tow bar DODGE RAM 2003 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 722 of 2895

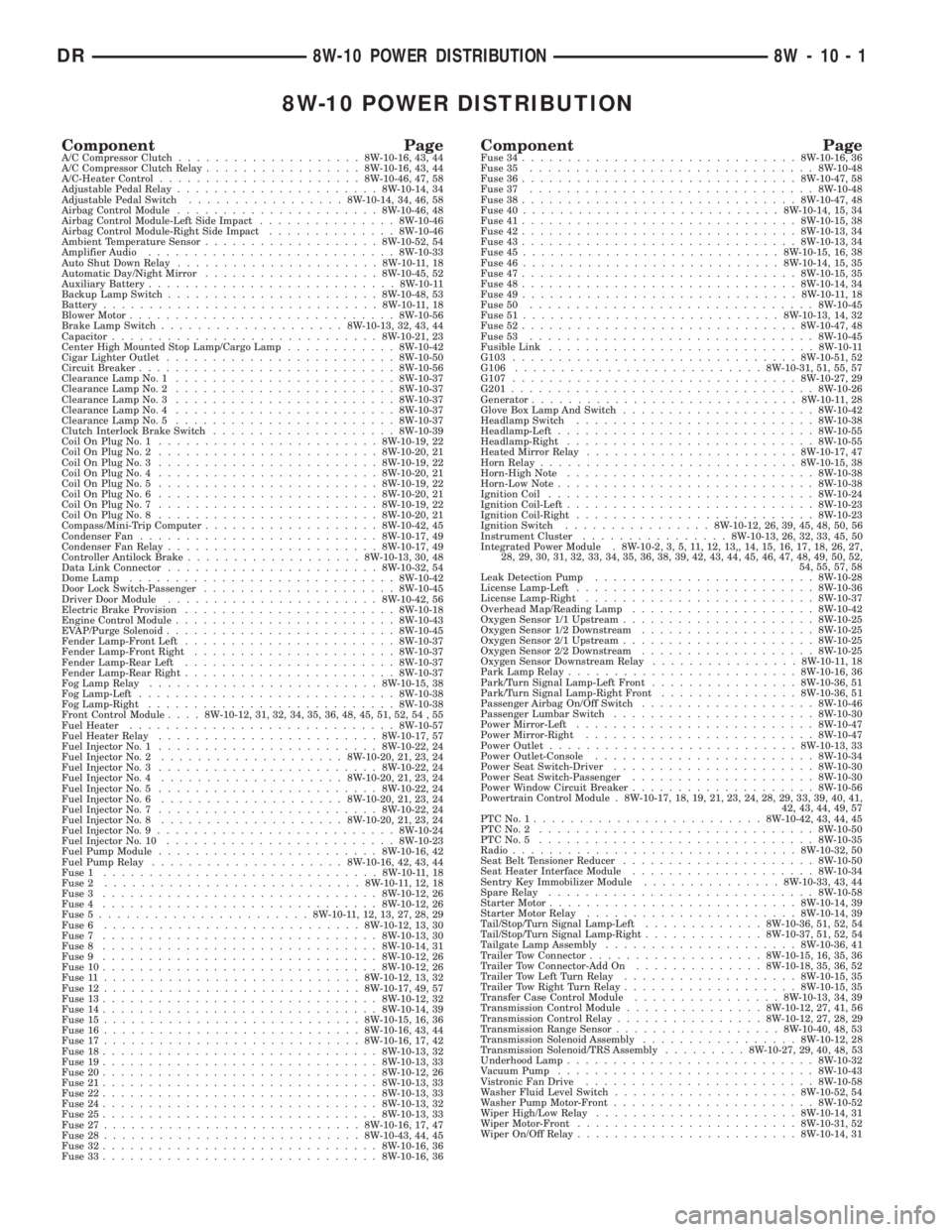

8W-10 POWER DISTRIBUTION

Component PageA/C Compressor Clutch....................8W-10-16, 43, 44

A/C Compressor Clutch Relay.................8W-10-16, 43, 44

A/C-Heater Control......................8W-10-46, 47, 58

Adjustable Pedal Relay......................8W-10-14, 34

Adjustable Pedal Switch.................8W-10-14, 34, 46, 58

Airbag Control Module......................8W-10-46, 48

Airbag Control Module-Left Side Impact...............8W-10-46

Airbag Control Module-Right Side Impact..............8W-10-46

Ambient Temperature Sensor...................8W-10-52, 54

Amplifier Audio...........................8W-10-33

Auto Shut Down Relay......................8W-10-11, 18

Automatic Day/Night Mirror...................8W-10-45, 52

Auxiliary Battery...........................8W-10-11

Backup Lamp Switch.......................8W-10-48, 53

Battery..............................8W-10-11, 18

Blower Motor.............................8W-10-56

Brake Lamp Switch....................8W-10-13, 32, 43, 44

Capacitor.............................8W-10-21, 23

Center High Mounted Stop Lamp/Cargo Lamp............8W-10-42

Cigar Lighter Outlet.........................8W-10-50

Circuit Breaker............................8W-10-56

Clearance Lamp No. 1........................8W-10-37

Clearance Lamp No. 2........................8W-10-37

Clearance Lamp No. 3........................8W-10-37

Clearance Lamp No. 4........................8W-10-37

Clearance Lamp No. 5........................8W-10-37

Clutch Interlock Brake Switch....................8W-10-39

Coil On Plug No. 1........................8W-10-19, 22

Coil On Plug No. 2........................8W-10-20, 21

Coil On Plug No. 3........................8W-10-19, 22

Coil On Plug No. 4........................8W-10-20, 21

Coil On Plug No. 5........................8W-10-19, 22

Coil On Plug No. 6........................8W-10-20, 21

Coil On Plug No. 7........................8W-10-19, 22

Coil On Plug No. 8........................8W-10-20, 21

Compass/Mini-Trip Computer...................8W-10-42, 45

Condenser Fan..........................8W-10-17, 49

Condenser Fan Relay.......................8W-10-17, 49

Controller Antilock Brake...................8W-10-13, 30, 48

Data Link Connector.......................8W-10-32, 54

Dome Lamp.............................8W-10-42

Door Lock Switch-Passenger.....................8W-10-45

Driver Door Module.......................8W-10-42, 56

Electric Brake Provision.......................8W-10-18

Engine Control Module........................8W-10-43

EVAP/Purge Solenoid.........................8W-10-45

Fender Lamp-Front Left.......................8W-10-37

Fender Lamp-Front Right......................8W-10-37

Fender Lamp-Rear Left.......................8W-10-37

Fender Lamp-Rear Right.......................8W-10-37

Fog Lamp Relay.........................8W-10-15, 38

Fog Lamp-Left............................8W-10-38

Fog Lamp-Right...........................8W-10-38

Front Control Module....8W-10-12, 31, 32, 34, 35, 36, 48, 45, 51, 52, 54 , 55

Fuel Heater.............................8W-10-57

Fuel Heater Relay........................8W-10-17, 57

Fuel Injector No. 1........................8W-10-22, 24

Fuel Injector No. 2....................8W-10-20, 21, 23, 24

Fuel Injector No. 3........................8W-10-22, 24

Fuel Injector No. 4....................8W-10-20, 21, 23, 24

Fuel Injector No. 5........................8W-10-22, 24

Fuel Injector No. 6....................8W-10-20, 21, 23, 24

Fuel Injector No. 7........................8W-10-22, 24

Fuel Injector No. 8....................8W-10-20, 21, 23, 24

Fuel Injector No. 9..........................8W-10-24

Fuel Injector No. 10.........................8W-10-23

Fuel Pump Module........................8W-10-16, 42

Fuel Pump Relay.....................8W-10-16, 42, 43, 44

Fuse 1..............................8W-10-11, 18

Fuse 2............................8W-10-11, 12, 18

Fuse 3..............................8W-10-12, 26

Fuse 4..............................8W-10-12, 26

Fuse 5.......................8W-10-11, 12, 13, 27, 28, 29

Fuse 6............................8W-10-12, 13, 30

Fuse 7..............................8W-10-13, 30

Fuse 8..............................8W-10-14, 31

Fuse 9..............................8W-10-12, 26

Fuse 10..............................8W-10-12, 26

Fuse 11............................8W-10-12, 13, 32

Fuse 12............................8W-10-17, 49, 57

Fuse 13..............................8W-10-12, 32

Fuse 14..............................8W-10-14, 39

Fuse 15............................8W-10-15, 16, 36

Fuse 16............................8W-10-16, 43, 44

Fuse 17............................8W-10-16, 17, 42

Fuse 18..............................8W-10-13, 32

Fuse 19..............................8W-10-13, 33

Fuse 20..............................8W-10-12, 26

Fuse 21..............................8W-10-13, 33

Fuse 22..............................8W-10-13, 33

Fuse 24..............................8W-10-13, 32

Fuse 25..............................8W-10-13, 33

Fuse 27............................8W-10-16, 17, 47

Fuse 28............................8W-10-43, 44, 45

Fuse 32..............................8W-10-16, 36

Fuse 33..............................8W-10-16, 36Component PageFuse 34..............................8W-10-16, 36

