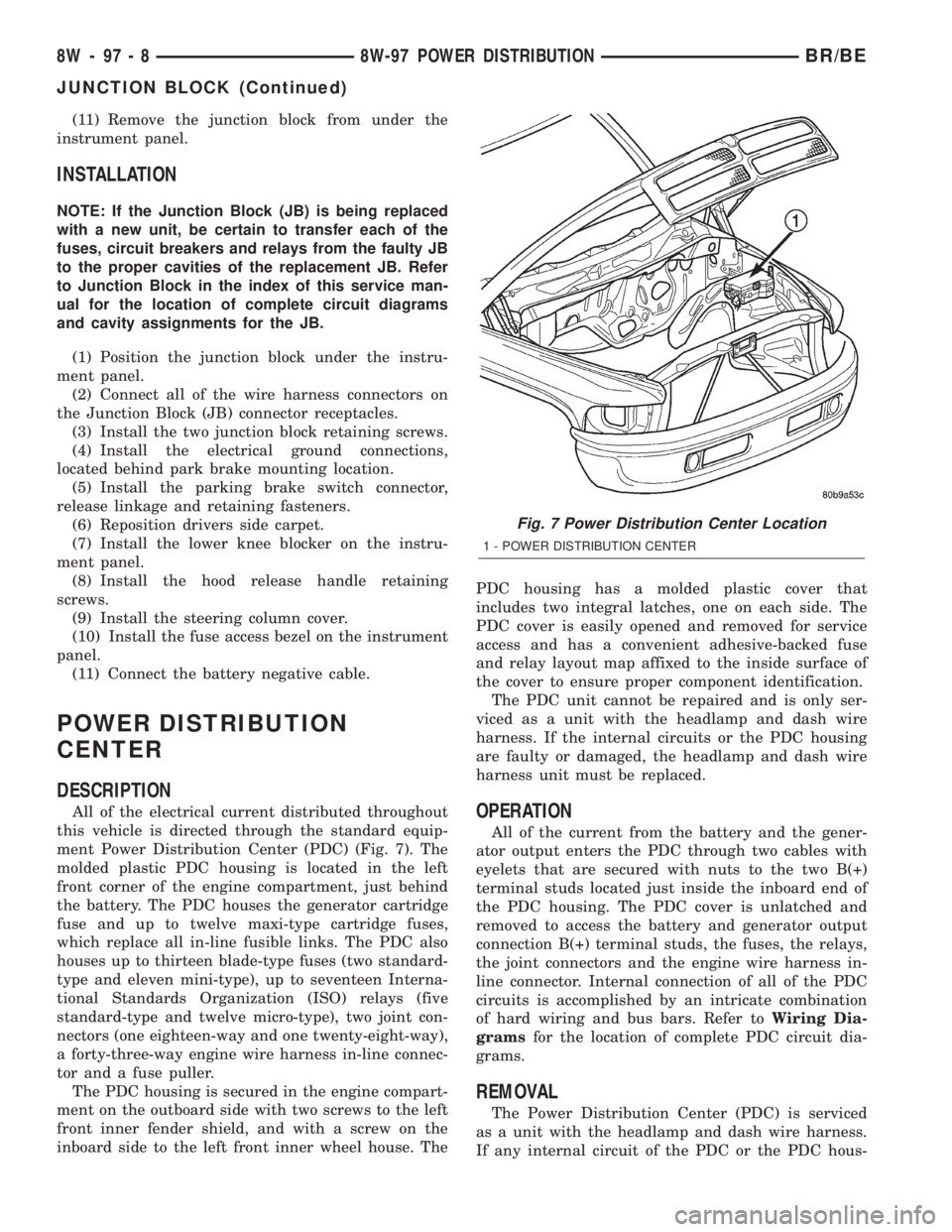

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the fuse access bezel from the instru-

ment panel.

(3) Remove the steering column cover (Refer to 23

- BODY/INSTRUMENT PANEL/STEERING COL-

UMN OPENING COVER - REMOVAL).

(4) Remove the hood release handle retaining

screws and position the handle assembly out of the

way.

(5) Remove the lower knee blocker from the instru-

ment panel.

(6) Pull drivers side carpet down, out of the way.

(7) Remove the parking brake switch connector,

release linkage and retaining fasteners and position

the assembly out the drivers door opening.

(8) Remove the electrical ground connections,

located behind park brake mounting location.

(9) Remove the two junction block retaining

screws. To access the upper retaining screw a 15 inch

long #2 Phillips screwdriver will be required. Access

the upper screw through hole in dash support brace.

(10) Reach through the outboard side of the instru-

ment panel steering column opening to access and

disconnect all of the wire harness connectors from

the Junction Block (JB) connector receptacles (Fig.

6).

Fig. 6 Junction Block Remove/Install

1 - I.P. End Bracket

2 - Junction Block

3 - Screws

BR/BE8W-97 POWER DISTRIBUTION 8W - 97 - 7

JUNCTION BLOCK (Continued)

Page 1067 of 2255

(11) Remove the junction block from under the

instrument panel.

