fuel pump FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 436 of 1226

303-00-1 4 Engine System - General Information 303-00-1 4

DIAGNOSIS AND TESTING

Symptom

Possible Sources

Action

Timing belt or timing chain

incorrectly tensioned.

CHECK the timing belt or

timing chain tension. INSTALL

a new timing belt or timing

chain as necessary. REFER to:

Timing Belt (303-01 Engine

-

I .25L Duratec-1 6V

(Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V

(Sigma), In-vehicle Repair),

Timing Chain (303-01 Engine

- 1.3L Duratec-8V (Rocam),

In-vehicle Repair),

Timing Chain (303-01 Engine

- 2.OL Duratec-HE (M14), In-

vehicle Repair),

Timing Belt

(303-01 Engine -

1.4L Duratorq-TDCi (DV)

Diesel, In-vehicle Repair),

Timing Belt (303-01 Engine

-

I .6L Duratorq-TDCi (DV)

Diesel, In-vehicle Repair).

Noisy running or engine noise

Engine components

- Pistons

- Piston rings

- Connecting rod big end,

main bearing or thrust

bearing journals

- Connecting rods bent or

damaged.

CHECK the engine compon-

ents for wear or damage. Make

sure all components are within

specification. INSTALL new

components as necessary.

Engine - Oil Leaks

NOTE: Before installing new gaskets or seals, make

sure that the fault is clearly established.

If the oil leak cannot be identified clearly by a visual

inspection, carry out an ultraviolet

(UV) test:

Ultraviolet (UV) Testing

1. Clean the engine and transmission with a

suitable cleaning fluid.

2. Pour the UV-test fluid in accordance with the

quantity specified by the manufacturer through

the oil filler neck into the engine and install the

oil filler cap.

A WARN1NG:Vehicles with manual transaxle,

shift the transaxle into Neutral. Failure to

follow this instruction may result in

personal injury.

3. Start the engine and let it run for about five

minutes. 4.

Switch off the engine.

N0TE:lf no leak can be found, road test the vehicle

under various loads and check the engine for leaks

again.

5. Check the engine for oil leaks using a suitable

UV lamp.

'

6. Rectify any leaks found and check the engine

for oil leaks.

Measure the compression pressure

N0TE:The powertrain control module (PCM)

receives an error message when the fuel pump

relay is removed or electrical components are

disconnected. This error message must be deleted

from the fault memory using WDS after completing

the compression test.

(' ,

'I N0TE:Valve clearance must be set correctly before

performing a compression test. Make sure the

engine is at the normal operating temperature.

