DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 1201 of 1502

21

- 200

TRANSMISSION

OVERHAUL—36RH/37RH

•

,

CLUTCH

s\/CAM

REAR

BAND

ADJUSTING

LEVER

Fig.

37

Removing

Overrunning

Clutch—36RH/37RH

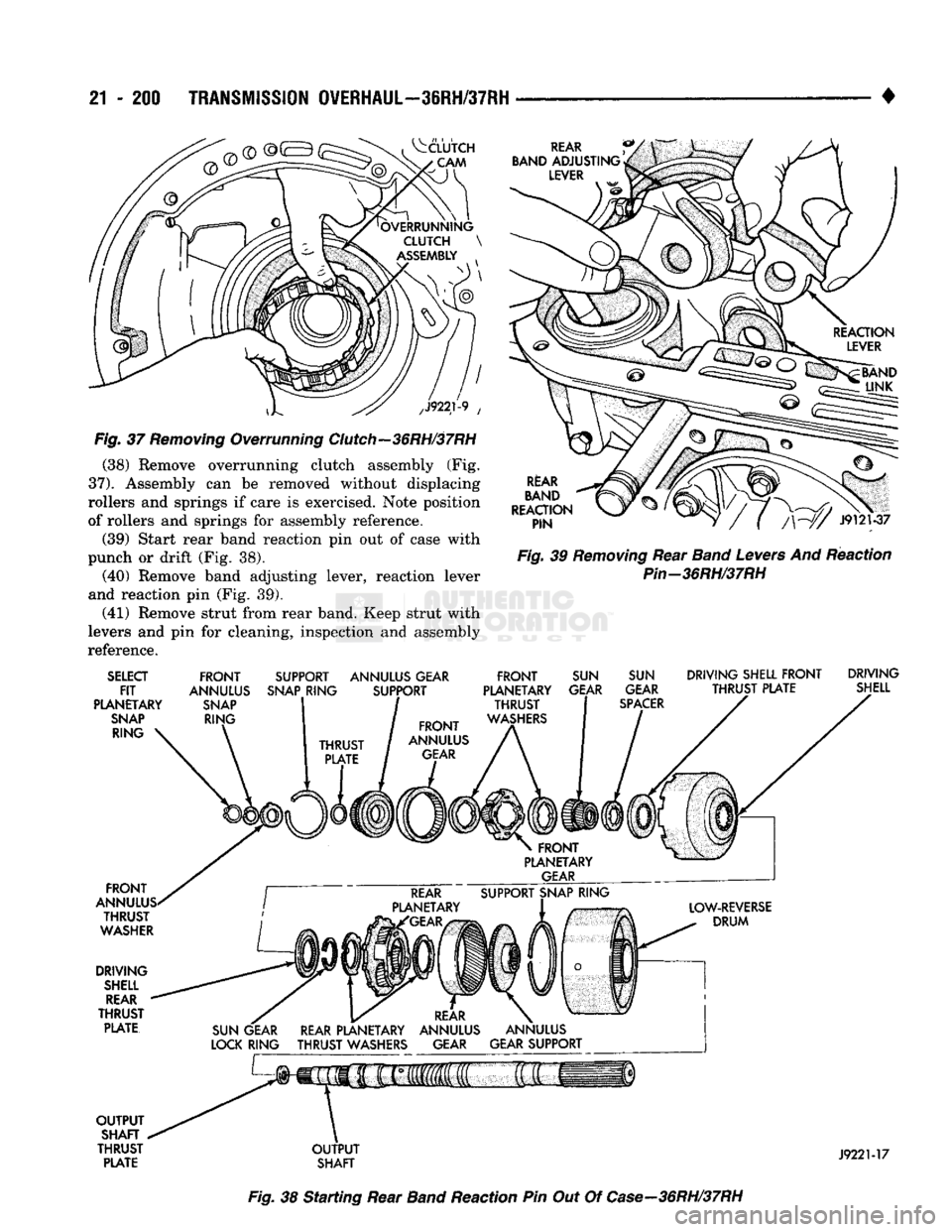

(38) Remove overrunning clutch assembly (Fig.

37).

Assembly can be removed without displacing

rollers and springs if care is exercised. Note position

of rollers and springs for assembly reference.

(39) Start rear band reaction pin out of case with

punch or drift (Fig. 38). (40) Remove band adjusting lever, reaction lever

and reaction pin (Fig. 39). (41) Remove strut from rear band. Keep strut with

levers and pin for cleaning, inspection and assembly

reference.

RtAR

BAND

REACTION PIN

Fig.

39

Removing

Rear

Band

Levers

And Reaction

Pin-36RH/37RH

SELECT

FIT

PLANETARY

SNAP

RING

FRONT

ANNULUS

SNAP

RING SUPPORT

SNAP

RING ANNULUS GEAR

SUPPORT

FRONT

ANNULUS

GEAR

FRONT

ANNULUS

THRUST

WASHER

DRIVING

SHELL

REAR

THRUST

PLATE

FRONT

PLANETARY

THRUST

WASHERS

SUN

GEAR

SUN

GEAR

SPACER

DRIVING SHELL

FRONT

DRIVING

THRUST

PLATE SHELL

SUN

GEAR

LOCK

RING

REAR

PLANETARY

THRUST

WASHERS

REAR

PLANETARY

GEAR

OUTPUT

SHAFT

THRUST

PLATE

OUTPUT

SHAFT

J9221-17

Fig.

