DODGE TOWN AND COUNTRY 2001 Service Manual

Manufacturer: DODGE, Model Year: 2001, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2001Pages: 2321, PDF Size: 68.09 MB

Page 1851 of 2321

ADJUSTMENT - DIFFERENTIAL SIDE GEAR

END PLAY

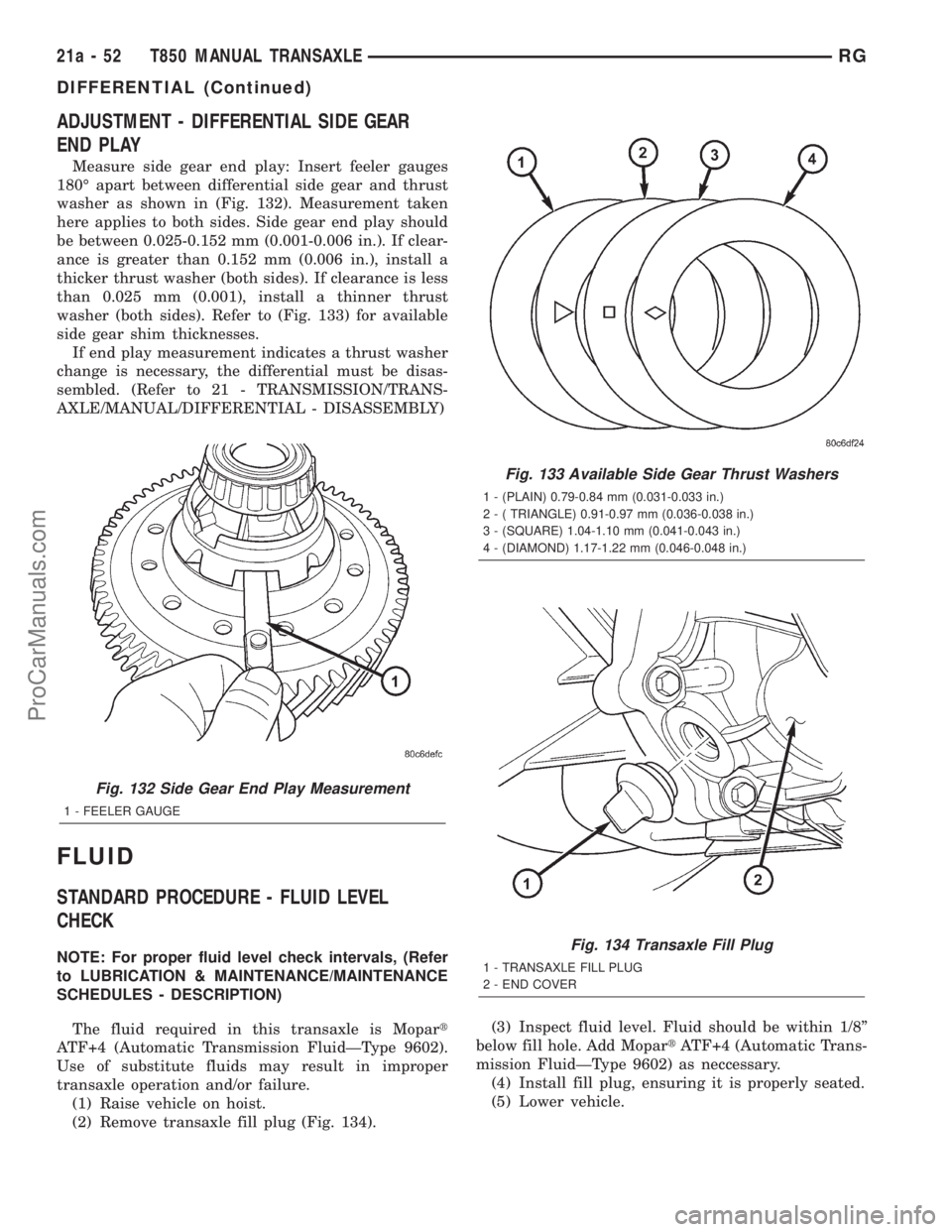

Measure side gear end play: Insert feeler gauges

180É apart between differential side gear and thrust

washer as shown in (Fig. 132). Measurement taken

here applies to both sides. Side gear end play should

be between 0.025-0.152 mm (0.001-0.006 in.). If clear-

ance is greater than 0.152 mm (0.006 in.), install a

thicker thrust washer (both sides). If clearance is less

than 0.025 mm (0.001), install a thinner thrust

washer (both sides). Refer to (Fig. 133) for available

side gear shim thicknesses.

If end play measurement indicates a thrust washer

change is necessary, the differential must be disas-

sembled. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/MANUAL/DIFFERENTIAL - DISASSEMBLY)

FLUID

STANDARD PROCEDURE - FLUID LEVEL

CHECK

NOTE: For proper fluid level check intervals, (Refer

to LUBRICATION & MAINTENANCE/MAINTENANCE

SCHEDULES - DESCRIPTION)

The fluid required in this transaxle is Mopart

ATF+4 (Automatic Transmission FluidÐType 9602).

Use of substitute fluids may result in improper

transaxle operation and/or failure.

