Ignition lock FORD FESTIVA 1991 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 47 of 454

SOLENOIDS & SOLENOID VALVES

SOLENOIDS & SOLENOID VALVES LOCATION

SWITCHES

SWITCHES LOCATION

MISCELLANEOUS

MISCELLANEOUS LOCATION

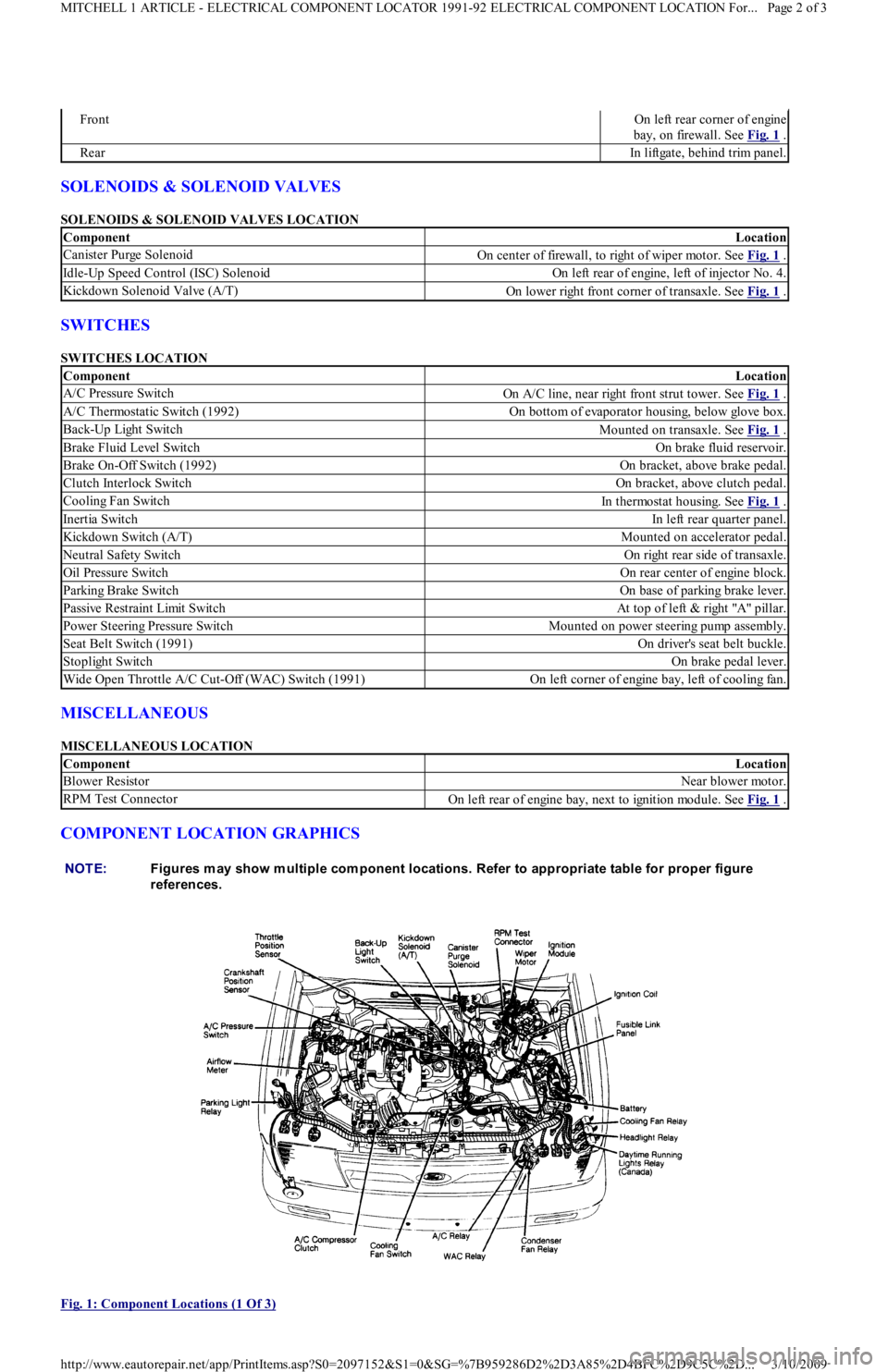

COMPONENT LOCATION GRAPHICS

Fig. 1: Component Locations (1 Of 3)

FrontOn left rear corner of engine

bay, on firewall. See Fig. 1

.

RearIn liftgate, behind trim panel.

ComponentLocation

Canister Purge SolenoidOn center of firewall, to right of wiper motor. See Fig. 1 .

Idle-Up Speed Control (ISC) SolenoidOn left rear of engine, left of injector No. 4.

Kickdown Solenoid Valve (A/T)On lower right front corner of transaxle. See Fig. 1 .

ComponentLocation

A/C Pressure SwitchOn A/C line, near right front strut tower. See Fig. 1 .

A/C Thermostatic Switch (1992)On bottom of evaporator housing, below glove box.

Back-Up Light SwitchMounted on transaxle. See Fig. 1 .

Brake Fluid Level SwitchOn brake fluid reservoir.

Brake On-Off Switch (1992)On bracket, above brake pedal.

Clutch Interlock SwitchOn bracket, above clutch pedal.

Cooling Fan SwitchIn thermostat housing. See Fig. 1 .

Inertia SwitchIn left rear quarter panel.

Kickdown Switch (A/T)Mounted on accelerator pedal.

Neutral Safety SwitchOn right rear side of transaxle.

Oil Pressure SwitchOn rear center of engine block.

Parking Brake SwitchOn base of parking brake lever.

Passive Restraint Limit SwitchAt top of left & right "A" pillar.

Power Steering Pressure SwitchMounted on power steering pump assembly.

Seat Belt Switch (1991)On driver's seat belt buckle.

Stoplight SwitchOn brake pedal lever.

Wide Open Throttle A/C Cut-Off (WAC) Switch (1991)On left corner of engine bay, left of cooling fan.

ComponentLocation

Blower ResistorNear blower motor.

RPM Test ConnectorOn left rear of engine bay, next to ignition module. See Fig. 1 .

NOTE:Figures m ay show m ultiple com ponent locations. Refer to appropriate table for proper figure

references.

Page 2 of 3 MITCHELL 1 ARTICLE - ELECTRICAL COMPONENT LOCATOR 1991-92 ELECTRICAL COMPONENT LOCATION For...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 49 of 454