2006.0 Fiesta 1212006 GI 52554en

procarmanuals.com

Page 440 of 1226

303-00-1 8 Engine System - General Information 303=00-18

DIAGNOSIS AND TESTING

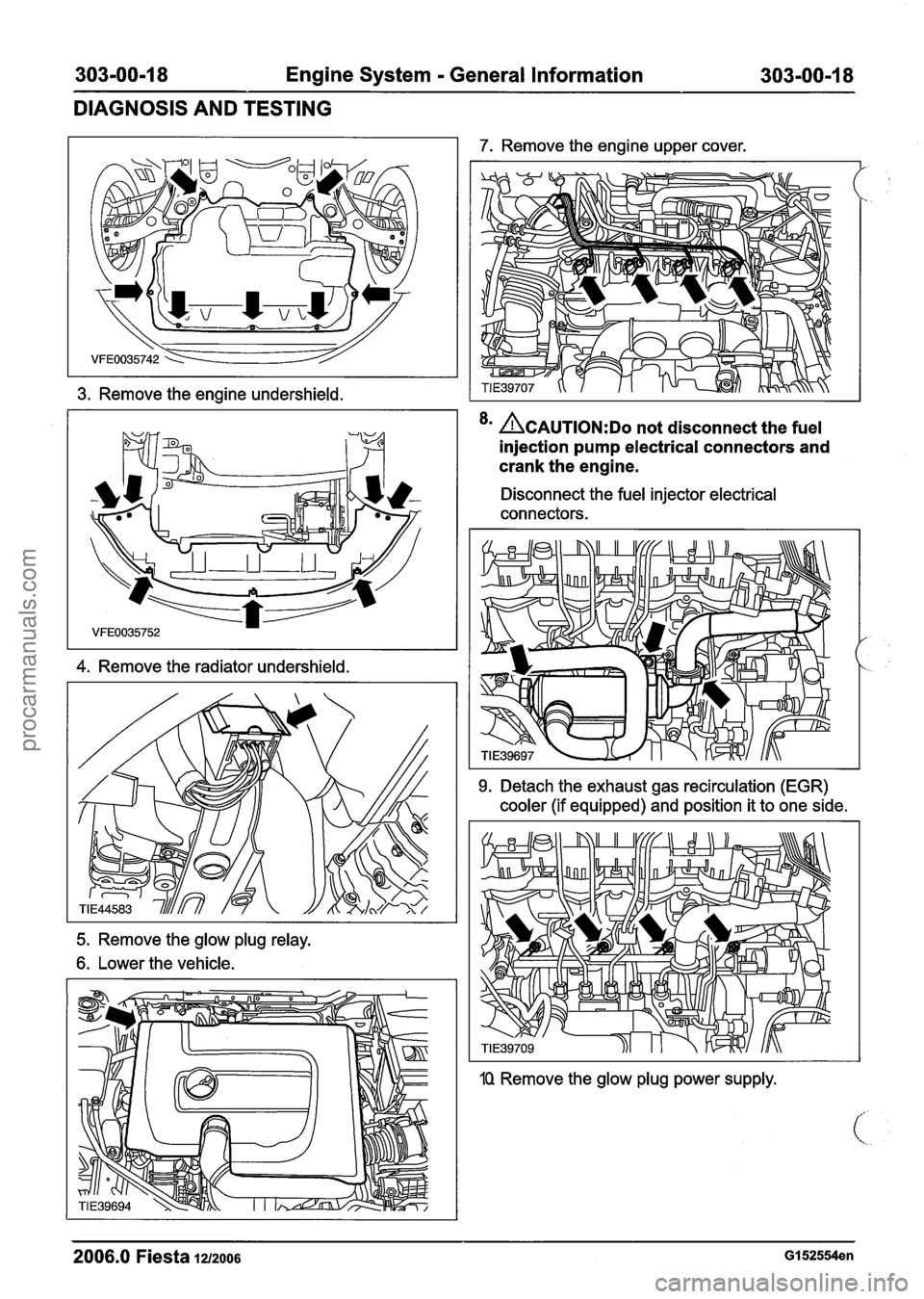

3. Remove the engine undershield.

4. Remove the radiator undershield.

7. Remove the engine upper cover.

<

8m ~CAUTION:DO not disconnect the fuel

injection pump electrical connectors and

crank the engine.

Disconnect the fuel injector electrical

connectors.

9. Detach the exhaust gas recirculation (EGR)

cooler (if equipped) and position it to one side.

5. Remove the glow plug relay.

6. Lower the vehicle.

1Q Remove the glow plug power supply.

