points FORD FIESTA 1989 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1989, Model line: FIESTA, Model: FORD FIESTA 1989Pages: 296, PDF Size: 10.65 MB

Page 15 of 296

connections - remake the connections or

renew the leads if a fault is found. Use the

same techniques to ensure that all earth

points in the engine compartment provide

good electrical contact through clean, metal-

to-metal joints, and that all are securely

fastened. (In addition to the earth connection

at the engine lifting eye, and that from the

transmission to the body/battery, there are

others in various places, so check carefully).

8Refer to Section 21 for details of spark plug

(HT) lead checks.

7 Valve clearance adjustment

2

Refer to Chapter 2, Part A.

8 Manual transmission oil level check

1

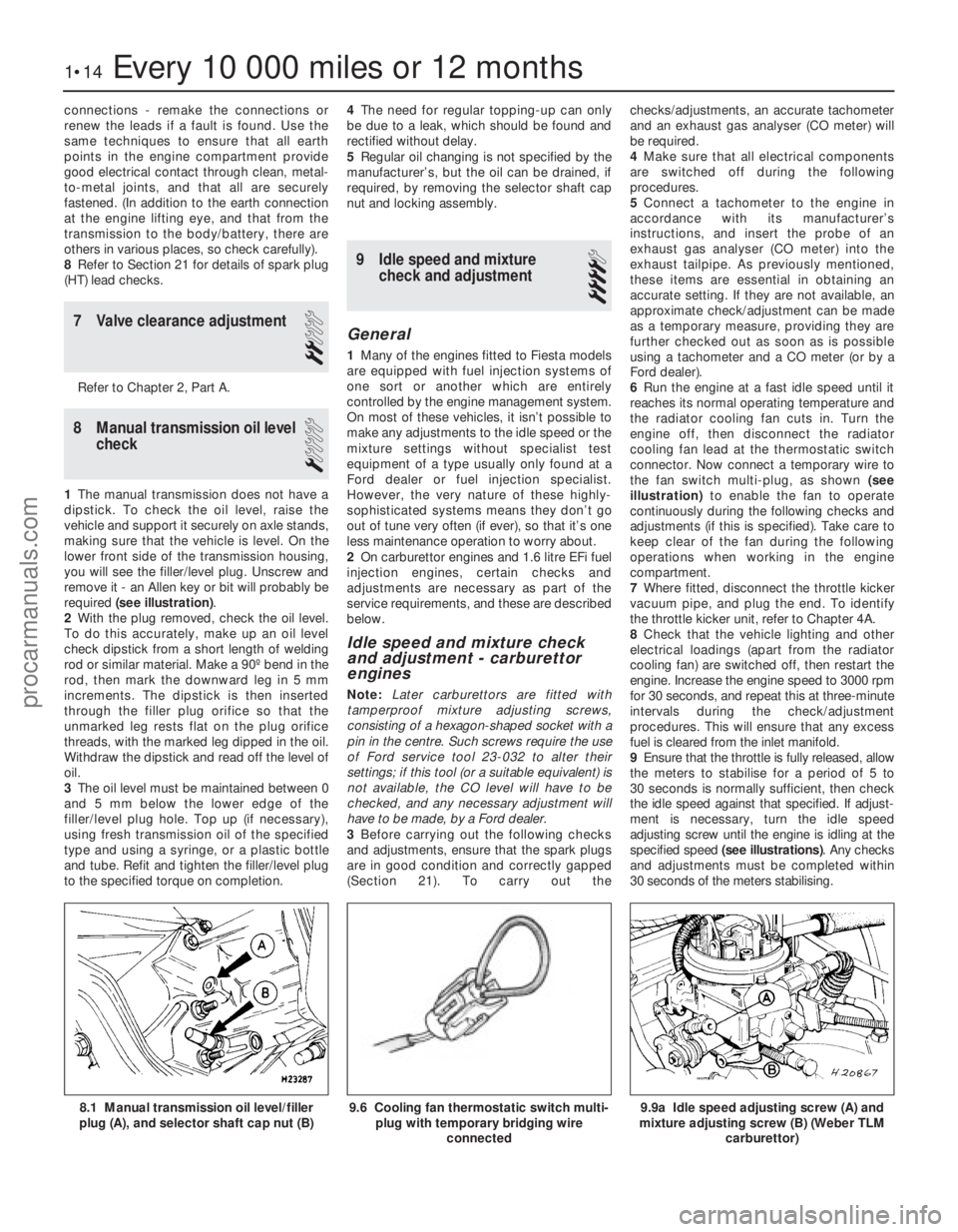

1The manual transmission does not have a

dipstick. To check the oil level, raise the

vehicle and support it securely on axle stands,

making sure that the vehicle is level. On the

lower front side of the transmission housing,

you will see the filler/level plug. Unscrew and

remove it - an Allen key or bit will probably be

required (see illustration) .

2 With the plug removed, check the oil level.

To do this accurately, make up an oil level

check dipstick from a short length of welding

rod or similar material. Make a 90º bend in the

rod, then mark the downward leg in 5 mm

increments. The dipstick is then inserted

through the filler plug orifice so that the

unmarked leg rests flat on the plug orifice

threads, with the marked leg dipped in the oil.

Withdraw the dipstick and read off the level of

oil.

3 The oil level must be maintained between 0

and 5 mm below the lower edge of the

filler/level plug hole. Top up (if necessary),

using fresh transmission oil of the specified

type and using a syringe, or a plastic bottle

and tube. Refit and tighten the filler/level plug

to the specified torque on completion. 4

The need for regular topping-up can only

be due to a leak, which should be found and

rectified without delay.

5 Regular oil changing is not specified by the

manufacturer’s, but the oil can be drained, if

required, by removing the selector shaft cap

nut and locking assembly.

9 Idle speed and mixture check and adjustment

4

General

1Many of the engines fitted to Fiesta models

are equipped with fuel injection systems of

one sort or another which are entirely

controlled by the engine management system.

On most of these vehicles, it isn’t possible to

make any adjustments to the idle speed or the

mixture settings without specialist test

equipment of a type usually only found at a

Ford dealer or fuel injection specialist.

However, the very nature of these highly-

sophisticated systems means they don’t go

out of tune very often (if ever), so that it’s one

less maintenance operation to worry about.

2 On carburettor engines and 1.6 litre EFi fuel

injection engines, certain checks and

adjustments are necessary as part of the

service requirements, and these are described

below.

Idle speed and mixture check

and adjustment - carburettor

engines

Note: Later carburettors are fitted with

tamperproof mixture adjusting screws,

consisting of a hexagon-shaped socket with a

pin in the centre. Such screws require the use

of Ford service tool 23-032 to alter their

settings; if this tool (or a suitable equivalent) is

not available, the CO level will have to be

checked, and any necessary adjustment will

have to be made, by a Ford dealer.

3 Before carrying out the following checks

and adjustments, ensure that the spark plugs

are in good condition and correctly gapped

(Section 21). To carry out the checks/adjustments, an accurate tachometer

and an exhaust gas analyser (CO meter) will

be required.

4

Make sure that all electrical components

are switched off during the following

procedures.

5 Connect a tachometer to the engine in

accordance with its manufacturer’s

instructions, and insert the probe of an

exhaust gas analyser (CO meter) into the

exhaust tailpipe. As previously mentioned,

these items are essential in obtaining an

accurate setting. If they are not available, an

approximate check/adjustment can be made

as a temporary measure, providing they are

further checked out as soon as is possible

using a tachometer and a CO meter (or by a

Ford dealer).