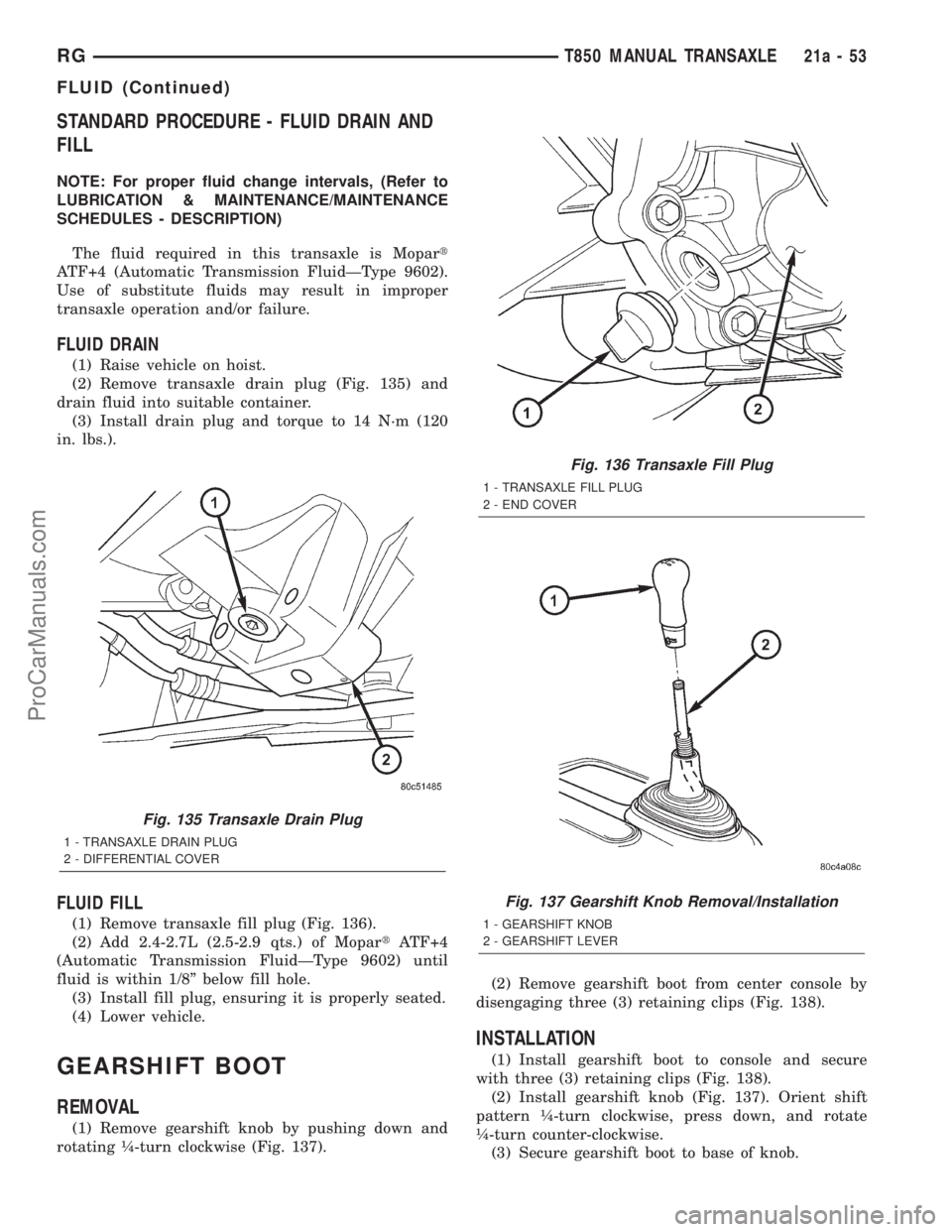

(1) Raise vehicle on hoist.

(2) Remove transaxle fill plug (Fig. 134).(3) Inspect fluid level. Fluid should be within 1/8º

below fill hole. Add MopartATF+4 (Automatic Trans-

mission FluidÐType 9602) as neccessary.

(4) Install fill plug, ensuring it is properly seated.

(5) Lower vehicle.

Fig. 132 Side Gear End Play Measurement

1 - FEELER GAUGE

Fig. 133 Available Side Gear Thrust Washers

1 - (PLAIN) 0.79-0.84 mm (0.031-0.033 in.)

2 - ( TRIANGLE) 0.91-0.97 mm (0.036-0.038 in.)

3 - (SQUARE) 1.04-1.10 mm (0.041-0.043 in.)

4 - (DIAMOND) 1.17-1.22 mm (0.046-0.048 in.)

Fig. 134 Transaxle Fill Plug

1 - TRANSAXLE FILL PLUG

2 - END COVER

21a - 52 T850 MANUAL TRANSAXLERG

DIFFERENTIAL (Continued)

ProCarManuals.com

Page 1852 of 2321

STANDARD PROCEDURE - FLUID DRAIN AND

FILL

NOTE: For proper fluid change intervals, (Refer to

LUBRICATION & MAINTENANCE/MAINTENANCE

SCHEDULES - DESCRIPTION)

The fluid required in this transaxle is Mopart

ATF+4 (Automatic Transmission FluidÐType 9602).

Use of substitute fluids may result in improper

transaxle operation and/or failure.

FLUID DRAIN

(1) Raise vehicle on hoist.

(2) Remove transaxle drain plug (Fig. 135) and

drain fluid into suitable container.

(3) Install drain plug and torque to 14 N´m (120

in. lbs.).

FLUID FILL

(1) Remove transaxle fill plug (Fig. 136).

(2) Add 2.4-2.7L (2.5-2.9 qts.) of MopartATF+4

(Automatic Transmission FluidÐType 9602) until

fluid is within 1/8º below fill hole.

(3) Install fill plug, ensuring it is properly seated.

(4) Lower vehicle.

