check engine FORD FESTIVA 1991 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 392 of 454

WHEEL BEARINGS

Wheel bearing preload is maintained by a selective spacer in the steering knuckle, between the inner and outer hub bearings. For adjustment

procedures and inspection, see WHEEL BEARING under REMOVAL & INSTALLATION.

BALL JOINT CHECKING

Raise and support vehicle until tire is just off ground. Move wheel vertically and check for play. If play is noticed between steering knuckle

and control arm, control arm assembly should be replaced. If play is present but ball joint is okay, wheel bearings should be checked for wear

and replaced if necessary.

REMOVAL & INSTALLATION

STABILIZER BAR

Removal & Installation (Festiva)

1. Remove stabilizer mounting bracket nuts and brackets. Remove split bushings from stabilizer bar. Remove stabilizer bushing nuts at

lower control arms. Remove rear dished washers and bushings.

2. To loosen stabilizer bar, pull forward from control arms. Remove front bushings and washers. Install control arm bushing washers on

ends of stabilizer and install control arm front bushings. Insert ends of stabilizer bar into control arm bushings and install rear bushings

and washers on stabilizer bar ends.

3. Install retaining nuts finger tight. Install split bushings on stabilizer cross bar with split side forward. Position split bushings next to

White locating marks on bar. Install stabilizer mounting brackets. Tighten all bolts and nuts to specification.

STRUT ASSEMBLY & COIL SPRING

Removal

1. Raise and support front of vehicle so struts are fully extended. Remove front wheels. Remove brake line clip from strut lower mounting

bracket and remove brake line.

2. Remove 2 bolts retaining strut lower bracket to steering knuckle. Working inside engine compartment, remove 2 nuts retaining strut

mounting block in strut tower. Disengage strut lower bracket from steering knuckle and lower strut from vehicle.

Disassembly & Reassembly

1. Using spring compressor, compress spring to unload strut. Pry out mounting block cap and remove strut upper nut and lock washer.

2. Remove strut mounting block and spacer plate. Remove washer, bearing seal and bearing from strut rod. Remove spring upper seat, seat

insulator and coil spring. Remove jounce bumper and dust shield from strut. Reverse disassembly procedure to install coil spring a n d

reassemble strut.

Installation

1. Position strut, with spacer plate installed, in strut tower with White alignment mark facing outward. Install and tighten nuts on upper

mounting block studs.

2. Install steering knuckle in strut lower bracket. To complete installation, reverse removal procedure. Tighten all bolts and nuts to

specification.

HUB & KNUCKLE ASSEMBLY

Removal

1. Raise and support vehicle. Remove wheel. Straighten staked edge of drive axle lock nut flange. DO NOT damage groove or threads in

end of drive axle. Apply brakes to prevent hub assembly from turning. Remove and discard drive axle lock nut.

2. Remove clip which secures brake hose to strut bracket. Remove cotter pin and tie rod end attaching nut. Using Tie Rod End Separator

(T85M-3395A), remove tie rod end from steering knuckle.

3. Remove brake caliper attaching bolts and remove assembly from steering knuckle. Do not allow caliper to hang by brake hose. Remove

clamp bolt and nut where lower control arm ball joint connects to steering knuckle.

4. Using a pry bar, pull down on lower control arm and release ball joint from steering knuckle. Remove 2 bolts which attach steering

knuckle between flanges of MacPherson strut bracket. Slide hub/knuckle assembly off end of drive axle. If binding is present or drive

hub is rusted to half-shaft, use a hub puller to push axle from drive hub.

Installation

1. Apply a thin coat of SAE 30 weight oil to drive axle splines. Slide steering knuckle/rotor/hub assembly onto drive axle. Stop at area

where uppermost arm of steering knuckle seats into MacPherson strut bracket.

2. To complete installation, reverse removal procedure. Install NEW drive axle lock nut. Tighten all bolts and nuts to specification. Stake

axle lock nut into shaft groove.

WHEEL BEARING NOTE:Inform ation for stabilizer bar rem oval and installation on Capri is not available from m anufacturer.

NOTE:Always use a new drive axle lock nut when servicing drive hub or drive axle.

CAUT ION: DO NOT use a pointed tool to stake nut. If lock nut flange cracks, even slightly, during staking process,

it m ust be replaced.

