reset DODGE RAM SRT-10 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1458 of 5267

When Monitored:

With the ignition on. Battery voltage greater than 10.4 volts.

Set Condition:

No BUS messages recieved from the BCM for 20 seconds.

Possible Causes

(D25) PCI BUS CIRCUIT OPEN

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.DTC RESET

Ignition on, engine not running.

With the scan tool, erase DTCs.

Cycle the ignition key on and off several times. Leaving the ignition on forat least 20 seconds.

With the scan tool, read DTCs.

Does the DTC reset?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.COMMUNICATE WITH FCM

With the scan tool, attempt to communicate with the FCM.

Can communication be established with the BCM?

Ye s>>

Go To 3

No>>

Refer to the Communication Category and perform the appropriate symptom related to no communica-

tion with FCM.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1485 of 5267

NOTE: If this vehicle is equipped with an Electronic Throttle Control system, and the APP Sensors, PCM, or

Throttle Body Assembly have been replaced, use the scan tool to perform theETC RELEARN function.

14. If the indicator ball shows a leak present, perform the smoke test indicated in the previous test and identify the

leak and repair. Perform this verification test when the repair is complete.

Didtheindicatorballindicatethealeakispresent?

Ye s>>

Repeat the DTC test to identify the leak and repair.

No>>

Repair is complete.

5.POWERTRAIN VERIFICATION TEST 4

NOTE: 1. After completing the Powertrain Verification Test the Transmission Verification Test must be per-

formed.

NOTE: 2. If the PCM has been replaced and the correct VIN and mileage have notbeen programmed, a DTC

will set in the ABS Module, Airbag Module and the SKIM/SKREEM.

NOTE: 3. If the vehicle is equipped with a Sentry Key Remote Entry, Secret Key data must be updated. Refer

to the Service Information for the PCM, SKIM/SKREEM and the Transponder (ignition key) for programming

information. Using the scan tool, program the Secret Key information intothe PCM using the PCM replaced

function under the WCM menu.

NOTE: 4. If this vehicle is equipped with an Electronic Throttle Control system, and the APP Sensors, PCM,

or Throttle Body Assembly have been replaced, use the scan tool to perform the ETC RELEARN function.

NOTE: 5. When replacing an O2 Sensor, the PCM RAM memory must be cleared, either by disconnecting the

PCM C1 connector or momentarily disconnecting the Battery negative terminal.

6. The NGC learns the characteristics of each O2 heater element and these old values should be cleared when

installing a new O2 sensor. The customermay experience driveability issues if this is not performed.

7. Inspect the vehicle to make sure that all engine components are properlyinstalled and connected. Reassemble

and reconnect components as necessary.

8. Connect the scan tool to the data link connector.

9. Make sure the fuel tank has at least a quarter tank of fuel. Turn off all accessories.

10. If the Catalyst was replaced, with the scan tool go to the MiscellaneousMenu Option

Catalyst Replacedand

press enter.

11. If a Comprehensive Component DTC was repaired, perform steps 12 - 14. Ifa Major OBDII Monitor DTC was

repaired skip those steps and continue verification.

12. After the ignition has been off for at least 10 seconds, restart the vehicle and run 2 minutes.

13. With the scan tool, monitor the appropriate pre-test enabling conditions until all conditions have been met. Once

the conditions have been met, switch screen to the appropriate OBDII monitor, (Audible beeps when the monitor is

running).

14. If the repaired OBDII trouble code has reset or was seen in the monitor while on the road test, the repair is not

complete. Check for any related technical service bulletins or flash updates and return to Engine Electrical Diag-

nostic List.

15. If the conditions cannot be duplicated, erase all DTCs with the Scan tool.

16. If another DTC has set, return to the Engine Electrical Diagnostic Listand follow the path specified for that DTC.

Did the OBDII Monitor run successfully and has the Good Trip Counter changed to one or more?

Ye s>>

Repair is complete.

No>>

Check for any related Technical Service Bulletins and/or refer to the appropriate Diagnostic Procedure.

Page 1523 of 5267

CAMSHAFT

DESCRIPTION

The camshafts consist of powdered metal steel lobes which are sinter-bonded to a steel tube. Four bearing journals

are machined into the camshaft. Camshaft end play is controlled by two thrust walls that border the nose piece

journal.

REMOVAL

CAUTION: When the timing chain is removed and the cylinder heads are still installed, DO NOT forcefully

rotate the camshafts or crankshaft independently of each other. Severe valve and/or piston damage can

occur.

CAUTION: When removing the cam sprocket, timing chains or camshaft, Failure to use Special Tool 8379

will result in hydraulic tensioner ratchet over extension, requiring timing chain cover removal to reset the

tensioner ratchet.

1. Remove cylinder head cover (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDERHEAD COVER(S) -

REMOVAL).