Fuse 35...............................8W-10-48

Fuse 36..............................8W-10-47, 58

Fuse 37...............................8W-10-48

Fuse 38..............................8W-10-47, 48

Fuse 40............................8W-10-14, 15, 34

Fuse 41..............................8W-10-15, 38

Fuse 42..............................8W-10-13, 34

Fuse 43..............................8W-10-13, 34

Fuse 45............................8W-10-15, 16, 38

Fuse 46............................8W-10-14, 15, 35

Fuse 47..............................8W-10-15, 35

Fuse 48..............................8W-10-14, 34

Fuse 49..............................8W-10-11, 18

Fuse 50...............................8W-10-45

Fuse 51............................8W-10-13, 14, 32

Fuse 52..............................8W-10-47, 48

Fuse 53...............................8W-10-45

Fusible Link.............................8W-10-11

G103...............................8W-10-51, 52

G106...........................8W-10-31, 51, 55, 57

G107...............................8W-10-27, 29

G201.................................8W-10-26

Generator.............................8W-10-11, 28

Glove Box Lamp And Switch.....................8W-10-42

Headlamp Switch..........................8W-10-38

Headlamp-Left............................8W-10-55

Headlamp-Right...........................8W-10-55

Heated Mirror Relay.......................8W-10-17, 47

Horn Relay............................8W-10-15, 38

Horn-High Note...........................8W-10-38

Horn-Low Note............................8W-10-38

Ignition Coil.............................8W-10-24

Ignition Coil-Left...........................8W-10-23

Ignition Coil-Right..........................8W-10-23

Ignition Switch................8W-10-12, 26, 39, 45, 48, 50, 56

Instrument Cluster................8W-10-13, 26, 32, 33, 45, 50

Integrated Power Module . 8W-10-2, 3, 5, 11, 12, 13,, 14, 15, 16, 17, 18, 26, 27,

28, 29, 30, 31, 32, 33, 34, 35, 36, 38, 39, 42, 43, 44, 45, 46, 47, 48, 49, 50, 52,

54, 55, 57, 58

Leak Detection Pump........................8W-10-28

License Lamp-Left..........................8W-10-36

License Lamp-Right.........................8W-10-37

Overhead Map/Reading Lamp....................8W-10-42

Oxygen Sensor 1/1 Upstream.....................8W-10-25

Oxygen Sensor 1/2 Downstream...................8W-10-25

Oxygen Sensor 2/1 Upstream.....................8W-10-25

Oxygen Sensor 2/2 Downstream...................8W-10-25

Oxygen Sensor Downstream Relay................8W-10-11, 18

Park Lamp Relay.........................8W-10-16, 36

Park/Turn Signal Lamp-Left Front................8W-10-36, 51

Park/Turn Signal Lamp-Right Front...............8W-10-36, 51

Passenger Airbag On/Off Switch...................8W-10-46

Passenger Lumbar Switch......................8W-10-30

Power Mirror-Left..........................8W-10-47

Power Mirror-Right.........................8W-10-47

Power Outlet...........................8W-10-13, 33

Power Outlet-Console........................8W-10-34

Power Seat Switch-Driver......................8W-10-30

Power Seat Switch-Passenger....................8W-10-30

Power Window Circuit Breaker....................8W-10-56

Powertrain Control Module . 8W-10-17, 18, 19, 21, 23, 24, 28, 29, 33, 39, 40, 41,

42, 43, 44, 49, 57

PTCNo.1.........................8W-10-42, 43, 44, 45

PTCNo.2 ..............................8W-10-50

PTCNo.5 ..............................8W-10-35

Radio...............................8W-10-32, 50

Seat Belt Tensioner Reducer.....................8W-10-50

Seat Heater Interface Module....................8W-10-34

Sentry Key Immobilizer Module...............8W-10-33, 43, 44

Spare Relay.............................8W-10-58

Starter Motor...........................8W-10-14, 39

Starter Motor Relay.......................8W-10-14, 39

Tail/Stop/Turn Signal Lamp-Left.............8W-10-36, 51, 52, 54

Tail/Stop/Turn Signal Lamp-Right.............8W-10-37, 51, 52, 54

Tailgate Lamp Assembly.....................8W-10-36, 41

Trailer Tow Connector...................8W-10-15, 16, 35, 36

Trailer Tow Connector-Add On..............8W-10-18, 35, 36, 52

Trailer Tow Left Turn Relay...................8W-10-15, 35

Trailer Tow Right Turn Relay...................8W-10-15, 35

Transfer Case Control Module................8W-10-13, 34, 39

Transmission Control Module...............8W-10-12, 27, 41, 56

Transmission Control Relay................8W-10-12, 27, 28, 29

Transmission Range Sensor..................8W-10-40, 48, 53

Transmission Solenoid Assembly.................8W-10-12, 28

Transmission Solenoid/TRS Assembly.........8W-10-27, 29, 40, 48, 53

Underhood Lamp...........................8W-10-32

Vacuum Pump............................8W-10-43

Vistronic Fan Drive.........................8W-10-58

Washer Fluid Level Switch....................8W-10-52, 54

Washer Pump Motor-Front......................8W-10-52

Wiper High/Low Relay......................8W-10-14, 31

Wiper Motor-Front........................8W-10-31, 52

Wiper On/Off Relay........................8W-10-14, 31

DR8W-10 POWER DISTRIBUTION 8W - 10 - 1

Page 1435 of 2895

STANDARD PROCEDURE

STANDARD PROCEDURE - REPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDUREÐHYDROSTATIC

LOCK

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Perform the Fuel Pressure Release Procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(2) Disconnect the negative cable(s) from the bat-

tery.