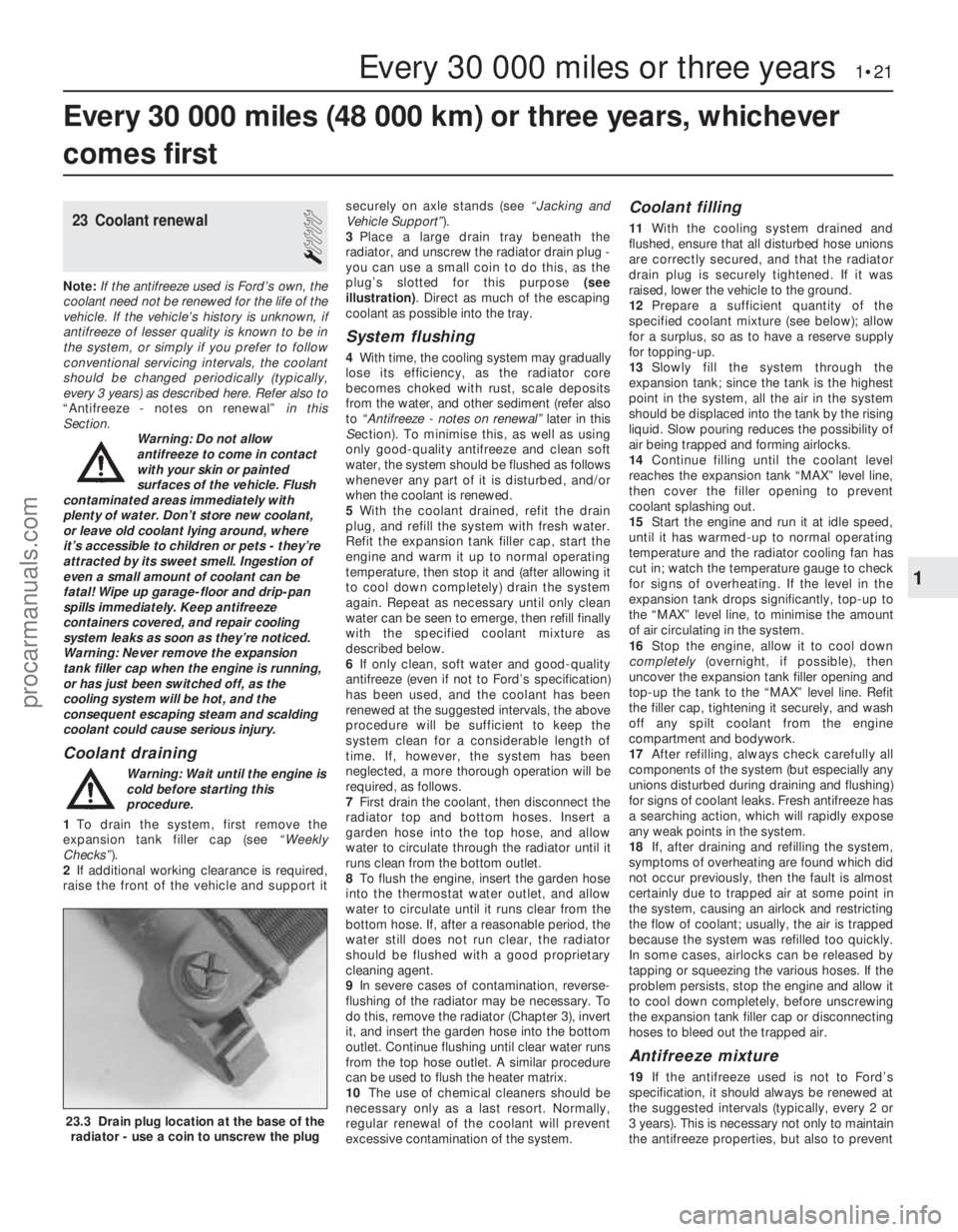

6 Run the engine at a fast idle speed until it

reaches its normal operating temperature and

the radiator cooling fan cuts in. Turn the

engine off, then disconnect the radiator

cooling fan lead at the thermostatic switch

connector. Now connect a temporary wire to

the fan switch multi-plug, as shown (see

illustration) to enable the fan to operate

continuously during the following checks and

adjustments (if this is specified). Take care to

keep clear of the fan during the following

operations when working in the engine

compartment.

7 Where fitted, disconnect the throttle kicker

vacuum pipe, and plug the end. To identify

the throttle kicker unit, refer to Chapter 4A.

8 Check that the vehicle lighting and other

electrical loadings (apart from the radiator

cooling fan) are switched off, then restart the

engine. Increase the engine speed to 3000 rpm

for 30 seconds, and repeat this at three-minute

intervals during the check/adjustment

procedures. This will ensure that any excess

fuel is cleared from the inlet manifold.

9 Ensure that the throttle is fully released, allow

the meters to stabilise for a period of 5 to

30 seconds is normally sufficient, then check

the idle speed against that specified. If adjust-

ment is necessary, turn the idle speed

adjusting screw until the engine is idling at the

specified speed (see illustrations) . Any checks

and adjustments must be completed within

30 seconds of the meters stabilising.

1•14Every 10 000 miles or 12 months

9.9a Idle speed adjusting screw (A) and

mixture adjusting screw (B) (Weber TLM

carburettor)9.6 Cooling fan thermostatic switch multi-plug with temporary bridging wire

connected8.1 Manual transmission oil level/filler

plug (A), and selector shaft cap nut (B)

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 22 of 296

23 Coolant renewal

1

Note: If the antifreeze used is Ford’s own, the

coolant need not be renewed for the life of the

vehicle. If the vehicle’s history is unknown, if

antifreeze of lesser quality is known to be in

the system, or simply if you prefer to follow

conventional servicing intervals, the coolant

should be changed periodically (typically,

every 3 years) as described here. Refer also to

“Antifreeze - notes on renewal” in this

Section.

Warning: Do not allow

antifreeze to come in contact

with your skin or painted

surfaces of the vehicle. Flush

contaminated areas immediately with

plenty of water. Don’t store new coolant,

or leave old coolant lying around, where

it’s accessible to children or pets - they’re

attracted by its sweet smell. Ingestion of

even a small amount of coolant can be

fatal! Wipe up garage-floor and drip-pan

spills immediately. Keep antifreeze

containers covered, and repair cooling

system leaks as soon as they’re noticed.

Warning: Never remove the expansion

tank filler cap when the engine is running,

or has just been switched off, as the

cooling system will be hot, and the

consequent escaping steam and scalding

coolant could cause serious injury.

Coolant draining

Warning: Wait until the engine is

cold before starting this

procedure.

1 To drain the system, first remove the

expansion tank filler cap (see “Weekly

Checks” ).

2 If additional working clearance is required,

raise the front of the vehicle and support it securely on axle stands (see

“Jacking and

Vehicle Support” ).

3 Place a large drain tray beneath the

radiator, and unscrew the radiator drain plug -

you can use a small coin to do this, as the

plug’s slotted for this purpose (see

illustration) . Direct as much of the escaping

coolant as possible into the tray.

System flushing

4 With time, the cooling system may gradually

lose its efficiency, as the radiator core

becomes choked with rust, scale deposits

from the water, and other sediment (refer also

to “Antifreeze - notes on renewal” later in this

S ection). To minimise this, as well as using

only good-quality antifreeze and clean soft

water, the system should be flushed as follows

whenever any part of it is disturbed, and/or

when the coolant is renewed.

5 With the coolant drained, refit the drain

plug, and refill the system with fresh water.

Refit the expansion tank filler cap, start the

engine and warm it up to normal operating

temperature, then stop it and (after allowing it

to cool down completely) drain the system

again. Repeat as necessary until only clean

water can be seen to emerge, then refill finally

with the specified coolant mixture as

described below.

6 If only clean, soft water and good-quality

antifreeze (even if not to Ford’s specification)

has been used, and the coolant has been

renewed at the suggested intervals, the above

procedure will be sufficient to keep the

system clean for a considerable length of

time. If, however, the system has been

neglected, a more thorough operation will be

required, as follows.

7 First drain the coolant, then disconnect the

radiator top and bottom hoses. Insert a

garden hose into the top hose, and allow

water to circulate through the radiator until it

runs clean from the bottom outlet.

8 To flush the engine, insert the garden hose

into the thermostat water outlet, and allow

water to circulate until it runs clear from the

bottom hose. If, after a reasonable period, the

water still does not run clear, the radiator

should be flushed with a good proprietary

cleaning agent.

9 In severe cases of contamination, reverse-

flushing of the radiator may be necessary. To

do this, remove the radiator (Chapter 3), invert

it, and insert the garden hose into the bottom

outlet. Continue flushing until clear water runs

from the top hose outlet. A similar procedure

can be used to flush the heater matrix.

10 The use of chemical cleaners should be

necessary only as a last resort. Normally,

regular renewal of the coolant will prevent

excessive contamination of the system.

Coolant filling

11 With the cooling system drained and

flushed, ensure that all disturbed hose unions

are correctly secured, and that the radiator

drain plug is securely tightened. If it was

raised, lower the vehicle to the ground.

12 Prepare a sufficient quantity of the

specified coolant mixture (see below); allow

for a surplus, so as to have a reserve supply

for topping-up.

13 Slowly fill the system through the

expansion tank; since the tank is the highest

point in the system, all the air in the system

should be displaced into the tank by the rising

liquid. Slow pouring reduces the possibility of

air being trapped and forming airlocks.

14 Continue filling until the coolant level

reaches the expansion tank “MAX” level line,

then cover the filler opening to prevent

coolant splashing out.

15 Start the engine and run it at idle speed,

until it has warmed-up to normal operating

temperature and the radiator cooling fan has

cut in; watch the temperature gauge to check

for signs of overheating. If the level in the

expansion tank drops significantly, top-up to

the “MAX” level line, to minimise the amount

of air circulating in the system.

16 Stop the engine, allow it to cool down

completely (overnight, if possible), then

uncover the expansion tank filler opening and

top-up the tank to the “MAX” level line. Refit

the filler cap, tightening it securely, and wash

off any spilt coolant from the engine

compartment and bodywork.

17 After refilling, always check carefully all

components of the system (but especially any

unions disturbed during draining and flushing)

for signs of coolant leaks. Fresh antifreeze has

a searching action, which will rapidly expose

any weak points in the system.