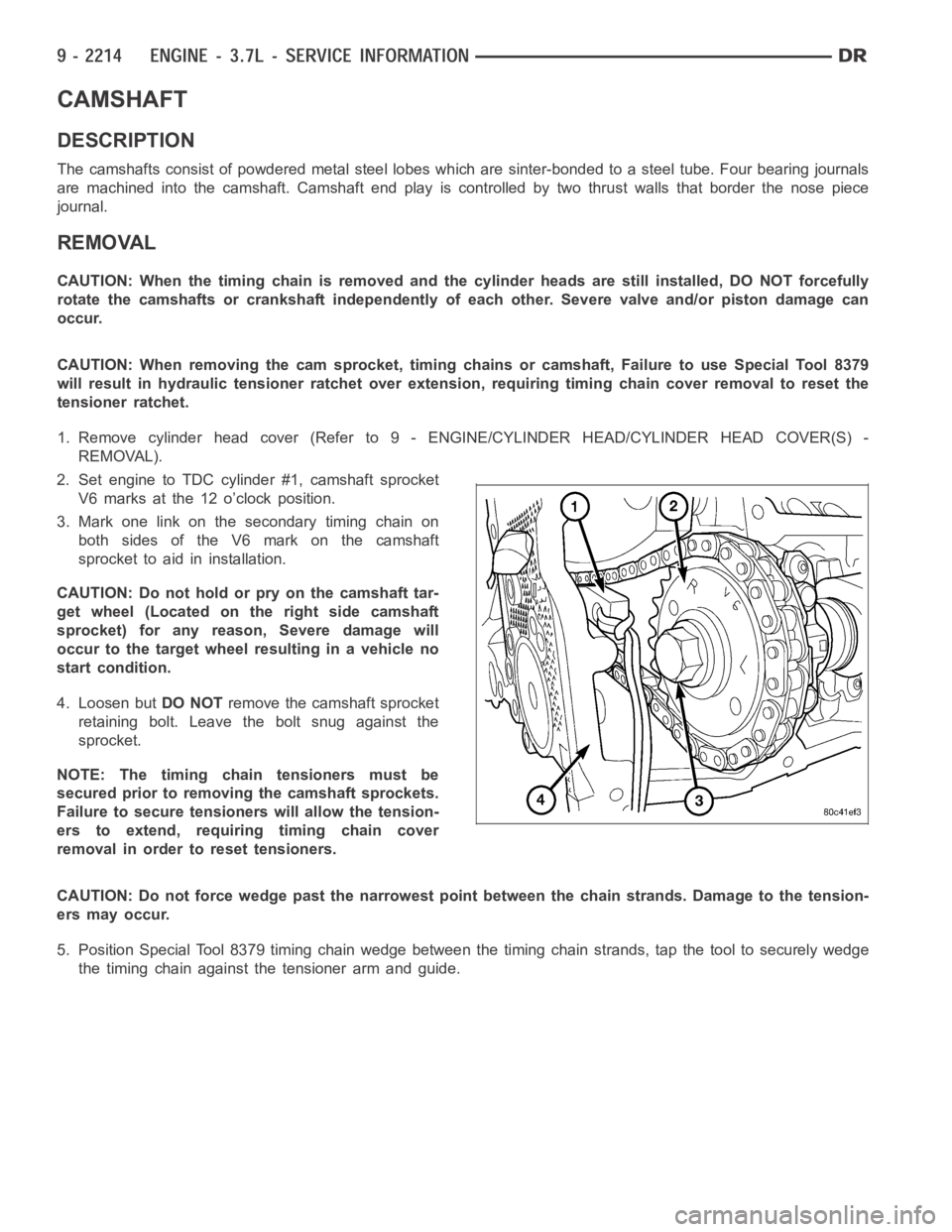

2. Set engine to TDC cylinder #1, camshaft sprocket

V6 marks at the 12 o’clock position.

3. Mark one link on the secondary timing chain on

both sides of the V6 mark on the camshaft

sprocket to aid in installation.

CAUTION: Do not hold or pry on the camshaft tar-

get wheel (Located on the right side camshaft

sprocket) for any reason, Severe damage will

occur to the target wheel resulting in a vehicle no

start condition.

4. Loosen butDO NOTremove the camshaft sprocket

retaining bolt. Leave the bolt snug against the

sprocket.

NOTE: The timing chain tensioners must be

secured prior to removing the camshaft sprockets.

Failure to secure tensioners will allow the tension-

erstoextend,requiringtimingchaincover

removal in order to reset tensioners.

CAUTION: Do not force wedge past the narrowest point between the chain strands. Damage to the tension-

ers may occur.

5. Position Special Tool 8379 timing chain wedge between the timing chain strands, tap the tool to securely wedge

the timing chain against the tensioner arm and guide.