Page 2 of 5 MITCHELL 1 ARTICLE - SUSPENSION - FRONT 1991-92 SUSPENSION Front

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 411 of 454

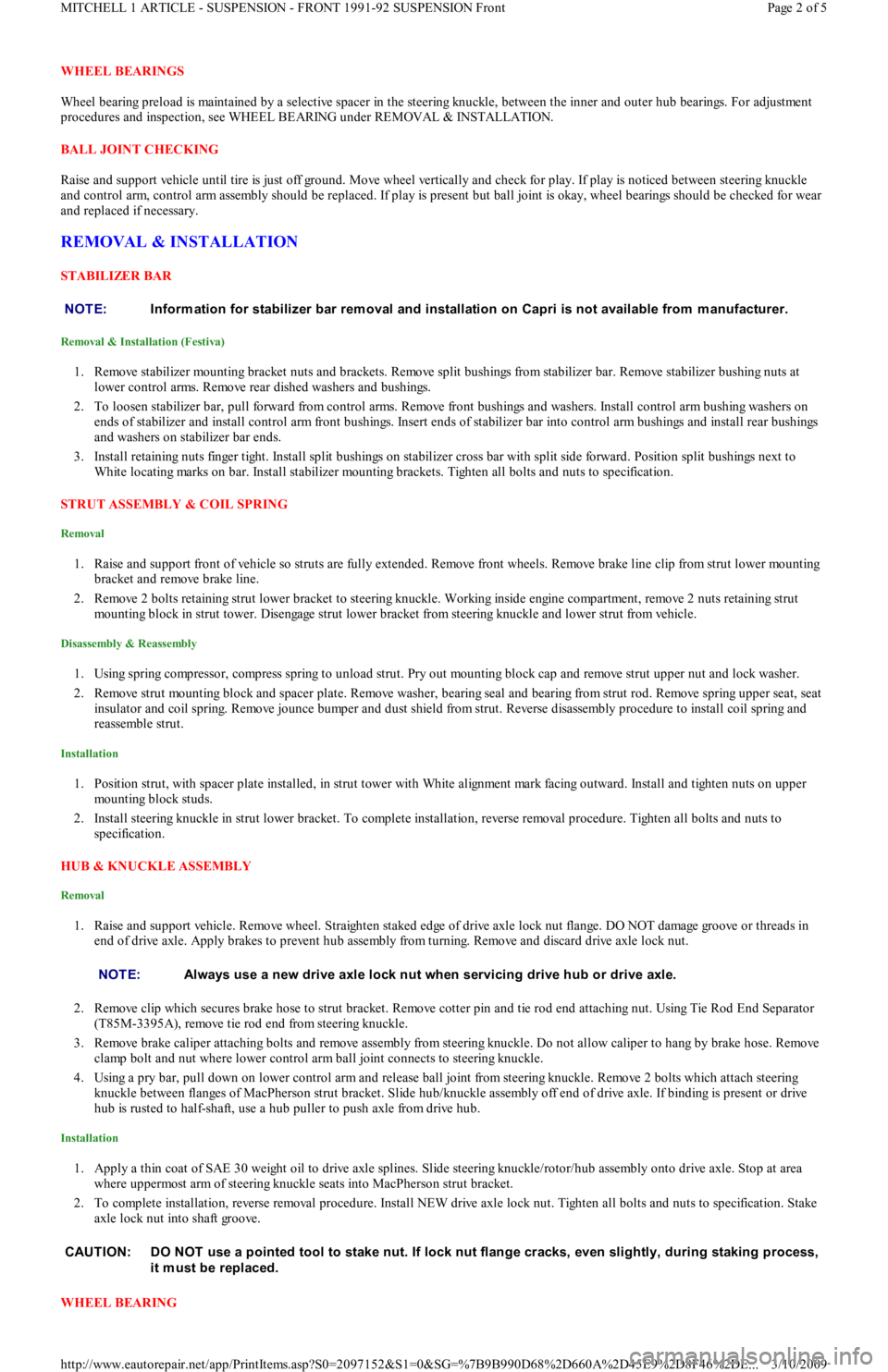

Fig. 3: Identifying Vacuum Diaphragm Rod Gauge

Courtesy of FORD MOTOR CO.

VALVE BODY R & I

Removal & Installation

Disconnect battery ground cable. Raise and support vehicle. Remove front fender splash shield and front splash shield. Drain transaxle fluid.

Unbolt and remove oil pan. Remove 9 valve body bolts. Remove valve body. Ensure care is used not to loose check ball and detent spring. To

install, reverse removal procedure. Fill transaxle with fluid. Check for leaks.

TROUBLESHOOTING

PRELIMINARY INSPECTION

1. Ensure vehicle is thoroughly road tested to verify driver's complaint. Determine if problem occurs during upshift, downshift, coasting or

engagement. If noise is diagnosed, check if noise is affected by RPM, vehicle speed, gear selection or temperature. Ensure vehicle is at

normal operating temperature when checking.

2. Inspect fluid level and condition. Visually inspect for vehicle modifications, electronic add-ons, fluid leaks and/or incorrect linkage

adjustment. See applicable symptom diagnosis.

SYMPTOM DIAGNOSIS

Engine Starts in "D", "2", "1" OR "R", or will not Start in "N" OR "P"

Check ignition and starter circuit. Shift linkage faulty or installed improperly. Park/Neutral switch and/or wiring faulty.

No Movement In Any Gear

Incorrect fluid level. Shift linkage faulty or out of adjustment. Incorrect oil pressure. Manual control valve faulty. Faulty oil pump. Leak in

hydraulic system. Parking linkage improperly adjusted.

No Movement In "D", Okay In Other Gears

Shift linkage faulty, out of adjustment or improperly installed. Incorrect oil pressure. Manual control valve faulty. Faulty one-way clutch.

No Movement In "D", "2" Or "1", Okay In "R"

Incorrect fluid level. Shift linkage faulty, out of adjustment or incorrectly installed. Incorrect oil pressure. Manual control valve faulty. Engine

performance poor or brakes improperly adjusted. Rear clutch faulty. Leak in hydraulic system.

No Movement In "R", Okay In Other Gears

Incorrect fluid level. Shift linkage faulty, out of adjustment or incorrectly installed. Incorrect oil pressure. Manual control valve faulty. Faulty

rear clutch, front clutch or low-reverse brake. Leak in hydraulic system.

Slippage

Page 3 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 414 of 454

Differential Noise

ATF contaminated or level incorrect. Bearings worn or has excessive preload. Teeth on gears worn or damaged or has excessive backlash.