18 If, after draining and refilling the system,

symptoms of overheating are found which did

not occur previously, then the fault is almost

certainly due to trapped air at some point in

the system, causing an airlock and restricting

the flow of coolant; usually, the air is trapped

because the system was refilled too quickly.

In some cases, airlocks can be released by

tapping or squeezing the various hoses. If the

problem persists, stop the engine and allow it

to cool down completely, before unscrewing

the expansion tank filler cap or disconnecting

hoses to bleed out the trapped air.

Antifreeze mixture

19 If the antifreeze used is not to Ford’s

specification, it should always be renewed at

the suggested intervals (typically, every 2 or

3 years). This is necessary not only to maintain

the antifreeze properties, but also to prevent

Every 30 000 miles (48 000 km) or three years, whichever

comes first

Every 30 000 miles or three years 1•21

23.3 Drain plug location at the base of the radiator - use a coin to unscrew the plug

1

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 26 of 296

the specified type of fluid. It is essential that

no dirt is introduced into the transmission

during this operation.

7Depending on the extent to which the fluid

was allowed to drain, it is possible that the

amount of fluid required when filling the

transmission may be more than the specified

amount (see “Lubricants, fluids and tyre

pressures” ). However, due to fluid remaining in

the system, it is more likely that less than the

specified amount will be required. Add about

half the specified amount, then run the engine

up to its normal operating temperature and

check the level on the dipstick. When the level

approaches the maximum mark, proceed as

detailed in Section 20 to check the level and

complete the final topping-up as described.

27 Handbrake adjustment

3

1 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Fully

release the handbrake.

2 Check that the handbrake cables are

correctly routed and secured by the retaining

clips at the appropriate points under the vehicle.

3 The handbrake is checked for adjustment

by measuring the amount of movement

possible in the handbrake adjuster plungers.

These are located on the inside face of each

rear brake backplate (see illustration) . Thetotal movement of the two plungers combined

should be between 0.5 and 2.0 mm. If the

movement measured is outside of this

tolerance, the handbrake is in need of

adjustment. Adjustment is made altering the

position of the in-line cable adjuster sleeve.

4

When adjustment to the handbrake is

necessary, a new adjustment sleeve locking

pin will be required, and this must therefore

be obtained before making the adjustment.

5 To adjust the handbrake, first ensure that it

is fully released, then firmly apply the

footbrake a few times to ensure that the rear

brake adjustment is taken up by the automatic

adjusters. Extract the locking pin from

the adjuster sleeve (see illustration), then

turn the sleeve to set the combined move-

ment of the plungers within the tolerance range specified (0.5 to 2.0 mm). Turn the

locking nut by hand as tight as is possible

(two clicks) against the adjustment sleeve.

Now grip the locknut with a suitable wrench,

and turn it a further two clicks (maximum).

6

Secure the adjustment by inserting the new

lock pin.

7 Check that the operation of the handbrake

is satisfactory, then lower the vehicle to the

ground, apply the handbrake and remove the

chocks from the front wheels.

28 Front wheel alignment check

4

Refer to Chapter 10, Section 29.

Every 30 000 miles or three years1•25

27.5 Handbrake cable adjuster locking

pin (A), locknut (B) and adjuster sleeve (C)27.3 Handbrake adjustment plunger

located on the inside face of each rear brake backplate

1

1595Ford Fiesta Remake

Every 40 000 miles

29 Timing belt renewal

4

Refer to Chapter 2, Part B or C as

applicable.

Every 60 000 miles

30 Fuel filter renewal

1

Warning: Petrol is extremely

flammable, so extra precautions

must be taken when working on

any part of the fuel system. Do

not smoke, or allow open flames or bare

light bulbs, near the work area. Also, do

not work in a garage if a natural gas-type appliance with a pilot light is present.

While performing any work on the fuel system, wear safety glasses, and have a

suitable (Class B) fire extinguisher on

hand. If you spill any fuel on your skin,

rinse it off immediately with soap and

water.

1

On fuel injection engines, an in-line fuel

filter is provided in the fuel pump outlet line.

The filter is located in the engine compartment

either below and behind the battery, or on the

left-hand side of the engine compartment

bulkhead. The renewal procedure is the same

for both locations. The filter performs a vital

role in keeping dirt and other foreign matter

out of the fuel system, and so must be renewed at regular intervals, or whenever you

have reason to suspect that it may be

clogged. It is always unpleasant working

under a vehicle - pressure-washing or hosing

clean the underbody in the filter’s vicinity will

make working conditions more tolerable, and

will reduce the risk of getting dirt into the fuel

system.

2

Depressurise the fuel system as described

in the relevant Part of Chapter 4.

3 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1), then position

a suitable container beneath the fuel filter to

catch escaping fuel. Have a rag handy to soak

procarmanuals.com

http://vnx.su

Page 34 of 296

cover). Using a new gasket, fit the timing

chain cover, centring it with the aid of the

crankshaft pulley - lubricate the seal contact

surfaces beforehand. Refit and tighten the

retaining bolts but, where applicable, leave

out the timing cover bolt which also secures

the water pump at this stage.

8Where applicable, refit the water pump as

described in Chapter 3.

9 Refit the crankshaft pulley as described in

the previous Section.

10 Refit the sump as described in Section 11.

10Timing chain, sprockets and

tensioner - removal,

inspection and refitting

3

Removal

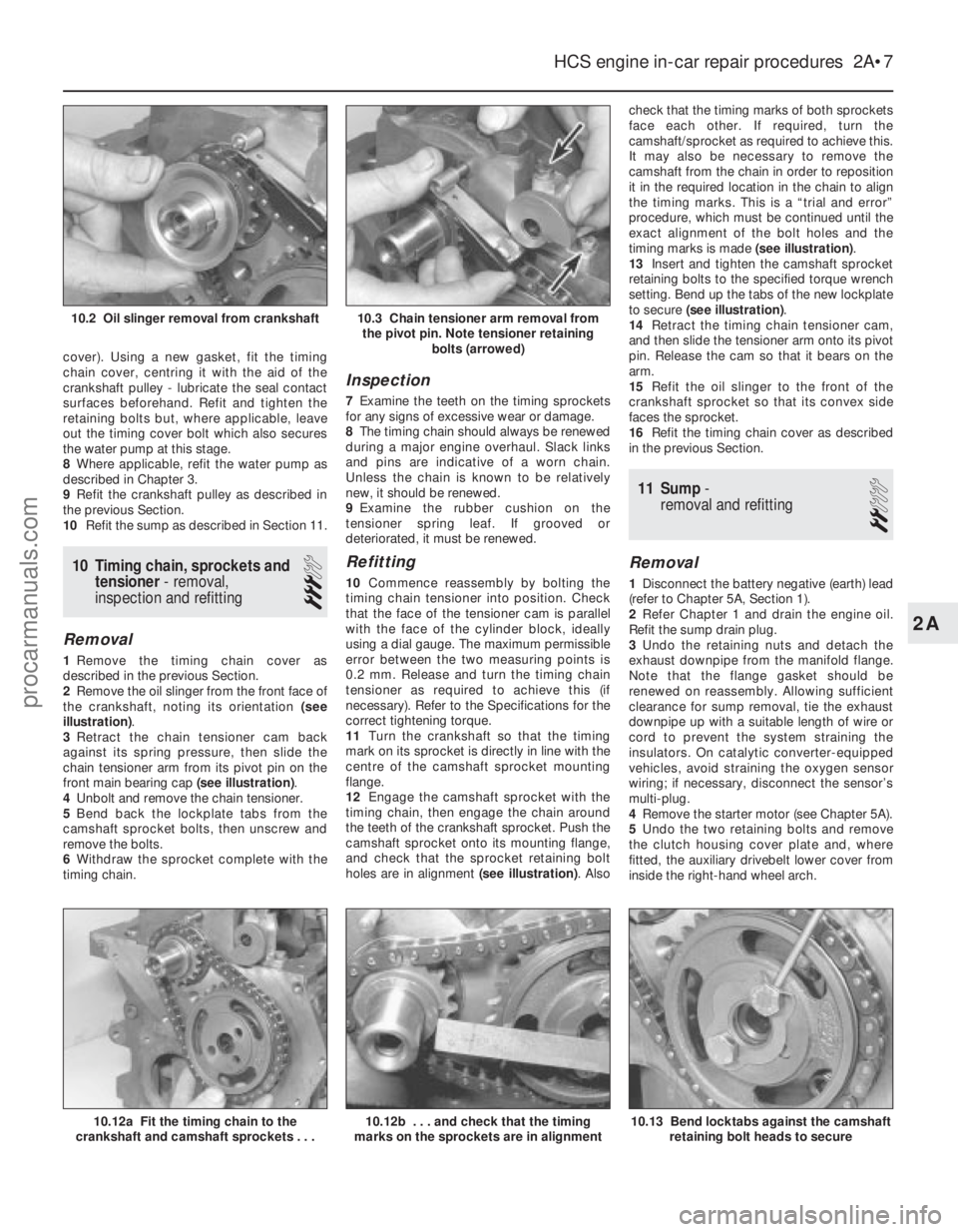

1 Remove the timing chain cover as

described in the previous Section.