Back To Article

FUSES & CIRCUIT BREAKERS

Fuses & Circuit Breakers 1988-93 Festiva

FUSES & FUSIBLE LINKS

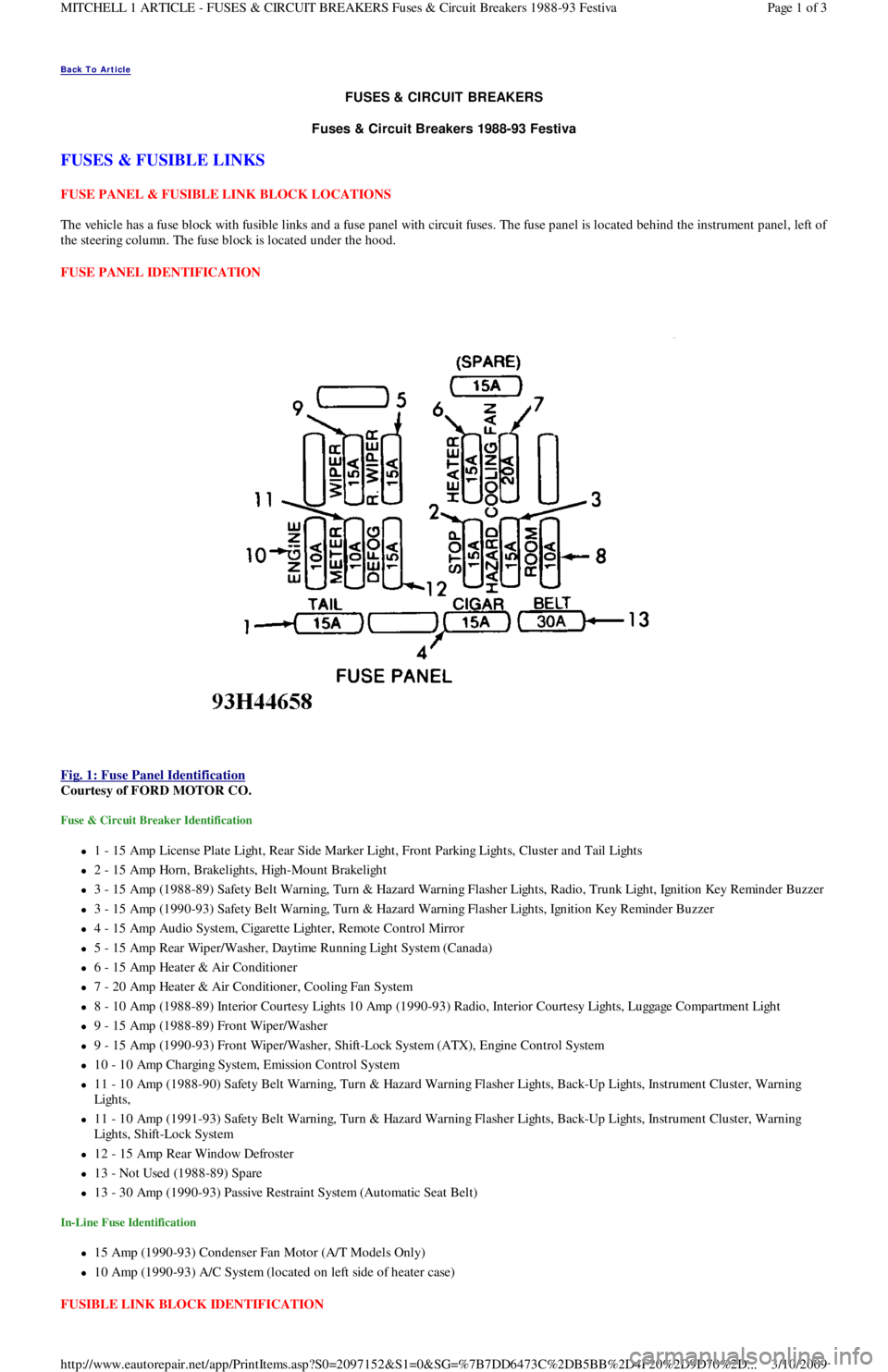

FUSE PANEL & FUSIBLE LINK BLOCK LOCATIONS

The vehicle has a fuse block with fusible links and a fuse panel with circuit fuses. The fuse panel is located behind the instrument panel, left o

f

the steering column. The fuse block is located under the hood.

FUSE PANEL IDENTIFICATION

Fig. 1: Fuse Panel Identification

Courtesy of FORD MOTOR CO.

Fuse & Circuit Breaker Identification

1 - 15 Amp License Plate Light, Rear Side Marker Ligh t , Fr o n t P a r kin g Ligh t s, C l u st e r a n d Ta il Ligh t s

2 - 15 Amp Horn, Brakelights, High-Mount Brakelight

3 - 15 Amp (1988-89) Safety Belt Warning, Turn & Hazard Warning Flasher Lights, Radio, Trunk Light, Ignition Key Reminder Buzzer

3 - 15 Amp (1990-93) Safety Belt Warning, Turn & Hazard Warning Flasher Lights, Ignition Key Reminder Buzzer

4 - 15 Amp Audio System, Cigarette Lighter, Remote Control Mirror

5 - 15 Amp Rear Wiper/Washer, Daytime Running Light System (Canada)

6 - 15 Amp Heater & Air Conditioner

7 - 20 Amp Heater & Air Conditioner, Cooling Fan System

8 - 10 Amp (1988-89) Interior Courtesy Lights 10 Amp (1990-93) Radio, Interior Courtesy Lights, Luggage Compartment Light

9 - 15 Amp (1988-89) Front Wiper/Washer

9 - 15 Amp (1990-93) Front Wiper/Washer, Shift-Lock System (ATX), Engine Control System

10 - 10 Amp Charging System, Emission Control System

11 - 10 Amp (1988-90) Safety Belt Warning, Turn & Hazard Warning Flasher Lights, Back-Up Lights, Instrument Cluster, Warning

Lights,

11 - 10 Amp (1991-93) Safety Belt Warning, Turn & Hazard Warning Flasher Lights, Back-Up Lights, Instrument Cluster, Warning

Lights, Shift-Lock System

12 - 15 Amp Rear Window Defroster

13 - Not Used (1988-89) Spare

13 - 30 Amp (1990-93) Passive Restraint System (Automatic Seat Belt)