TESTING

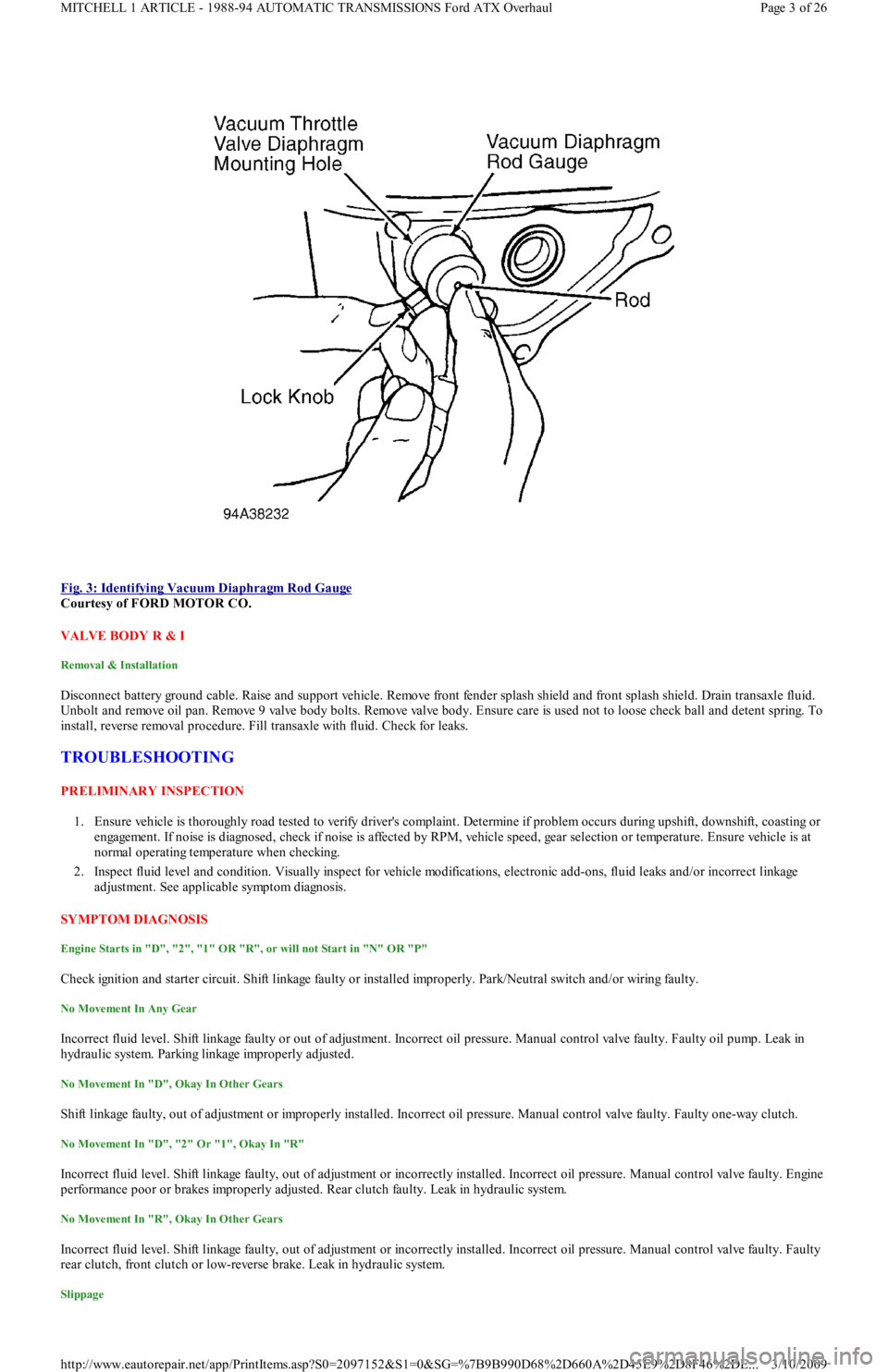

PARK/NEUTRAL SWITCH TEST

1. Ensure engine starts in "P" or "N". Ensure back-up lights glow when ignition is on and selector lever in "R". If park/neutral switch is not

operating properly, disconnect connector at transaxle and check continuity between terminals. See Fig. 4

. If continuity is not as

indicated, replace park/neutral switch.

Fig. 4: Testing Park/Neutral Switch

Courtesy of FORD MOTOR CO.

KICKDOWN (DOWNSHIFT) SOLENOID TEST

1.Check Fuse

Ensure ignition is off. Inspect condition of 15 amp METER fuse located in interior fuse junction panel. If fuse is okay, go to step 4). If

fuse is blown, go to next step.

2.Check System

Ensure ignition is off. Replace 15 amp fuse. Turn ignition on. If fuse blows, go to next step. If fuse is okay, go to step 4).

3.Check For Short To Ground

Turn ignition off. Remove 15 amp METER fuse. Disconnect kickdown switch harness connector. Check continuity between

Black/Yellow wire terminal of interior fuse holder and ground. If continuity exists, inspect and repair short circuit as needed. If

continuity does not exist, replace 15 amp fuse. Go to next step.

4.Check Power Supply To Kickdown Switch

Ensure ignition is off. Disconnect kickdown switch harness connector. Turn ignition on. Measure voltage between Black/Yellow wire

terminal of kickdown switch harness connector and ground. If voltage is more than 10 volts, go to next step. If voltage is 10 volts or less,

Page 6 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 415 of 454

inspect and repair circuit between switch harness connector and fuse panel.

5.Check Kickdown Switch

Turn ignition off. Check continuity between kickdown switch terminals. Continuity should only exist with accelerator fully depressed. I

f

switch is functioning correctly, go to next step. Replace switch if it failed testing. Road test vehicle to verify repair.

6.Check Circuit Between Kickdown Switch & Kickdown Solenoid

Ensure ignition is off. Disconnect kickdown switch harness connector. Disconnect kickdown solenoid harness connector. Check

continuity of White/Black wire between switch harness connector and solenoid harness connector. If continuity does not exist, inspect

and repair open circuit as needed. If continuity exists, check continuity between White/Black wire terminal at solenoid harness

connector and ground. If continuity exists, inspect and repair short circuit as needed. If continuity does not exist, replace kickdown

solenoid.

VACUUM THROTTLE VALVE DIAPHRAGM (MODULATOR) TEST

1.Check System Integrity

Inspect all vacuum hoses and connections for leaks or damage. Disconnect vacuum hose at diaphragm connection and inspect for

leaking ATF. Repair as needed. Go to next step.

2.Check Vacuum At Modulator

Ensure ignition is off. Disconnect vacuum hose at modulator valve and connect vacuum gauge to hose. Start and run engine at idle.

Vacuum should be 15-22 In. Hg. If vacuum is not within specification, inspect and repair vacuum hose. If vacuum is within specification,

go to next step.

3.Check Modulator Valve Function

Turn ignition off. Remove modulator valve from transaxle. Connect hand-held vacuum pump to valve. Apply 16-20 In. Hg of vacuum.

Ensure vacuum is held by valve. Release vacuum and verify that valve moves freely. If valve is functioning correctly, go to next step.

Replace valve if it fails testing.