(3) Inspect air cleaner, induction system, and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the spark plugs.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (coolant, fuel,

oil, etc.).

(7) Be sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt a small amount of engine oil into the

cylinders to lubricate the walls. This will prevent

damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 41 N´m (30 ft. lbs.) torque.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N´m (25 ft. lbs.) torque.

(13) Install a new oil filter.(14) Fill engine crankcase with the specified

amount and grade of oil. (Refer to LUBRICATION &

MAINTENANCE - SPECIFICATIONS).

(15) Connect the negative cable(s) to the battery.

(16) Start the engine and check for any leaks.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove the air cleaner resonator and duct

work as an assembly.

(3) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(4) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(5) Remove the viscous fan/drive (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(6) Remove radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(7) Remove the upper crossmember and top core

support.

NOTE: It is not necessary to drain A/C system for

engine removal.

(8) Remove the A/C compressor with the lines

attached. Secure compressor out of the way.

(9) Remove generator assembly (Refer to 8 -

ELECTRICAL/CHARGING/GENERATOR - REMOV-

AL).

(10) Perform the Fuel System Pressure Release

procedure (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY - STANDARD PROCEDURE).

(11) Remove the intake manifold and IAFM as an

assembly(Refer to 9 - ENGINE/MANIFOLDS/IN-

TAKE MANIFOLD - REMOVAL).

(12) Disconnect the heater hoses.

NOTE: It is not necessary to disconnect P/S hoses

from pump, for P/S pump removal.

(13) Remove the power steering pump and set

aside.

(14) Disconnect the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

(15) Raise and support the vehicle on a hoist and

drain the engine oil.

(16) Remove engine front mount thru-bolt nuts.

(17) Disconnect the transmission oil cooler lines

from their retainers at the oil pan bolts.

(18) Disconnect exhaust pipe at manifolds.

(19) Disconnect the starter wires. Remove starter

motor (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - REMOVAL).

9 - 186 ENGINE - 5.7LDR

ENGINE - 5.7L (Continued)

Page 1482 of 2895

(1) Perform the Fuel Pressure Release Procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(2) Disconnect the negative cable(s) from the bat-

tery.

(3) Inspect air cleaner, induction system, and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the spark plugs.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (coolant, fuel,

oil, etc.).

(7) Be sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt a small amount of engine oil into the

cylinders to lubricate the walls. This will prevent

damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 41 N´m (30 ft. lbs.) torque.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N´m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil. (Refer to LUBRICATION &

MAINTENANCE - SPECIFICATIONS).

(15) Connect the negative cable(s) to the battery.

(16) Start the engine and check for any leaks.

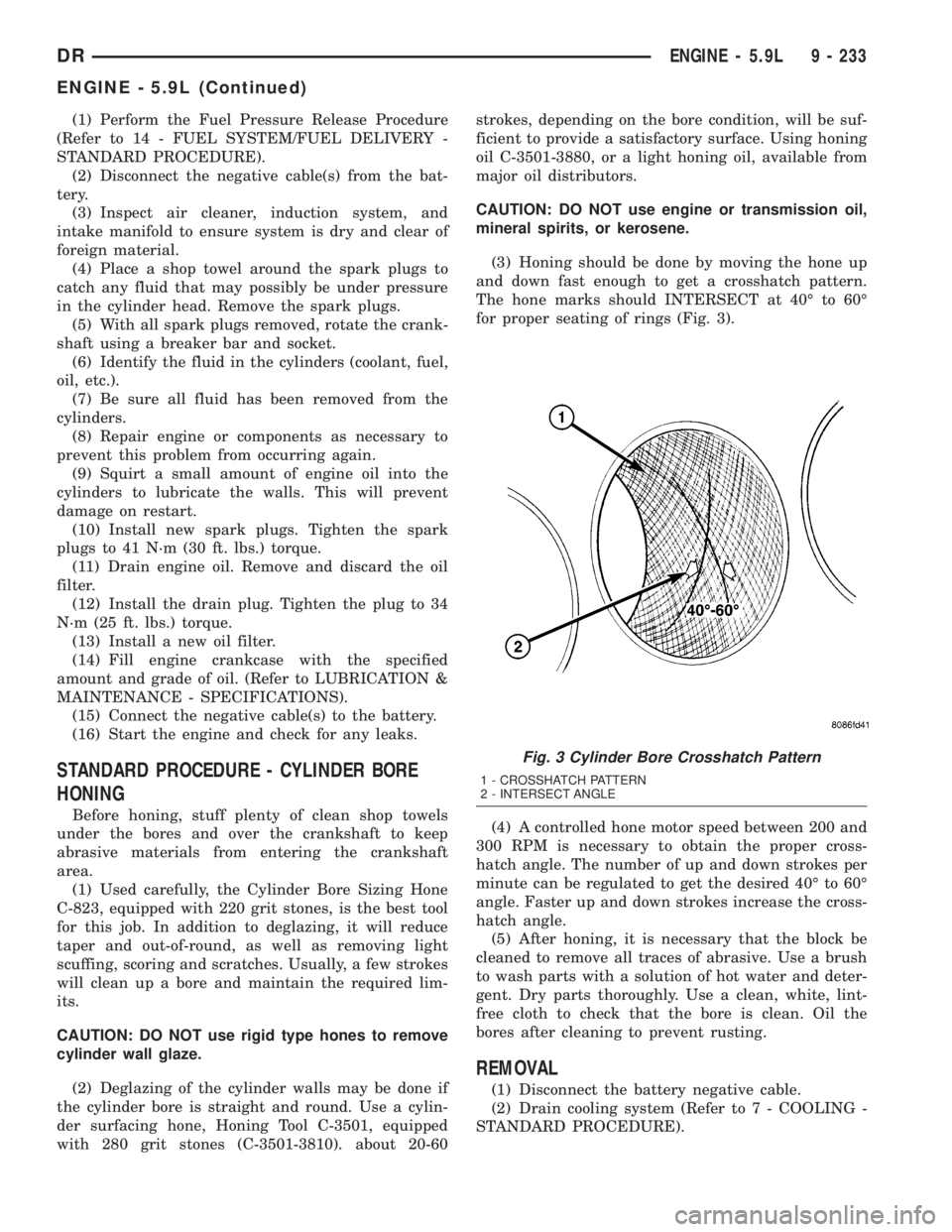

STANDARD PROCEDURE - CYLINDER BORE

HONING

Before honing, stuff plenty of clean shop towels

under the bores and over the crankshaft to keep

abrasive materials from entering the crankshaft

area.

(1) Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round, as well as removing light

scuffing, scoring and scratches. Usually, a few strokes

will clean up a bore and maintain the required lim-

its.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). about 20-60strokes, depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Using honing

oil C-3501-3880, or a light honing oil, available from

major oil distributors.

CAUTION: DO NOT use engine or transmission oil,

mineral spirits, or kerosene.

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.

The hone marks should INTERSECT at 40É to 60É

for proper seating of rings (Fig. 3).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 40É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

Fig. 3 Cylinder Bore Crosshatch Pattern

1 - CROSSHATCH PATTERN

2 - INTERSECT ANGLE

DRENGINE - 5.9L 9 - 233

ENGINE - 5.9L (Continued)

Page 1539 of 2895

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDUREÐHYDROSTATIC

LOCK

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Disconnect the negative cable(s) from the bat-

tery.