38 Starting Rear

Band

Reaction Pin Out Of

Case—36RH/37RH

Page 1202 of 1502

•

TRANSMISSION

OVERHAUL—38RH/37RH

21 - 201

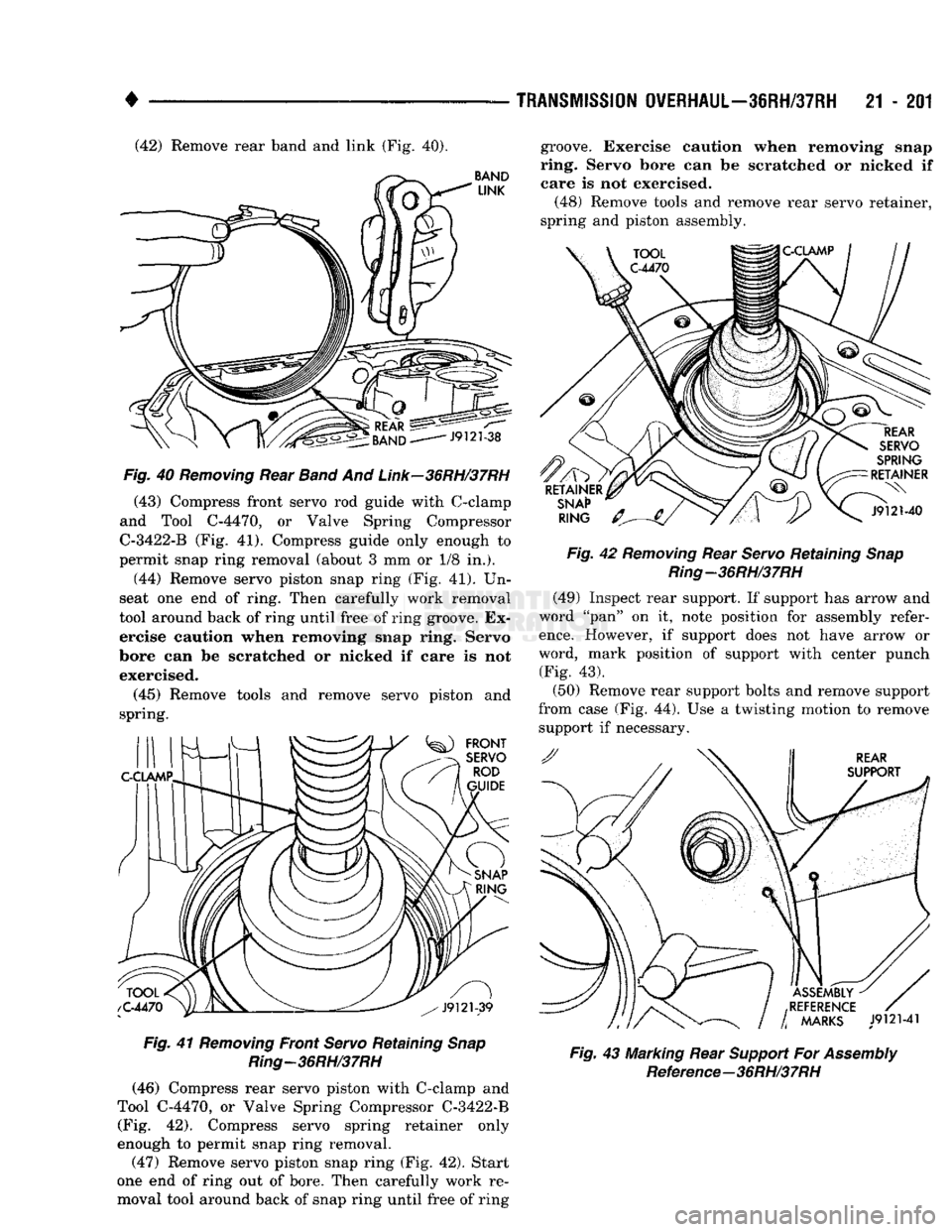

(42) Remove rear band and link (Fig. 40).

Fig.

40

Removing

Rear

Band

And

Link—36RH/37RH

(43) Compress front servo rod guide with C-clamp

and Tool C-4470, or Valve Spring Compressor

C-3422-B (Fig. 41). Compress guide only enough to

permit snap ring removal (about 3 mm or 1/8 in.).

(44) Remove servo piston snap ring (Fig. 41). Un

seat one end of ring. Then carefully work removal

tool around back of ring until free of ring groove. Ex ercise caution when removing snap ring. Servo

bore can be scratched or nicked if care is not exercised.

(45) Remove tools and remove servo piston and

spring.

Fig.

41

Removing

Front

Servo

Retaining

Snap

Ring—36RH/37RH (46) Compress rear servo piston with C-clamp and

Tool C-4470, or Valve Spring Compressor C-3422-B (Fig. 42). Compress servo spring retainer only

enough to permit snap ring removal.

(47) Remove servo piston snap ring (Fig. 42). Start

one end of ring out of bore. Then carefully work re

moval tool around back of snap ring until free of ring groove. Exercise caution when removing snap

ring. Servo bore can be scratched or nicked if

care is not exercised.

(48) Remove tools and remove rear servo retainer,

spring and piston assembly.

Fig.

42

Removing

Rear

Servo

Retaining

Snap

Ring—36RH/37RH

(49) Inspect rear support. If support has arrow and

word "pan" on it, note position for assembly refer

ence.

However, if support does not have arrow or

word, mark position of support with center punch

(Fig. 43).

(50) Remove rear support bolts and remove support

from case (Fig. 44). Use a twisting motion to remove support if necessary.

Fig.

43 Marking Rear

Support

For

Assembly

Reference-36RH/37RH

Page 1203 of 1502

21

- 202

TRANSMISSION

OVERHAUL—36RH/37RH

•

Fig.

44

Removing

Rear Support—36RH/37RH

OVERHAUL

SERVICE

INFORMATION

Inspect

all the

transmission bushings during over

haul. Bushing condition

is

important

as

worn, scored

bushings contribute

to low

pressures, clutch slip

and

accelerated wear

of

other components. Replace worn,

or scored bushings,

or if

doubt exists about bushing

condition. Use recommended tools

to

replace bushings.

The

tools

are

sized

and

designed

to

remove, install

and

seat bushings correctly.

The

bushing replacement

tools

are

included

in

Bushing Tool

Set

C-3887-B. Pre-sized service bushings

are

available

for re

placement purposes. Only

the sun

gear bushings

are

not serviced.

Low

cost

of the sun

gear assembly

makes

it

easier

to

simply replace

the

gear

and

bush

ings

as an

assembly. Heli-Coil inserts

are

recommended

for

repairing

damaged, stripped

or

worn threads

in

aluminum

parts.

These inserts

are

available from most automo

tive jobbers. Stainless steel inserts

are

preferred. The

use of

crocus cloth

is

permissible where neces

sary, providing

it is

used carefully. When used

on

valves,

use

extreme care

to

avoid rounding

off

sharp

edges.

Sharp edges

are

vital

as

they prevent foreign

matter from getting between

the

valve

and

valve

bore.

Do

not

reuse

oil

seals, gaskets, seal rings,

or

O-rings during overhaul. Replace these parts

as a

matter

of

course. Also

do not

reuse snap rings

or

E-clips that

are

bent

or

distorted. Replace these parts as well.

Lubricate transmission parts with Mopar

ATF

Plus,

Type

7176

transmission fluid during assembly.

This

is the

preferred fluid

for use in

36RH/37RH transmissions.

Use

Mopar Dexron

II

only when

ATF

Plus

is not

readily available.

Use Ru-Glyde, Door-Eze,

or

petroleum jelly

to pre-

lubricate seals, O-rings,

and

thrust washers. Petro

leum jelly

can

also

be

used

to

hold parts

in

place during reassembly.

TRANSMISSION CASE

CLEAN1NI

AND

INSPECTION

Clean

the

case

in a

solvent tank. Flush

the

case

bores

and

fluid passages thoroughly with solvent.

Dry

the

case

and all

fluid passages with compressed air.

Be

sure

all

solvent

is

removed from

the

case

and

that

all

fluid passages

are

clear. Do

not use

shop towels

or

rags

to dry the

ease

(or

any

other transmission component) unless

they

are

made from lint-free materials. Lint will

readily adhere

to

case surfaces

and

transmission components

and

will circulate throughout

the

transmission after assembly.

A

sufficient quan

tity

of

lint

can

block fluid passages

and

interfere with valve body operation. Inspect

the

case

for

cracks, porous spots, worn

servo bores,

or

damaged threads. Damaged threads

can

be

repaired with Helicoil thread inserts. How

ever,

the

case will have

to be

replaced

if it

exhibits

damage

or

wear. Lubricate

the

front band adjusting screw with

pe

troleum jelly

and

thread

it

part

way

into

the

case.

Be

sure

the

screw turns freely

and

does

not

bind. Remount

the

transmission case

in

Repair Stand

C-3750-B after cleaning

and

inspection.

EXTENSION

HOUSING

AND PARK

LOCK

COMPONENTS

Clean

the

housing

and

park lock components

in

solvent

and dry

them with compressed

air.