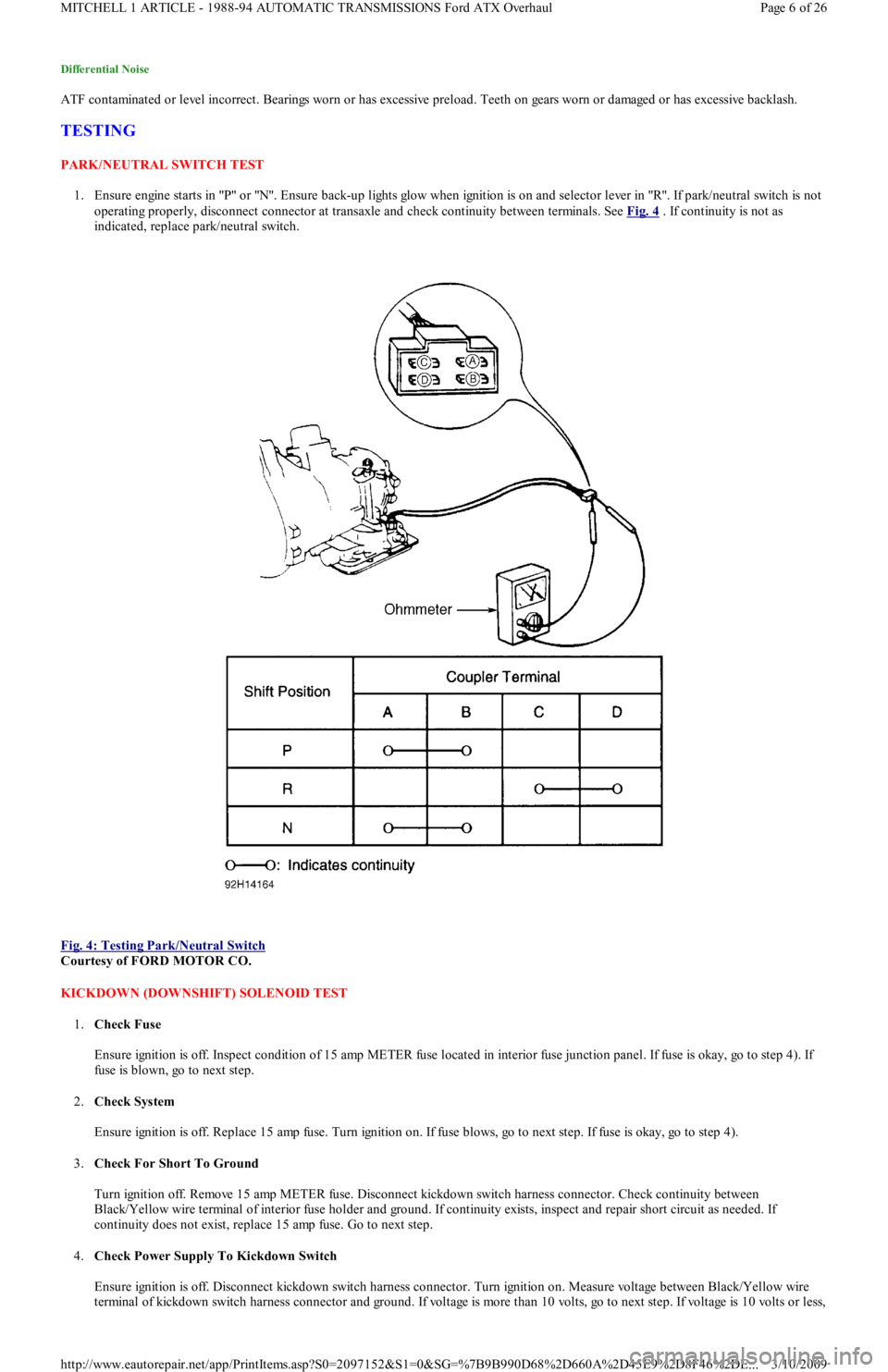

4.Check Vacuum Diaphragm Rod

With modulator removed, measure depth of vacuum throttle valve (dimension "N"). See Fig. 5

. Measure length of throttle control valve

rod. Ensure correct length rod is installed. Refer to the THROTTLE VALVE ROD DIMENSION CHART

. If correct rod is installed

in transaxle, inspect operation of vacuum throttle valve in valve body. Install correct rod length as needed.

THROTTLE VALVE ROD DIMENSION CHART

Fig. 5: Measuring Vacuum Throttle Valve Depth

Courtesy of FORD MOTOR CO.

STALL TEST

Testing Precautions

When testing, DO NOT hold throttle open longer than five (5) seconds. Shift to "N" and allow engine to idle for at least two (2) minutes

between tests to cool transaxle. If engine speed exceeds specification, release accelerator immediately as clutch or band slippage is indicated.

"N" Dimension: In. (mm)Rod Length: In. (mm)

1.0 (25.4)1.16 (29.5)

1.0-1.02 (25.4-25.9)1.18 (30.0)

1.02-1.04 (25.9-26.4)1.20 (30.5)

1.04-1.06 (25.9-26.4)1.22 (31.0)

1.06-1.08 (26.9-27.4)1.24 (31.5)

Page 7 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 417 of 454

CLUTCH & BAND APPLICATION

CLUTCH & BAND APPLICATION CHART

HYDRAULIC PRESSURE TESTS

LINE PRESSURE TEST

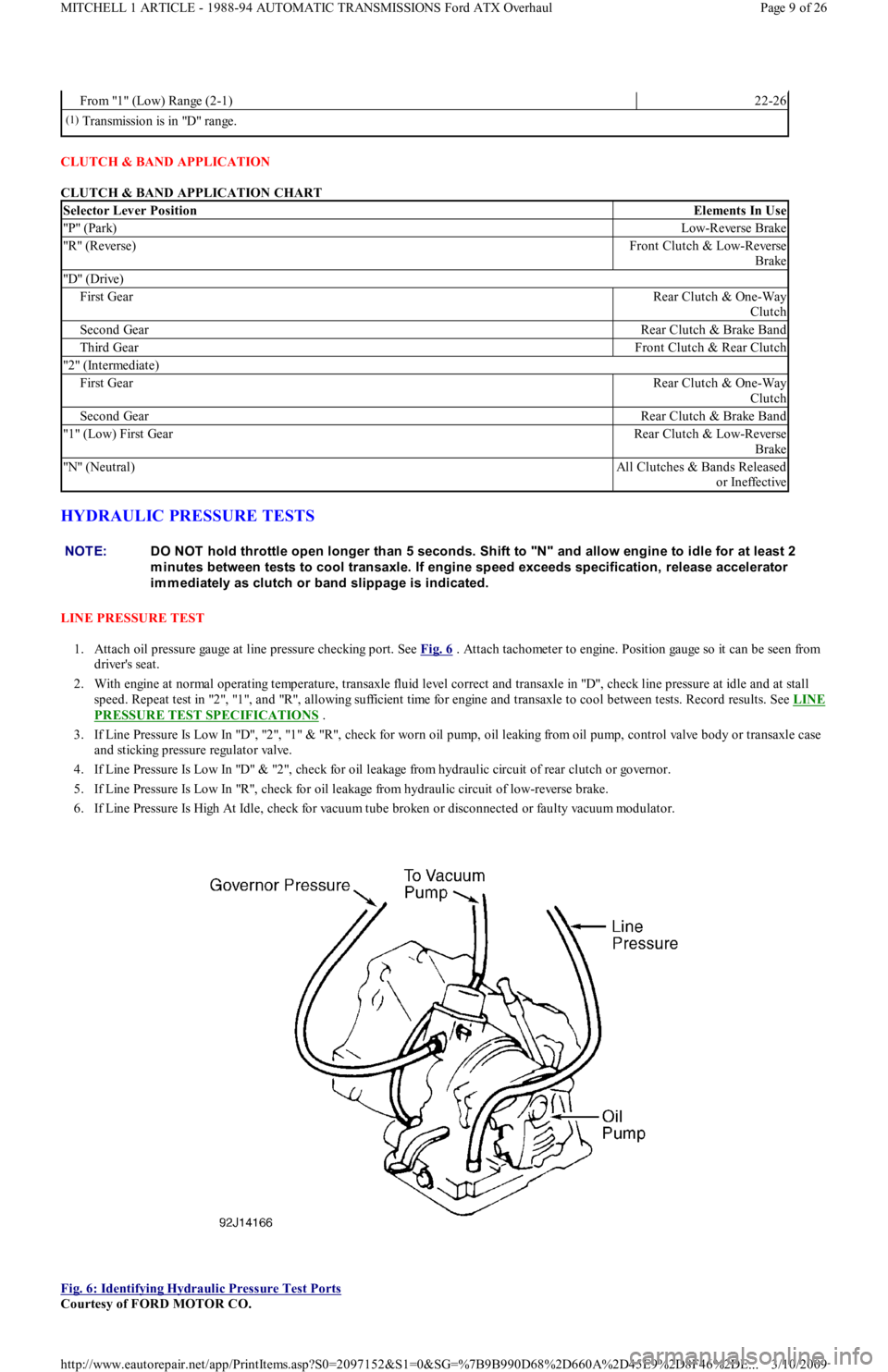

1. Attach oil pressure gauge at line pressure checking port. See Fig. 6

. Attach tachometer to engine. Position gauge so it can be seen from

driver's seat.

2. With engine at normal operating temperature, transaxle fluid level correct and transaxle in "D", check line pressure at idle and at stall

sp eed . Rep eat t est in "2 ", "1 ", an d "R", al l o win g su fficien t t ime for engine and transaxle to cool between tests. Record results. See LINE

PRESSURE TEST SPECIFICATIONS .