2006.0 Fiesta 1212006 GI 52554en

procarmanuals.com

Page 442 of 1226

303-00-20 Engine System - General Information 303-00-20

DIAGNOSIS AND TESTING

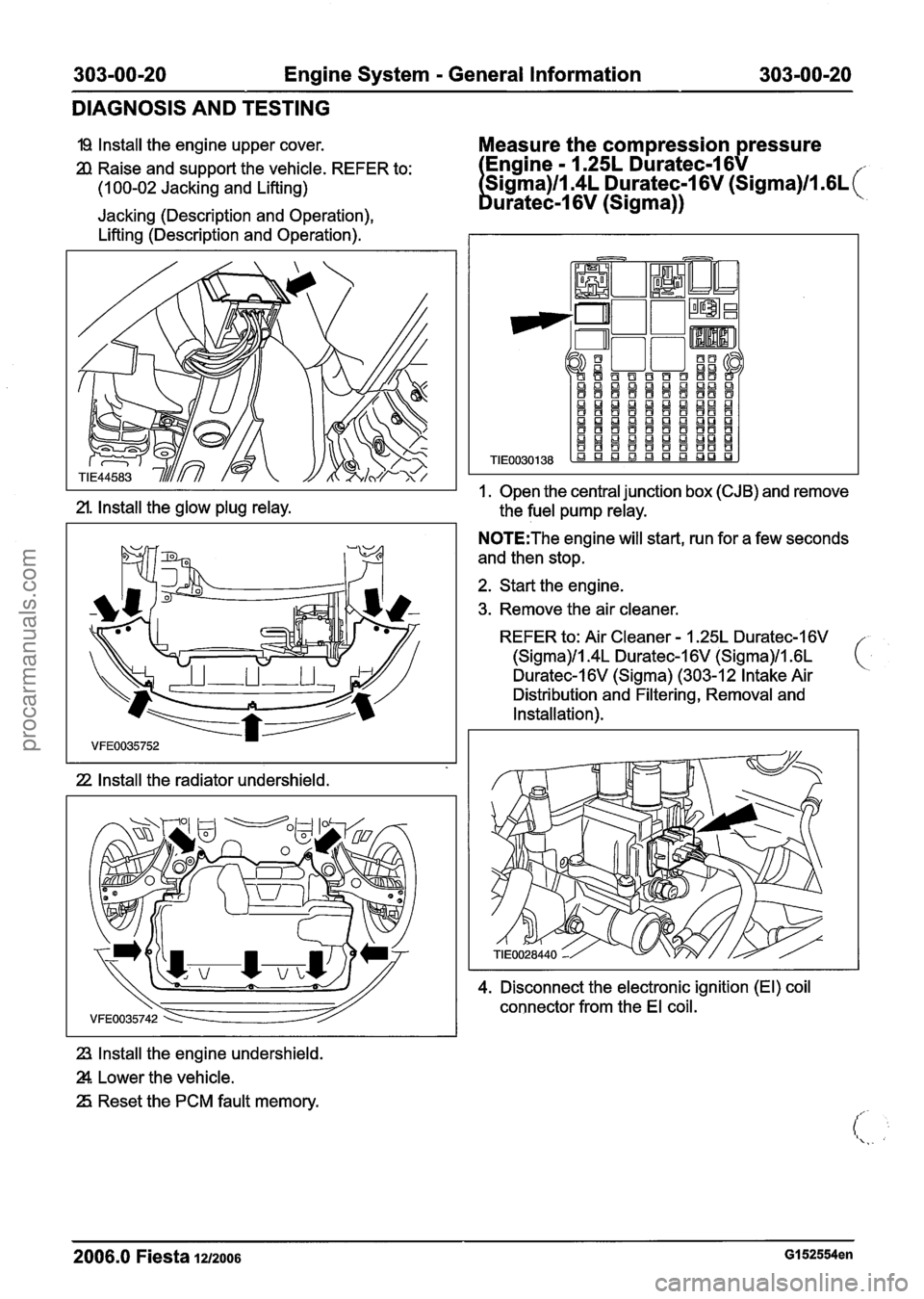

I9 Install the engine upper cover. Measure the compression pressure

2l Raise and support the vehicle. REFER to: - 1.25L Duratec-1 6V

(1 00-02 Jacking and Lifting) 6V (sigrna)/l .GL (

Jacking (Description and Operation),

Lifting (Description and Operation).

2l. Install the glow plug relay.

22 Install the radiator undershield.

23, Install the engine undershield.

Z. Lower the vehicle.

25 Reset the PCM fault memory.

I. Open the central junction box (CJB) and remove

the

fuel pump relay.

N0TE:The engine will start, run for a few seconds

and then stop.

2. Start the engine.

3. Remove the air

cleaner.

REFER to: Air Cleaner - 1.25L Duratec-1 6V

(Sigma)/l.4L Duratec-1 6V (Sigma)ll .6L ( Duratec-I 6V (Sigma) (303-1 2 Intake Air

Distribution and

Filtering, Removal and

Installation).

4. Disconnect the electronic ignition (El) coil

connector from the El coil.

- -- - - -

2006.0 Fiesta 1212006 GI 52554en

procarmanuals.com

Page 444 of 1226

303-00-22 Engine System - General Information 303-00-22

DIAGNOSIS AND TESTING

11. Install the fuel pump relay.

I2 Install the air cleaner.

REFER to: Air Cleaner - 1.25L Duratec-1 6V

(Sigma)/l.4L Duratec-16V (Sigma)/l .6L

Duratec-I 6V (Sigma) (303-1 2 Intake Air

Distribution and

Filtering, Removal and

Installation).

13 Using worldwide diagnostic system (WDS), clear

the fault codes from the PCM.