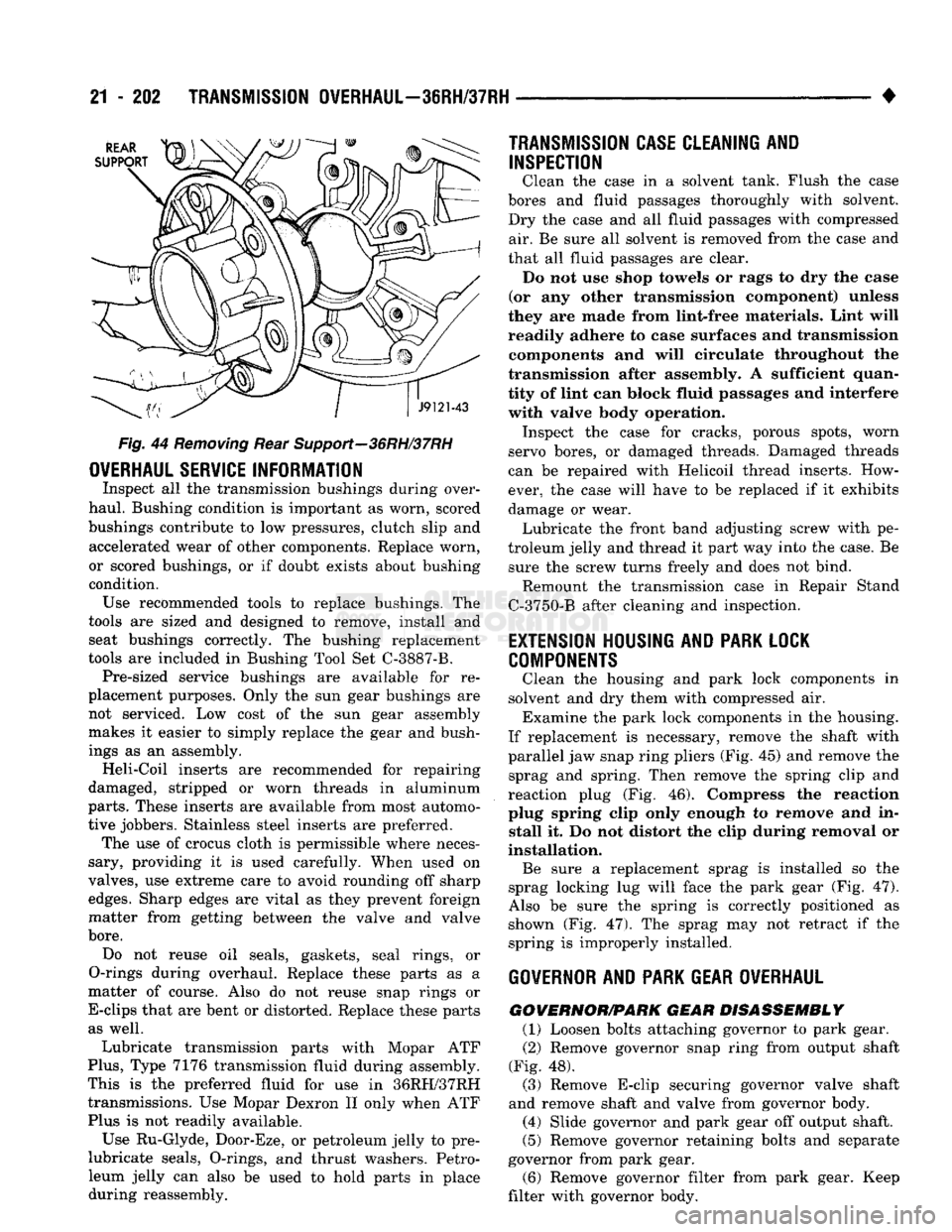

Examine

the

park lock components

in the

housing.

If replacement

is

necessary, remove

the

shaft with

parallel

jaw

snap ring pliers

(Fig. 45) and

remove

the

sprag

and

spring. Then remove

the

spring clip

and

reaction plug

(Fig. 46).

Compress

the

reaction

plug spring clip only enough

to

remove

and in

stall

it. Do not

distort

the

clip during removal

or

installation. Be sure

a

replacement sprag

is

installed

so the

sprag locking

lug

will face

the

park gear

(Fig. 47).

Also

be

sure

the

spring

is

correctly positioned

as

shown

(Fig. 47). The

sprag

may not

retract

if the

spring

is

improperly installed.

GOVERNOR

AND PARK

GEAR OVERHAUL

GOWERNOR/PARK

GEAR DISASSEMBLY

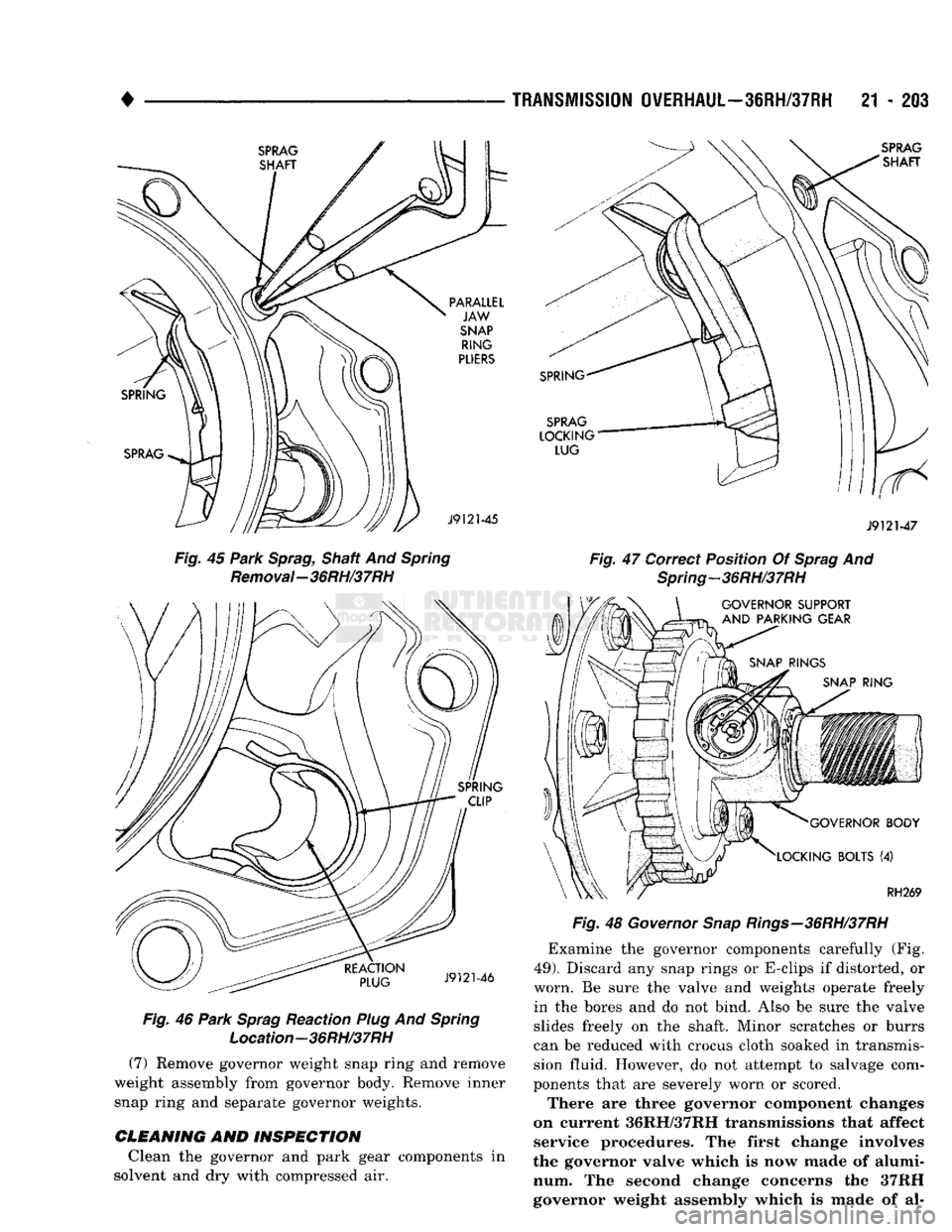

(1) Loosen bolts attaching governor

to

park gear.