3 . If Lin e Pressu re Is Lo w In "D", "2 ", "1 " & "R", ch eck fo r worn oil pump, oil leaking from oil pump, control valve body or transaxle case

and sticking pressure regulator valve.

4. If Line Pressure Is Low In "D" & "2", check for oil leakage from hydraulic circuit of rear clutch or governor.

5. If Line Pressure Is Low In "R", check for oil leakage from hydraulic circuit of low-reverse brake.

6. If Line Pressure Is High At Idle, check for vacuum tube broken or disconnected or faulty vacuum modulator.

Fig. 6: Identifying Hydraulic Pressure Test Ports

Courtesy of FORD MOTOR CO.

From "1" (Low) Range (2-1)22-26

(1)Transmission is in "D" range.

Selector Lever PositionElements In Use

"P" (Park)Low-Reverse Brake

"R" (Reverse)Front Clutch & Low-Reverse

Brake

"D" (Drive)

First GearRear Clutch & One-Way

Clutch

Second GearRear Clutch & Brake Band

Third GearFront Clutch & Rear Clutch

"2" (Intermediate)

First GearRear Clutch & One-Way

Clutch

Second GearRear Clutch & Brake Band

"1" (Low) First GearRear Clutch & Low-Reverse

Brake

"N" (Neutral)All Clutches & Bands Released

o r In effect ive

NOTE:DO NOT hold throttle open longer than 5 seconds. Shift to "N" and allow engine to idle for at least 2

m inutes between tests to cool transaxle. If engine speed exceeds specification, release accelerator

im m ediately as clutch or band slippage is indicated.

Page 9 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 418 of 454

LINE PRESSURE TEST SPECIFICATIONS (ASPIRE)

LINE PRESSURE TEST SPECIFICATIONS (ALL EXCEPT ASPIRE)

LINE PRESSURE CUT-BACK TEST

1. Connect oil pressure gauges to line pressure and governor pressure ports. See Fig. 6

. Position gauges so they can be seen from driver's

seat.

2. Connect a hand-held vacuum pump to vacuum modulator. See Fig. 6

. Position vacuum pump so it can be operated from driver's seat.

With shift lever in "D", gradually increase engine RPM and observe pressure gauge readings. Record results.

3. With shift lever in "D", gradually increase engine RPM, and apply 8 in. Hg to vacuum modulator. When line pressure reading suddenly

decreases, observe the governor pressure gauge. Refer to LINE PRESSURE CUT

-BACK TEST SPECIFICATIONS .

4. If governor pressure gauge readings are not within specifications, ensure rod in vacuum modulator is installed. If a rod is installed, rod

length may be incorrect or vacuum throttle valve is sticking. See VACUUM THROTTLE VALVE DIAPHRAGM (MODULATOR)

under TESTING.

LINE PRESSURE CUT-BACK TEST SPECIFICATIONS

GOVERNOR PRESSURE TEST

1. Attach oil pressure gauge to governor pressure check port. See Fig. 6

. Position gauge so that it may be seen from driver's seat. Shift

transaxle into "D" and road test vehicle.

2. Accelerate vehicle smoothly and record governor pressure readings at 20, 35 and 55 MPH. See GOVERNOR PRESSURE

SPECIFICATIONS . If pressure gauge readings are not within specifications, check for fluid leakage in line pressure hydraulic circuit

and/or governor pressure hydraulic circuit. Also check for a faulty governor.

GOVERNOR PRESSURE SPECIFICATIONS

REMOVAL & INSTALLATION

See the appropriate TRANSMISSION REMOVAL & INSTALLATION - A/T article in this section. Refer to the following menu:

TORQUE CONVERTER

The torque converter is a sealed unit and cannot be serviced. Check for cracked or worn ring in seal area. Measure bushing in converter boss.

If I.D. is larger than 2.090" (53.08 mm) on Aspire, 1.302" (33.075 mm) on Festiva and Tracer, replace torque converter. If metal particles are

found in ATF, replace torque converter. To clean torque converter, flush with solvent, drain and flush with ATF and drain ATF.

TRANSAXLE DISASSEMBLY

1. Remove torque converter. Attach transaxle to appropriate holding fixture. Remove park/neutral switch, kickdown solenoid and vacuum

modulator with rod. Remove oil dipstick and tube. Remove speedometer driven gear retaining bolt and lift out gear assembly. Remove

oil pump drive shaft and turbine shaft.

2. Remove oil pan. Remove valve body. DO NOT lose check ball and spring. Position transaxle with oil pump facing downward. With

flat-blade screwdriver inserted in wide slot between front clutch drum and sun shell, pry down on front clutch drum. Do this seve r a l

times as you rotate assembly 2 complete revolutions.

3. Using a feeler gauge, measure front clutch drum end play. See Fig. 7

. Check clearance of small slot between front clutch drum tabs and

Applicationpsi (kg/cm2 )

At Idle

"D"46-54 (3.2-3.8)

"2 "150-166 (10.5-11.7)

"R"76-95 (5.3-6.7)

At Stall Speed

"D"141-157 (9.9-11.0)

"2 "150-166 (10.5-11.7)

"R"251-262 (17.6-18.4)

Applicationpsi (kg/cm2 )

At Idle

"D"43-57 (3.0-4.0)

"2 "114-171 (8.0-12.0)

"R"57-110 (4.0-7.0)

At Stall Speed

"D"128-156 (9.0-11.0)

"2 "114-171 (8.0-12.0)

"R"228-270 (16.0-19.0)

Vacuum Pump ReadingGovernor Pressure psi (kg/cm2 )

0 in. Hg (Atmosphere)14-23 (.98-1.6)

8 in. Hg6-14 (.42-.98)

Applicationpsi (kg/cm2 )

Aspire & Festiva

20 MPH13-21 (.9-1.5)

35 MPH25-35 (1.8-2.5)

55 MPH58-70 (4.0-4.8)

Page 10 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 436 of 454

Back To Article

T RANSMISSION SERVICING - A/T

1988-93 T RANSMISSION SERVICING Ford Motor Co. Autom atic T ransm ission

IDENTIFICATION

AUTOMATIC TRANSMISSION APPLICATIONS

LUBRICATION

SERVICE INTERVALS

Check fluid level at every engine oil change. Fluid, filter changes and band adjustments are not required under normal operation. Under severe

service operating conditions, change fluid every 30 months or 30,000 miles. Adjust band when fluid is changed.

CHECKING FLUID LEVEL

With transmission at normal operating temperature, place vehicle on level surface. Apply parking brake and run engine at idle. Run gearshift

lever through all positions, ending in Park. With engine running, fluid level should be between "F" and "L" marks. DO NOT overfill.

RECOMMENDED FLUID

Use Dexron-II ATF.