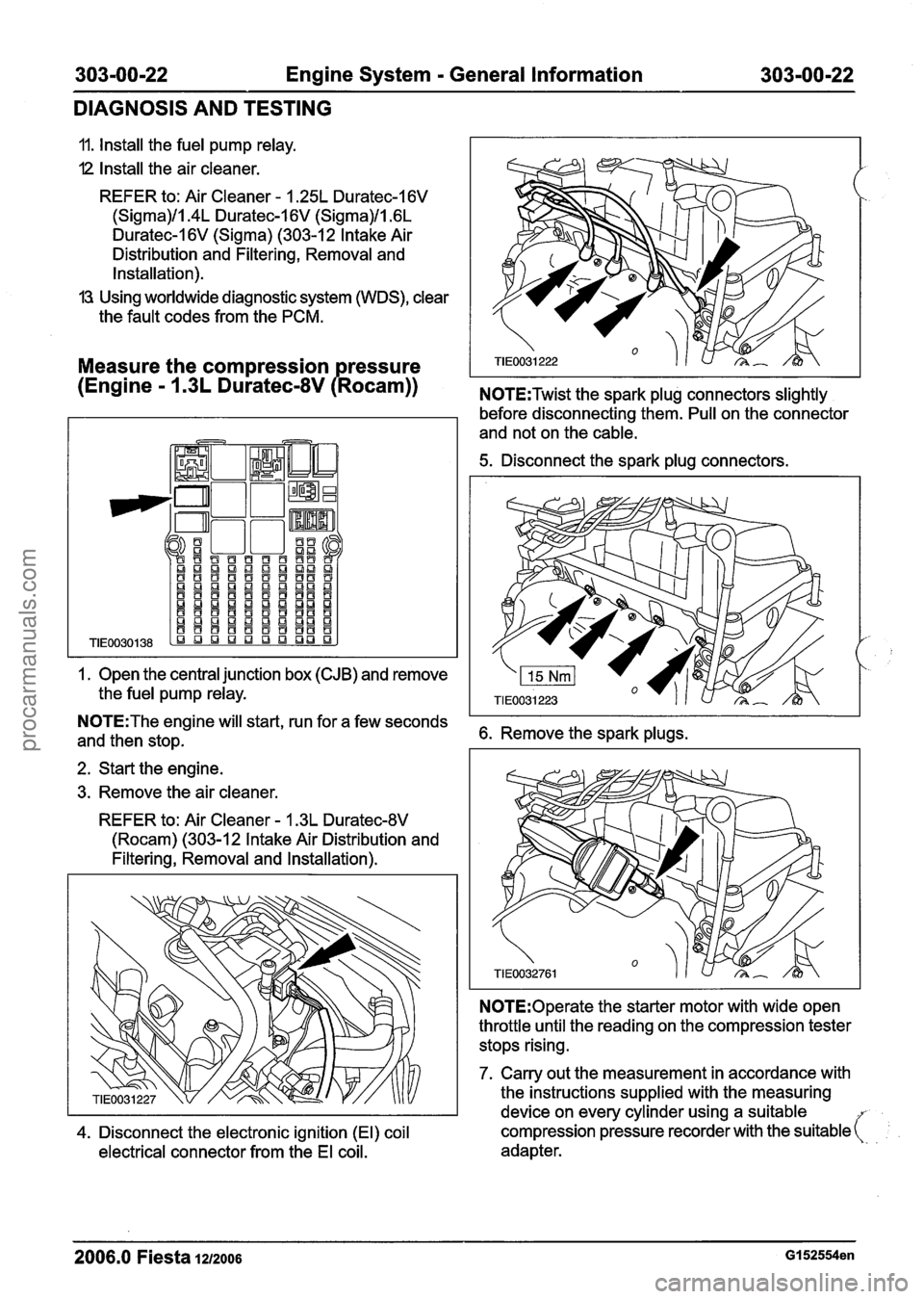

Measure the compression ressure

(Engine

- 1 .3L Duratec-8V P Rocam)) N0TE:Twist the spark plug connectors slightly

1. Open the

central junction box (CJB) and remove

the

fuel pump relay.

before disconnecting them. Pull on the connector

and not on the

cable.

5. Disconnect the spark plug connectors.

N0TE:The engine will start, run for a few seconds

and then stop. 6. Remove the spark plugs.

2. Start the engine.

3. Remove the air

cleaner.

REFER to: Air Cleaner - 1.3L Duratec-8V

(Rocam) (303-12 Intake Air Distribution and

Filtering, Removal and Installation).

N0TE:Operate the starter motor with wide open

throttle until the reading on the compression tester

stops rising.

7. Carry out the measurement in accordance with

the instructions

supplied with the measuring

device on every

cylinder using a suitable

4. Disconnect the electronic ignition (El) coil compression pressure recorder

with the suitable (:

electrical connector from the El coil. adapter.