(2) Remove governor snap ring from output shaft

(Fig.

48).

(3) Remove E-clip securing governor valve shaft

and remove shaft

and

valve from governor body. (4) Slide governor

and

park gear

off

output shaft.

(5) Remove governor retaining bolts

and

separate

governor from park gear.

(6) Remove governor filter from park gear. Keep

filter with governor body.

Page 1204 of 1502

•

TRANSMISSION

OVERHAUL—36RH/37RH

21 - 203

Fig. 45 Park Sprag, Shaft And Spring Removal-36RH/37RH Fig. 46 Park Sprag Reaction Plug And Spring

Location-36RH/37RH

(7) Remove governor weight snap ring and remove

weight assembly from governor body. Remove inner

snap ring and separate governor weights. Fig. 48 Governor Snap Rings—36RH/37RH

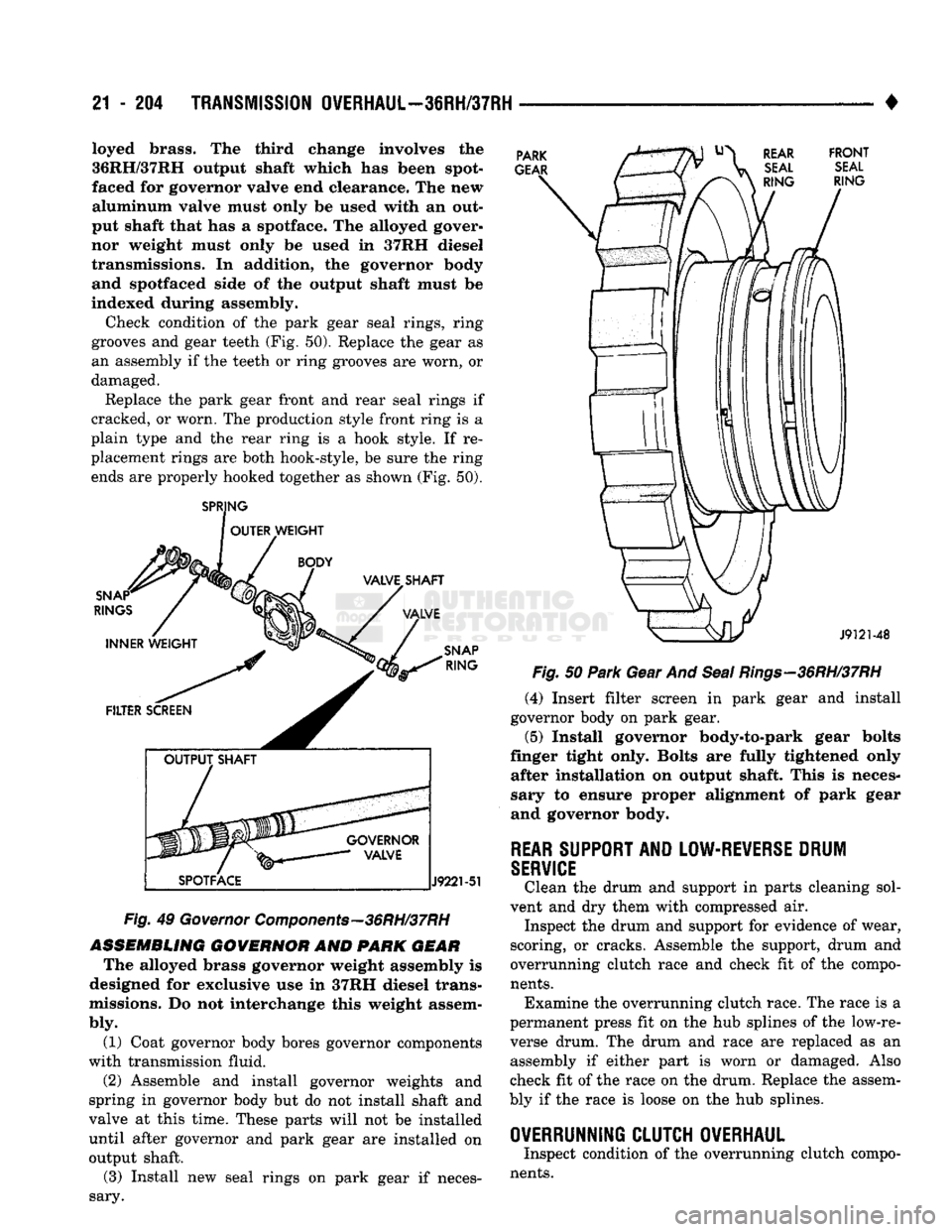

Examine the governor components carefully (Fig.

49).

Discard any snap rings or E-clips if distorted, or

worn. Be sure the valve and weights operate freely in the bores and do not bind. Also be sure the valve

slides freely on the shaft. Minor scratches or burrs

can be reduced with crocus cloth soaked in transmis

sion fluid. However, do not attempt to salvage com

ponents that are severely worn or scored.

There are three governor component changes

on current 36RH/37RH transmissions that affect service procedures. The first change involves

the governor valve which is now made of alumi num. The second change concerns the 37RH

governor weight assembly which is made of al-

CLEANING

AND

INSPECTION

Clean the governor and park gear components in

solvent and dry with compressed air.

Page 1205 of 1502

21 - 204

TRANSMISSION OVERHAUL—36RH/37RH

• loyed

brass.

The third change involves the

36RH/37RH

output

shaft

which

has been spot-

faced for governor valve end clearance. The new

aluminum

valve must only be used with an

out

put

shaft that

has a spotface. The alloyed gover

nor weight

must

only be

used

In 37RH diesel

transmissions. In addition, the governor body and spotfaced side of the output shaft must be

indexed during assembly.

