check oil FORD FIESTA 2007 Owner's Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 900 of 1226

Engine Emission Control - 2.OL Duratec-HE

303-08B-6

(MI41 303-08B-6

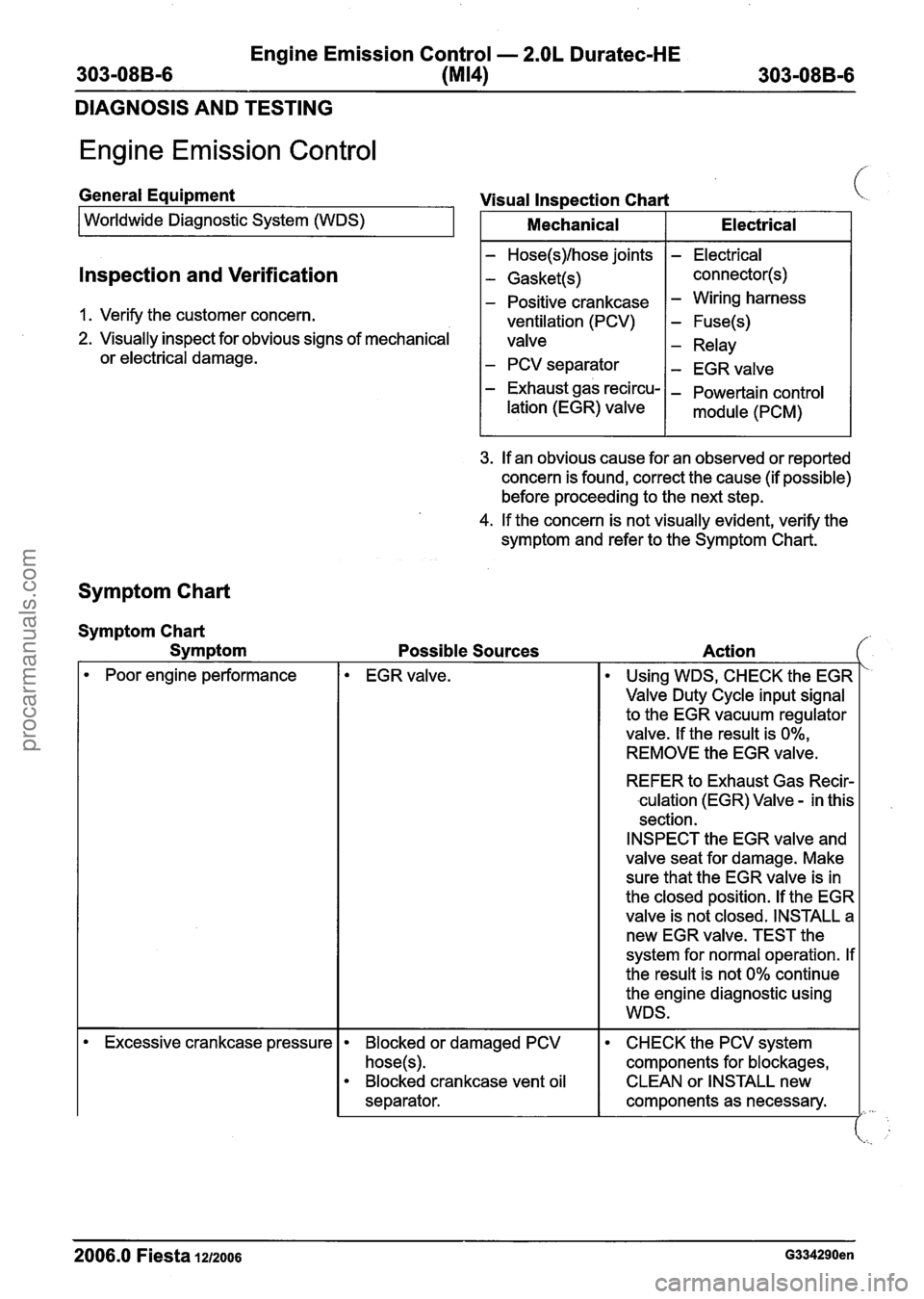

DIAGNOSIS AND TESTING

Engine Emission Control

lnspection and Verification

General Equipment Visual Inspection Chart L..

I. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical

or electrical damage.

Worldwide Diagnostic System

(WDS)

- Hose(s)/hose joints

- Gasket(s)

- Positive crankcase

ventilation (PCV)

valve

- PCV separator

Mechanical

- Exhaust gas recircu-

lation (EGR) valve

Electrical

- Electrical

con

nector(s)

- Wiring harness

- Fuse(s)

- Relay

- EGRvalve

- Powertain control

module (PCM)

3. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the concern is not visually evident, verify the

symptom and refer to the Symptom Chart.

Symptom Chart

Symptom Chart

Symptom Possible Sources Action

I

Poor engine performance EGR valve.

Using WDS, CHECK the EGR

Valve Duty Cycle input signal

I to the EGR vacuum regulator

valve. If the result is 0%,

REMOVE the EGR valve.

REFER to Exhaust Gas Recir-

culation (EGR) Valve

- in this

section.

INSPECT the EGR valve and

valve seat for damage. Make

sure that the EGR valve is in

the closed position. If the EGR

valve is not closed. INSTALL

a

new EGR valve. TEST the

system for normal operation. If

the result is not 0% continue

the engine diagnostic using

WDS.

2006.0 Fiesta 1212006 G334290en

Excessive crankcase pressure Blocked or damaged PCV

hose(s).

Blocked crankcase vent oil

separator. CHECK

the PCV system

components for blockages, CLEAN or INSTALL new

components as necessary.