2006.0 Fiesta 1212006 GI 52554en

procarmanuals.com

Page 445 of 1226

303-00-23 Engine System - General Information 303-00-23

DIAGNOSIS AND TESTING

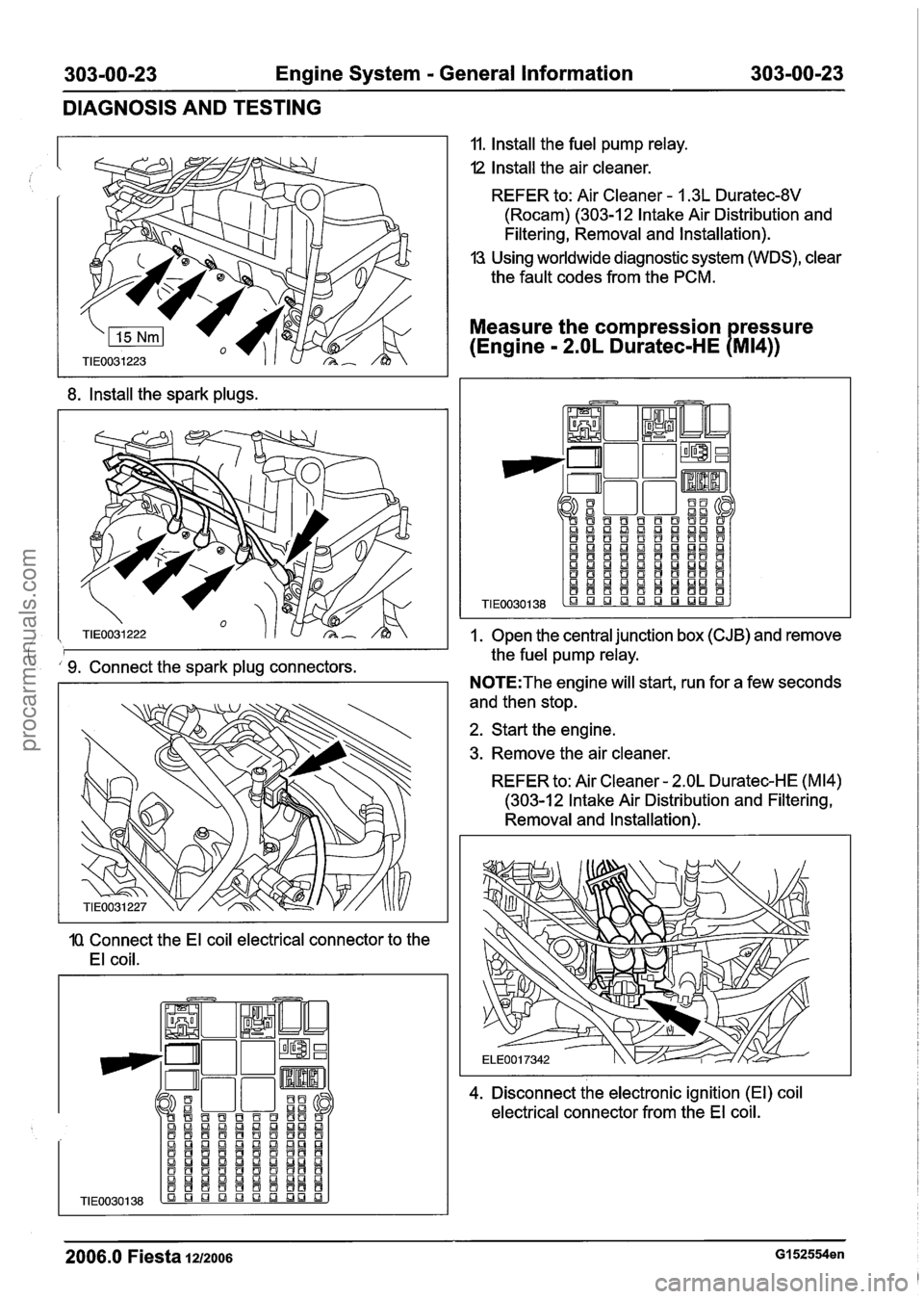

8. Install the spark plugs.

9. Connect the spark plug connectors.

1Q Connect the El coil electrical connector to the

El coil. 11.

Install the fuel pump relay.

I2 Install the air cleaner.

REFER to: Air Cleaner

- 1.3L Duratec-8V

(Rocam) (303-1 2 Intake Air Distribution and

Filtering, Removal and Installation).

13 Using worldwide diagnostic system (WDS), clear

the fault codes from the PCM.

Measure the compression ressure

(Engine

- 2.OL Duratec-HE PMI~))

1. Open the central junction box (CJB) and remove

the fuel pump relay.

N0TE:The engine will start, run for a few seconds

and then stop.

2. Start the engine.

3. Remove the air cleaner.

REFER to: Air Cleaner

- 2.OL Duratec-HE (M14)

(303-1 2 Intake Air Distribution and Filtering,

Removal and Installation).

4. Disconnect

the electronic ignition (El) coil

electrical connector from the El coil.

2006.0 Fiesta 1212006 GI 52554en

procarmanuals.com

Page 447 of 1226

303-00-25 Engine System - General Information 303-00-25

DIAGNOSIS AND TESTING

11. Install the fuel pump relay.

-. 12 Install the air cleaner.

REFER to: Air Cleaner

- 2.OL Duratec-HE (M14)

(303-12 Intake Air Distribution and Filtering,

Removal and Installation).