FLUID CAPACITIES

TRANSMISSION REFILL CAPACITIES

DRAINING & REFILLING

1. Remove undercover and side cover to gain access to transaxle oil pan. Remove drain plug and drain fluid. Remove oil pan and discard

gasket. Clean or replace filter screen as necessary. Tighten screen bolts to 71-97 INCH lbs. (8-11 N.m).

2. Install oil pan bolts. Tighten bolts to 44-71 INCH lbs. (5-8 N.m). On all models, install drain plug with NEW washer. Tighten plug to

29-40 ft. lbs. (39-54 N.m).

3. Install undercover and side cover. Add about 3 qts. of specified ATF through dipstick guide tube. DO NOT overfill. Run engine to

normal operating temperature and check fluid level.

ADJUSTMENTS

NEUTRAL SAFETY SWITCH

Combination neutral safety and back-up light switch is screwed into transaxle case. No adjustments are necessary.

SHIFT CONTROL CABLE

1. Disconnect negative battery cable. Remove shift console. Place shift lever in Park. Remove shift lever knob and lock nut. Remove 4 shift

quadrant attaching screws.

2. Loosen shift cable adjuster nuts until they reach end of cable threads. See Fig. 1

. Place shift lever in Park. Tighten lower adjustment

nut until it lightly touches "T" joint, then tighten upper adjustment nut to 80-97 INCH lbs. (9-11 N.m).

3. Lightly press selector push rod and make sure guide pin clearance is correct. See Fig. 2

. Check guide pin clearance when shift lever is

in Neutral and Drive. Readjust shift cable as necessary.

4. Install 4 shift quadrant attaching screws, shift lever knob, lock nut and shift console. Connect negative battery cable.

ModelTransmission

FestivaATX/3HAT

NOTE:Capacities given are approxim ate refill am ounts that apply to overhaul situation. Correct fluid level

should be determ ined by m ark on dipstick.

ApplicationQts. (L)

ATX/3HAT5.6 (5.3)

CAUT ION: DO NOT use any type of gasket sealer or RT V on oil pan gasket. DO NOT overtighten.

CAUT ION: After com pleting linkage adjustm ents, be sure neutral safety switch operates properly. With parking

brake and service brakes applied, try to start engine in each gear position. Engine m ust crank only

when gearshift lever is in Neutral and Park.

Page 1 of 4 MITCHELL 1 ARTICLE - TRANSMISSION SERVICING - A/T 1988-93 TRANSMISSION SERVICING Ford Motor Co. Aut

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 441 of 454

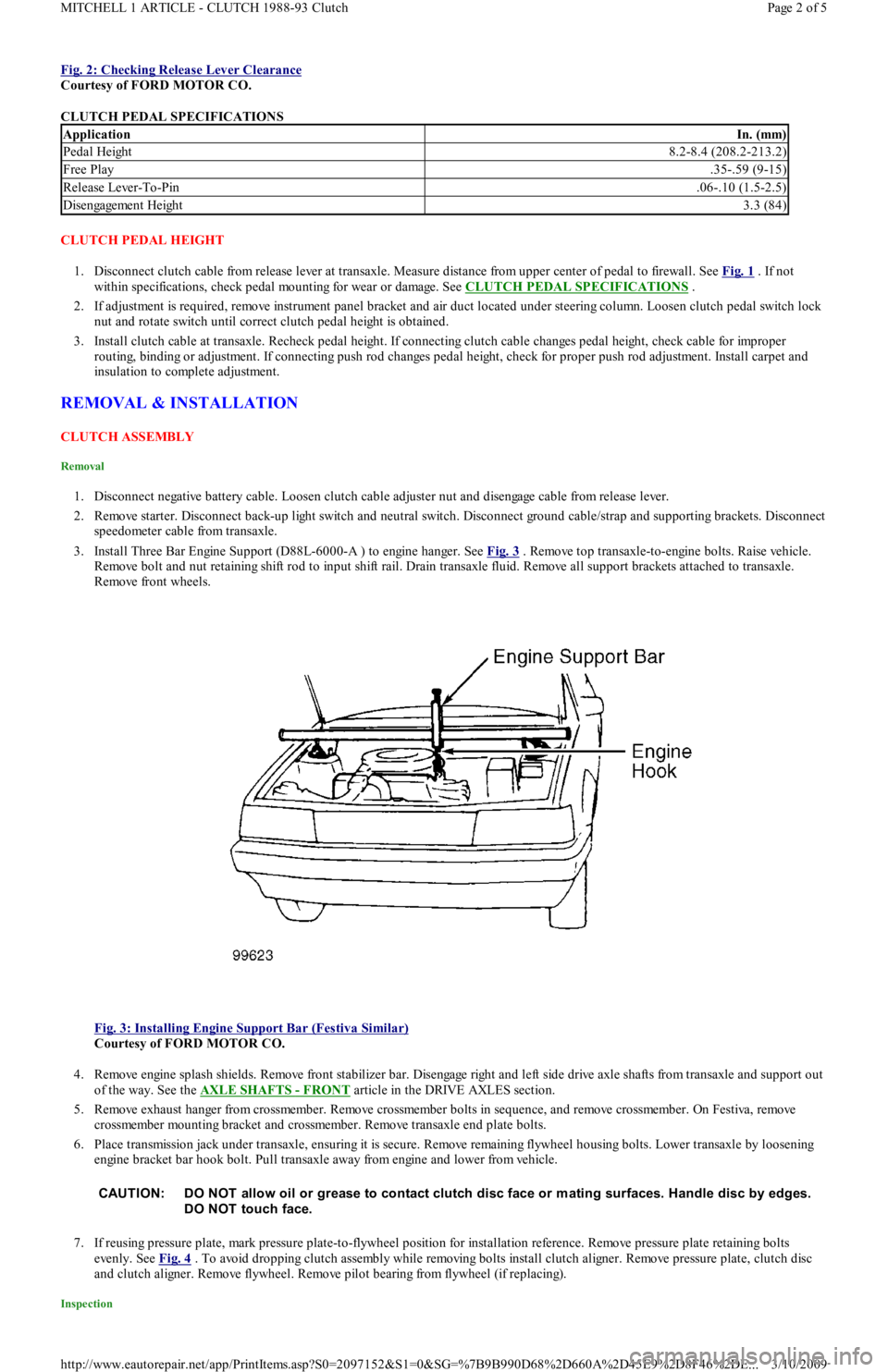

Fig. 2: Checking Release Lever Clearance

Courtesy of FORD MOTOR CO.

CLUTCH PEDAL SPECIFICATIONS

CLUTCH PEDAL HEIGHT

1. Disconnect clutch cable from release lever at transaxle. Measure distance from upper center of pedal to firewall. See Fig. 1

. If not

within specifications, check pedal mounting for wear or damage. See CLUTCH PEDAL SPECIFICATIONS

.

2. If adjustment is required, remove instrument panel bracket and air duct located under steering column. Loosen clutch pedal switch lock

nut and rotate switch until correct clutch pedal height is obtained.