procarmanuals.com

Page 912 of 1226

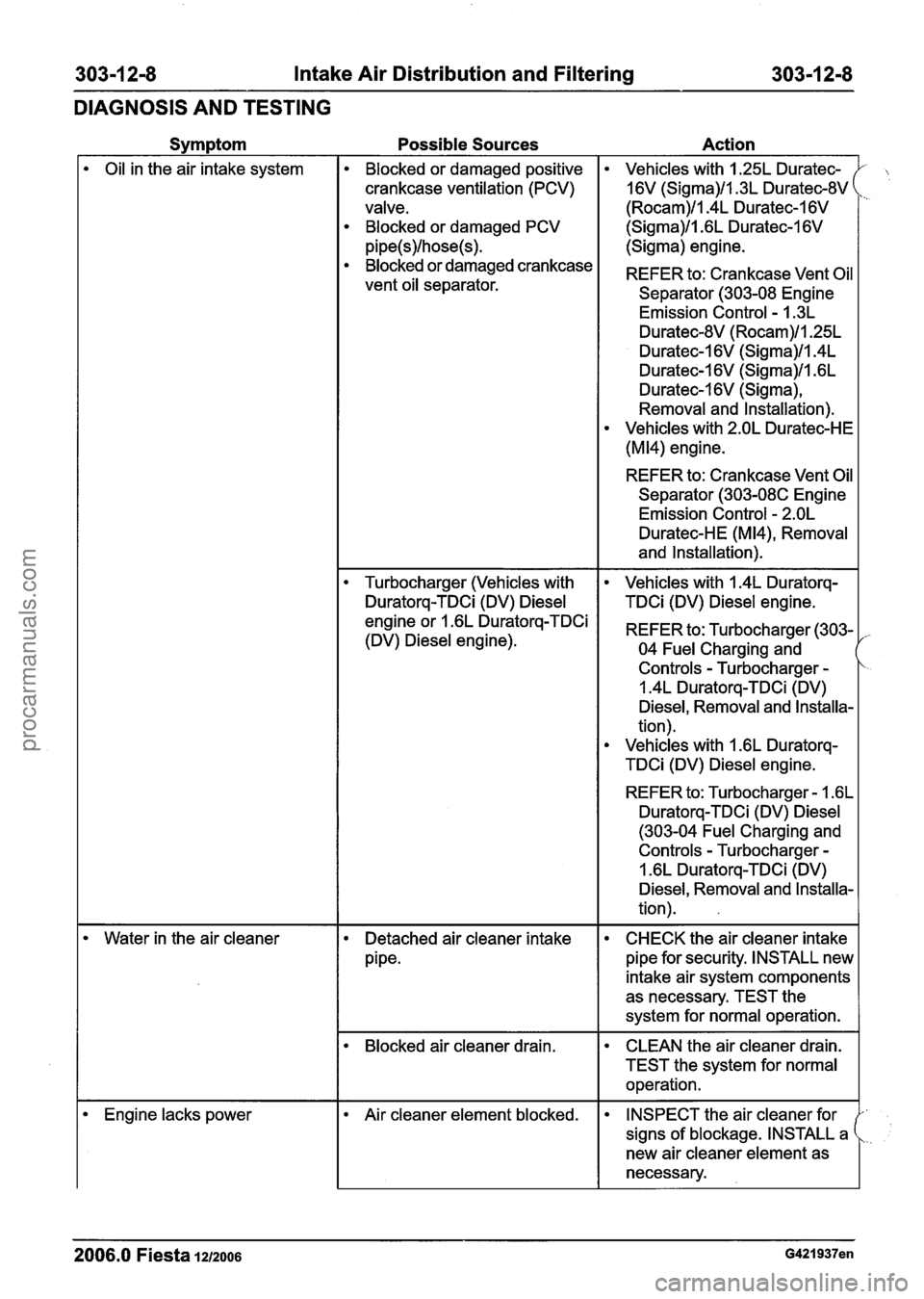

303-1 2-8 Intake Air Distribution and Filtering 303-1 2-8

DIAGNOSIS AND TESTING

Svm~tom Possible Sources Action

Oil in the air intake system Blocked or damaged positive

crankcase

ventilation (PCV)

valve.

Blocked or damaged PCV

pipe(s)/hose(s).

Blocked or damaged crankcase

vent

oil separator.

Vehicles with 1.25L Duratec-

16V

(Sigma)/l.3L Duratec-8V (

(Rocam)/l.4L Duratec-I 6V

(Sigma)/l .6L Duratec-1 6V

(Sigma) engine.

REFER to: Crankcase Vent

Oil

Separator (303-08 Engine

Emission

Control - 1.3L

Duratec-8V (Rocam)/l.25L

Duratec-I 6V (Sigma)/l.4L

Duratec-I 6V (Sigma)/l .6L

Duratec-1

6V (Sigma),

Removal and Installation).

Vehicles with 2.0L Duratec-HE

(M14) engine.

REFER to: Crankcase Vent

Oil

Separator (303-08C Engine

Emission

Control - 2.OL

Duratec-HE (M14), Removal

and Installation).

Turbocharger (Vehicles with

Duratorq-TDCi (DV)

Diesel

engine or 1.6L Duratorq-TDCi

(DV)

Diesel engine).

Vehicles with 1.4L Duratorq-

TDCi (DV)

Diesel engine.

REFER to: Turbocharger (303- 04

Fuel Charging and

Controls - Turbocharger -

1.4L Duratorq-TDCi (DV)

Diesel, Removal and Installa-

tion).

Vehicles with I .6L Duratorq-

TDCi (DV)

Diesel engine.

REFER to: Turbocharger

- I .6L

Duratorq-TDCi (DV)

Diesel

(303-04 Fuel Charging and

Controls - Turbocharger -

1.6L Duratorq-TDCi (DV)

Diesel, Removal and Installa-

tion).

Water in the air cleaner Detached air cleaner intake

pipe. CHECK

the air cleaner intake

pipe for security. INSTALL new

intake air system components

as necessary. TEST the

system for

normal operation.

Blocked air cleaner drain. CLEAN

the air cleaner drain.

TEST the system for

normal

operation.

Engine lacks power

Air cleaner element blocked. INSPECT the air cleaner for ,.

new air cleaner element as

i signs of blockage. INSTALL a .