INSTALLATION

NOTE: If the Junction Block (JB) is being replaced

with a new unit, be certain to transfer each of the

fuses, circuit breakers and relays from the faulty JB

to the proper cavities of the replacement JB. Refer

to Junction Block in the index of this service man-

ual for the location of complete circuit diagrams

and cavity assignments for the JB.

(1) Position the junction block under the instru-

ment panel.

(2) Connect all of the wire harness connectors on

the Junction Block (JB) connector receptacles.

(3) Install the two junction block retaining screws.

(4) Install the electrical ground connections,

located behind park brake mounting location.

(5) Install the parking brake switch connector,

release linkage and retaining fasteners.

(6) Reposition drivers side carpet.

(7) Install the lower knee blocker on the instru-

ment panel.

(8) Install the hood release handle retaining

screws.

(9) Install the steering column cover.

(10) Install the fuse access bezel on the instrument

panel.

(11) Connect the battery negative cable.

POWER DISTRIBUTION

CENTER

DESCRIPTION

All of the electrical current distributed throughout

this vehicle is directed through the standard equip-

ment Power Distribution Center (PDC) (Fig. 7). The

molded plastic PDC housing is located in the left

front corner of the engine compartment, just behind

the battery. The PDC houses the generator cartridge

fuse and up to twelve maxi-type cartridge fuses,

which replace all in-line fusible links. The PDC also

houses up to thirteen blade-type fuses (two standard-

type and eleven mini-type), up to seventeen Interna-

tional Standards Organization (ISO) relays (five

standard-type and twelve micro-type), two joint con-

nectors (one eighteen-way and one twenty-eight-way),

a forty-three-way engine wire harness in-line connec-

tor and a fuse puller.

The PDC housing is secured in the engine compart-

ment on the outboard side with two screws to the left

front inner fender shield, and with a screw on the

inboard side to the left front inner wheel house. ThePDC housing has a molded plastic cover that

includes two integral latches, one on each side. The

PDC cover is easily opened and removed for service

access and has a convenient adhesive-backed fuse

and relay layout map affixed to the inside surface of

the cover to ensure proper component identification.

The PDC unit cannot be repaired and is only ser-

viced as a unit with the headlamp and dash wire

harness. If the internal circuits or the PDC housing

are faulty or damaged, the headlamp and dash wire

harness unit must be replaced.OPERATION

All of the current from the battery and the gener-

ator output enters the PDC through two cables with

eyelets that are secured with nuts to the two B(+)

terminal studs located just inside the inboard end of

the PDC housing. The PDC cover is unlatched and

removed to access the battery and generator output

connection B(+) terminal studs, the fuses, the relays,

the joint connectors and the engine wire harness in-

line connector. Internal connection of all of the PDC

circuits is accomplished by an intricate combination

of hard wiring and bus bars. Refer toWiring Dia-

gramsfor the location of complete PDC circuit dia-

grams.

REMOVAL

The Power Distribution Center (PDC) is serviced

as a unit with the headlamp and dash wire harness.

If any internal circuit of the PDC or the PDC hous-

Fig. 7 Power Distribution Center Location

1 - POWER DISTRIBUTION CENTER

8W - 97 - 8 8W-97 POWER DISTRIBUTIONBR/BE

JUNCTION BLOCK (Continued)