13 Reset the PCM fault memory.

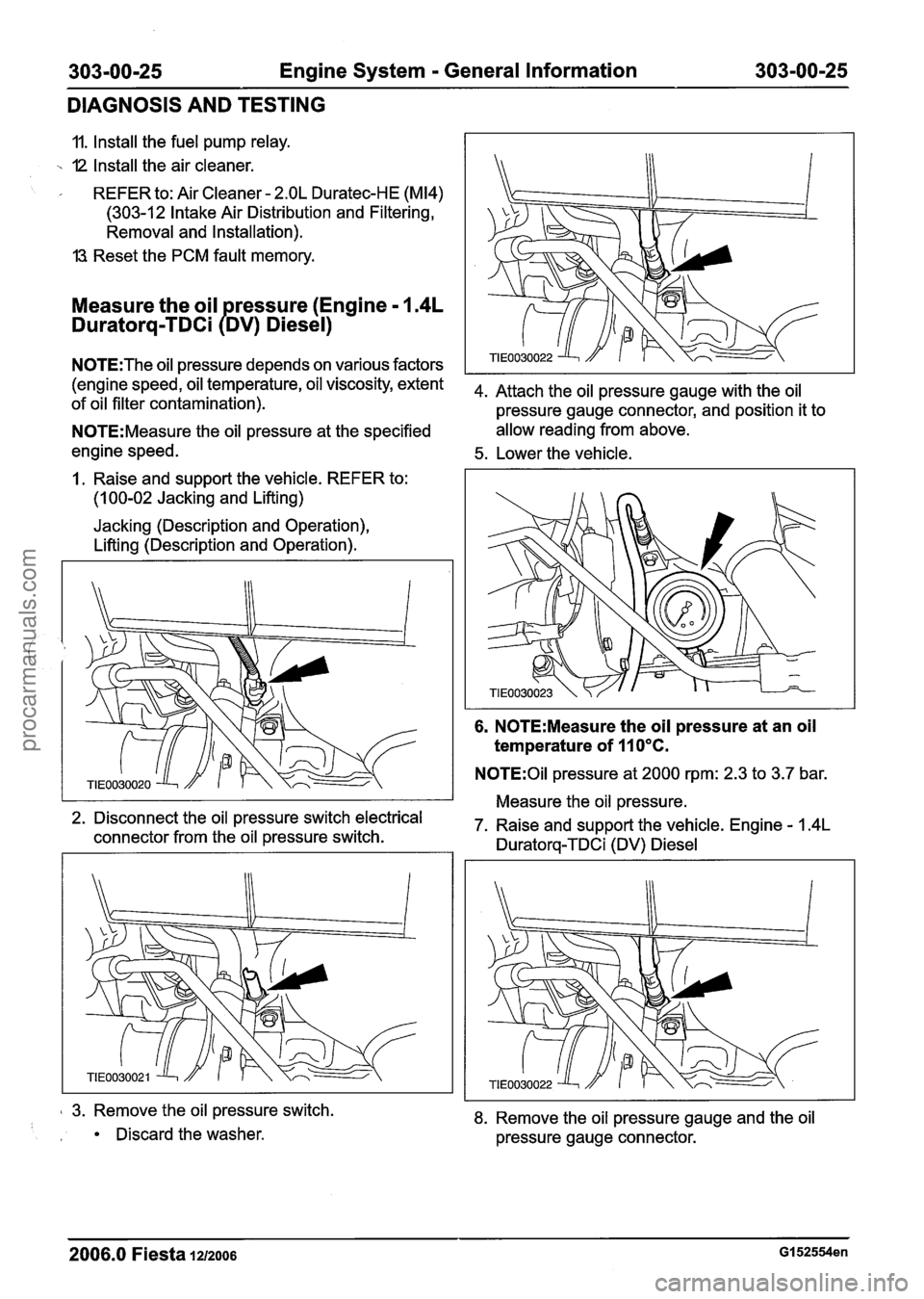

Measure the oil ressure (Engine - 1.4L

Duratorq-TDCi PDv) Diesel)

N0TE:The oil pressure depends on various factors

(engine speed, oil temperature, oil viscosity, extent

4m Attach the oil pressure gauge with the oil of oil filter contamination).

pressure gauge connector, and position it to

N0TE:Measure the oil pressure at the specified allow reading

from above.

engine speed.

5. Lower the vehicle.

I. Raise and support the vehicle. REFER to:

(1 00-02 Jacking and Lifting)

Jacking (Description and Operation),

Lifting (Description and Operation).

6. N0TE:Measure the oil pressure at an oil

temperature of 410°C.

N0TE:OiI pressure at 2000 rpm: 2.3 to 3.7 bar.

Measure the oil pressure.

2. Disconnect the oil pressure switch electrical

7. Raise and support the vehicle. Engine

- 1.4L connector from the oil pressure switch.

Duratorq-TDCi (DV) Diesel

3. Remove the oil pressure switch.

Discard the washer.

8. Remove the oil pressure gauge and the oil

pressure gauge connector.