necessary. I_

2006.0 Fiesta 1212006 G421937en

procarmanuals.com

Page 939 of 1226

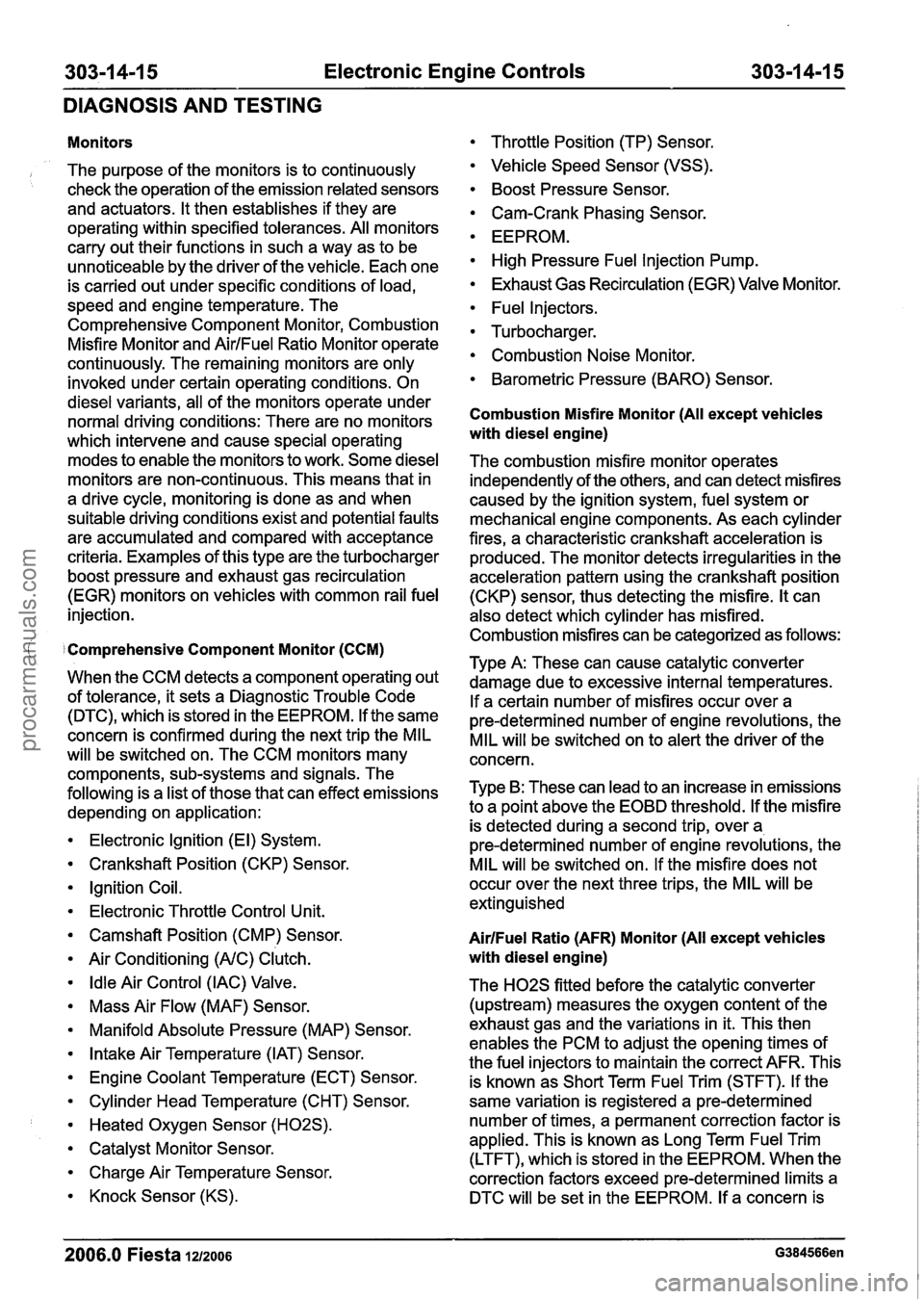

303-1 4-1 5 Electronic Engine Controls 303-1 4-1 5

DIAGNOSIS AND TESTING

Monitors

The purpose of the monitors is to continuously

check the operation of the emission related sensors

and actuators. It then establishes if they are

operating within specified tolerances. All monitors

carry out their functions in such a way as to be

unnoticeable by the driver of the vehicle. Each one

is carried out under specific conditions of load,

speed and engine temperature. The Comprehensive Component Monitor, Combustion

Misfire Monitor and

AirIFuel Ratio Monitor operate

continuously. The remaining monitors are only

invoked under certain operating conditions. On

diesel variants, all of the monitors operate under

normal driving conditions: There are no monitors

which intervene and cause special operating

modes to enable the monitors to work. Some diesel

monitors are non-continuous. This means that in

a drive cycle, monitoring is done as and when

suitable driving conditions exist and potential faults

are accumulated and compared with acceptance

criteria. Examples of this type are the turbocharger

boost pressure and exhaust gas recirculation

(EGR) monitors on vehicles with common rail fuel

injection.

( Comprehensive Component Monitor (CCM)

When the CCM detects a component operating out

of tolerance, it sets a Diagnostic Trouble Code

(DTC), which is stored in the EEPROM. If the same

concern is confirmed during the next trip the MIL

will be switched on. The CCM monitors many

components, sub-systems and signals. The

following is a list of those that can effect emissions

depending on application:

Electronic Ignition (El) System.

Crankshaft Position (CKP) Sensor.

Ignition Coil.

Electronic Throttle Control Unit.

Camshaft Position (CMP) Sensor.

Air Conditioning

(AIC) Clutch.

Idle Air Control (IAC) Valve.

Mass Air Flow (MAF) Sensor.

Manifold Absolute Pressure (MAP) Sensor.

Intake Air Temperature (IAT) Sensor.

Engine Coolant Temperature (ECT) Sensor.

Cylinder Head Temperature (CHT) Sensor.

Heated Oxygen Sensor

(H02S).

Catalyst Monitor Sensor.

Charge Air Temperature Sensor.

Knock Sensor (KS).

Throttle Position (TP) Sensor.

Vehicle Speed Sensor (VSS).

Boost Pressure Sensor.

Cam-Crank Phasing Sensor.

EEPROM.

High Pressure Fuel Injection Pump.

Exhaust Gas Recirculation (EGR) Valve Monitor.

Fuel Injectors.

Turbocharger.

Combustion Noise Monitor.

Barometric Pressure (BARO) Sensor.

Combustion Misfire Monitor (All except vehicles

with diesel engine)

The combustion misfire monitor operates independently of the others, and can detect misfires

caused by the ignition system, fuel system or

mechanical engine components. As each cylinder

fires, a characteristic crankshaft acceleration is

produced. The monitor detects irregularities in the

acceleration pattern using the crankshaft position (CKP) sensor, thus detecting the misfire. It can

also detect which cylinder has misfired.

Combustion misfires can be categorized as follows:

Type

A: These can cause catalytic converter

damage due to excessive internal temperatures.

If a certain number of misfires occur over a

pre-determined number of engine revolutions, the

MIL will be switched on to alert the driver of the

concern.

Type B: These can lead to an increase in emissions

to a point above the EOBD threshold. If the misfire

is detected during a second trip, over a,

pre-determined number of engine revolutions, the

MIL will be switched on. If the misfire does not

occur over the next three trips, the MIL will be

extinguished

AirIFuel Ratio (AFR) Monitor (All except vehicles

with diesel engine)