(2) Inspect air cleaner, induction system, and

intake manifold to ensure system is dry and clear of

foreign material.

(3) Place a shop towel around the fuel injectors to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the fuel injectors (Refer

to 14 - FUEL SYSTEM/FUEL INJECTION/FUEL

INJECTOR - REMOVAL).

(4) With all injectors removed, rotate the crank-

shaft using the crankshaft barring tool (PN 7471±B).

(5) Identify the fluid in the cylinders (coolant, fuel,

oil, etc.).

(6) Be sure all fluid has been removed from the

cylinders.

(7) Repair engine or components as necessary to

prevent this problem from occurring again.

(8) Squirt a small amount of engine oil into the

cylinders to lubricate the walls. This will prevent

damage on restart.

(9) Install fuel injectors (Refer to 14 - FUEL SYS-

TEM/FUEL INJECTION/FUEL INJECTOR -

INSTALLATION).

(10) Drain engine oil. Remove and discard the oil

filter (Refer to 9 - ENGINE/LUBRICATION/OIL FIL-

TER - REMOVAL).

(11) Install the drain plug. Tighten the plug to 50

N´m (37 ft. lbs.) torque.

(12) Install a new oil filter (Refer to 9 - ENGINE/

LUBRICATION/OIL FILTER - INSTALLATION).

(13) Fill engine crankcase with the specified

amount and grade of oil (Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES - SPECIFICA-

TIONS).

(14) Connect the negative cable(s) to the battery.

(15) Start the engine and check for any leaks.

REMOVAL

REMOVALÐENGINE

(1) Disconnect both battery negative cables.

(2) Disconnect engine grid heater harness at grid

heater relays.(3) Disconnect electrical connections from rear of

alternator.

(4) Recover A/C refrigerant. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE).

(5) Raise vehicle on a hoist.

(6) Drain engine coolant (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(7) Remove engine oil drain plug and drain engine

oil.

(8) Remove fan/drive assembly. Refer to Section 7

± Fan/Drive Removal

(9) Remove radiator upper hose.

(10) Remove upper fan shroud mounting bolts.

(11) Disconnect the coolant recovery bottle hose

from the radiator fill neck and remove bottle.

(12) Using a 36mm wrench, remove viscous fan/

drive assembly. (Refer to 7 - COOLING/ENGINE/RA-

DIATOR FAN - REMOVAL).

(13) Remove cooling fan and shroud together.

(14) Disconnect heater core supply and return

hoses from the cylinder head fitting and coolant pipe.

(15) Raise vehicle on a hoist.

(16) Remove transmission and transfer case (if

equipped).

(17) Disconnect exhaust pipe from turbocharger

extension pipe.

(18) Disconnect engine harness to vehicle harness

connectors.

(19) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL).

(20) Remove flywheel/flexplate.

(21) Remove transmission adapter

(22) Disconnect A/C suction/discharge hose from

the rear of the A/C compressor.

(23) Lower vehicle.

(24) Disconnect lower radiator hose from radiator

outlet.

(25) Automatic transmission models:

(26) Disconnect transmission oil cooler lines from

in front of radiator using special tool #6931

(27) Remove radiator. (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(28) If A/C equipped, disconnect A/C condenser

refrigerant lines.

(29) Disconnect charge air cooler piping.

(30) Remove charge air cooler mounting bolts.

(31) Remove charge air cooler (and A/C condenser

if equipped) from vehicle.

(32) Remove damper and speed indicator ring from

front of engine.

(33) Disconnect engine block heater connector.

(34) Disconnect A/C compressor and pressure sen-

sor electrical connectors.

9 - 290 ENGINE 5.9L DIESELDR

ENGINE 5.9L DIESEL (Continued)

Page 1581 of 2895

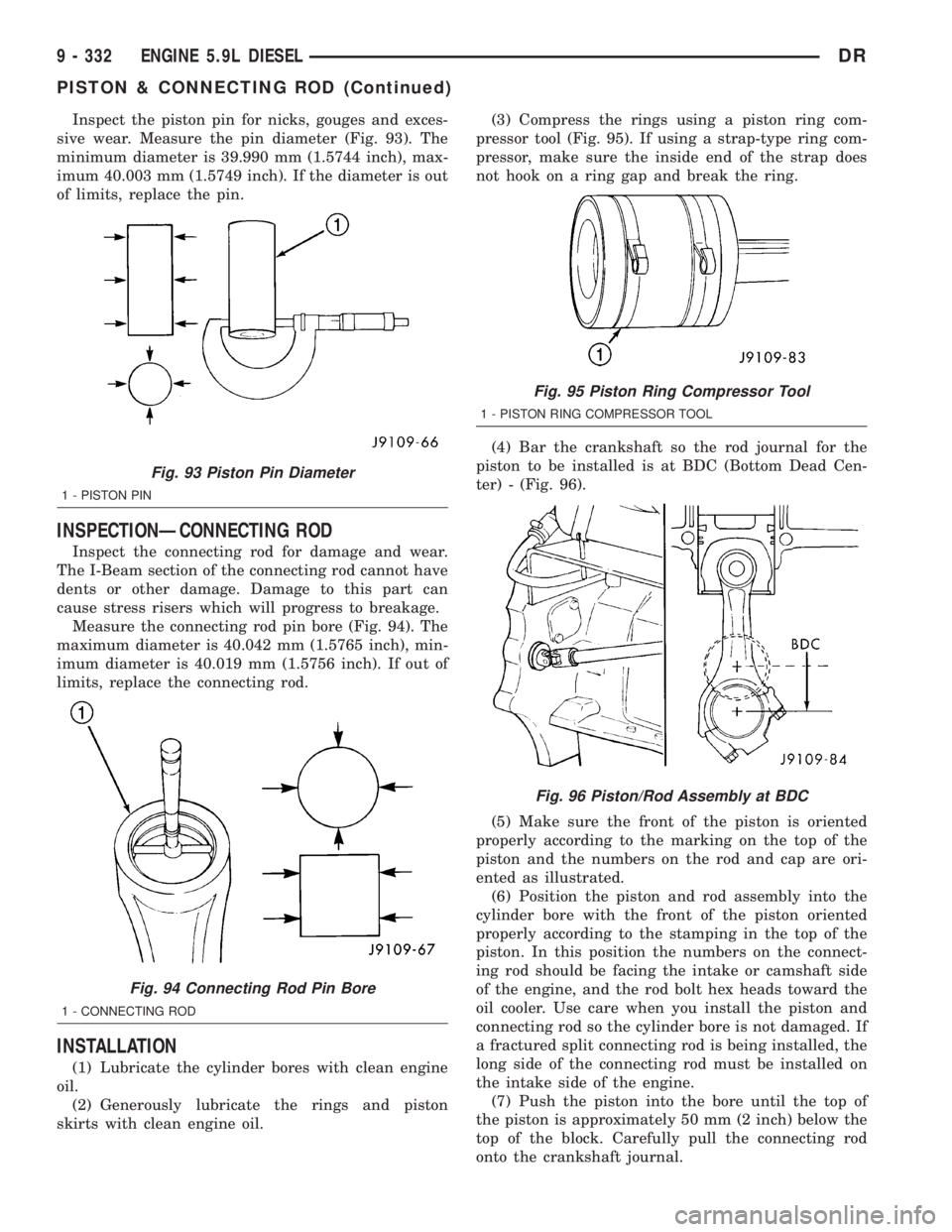

Inspect the piston pin for nicks, gouges and exces-

sive wear. Measure the pin diameter (Fig. 93). The

minimum diameter is 39.990 mm (1.5744 inch), max-

imum 40.003 mm (1.5749 inch). If the diameter is out

of limits, replace the pin.