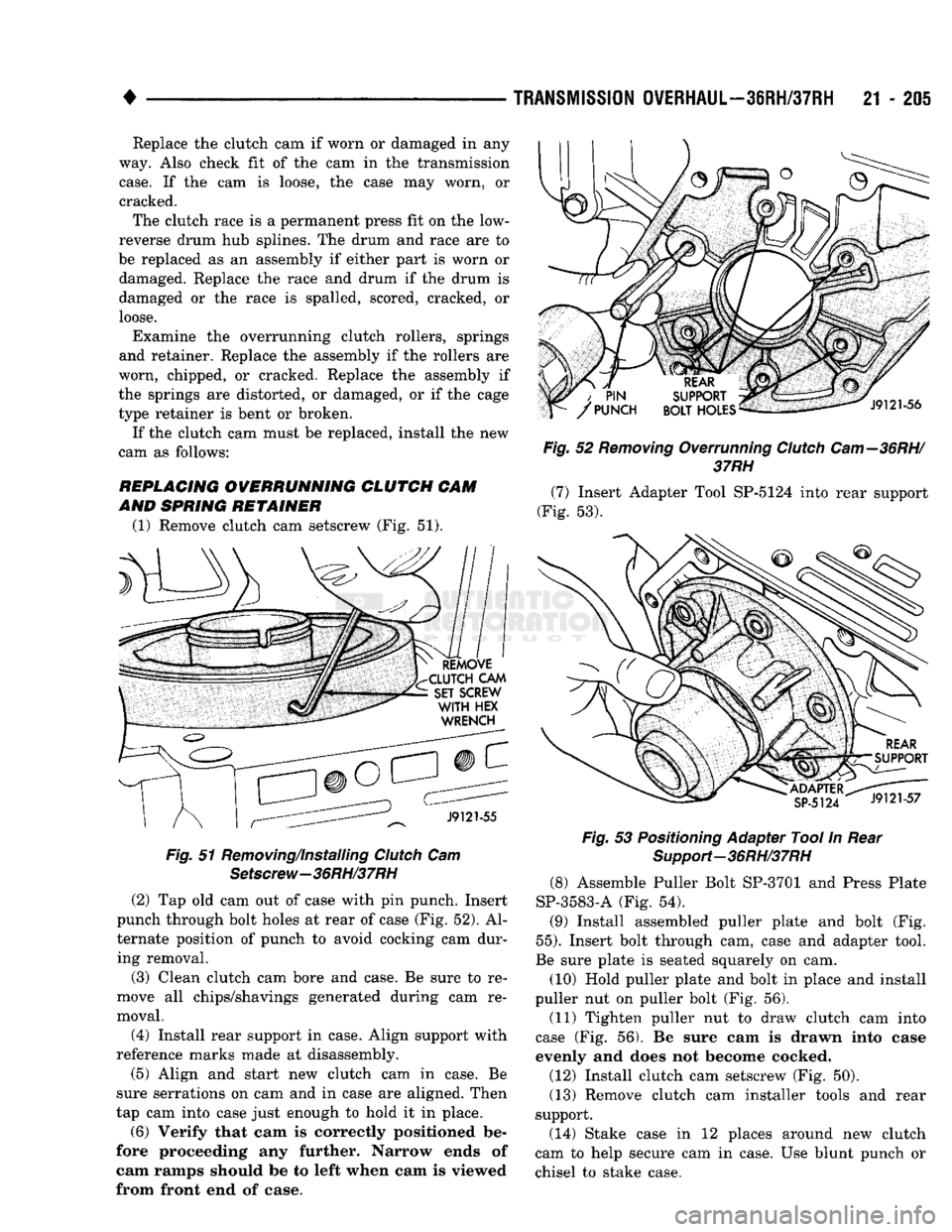

Check condition of the park gear seal rings, ring

grooves and gear teeth (Fig. 50). Replace the gear as

an assembly if the teeth or ring grooves are worn, or damaged.

Replace the park gear front and rear seal rings if

cracked, or worn. The production style front ring is a

plain type and the rear ring is a hook style. If re

placement rings are both hook-style, be sure the ring ends are properly hooked together as shown (Fig. 50).

SPRJNG

OUTER WEIGHT PARK

GEAR REAR FRONT

SEAL SEAL

RING

RING SNAP*

RINGS

INNER WEIGHT VALVET SHAFT

VALVE

SNAP

RING

FILTER SCREEN

GOVERNOR VALVE

SPOTFACE

J9221-51

Fig.

49

Governor

Components—36RH/37RH

ASSEMBLING

GOVERNOR

AND PARK

GEAR

The alloyed brass governor weight assembly is

designed for exclusive use in 37RH diesel trans

missions. Do not interchange this weight assem

bly.

(1) Coat governor body bores governor components

with transmission fluid.

(2) Assemble and install governor weights and

spring in governor body but do not install shaft and

valve at this time. These parts will not be installed until after governor and park gear are installed on output shaft.

(3) Install new seal rings on park gear if neces

sary.

J9121-48

Fig.

50

Park

Gear And

Seal

Rings—36RH/37RH

(4) Insert filter screen in park gear and install

governor body on park gear.

(5)

Install governor body-to-park gear bolts

finger tight only. Bolts are fully tightened only after installation on output shaft. This is neces

sary to ensure proper alignment of park gear

and governor body.

REAR

SUPPORT

AND

LOW-REVERSE

DRUM

SERVICE

Clean the drum and support in parts cleaning sol

vent and dry them with compressed air. Inspect the drum and support for evidence of wear,

scoring, or cracks. Assemble the support, drum and

overrunning clutch race and check fit of the compo

nents.

Examine the overrunning clutch race. The race is a

permanent press fit on the hub splines of the low-re

verse drum. The drum and race are replaced as an assembly if either part is worn or damaged. Also

check fit of the race on the drum. Replace the assem

bly if the race is loose on the hub splines.

OVERRUNNING CLUTCH OVERHAUL

Inspect condition of the overrunning clutch compo

nents.

Page 1206 of 1502

•

TRANSMISSION

OVERHAUL—36RH/37RH

21 - 201 Replace the clutch cam if worn or damaged in any

way. Also check fit of the cam in the transmission

case.

If the cam is loose, the case may worn, or

cracked.

The clutch race is a permanent press fit on the low-

reverse drum hub splines. The drum and race are to

be replaced as an assembly if either part is worn or damaged. Replace the race and drum if the drum is

damaged or the race is spalled, scored, cracked, or

loose.

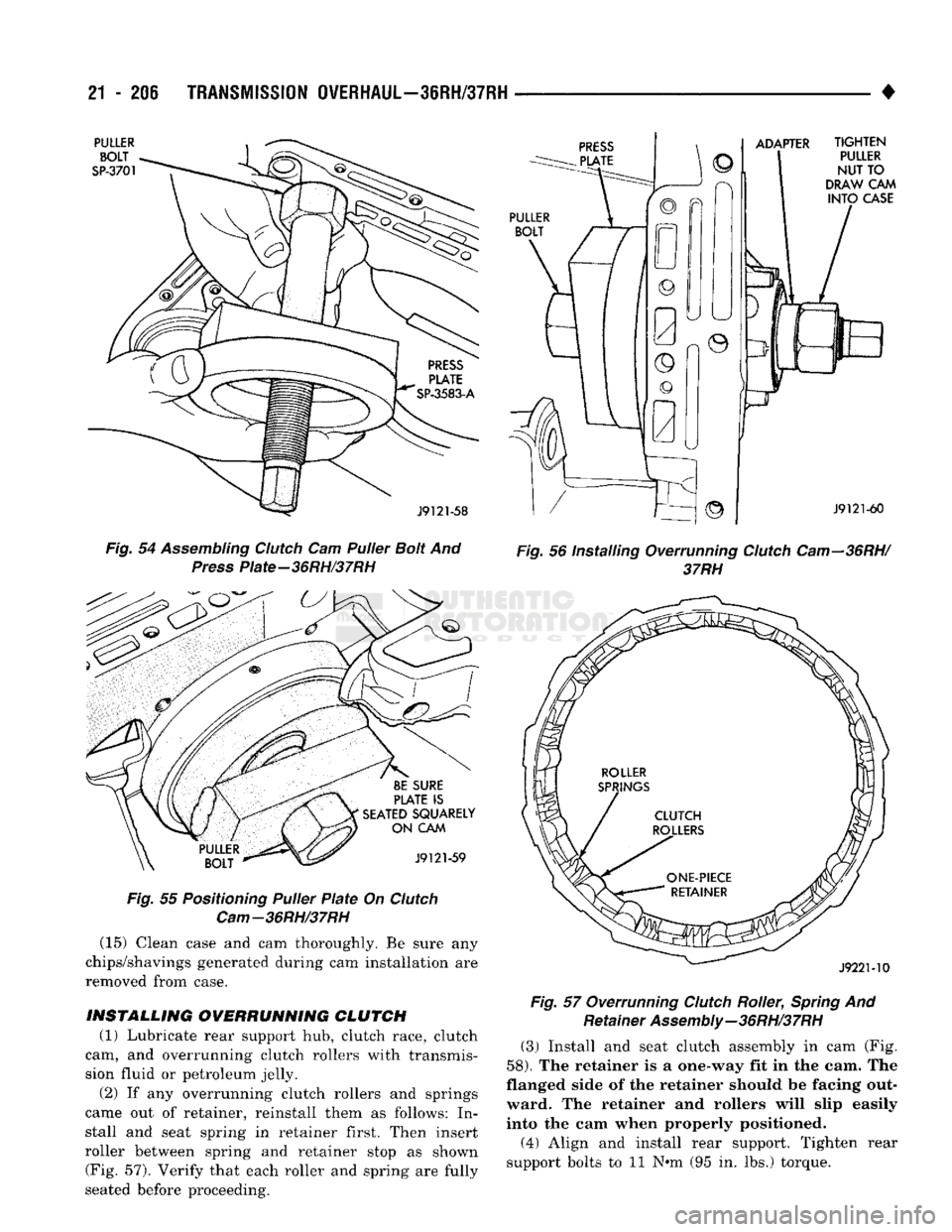

Examine the overrunning clutch rollers, springs

and retainer. Replace the assembly if the rollers are

worn, chipped, or cracked. Replace the assembly if

the springs are distorted, or damaged, or if the cage

type retainer is bent or broken.