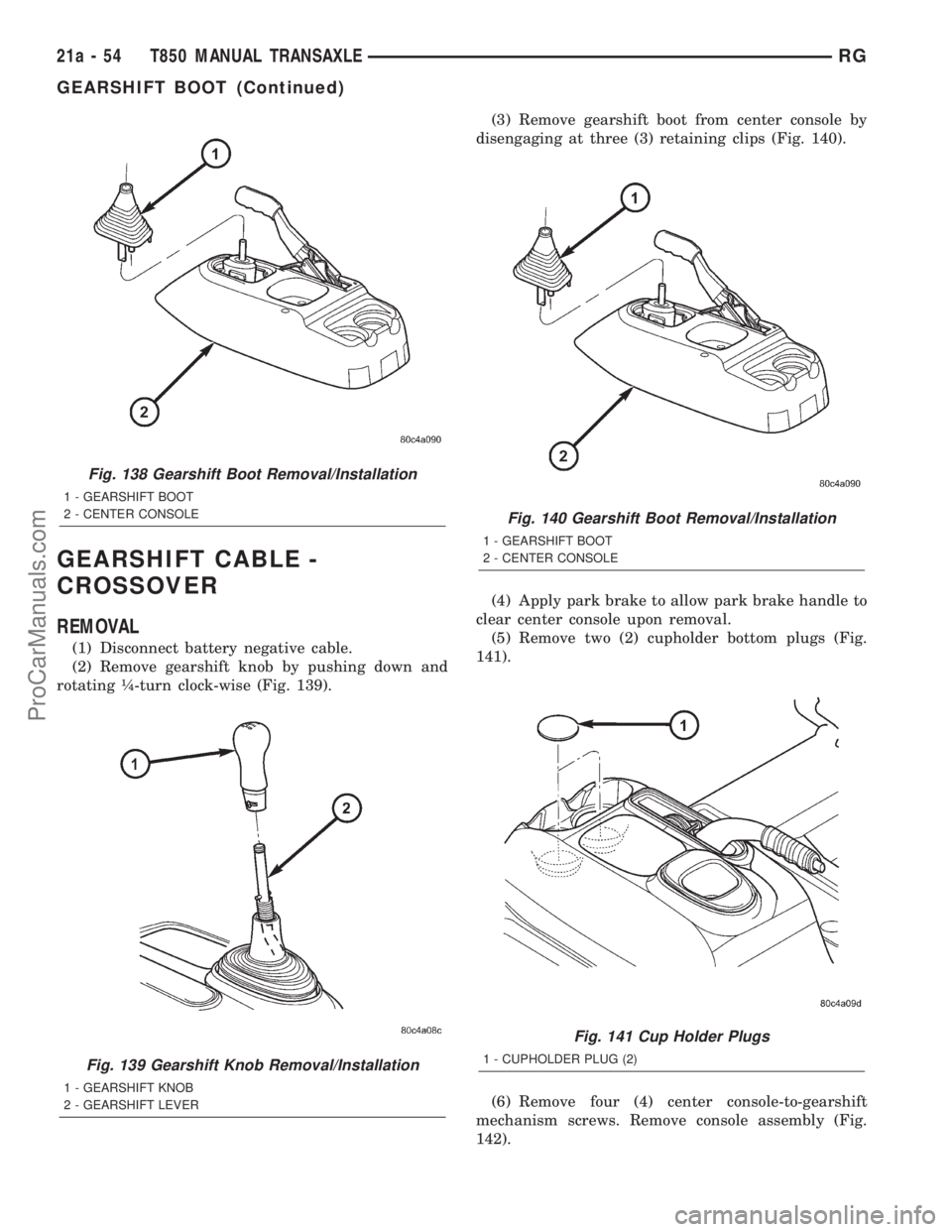

GEARSHIFT BOOT

REMOVAL

(1) Remove gearshift knob by pushing down and

rotating ò-turn clockwise (Fig. 137).(2) Remove gearshift boot from center console by

disengaging three (3) retaining clips (Fig. 138).

INSTALLATION

(1) Install gearshift boot to console and secure

with three (3) retaining clips (Fig. 138).

(2) Install gearshift knob (Fig. 137). Orient shift

pattern ò-turn clockwise, press down, and rotate

ò-turn counter-clockwise.

(3) Secure gearshift boot to base of knob.

Fig. 135 Transaxle Drain Plug

1 - TRANSAXLE DRAIN PLUG

2 - DIFFERENTIAL COVER

Fig. 136 Transaxle Fill Plug

1 - TRANSAXLE FILL PLUG

2 - END COVER

Fig. 137 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

RGT850 MANUAL TRANSAXLE21a-53

FLUID (Continued)

ProCarManuals.com

Page 1853 of 2321

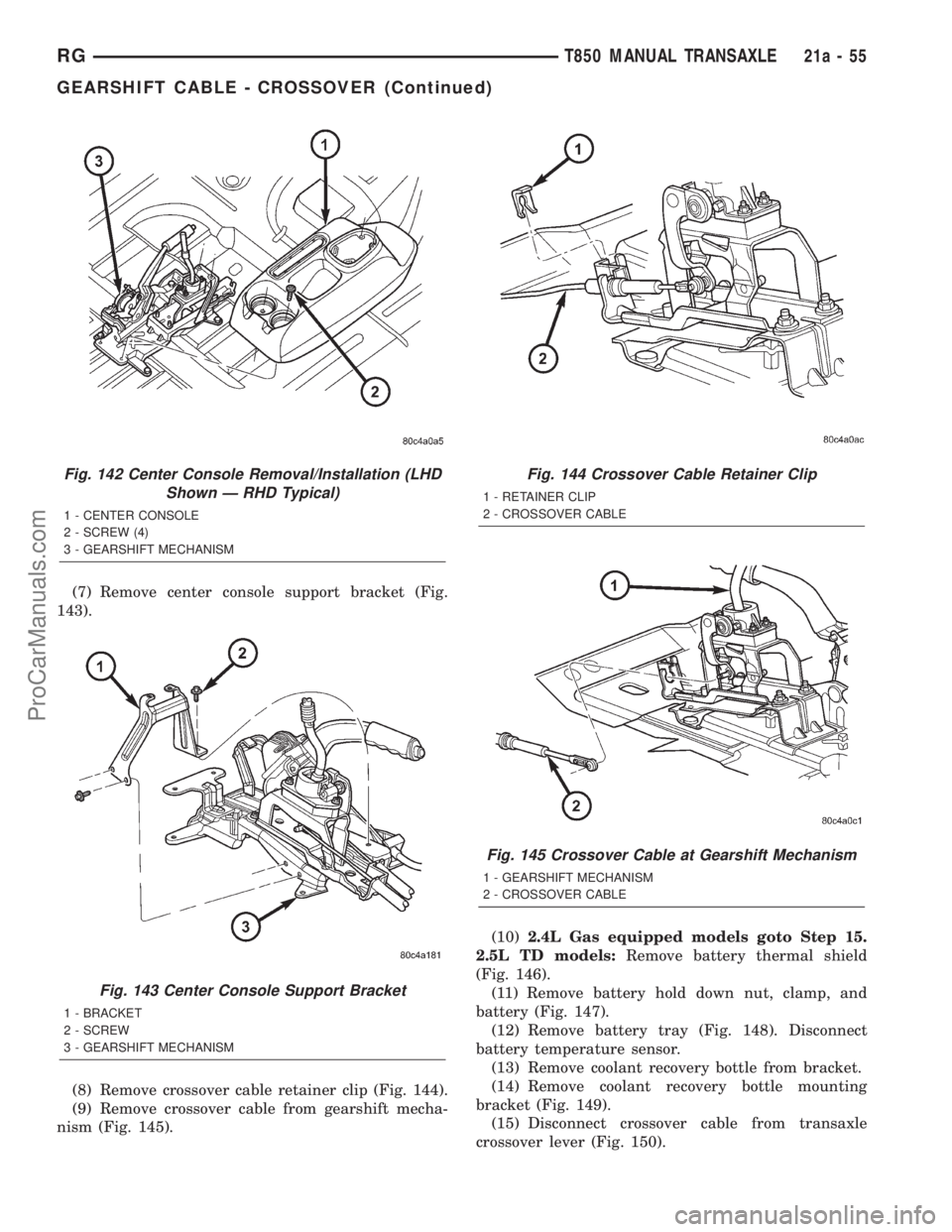

GEARSHIFT CABLE -

CROSSOVER

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove gearshift knob by pushing down and

rotating ò-turn clock-wise (Fig. 139).(3) Remove gearshift boot from center console by

disengaging at three (3) retaining clips (Fig. 140).