INSPECTIONÐCONNECTING ROD

Inspect the connecting rod for damage and wear.

The I-Beam section of the connecting rod cannot have

dents or other damage. Damage to this part can

cause stress risers which will progress to breakage.

Measure the connecting rod pin bore (Fig. 94). The

maximum diameter is 40.042 mm (1.5765 inch), min-

imum diameter is 40.019 mm (1.5756 inch). If out of

limits, replace the connecting rod.

INSTALLATION

(1) Lubricate the cylinder bores with clean engine

oil.

(2) Generously lubricate the rings and piston

skirts with clean engine oil.(3) Compress the rings using a piston ring com-

pressor tool (Fig. 95). If using a strap-type ring com-

pressor, make sure the inside end of the strap does

not hook on a ring gap and break the ring.

(4) Bar the crankshaft so the rod journal for the

piston to be installed is at BDC (Bottom Dead Cen-

ter) - (Fig. 96).

(5) Make sure the front of the piston is oriented

properly according to the marking on the top of the

piston and the numbers on the rod and cap are ori-

ented as illustrated.

(6) Position the piston and rod assembly into the

cylinder bore with the front of the piston oriented

properly according to the stamping in the top of the

piston. In this position the numbers on the connect-

ing rod should be facing the intake or camshaft side

of the engine, and the rod bolt hex heads toward the

oil cooler. Use care when you install the piston and

connecting rod so the cylinder bore is not damaged. If

a fractured split connecting rod is being installed, the

long side of the connecting rod must be installed on

the intake side of the engine.

(7) Push the piston into the bore until the top of

the piston is approximately 50 mm (2 inch) below the

top of the block. Carefully pull the connecting rod

onto the crankshaft journal.

Fig. 93 Piston Pin Diameter

1 - PISTON PIN

Fig. 94 Connecting Rod Pin Bore

1 - CONNECTING ROD

Fig. 95 Piston Ring Compressor Tool

1 - PISTON RING COMPRESSOR TOOL

Fig. 96 Piston/Rod Assembly at BDC

9 - 332 ENGINE 5.9L DIESELDR

PISTON & CONNECTING ROD (Continued)

Page 1610 of 2895

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of air

when squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobic

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4oz./16 oz. can w/applicator.

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier than using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - REPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDUREÐHYDROSTATIC

LOCK

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Perform the Fuel Pressure Release Procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(2) Disconnect the negative cable(s) from the bat-

tery.

(3) Inspect air cleaner, induction system, and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the spark plugs.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (coolant, fuel,

oil, etc.).

(7) Be sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt a small amount of engine oil into the

cylinders to lubricate the walls. This will prevent

damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 41 N´m (30 ft. lbs.) torque.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N´m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil. (Refer to LUBRICATION &

MAINTENANCE - SPECIFICATIONS).

(15) Connect the negative cable(s) to the battery.

(16) Start the engine and check for any leaks.

REMOVAL

(1) Remove the battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

DRENGINE 8.0L 9 - 361

ENGINE 8.0L (Continued)

Page 1958 of 2895

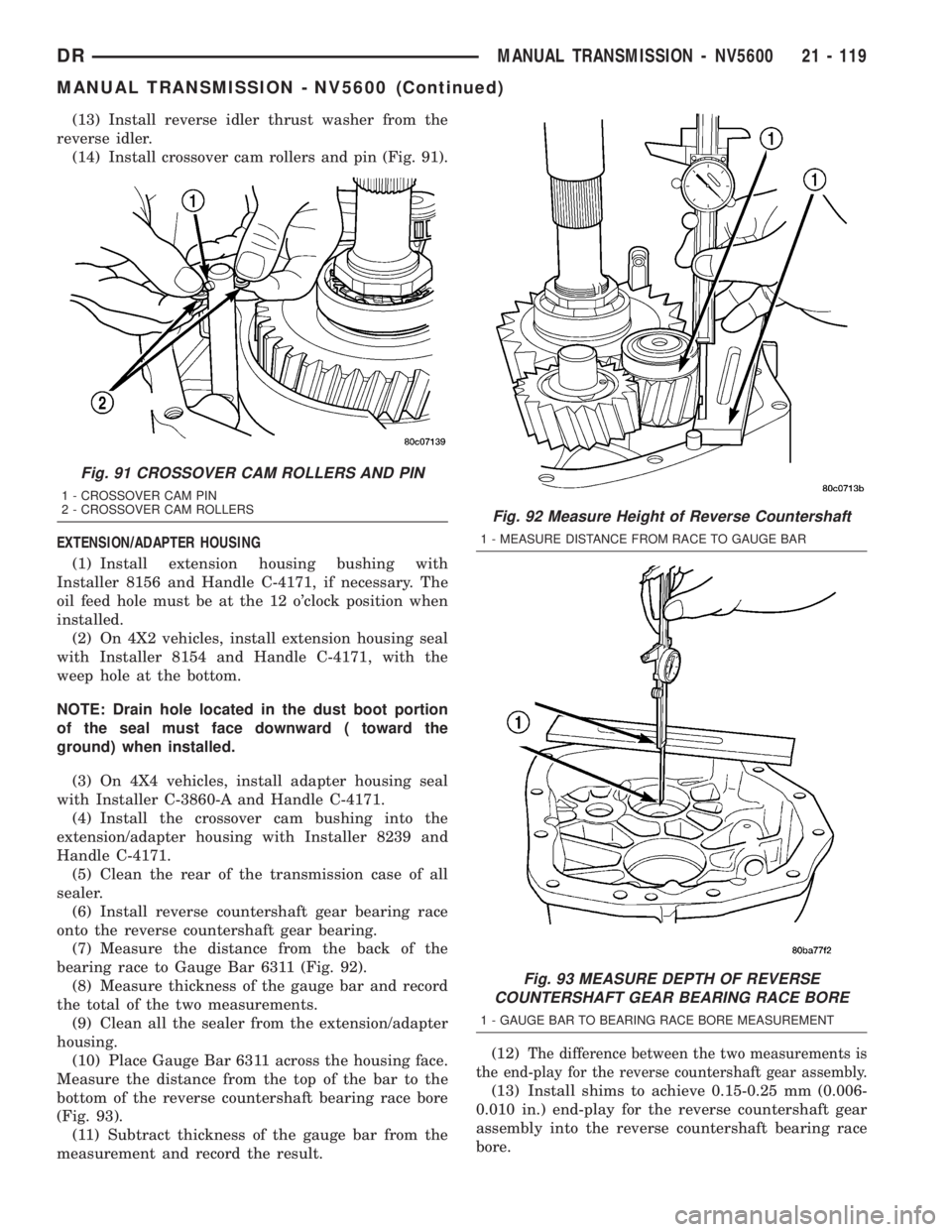

(13) Install reverse idler thrust washer from the

reverse idler.

(14) Install crossover cam rollers and pin (Fig. 91).

EXTENSION/ADAPTER HOUSING

(1) Install extension housing bushing with

Installer 8156 and Handle C-4171, if necessary. The

oil feed hole must be at the 12 o'clock position when

installed.