In-Line Fuse Identification

15 Amp (1990-93) Condenser Fan Motor (A/T Models Only)

10 Amp (1990-93) A/C System (located on left side of heater case)

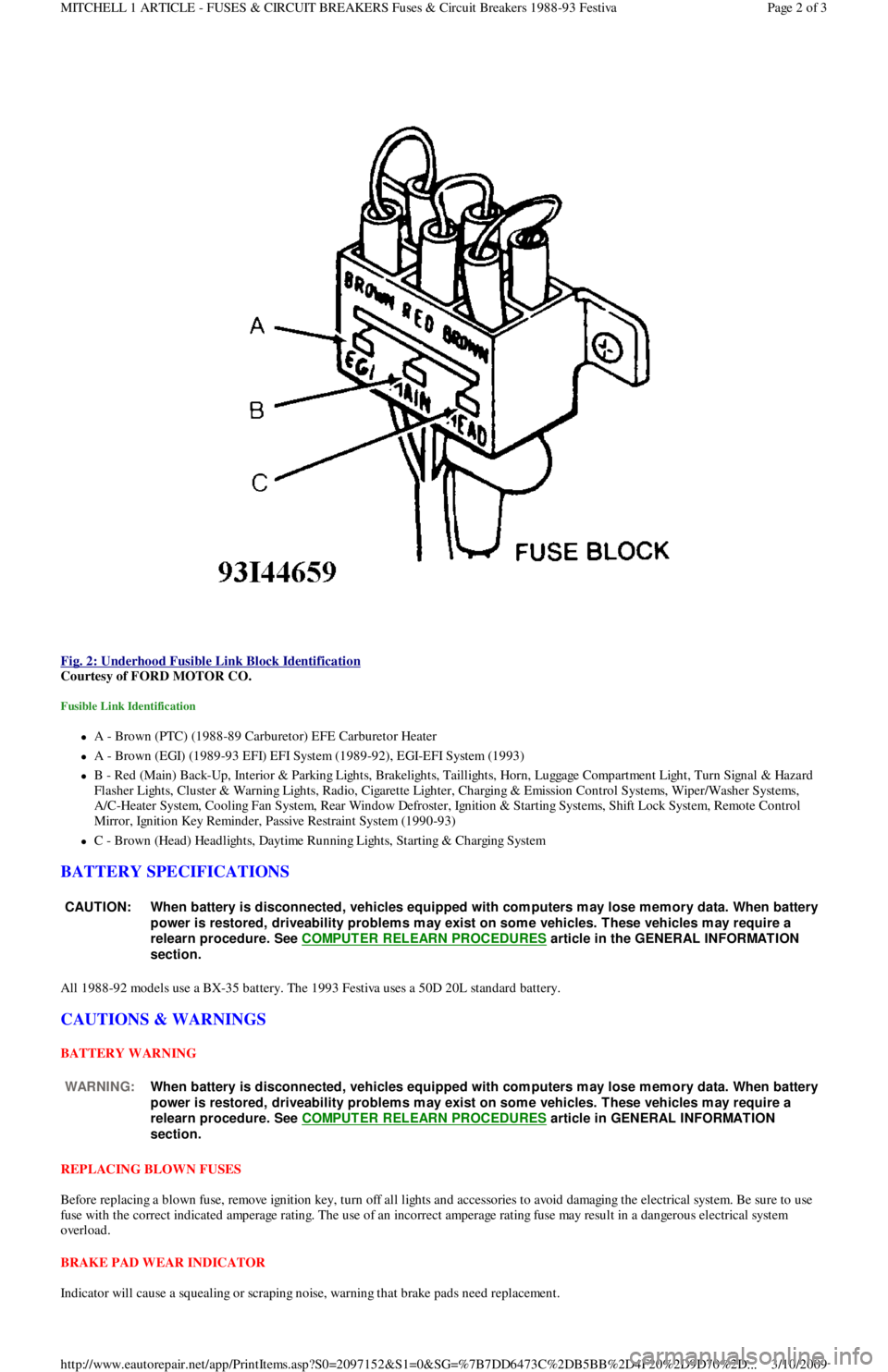

FUSIBLE LINK BLOCK IDENTIFICATION

Page 1 of 3 MITCHELL 1 ARTICLE - FUSES & CIRCUIT BREAKERS Fuses & Circuit Breakers 1988-93 Festiva

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 50 of 454

Fig. 2: Underhood Fusible Link Block Identification

Courtesy of FORD MOTOR CO.

Fusible Link Identification

A - Brown (PTC) (1988-89 Carburetor) EFE Carburetor Heater

A - Brown (EGI) (1989-93 EFI) EFI System (1989-92), EGI-EFI System (1993)

B - Red (Main) Back-Up, Interior & Parking Lights, Brakelights, Taillights, Horn, Luggage Compartment Light, Turn Signal & Hazard

F l a sh e r Ligh t s, C l u st e r & Wa r n in g Ligh t s, R a d io , C iga r e t t e Ligh t e r , C h a r gin g & E missio n C o n t r o l S yst e ms, Wip e r / Wa sh e r S yst e ms,

A/C-Heater System, Cooling Fan System, Rear Window Defroster, Ignition & Starting Systems, Shift Lock System, Remote Control

Mirror, Ignition Key Reminder, Passive Restraint System (1990-93)

C - Brown (Head) Headlights, Daytime Running Lights, Starting & Charging System

BATTERY SPECIFICATIONS

All 1988-92 models use a BX-35 battery. The 1993 Festiva uses a 50D 20L standard battery.

CAUTIONS & WARNINGS

BATTERY WARNING

REPLACING BLOWN FUSES

Before replacing a blown fuse, remove ignition key, turn off all lights and accessories to avoid damaging the electrical system. Be sure to use

fuse with the correct indicated amperage rating. The use of an incorrect amperage rating fuse may result in a dangerous electrical system

overload.

BRAKE PAD WEAR INDICATOR

Indicator will cause a squealing or scraping noise, warning that brake pads need replacement.

CAUT ION: When battery is disconnected, vehicles equipped with com puters m ay lose m em ory data. When battery

power is restored, driveability problem s m ay exist on som e vehicles. T hese vehicles m ay require a

relearn procedure. See COMPUTER RELEARN PROCEDURES

article in the GENERAL INFORMAT ION

section.

WARNING:When battery is disconnected, vehicles equipped with com puters m ay lose m em ory data. When battery

power is restored, driveability problem s m ay exist on som e vehicles. T hese vehicles m ay require a

relearn procedure. See COMPUTER RELEARN PROCEDURES

article in GENERAL INFORMAT ION

section.

Page 2 of 3 MITCHELL 1 ARTICLE - FUSES & CIRCUIT BREAKERS Fuses & Circuit Breakers 1988-93 Festiva

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 65 of 454

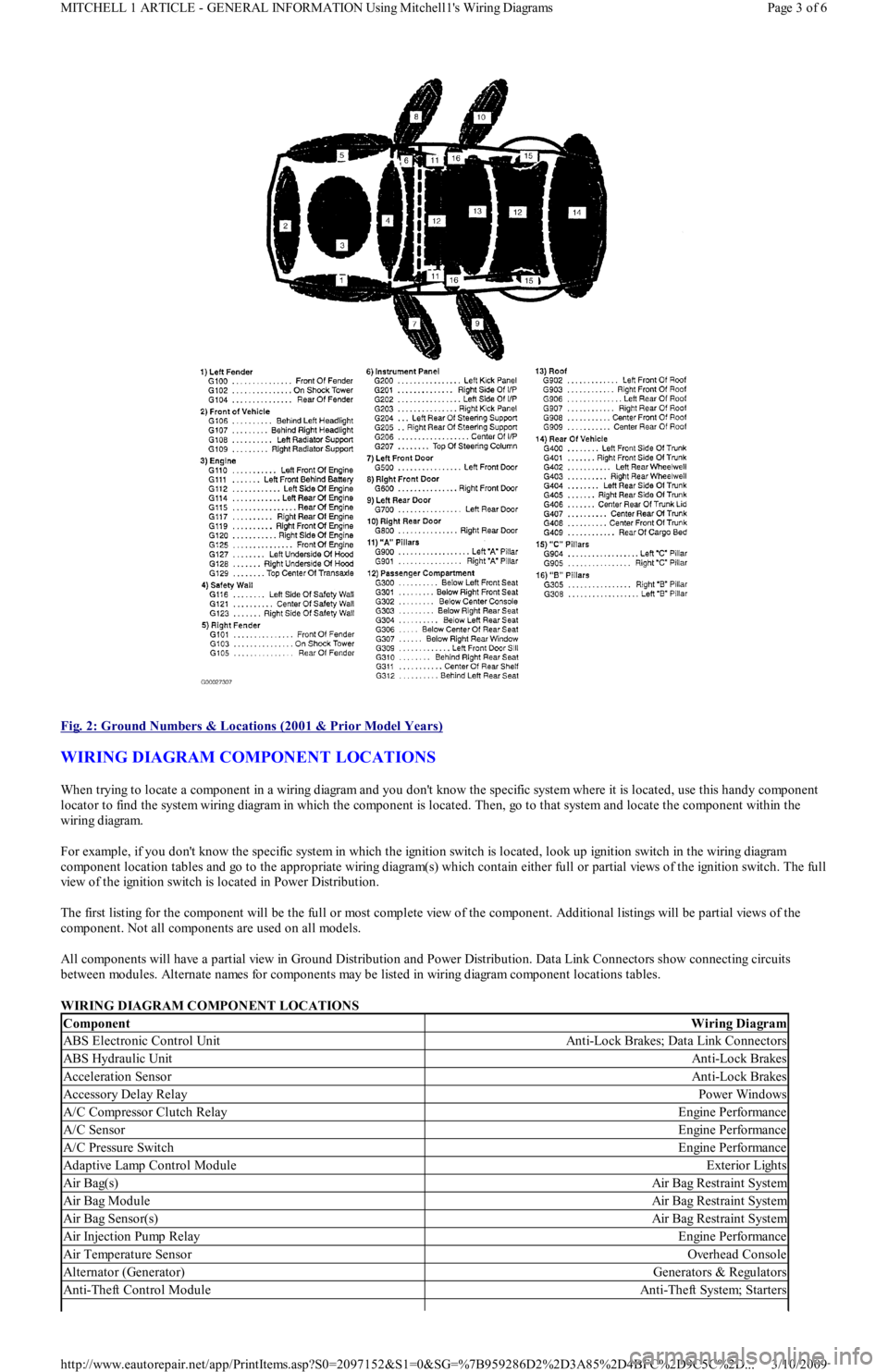

Fig. 2: Ground Numbers & Locations (2001 & Prior Model Years)

WIRING DIAGRAM COMPONENT LOCATIONS

When trying to locate a component in a wiring diagram and you don't know the specific system where it is located, use this handy component

locator to find the system wiring diagram in which the component is located. Then, go to that system and locate the component within the

wiring diagram.