The H02S fitted before the catalytic converter

(upstream) measures the oxygen content of the

exhaust gas and the variations in it. This then

enables the PCM to adjust the opening times of

the fuel injectors to maintain the correct AFR. This

is known as Short Term Fuel Trim (STFT). If the

same variation is registered a pre-determined

number of times, a permanent correction factor is

applied. This is known as Long Term Fuel Trim

(LTFT), which is stored in the EEPROM. When the

correction factors exceed pre-determined limits a

DTC will be set in the EEPROM. If a concern is

2006.0 Fiesta 1212006 G384566en

procarmanuals.com

Page 943 of 1226

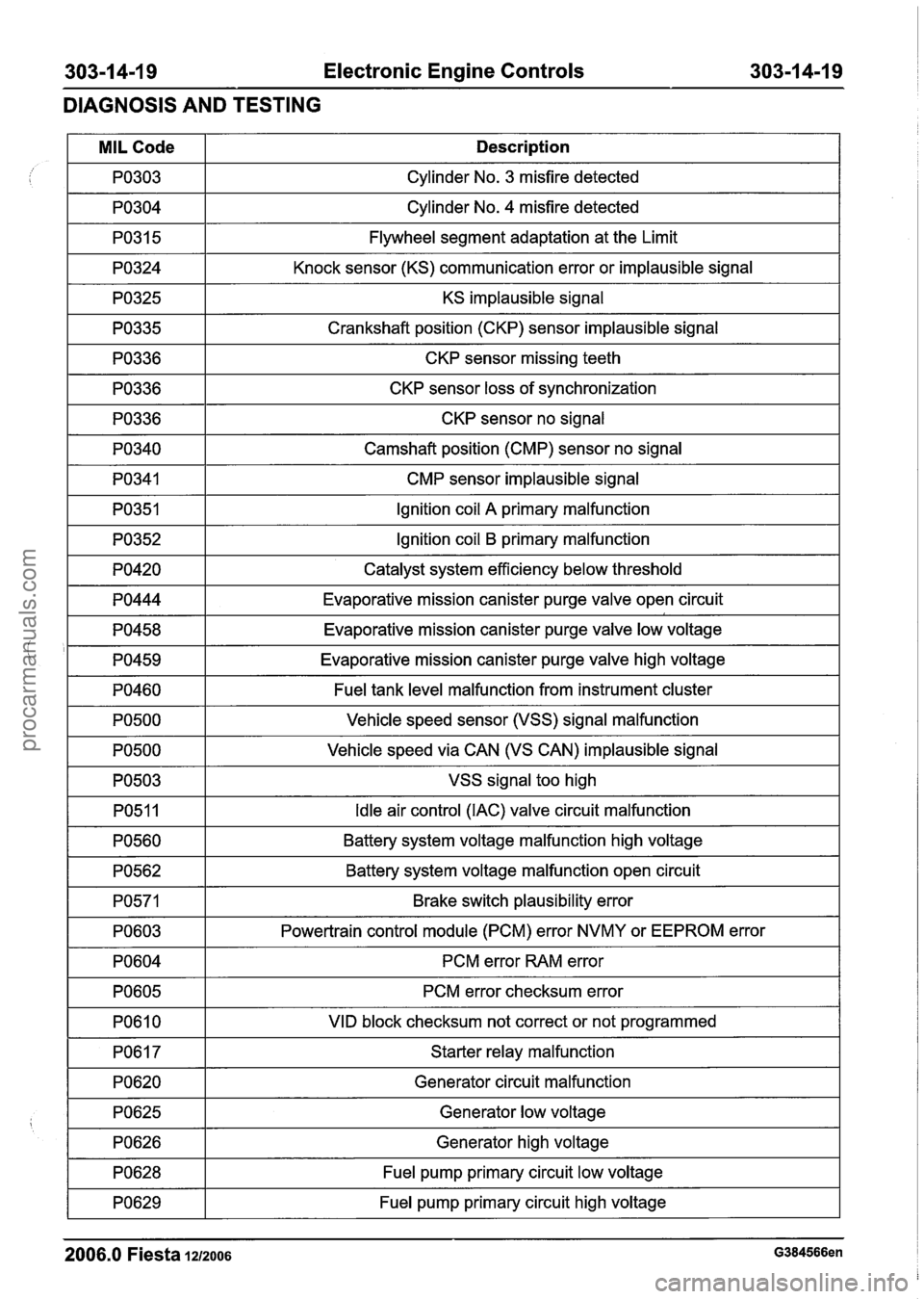

Electronic Engine Controls

DIAGNOSIS AND TESTING

I PO304 I Cylinder No. 4 misfire detected I

/ I

KS implausible signal I

MIL Code

PO303

PO31 5

PO324

1 PO335 1 Crankshaft position (CKP) sensor implausible signal I

Description

Cylinder No. 3 misfire detected

Flywheel segment adaptation at the Limit

Knock sensor (KS) communication error or implausible signal

1 PO336 1 CKP sensor missing teeth I

1 PO336 1 CKP sensor loss of synchronization I

1 PO336 1 CKP sensor no signal I

I PO340 I Camshaft position (CMP) sensor no signal I

I PO341 I CMP sensor implausible signal I

I PO351 I Ignition coil A primary malfunction I

1 PO352 1 Ignition coil B primary malfunction I

I PO420 I Catalyst system efficiency below threshold I

1 PO444 1 Evaporative mission canister purge valve open circuit I

1 PO458 1 Evaporative mission canister purge valve low voltage I

I '1 PO459 1 Evaporative mission canister purge valve high voltage I

I PO460 I Fuel tank level malfunction from instrument cluster I

-3 I VSS signal too high I

PO500

PO500

Vehicle speed sensor (VSS) signal malfunction

Vehicle speed via CAN (VS CAN) implausible signal

PO51 1

PO560

I PO603 I Powertrain control module (PCM) error NVMY or EEPROM error 1

Idle air control (IAC) valve circuit malfunction

Battery system voltage malfunction high voltage

PO562

PO571

I PO604 I PCM error RAM error I

Battery system voltage malfunction open circuit

Brake switch plausibility error

PO605 I PCM error checksum error I

I PO610 I VID block checksum not correct or not programmed I

I PO617 I Starter relay malfunction I

I PO620 I Generator circuit malfunction I

1 PO628 1 Fuel pump primary circuit low voltage I

I

7 1 Fuel pump primary circuit high voltage I

2006.0 Fiesta 1212006 G384566en

PO625

PO626

Generator low voltage

Generator high voltage

procarmanuals.com

Page 1008 of 1226

Automatic TransmissionlTransaxle -

Vehicles With: 4-Speed Automatic

307-01 -48 Transmission (AW81-40) 307-01 -48

DIAGNOSIS AND TESTING

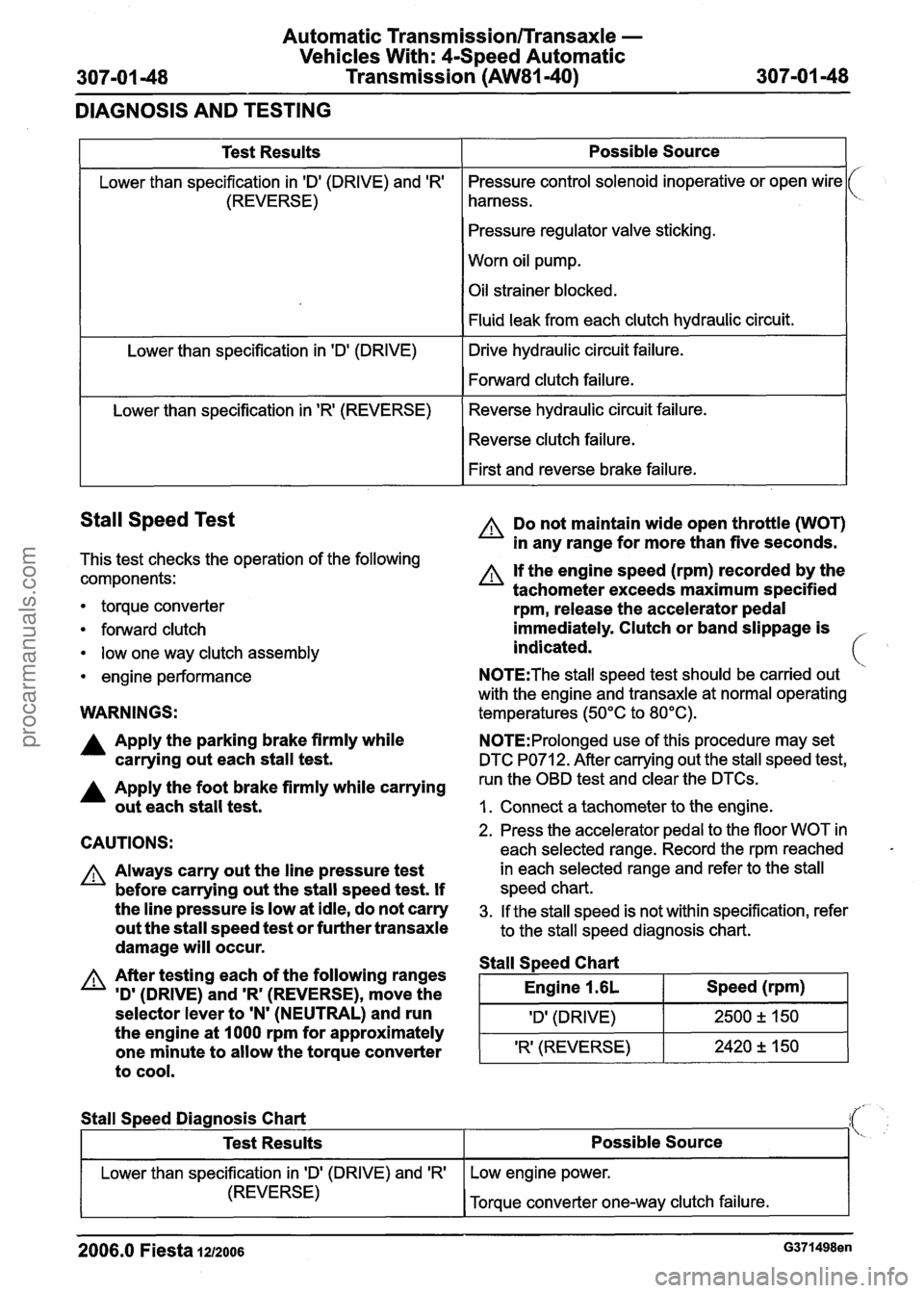

Stall Speed Test

This test checks the operation of the following

components:

1

Test Results

Lower than specification in 'Dl (DRIVE) and 'R'

(REVERSE)

Lower than specification in

'Dl (DRIVE)

Lower than specification in

'R' (REVERSE)

torque converter

forward clutch

low one way clutch assembly

engine performance

Possible Source

Pressure control solenoid inoperative or open wire

harness.