(2) On 4X2 vehicles, install extension housing seal

with Installer 8154 and Handle C-4171, with the

weep hole at the bottom.

NOTE: Drain hole located in the dust boot portion

of the seal must face downward ( toward the

ground) when installed.

(3) On 4X4 vehicles, install adapter housing seal

with Installer C-3860-A and Handle C-4171.

(4) Install the crossover cam bushing into the

extension/adapter housing with Installer 8239 and

Handle C-4171.

(5) Clean the rear of the transmission case of all

sealer.

(6) Install reverse countershaft gear bearing race

onto the reverse countershaft gear bearing.

(7) Measure the distance from the back of the

bearing race to Gauge Bar 6311 (Fig. 92).

(8) Measure thickness of the gauge bar and record

the total of the two measurements.

(9) Clean all the sealer from the extension/adapter

housing.

(10) Place Gauge Bar 6311 across the housing face.

Measure the distance from the top of the bar to the

bottom of the reverse countershaft bearing race bore

(Fig. 93).

(11) Subtract thickness of the gauge bar from the

measurement and record the result.(12)

The difference between the two measurements is

the end-play for the reverse countershaft gear assembly.

(13) Install shims to achieve 0.15-0.25 mm (0.006-

0.010 in.) end-play for the reverse countershaft gear

assembly into the reverse countershaft bearing race

bore.

Fig. 91 CROSSOVER CAM ROLLERS AND PIN

1 - CROSSOVER CAM PIN

2 - CROSSOVER CAM ROLLERS

Fig. 92 Measure Height of Reverse Countershaft

1 - MEASURE DISTANCE FROM RACE TO GAUGE BAR

Fig. 93 MEASURE DEPTH OF REVERSE

COUNTERSHAFT GEAR BEARING RACE BORE

1 - GAUGE BAR TO BEARING RACE BORE MEASUREMENT

DRMANUAL TRANSMISSION - NV5600 21 - 119

MANUAL TRANSMISSION - NV5600 (Continued)

Page 2090 of 2895

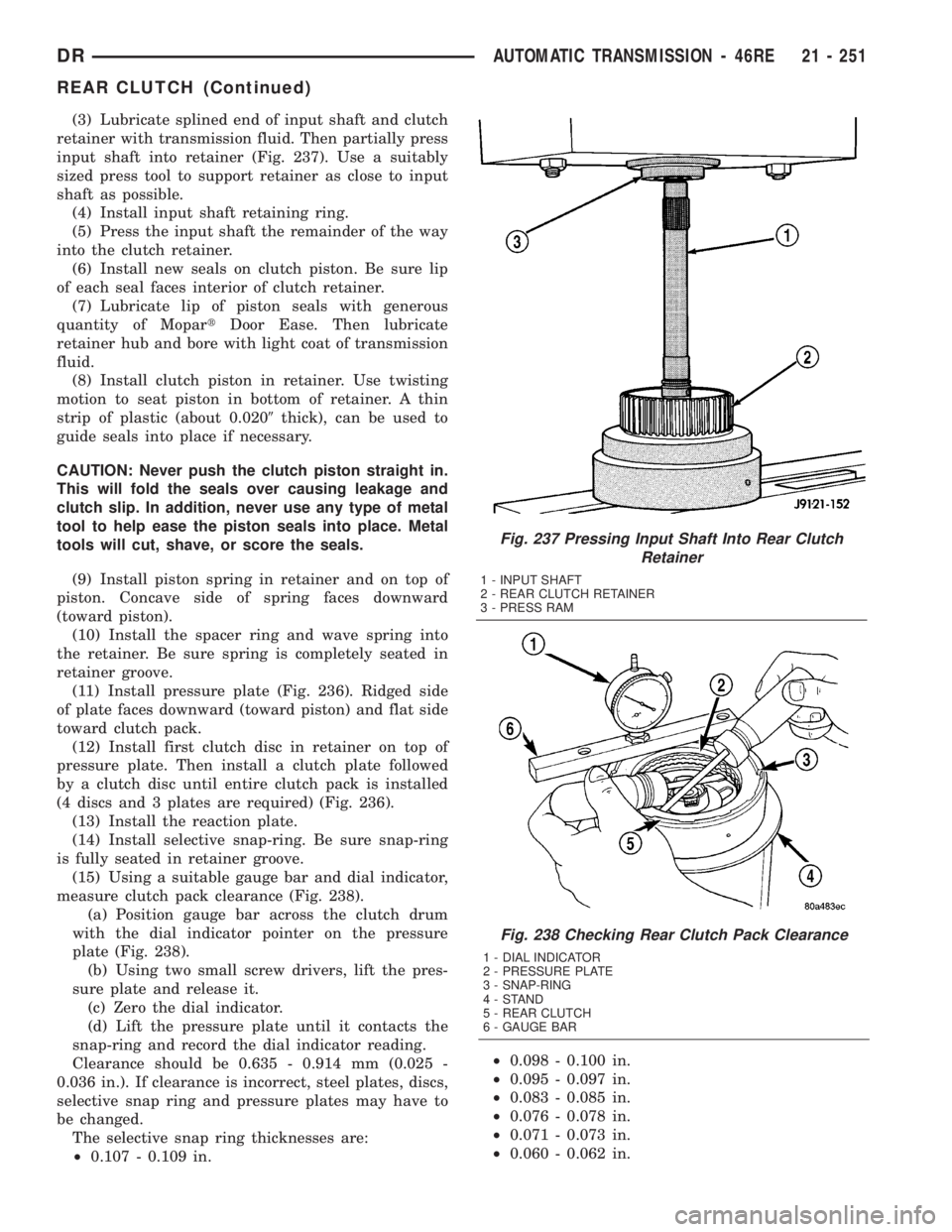

(3) Lubricate splined end of input shaft and clutch

retainer with transmission fluid. Then partially press

input shaft into retainer (Fig. 237). Use a suitably

sized press tool to support retainer as close to input

shaft as possible.

(4) Install input shaft retaining ring.

(5) Press the input shaft the remainder of the way

into the clutch retainer.

(6) Install new seals on clutch piston. Be sure lip

of each seal faces interior of clutch retainer.

(7) Lubricate lip of piston seals with generous

quantity of MopartDoor Ease. Then lubricate

retainer hub and bore with light coat of transmission

fluid.

(8) Install clutch piston in retainer. Use twisting

motion to seat piston in bottom of retainer. A thin

strip of plastic (about 0.0209thick), can be used to

guide seals into place if necessary.

CAUTION: Never push the clutch piston straight in.

This will fold the seals over causing leakage and

clutch slip. In addition, never use any type of metal

tool to help ease the piston seals into place. Metal

tools will cut, shave, or score the seals.

(9) Install piston spring in retainer and on top of

piston. Concave side of spring faces downward

(toward piston).

(10) Install the spacer ring and wave spring into

the retainer. Be sure spring is completely seated in

retainer groove.

(11) Install pressure plate (Fig. 236). Ridged side

of plate faces downward (toward piston) and flat side

toward clutch pack.

(12) Install first clutch disc in retainer on top of

pressure plate. Then install a clutch plate followed

by a clutch disc until entire clutch pack is installed

(4 discs and 3 plates are required) (Fig. 236).

(13) Install the reaction plate.

(14) Install selective snap-ring. Be sure snap-ring

is fully seated in retainer groove.

