run flat FIAT 500E 2016 2.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2016, Model line: 500E, Model: FIAT 500E 2016 2.GPages: 132, PDF Size: 4.59 MB

Page 89 of 132

NOTE:

Tire pressures change by approximately 1 psi (7 kPa) per 12° F (7° C) of air tempera-

ture change.Keep this in mind when checking tire pressure inside a garage, especially in

the Winter.Example: If garage temperature is 68°F (20°C) and the outside temperature

is 32°F (0°C), then the cold tire inflation pressure should be increased by 3 psi (21 kPa),

which equals 1 psi (7 kPa) for every 12°F (7°C) for this outside temperature condition.

CAUTION!

The TPMS has been optimized for the original equipment tires and wheels.TPMS pres-

sures and warning have been established for the tire size equipped on your vehicle.

Undesirable system operation or sensor damage may result when using replacement

equipment that is not of the same size, type, and/or style.Aftermarket wheels can cause

sensor damage.Do not use tire sealant from a can, or balance beads if your vehicle is

equipped with a TPMS, as damage to the sensors may result.

– Electronic Stability Control (ESC) Activation / Malfunction Indicator Light

The “ESC Activation/Malfunction Indicator Light” in the instrument cluster will come on

for four seconds when the ignition switch is turned to the ON/RUN position.If the “ESC

Activation/Malfunction Indicator Light” comes on continuously with the engine running, a

malfunction has been detected in the ESC system.If this light remains on, see your au-

thorized dealer as soon as possible to have the problem diagnosed and corrected.

NOTE:

•The “ESC Off Indicator Light” and the “ESC Activation/Malfunction Indicator Light”

come on momentarily each time the ignition switch is turned to ON/RUN.

•Each time the ignition is turned to ON/RUN, the ESC system will be ON even if it

was turned off previously.

•ESC Activation/Malfunction Light can blink during a ESC or TC intervention.

WHAT TO DO IN EMERGENCIES

87

Page 94 of 132

Sealing A Tire With Tire Service Kit

(A) Whenever You Stop To Use Tire Service Kit:

1.Pull over to a safe location and turn on the vehicle’s Hazard Warning flashers.

2.Verify that the valve stem (on the wheel with the deflated tire) is in a position that is

near to the ground.This will allow the Tire Service Kit Hoses (6) and (7) to reach the

valve stem and keep the Tire Service Kit flat on the ground.This will provide the best

positioning of the kit when injecting the sealant into the deflated tire and running the

air pump.Move the vehicle as necessary to place the valve stem in this position be-

fore proceeding.

3.Place the transmission in PARK (auto transmission) or in Gear (manual transmission)

and place the ignition in the OFF position.

4.Set the parking brake.

(B) Setting Up To Use Tire Service Kit:

1.Push in the Mode Select Knob (5) and turn to the Sealant Mode position.

2.Uncoil the Sealant Hose (6) and then remove the cap from the fitting at the end of

the hose.

3.Place the Tire Service Kit flat on the ground next to the deflated tire.

4.Remove the cap from the valve stem and then screw the fitting at the end of the

Sealant Hose (6) onto the valve stem.

5.Uncoil the Power Plug (8) and insert the plug into the vehicle’s 12 Volt power outlet.

NOTE:

Do not remove foreign objects (e.g., screws or nails) from the tire.

(C) Injecting Tire Service Kit Sealant Into The Deflated Tire:

•Always start the engine before turning ON the Tire Service Kit.

NOTE:

Manual transmission vehicles must have the parking brake engaged and the gear selector

in NEUTRAL.

•After pushing the Power Button (4), the sealant (white fluid) will flow from the Sealant

Bottle (1) through the Sealant Hose (6) and into the tire.

NOTE:

Sealant may leak out through the puncture in the tire.