Page 1544 of 5267

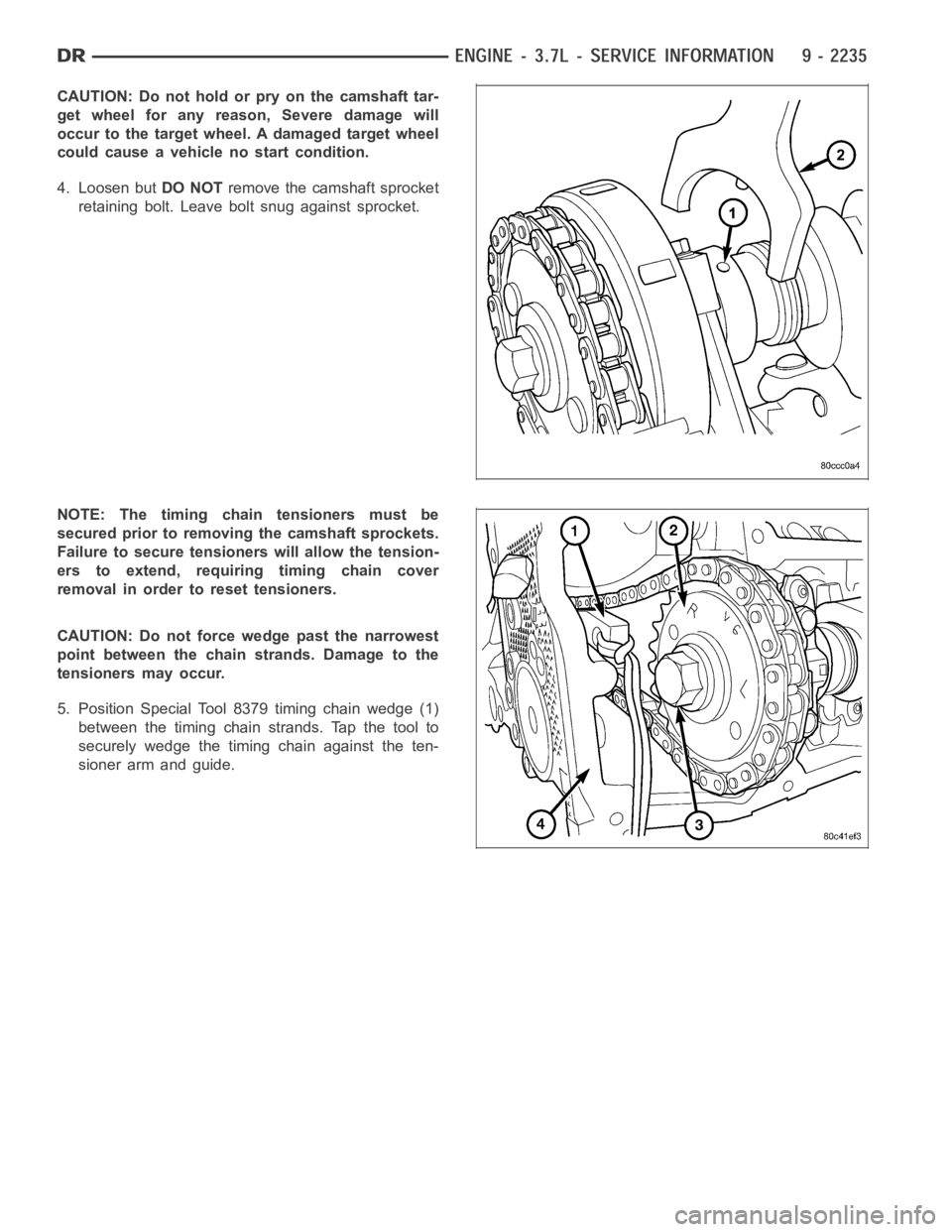

CAUTION: Do not hold or pry on the camshaft tar-

get wheel for any reason, Severe damage will

occur to the target wheel. A damaged target wheel

could cause a vehicle no start condition.

4. Loosen butDO NOTremove the camshaft sprocket

retaining bolt. Leave bolt snug against sprocket.

NOTE: The timing chain tensioners must be

secured prior to removing the camshaft sprockets.

Failure to secure tensioners will allow the tension-

erstoextend,requiringtimingchaincover

removal in order to reset tensioners.

CAUTION: Do not force wedge past the narrowest

point between the chain strands. Damage to the

tensioners may occur.

5. Position Special Tool 8379 timing chain wedge (1)

between the timing chain strands. Tap the tool to

securely wedge the timing chain against the ten-

sioner arm and guide.