3. Install clutch cable at transaxle. Recheck pedal height. If connecting clutch cable changes pedal height, check cable for improper

routing, binding or adjustment. If connecting push rod changes pedal height, check for proper push rod adjustment. Install carpet and

insulation to complete adjustment.

REMOVAL & INSTALLATION

CLUTCH ASSEMBLY

Removal

1. Disconnect negative battery cable. Loosen clutch cable adjuster nut and disengage cable from release lever.

2. Remove starter. Disconnect back-up light switch and neutral switch. Disconnect ground cable/strap and supporting brackets. Disconnect

speedometer cable from transaxle.

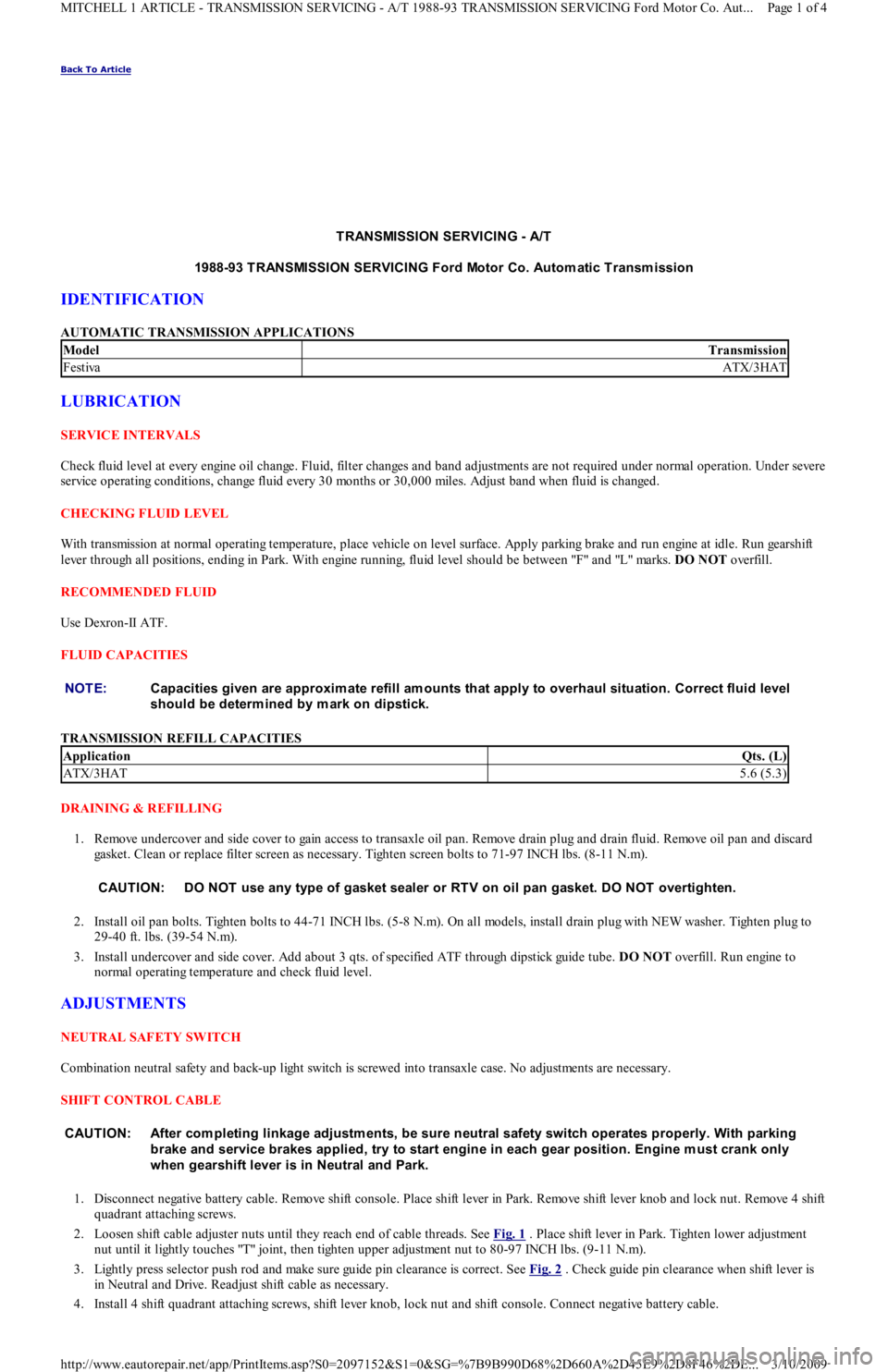

3. Install Three Bar Engine Support (D88L-6000-A ) to engine hanger. See Fig. 3

. Remove top transaxle-to-engine bolts. Raise vehicle.

Remove bolt and nut retaining shift rod to input shift rail. Drain transaxle fluid. Remove all support brackets attached to transaxle.

Remove front wheels.

Fig. 3: Installing Engine Support Bar (Festiva Similar)

Courtesy of FORD MOTOR CO.

4. Remove engine splash shields. Remove front stabilizer bar. Disengage right and left side drive axle shafts from transaxle and support out

of the way. See the AXLE SHAFTS

- FRONT article in the DRIVE AXLES section.

5. Remove exhaust hanger from crossmember. Remove crossmember bolts in sequence, and remove crossmember. On Festiva, remove

crossmember mounting bracket and crossmember. Remove transaxle end plate bolts.

6. Place transmission jack under transaxle, ensuring it is secure. Remove remaining flywheel housing bolts. Lower transaxle by loosening

engine bracket bar hook bolt. Pull transaxle away from engine and lower from vehicle.

7. If reusing pressure plate, mark pressure plate-to-flywheel position for installation reference. Remove pressure plate retaining bolts

evenly. See Fig. 4

. To avoid dropping clutch assembly while removing bolts install clutch aligner. Remove pressure plate, clutch disc

and clutch aligner. Remove flywheel. Remove pilot bearing from flywheel (if replacing).

Inspection

ApplicationIn. (mm)

Pedal Height8.2-8.4 (208.2-213.2)

Free Play.35-.59 (9-15)

Release Lever-To-Pin.06-.10 (1.5-2.5)

Disengagement Height3.3 (84)

CAUT ION: DO NOT allow oil or grease to contact clutch disc face or m ating surfaces. Handle disc by edges.

DO NOT touch face.

Page 2 of 5 MITCHELL 1 ARTICLE - CLUTCH 1988-93 Clutch

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 442 of 454

1. Check pressure plate surfaces for scoring, cracks or discoloration. Remove minor scratches or discoloration with fine emery cloth. Check

pressure plate diaphragm spring fingers for discoloration, scoring, broken or bent segments. Ensure all spring ends are the same height.

2. Check clutch disc lining surface for hardening or presence of oil. Check for worn clutch disc lining. Check for loose lining rivets.