For example, if you don't know the specific system in which the ignition switch is located, look up ignition switch in the wiring diagram

component location tables and go to the appropriate wiring diagram(s) which contain either full or partial views of the ignition switch. The full

view of the ignition switch is located in Power Distribution.

The first listing for the component will be the full or most complete view of the component. Additional listings will be partial views of the

component. Not all components are used on all models.

All components will have a partial view in Ground Distribution and Power Distribution. Data Link Connectors show connecting circuits

between modules. Alternate names for components may be listed in wiring diagram component locations tables.

WIRING DIAGRAM COMPONENT LOCATIONS

ComponentWiring Diagram

ABS Electronic Control UnitAnti-Lock Brakes; Data Link Connectors

ABS Hydraulic UnitAnti-Lock Brakes

Acceleration SensorAnti-Lock Brakes

Accessory Delay RelayPower Windows

A/C Compressor Clutch RelayEngine Performance

A/C SensorEngine Performance

A/C Pressure SwitchEngine Performance

Adaptive Lamp Control ModuleExterior Lights

Air Bag(s)Air Bag Restraint System

Air Bag ModuleAir Bag Restraint System

Air Bag Sensor(s)Air Bag Restraint System

Air Injection Pump RelayEngine Performance

Air Temperature SensorOverhead Console

Alternator (Generator)Generators & Regulators

Anti-Theft Control ModuleAnti-Theft System; Starters

Page 3 of 6 MITCHELL 1 ARTICLE - GENERAL INFORMATION Using Mitchell1's Wiring Diagrams

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 67 of 454

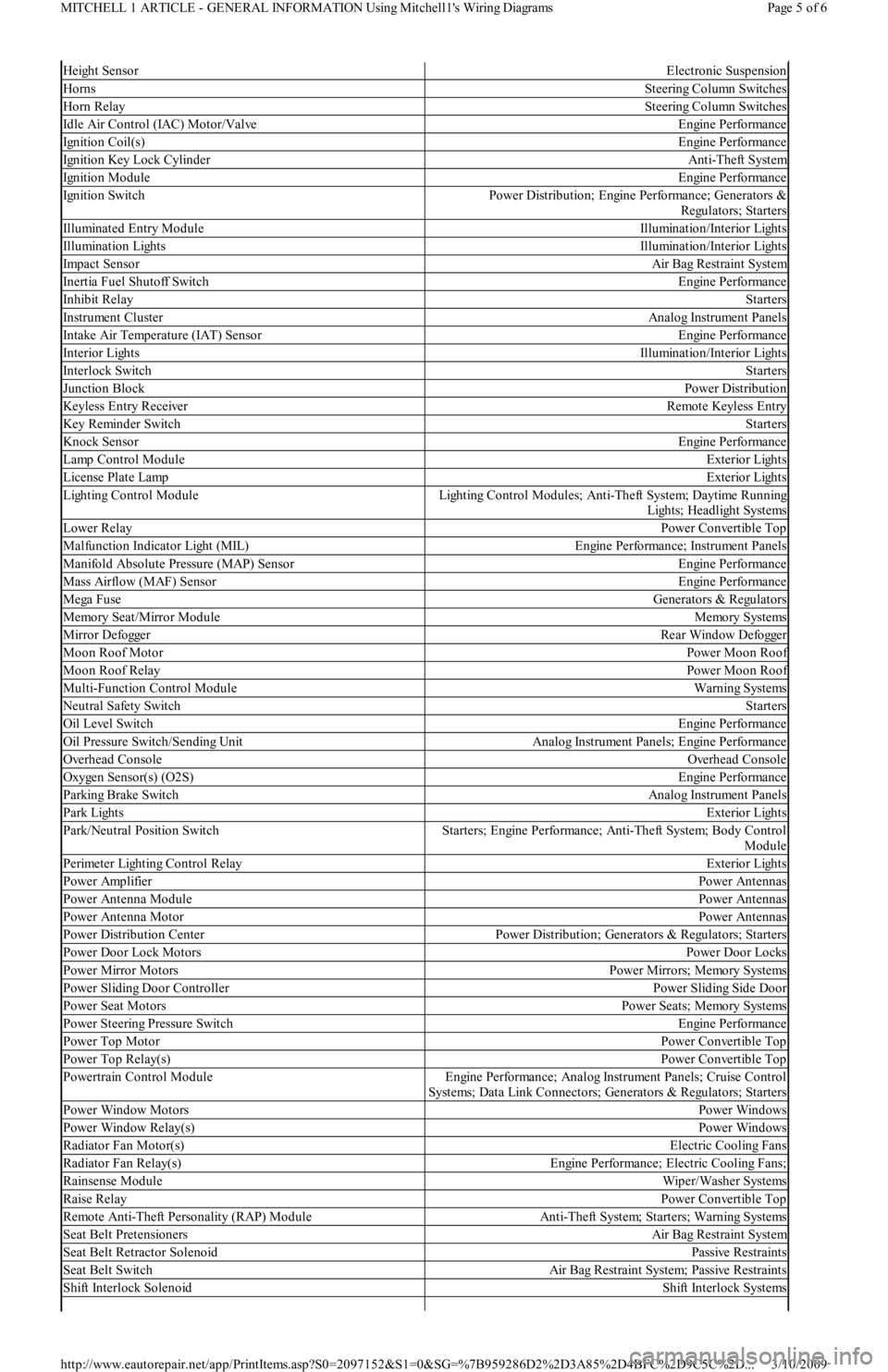

Height SensorElectronic Suspension

HornsSteering Column Switches

Horn RelaySteering Column Switches

Idle Air Control (IAC) Motor/ValveEngine Performance

Ignition Coil(s)Engine Performance

Ignition Key Lock CylinderAnti-Theft System

Ignition ModuleEngine Performance

Ignition SwitchPower Distribution; Engine Performance; Generators &

Regulators; Starters

Illuminated Entry ModuleIllumination/Interior Lights

Illumination LightsIllumination/Interior Lights

Impact SensorAir Bag Restraint System

Inertia Fuel Shutoff SwitchEngine Performance

In h ib it Rel ayStarters

Instrument ClusterAnalog Instrument Panels

Intake Air Temperature (IAT) SensorEngine Performance

Interior LightsIllumination/Interior Lights

In t erl o ck Swit chStarters

Junction BlockPower Distribution

Keyless Entry ReceiverRemote Keyless Entry

Key Reminder SwitchStarters

Knock SensorEngine Performance

Lamp Control ModuleExterior Lights

License Plate LampExterior Lights

Lighting Control ModuleLighting Control Modules; Anti-Theft System; Daytime Running