2 Remove the oil slinger from the front face of

the crankshaft, noting its orientation (see

illustration) .

3 Retract the chain tensioner cam back

against its spring pressure, then slide the

chain tensioner arm from its pivot pin on the

front main bearing cap (see illustration).

4 Unbolt and remove the chain tensioner.

5 Bend back the lockplate tabs from the

camshaft sprocket bolts, then unscrew and

remove the bolts.

6 Withdraw the sprocket complete with the

timing chain.

Inspection

7 Examine the teeth on the timing sprockets

for any signs of excessive wear or damage.

8 The timing chain should always be renewed

during a major engine overhaul. Slack links

and pins are indicative of a worn chain.

Unless the chain is known to be relatively

new, it should be renewed.

9 Examine the rubber cushion on the

tensioner spring leaf. If grooved or

deteriorated, it must be renewed.

Refitting

10 Commence reassembly by bolting the

timing chain tensioner into position. Check

that the face of the tensioner cam is parallel

with the face of the cylinder block, ideally

using a dial gauge. The maximum permissible

error between the two measuring points is

0.2 mm. Release and turn the timing chain

tensioner as required to achieve this (if

necessary). Refer to the Specifications for the

correct tightening torque.

11 Turn the crankshaft so that the timing

mark on its sprocket is directly in line with the

centre of the camshaft sprocket mounting

flange.

12 Engage the camshaft sprocket with the

timing chain, then engage the chain around

the teeth of the crankshaft sprocket. Push the

camshaft sprocket onto its mounting flange,

and check that the sprocket retaining bolt

holes are in alignment (see illustration). Alsocheck that the timing marks of both sprockets

face each other. If required, turn the

camshaft/sprocket as required to achieve this.

It may also be necessary to remove the

camshaft from the chain in order to reposition

it in the required location in the chain to align

the timing marks. This is a “trial and error”

procedure, which must be continued until the

exact alignment of the bolt holes and the

timing marks is made

(see illustration).

13 Insert and tighten the camshaft sprocket

retaining bolts to the specified torque wrench

setting. Bend up the tabs of the new lockplate

to secure (see illustration) .

14 Retract the timing chain tensioner cam,

and then slide the tensioner arm onto its pivot

pin. Release the cam so that it bears on the

arm.

15 Refit the oil slinger to the front of the

crankshaft sprocket so that its convex side

faces the sprocket.

16 Refit the timing chain cover as described

in the previous Section.

11 Sump -

removal and refitting

2

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Refer Chapter 1 and drain the engine oil.

Refit the sump drain plug.

3 Undo the retaining nuts and detach the

exhaust downpipe from the manifold flange.

Note that the flange gasket should be

renewed on reassembly. Allowing sufficient

clearance for sump removal, tie the exhaust

downpipe up with a suitable length of wire or

cord to prevent the system straining the

insulators. On catalytic converter-equipped

vehicles, avoid straining the oxygen sensor

wiring; if necessary, disconnect the sensor’s

multi-plug.

4 Remove the starter motor (see Chapter 5A).

5 Undo the two retaining bolts and remove

the clutch housing cover plate and, where

fitted, the auxiliary drivebelt lower cover from

inside the right-hand wheel arch.

HCS engine in-car repair procedures 2A•7

10.12a Fit the timing chain to the

crankshaft and camshaft sprockets . . .

10.3 Chain tensioner arm removal from the pivot pin. Note tensioner retaining bolts (arrowed)10.2 Oil slinger removal from crankshaft

10.13 Bend locktabs against the camshaftretaining bolt heads to secure10.12b . . . and check that the timing

marks on the sprockets are in alignment

2A

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 47 of 296

the crankshaft pulley, then with a spanner

engaged on the crankshaft pulley bolt, turn

the crankshaft over to set the engine at TDC

for No 1 piston on compression (see Sec-

tion 3).

8Remove the camshaft sprocket as

described in Section 9.

9 Extract the camshaft oil seal as described

in Section 10.

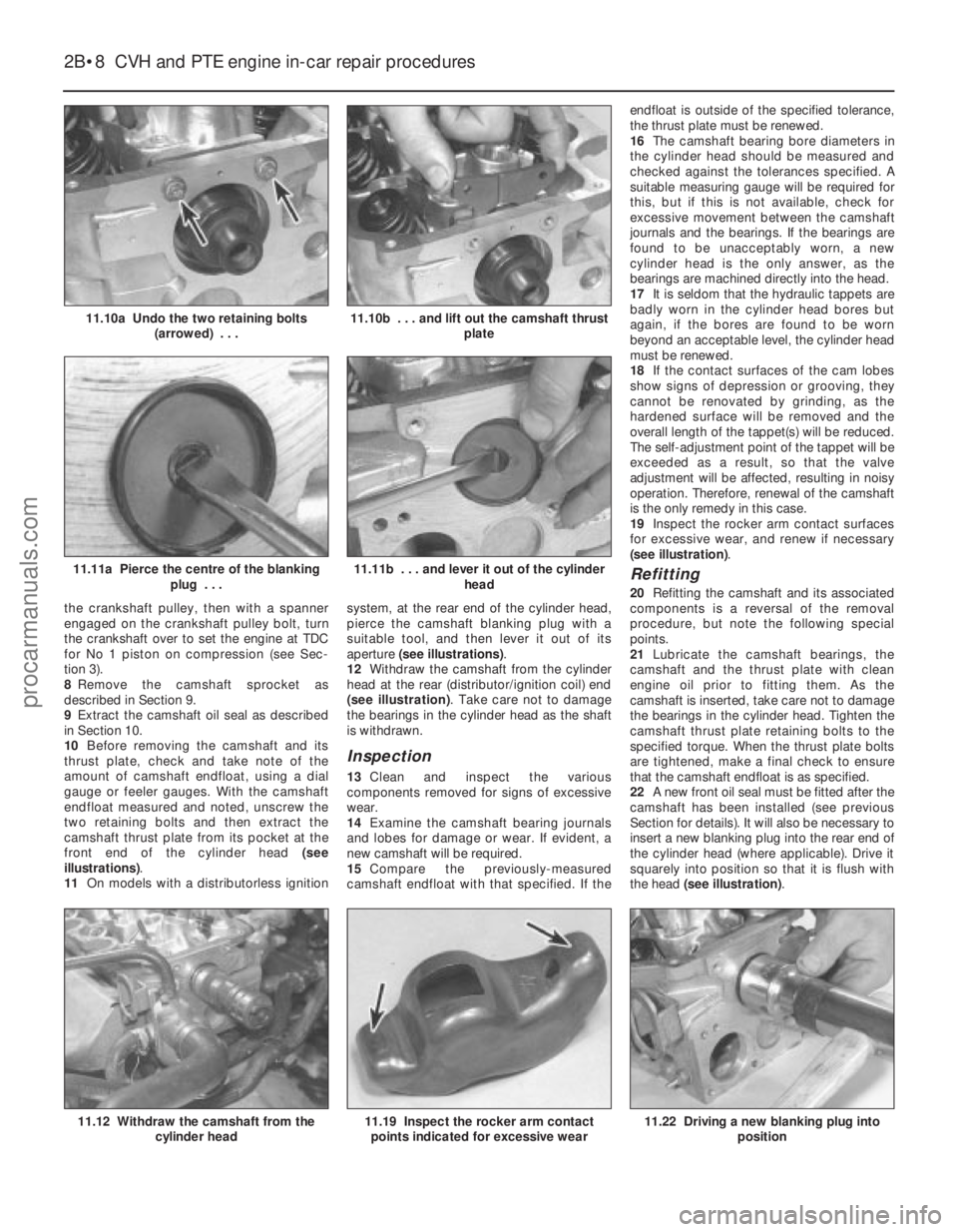

10 Before removing the camshaft and its

thrust plate, check and take note of the

amount of camshaft endfloat, using a dial

gauge or feeler gauges. With the camshaft

endfloat measured and noted, unscrew the

two retaining bolts and then extract the

camshaft thrust plate from its pocket at the

front end of the cylinder head (see

illustrations) .

11 On models with a distributorless ignition system, at the rear end of the cylinder head,

pierce the camshaft blanking plug with a

suitable tool, and then lever it out of its

aperture

(see illustrations) .

12 Withdraw the camshaft from the cylinder

head at the rear (distributor/ignition coil) end

(see illustration) . Take care not to damage

the bearings in the cylinder head as the shaft

is withdrawn.

Inspection

13 Clean and inspect the various

components removed for signs of excessive

wear.

14 Examine the camshaft bearing journals

and lobes for damage or wear. If evident, a

new camshaft will be required.

15 Compare the previously-measured

camshaft endfloat with that specified. If the endfloat is outside of the specified tolerance,

the thrust plate must be renewed.