Page 1666 of 5267

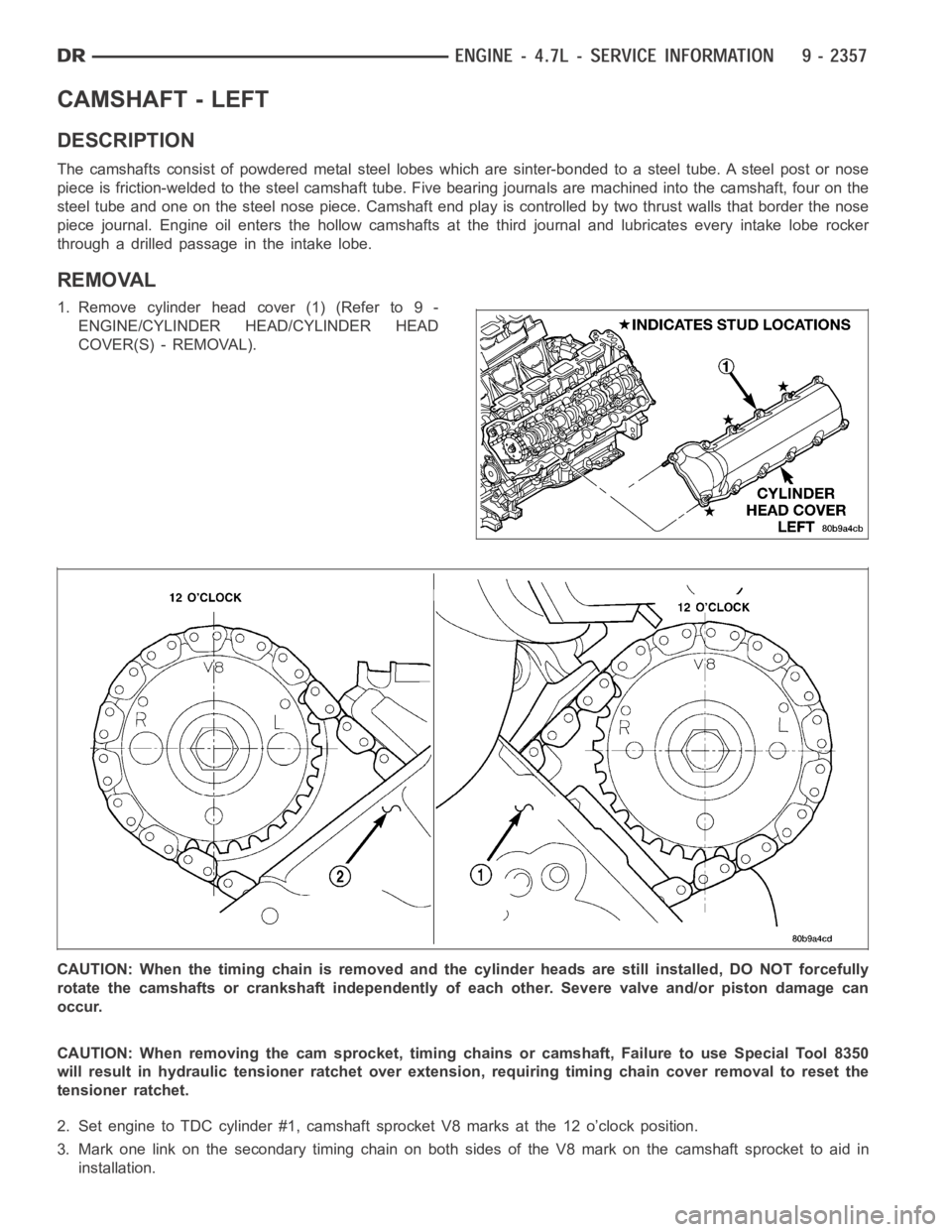

CAMSHAFT - LEFT

DESCRIPTION

The camshafts consist of powdered metal steel lobes which are sinter-bonded to a steel tube. A steel post or nose

piece is friction-welded to the steel camshaft tube. Five bearing journals are machined into the camshaft, four on the

steel tube and one on the steel nose piece. Camshaft end play is controlled by two thrust walls that border the nose

piece journal. Engine oil enters the hollow camshafts at the third journaland lubricates every intake lobe rocker

throughadrilledpassageintheintakelobe.

REMOVAL

1. Remove cylinder head cover (1) (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

CAUTION: When the timing chain is removed and the cylinder heads are still installed, DO NOT forcefully

rotate the camshafts or crankshaft independently of each other. Severe valve and/or piston damage can

occur.

CAUTION: When removing the cam sprocket, timing chains or camshaft, Failure to use Special Tool 8350

will result in hydraulic tensioner ratchet over extension, requiring timing chain cover removal to reset the

tensioner ratchet.

2. Set engine to TDC cylinder #1, camshaft sprocket V8 marks at the 12 o’clock position.

3. Mark one link on the secondary timing chain on both sides of the V8 mark on the camshaft sprocket to aid in

installation.