2006.0 Fiesta 1212006 GI 52554en

procarmanuals.com

Page 610 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)ll.4L

303-01 A-I 34 Duratec-1 6V (Sigma)ll .6L Duratec-I 6V (Sigma) 303-01 A-1 34

INSTALLATION

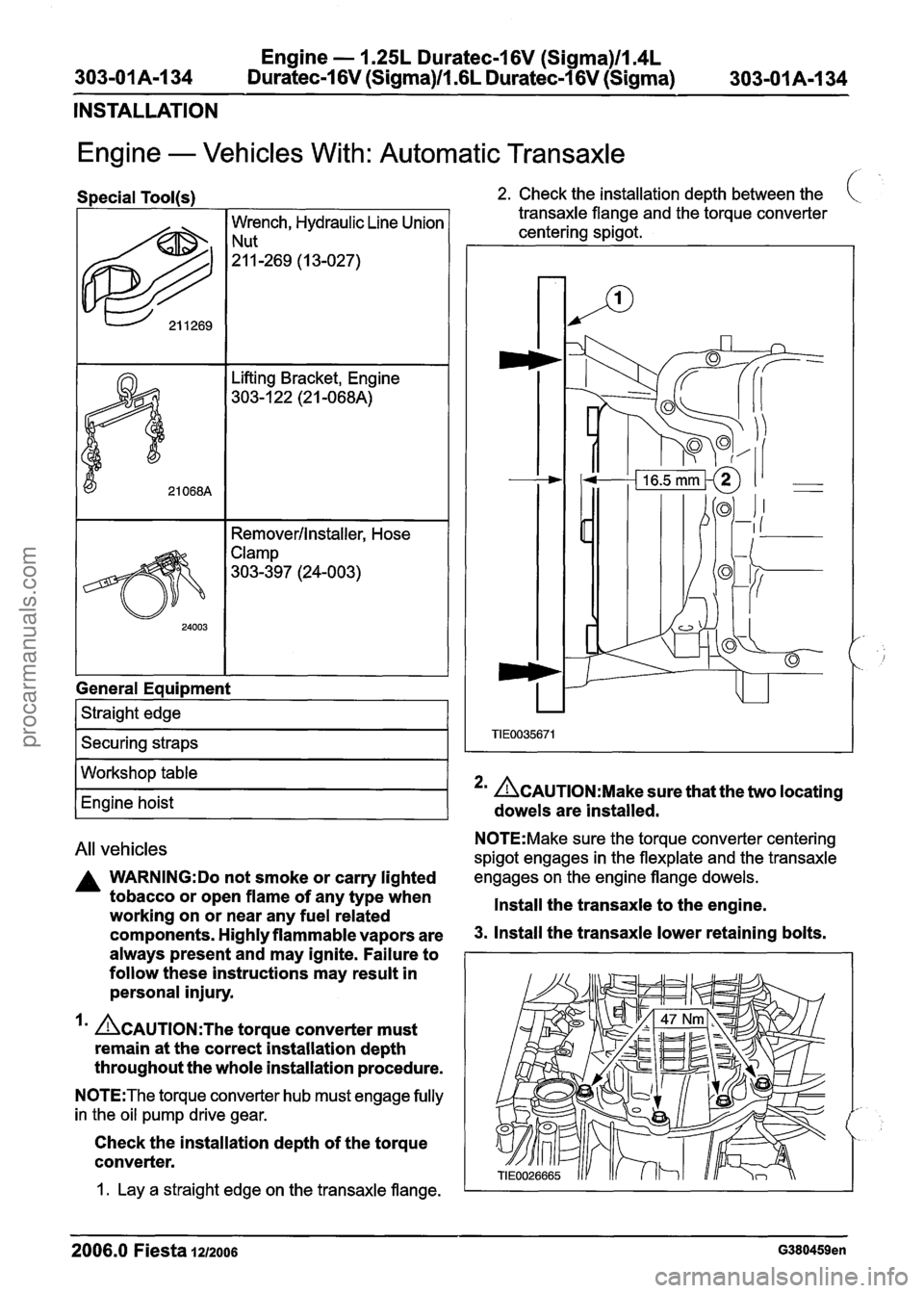

Engine - Vehicles With: Autom

Special Tool(s)

I I Remover/lnstaller, Hose (

General Eaui~ment

1 Straight edge I

I Securing straps I

atic Transaxle

2. Check the installation depth between the

transaxle flange and the torque converter c

centering spigot.

All vehicles N0TE:Make sure the torque converter centering

spigot engages in the flexplate and the transaxle

A WARNING:Do not smoke or carry lighted engages on the engine flange dowels.

tobacco or open flame of any type when

Install the transaxle to the engine.

working on or near any fuel related

components. Highly flammable vapors are 3. Install the transaxle lower retaining bolts.

always present and may ignite. Failure to I I

Workshop table

Engine hoist

follow these instructions may result in

personal injury.