Page 2029 of 2255

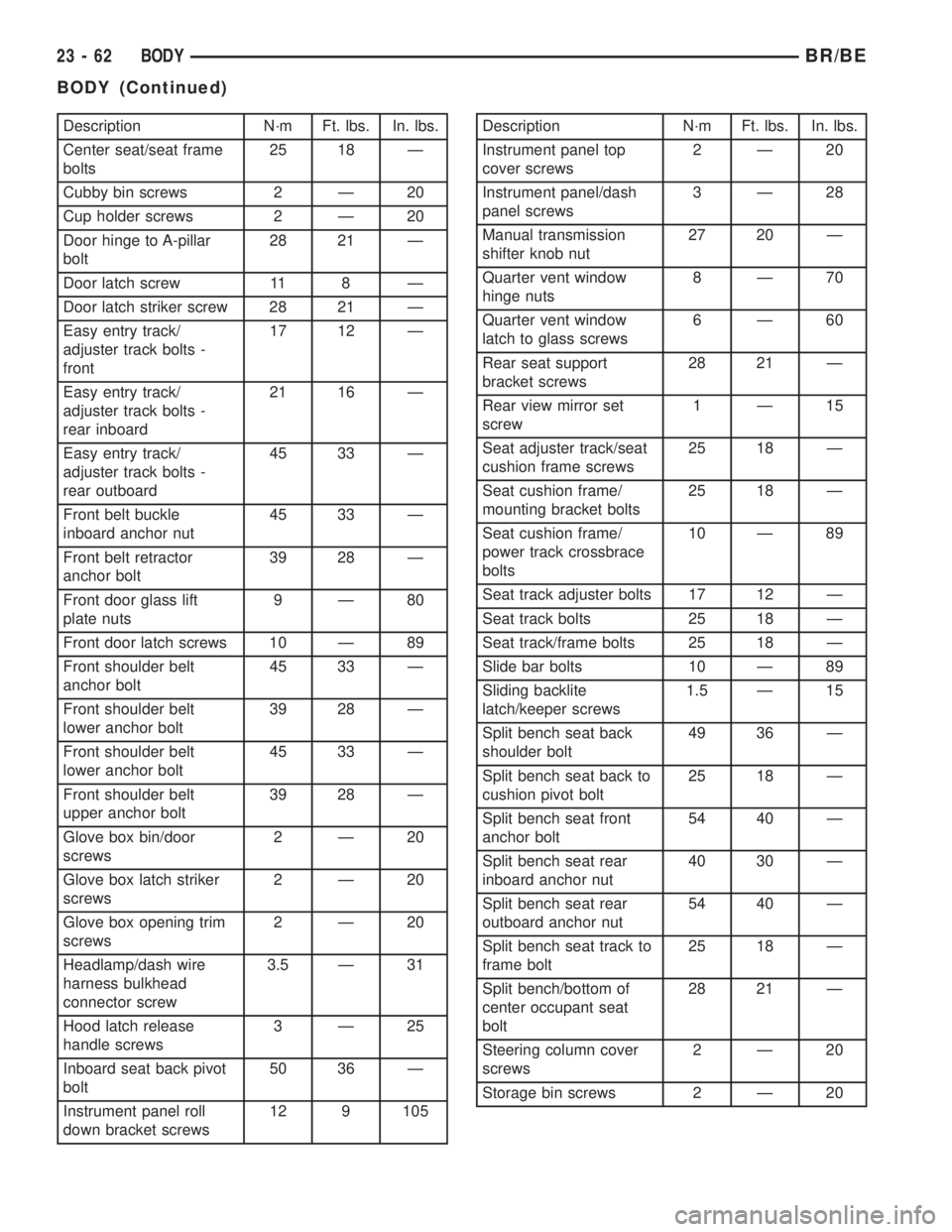

Description N´m Ft. lbs. In. lbs.

Center seat/seat frame

bolts25 18 Ð

Cubby bin screws 2 Ð 20

Cup holder screws 2 Ð 20

Door hinge to A-pillar

bolt28 21 Ð

Door latch screw 11 8 Ð

Door latch striker screw 28 21 Ð

Easy entry track/

adjuster track bolts -

front17 12 Ð

Easy entry track/

adjuster track bolts -

rear inboard21 16 Ð

Easy entry track/

adjuster track bolts -

rear outboard45 33 Ð

Front belt buckle

inboard anchor nut45 33 Ð

Front belt retractor

anchor bolt39 28 Ð

Front door glass lift

plate nuts9Ð80

Front door latch screws 10 Ð 89

Front shoulder belt

anchor bolt45 33 Ð

Front shoulder belt

lower anchor bolt39 28 Ð

Front shoulder belt

lower anchor bolt45 33 Ð

Front shoulder belt

upper anchor bolt39 28 Ð

Glove box bin/door

screws2Ð20

Glove box latch striker

screws2Ð20

Glove box opening trim

screws2Ð20

Headlamp/dash wire

harness bulkhead

connector screw3.5 Ð 31

Hood latch release

handle screws3Ð25

Inboard seat back pivot

bolt50 36 Ð

Instrument panel roll

down bracket screws12 9 105Description N´m Ft. lbs. In. lbs.

Instrument panel top

cover screws2Ð20

Instrument panel/dash

panel screws3Ð28

Manual transmission

shifter knob nut27 20 Ð

Quarter vent window

hinge nuts8Ð70

Quarter vent window

latch to glass screws6Ð60

Rear seat support

bracket screws28 21 Ð

Rear view mirror set

screw1Ð15

Seat adjuster track/seat

cushion frame screws25 18 Ð

Seat cushion frame/

mounting bracket bolts25 18 Ð

Seat cushion frame/

power track crossbrace

bolts10 Ð 89

Seat track adjuster bolts 17 12 Ð

Seat track bolts 25 18 Ð

Seat track/frame bolts 25 18 Ð

Slide bar bolts 10 Ð 89

Sliding backlite

latch/keeper screws1.5 Ð 15

Split bench seat back

shoulder bolt49 36 Ð

Split bench seat back to

cushion pivot bolt25 18 Ð

Split bench seat front

anchor bolt54 40 Ð

Split bench seat rear

inboard anchor nut40 30 Ð

Split bench seat rear

outboard anchor nut54 40 Ð

Split bench seat track to

frame bolt25 18 Ð

Split bench/bottom of

center occupant seat

bolt28 21 Ð

Steering column cover

screws2Ð20

Storage bin screws 2 Ð 20

23 - 62 BODYBR/BE

BODY (Continued)