16

The camshaft bearing bore diameters in

the cylinder head should be measured and

checked against the tolerances specified. A

suitable measuring gauge will be required for

this, but if this is not available, check for

excessive movement between the camshaft

journals and the bearings. If the bearings are

found to be unacceptably worn, a new

cylinder head is the only answer, as the

bearings are machined directly into the head.

17 It is seldom that the hydraulic tappets are

badly worn in the cylinder head bores but

again, if the bores are found to be worn

beyond an acceptable level, the cylinder head

must be renewed.

18 If the contact surfaces of the cam lobes

show signs of depression or grooving, they

cannot be renovated by grinding, as the

hardened surface will be removed and the

overall length of the tappet(s) will be reduced.

The self-adjustment point of the tappet will be

exceeded as a result, so that the valve

adjustment will be affected, resulting in noisy

operation. Therefore, renewal of the camshaft

is the only remedy in this case.

19 Inspect the rocker arm contact surfaces

for excessive wear, and renew if necessary

(see illustration) .

Refitting

20Refitting the camshaft and its associated

components is a reversal of the removal

procedure, but note the following special

points.

21 Lubricate the camshaft bearings, the

camshaft and the thrust plate with clean

engine oil prior to fitting them. As the

camshaft is inserted, take care not to damage

the bearings in the cylinder head. Tighten the

camshaft thrust plate retaining bolts to the

specified torque. When the thrust plate bolts

are tightened, make a final check to ensure

that the camshaft endfloat is as specified.

22 A new front oil seal must be fitted after the

camshaft has been installed (see previous

Section for details). It will also be necessary to

insert a new blanking plug into the rear end of

the cylinder head (where applicable). Drive it

squarely into position so that it is flush with

the head (see illustration) .

2B•8 CVH and PTE engine in-car repair procedures

11.22 Driving a new blanking plug into

position11.19 Inspect the rocker arm contactpoints indicated for excessive wear11.12 Withdraw the camshaft from the cylinder head

11.11b . . . and lever it out of the cylinder

head11.11a Pierce the centre of the blankingplug . . .

11.10b . . . and lift out the camshaft thrust plate11.10a Undo the two retaining bolts(arrowed) . . .

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 50 of 296

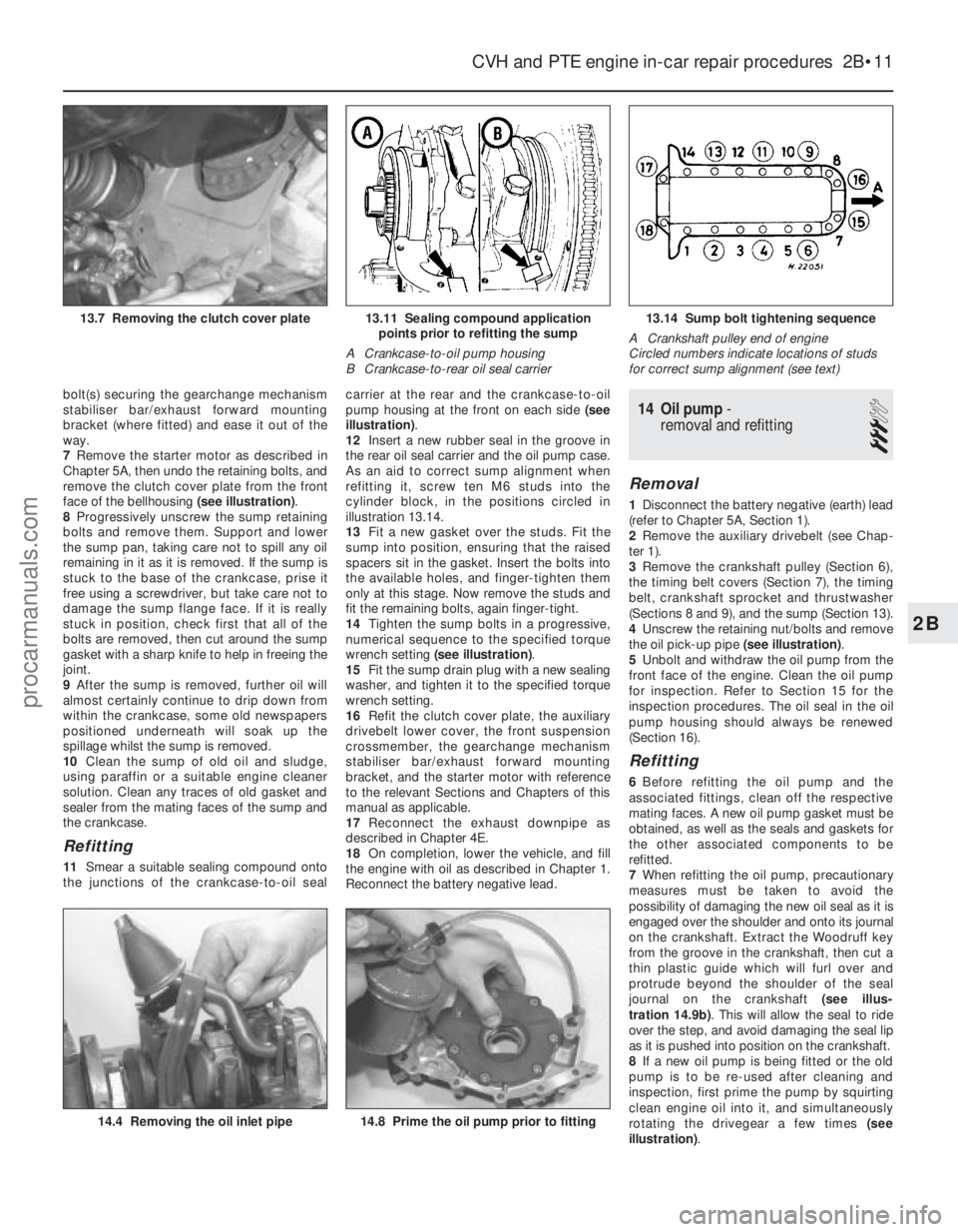

bolt(s) securing the gearchange mechanism

stabiliser bar/exhaust forward mounting

bracket (where fitted) and ease it out of the

way.

7Remove the starter motor as described in

Chapter 5A, then undo the retaining bolts, and

remove the clutch cover plate from the front

face of the bellhousing (see illustration).

8 Progressively unscrew the sump retaining

bolts and remove them. Support and lower

the sump pan, taking care not to spill any oil

remaining in it as it is removed. If the sump is

stuck to the base of the crankcase, prise it

free using a screwdriver, but take care not to

damage the sump flange face. If it is really

stuck in position, check first that all of the

bolts are removed, then cut around the sump

gasket with a sharp knife to help in freeing the

joint.

9 After the sump is removed, further oil will

almost certainly continue to drip down from

within the crankcase, some old newspapers

positioned underneath will soak up the

spillage whilst the sump is removed.

10 Clean the sump of old oil and sludge,

using paraffin or a suitable engine cleaner

solution. Clean any traces of old gasket and

sealer from the mating faces of the sump and

the crankcase.