Page 1667 of 5267

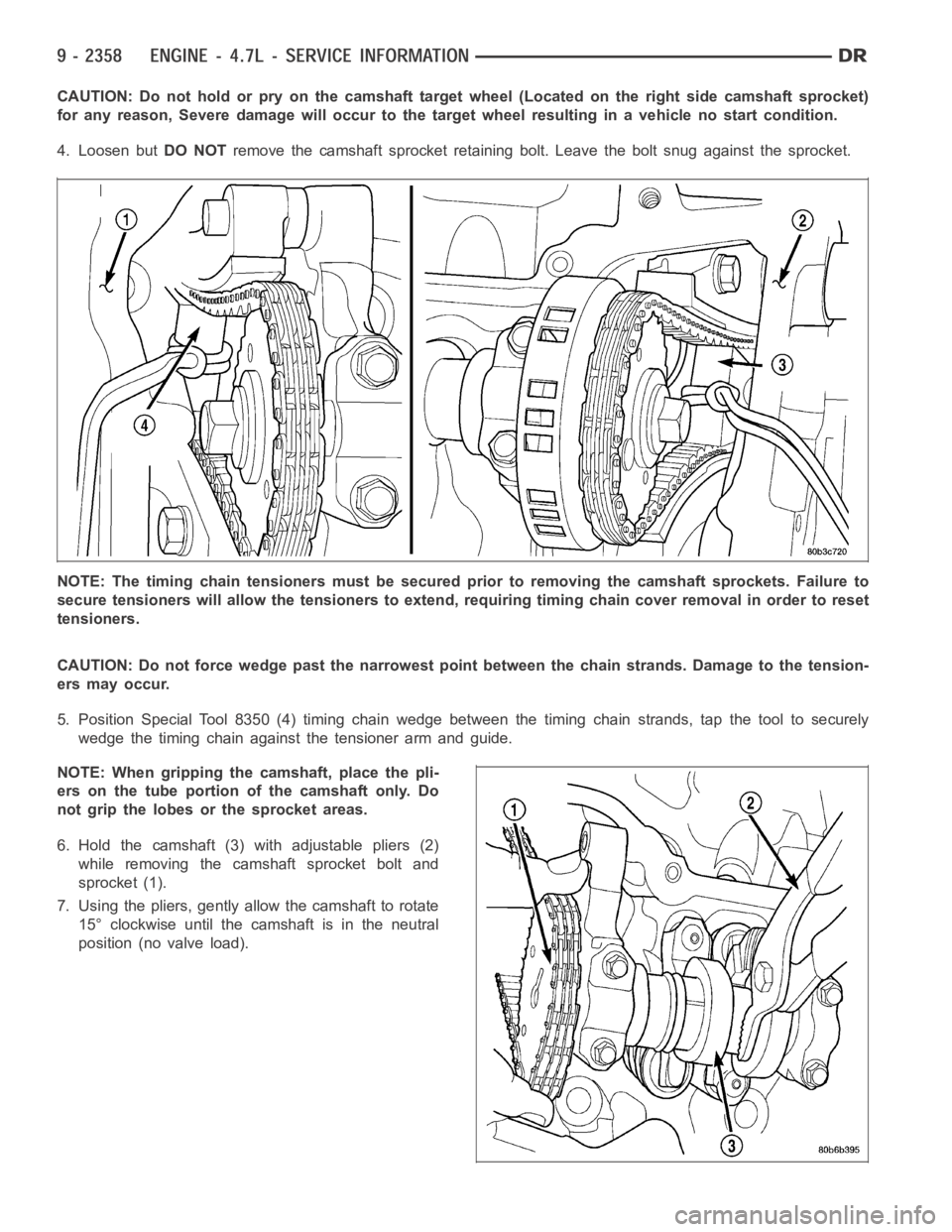

CAUTION: Do not hold or pry on the camshaft target wheel (Located on the right side camshaft sprocket)

for any reason, Severe damage will occur to the target wheel resulting in a vehicle no start condition.

4. Loosen butDO NOTremove the camshaft sprocket retaining bolt. Leave the bolt snug against the sprocket.

NOTE: The timing chain tensioners must be secured prior to removing the camshaft sprockets. Failure to

secure tensioners will allow the tensioners to extend, requiring timing chain cover removal in order to reset

tensioners.

CAUTION: Do not force wedge past the narrowest point between the chain strands. Damage to the tension-

ers may occur.

5. Position Special Tool 8350 (4) timing chain wedge between the timing chain strands, tap the tool to securely

wedge the timing chain against the tensioner arm and guide.

NOTE: When gripping the camshaft, place the pli-

ers on the tube portion of the camshaft only. Do

not grip the lobes or the sprocket areas.

6. Hold the camshaft (3) with adjustable pliers (2)

while removing the camshaft sprocket bolt and

sprocket (1).

7. Using the pliers, gently allow the camshaft to rotate

15° clockwise until the camshaft is in the neutral

position (no valve load).