Page 2058 of 2255

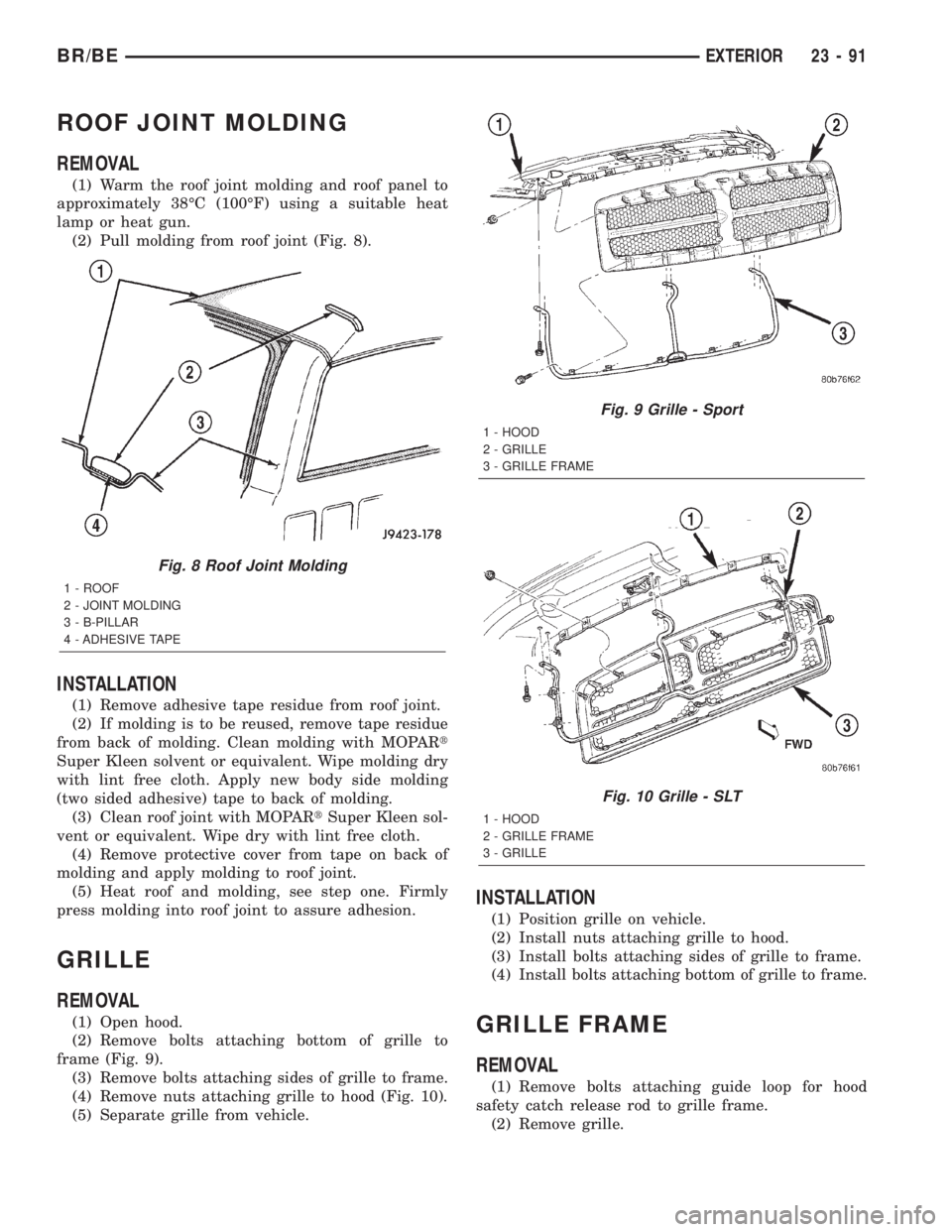

ROOF JOINT MOLDING

REMOVAL

(1) Warm the roof joint molding and roof panel to

approximately 38ÉC (100ÉF) using a suitable heat

lamp or heat gun.

(2) Pull molding from roof joint (Fig. 8).

INSTALLATION

(1) Remove adhesive tape residue from roof joint.

(2) If molding is to be reused, remove tape residue

from back of molding. Clean molding with MOPARt

Super Kleen solvent or equivalent. Wipe molding dry

with lint free cloth. Apply new body side molding

(two sided adhesive) tape to back of molding.

(3) Clean roof joint with MOPARtSuper Kleen sol-

vent or equivalent. Wipe dry with lint free cloth.

(4) Remove protective cover from tape on back of

molding and apply molding to roof joint.

(5) Heat roof and molding, see step one. Firmly

press molding into roof joint to assure adhesion.

GRILLE

REMOVAL

(1) Open hood.

(2) Remove bolts attaching bottom of grille to

frame (Fig. 9).

(3) Remove bolts attaching sides of grille to frame.

(4) Remove nuts attaching grille to hood (Fig. 10).

(5) Separate grille from vehicle.

INSTALLATION

(1) Position grille on vehicle.

(2) Install nuts attaching grille to hood.

(3) Install bolts attaching sides of grille to frame.

(4) Install bolts attaching bottom of grille to frame.