If the clutch cam must be replaced, install the new

cam as follows:

REPLACING OVERRUNNING CLUTCH CAM

AND SPRING RETAINER (1) Remove clutch cam setscrew (Fig. 51). Fig. 51 Removing/installing Clutch Cam

Setscrew-36RH/37RH

(2) Tap old cam out of case with pin punch. Insert

punch through bolt holes at rear of case (Fig. 52). Al

ternate position of punch to avoid cocking cam dur ing removal.

(3) Clean clutch cam bore and case. Be sure to re

move all chips/shavings generated during cam re

moval.

(4) Install rear support in case. Align support with

reference marks made at disassembly. (5) Align and start new clutch cam in case. Be

sure serrations on cam and in case are aligned. Then

tap cam into case just enough to hold it in place.

(6)

Verify that cam is correctly positioned be

fore proceeding any further. Narrow ends of cam ramps should be to left when cam is viewed

from front end of case. Fig. 52 Removing Overrunning Clutch

Cam—36RH/

37RH (7) Insert Adapter Tool SP-5124 into rear support

(Fig. 53). Fig. 53 Positioning Adapter Tool In Rear

Support-36RH/37RH (8) Assemble Puller Bolt SP-3701 and Press Plate

SP-3583-A (Fig. 54).

(9) Install assembled puller plate and bolt (Fig.

55).

Insert bolt through cam, case and adapter tool.

Be sure plate is seated squarely on cam.

(10) Hold puller plate and bolt in place and install

puller nut on puller bolt (Fig. 56). (11) Tighten puller nut to draw clutch cam into

case (Fig. 56). Be sure cam Is

drawn Into

case

evenly and does not become cocked.

(12) Install clutch cam setscrew (Fig. 50).

(13) Remove clutch cam installer tools and rear

support.

(14) Stake case in 12 places around new clutch

cam to help secure cam in case. Use blunt punch or

chisel to stake case.

Page 1207 of 1502

21

- 206

TRANSMISSION

OVERHAUL—36RH/37RH

•

PULLER

BOLT

SP-3701

ADAPTER

J9121-58

Fig.

54

Assembling

Clutch

Cam Puller

Bolt

And

Press

Piate-36RH/37RH

BE

SURE

PLATE

IS

SEATED

SQUARELY

ON

CAM

J9121-59

Fig.

55

Positioning

Puller

Plate

On

Clutch

Cam-36RH/37RH (15) Clean case and cam thoroughly. Be sure any

chips/shavings generated during cam installation are

removed from case.

INSTALLING

OVERRUNNING

CLUTCH

(1) Lubricate rear support hub, clutch race, clutch

cam, and overrunning clutch rollers with transmis

sion fluid or petroleum jelly.

(2) If any overrunning clutch rollers and springs

came out of retainer, reinstall them as follows: In stall and seat spring in retainer first. Then insert

roller between spring and retainer stop as shown (Fig. 57). Verify that each roller and spring are fully

seated before proceeding.

TIGHTEN

PULLER

NUT TO

DRAW

CAM

INTO

CASE

J9121-60

Fig.

56 Installing Overrunning

Clutch

Cam—36RH/

37RH

J922M0

Fig.

57 Overrunning

Clutch

Roller,

Spring

And Retainer

Assembly—36RH/37RH

(3) Install and seat clutch assembly in cam (Fig.

58).

The retainer is a one-way fit in the cam. The

flanged side of the retainer should be facing out ward. The retainer and rollers will slip easily

into the cam when properly positioned.

(4) Align and install rear support. Tighten rear

support bolts to 11 N#m (95 in. lbs.) torque.

Page 1208 of 1502

TRANSMISSION

OVERHAUL—36RH/37RH

21 - 207

Fig.

58 Overrunning Clutch Seated in

Cam—36RH/

37RH

Checking

Clutch

Operation

(1) Temporarily install low-reverse drum to check

overrunning clutch operation.

(2) Tilt drum slightly and carefully engage clutch

race in clutch rollers.

(3) Raise drum to level position. Then rotate drum

in clockwise direction until fully seated.

(4) Check clutch operation by turning low-reverse

drum back and forth. Drum should rotate freely in

clockwise direction but lock in counterclockwise di

rection.

(5) Remove low-reverse drum after checking clutch

operation.