Lights; Headlight Systems

Lower RelayPower Convertible Top

Malfunction Indicator Light (MIL)Engine Performance; Instrument Panels

Manifold Absolute Pressure (MAP) SensorEngine Performance

Mass Airflow (MAF) SensorEngine Performance

Mega FuseGenerators & Regulators

Memory Seat/Mirror ModuleMemory Systems

M ir r o r De fo gge rRear Window Defogger

Moon Roof MotorPower Moon Roof

Moon Roof RelayPower Moon Roof

Multi-Function Control ModuleWarning Systems

Neutral Safety SwitchStarters

Oil Level SwitchEngine Performance

Oil Pressure Switch/Sending UnitAnalog Instrument Panels; Engine Performance

Overhead ConsoleOverhead Console

Oxygen Sensor(s) (O2S)Engine Performance

Parking Brake SwitchAnalog Instrument Panels

Park LightsExterior Lights

Park/Neutral Position SwitchStarters; Engine Performance; Anti-Theft System; Body Control

Module

Perimeter Lighting Control RelayExterior Lights

Power AmplifierPower Antennas

Power Antenna ModulePower Antennas

Power Antenna MotorPower Antennas

Power Distribution CenterPower Distribution; Generators & Regulators; Starters

Power Door Lock MotorsPower Door Locks

Power Mirror MotorsPower Mirrors; Memory Systems

Power Sliding Door ControllerPower Sliding Side Door

Power Seat MotorsPower Seats; Memory Systems

Power Steering Pressure SwitchEngine Performance

Power Top MotorPower Convertible Top

Power Top Relay(s)Power Convertible Top

Powertrain Control ModuleEngine Performance; Analog Instrument Panels; Cruise Control

Systems; Data Link Connectors; Generators & Regulators; Starters

Power Window MotorsPower Windows

Power Window Relay(s)Power Windows

Radiator Fan Motor(s)Electric Cooling Fans

Radiator Fan Relay(s)Engine Performance; Electric Cooling Fans;

Rainsense ModuleWiper/Washer Systems

Raise RelayPower Convertible Top

Remote Anti-Theft Personality (RAP) ModuleAnti-Theft System; Starters; Warning Systems

Seat Belt PretensionersAir Bag Restraint System

Seat Belt Retractor SolenoidPassive Restraints

Seat Belt SwitchAir Bag Restraint System; Passive Restraints

Shift Interlock SolenoidShift Interlock Systems

Page 5 of 6 MITCHELL 1 ARTICLE - GENERAL INFORMATION Using Mitchell1's Wiring Diagrams

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 69 of 454

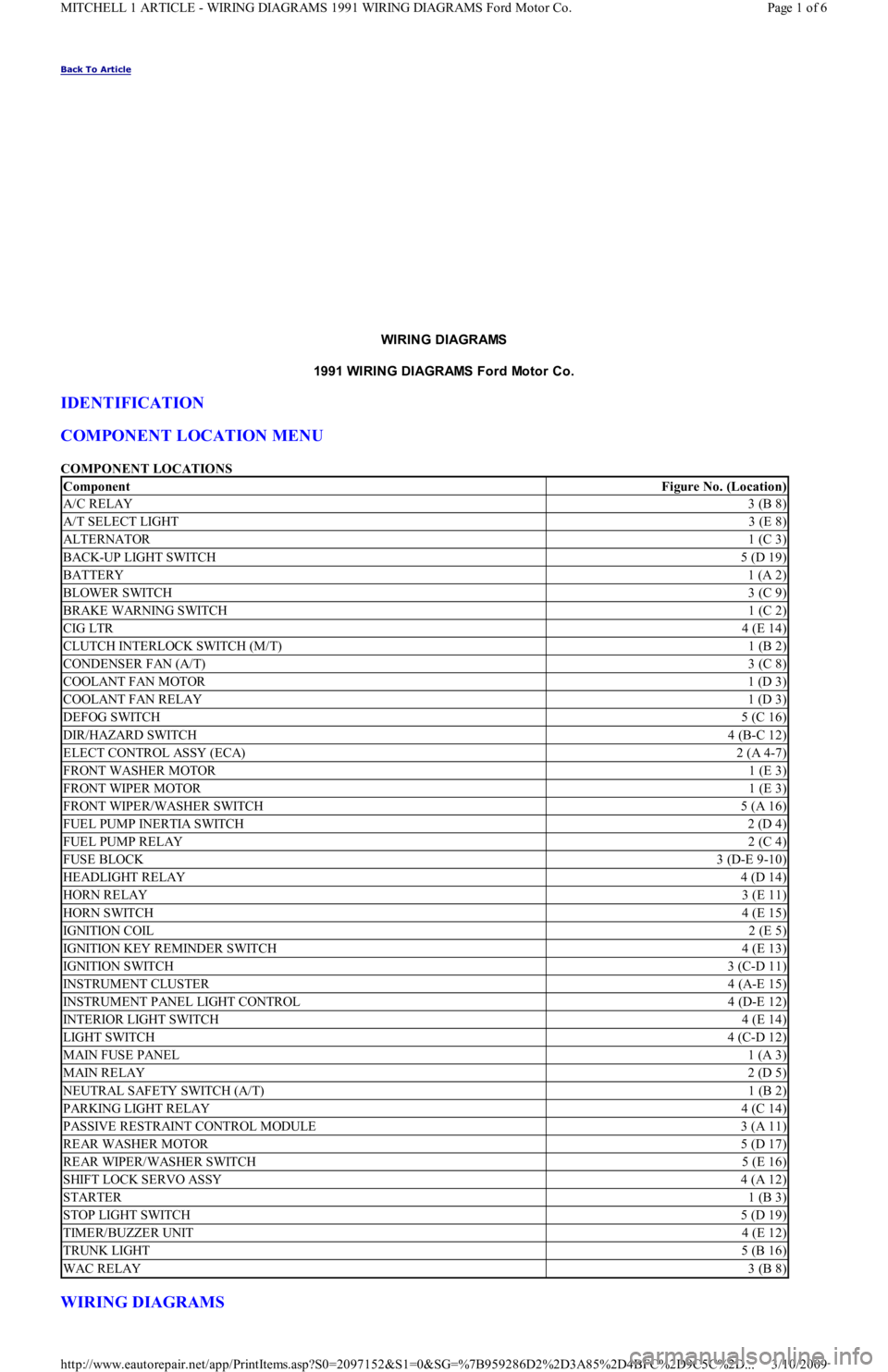

Back To Article

WIRING DIAGRAMS

1991 WIRING DIAGRAMS Ford Motor Co.

IDENTIFICATION

COMPONENT LOCATION MENU

COMPONENT LOCATIONS

WIRING DIAGRAMS

ComponentFigure No. (Location)

A/C RELAY3 (B 8)

A/T SELECT LIGHT3 (E 8)

ALTERNATOR1 (C 3)

BACK-UP LIGHT SWITCH5 (D 19)

BATTERY1 (A 2)

BLOWER SWITCH3 (C 9)

BRAKE WARNING SWITCH1 (C 2)

CIG LTR4 (E 14)

CLUTCH INTERLOCK SWITCH (M/T)1 (B 2)

CONDENSER FAN (A/T)3 (C 8)

COOLANT FAN MOTOR1 (D 3)

COOLANT FAN RELAY1 (D 3)

DEFOG SWITCH5 (C 16)

DIR/HAZARD SWITCH4 (B-C 12)

ELECT CONTROL ASSY (ECA)2 (A 4-7)

FRONT WASHER MOTOR1 (E 3)

FRONT WIPER MOTOR1 (E 3)

FRONT WIPER/WASHER SWITCH5 (A 16)

FUEL PUMP INERTIA SWITCH2 (D 4)

FUEL PUMP RELAY2 (C 4)

FUSE BLOCK3 (D-E 9-10)

HEADLIGHT RELAY4 (D 14)

HORN RELAY3 (E 11)

HORN SWITCH4 (E 15)

IGNITION COIL2 (E 5)