Page 1672 of 5267

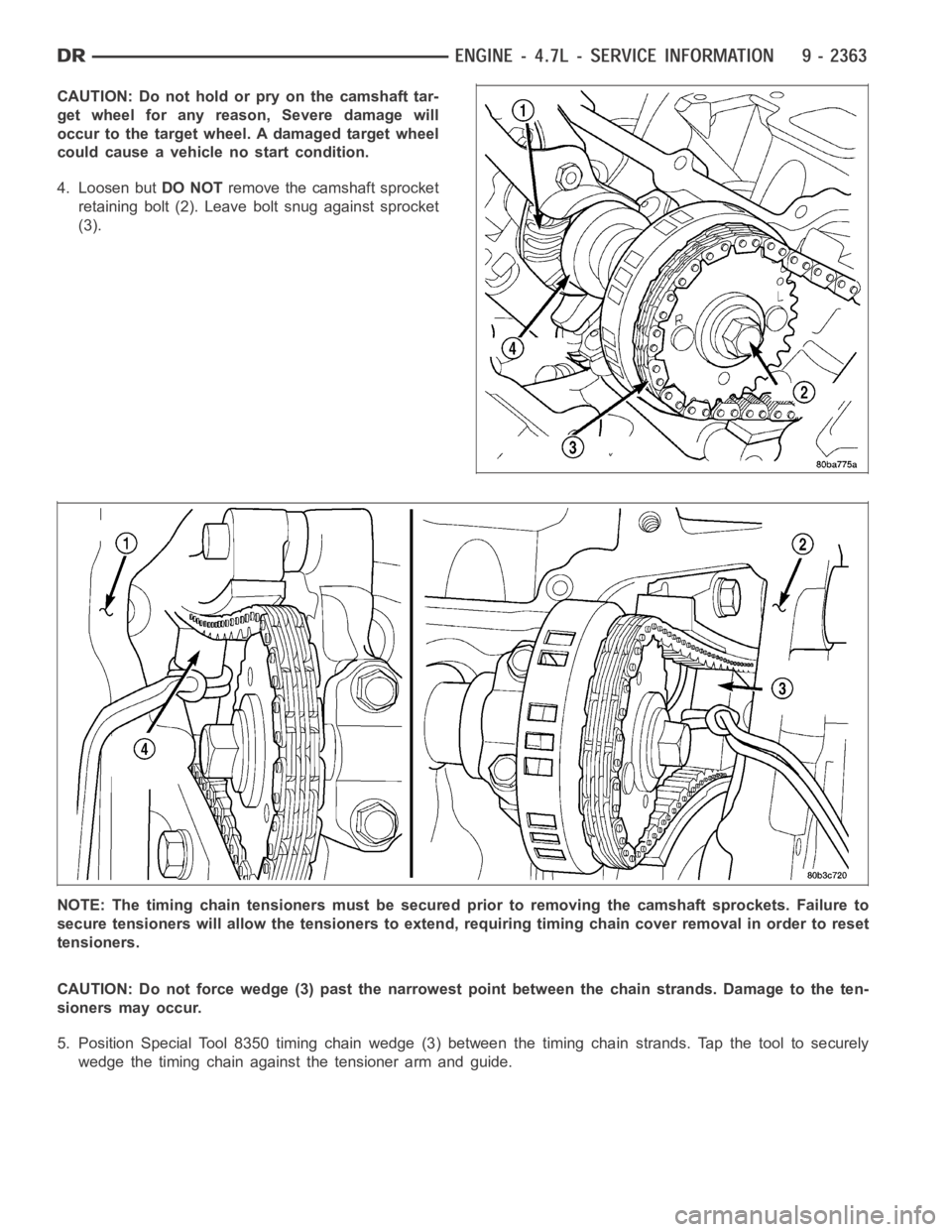

CAUTION: Do not hold or pry on the camshaft tar-

get wheel for any reason, Severe damage will

occur to the target wheel. A damaged target wheel

could cause a vehicle no start condition.

4. Loosen butDO NOTremove the camshaft sprocket

retaining bolt (2). Leave bolt snug against sprocket

(3).

NOTE: The timing chain tensioners must be secured prior to removing the camshaft sprockets. Failure to

secure tensioners will allow the tensioners to extend, requiring timing chain cover removal in order to reset

tensioners.

CAUTION: Do not force wedge (3) past the narrowest point between the chain strands. Damage to the ten-

sioners may occur.

5. Position Special Tool 8350 timing chain wedge (3) between the timing chain strands. Tap the tool to securely

wedge the timing chain against the tensioner arm and guide.