Pressure regulator valve sticking.

Worn oil pump.

Oil strainer blocked.

Fluid leak from each clutch hydraulic circuit.

Drive hydraulic circuit failure.

Forward clutch failure.

Reverse hydraulic circuit failure. Reverse clutch failure.

First and reverse brake failure.

WARNINGS:

A Do not maintain wide open throttle (WOT)

in any range for more than five seconds.

A If the engine speed (rpm) recorded by the

tachometer exceeds maximum specified

rpm, release the accelerator pedal

immediately. Clutch or band slippage is

indicated.

N0TE:The stall speed test should be carried out

with the engine and transaxle at normal operating

temperatures (50°C to 80°C).

A Apply the parking brake firmly while N0TE:Prolonged use of this procedure may set

carrying out each stall test. DTC PO71 2. After carrying out the stall speed test,

A Apply the foot brake firmly while carrying run the OBD test and clear the DTCs.

out each stall test. I. Connect a tachometer to the engine.

CAUTIONS:

A Always carry out the line pressure test

before carrying out the stall speed test. If

the line pressure is low at idle, do not carry

out the stall speed test or further transaxle

damage will occur.

A After testing each of the following ranges

'D'

(DRIVE) and 'R' (REVERSE), move the

selector lever to

'N' (NEUTRAL) and run

the engine at 1000 rpm for approximately

one minute to allow the torque converter

to cool.

2. Press the accelerator pedal to the floor WOT in

each selected range. Record the rpm reached

in each selected range and refer to the stall

speed chart.

3. If the stall speed is not within specification, refer

to the stall speed diagnosis chart.

Stall S~eed Chart

I Engine 1.6L I Speed (rpm) I

I 'Dl (DRIVE) I 2500 2 150 1

'R' (REVERSE) 2420 +, 150 -

Stall

Speed Diagnosis Chart

2006.0 Fiesta 1212006 G371498en

Test Results

Lower than specification in ID' (DRIVE) and 'R'

(REVERSE)

Possible Source

Low engine power.

Torque converter one-way clutch failure.

procarmanuals.com

Page 1011 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -51 Transmission (AW81-40) 307-01 -51 -

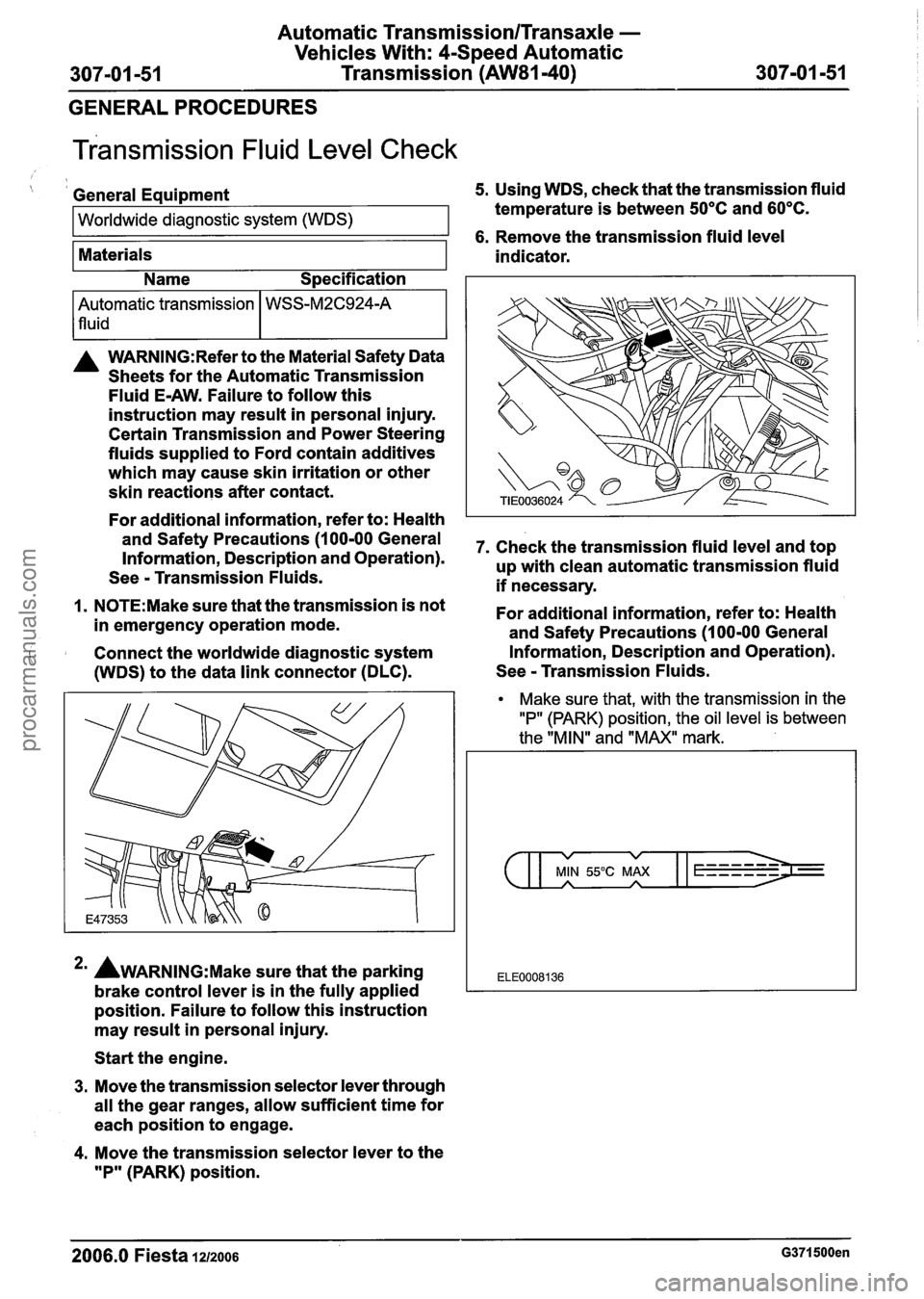

GENERAL PROCEDURES

~ransmission Fluid Level Check

( I General Equipment 5. Using WDS, check that the transmission fluid

Worldwide diagnostic system (WDS) temperature is between 50°C and 60°C.

1 6. Remove the transmission fluid level

Materials

A WARN1NG:Refer to the Material Safety Data

Sheets for the Automatic Transmission

Fluid

E-AW. Failure to follow this

instruction may result in personal injury.

Certain Transmission and Power Steering

fluids supplied to Ford contain additives

which may cause skin irritation or other

skin reactions after contact.

For additional information, refer to: Health

and Safety Precautions (1 00-00 General

Information, Description and Operation).

See

- Transmission Fluids.

1. N0TE:Make sure that the transmission is not

in emergency operation mode.

Connect the worldwide diagnostic system

(WDS) to the data link connector (DLC). indicator.

Automatic transmission

lfluid

*' AWARNING:M~~~ sure that

the parking

brake control lever is in the fully applied

position. Failure to follow this instruction

may result in personal injury.

Name

Specification

WSS-M2C924-A

Start the engine.

3. Move the transmission selector lever through

all the gear ranges, allow sufficient time for

each position to engage.

4. Move the transmission selector lever to the

"P" (PARK) position. 7.

Check the transmission fluid level and top

up with clean automatic transmission fluid

if necessary.

For additional information, refer to: Health

and Safety Precautions (1 00-00 General

Information, Description and Operation).

See

- Transmission Fluids.