IGNITION KEY REMINDER SWITCH4 (E 13)

IGNITION SWITCH3 (C-D 11)

INSTRUMENT CLUSTER4 (A-E 15)

INSTRUMENT PANEL LIGHT CONTROL4 (D-E 12)

INTERIOR LIGHT SWITCH4 (E 14)

LIGHT SWITCH4 (C-D 12)

MAIN FUSE PANEL1 (A 3)

MAIN RELAY2 (D 5)

NEUTRAL SAFETY SWITCH (A/T)1 (B 2)

PARKING LIGHT RELAY4 (C 14)

PASSIVE RESTRAINT CONTROL MODULE3 (A 11)

REAR WASHER MOTOR5 (D 17)

REAR WIPER/WASHER SWITCH5 (E 16)

SHIFT LOCK SERVO ASSY4 (A 12)

STARTER1 (B 3)

STOP LIGHT SWITCH5 (D 19)

TIMER/BUZZER UNIT4 (E 12)

TRUNK LIGHT5 (B 16)

WAC RELAY3 (B 8)

Page 1 of 6 MITCHELL 1 ARTICLE - WIRING DIAGRAMS 1991 WIRING DIAGRAMS Ford Motor Co.

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 102 of 454

levels to proper level.

Removal (1.6L & 1.6L Turbo)

1. Relieve fuel pressure and discharge air conditioning system (if equipped). See FUEL PRESSURE RELEASE under REMOVAL &

INSTALLATION. Disconnect and remove battery, battery tray and battery tray support bracket.

2. Release wiring harness retaining straps from battery support tray. Disconnect windshield washer supply hose between fluid reservoir and

hood. Mark hinge locations and remove hood.

3. Disconnect intake air tube and wiring to ignition coil and vane airflow meter. Remove air cleaner/vane airflow meter assembly. Remove

air cleaner assembly support brackets. Disconnect intercooler hoses from turbocharger (if equipped).

4. Drain engine coolant and remove radiator. Disconnect accelerator cable, and remove retaining bracket from cam cover. Position cable to

one side.

5. Disconnect and plug fuel lines at fuel filter and pressure regulator. Disconnect power brake booster manifold vacuum hose from

manifold. Disconnect heater hoses at heater core tubes. Label and remove vacuum hoses located at throttle body.

6. For manual transaxle turbocharged vehicles, disconnect clutch cable and remove support bracket and cable from transmission. On non-

turbo vehicles, disconnect clutch slave hydraulic line. For automatic transaxle, remove transaxle cooler lines.

7. Disconnect starter wiring at starter. Remove harness from locating strap on bracket. Disconnect alternator wiring. Disconnect wiring

from engine coolant sensors located on rear of engine block. Remove ground connection at bracket on thermostat cover. Disconnect O2

sensor wire, main wiring harness connector, TPS connector (turbocharged only), knock sensor connector, distributor wiring and

transaxle wiring. Disconnect ground wire and strap at front of engine, and reinstall lifting eye.

8. Remove engine oil dipstick and retaining clip. Remove power steering pump from mounting bracket. Remove power steering pump

mounting bracket. With hoses attached, position pump aside. Remove upper air conditioning compressor retaining bolts (if equipped).

9. Raise vehicle on hoist. Drain engine oil and cooling system. On vehicles with air conditioning, remove lower air conditioning

compressor mounting bolts, and position compressor out of way.

10. Remove front wheels and tires. Remove front ball joints-to-ste e r in g kn u c kl e s r e t a in in g b o l t s. R e mo ve sp l a sh gu a r d s. Dr a in t ransmission

oil and remove half shafts from differential. Remove front exhaust pipe bracket located on lower side of engine. Disconnect front

exhaust pipe from exhaust manifold, or turbocharger (if equipped).

11. Remove frame support bar-to-engine support bolt. Loosen right control arm bolt and, pivot support bar downward. Disengage rubber

exhaust hangers located directly behind catalytic converter. Allow exhaust system to hang down 6 inches, and support system with

mechanic's wire. Unbolt shift linkage and stabilizer bar at transaxle. Remove nuts from front and rear engine mounts, and lower vehicle.

12. Attach chains onto lift eyes at ends of cylinder head, and support engine with hoist. Remove RH engine mount through bolt. Raise

engine off mounts and slightly pivot engine/transaxle assembly. Disconnect oil pressure sensor and route starter/alternator wiring

harness from engine. Carefully lift engine/transaxle assembly, turn assembly while raising to clear brake master cylinder, shift linkage

universal joint, radiator support and air conditioning lines (if equipped).

13. Remove intake manifold support bracket. Remove gusset plate(s) (if equipped). Remove starter. Remove transaxle-to-engine retaining

bolts. Identify bolts to ensure correct installation. Separate transaxle from engine. On manual transaxle, remove pressure plate, clutch

disc and flywheel. On automatic transaxle, remove flexplate.

Installation (1.6L & 1.6L Turbo)

1. Install transaxle to engine in reverse order of removal. Attach hoist to engine/transaxle assembly and position assembly in vehicle.

Before engine contacts mounts, route starter, alternator and oil pressure sensor wiring, and connect oil pressure sensor. Lower engine

until front mount seats on crossmember. Install through bolt on RH engine mount. DO NOT tighten bolt.

2. Remove hoist. Raise vehicle and support with jackstands. Align rear engine mount to crossmember, and install retaining nuts to front

and rear engine mounts. Tighten nuts to specification. See TORQUE SPECIFICATIONS

table at end of article.

3. On manual transaxles, connect shift coupling and stabilizer. Tighten to specification. On automatic transaxles, connect shift linkage and

oil cooler lines. Tighten linkage retaining bolt, shift cable pivot and oil cooler hose clamps to specification. Connect front exhaust pipe

to manifold (or turbocharger). Install exhaust pipe to support bracket. Tighten bolts to specification. Tighten manifold (or turbocharger)

to specification. Attach rubber exhaust hangers. Position cross brace. Tighten retaining nut and bolt and right control arm front bolt.

4. Install drive axles. Install ball joint retaining bolts and tighten to specification. Mount A/C Compressor to engine (if equipped). Tighten

lower retaining bolts to specification. Install splash guards. Install tire and wheel assemblies. Tighten retaining nuts to specification.

5. Lower vehicle. Install upper A/C compressor retaining bolts (if equipped). Tighten bolts to specification. Tighten RH engine mo u n t

through bolt to specification. Connect alternator wiring.

6. Position power steering pump bracket on stud. Lower pump into engine compartment. Install power steering pump bracket retaining

bolts and nut. Tighten to specification. Install power steering pump and belt. Tighten adjustment nut and pivot bolt to specification.

7. Install engine oil dipstick and retaining clip. Install ground strap and ground wire to cylinder head. Install clutch cable (if equipped).

Connect clutch hydraulic line if equipped with manual transaxle or naturally aspirated. Connect transmission electrical connectors.

Connect fuel lines to fuel filter and pressure regulator. Install intake air tube to throttle body.

8. Install intercooler hoses on turbocharged models. Install air cleaner assembly brackets. Install air cleaner assembly with airflow meter

attached. Install intake air tube. Install coil and airflow meter connectors. Connect coolant crankcase and air bypass hoses. Install

vacuum hoses as noted in disassembly.

9. Connect accelerator cable. Install retaining bracket. Install power brake booster hose. Remove speedometer cable from transaxle. Fill

transaxle to specification. See CAPACITIES in SERVICE & ADJUSTMENT SPECIFICATIONS article. Install speedometer cable.

Connect speedometer cable connector. Fill engine oil to capacity.

10. Install radiator/fan assembly. Tighten bracket retaining bolts to specification. Connect coolant hoses and fan electrical connector. Fill

coolant to specification.