Measure depth of rivet heads. Minimum allowable rivet depth is .012" (0.3 mm). Check for wear or rust on splines. Rust may be

removed with emery cloth.

3. Check flywheel surface for marks, scoring or discoloration. Minor surface repairs may be removed with fine emery cloth. Flywheel must

be machined if scoring, runout, or discoloration is excessive. Maximum flywheel runout is .008" (0.2 mm). Check for damaged or worn

ring gear teeth.

4. Check pilot bearing for wear. Check clutch release/throw out bearing for damage or wear at contact points. Rotate bearing in both

directions and check for binding or abnormal noise.

Installation

1. Replace release bearing and/or pilot bearing as necessary. Clean sealant from flywheel attaching bolt threads. Replace bolts if sealant

cannot be removed. Coat bolt threads with Stud/Bearing Mount Sealer (EOAZ-19554-B ), and install flywheel. Tighten bolts in a

diagonal sequence to specification. See TORQUE SPECIFICATIONS

at the end of this article.

2. Position clutch disc on flywheel with damper springs facing away from flywheel. Hold clutch disc in place with Clutch Aligner (T77F-

7137-A ). Position pressure plate over clutch disc. See Fig. 4

.

3. If reusing original pressure plate, align marks made during removal. Install pressure plate retaining bolts. Alternately tighten bolts to

specification. See TORQUE SPECIFICATIONS

at the end of this article. Remove clutch aligner. Place transaxle on transmission jack.

4. Lightly coat input shaft splines with Clutch Grease (C1AZ-19590-B ). Install transaxle, taking care to align input shaft through the

clutch disc spline. Align clutch housing onto engine guide bushings.

5. Install transaxle lower attaching bolts and tighten to specification. Using transaxle jack, raise transaxle to correct height and tighten

engine bracket bar hook. Install front engine mount and bracket and tighten to specification. Install starter and lower mounting b o l t s,

tighten to specification.

6. Install control rod to transaxle and tighten bolts and nuts to specification. On Festiva, install crossmember and support braces. Install

support braces. On all models, install exhaust hanger to crossmember. Remove transaxle jack.

7. Install new circlips on each half-shaft with gap at top of clip grove and slide into transaxle differential. After circlip snaps into place,

pull outward on hubs to confirm half-shafts are retained by circlip. Install front suspension components, wire harness, underbody and

fender splash shields and front tire assemblies.

8. Connect neutral and back-up light switch and ground wire. Fill transaxle with Mercon ATF transmission fluid to specification. In st al l

and adjust clutch cable or slave cylinder line bracket. Lower vehicle and remove engine support bar. Install speedometer cable into

transaxle.

9. Install battery and/or connect battery cable. Install air cleaner. Adjust pedal free play. See CLUTCH PEDAL FREE PLAY

under

ADJUSTMENTS. Recheck transaxle fluid level and road test vehicle.

Fig. 4: Exploded View Of Clutch Assembly

Courtesy of FORD MOTOR CO.

CLUTCH RELEASE BEARING & FORK

Removal

Remove transaxle. Remove release lever bolt and slide release bearing off. See Fig. 4 . Remove release lever shaft and remove release lever. CAUT ION: T ransaxle alum inum alloy construction requires precise tightening of m ounting bolts. T orque

specifications m ust be strictly adhered to. See T ORQUE SPECIFICAT IONS

.

NOTE:T he clutch release bearing is pre-lubricated and perm anently sealed. DO NOT clean release bearing in

solvent.

Page 3 of 5 MITCHELL 1 ARTICLE - CLUTCH 1988-93 Clutch

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 443 of 454

Inspection

Check release bearing rotation operation for roughness, sticking and noise. Check release lever and transaxle front bearing retainer for wear or

damage. Ensure bearing slides smoothly on transaxle input shaft. Check release lever shaft for bent, worn or damaged condition. Check all

mating surfaces for wear or damage. Replace worn or defective components.

Installation

Apply light film of grease to transmission front bearing retainer lever-to-bearing surfaces and release lever contact surface. Align bolt hole in

release lever and shaft. Apply Stud/Bearing Sealant (E0AZ-19554-B ) to release lever bolt. Fill grease groove in release bearing hub and

remove any excess grease. Install release lever return spring. To complete installation, reverse removal procedure.

PILOT BEARING

Removal & Installation

Remove transaxle, pressure plate, clutch disc and flywheel. Drive pilot bearing out of flywheel using a driver that makes full contact with

bearing outer race. Reverse procedure for installation.

CLUTCH CABLE

Removal & Installation

1. Disconnect clutch cable from release lever. Remove nuts retaining clutch cable at firewall. Unhook clutch cable at clutch pedal.

2. Remove clutch cable from engine compartment side. To install, apply lithium grease to pedal cable hook and joint between release lever

and pin. Reverse removal procedure to complete installation. See Fig. 2

.

OVERHAUL

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

TRANSAXLE FLUID LEVELS

TRANSAXLE FLUID LEVELS NOTE:DO NOT rem ove pilot bearing unless necessary.

NOTE:Manufacturer does not provide overhaul inform ation for clutch m aster cylinder and clutch release

cylinder.

ApplicationFt. Lbs. (Nm)

Clutch Cable Bracket Nuts12-17 (16-23)

Clutch Pedal Push Rod Lock Nut9-13 (12-17)

Clutch Pedal Through Bolt Nut15-26 (20-35)

Crossmember

"A" Bo l t s47-66 (64-89)

"B" Bo l t21-34 (28-46)

Crossmember Brace (Front)23-34 (31-46)

Crossmember Brace69-86 (93-117)

Engine Mount Bolt (No. 2)33-48 (45-65)

Engine-To-Transaxle46-66 (63-89)

Flywheel Housing-To-Engine Bolt46-66 (63-89)

Flywheel-To-Crankshaft Bolt71-76 (96-103)

Front Wheel Lug Nut66-89 (90-120)

Lower Ball Joint Pinch Bolt32-40 (43-54)

Master Cylinder Retaining Nuts14-19 (19-26)

Pressure Plate-To-Flywheel Bolt13-20 (18-27)

Rear Engine Cover-To-Housing Bolt28-38 (38-51)

Rear Mount-To-Transmission Bolt50-70 (68-95)

Rear Transmission Mount-To-Body Bolt25-35 (34-48)

Release Fork Attaching Bolt26-30 (35-41)

Slave Cylinder Retaining Bolts12-17 (16-23)

Stabilizer Bracket-To-Body Bolt33-41 (45-56)

Starter Motor-To-Mount Bolt23-34 (31-46)

Transaxle Drain Plug29-40 (39-54)

INCH Lbs. (N.m)

Release Lever Bolt71-97 (8-11)

Speedometer Drive Gear Bolt69-106 (7.8-12)

ApplicationSpecification

Festiva2.6 Qts. (2.5L)

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Page 4 of 5 MITCHELL 1 ARTICLE - CLUTCH 1988-93 Clutch

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...