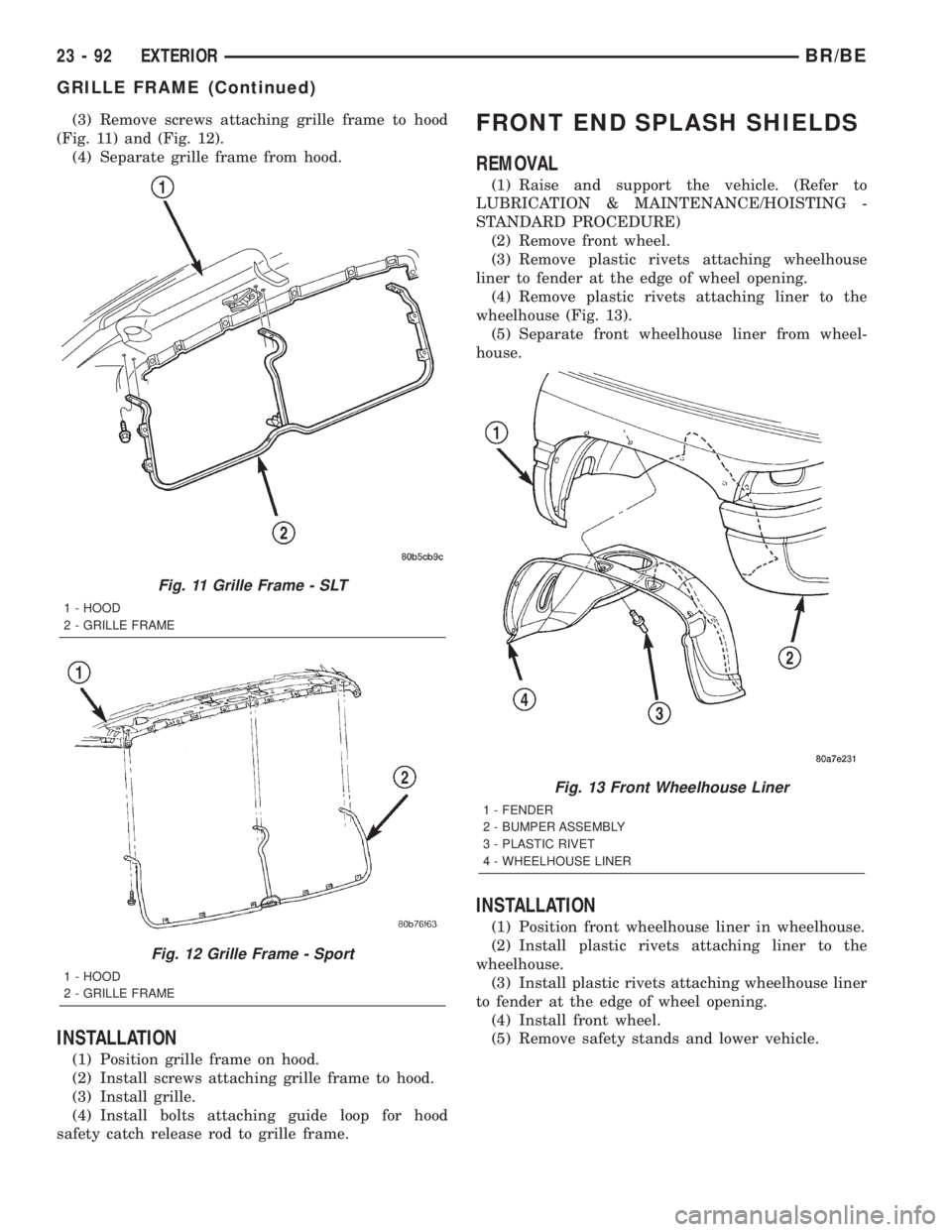

GRILLE FRAME

REMOVAL

(1) Remove bolts attaching guide loop for hood

safety catch release rod to grille frame.

(2) Remove grille.

Fig. 8 Roof Joint Molding

1 - ROOF

2 - JOINT MOLDING

3 - B-PILLAR

4 - ADHESIVE TAPE

Fig. 9 Grille - Sport

1 - HOOD

2 - GRILLE

3 - GRILLE FRAME

Fig. 10 Grille - SLT

1 - HOOD

2 - GRILLE FRAME

3 - GRILLE

BR/BEEXTERIOR 23 - 91

Page 2059 of 2255

(3) Remove screws attaching grille frame to hood

(Fig. 11) and (Fig. 12).

(4) Separate grille frame from hood.

INSTALLATION

(1) Position grille frame on hood.

(2) Install screws attaching grille frame to hood.

(3) Install grille.

(4) Install bolts attaching guide loop for hood

safety catch release rod to grille frame.

FRONT END SPLASH SHIELDS

REMOVAL

(1) Raise and support the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

(2) Remove front wheel.

(3) Remove plastic rivets attaching wheelhouse

liner to fender at the edge of wheel opening.

(4) Remove plastic rivets attaching liner to the

wheelhouse (Fig. 13).

(5) Separate front wheelhouse liner from wheel-

house.

INSTALLATION

(1) Position front wheelhouse liner in wheelhouse.

(2) Install plastic rivets attaching liner to the

wheelhouse.

(3) Install plastic rivets attaching wheelhouse liner

to fender at the edge of wheel opening.

(4) Install front wheel.

(5) Remove safety stands and lower vehicle.