WHAT TO DO IN EMERGENCIES

92

Page 95 of 132

If the sealant (white fluid) does not flow within0–10seconds through the Sealant

Hose (6):

1.Push the Power Button (4) to turn Off the Tire Service Kit.Disconnect the Sealant

Hose (6) from the valve stem.Make sure the valve stem is free of debris.Reconnect

the Sealant Hose (6) to the valve stem.Check that the Mode Select Knob (5) is in

the Sealant Mode position and not Air Mode.Push the Power Button (4) to turn On

the Tire Service Kit.

2.Connect the Power Plug (8) to a different 12 Volt power outlet in your vehicle or

another vehicle, if available.Make sure the engine is running before turning ON the

Tire Service Kit.

3.The Sealant Bottle (1) may be empty due to previous use.Call for assistance.

NOTE:

If the Mode Select Knob (5) is on Air Mode and the pump is operating, air will dispense

from the Air Pump Hose (7) only, not the Sealant Hose (6).

If the sealant (white fluid) does flow through the Sealant Hose (6):

1.Continue to operate the pump until sealant is no longer flowing through hose (typi-

cally takes 30 - 70 seconds).As the sealant flows through the Sealant Hose (6), the

Pressure Gauge (3) can read as high as 70 psi (4.8 Bar).The Pressure Gauge (3) will

decrease quickly from approximately 70 psi (4.8 Bar) to the actual tire pressure when

the Sealant Bottle (1) is empty.

2.The pump will start to inject air into the tire immediately after the Sealant Bottle (1)

is empty.Continue to operate the pump and inflate the tire to the pressure indicated

on the tire pressure label on the driver-side latch pillar (recommended pressure).

Check the tire pressure by looking at the Pressure Gauge (3).

If the tire does not inflate to at least 26 psi (1.8 Bar) pressure within 15 minutes:

•The tire is too badly damaged.Do not attempt to drive the vehicle further.Call for

assistance.

NOTE:

If the tire becomes over-inflated, push the Deflation Button to reduce the tire pressure

to the recommended inflation pressure before continuing.

If the tire inflates to the recommended pressure or is at least 26 psi (1.8 Bar) pressure

within 15 minutes:

1.Push the Power Button (4) to turn off the Tire Service Kit.

2.Remove the Speed Limit sticker from the top of the Sealant Bottle (1) and place the

sticker on the instrument panel.

3.Immediately disconnect the Sealant Hose (6) from the valve stem, reinstall the cap on

the fitting at the end of the hose, and place the Tire Service Kit in the vehicle storage

location.Quickly proceed to (D) “Drive Vehicle.”