(4) Apply park brake to allow park brake handle to

clear center console upon removal.

(5) Remove two (2) cupholder bottom plugs (Fig.

141).

(6) Remove four (4) center console-to-gearshift

mechanism screws. Remove console assembly (Fig.

142).

Fig. 138 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 139 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 140 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 141 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

21a - 54 T850 MANUAL TRANSAXLERG

GEARSHIFT BOOT (Continued)

ProCarManuals.com

Page 1854 of 2321

(7) Remove center console support bracket (Fig.

143).

(8) Remove crossover cable retainer clip (Fig. 144).

(9) Remove crossover cable from gearshift mecha-

nism (Fig. 145).(10)2.4L Gas equipped models goto Step 15.

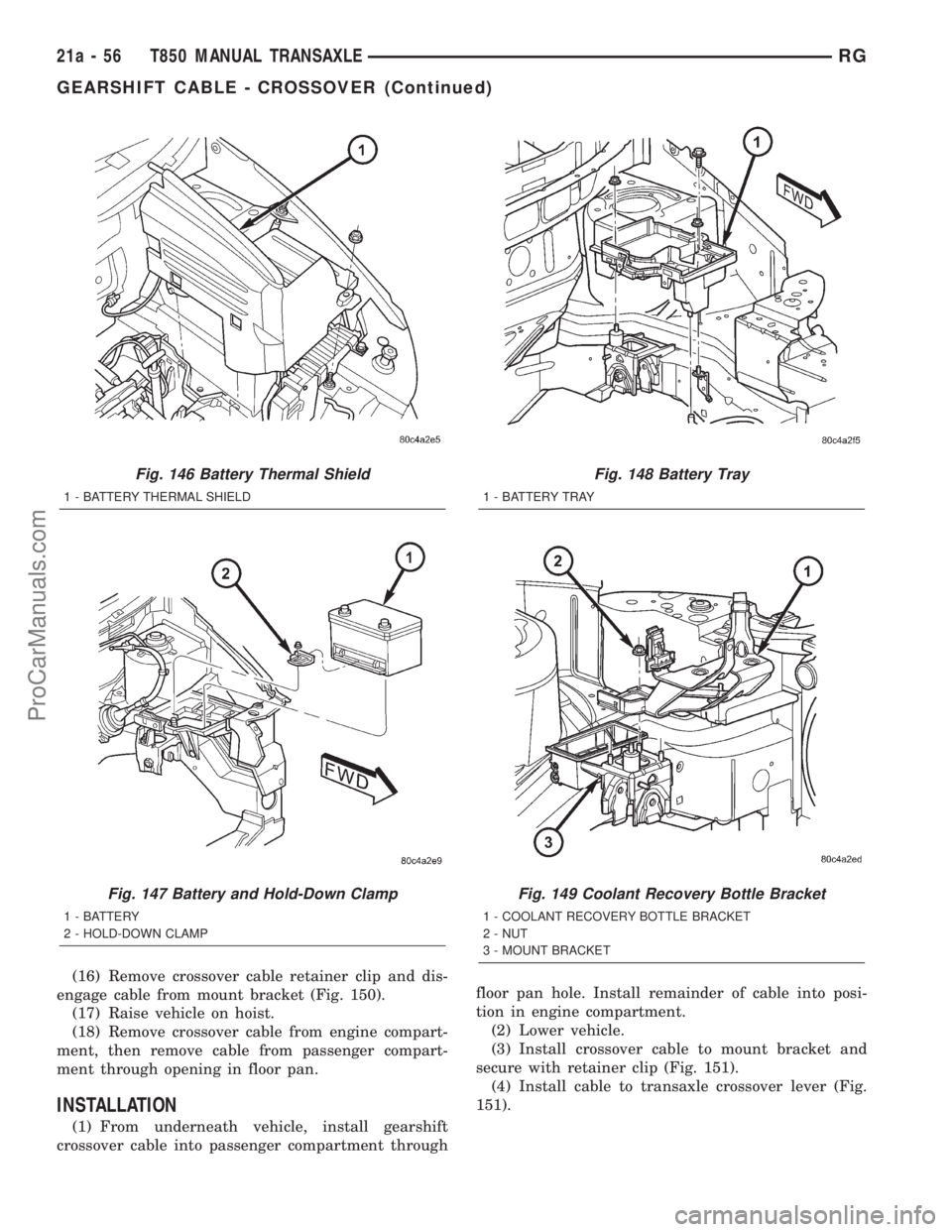

2.5L TD models:Remove battery thermal shield

(Fig. 146).

(11) Remove battery hold down nut, clamp, and

battery (Fig. 147).

(12) Remove battery tray (Fig. 148). Disconnect

battery temperature sensor.

(13) Remove coolant recovery bottle from bracket.

(14) Remove coolant recovery bottle mounting

bracket (Fig. 149).