Fig. 11 Grille Frame - SLT

1 - HOOD

2 - GRILLE FRAME

Fig. 12 Grille Frame - Sport

1 - HOOD

2 - GRILLE FRAME

Fig. 13 Front Wheelhouse Liner

1 - FENDER

2 - BUMPER ASSEMBLY

3 - PLASTIC RIVET

4 - WHEELHOUSE LINER

23 - 92 EXTERIORBR/BE

GRILLE FRAME (Continued)

Page 2067 of 2255

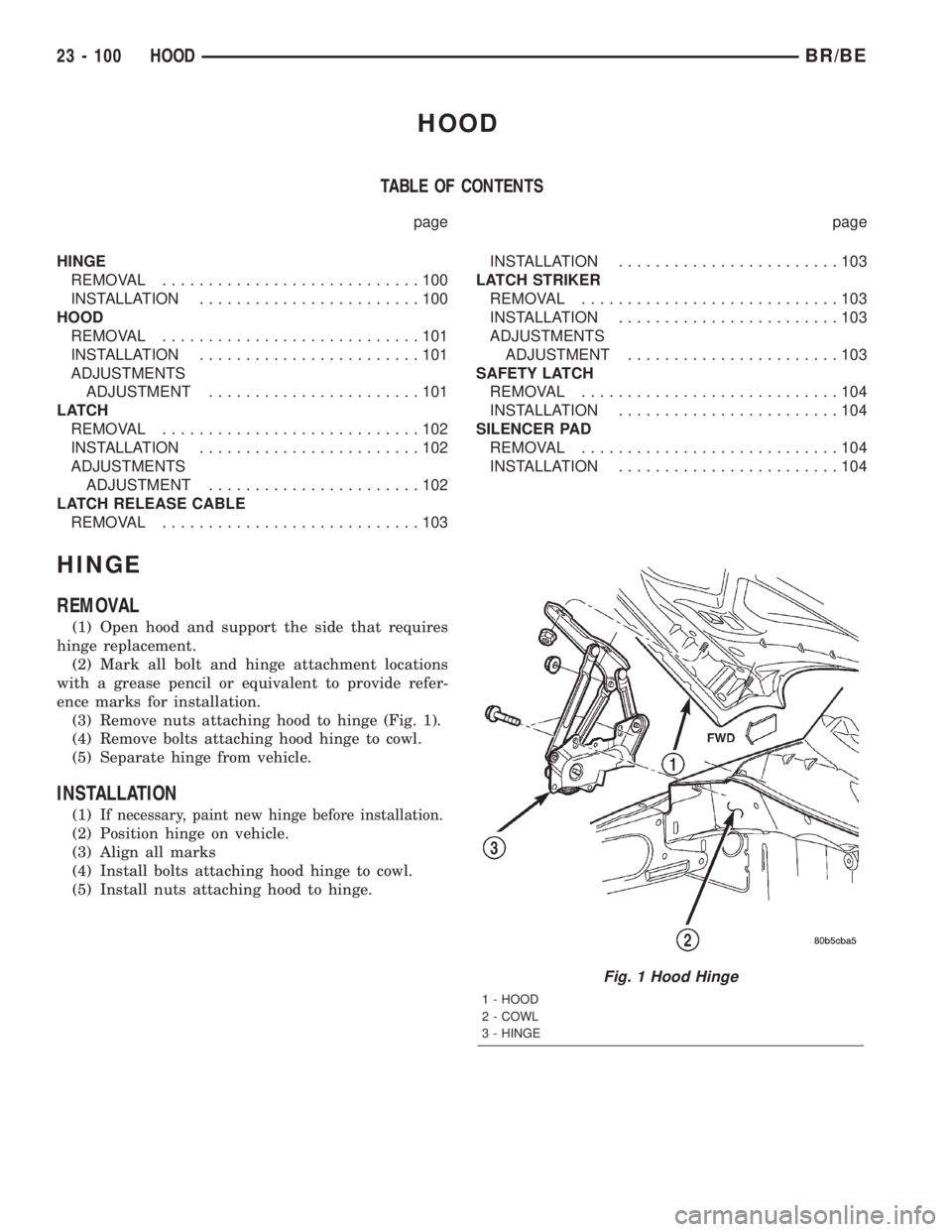

HOOD

TABLE OF CONTENTS

page page

HINGE

REMOVAL............................100

INSTALLATION........................100

HOOD

REMOVAL............................101

INSTALLATION........................101

ADJUSTMENTS

ADJUSTMENT.......................101

LATCH

REMOVAL............................102

INSTALLATION........................102

ADJUSTMENTS

ADJUSTMENT.......................102

LATCH RELEASE CABLE

REMOVAL............................103INSTALLATION........................103

LATCH STRIKER

REMOVAL............................103

INSTALLATION........................103

ADJUSTMENTS

ADJUSTMENT.......................103

SAFETY LATCH

REMOVAL............................104

INSTALLATION........................104

SILENCER PAD

REMOVAL............................104

INSTALLATION........................104

HINGE

REMOVAL

(1) Open hood and support the side that requires

hinge replacement.

(2) Mark all bolt and hinge attachment locations

with a grease pencil or equivalent to provide refer-

ence marks for installation.

(3) Remove nuts attaching hood to hinge (Fig. 1).

(4) Remove bolts attaching hood hinge to cowl.

(5) Separate hinge from vehicle.

INSTALLATION

(1)If necessary, paint new hinge before installation.

(2) Position hinge on vehicle.

(3) Align all marks

(4) Install bolts attaching hood hinge to cowl.

(5) Install nuts attaching hood to hinge.