Make sure that, with the transmission in the

"P" (PARK) position, the oil level is between

the "MIN" and "MAX" mark.

v v

MIN 55°C MAX A A

ELE0008136

2006.0 Fiesta 1212006 G371500en

procarmanuals.com

Page 1029 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

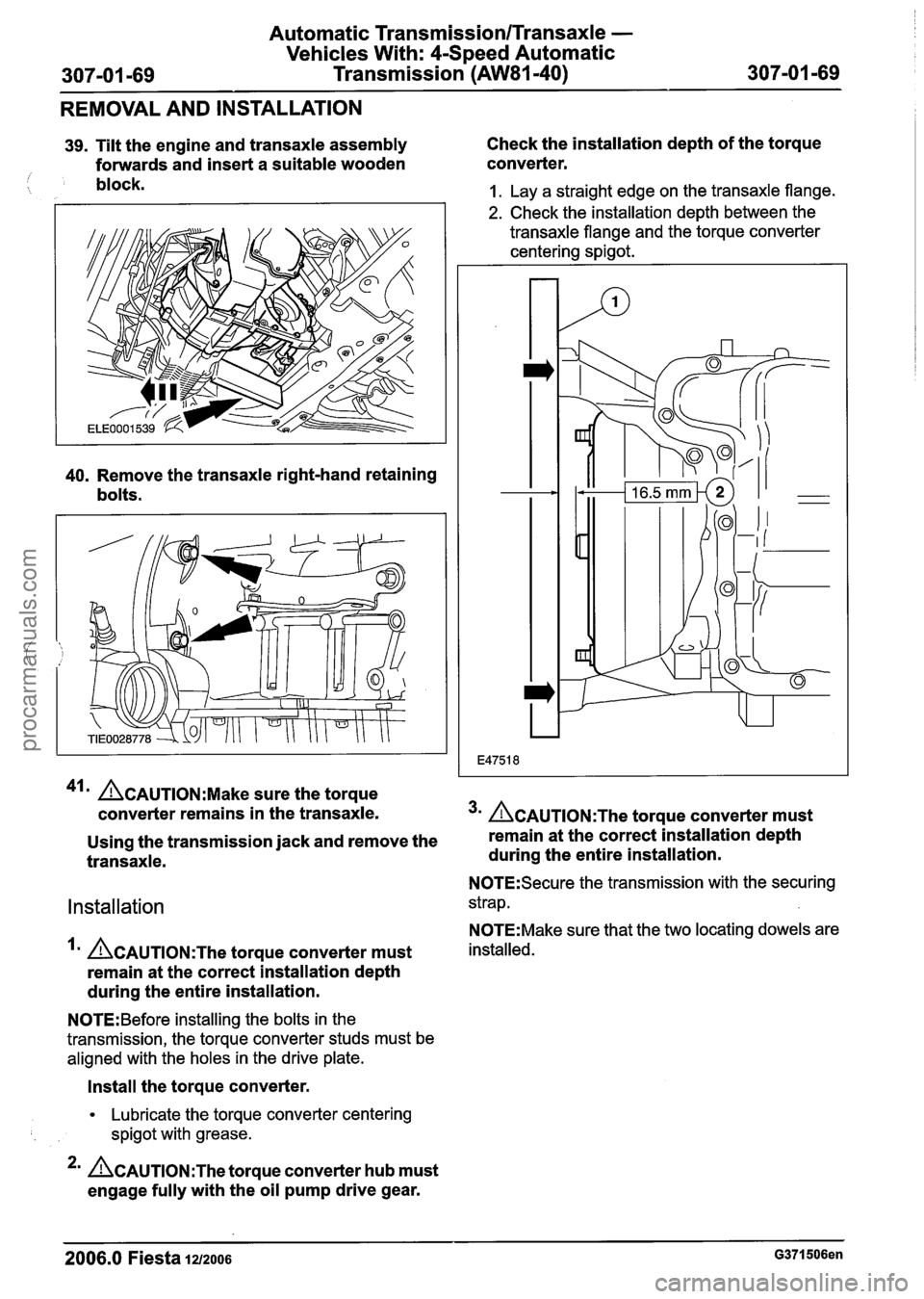

REMOVAL AND INSTALLATION

39. Tilt the engine and transaxle assembly Check

the installation depth of the torque

forwards and insert a suitable wooden converter.

/ block. 1. Lay

a straight edge on the transaxle flange.

2. Check the installation depth between the

transaxle flange and the torque converter

centering spigot.

40. Remove the transaxle right-hand retaining

bolts.

41m ~CAUTION:M~~~ sure the torque

converter remains in the transaxle.

3m ~CAUTION:T~~ torque converter must

Using the transmission jack and remove the remain

at the correct installation depth

transaxle. during the entire installation.

N0TE:Secure the transmission with the securing

Installation strap.

N0TE:Make sure that the two locating dowels are

ACAUTION:T~~ torque converter must installed.

remain at the correct installation depth

during the entire installation.

N0TE:Before installing the bolts in the

transmission, the torque converter studs must be

aligned with the holes in the drive plate.

Install the torque converter.

Lubricate the torque converter centering

spigot with grease.

*' ACAUTION:T~~ torque converter hub must

engage fully with the oil pump drive gear.