(15) Using a suitable gauge bar and dial indicator,

measure clutch pack clearance (Fig. 238).

(a) Position gauge bar across the clutch drum

with the dial indicator pointer on the pressure

plate (Fig. 238).

(b) Using two small screw drivers, lift the pres-

sure plate and release it.

(c) Zero the dial indicator.

(d) Lift the pressure plate until it contacts the

snap-ring and record the dial indicator reading.

Clearance should be 0.635 - 0.914 mm (0.025 -

0.036 in.). If clearance is incorrect, steel plates, discs,

selective snap ring and pressure plates may have to

be changed.

The selective snap ring thicknesses are:

²0.107 - 0.109 in.²0.098 - 0.100 in.

²0.095 - 0.097 in.

²0.083 - 0.085 in.

²0.076 - 0.078 in.

²0.071 - 0.073 in.

²0.060 - 0.062 in.

Fig. 237 Pressing Input Shaft Into Rear Clutch

Retainer

1 - INPUT SHAFT

2 - REAR CLUTCH RETAINER

3 - PRESS RAM

Fig. 238 Checking Rear Clutch Pack Clearance

1 - DIAL INDICATOR

2 - PRESSURE PLATE

3 - SNAP-RING

4-STAND

5 - REAR CLUTCH

6 - GAUGE BAR

DRAUTOMATIC TRANSMISSION - 46RE 21 - 251

REAR CLUTCH (Continued)