11. Install hood and connect washer hose. Install battery tray support, battery tray, battery and battery hold-down. Connect battery

terminal. Evacuate and charge air conditioning system (if equipped). Road test vehicle and inspect for leaks.

INTAKE MANIFOLD

Removal (1.3L)

CAUT ION: DO NOT allow com pressor to hang by hoses. T ie up com pressor with m echanic's wire.

Page 2 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 104 of 454

1. Position new gasket on exhaust manifold, and install turbocharger onto studs. Install 4 retaining nuts and tighten to specification. See

TORQUE SPECIFICATIONS

table at end of article.

2. Remove oil supply line from turbocharger. Position new (2-piece) exhaust gasket on cylinder head with heavy gasket installed first .

Carefully position turbocharger assembly in engine compartment and slide exhaust manifold on studs. Position heater tube bracket onto

exhaust stud. Install 11 retaining nuts onto exhaust manifold and tighten to specification. See TORQUE SPECIFICATIONS

table at

end of article. Tighten heater tube clamp bolt securely.

3. Raise vehicle. Position new gasket and install 2 retaining bolts on heater tube outlet. Install 2 retaining bolts into turbocharger support

bracket and tighten bolts to specification.

4. Connect coolant return hose. Connect oil return hose and secure with clamp. Position exhaust pipe onto turbocharger, and start nuts

and washers. Install 2 retaining bolts on exhaust hanger at engine. Slide on 2 rubber exhaust hangers at catalytic converter. Tighten

exhaust pipe retaining nuts to specification. Lower vehicle.

5. Install retaining bolt and brass washers on oil supply line, carefully position oil line into vehicle and hand-start bolt into engine block.

Connect and finger tighten oil line to turbocharger. Tighten oil line bolt and oil supply line on turbocharger to specification.

6. Connect coolant supply hose. Position air cleaner duct tube on turbocharger and tighten clamp. Install 2 screws retaining air cleaner

duct tube. Position power steering pump bracket on engine, and install 2 retaining bolts and one retaining nut. Tighten to specification.

Position power steering pump on mounting bracket, and install though bolt and adjuster. Connect lower radiator hose. Install power

steering belt. Position upper heat shield and install 2 retaining bolts finger tight.

7. Position lower heat shield and install three retaining bolts finger tight. Tighten all heat shield bolts to specification. Connect O2 sensor

and install connector into its retaining clip. See TORQUE SPECIFICATIONS

table at end of article. Position intercooler hose on

turbocharger and secure with clamp. Install throttle body air intake tube. Connect negative battery cable. Refill cooling system.

CYLINDER HEAD

Removal (1.3L)

1. Disconnect battery ground cable. Mark and disconnect fuel lines at fuel pump. Remove accessory belts, water pump pulley, crankshaft

pulley, timing belt covers, timing belt tensioner, timing belt, valve cover and exhaust and intake manifolds. Drain cooling system.

2. Mark and remove electrical connectors and vacuum hoses. Remove spark plug wires from spark plugs, and remove spark plugs. Remove

distributor cap. Disconnect vacuum hoses and distributor wiring.

3. Index distributor-to-mount position and remove hold-down bolt. Remove distributor assembly. Remove engine ground strap. Remove

front and rear engine lifting hooks. Remove upper radiator hose, by-pass hose and bracket.

4. Remove bolts retaining rocker arm shaft. Remove rocker arm assemblies. Remove cylinder head bolts. Remove head and gasket.

Inspection (1.3L)

1. Thoroughly clean and check gasket mating surface of cylinder head and block. Check cylinder for cracks, nicks, burrs or damage. Using

a straightedge and feeler gauge, check warpage over entire gasket area. Ensure cylinder head and/or block warpage does not

exceed .006" (.15 mm).

2. If warpage exceeds .006" (.15 mm), machine cylinder head and/or block gasket surface. Maximum machining allowed is .008" (.20 mm).

If more machining is required, replace block and/or cylinder head.

Installation (1.3L)

1. Place new head gasket properly on block. Carefully place cylinder head in position on block. Install head bolts. Tighten bolts in

sequence and in 2 steps. See Fig. 1

.

2. While tightening rocker arm shaft, slide shaft springs away from retaining bolt to prevent pinching springs. Tighten rocker arm shaft bolts

in sequence and to specification. See Fig. 5

. To complete installation, reverse removal procedure. Tighten all bolts/nuts to

specification. Fill all fluids to proper levels. NOTE:T urbocharger-to-exhaust m anifold m ounting nuts are of special quality. Ensure correct nuts are

used.

NOTE:Ensure one brass washer is positioned on each side of oil line fitting.

NOTE:Feed O2 sensor wire through upper heat shield. Install wire retainer under LH bolt.

NOTE:If turbocharger was replaced: Disconnect ignition coil, crank engine for 20 seconds, connect ignition

coil, start engine and run at idle for 30 seconds and check for leaks.

NOTE:If original tim ing belt is being reused, m ark direction of rotation for installation reference.

Page 4 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 180 of 454

connector to corresponding terminals on TP sensor connector. Turn ignition on. Measure voltage between TP and SIGRTN terminals on

TP sensor while opening throttle. Compare voltage to specification in TP SENSOR OUTPUT VOLTAGE

table. If voltage is within

specification, repair TP wire to ECA. Go to next step if voltage is not within specification.

3. Turn ignition off. Unplug TP harness connector. Turn ignition on. Measure voltage between VREF and SIGRTN wires on TP harness

connect-or. If voltage is 4-5 volts, replace TP sensor. If voltage is not 4.5-5.5 volts, go to next step.

4. Measure voltage between VREF wire on TP harness connector and ground. If voltage is 4-5 volts, adjust or replace throttle position

sensor. If voltage is not 4-5 volts, go to PINPOINT TEST VREF

.