2006.0 Fiesta 1212006 G371506en

procarmanuals.com

Page 1061 of 1226

Manual Transmission/Transaxle and Clutch -

308-00-3 General Information 308-00-3

DIAGNOSIS AND TESTING

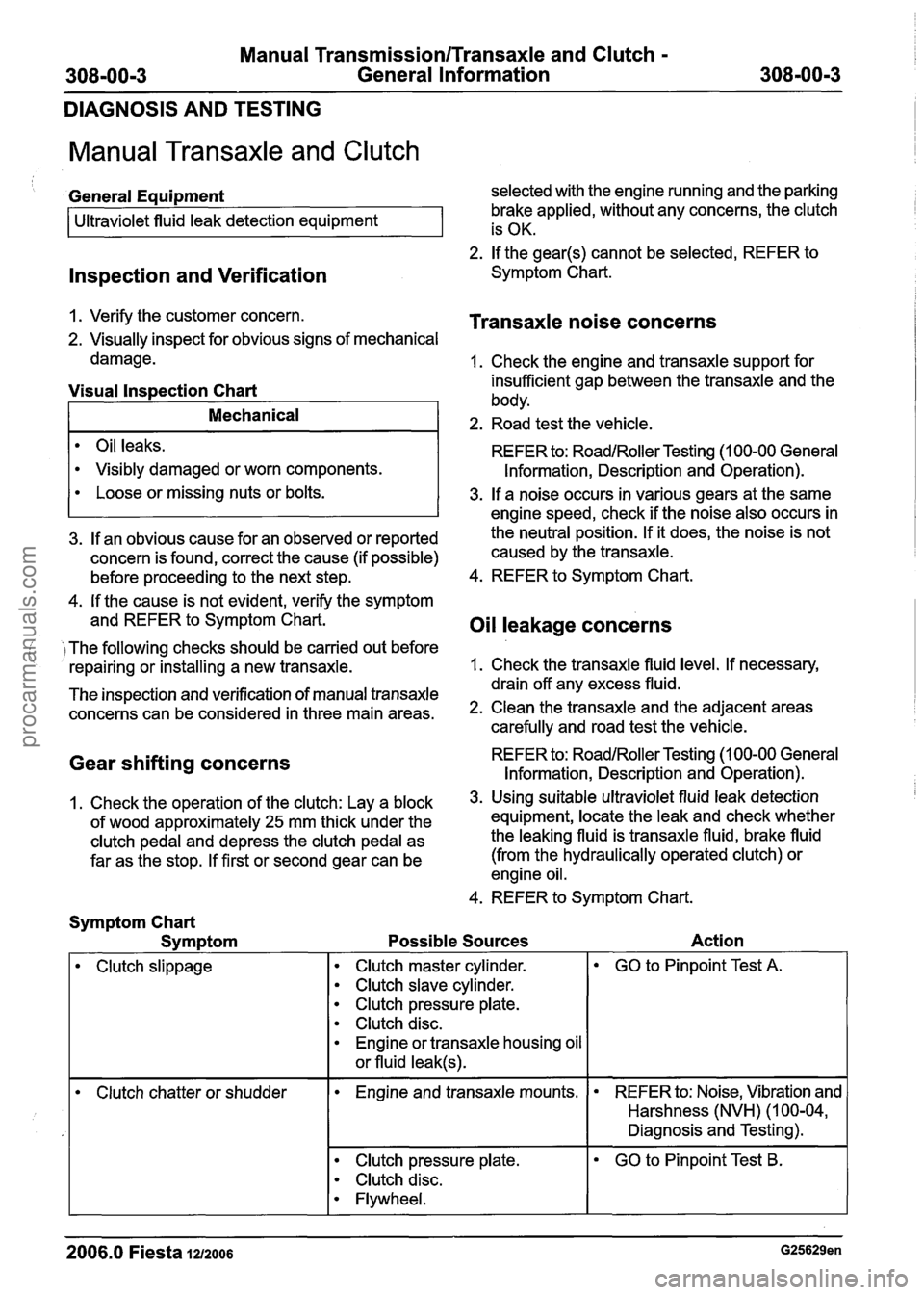

Manual Transaxle and Clutch

lnspection and Verification

General Equipment selected with the engine running and the parking

brake applied, without any concerns, the clutch

2. If the gear@) cannot be selected, REFER to

Symptom Chart.

Ultraviolet

fluid leak detection equipment

1. Verify the customer concern.

Transaxle noise concerns

2. Visually inspect for obvious signs of mechanical is

OK.

damage. 1. Check the engine and transaxle support for

Oil leaks.

Visibly damaged or worn components.

Visual lnspection Chart insufficient gap between the transaxle and the

body.

REFER to:

RoadlRoller Testing (1 00-00 General

Information, Description and Operation).

Mechanical 2. Road test the vehicle.

4. If the cause is not evident, verify the symptom

and REFER to Symptom Chart.

Oil leakage concerns

Loose or missing nuts or bolts.

( I The following checks should be carried out before

repairing or installing a new transaxle. 1.

Check the transaxle fluid level. If necessary,

3. If a noise occurs in various gears at the same

- - drain off any excess fluid.

The inspection and verification of manual transaxle

concerns can be considered in three main areas. 2. Clean the transaxle and the adjacent areas

carefully and road test the vehicle.

engine speed,

check if the noise also occurs in

3. If an obvious cause for an observed or reported the neutral position.

If it does, the noise is not

concern is found, correct the cause (if possible) caused

by the transaxle.

before proceeding to the next step. 4.

REFER to Symptom Chart.

Gear shifting concerns REFER to: RoadlRoller Testing (1 00-00 General

Information, Description and Operation).

1, Check the operation of the clutch: Lay a block 3. U~ing suitable ultraviolet fluid leak detection

of wood approximately

25 mm thick under the equipment, locate

the leak and check whether

clutch pedal and depress the clutch pedal as the leaking fluid

is transaxle fluid, brake fluid

far as the stop. If first or second gear can be (from the hydraulically operated clutch)

or

engine oil.

4. REFER to Symptom Chart.

Symptom Chart

Symptom Possible Sources Action

I

Clutch slippage Clutch master

cylinder.

Clutch slave cylinder.

Clutch pressure plate.

Clutch disc.

Engine or transaxle housing oil

or fluid

leak@).

GO to Pinpoint Test A.

Clutch chatter or shudder Engine and transaxle

mounts. REFER to:

Noise, Vibration and

Harshness (NVH) (1 00-04,

Diagnosis and Testing).

Clutch pressure plate.

Clutch disc.

Flywheel.

--

GO to Pinpoint Test B.

- -

2006.0 Fiesta 1212006 G25629en

procarmanuals.com

Page 1065 of 1226

Manual TransmissionlTransaxle and Clutch -

308-00-7 General Information 308-00-7

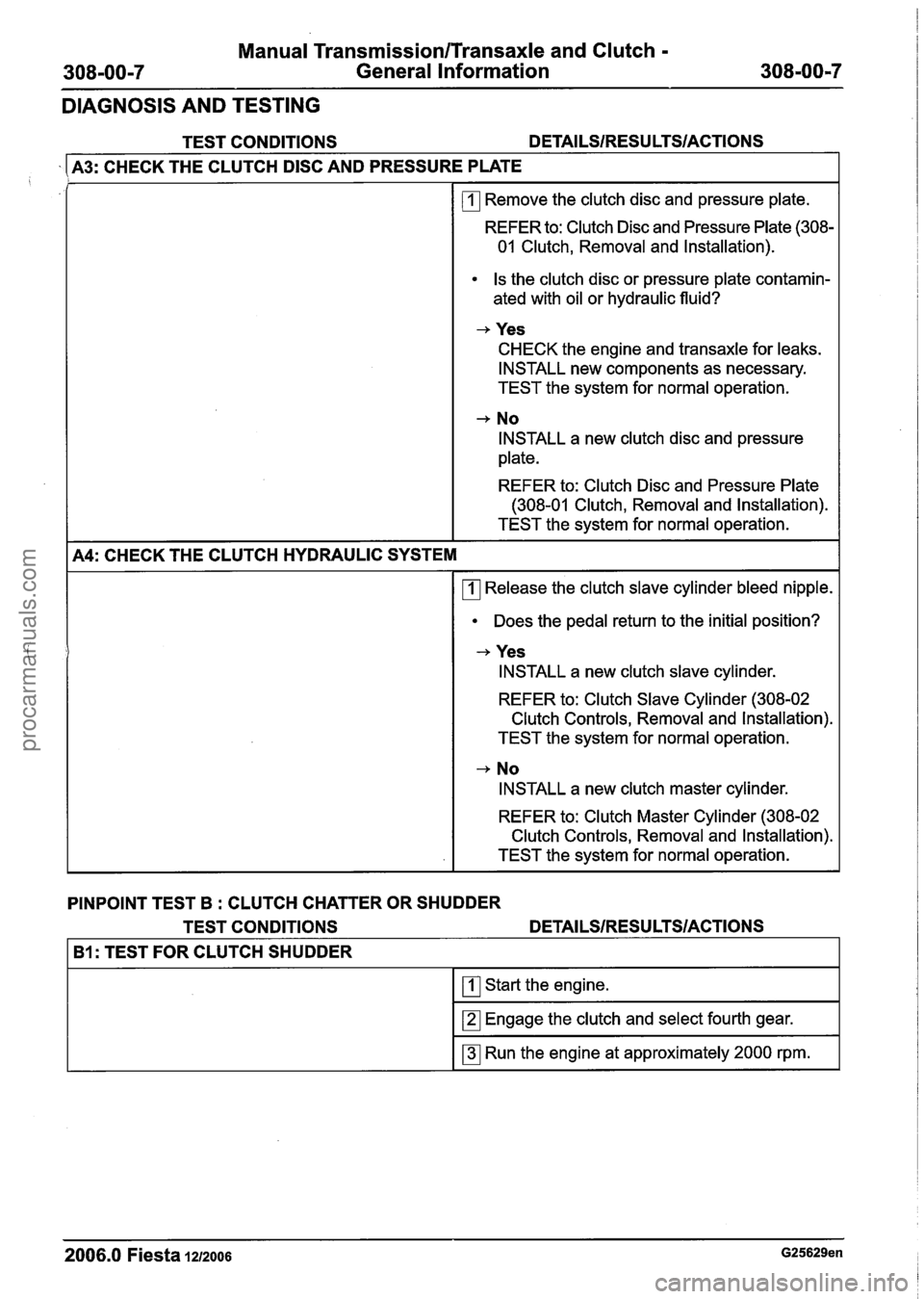

DIAGNOSIS AND TESTING

TEST CONDITIONS DETAl LSIRESU LTSIACTIONS

PINPOINT TEST

B : CLUTCH CHATTER OR SHUDDER

TEST CONDITIONS

DETAILSIRESU LTSIACTIONS

B1: TEST FOR CLUTCH SHUDDER

Start the engine.