Page 2890 of 2895

TIRE REVOLUTIONS PER MILE,

SPECIFICATIONS.....................22-10

TIRE ROTATION - STANDARD

PROCEDURE.........................22-2

TIRE WEAR PATTERNS - DIAGNOSIS

AND TESTING........................22-8

TIRES - DESCRIPTION.................22-5

TIRES - DESCRIPTION, RADIAL - PLY.....22-6

TIRES - DESCRIPTION, REPLACEMENT....22-6

TIRE/VEHICLE LEAD - DIAGNOSIS AND

TESTING............................22-8

TO COOLER - INSTALLATION, RETURN

HOSE - GEAR..................19-43,19-44

TO COOLER - INSTALLATION, RETURN

HOSE - RESERVOIR.............19-43,19-44

TO COOLER - REMOVAL, RETURN HOSE

- GEAR............................19-43

TO COOLER - REMOVAL, RETURN HOSE

- RESERVOIR..................19-43,19-44

TO GROUND - STANDARD PROCEDURE,

TESTING FOR A SHORT.............8W-01-9

TO GROUND ON FUSES POWERING

SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR A SHORT . 8W-01-10

TO OIL COOLER - INSTALLATION, AIR.....7-75

TO OIL COOLER - REMOVAL, AIR.........7-74

TO OIL COOLER - REMOVAL, WATER......7-74

TO USE WIRING DIAGRAMS -

DESCRIPTION, HOW................8W-01-1

TOE ADJUSTMENT - STANDARD

PROCEDURE..........................2-4

TOE ADJUSTMENT - STANDARD

PROCEDURE, CAMBER, CASTER..........2-4

TOOL - ADJUSTMENT, WITH ADJUSTING . . . 5-36

TOOLS - 4.7L ENGINE, SPECIAL.........9-102

TOOLS - 5.7L ENGINE, SPECIAL.........9-192

TOOLS - 5.9L DIESEL ENGINE, SPECIAL . . 9-294

TOOLS - 5.9L ENGINE, SPECIAL.........9-240

TOOLS - 8.0L ENGINE, SPECIAL.........9-367

TOOLS - 9 1/4 AA, SPECIAL.............2-29

TOOLS - BASE BRAKES, SPECIAL.........5-5

TOOLS - BATTERY SYSTEM SPECIAL

TOOLS, SPECIAL......................8F-7

TOOLS - BODY, SPECIAL...............23-14

TOOLS - COOLING, SPECIAL.............7-20

TOOLS - DIESEL FUEL SYSTEM,

SPECIAL...........................14-60

TOOLS - FRONT SUSPENSION, SPECIAL . . . 2-11

TOOLS - FUEL SYSTEM, SPECIAL........14-5

TOOLS - OVERHEAD CONSOLE, SPECIAL . . 8M-6

TOOLS - POWER DISTRIBUTION

SYSTEMS, SPECIAL................8W-97-2

TOOLS - POWER STEERING GEAR,

SPECIAL...........................19-22

TOOLS - RE TRANSMISSION, SPECIAL . . 21-189,

21-370

TOOLS - RFE TRANSMISSION, SPECIAL . . 21-535

TOOLS - STEERING LINKAGE, SPECIAL . . . 19-35

TOOLS - STEERING, SPECIAL............19-5

TOOLS - TRANSFER CASE NV271/NV273,

SPECIAL....................21-650,21-714

TOOLS - WHEEL ALIGNMENT, SPECIAL.....2-7

TOOLS - WIRING/TERMINAL, SPECIAL . 8W-01-10

TOOLS, DIAGNOSIS AND TESTING -

SPECIAL............................11-4

TOOLS, FRONT AXLE - 9 1/4 AA -

SPECIAL............................3-53

TOOLS, FRONT AXLE - C205F - SPECIAL . . . 3-30

TOOLS, HALF SHAFT - SPECIAL..........3-12

TOOLS, HEADLAMP ALIGNMENT -

SPECIAL............................8L-7

TOOLS, MANUAL TRANSMISSION -

NV3500 - SPECIAL...................21-40

TOOLS, MANUAL TRANSMISSION -

NV4500 - SPECIAL...................21-79

TOOLS, MANUAL TRANSMISSION -

NV5600 - SPECIAL..................21-122

TOOLS, PROPELLER SHAFT - SPECIAL.....3-6

TOOLS, REAR AXLE - 10 1/2 AA -

SPECIAL...........................3-108

TOOLS, REAR AXLE - 11 1/2 AA -

SPECIAL

...........................3-135

TOOLS, REAR AXLE - 9 1/4 - SPECIAL

.....3-80

TOOLS, SPECIAL TOOLS - BATTERY

SYSTEM SPECIAL

.....................8F-7

TOOLS, SPECIFICATIONS - SPECIAL

.......9-16

TOP COVER - INSTALLATION,

INSTRUMENT PANEL

..................23-60TOP COVER - REMOVAL, INSTRUMENT

PANEL.............................23-59

TORSION BAR - DESCRIPTION...........2-25

TORSION BAR - INSTALLATION..........2-26

TORSION BAR - OPERATION.............2-25

TORSION BAR - REMOVAL..............2-25

TORSION BAR CROSS MEMBER

BUSHING - INSTALLATION..............2-14

TORSION BAR CROSSMEMBER

BUSHING - REMOVAL..................2-12

TOUCH-UP - DESCRIPTION, PAINT.......23-75

TOUCH-UP - STANDARD PROCEDURE,

PAINT.............................23-75

TOW HOOK ASSEMBLY - INSTALLATION,

FRONT.............................13-26

TOW HOOK ASSEMBLY - REMOVAL,

FRONT.............................13-26

TOW WIRING - DESCRIPTION, TRAILER . . 8L-22

TOWING - STANDARD PROCEDURE.......0-15

TRACK - DESCRIPTION, POWER SEAT....8N-18

TRACK - DIAGNOSIS AND TESTING,

POWER SEAT.......................8N-18

TRACK - INSTALLATION, POWER SEAT . . . 8N-19

TRACK - INSTALLATION, SEAT..........23-83

TRACK - OPERATION, POWER SEAT.....8N-18

TRACK - REMOVAL, POWER SEAT.......8N-19

TRACK - REMOVAL, SEAT..............23-83

TRACK BAR - INSTALLATION...........19-37

TRACK BAR - REMOVAL................19-37

TRAC-RITE - ASSEMBLY, DIFFERENTIAL . . 3-120,

3-147

TRAC-RITE - CLEANING, DIFFERENTIAL . . 3-119,

3-146

TRAC-RITE - DESCRIPTION,

DIFFERENTIAL..................3-118,3-145

TRAC-RITE - DISASSEMBLY,

DIFFERENTIAL..................3-118,3-145

TRAC-RITE - INSPECTION, DIFFERENTIAL . 3-119,

3-146

TRAC-RITE - OPERATION, DIFFERENTIAL . 3-118,

3-145

TRAILER HITCH - INSTALLATION........13-25

TRAILER HITCH - REMOVAL............13-25

TRAILER TOW WIRING - DESCRIPTION . . . 8L-22

TRANS COOLER - 5.9L DIESEL -

DESCRIPTION........................7-73

TRANS COOLER - 5.9L DIESEL -

OPERATION..........................7-74

TRANS TEMP INDICATOR -

DESCRIPTION.......................8J-38

TRANS TEMP INDICATOR - OPERATION . . . 8J-38

TRANSDUCER - DESCRIPTION, A/C

PRESSURE.........................24-15

TRANSDUCER - DIAGNOSIS AND

TESTING, A/C PRESSURE..............24-15

TRANSDUCER - INSTALLATION, A/C

PRESSURE.........................24-16

TRANSDUCER - OPERATION, A/C

PRESSURE.........................24-15

TRANSDUCER - REMOVAL, A/C

PRESSURE.........................24-16

TRANSFER CASE - NV241 GENII -

ASSEMBLY.........................21-604

TRANSFER CASE - NV241 GENII -

CLEANING

.........................21-602

TRANSFER CASE - NV241 GENII -

DESCRIPTION

.........................0-4

TRANSFER CASE - NV241 GENII -

DESCRIPTION

......................21-591

TRANSFER CASE - NV241 GENII -

DIAGNOSIS AND TESTING

............21-592

TRANSFER CASE - NV241 GENII -

DISASSEMBLY

......................21-593

TRANSFER CASE - NV241 GENII -

INSPECTION

.......................21-602

TRANSFER CASE - NV241 GENII -

INSTALLATION

......................21-614

TRANSFER CASE - NV241 GENII -

OPERATION

........................21-591

TRANSFER CASE - NV241 GENII -

REMOVAL

.........................21-593

TRANSFER CASE - NV243 - ASSEMBLY

. . 21-670

TRANSFER CASE - NV243 - CLEANING

. . 21-668

TRANSFER CASE - NV243 -

DESCRIPTION

.........................0-4

TRANSFER CASE - NV243 -

DESCRIPTION

......................21-658TRANSFER CASE - NV243 - DIAGNOSIS

AND TESTING......................21-659

TRANSFER CASE - NV243 -

DISASSEMBLY......................21-660

TRANSFER CASE - NV243 - INSPECTION . 21-668

TRANSFER CASE - NV243 -

INSTALLATION......................21-679

TRANSFER CASE - NV243 - OPERATION . 21-659

TRANSFER CASE - NV243 - REMOVAL . . . 21-660

TRANSFER CASE - NV271 - ASSEMBLY . . 21-637

TRANSFER CASE - NV271 - CLEANING . . 21-635

TRANSFER CASE - NV271 -

DESCRIPTION.........................0-4

TRANSFER CASE - NV271 -

DESCRIPTION......................21-623

TRANSFER CASE - NV271 - DIAGNOSIS

AND TESTING......................21-624

TRANSFER CASE - NV271 -

DISASSEMBLY......................21-625

TRANSFER CASE - NV271 - INSPECTION . 21-635

TRANSFER CASE - NV271 -

INSTALLATION......................21-649

TRANSFER CASE - NV271 - OPERATION . 21-623

TRANSFER CASE - NV271 - REMOVAL . . . 21-625

TRANSFER CASE - NV273 - ASSEMBLY . . 21-701

TRANSFER CASE - NV273 - CLEANING . . 21-698

TRANSFER CASE - NV273 -

DESCRIPTION.........................0-4

TRANSFER CASE - NV273 -

DESCRIPTION......................21-687

TRANSFER CASE - NV273 - DIAGNOSIS

AND TESTING......................21-688

TRANSFER CASE - NV273 -

DISASSEMBLY......................21-689

TRANSFER CASE - NV273 - INSPECTION . 21-699

TRANSFER CASE - NV273 -

INSTALLATION......................21-713

TRANSFER CASE - NV273 - OPERATION . 21-688

TRANSFER CASE - NV273 - REMOVAL . . . 21-689

TRANSFER CASE CONTROL MODULE -

DESCRIPTION.......................8E-15

TRANSFER CASE CONTROL MODULE -

OPERATION.........................8E-15

TRANSFER CASE, NV241 GENII........21-614

TRANSFER CASE, NV241/NV243 . . 21-615,21-680

TRANSFER CASE, NV243.............21-680

TRANSFER CASE, NV271.............21-649

TRANSFER CASE NV271/NV273, SPECIAL

TOOLS......................21-650,21-714

TRANSFER CASE, NV273.............21-713

TRANSFER CASE SKID PLATE -

INSTALLATION.......................13-26

TRANSFER CASE SKID PLATE -

REMOVAL..........................13-26

TRANSFER PUMP - DESCRIPTION, FUEL . . 14-75

TRANSFER PUMP - INSTALLATION, FUEL . 14-76

TRANSFER PUMP - OPERATION, FUEL....14-76

TRANSFER PUMP - REMOVAL, FUEL.....14-76

TRANSMISSION - 45RFE/545RFE -

DESCRIPTION, AUTOMATIC............21-489

TRANSMISSION - 45RFE/545RFE -

OPERATION, AUTOMATIC.............21-490

TRANSMISSION - 46RE - DESCRIPTION,

AUTOMATIC

........................21-131

TRANSMISSION - 46RE - OPERATION,

AUTOMATIC

........................21-133

TRANSMISSION - 48RE - DESCRIPTION,

AUTOMATIC

........................21-312

TRANSMISSION - 48RE - OPERATION,

AUTOMATIC

........................21-314

TRANSMISSION - CLEANING

..........21-104

TRANSMISSION - DESCRIPTION,

MANUAL

.............................0-4

TRANSMISSION - DIAGNOSIS AND

TESTING, AUTOMATIC

....21-139,21-320,21-491

TRANSMISSION - NV3500 - ASSEMBLY,

MANUAL

...........................21-17

TRANSMISSION - NV3500 - CLEANING,

MANUAL

...........................21-15

TRANSMISSION - NV3500 -

DESCRIPTION, MANUAL

................21-1

TRANSMISSION - NV3500 - DIAGNOSIS

AND TESTING, MANUAL

................21-3

TRANSMISSION - NV3500 -

DISASSEMBLY, MANUAL

................21-4

TRANSMISSION - NV3500 -

INSPECTION, MANUAL

................21-15

DRINDEX 35

Description Group-Page Description Group-Page Description Group-Page