Fig. 1 Hood Hinge

1 - HOOD

2 - COWL

3 - HINGE

23 - 100 HOODBR/BE

Page 2069 of 2255

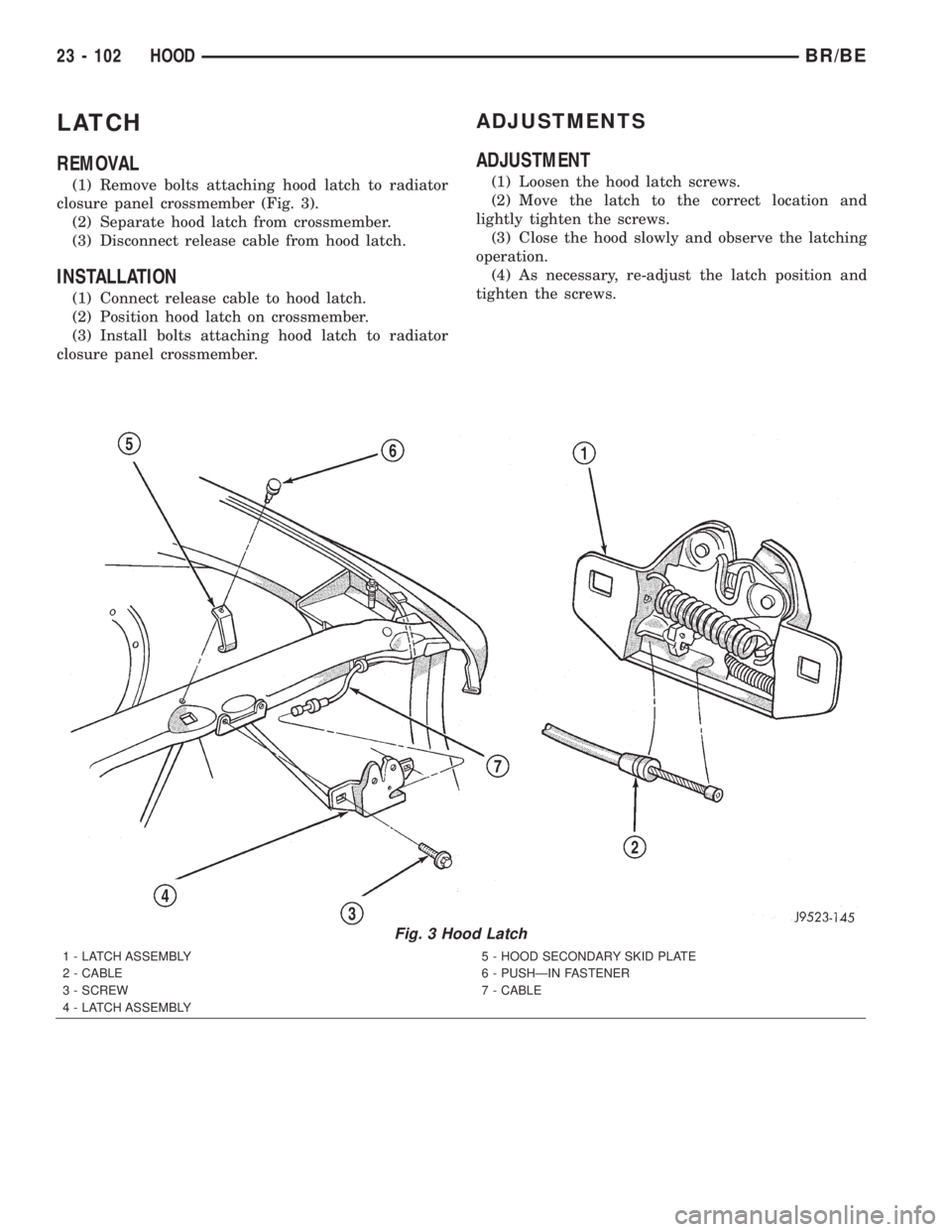

LATCH

REMOVAL

(1) Remove bolts attaching hood latch to radiator

closure panel crossmember (Fig. 3).

(2) Separate hood latch from crossmember.

(3) Disconnect release cable from hood latch.

INSTALLATION

(1) Connect release cable to hood latch.

(2) Position hood latch on crossmember.

(3) Install bolts attaching hood latch to radiator

closure panel crossmember.

ADJUSTMENTS

ADJUSTMENT

(1) Loosen the hood latch screws.

(2) Move the latch to the correct location and

lightly tighten the screws.

(3) Close the hood slowly and observe the latching

operation.

(4) As necessary, re-adjust the latch position and

tighten the screws.