Engage the clutch and select fourth gear.

Run the engine at approximately 2000 rpm.

A3: CHECK THE CLUTCH DISC AND PRESSURE PLATE

rn Remove the clutch disc and pressure plate.

REFER to: Clutch Disc and Pressure Plate

(308-

01 Clutch, Removal and lnstallation).

Is the clutch disc or pressure plate contamin-

ated with oil or hydraulic fluid?

-+ Yes

CHECK the engine and transaxle for leaks.

INSTALL new components as necessary.

TEST the system for normal operation.

-+ No

INSTALL a new clutch disc and pressure

plate.

REFER to: Clutch Disc and Pressure Plate

(308-01 Clutch, Removal and lnstallation).

TEST the system for normal operation.

A4: CHECK THE CLUTCH HYDRAULIC SYSTEM

rn Release the clutch slave cylinder bleed nipple.

Does the pedal return to the initial position?

--+ Yes

INSTALL a new clutch slave cylinder.

REFER to: Clutch Slave Cylinder (308-02

Clutch Controls, Removal and Installation).

TEST the system for normal operation.

--+ No

INSTALL a new clutch master cylinder.

REFER to: Clutch Master Cylinder (308-02

Clutch Controls, Removal and lnstallation).

TEST the system for normal operation.

2006.0 Fiesta 1212006 G25629en

procarmanuals.com

Page 1066 of 1226

Manual Transmission/Transaxle and Clutch -

General Information

DIAGNOSIS AND TESTING

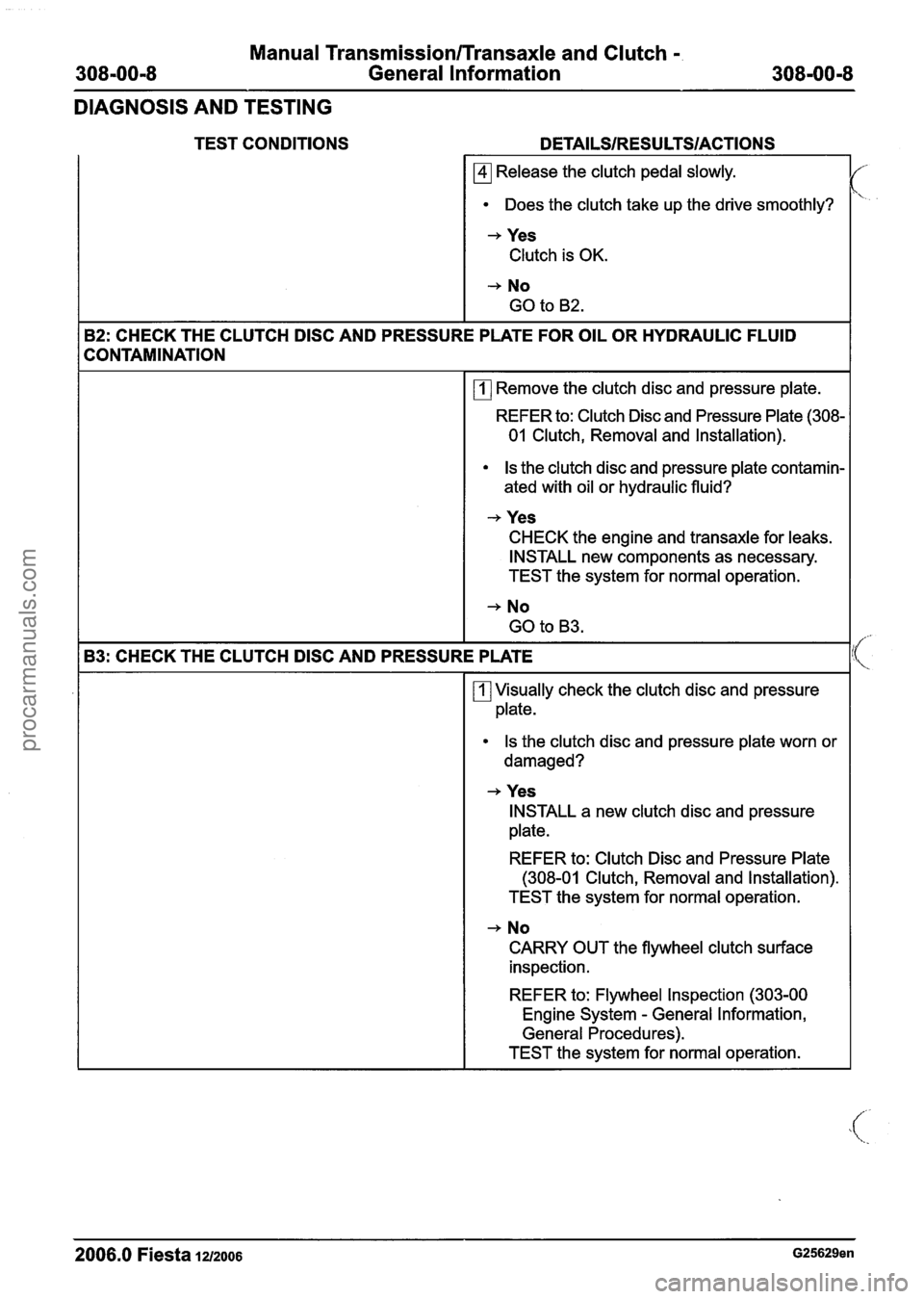

TEST CONDITIONS

Release the clutch pedal slowly.

Does the clutch take up the drive smoothly?

-+ Yes

Clutch is OK.

-+ No

GO to

B2.

B2: CHECK THE CLUTCH DlSC AND PRESSURE PLATE FOR OIL OR HYDRAULIC FLUID

CONTAMINATION

rn Remove the clutch disc and pressure plate.

REFER to: Clutch Disc and Pressure Plate (308-

01 Clutch, Removal and Installation).

Is the clutch disc and pressure plate contamin-

ated with oil or hydraulic fluid?

-+ Yes

CHECK the engine and transaxle for leaks.

INSTALL new components as necessary.

TEST the system for normal operation.

-+ No

GO to B3.

B3: CHECK THE CLUTCH

DlSC AND PRESSURE PLATE

rn Visually check the clutch disc and pressure

plate.

Is the clutch disc and pressure plate worn or

damaged?

-+ Yes INSTALL a new clutch disc and pressure

plate.

REFER to: Clutch Disc and Pressure Plate

(308-01 Clutch, Removal and Installation).

TEST the system for normal operation.

-+ No

CARRY OUT the flywheel clutch surface

inspection.

REFER to: Flywheel Inspection (303-00

Engine System

- General Information,

General Procedures).

TEST the system for normal operation.

2006.0 Fiesta 12/2006 G25629en

procarmanuals.com