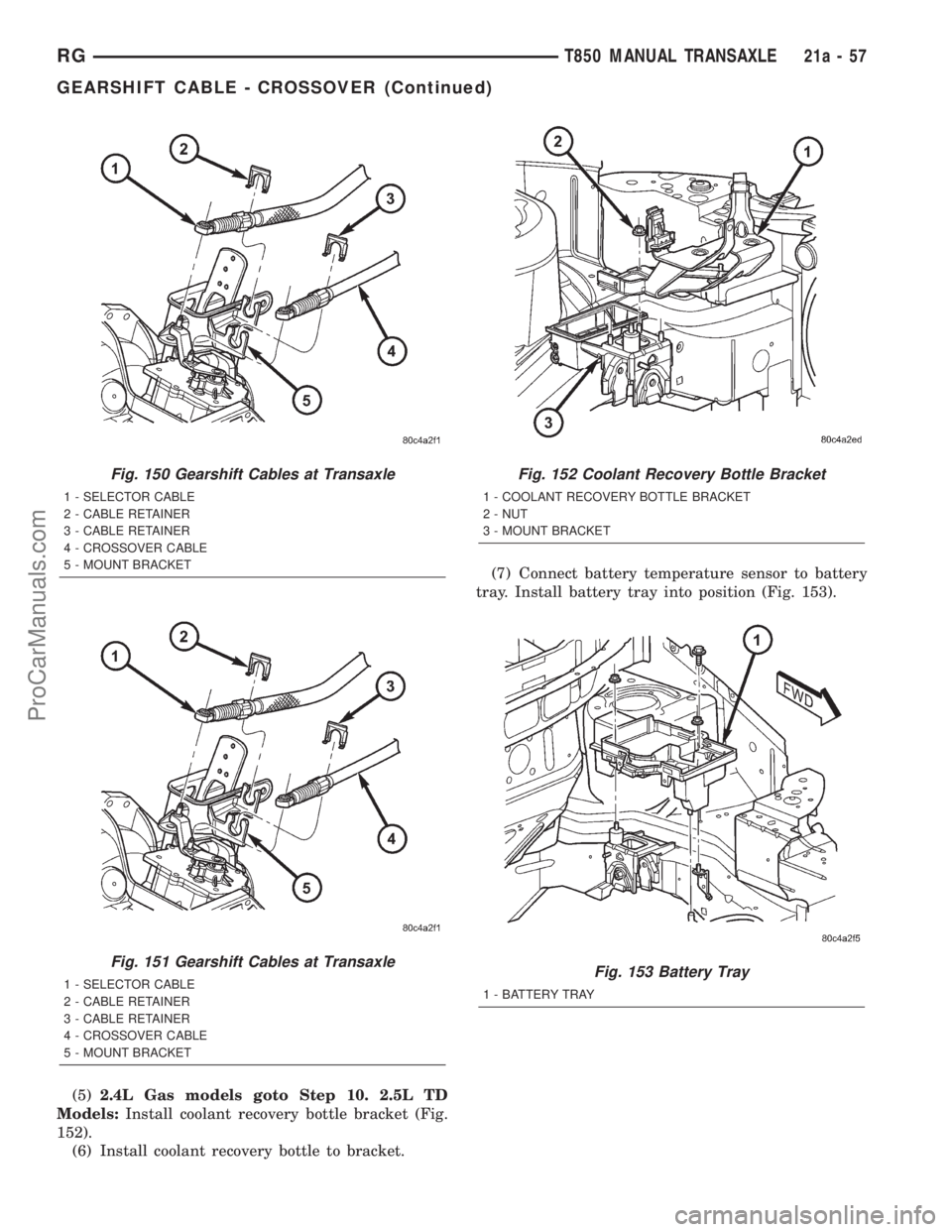

(15) Disconnect crossover cable from transaxle

crossover lever (Fig. 150).

Fig. 142 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 143 Center Console Support Bracket

1 - BRACKET

2 - SCREW

3 - GEARSHIFT MECHANISM

Fig. 144 Crossover Cable Retainer Clip

1 - RETAINER CLIP

2 - CROSSOVER CABLE

Fig. 145 Crossover Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - CROSSOVER CABLE

RGT850 MANUAL TRANSAXLE21a-55

GEARSHIFT CABLE - CROSSOVER (Continued)

ProCarManuals.com

Page 1855 of 2321

(16) Remove crossover cable retainer clip and dis-

engage cable from mount bracket (Fig. 150).

(17) Raise vehicle on hoist.

(18) Remove crossover cable from engine compart-

ment, then remove cable from passenger compart-

ment through opening in floor pan.

INSTALLATION

(1) From underneath vehicle, install gearshift

crossover cable into passenger compartment throughfloor pan hole. Install remainder of cable into posi-

tion in engine compartment.

(2) Lower vehicle.

(3) Install crossover cable to mount bracket and

secure with retainer clip (Fig. 151).

(4) Install cable to transaxle crossover lever (Fig.

151).

Fig. 146 Battery Thermal Shield

1 - BATTERY THERMAL SHIELD

Fig. 147 Battery and Hold-Down Clamp

1 - BATTERY

2 - HOLD-DOWN CLAMP

Fig. 148 Battery Tray

1 - BATTERY TRAY

Fig. 149 Coolant Recovery Bottle Bracket

1 - COOLANT RECOVERY BOTTLE BRACKET

2 - NUT

3 - MOUNT BRACKET

21a - 56 T850 MANUAL TRANSAXLERG

GEARSHIFT CABLE - CROSSOVER (Continued)

ProCarManuals.com

Page 1856 of 2321

(5)2.4L Gas models goto Step 10. 2.5L TD

Models:Install coolant recovery bottle bracket (Fig.

152).

(6) Install coolant recovery bottle to bracket.(7) Connect battery temperature sensor to battery

tray. Install battery tray into position (Fig. 153).

Fig. 150 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

Fig. 151 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

Fig. 152 Coolant Recovery Bottle Bracket

1 - COOLANT RECOVERY BOTTLE BRACKET

2 - NUT

3 - MOUNT BRACKET

Fig. 153 Battery Tray

1 - BATTERY TRAY

RGT850 MANUAL TRANSAXLE21a-57

GEARSHIFT CABLE - CROSSOVER (Continued)