Refitting

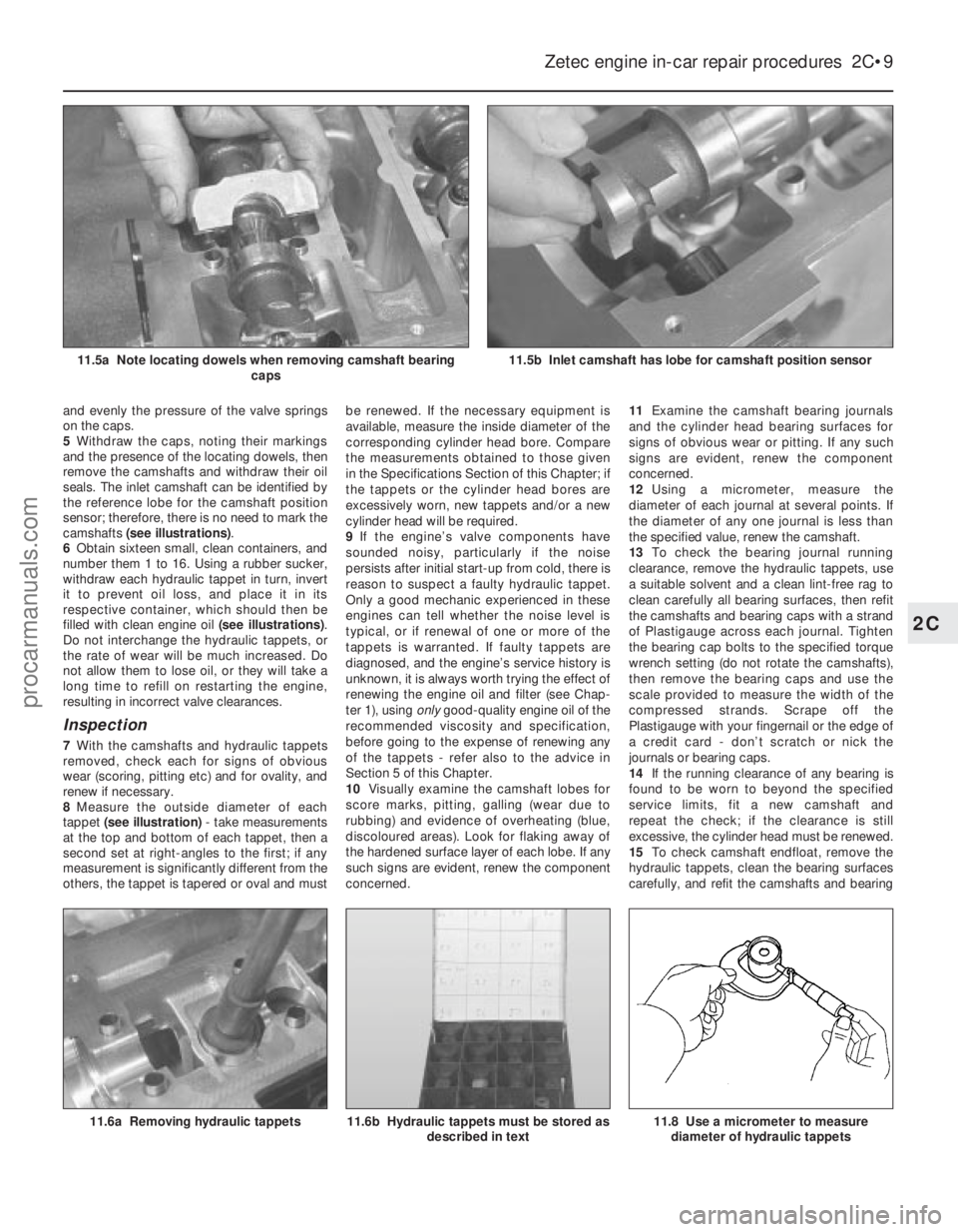

11 Smear a suitable sealing compound onto

the junctions of the crankcase-to-oil seal carrier at the rear and the crankcase-to-oil

pump housing at the front on each side

(see

illustration) .

12 Insert a new rubber seal in the groove in

the rear oil seal carrier and the oil pump case.

As an aid to correct sump alignment when

refitting it, screw ten M6 studs into the

cylinder block, in the positions circled in

illustration 13.14.

13 Fit a new gasket over the studs. Fit the

sump into position, ensuring that the raised

spacers sit in the gasket. Insert the bolts into

the available holes, and finger-tighten them

only at this stage. Now remove the studs and

fit the remaining bolts, again finger-tight.

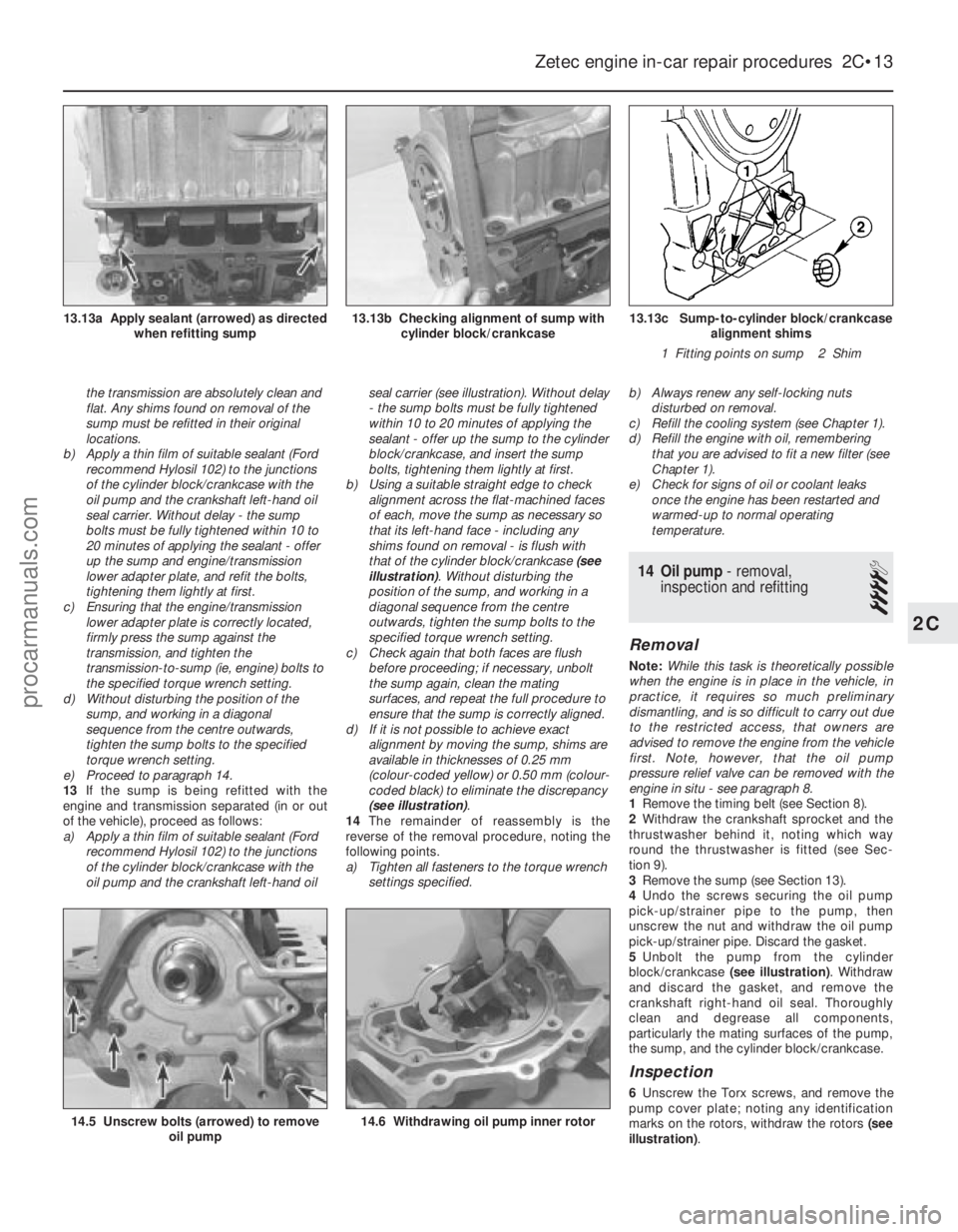

14 Tighten the sump bolts in a progressive,

numerical sequence to the specified torque

wrench setting (see illustration) .

15 Fit the sump drain plug with a new sealing

washer, and tighten it to the specified torque

wrench setting.

16 Refit the clutch cover plate, the auxiliary

drivebelt lower cover, the front suspension

crossmember, the gearchange mechanism

stabiliser bar/exhaust forward mounting

bracket, and the starter motor with reference

to the relevant Sections and Chapters of this

manual as applicable.

17 Reconnect the exhaust downpipe as

described in Chapter 4E.

18 On completion, lower the vehicle, and fill

the engine with oil as described in Chapter 1.

Reconnect the battery negative lead.

14 Oil pump -

removal and refitting

3

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Remove the auxiliary drivebelt (see Chap-

ter 1).

3 Remove the crankshaft pulley (Section 6),

the timing belt covers (Section 7), the timing

belt, crankshaft sprocket and thrustwasher

(Sections 8 and 9), and the sump (Section 13).

4 Unscrew the retaining nut/bolts and remove

the oil pick-up pipe (see illustration).

5 Unbolt and withdraw the oil pump from the

front face of the engine. Clean the oil pump

for inspection. Refer to Section 15 for the

inspection procedures. The oil seal in the oil

pump housing should always be renewed

(Section 16).

Refitting

6 Before refitting the oil pump and the

associated fittings, clean off the respective

mating faces. A new oil pump gasket must be

obtained, as well as the seals and gaskets for

the other associated components to be

refitted.

7 When refitting the oil pump, precautionary

measures must be taken to avoid the

possibility of damaging the new oil seal as it is

engaged over the shoulder and onto its journal

on the crankshaft. Extract the Woodruff key

from the groove in the crankshaft, then cut a

thin plastic guide which will furl over and

protrude beyond the shoulder of the seal

journal on the crankshaft (see illus-

tration 14.9b) . This will allow the seal to ride

over the step, and avoid damaging the seal lip

as it is pushed into position on the crankshaft.

8 If a new oil pump is being fitted or the old

pump is to be re-used after cleaning and

inspection, first prime the pump by squirting

clean engine oil into it, and simultaneously

rotating the drivegear a few times (see

illustration) .

CVH and PTE engine in-car repair procedures 2B•11

13.14 Sump bolt tightening sequence

A Crankshaft pulley end of engine

Circled numbers indicate locations of studs

for correct sump alignment (see text)13.11 Sealing compound application points prior to refitting the sump

A Crankcase-to-oil pump housing

B Crankcase-to-rear oil seal carrier13.7 Removing the clutch cover plate

14.8 Prime the oil pump prior to fitting14.4 Removing the oil inlet pipe

2B

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 62 of 296

and evenly the pressure of the valve springs

on the caps.