WHAT TO DO IN EMERGENCIES

93

Page 102 of 132

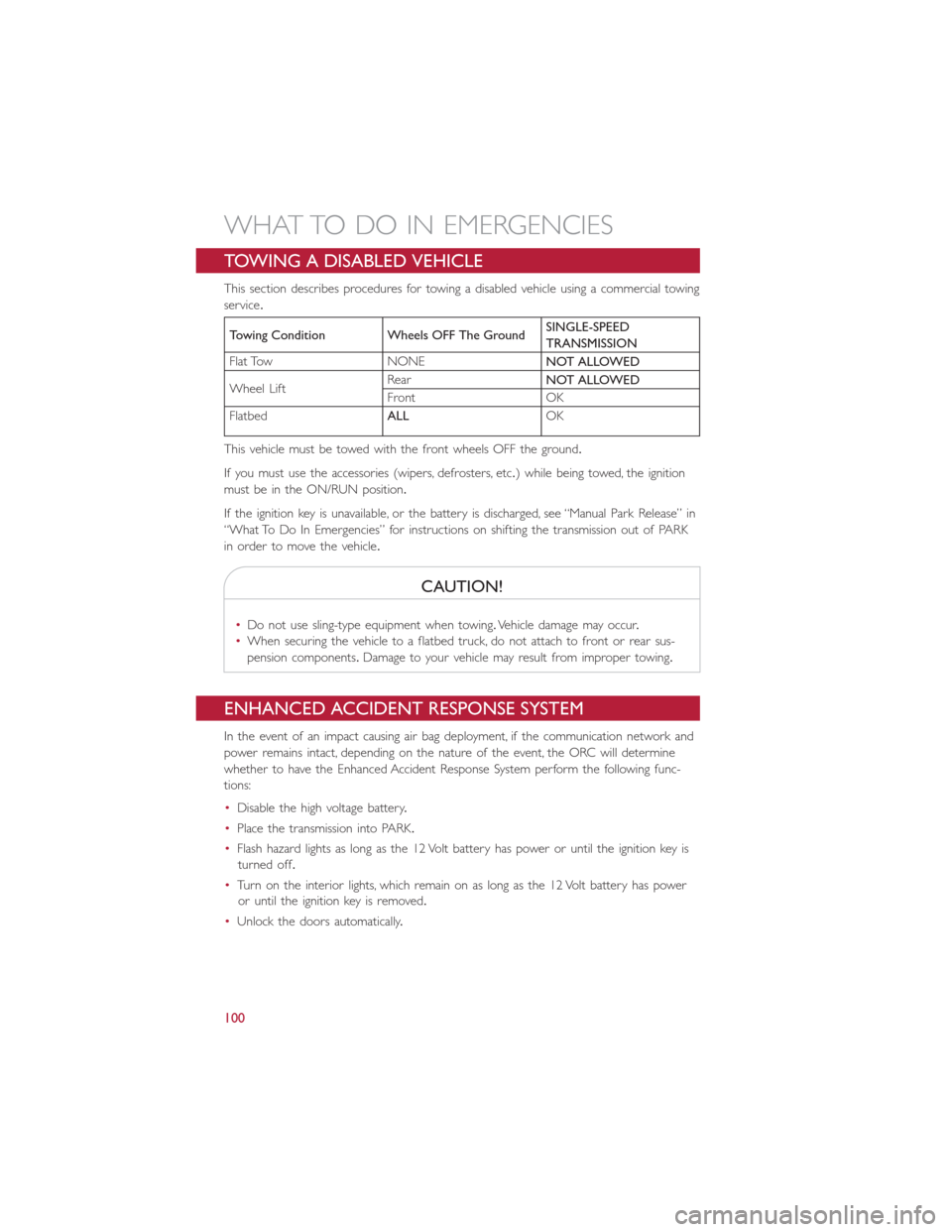

TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled vehicle using a commercial towing

service.

Towing Condition Wheels OFF The GroundSINGLE-SPEED

TRANSMISSION

Flat Tow NONE

NOT ALLOWED

Wheel LiftRear

NOT ALLOWED

Front OK

Flatbed

ALLOK

This vehicle must be towed with the front wheels OFF the ground.

If you must use the accessories (wipers, defrosters, etc.) while being towed, the ignition

must be in the ON/RUN position.

If the ignition key is unavailable, or the battery is discharged, see “Manual Park Release” in

“What To Do In Emergencies” for instructions on shifting the transmission out of PARK

in order to move the vehicle.

CAUTION!

•Do not use sling-type equipment when towing.Vehicle damage may occur.

•When securing the vehicle to a flatbed truck, do not attach to front or rear sus-

pension components.Damage to your vehicle may result from improper towing.

ENHANCED ACCIDENT RESPONSE SYSTEM

In the event of an impact causing air bag deployment, if the communication network and

power remains intact, depending on the nature of the event, the ORC will determine

whether to have the Enhanced Accident Response System perform the following func-

tions:

•Disable the high voltage battery.

•Place the transmission into PARK.

•Flash hazard lights as long as the 12 Volt battery has power or until the ignition key is

turned off.

•Turn on the interior lights, which remain on as long as the 12 Volt battery has power

or until the ignition key is removed.

•Unlock the doors automatically.

WHAT TO DO IN EMERGENCIES

100