Fig. 3 Hood Latch

1 - LATCH ASSEMBLY

2 - CABLE

3 - SCREW

4 - LATCH ASSEMBLY5 - HOOD SECONDARY SKID PLATE

6 - PUSHÐIN FASTENER

7 - CABLE

23 - 102 HOODBR/BE

Page 2070 of 2255

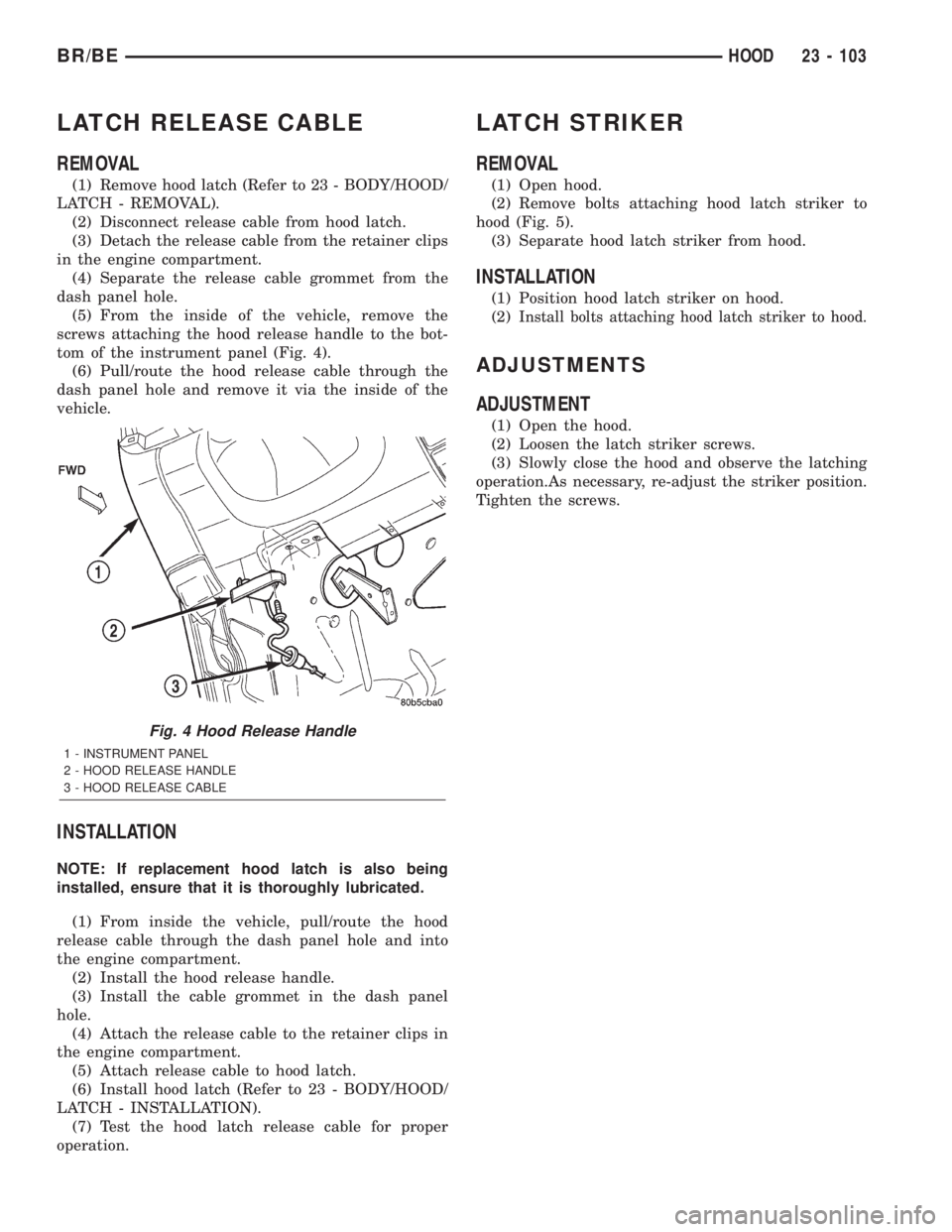

LATCH RELEASE CABLE

REMOVAL

(1) Remove hood latch (Refer to 23 - BODY/HOOD/

LATCH - REMOVAL).

(2) Disconnect release cable from hood latch.

(3) Detach the release cable from the retainer clips

in the engine compartment.

(4) Separate the release cable grommet from the

dash panel hole.

(5) From the inside of the vehicle, remove the

screws attaching the hood release handle to the bot-

tom of the instrument panel (Fig. 4).

(6) Pull/route the hood release cable through the

dash panel hole and remove it via the inside of the

vehicle.

INSTALLATION

NOTE: If replacement hood latch is also being

installed, ensure that it is thoroughly lubricated.

(1) From inside the vehicle, pull/route the hood

release cable through the dash panel hole and into

the engine compartment.

(2) Install the hood release handle.

(3) Install the cable grommet in the dash panel

hole.

(4) Attach the release cable to the retainer clips in

the engine compartment.

(5) Attach release cable to hood latch.

(6) Install hood latch (Refer to 23 - BODY/HOOD/

LATCH - INSTALLATION).

(7) Test the hood latch release cable for proper

operation.

LATCH STRIKER

REMOVAL

(1) Open hood.

(2) Remove bolts attaching hood latch striker to

hood (Fig. 5).

(3) Separate hood latch striker from hood.

INSTALLATION

(1) Position hood latch striker on hood.

(2)

Install bolts attaching hood latch striker to hood.

ADJUSTMENTS

ADJUSTMENT

(1) Open the hood.

(2) Loosen the latch striker screws.

(3) Slowly close the hood and observe the latching

operation.As necessary, re-adjust the striker position.

Tighten the screws.

Fig. 4 Hood Release Handle

1 - INSTRUMENT PANEL

2 - HOOD RELEASE HANDLE

3 - HOOD RELEASE CABLE

BR/BEHOOD 23 - 103