Page 1919 of 5267

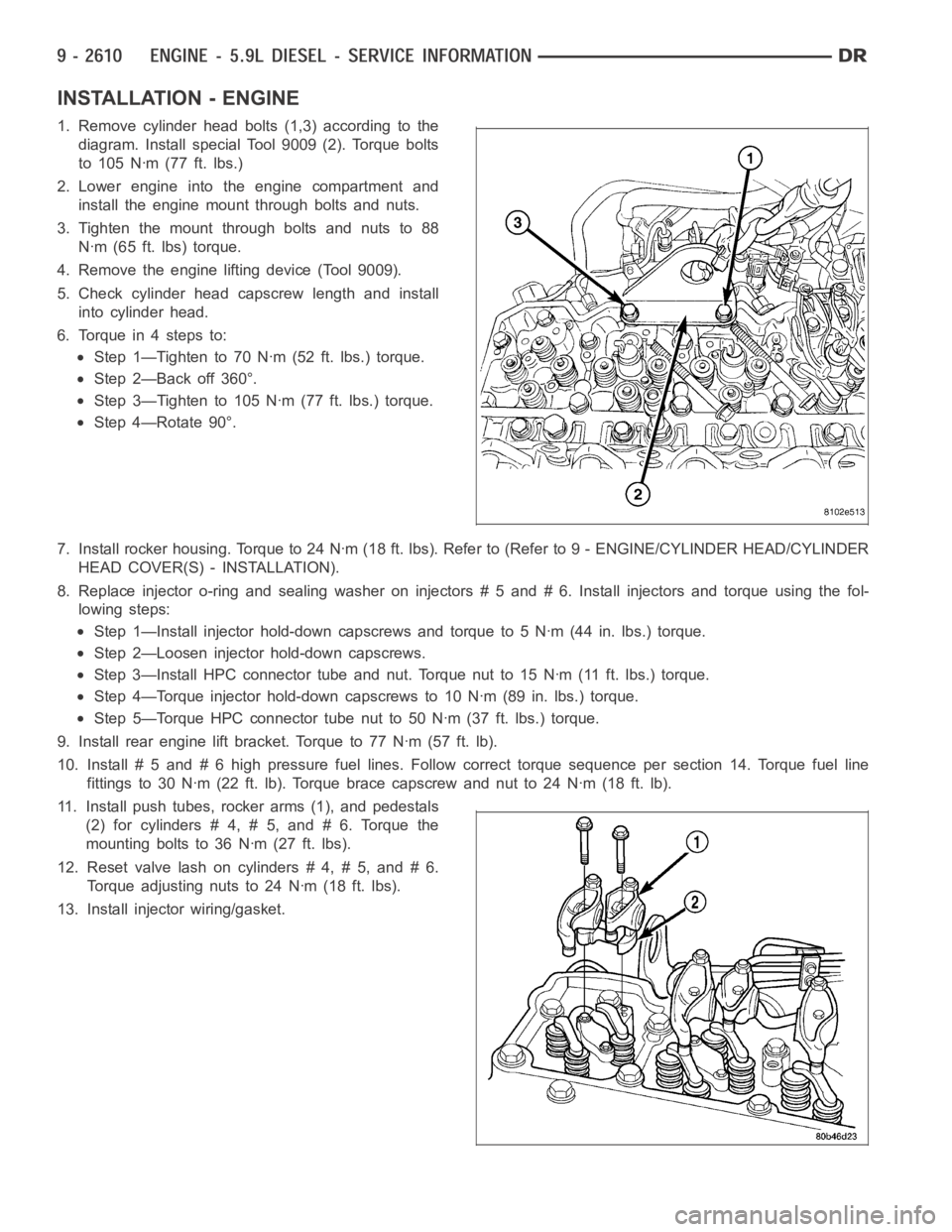

INSTALLATION - ENGINE

1. Remove cylinder head bolts (1,3) according to the

diagram. Install special Tool 9009 (2). Torque bolts

to 105 Nꞏm (77 ft. lbs.)

2. Lower engine into the engine compartment and

install the engine mount through bolts and nuts.

3. Tighten the mount through bolts and nuts to 88

Nꞏm (65 ft. lbs) torque.

4. Remove the engine lifting device (Tool 9009).

5. Check cylinder head capscrew length and install

into cylinder head.

6. Torque in 4 steps to:

Step 1—Tighten to 70 Nꞏm (52 ft. lbs.) torque.

Step 2—Back off 360°.

Step 3—Tighten to 105 Nꞏm (77 ft. lbs.) torque.

Step 4—Rotate 90°.

7. Install rocker housing. Torque to 24 Nꞏm (18 ft. lbs). Refer to (Refer to 9- ENGINE/CYLINDER HEAD/CYLINDER

HEAD COVER(S) - INSTALLATION).

8. Replace injector o-ring and sealing washer on injectors # 5 and # 6. Install injectors and torque using the fol-

lowing steps:

Step 1—Install injector hold-down capscrews and torque to 5 Nꞏm (44 in. lbs.) torque.

Step 2—Loosen injector hold-down capscrews.

Step 3—Install HPC connector tube and nut. Torque nut to 15 Nꞏm (11 ft. lbs.)torque.

Step 4—Torque injector hold-down capscrews to 10 Nꞏm (89 in. lbs.) torque.

Step 5—Torque HPC connector tube nut to 50 Nꞏm (37 ft. lbs.) torque.

9. Install rear engine lift bracket. Torque to 77 Nꞏm (57 ft. lb).

10. Install # 5 and # 6 high pressure fuel lines. Follow correct torque sequence per section 14. Torque fuel line

fittings to 30 Nꞏm (22 ft. lb). Torque brace capscrew and nut to 24 Nꞏm (18 ft.lb).

11. Install push tubes, rocker arms (1), and pedestals

(2) for cylinders # 4, # 5, and # 6. Torque the

mounting bolts to 36 Nꞏm (27 ft. lbs).

12. Reset valve lash on cylinders # 4, # 5, and # 6.

Torque adjusting nuts to 24 Nꞏm (18 ft. lbs).

13. Install injector wiring/gasket.

Page 1930 of 5267

ENGINE DATA PLATE

DESCRIPTION

The engine data plate contains specific information

that is helpful to servicing and obtaining parts for the

engine. The data plate is on the cylinder head cover.

Information that can be found on the data plate

includes:

Engine Part Number

Date of Engine Manufacture

Engine Serial Number

Control Parts List (CPL)

Engine Rated Horsepower

Engine Firing Order

Engine Displacement

Valve Lash Reset Specifications

If the engine data plate is missing or not legible, the engine serial numberis used for engine identification. The

engine serial number is stamped on the right side of the block, on top of the oil cooler cavity.