ProCarManuals.com

Page 1857 of 2321

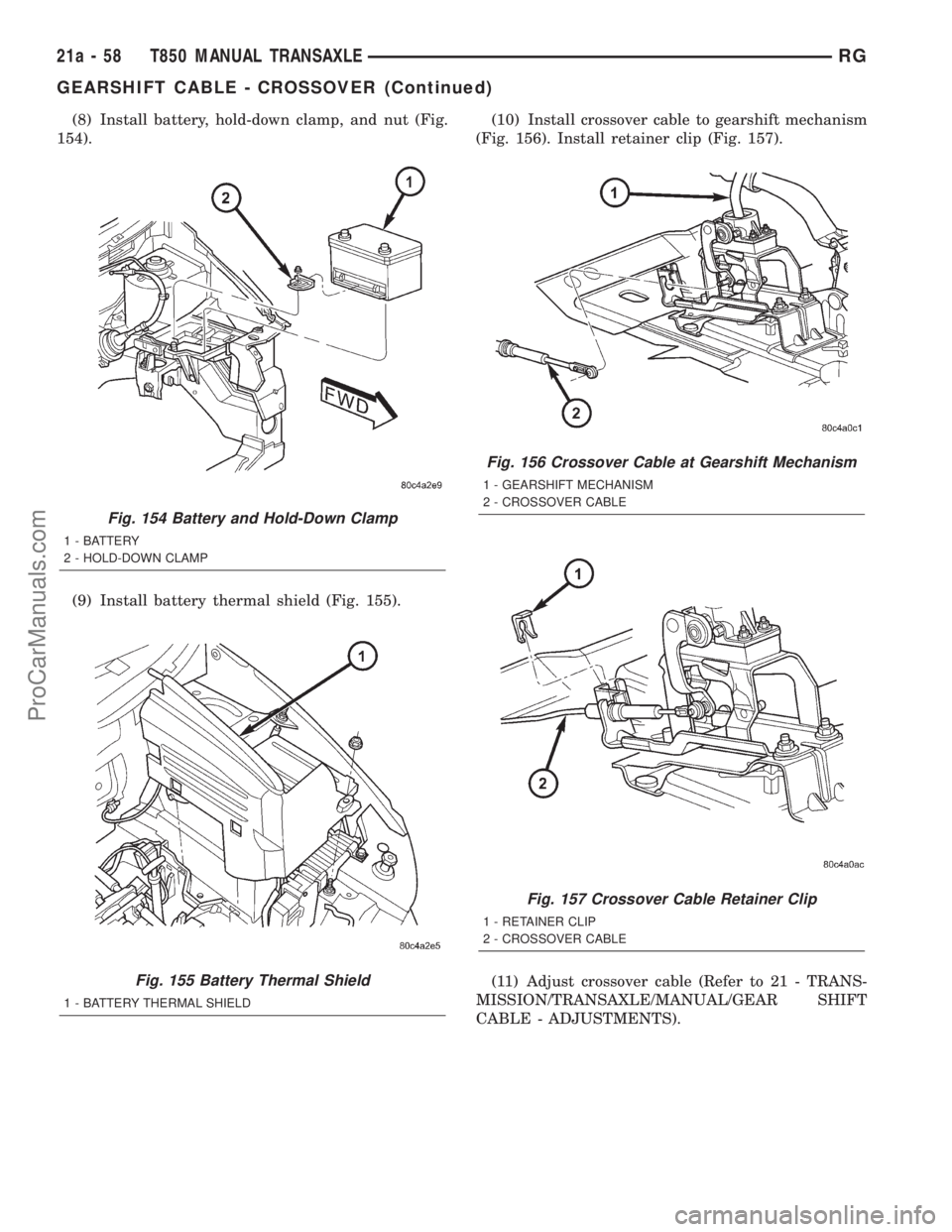

(8) Install battery, hold-down clamp, and nut (Fig.

154).

(9) Install battery thermal shield (Fig. 155).(10) Install crossover cable to gearshift mechanism

(Fig. 156). Install retainer clip (Fig. 157).

(11) Adjust crossover cable (Refer to 21 - TRANS-

MISSION/TRANSAXLE/MANUAL/GEAR SHIFT

CABLE - ADJUSTMENTS).

Fig. 154 Battery and Hold-Down Clamp

1 - BATTERY

2 - HOLD-DOWN CLAMP

Fig. 155 Battery Thermal Shield

1 - BATTERY THERMAL SHIELD

Fig. 156 Crossover Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - CROSSOVER CABLE

Fig. 157 Crossover Cable Retainer Clip

1 - RETAINER CLIP

2 - CROSSOVER CABLE

21a - 58 T850 MANUAL TRANSAXLERG

GEARSHIFT CABLE - CROSSOVER (Continued)