5Withdraw the caps, noting their markings

and the presence of the locating dowels, then

remove the camshafts and withdraw their oil

seals. The inlet camshaft can be identified by

the reference lobe for the camshaft position

sensor; therefore, there is no need to mark the

camshafts (see illustrations) .

6 Obtain sixteen small, clean containers, and

number them 1 to 16. Using a rubber sucker,

withdraw each hydraulic tappet in turn, invert

it to prevent oil loss, and place it in its

respective container, which should then be

filled with clean engine oil (see illustrations).

Do not interchange the hydraulic tappets, or

the rate of wear will be much increased. Do

not allow them to lose oil, or they will take a

long time to refill on restarting the engine,

resulting in incorrect valve clearances.

Inspection

7 With the camshafts and hydraulic tappets

removed, check each for signs of obvious

wear (scoring, pitting etc) and for ovality, and

renew if necessary.

8 Measure the outside diameter of each

tappet (see illustration) - take measurements

at the top and bottom of each tappet, then a

second set at right-angles to the first; if any

measurement is significantly different from the

others, the tappet is tapered or oval and must be renewed. If the necessary equipment is

available, measure the inside diameter of the

corresponding cylinder head bore. Compare

the measurements obtained to those given

in the Specifications Section of this Chapter; if

the tappets or the cylinder head bores are

excessively worn, new tappets and/or a new

cylinder head will be required.

9

If the engine’s valve components have

sounded noisy, particularly if the noise

persists after initial start-up from cold, there is

reason to suspect a faulty hydraulic tappet.

Only a good mechanic experienced in these

engines can tell whether the noise level is

typical, or if renewal of one or more of the

tappets is warranted. If faulty tappets are

diagnosed, and the engine’s service history is

unknown, it is always worth trying the effect of

renewing the engine oil and filter (see Chap-

ter 1), using onlygood-quality engine oil of the

recommended viscosity and specification,

before going to the expense of renewing any

of the tappets - refer also to the advice in

Section 5 of this Chapter.

10 Visually examine the camshaft lobes for

score marks, pitting, galling (wear due to

rubbing) and evidence of overheating (blue,

discoloured areas). Look for flaking away of

the hardened surface layer of each lobe. If any

such signs are evident, renew the component

concerned. 11

Examine the camshaft bearing journals

and the cylinder head bearing surfaces for

signs of obvious wear or pitting. If any such

signs are evident, renew the component

concerned.

12 Using a micrometer, measure the

diameter of each journal at several points. If

the diameter of any one journal is less than

the specified value, renew the camshaft.

13 To check the bearing journal running

clearance, remove the hydraulic tappets, use

a suitable solvent and a clean lint-free rag to

clean carefully all bearing surfaces, then refit

the camshafts and bearing caps with a strand

of Plastigauge across each journal. Tighten

the bearing cap bolts to the specified torque

wrench setting (do not rotate the camshafts),

then remove the bearing caps and use the

scale provided to measure the width of the

compressed strands. Scrape off the

Plastigauge with your fingernail or the edge of

a credit card - don’t scratch or nick the

journals or bearing caps.

14 If the running clearance of any bearing is

found to be worn to beyond the specified

service limits, fit a new camshaft and

repeat the check; if the clearance is still

excessive, the cylinder head must be renewed.

15 To check camshaft endfloat, remove the

hydraulic tappets, clean the bearing surfaces

carefully, and refit the camshafts and bearing

Zetec engine in-car repair procedures 2C•9

11.6a Removing hydraulic tappets

11.5b Inlet camshaft has lobe for camshaft position sensor11.5a Note locating dowels when removing camshaft bearing caps

11.8 Use a micrometer to measurediameter of hydraulic tappets11.6b Hydraulic tappets must be stored as described in text

2C

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 65 of 296

25As the cylinder head is such a heavy and

awkward assembly to refit with manifolds, it is

helpful to make up a pair of guide studs from

two 10 mm (thread size) studs approximately

90 mm long, with a screwdriver slot cut in one

end - two old cylinder head bolts with their

heads cut off would make a good starting

point. Screw these guide studs, screwdriver

slot upwards to permit removal, into the bolt

holes at diagonally-opposite corners of the

cylinder block surface (or into those where the

locating dowels are fitted); ensure that

approximately 70 mm of stud protrudes

above the gasket.

26 Refit the cylinder head, sliding it down the

guide studs (if used) and locating it on the

dowels. Unscrew the guide studs (if used)

when the head is in place.

27 Fit the new cylinder head bolts dry ( do not

oil their threads); carefully enter each into its

hole and screw it in, by hand only, until finger-

tight.

28 Working progressively and in the

sequence shown, use first a torque wrench,

then an ordinary socket extension bar and an

angle gauge, to tighten the cylinder head bolts

in the stages given in the Specifications

Section of this Chapter (see illustrations).

Note: Once tightened correctly, following this

procedure, the cylinder head bolts do not

require check-tightening, and must notbe re-

torqued.

29 Refit the hydraulic tappets (if removed),

the camshafts, their oil seals and sprockets

(see Sections 11, 10 and 9, as appropriate).

Temporarily refit the crankshaft pulley, and

rotate the crankshaft clockwise to return the

pulley notches to the TDC position described

in Section 3.

30 Refit the earth lead to the lifting eye

31 Refit the timing belt and covers, checking

the camshaft alignment (valve timing) and

setting the timing belt tension, as described in

Section 8.

32 The remainder of reassembly is the

reverse of the removal procedure, noting the

following points:

a) Tighten all fasteners to the torque wrench settings specified.

b) Refill the cooling system, and top-up the engine oil (see Chapter 1 and “Weekly

Checks”).

c) Check all disturbed joints for signs of oil or coolant leakage, once the engine has

been restarted and warmed-up to normal

operating temperature.

d) If the power steering hoses where

disconnected, bleed the system as

described in Chapter 10 after

reconnection.

13 Sump -

removal and refitting

2

Removal

Note: The full procedure outlined below must

be followed, so that the mating surfaces can

be cleaned and prepared to achieve an oil-

tight joint on reassembly, and so that the

sump can be aligned correctly; depending on

your skill and experience, and the tools and

facilities available, it may be that this task can

be carried out only with the engine removed

from the vehicle. Note that the sump gasket

must be renewed whenever it is disturbed.

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Drain the engine oil, then clean and refit the

engine oil drain plug, tightening it to the

specified torque wrench setting. Although not

strictly necessary as part of the dismantling

procedure, owners are advised to remove and

discard the oil filter, so that it can be renewed

with the oil (see Chapter 1).

3 Refer to Chapter 5A and remove the starter

motor.

4 Remove the auxiliary drivebelt cover (see

Chapter 1).

5 Unplug the electrical connector(s) to

disconnect the oxygen sensor.

6 Unscrew the nuts to disconnect the

exhaust system front downpipe from the

manifold, then either unhook all the system’s

rubber mountings and withdraw the complete

exhaust system from under the vehicle, or

remove only the downpipe/catalytic converter

(see Chapter 4E for details). 7

Unscrew the sump-to-transmission bolts,

also any securing the engine/transmission

lower adapter plate.

8 Progressively unscrew the sump retaining

bolts. Break the joint by striking the sump with

the palm of the hand, then lower the sump

and withdraw it with the engine/transmission

lower adapter plate (where fitted); note the

presence of any shims between the sump and

transmission.

9 Remove and discard the sump gasket; this

must be renewed as a matter of course

whenever it is disturbed.

10 While the sump is removed, take the

opportunity to remove the oil pump pick-

up/strainer pipe and to clean it (see Sec-

tion 14).Refitting

11 On reassembly, thoroughly clean and

degrease the mating surfaces of the cylinder

block/crankcase and sump, then use a clean

rag to wipe out the sump and the engine’s

interior. If the oil pump pick-up/strainer pipe

was removed, fit a new gasket and refit the

pipe, tightening its screws to the specified

torque wrench setting. Fit the new gasket to

the sump mating surface so that the gasket

fits into the sump groove (see illustration).

12 If the sump is being refitted with the

engine/transmission still connected and in the

vehicle, proceed as follows:

a) Check that the mating surfaces of the sump, the cylinder block/crankcase and

2C•12 Zetec engine in-car repair procedures

13.11 Ensure gasket is located correctly in sump groove

12.28c . . . and to Stage 3 using angle gauge12.28b Tightening cylinder head bolts

(Stages 1 and 2) using torque wrench . . .12.28a Cylinder head bolt tightening sequence

Note: View from rear of vehicle

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 66 of 296

the transmission are absolutely clean and

flat. Any shims found on removal of the

sump must be refitted in their original

locations.

b) Apply a thin film of suitable sealant (Ford

recommend Hylosil 102) to the junctions

of the cylinder block/crankcase with the

oil pump and the crankshaft left-hand oil

seal carrier. Without delay - the sump

bolts must be fully tightened within 10 to

20 minutes of applying the sealant - offer

up the sump and engine/transmission

lower adapter plate, and refit the bolts,

tightening them lightly at first.

c) Ensuring that the engine/transmission

lower adapter plate is correctly located,

firmly press the sump against the

transmission, and tighten the

transmission-to-sump (ie, engine) bolts to

the specified torque wrench setting.

d) Without disturbing the position of the

sump, and working in a diagonal

sequence from the centre outwards,

tighten the sump bolts to the specified

torque wrench setting.

e) Proceed to paragraph 14.