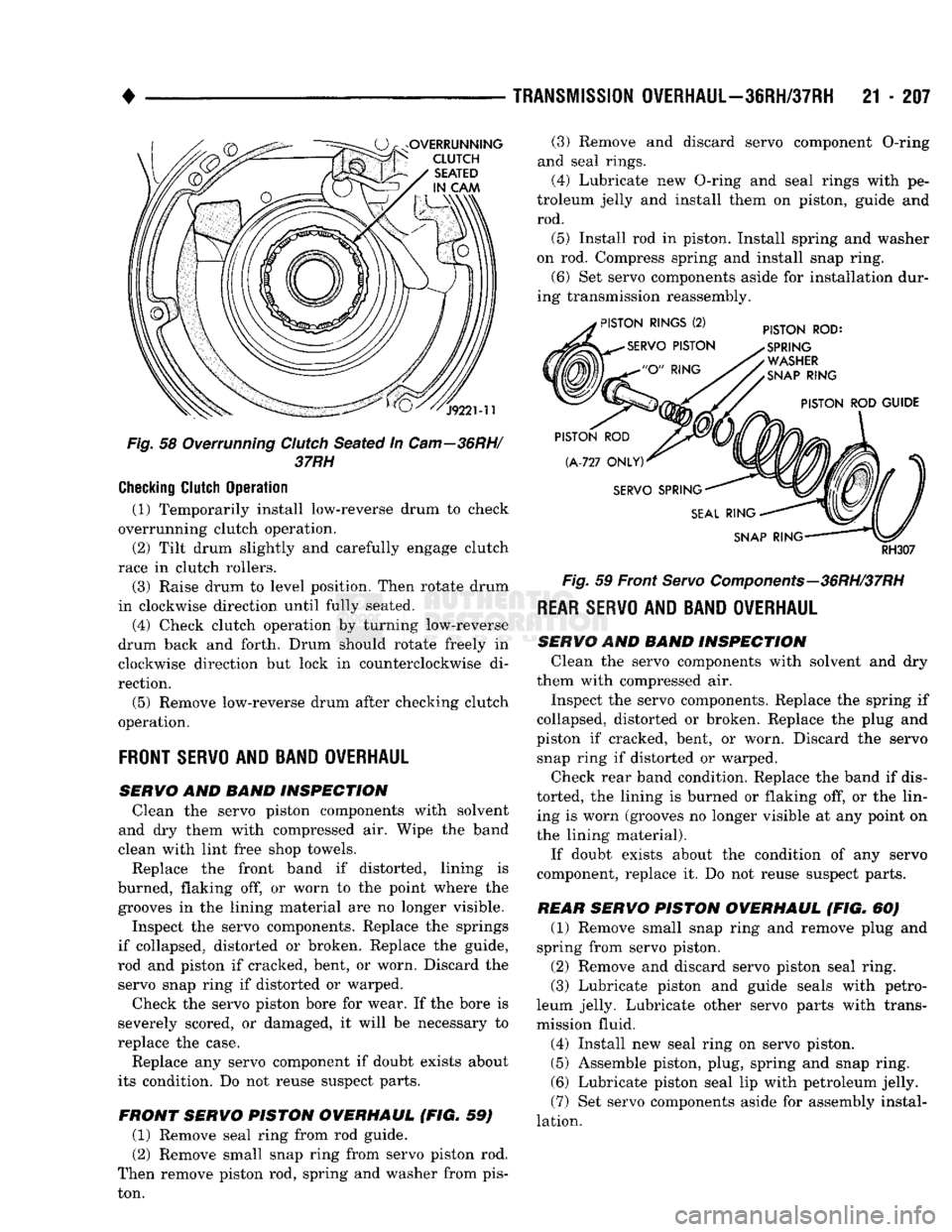

FRONT

SERVO

AND BAND OVERHAUL

SERVO

AND BAND INSPECTION Clean the servo piston components with solvent

and dry them with compressed air. Wipe the band

clean with lint free shop towels.

Replace the front band if distorted, lining is

burned, flaking off, or worn to the point where the grooves in the lining material are no longer visible.

Inspect the servo components. Replace the springs

if collapsed, distorted or broken. Replace the guide,

rod and piston if cracked, bent, or worn. Discard the servo snap ring if distorted or warped.

Check the servo piston bore for wear. If the bore is

severely scored, or damaged, it will be necessary to

replace the case.

Replace any servo component if doubt exists about

its condition. Do not reuse suspect parts.

FRONT SERVO PISTON OVERHAUL (FIG. 59) (1) Remove seal ring from rod guide.

(2) Remove small snap ring from servo piston rod.

Then remove piston rod, spring and washer from pis

ton. (3) Remove and discard servo component O-ring

and seal rings.

(4)

Lubricate new O-ring and seal rings with pe

troleum jelly and install them on piston, guide and rod.

(5) Install rod in piston. Install spring and washer

on rod. Compress spring and install snap ring.

(6) Set servo components aside for installation dur

ing transmission reassembly.

RH307

Fig.

59 Front

Servo

Components—36RH/37RH

REAR SERVO

AND BAND OVERHAUL

SERVO AND BAND INSPECTION Clean the servo components with solvent and dry

them with compressed air.

Inspect the servo components. Replace the spring if

collapsed, distorted or broken. Replace the plug and

piston if cracked, bent, or worn. Discard the servo snap ring if distorted or warped.

Check rear band condition. Replace the band if dis

torted, the lining is burned or flaking off, or the lin ing is worn (grooves no longer visible at any point on

the lining material).

If doubt exists about the condition of any servo

component, replace it. Do not reuse suspect parts.

REAR SERVO PISTON OVERHAUL (FIG. 60) (1) Remove small snap ring and remove plug and

spring from servo piston.

(2) Remove and discard servo piston seal ring.

(3) Lubricate piston and guide seals with petro

leum jelly. Lubricate other servo parts with trans

mission fluid.

(4) Install new seal ring on servo piston.

(5) Assemble piston, plug, spring and snap ring. (6) Lubricate piston seal lip with petroleum jelly.

(7) Set servo components aside for assembly instal

lation.

Page 1209 of 1502

21

- 208

TRANSMISSION OVERHAUL—36RH/37RH

•

SNAP

RING

PISTON

SEAL

PISTON

PLUG

SPRING

RETAINER

SNAP

RING

PISTON

CUSHION

SPRING

PISTON

SPRING

J9121-64

Fig.

60 Rear

Servo

Components—36RH/37RH

OIL PUMP AND REACTION SHAFT SUPPORT

OVERHAUL

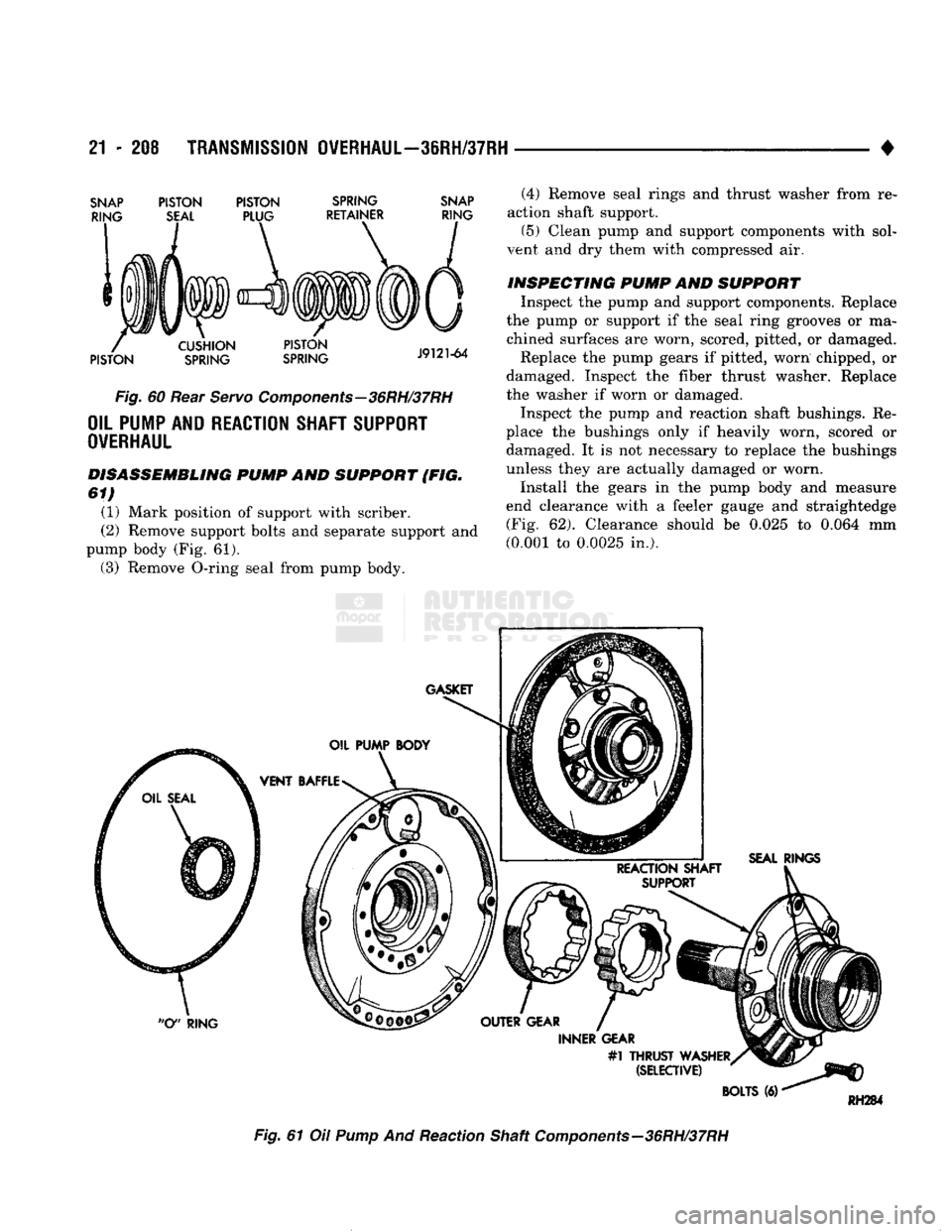

DISASSEMBLING PUMP AND SUPPORT (FIG.