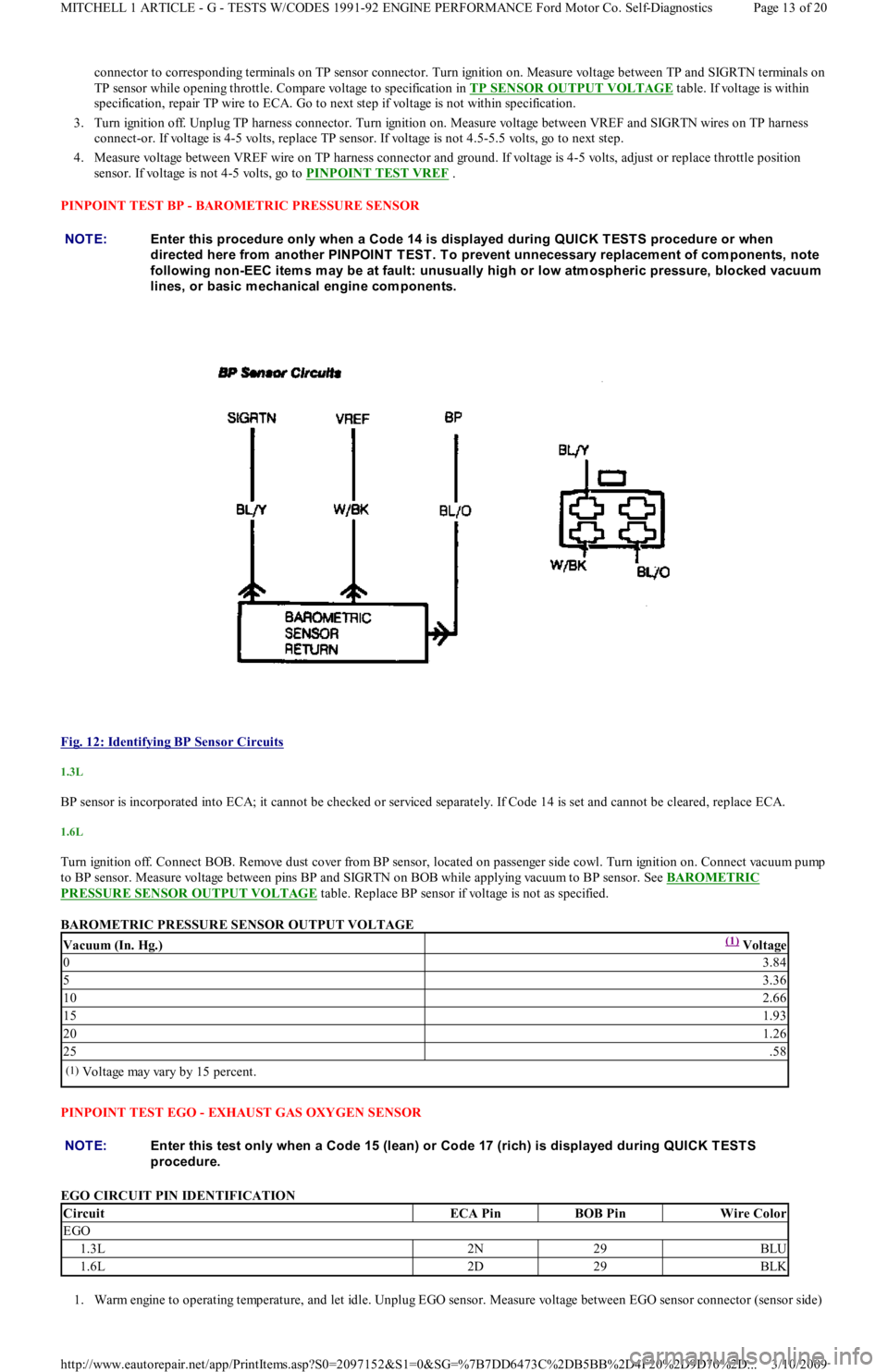

PINPOINT TEST BP - BAROMETRIC PRESSURE SENSOR

Fig. 12: Identifying BP Sensor Circuits

1.3L

BP sensor is incorporated into ECA; it cannot be checked or serviced separately. If Code 14 is set and cannot be cleared, replace ECA.

1.6L

Turn ignition off. Connect BOB. Remove dust cover from BP sensor, located on passenger side cowl. Turn ignition on. Connect vacuum pump

to BP sensor. Measure voltage between pins BP and SIGRTN on BOB while applying vacuum to BP sensor. See BAROMETRIC

PRESSURE SENSOR OUTPUT VOLTAGE table. Replace BP sensor if voltage is not as specified.

BAROMETRIC PRESSURE SENSOR OUTPUT VOLTAGE

PINPOINT TEST EGO - EXHAUST GAS OXYGEN SENSOR

EGO CIRCUIT PIN IDENTIFICATION

1. Warm engine to operating temperature, and let idle. Unplug EGO sensor. Measure voltage between EGO sensor connector (sensor side) NOTE:Enter this procedure only when a Code 14 is displayed during QUICK T EST S procedure or when

directed here from another PINPOINT T EST . T o prevent unnecessary replacem ent of com ponents, note

following non-EEC item s m ay be at fault: unusually high or low atm ospheric pressure, blocked vacuum

lines, or basic m echanical engine com ponents.

Vacuum (In. Hg.)(1) Voltage

03.84

53.36

102.66

151.93

201.26

25.58

(1)Voltage may vary by 15 percent.

NOTE:Enter this test only when a Code 15 (lean) or Code 17 (rich) is displayed during QUICK TESTS

procedure.

CircuitECA PinBOB PinWire Color

EGO

1.3L2N29BLU

1.6L2D29BLK

Page 13 of 20 MITCHELL 1 ARTICLE - G - TESTS W/CODES 1991-92 ENGINE PERFORMANCE Ford Motor Co. Self-Diagnostics

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 195 of 454

IDLE SPEED

While the engine is cold, the Idle Speed Control By-Pass Air (ISC-BPA) Valve increases idle speed to warm the engine quickly. At engine

temperatures less than 140°F (60°C), the valve is open. As the engine warms, the valve begins to close. The valve is fully closed at engine

temperatures higher than 140°F (60°C). Idle speed is also affected by various switches, sensors and load on the engine.

ELECTRONIC IGNITION SYSTEM

CAPRI

A pick-up coil within the distributor sends a signal to a Distributor-Mounted Ignition Module With Vacuum Advance (DMIVA) within the

distributor. The DMIVA then sends a signal which fires the coil. When the coil fires, the distributor directs high voltage current to the spark

plugs. The DMIVA system operates independently of the ECA.

FESTIVA

A pick-up coil within the distributor sends a signal to a transistorized ignition module on the coil bracket. A timing signal also goes from the

ECA to the ignition module. The ignition module then sends a signal which fires the coil. When the coil fires, the distributor directs high

voltage current to the spark plugs.

IGNITION TIMING CONTROL SYSTEM

CAPRI

Spark timing is controlled by vacuum and centrifugal advance mechanisms and by a signal from the ECA. The ECA does not affect ignition

timing on turbo models. On turbo models, a knock sensor and control unit retard ignition timing when knock occurs.

FESTIVA

The ECA generates a spark timing signal from data received from the BP, CPS and VAF. This signal goes to the ignition module. The ignition

module then sends a signal to fire the coil.

HIGH ALTITUDE SPARK ADVANCE CORRECTION

A barometric pressure sensor is incorporated into the ECA on Festiva and is a separate component on Capri. At high altitudes, the ECA sends

a signal to the ignition module to advance ignition timing. This feature is not used on turbo models.

KNOCK SENSOR (CAPRI)

A Knock Sensor (KS) generates a signal when knock occurs. A control unit processes this signal and then sends it to the ignition module to

retard spark timing. The KS is located in the engine block, near the oil pressure switch. This device is only used on 1.6L turbo engines.

KNOCK CONTROL UNIT (CAPRI)

The Knock Control Unit filters normal engine vibration signals from the KS, then sends a signal to the ignition module to retard spark timing.

This unit, used only on 1.6L turbo engines, is located on right side of engine compartment.

EMISSION SYSTEMS

DECELERATION SYSTEM (DASHPOT)

The deceleration control system closes the throttle plate gradually during deceleration. The dashpot prevents engine stalling on deceleration

and provides a smooth transition from deceleration to sudden acceleration.

EVAPORATIVE SYSTEM

CARBON CANISTER

The carbon canister stores vapors from the fuel tank until they are purged and burned in the engine. On Festiva, carbon canister is

located under the brake booster. On Capri, carbon canister is located on the right side of the engine compartment near the cowl panel.

CANISTER PURGE SOLENOID

This component is connected between the carbon canister and intake manifold. When the ECA sends a signal to the solenoid to open,

fuel vapors in the carbon canister are drawn into the engine.

CANISTER PURGE VALVE

This valve opens to purge vapors from the carbon canister into the engine intake system. The valve is part of the canister purge solenoid.

ROLLOVER VENT VALVE

This valve, located in front of the fuel tank, blocks the vapor line in case of vehicle rollover.

This valve, located in front of the fuel tank, blocks the vapor line in case of vehicle rollover.

CATALYTIC CONVERTER

The catalytic converter is in the exhaust system, between the exhaust manifold and the muffler. It converts certain pollutants in the exhaust

Page 5 of 6 MITCHELL 1 ARTICLE - E - THEORY/OPERATION 1991 ENGINE PERFORMANCE Ford/Mercury Theory & Operation

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...