ProCarManuals.com

Page 1858 of 2321

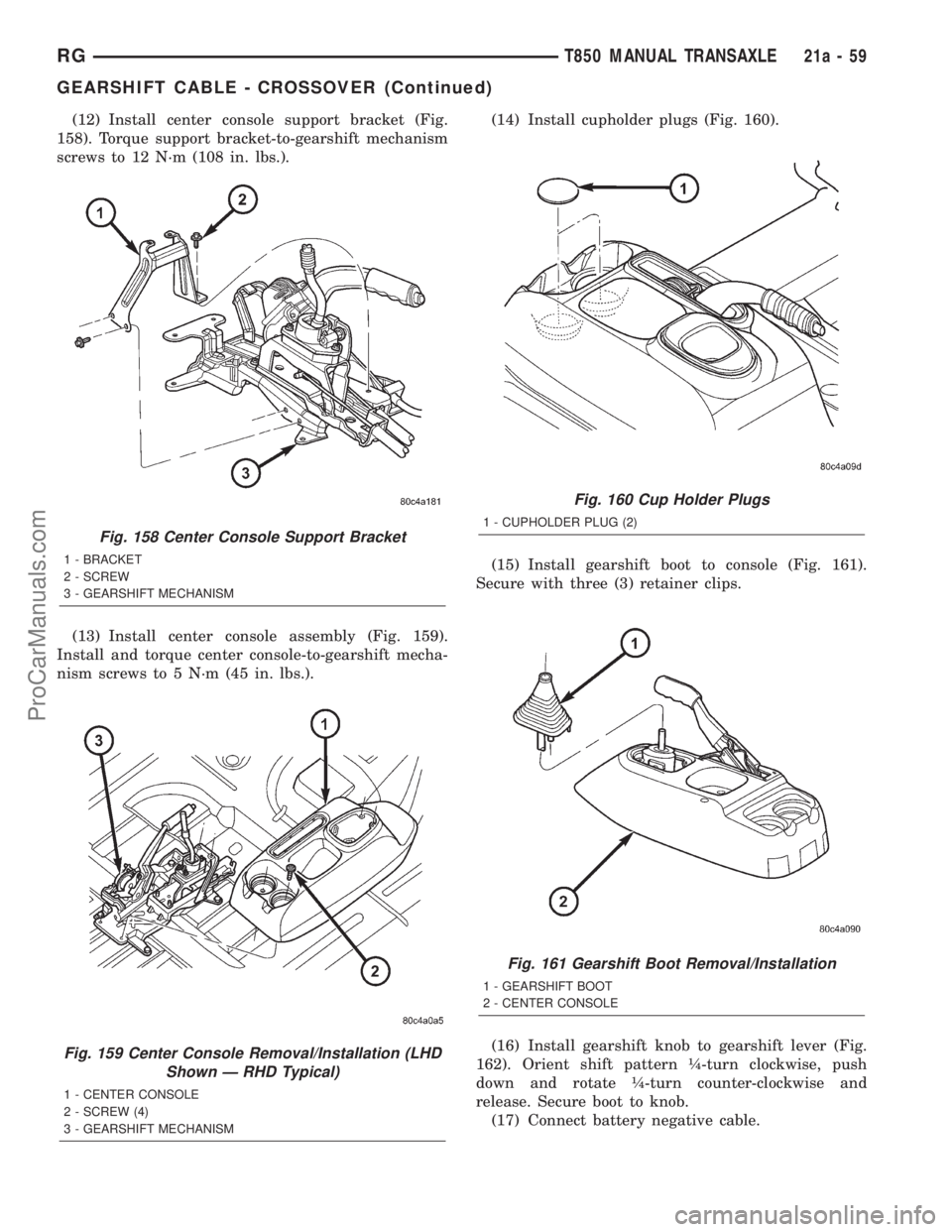

(12) Install center console support bracket (Fig.

158). Torque support bracket-to-gearshift mechanism

screws to 12 N´m (108 in. lbs.).

(13) Install center console assembly (Fig. 159).

Install and torque center console-to-gearshift mecha-

nism screws to 5 N´m (45 in. lbs.).(14) Install cupholder plugs (Fig. 160).

(15) Install gearshift boot to console (Fig. 161).

Secure with three (3) retainer clips.

(16) Install gearshift knob to gearshift lever (Fig.

162). Orient shift pattern ò-turn clockwise, push

down and rotate ò-turn counter-clockwise and

release. Secure boot to knob.

(17) Connect battery negative cable.

Fig. 158 Center Console Support Bracket

1 - BRACKET

2 - SCREW

3 - GEARSHIFT MECHANISM

Fig. 159 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 160 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

Fig. 161 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

RGT850 MANUAL TRANSAXLE21a-59

GEARSHIFT CABLE - CROSSOVER (Continued)

ProCarManuals.com

Page 1859 of 2321

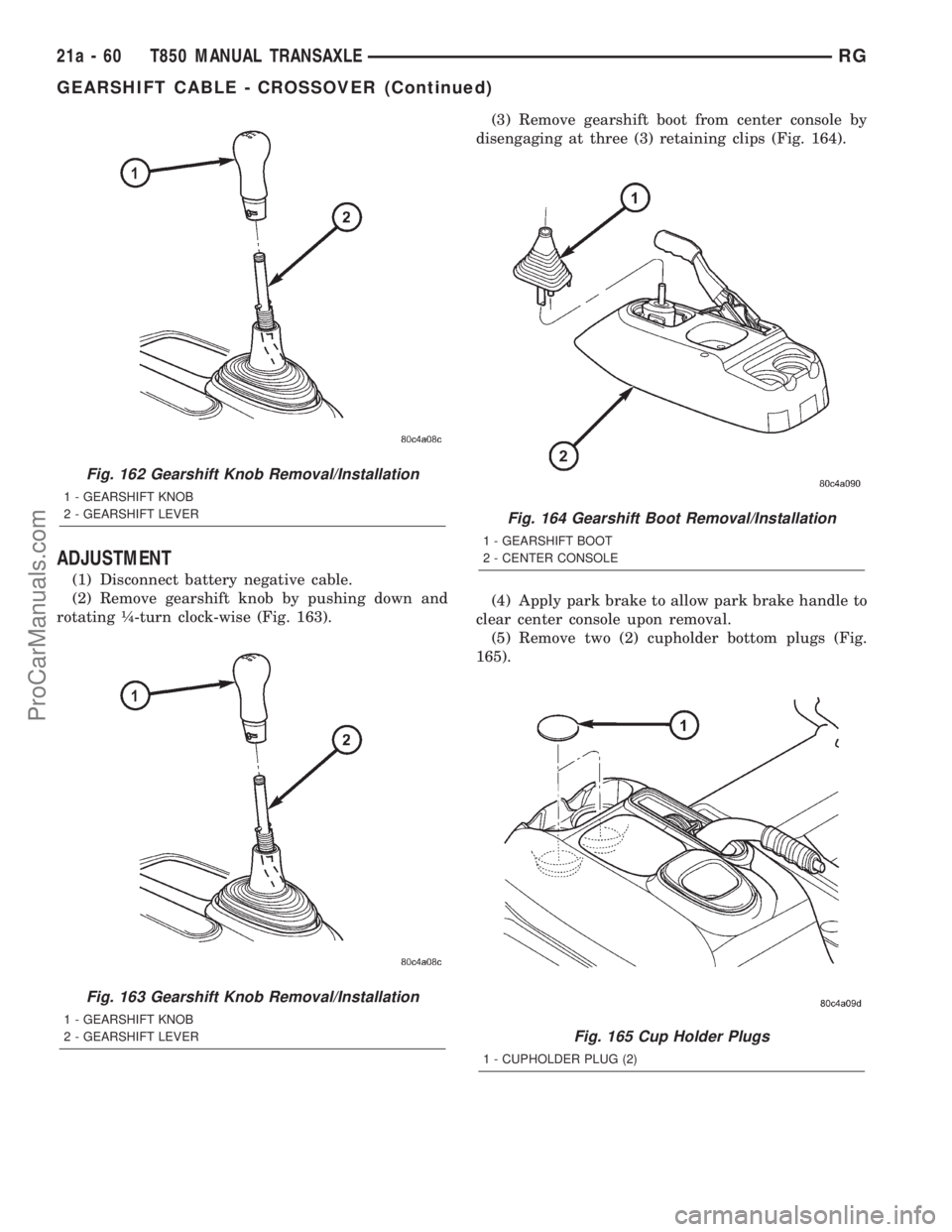

ADJUSTMENT

(1) Disconnect battery negative cable.