Page 1931 of 5267

AIR CLEANER ELEMENT

REMOVAL

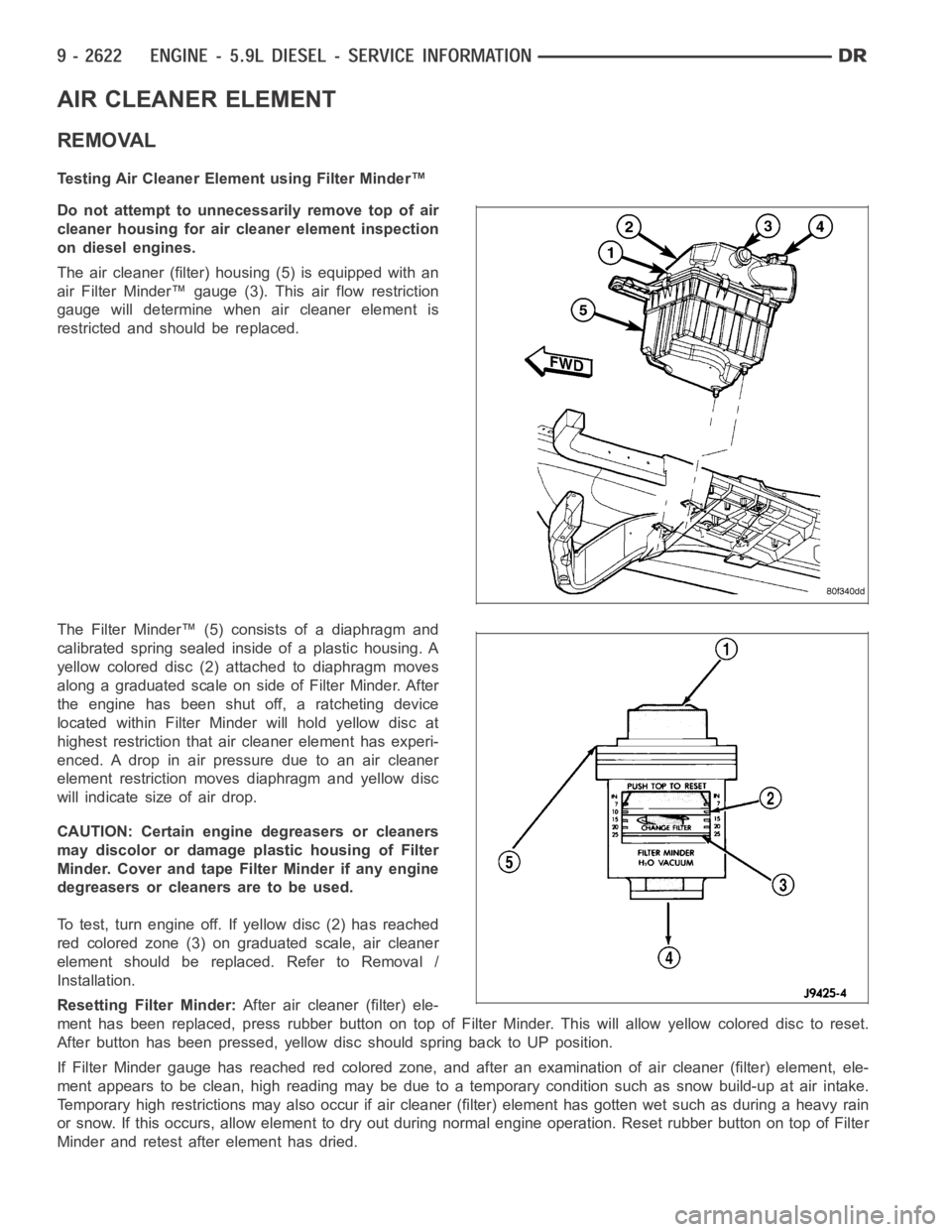

Testing Air Cleaner Element using Filter Minder™

Do not attempt to unnecessarily remove top of air

cleaner housing for air cleaner element inspection

on diesel engines.

The air cleaner (filter) housing (5) is equipped with an

air Filter Minder™ gauge (3). This air flow restriction

gauge will determine when air cleaner element is

restricted and should be replaced.

The Filter Minder™ (5) consists of a diaphragm and

calibrated spring sealed inside of a plastic housing. A

yellow colored disc (2) attached to diaphragm moves

along a graduated scale on side of Filter Minder. After

the engine has been shut off, a ratcheting device

located within Filter Minder will hold yellow disc at

highest restriction that air cleaner element has experi-

enced. A drop in air pressure due to an air cleaner

element restriction moves diaphragm and yellow disc

will indicate size of air drop.

CAUTION: Certain engine degreasers or cleaners

may discolor or damage plastic housing of Filter

Minder. Cover and tape Filter Minder if any engine

degreasers or cleaners are to be used.

To test, turn engine off. If yellow disc (2) has reached

red colored zone (3) on graduated scale, air cleaner

element should be replaced. Refer to Removal /

Installation.

Resetting Filter Minder:After air cleaner (filter) ele-

ment has been replaced, press rubber button on top of Filter Minder. This will allow yellow colored disc to reset.

After button has been pressed, yellow disc should spring back to UP position.

If Filter Minder gauge has reached red colored zone, and after an examination of air cleaner (filter) element, ele-

ment appears to be clean, high reading may be due to a temporary condition such as snow build-up at air intake.

Temporary high restrictions may also occur if air cleaner (filter) element has gotten wet such as during a heavy rain

or snow. If this occurs, allow element to dry out during normal engine operation. Reset rubber button on top of Filter

Minder and retest after element has dried.