13 If the sump is being refitted with the

engine and transmission separated (in or out

of the vehicle), proceed as follows:

a) Apply a thin film of suitable sealant (Ford recommend Hylosil 102) to the junctions

of the cylinder block/crankcase with the

oil pump and the crankshaft left-hand oil seal carrier (see illustration). Without delay

- the sump bolts must be fully tightened

within 10 to 20 minutes of applying the

sealant - offer up the sump to the cylinder

block/crankcase, and insert the sump

bolts, tightening them lightly at first.

b) Using a suitable straight edge to check

alignment across the flat-machined faces

of each, move the sump as necessary so

that its left-hand face - including any

shims found on removal - is flush with

that of the cylinder block/crankcase (see

illustration) . Without disturbing the

position of the sump, and working in a

diagonal sequence from the centre

outwards, tighten the sump bolts to the

specified torque wrench setting.

c) Check again that both faces are flush

before proceeding; if necessary, unbolt

the sump again, clean the mating

surfaces, and repeat the full procedure to

ensure that the sump is correctly aligned.

d) If it is not possible to achieve exact

alignment by moving the sump, shims are

available in thicknesses of 0.25 mm

(colour-coded yellow) or 0.50 mm (colour-

coded black) to eliminate the discrepancy

(see illustration) .

14 The remainder of reassembly is the

reverse of the removal procedure, noting the

following points.

a) Tighten all fasteners to the torque wrench settings specified. b)

Always renew any self-locking nuts

disturbed on removal.

c) Refill the cooling system (see Chapter 1).

d) Refill the engine with oil, remembering

that you are advised to fit a new filter (see

Chapter 1).

e) Check for signs of oil or coolant leaks once the engine has been restarted and

warmed-up to normal operating

temperature.

14 Oil pump - removal,

inspection and refitting

4

Removal

Note: While this task is theoretically possible

when the engine is in place in the vehicle, in

practice, it requires so much preliminary

dismantling, and is so difficult to carry out due

to the restricted access, that owners are

advised to remove the engine from the vehicle

first. Note, however, that the oil pump

pressure relief valve can be removed with the

engine in situ - see paragraph 8.

1 Remove the timing belt (see Section 8).

2 Withdraw the crankshaft sprocket and the

thrustwasher behind it, noting which way

round the thrustwasher is fitted (see Sec-

tion 9).

3 Remove the sump (see Section 13).

4 Undo the screws securing the oil pump

pick-up/strainer pipe to the pump, then

unscrew the nut and withdraw the oil pump

pick-up/strainer pipe. Discard the gasket.

5 Unbolt the pump from the cylinder

block/crankcase (see illustration). Withdraw

and discard the gasket, and remove the

crankshaft right-hand oil seal. Thoroughly

clean and degrease all components,

particularly the mating surfaces of the pump,

the sump, and the cylinder block/crankcase.

Inspection

6 Unscrew the Torx screws, and remove the

pump cover plate; noting any identification

marks on the rotors, withdraw the rotors (see

illustration) .

Zetec engine in-car repair procedures 2C•13

13.13c Sump-to-cylinder block/crankcase

alignment shims

1 Fitting points on sump 2 Shim13.13b Checking alignment of sump with cylinder block/crankcase13.13a Apply sealant (arrowed) as directed when refitting sump

14.6 Withdrawing oil pump inner rotor14.5 Unscrew bolts (arrowed) to remove oil pump

2C

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 69 of 296

4Check the mountings to see if the rubber is

cracked, hardened or separated from the

metal components. Sometimes, the rubber

will split right down the centre.

5 Check for relative movement between each

mounting’s brackets and the engine/

transmission or body (use a large screwdriver

or lever to attempt to move the mountings). If

movement is noted, lower the engine and

check-tighten the mounting fasteners.

Renewal

6 The engine mountings can be removed if

the weight of the engine/transmission is

supported by one of the following alternative

methods.

7 Either support the weight of the assembly

from underneath using a jack and a suitable

piece of wood between the jack saddle and

the sump or transmission (to prevent

damage), or from above by attaching a hoist

to the engine. A third method is to use a

suitable support bar with end pieces which

will engage in the water channel each side of

the bonnet lid aperture. Using an adjustable

hook and chain connected to the engine, the

weight of the engine and transmission can

then be taken from the mountings.

Engine front right-hand mounting

8 This mounting consists of a two-piece

bracket bolted to the inner wing panel,

connected by the bonded-rubber mounting

itself to a (Y-shaped) bracket, bolted (via the

alternator mounting bracket) to the cylinder

block (see illustration) .

9 Unscrew the three bolts securing the front

right-hand mounting bracket to the alternator

mounting bracket.

10 Unscrew the bolts securing the mounting

bracket to the inner wing panel and chassis

rail and withdraw the mounting assembly.

Engine rear right-hand mounting

11 This mounting consists of the bonded-

rubber mounting secured to the inner wing

panel by a (horizontal) bolt, accessible from

within the wheel arch, and a (vertical) stud, the

retaining nut of which is accessible from the

engine compartment. The mounting is bolted

to a bracket, which is in turn bolted to the

cylinder block.

12 Unbolt the mounting from the body by

unscrewing first the single nut (and washer)

immediately to the rear of the timing belt

cover, then the bolt in the wheel arch.

13 Unbolt the mounting from the cylinder

block bracket and withdraw the mounting

assembly.

Transmission bearer and mountings

14 On XR2i models, remove the front

suspension crossmember as described in

Chapter 10.

15 Unscrew and remove the two nuts

securing the mountings (front and rear) to the

transmission bearer

16 Support the transmission bearer, then

undo and remove the four retaining bolts from

the floorpan, two at the front and two at the

rear, and lower the transmission bearer from

the vehicle. Note plate fitment, as applicable,

for reassembly.

17 To remove the mountings from the

transmission, unscrew the upper bolt and

lower stud (front mounting) or the three nuts

(rear mounting) and withdraw the relevant

mounting and bracket assembly from the

transmission.

All mountings

18 Refitting of all mountings is a reversal of

removal. Make sure that the original sequence

of assembly of washers and plates is

maintained.

19 Do not fully tighten any mounting bolts

until they are all located. As the mounting

bolts and nuts are tightened, check that the

mounting rubbers do not twist.

17 Flywheel/driveplate -

removal, inspection and

refitting

3

Removal

1 Remove the transmission (see the relevant

Part of Chapter 7).

2 Where appropriate, remove the clutch

(Chapter 6).

3 Use a centre-punch or paint to make alignment marks on the flywheel/driveplate

and crankshaft, to ensure correct alignment

during refitting.

4

Prevent the flywheel/driveplate from turning

by locking the ring gear teeth, or by bolting a

strap between the flywheel/driveplate and the

cylinder block/crankcase. Slacken the bolts

evenly until all are free.

5 Remove each bolt in turn, and ensure that

new replacements are obtained for

reassembly; these bolts are subjected to

severe stresses, and so must be renewed,

regardless of their apparent condition,

whenever they are disturbed.

6 Noting the reinforcing plate (automatic

transmission models only), withdraw the

flywheel/driveplate; do not drop it - it is very

heavy.

Inspection

7 Clean the flywheel/driveplate to remove

grease and oil. Inspect the surface for cracks,

rivet grooves, burned areas and score marks.

Light scoring can be removed with emery

cloth. Check for cracked and broken ring gear

teeth. Lay the flywheel/driveplate on a flat

surface, and use a straight edge to check for

warpage.

8 Clean and inspect the mating surfaces of

the flywheel/driveplate and the crankshaft. If

the crankshaft left-hand seal is leaking, renew

it (see Section 15) before refitting the

flywheel/driveplate.

9 While the flywheel/driveplate is removed,

clean carefully its inboard (right-hand) face,

particularly the recesses which serve as the

reference points for the crankshaft speed/

position sensor. Clean the sensor’s tip, and

check that the sensor is securely fastened.

Refitting

10 On refitting, ensure that the engine/

transmission adapter plate is in place (where

necessary), then fit the flywheel/driveplate to

the crankshaft so that all bolt holes align - it

will fit only one way - check this using the

marks made on removal. Do not forget the

reinforcing plate (automatic transmission

models).

11 Lock the flywheel/driveplate by the

method used on dismantling. Working in a

diagonal sequence to tighten them evenly,

and increasing to the final amount in two or

three stages, tighten the new bolts to the

specified torque wrench setting.

12 The remainder of reassembly is the

reverse of the removal procedure, referring to

the relevant text for details where required.

2C•16 Zetec engine in-car repair procedures

16.8 Engine front right-hand mounting

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su