(2) Remove gearshift knob by pushing down and

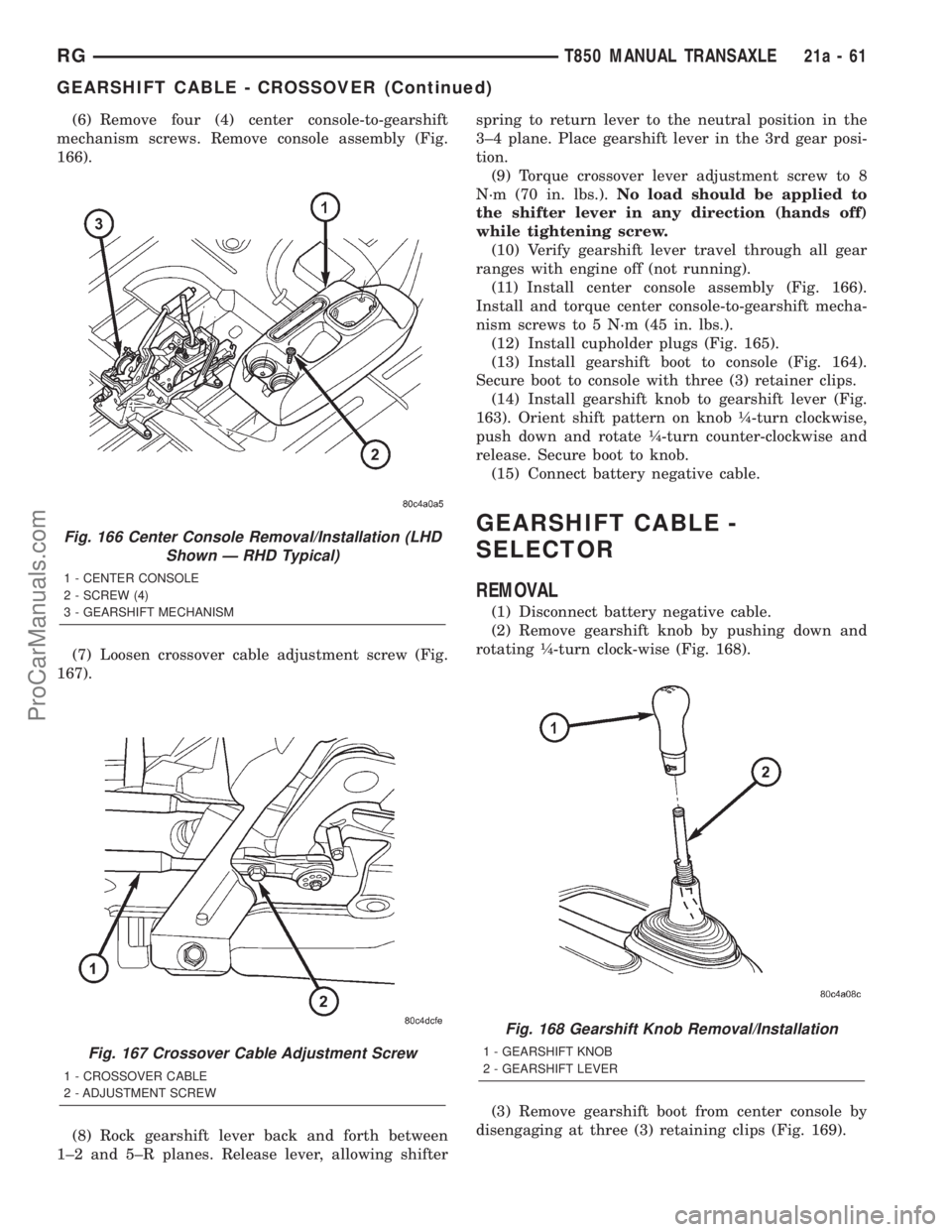

rotating ò-turn clock-wise (Fig. 163).(3) Remove gearshift boot from center console by

disengaging at three (3) retaining clips (Fig. 164).

(4) Apply park brake to allow park brake handle to

clear center console upon removal.

(5) Remove two (2) cupholder bottom plugs (Fig.

165).

Fig. 162 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 163 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 164 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 165 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

21a - 60 T850 MANUAL TRANSAXLERG

GEARSHIFT CABLE - CROSSOVER (Continued)

ProCarManuals.com

Page 1860 of 2321

(6) Remove four (4) center console-to-gearshift

mechanism screws. Remove console assembly (Fig.

166).

(7) Loosen crossover cable adjustment screw (Fig.

167).

(8) Rock gearshift lever back and forth between

1±2 and 5±R planes. Release lever, allowing shifterspring to return lever to the neutral position in the

3±4 plane. Place gearshift lever in the 3rd gear posi-

tion.

(9) Torque crossover lever adjustment screw to 8

N´m (70 in. lbs.).No load should be applied to

the shifter lever in any direction (hands off)

while tightening screw.

(10) Verify gearshift lever travel through all gear

ranges with engine off (not running).

(11) Install center console assembly (Fig. 166).

Install and torque center console-to-gearshift mecha-

nism screws to 5 N´m (45 in. lbs.).

(12) Install cupholder plugs (Fig. 165).

(13) Install gearshift boot to console (Fig. 164).

Secure boot to console with three (3) retainer clips.

(14) Install gearshift knob to gearshift lever (Fig.

163). Orient shift pattern on knob ò-turn clockwise,

push down and rotate ò-turn counter-clockwise and

release. Secure boot to knob.

(15) Connect battery negative cable.

GEARSHIFT CABLE -

SELECTOR

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove gearshift knob by pushing down and

rotating ò-turn clock-wise (Fig. 168).

(3) Remove gearshift boot from center console by

disengaging at three (3) retaining clips (Fig. 169).

Fig. 166 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 167 Crossover Cable Adjustment Screw

1 - CROSSOVER CABLE

2 - ADJUSTMENT SCREW

Fig. 168 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

RGT850 MANUAL TRANSAXLE21a-61

GEARSHIFT CABLE - CROSSOVER (Continued)

ProCarManuals.com