61)

(1) Mark position of support with scriber.

(2) Remove support bolts and separate support and

pump body (Fig. 61). (3) Remove O-ring seal from pump body. (4) Remove seal rings and thrust washer from re

action shaft support. (5) Clean pump and support components with sol

vent and dry them with compressed air.

INSPECTING PUMP AND SUPPORT Inspect the pump and support components. Replace

the pump or support if the seal ring grooves or ma chined surfaces are worn, scored, pitted, or damaged. Replace the pump gears if pitted, worn chipped, or

damaged. Inspect the fiber thrust washer. Replace

the washer if worn or damaged.

Inspect the pump and reaction shaft bushings. Re

place the bushings only if heavily worn, scored or

damaged. It is not necessary to replace the bushings

unless they are actually damaged or worn.

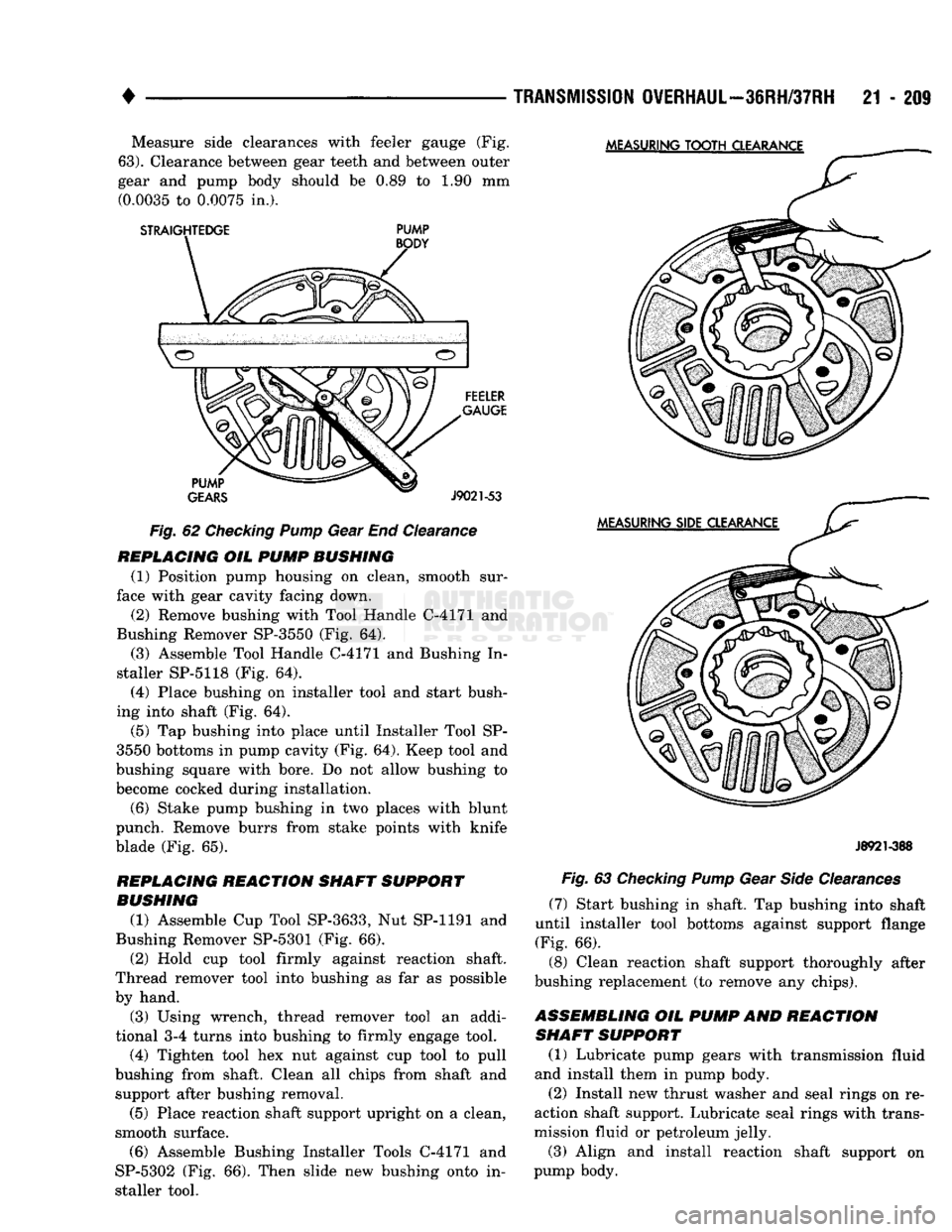

Install the gears in the pump body and measure

end clearance with a feeler gauge and straightedge (Fig. 62). Clearance should be 0.025 to 0.064 mm

(0.001 to 0.0025 in.).

Fig.

61 Oil

Pump

And Reaction Shaft

Components—36RH/37RH

Page 1210 of 1502

•

TRANSMISSION

OVERHAUL—36RH/37RH

21 - 209 Measure side clearances with feeler gauge (Fig.

63).

Clearance between gear teeth and between outer

gear and pump body should be 0.89 to 1.90 mm (0.0035 to 0.0075 in.).

STRAIGHTEDGE

PUMP

Fig.

62

Checking Pump

Gear End Clearance

REPLACING

OIL

PUMP BUSHING

(1) Position pump housing on clean, smooth sur

face with gear cavity facing down.

(2) Remove bushing with Tool Handle C-4171 and

Bushing Remover SP-3550 (Fig. 64).

(3) Assemble Tool Handle C-4171 and Bushing In

staller SP-5118 (Fig. 64). (4) Place bushing on installer tool and start bush

ing into shaft (Fig. 64).

(5) Tap bushing into place until Installer Tool SP-

3550 bottoms in pump cavity (Fig. 64). Keep tool and

bushing square with bore. Do not allow bushing to

become cocked during installation.

(6) Stake pump bushing in two places with blunt

punch. Remove burrs from stake points with knife

blade (Fig. 65).

REPLACING

REACTION SHAFT SUPPORT

BUSHING

(1) Assemble Cup Tool SP-3633, Nut SP-1191 and

Bushing Remover SP-5301 (Fig. 66). (2) Hold cup tool firmly against reaction shaft.

Thread remover tool into bushing as far as possible

by hand.

(3) Using wrench, thread remover tool an addi

tional 3-4 turns into bushing to firmly engage tool.

(4) Tighten tool hex nut against cup tool to pull

bushing from shaft. Clean all chips from shaft and support after bushing removal.

(5) Place reaction shaft support upright on a clean,

smooth surface.

(6) Assemble Bushing Installer Tools C-4171 and

SP-5302 (Fig. 66). Then slide new bushing onto in

staller tool.

J8921-388

Fig.

63

Checking Pump

Gear

Side

Clearances

(7) Start bushing in shaft. Tap bushing into shaft

until installer tool bottoms against support flange

(Fig. 66).

(8) Clean reaction shaft support thoroughly after

bushing replacement (to remove any chips).

ASSEMBLING

OIL

PUMP

AND

REACTION SHAFT SUPPORT

(1) Lubricate pump gears with transmission fluid

and install them in pump body.

(2) Install new thrust washer and seal rings on re

action shaft support. Lubricate seal rings with trans

mission fluid or petroleum jelly.

(3) Align and install reaction shaft support on

pump body.