'' &AUTION:T~~ torque converter must

remain at the correct installation depth

throughout the whole installation procedure.

N0TE:The torque converter hub must engage fully

in the oil pump drive gear.

Check the installation depth of the torque

converter.

*' &AUTION:M~~~ sure that the two locating

dowels are installed.

1. Lay a straight edge on the transaxle flange. I

2006.0 Fiesta 1212006 G380459en

procarmanuals.com

Page 700 of 1226

303-01 B-78 Engine - 2.OL Duratec-HE (M14) 303-01 B-78

REMOVAL

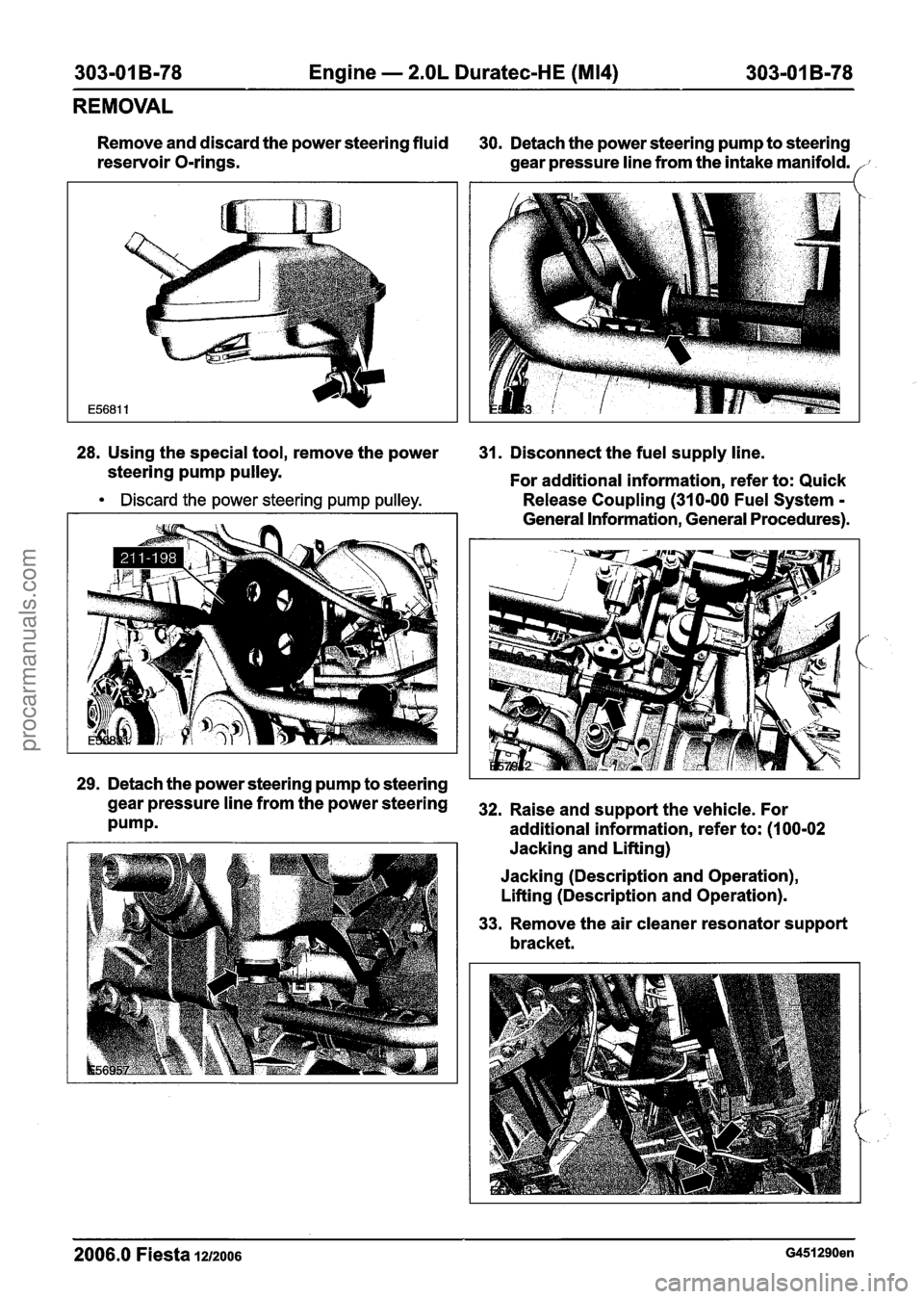

Remove and discard the power steering fluid

30. Detach the power steering pump to steering

reservoir O-rings.

gear pressure line from the intake manifold.

28. Using the special tool, remove the power

31. Disconnect the fuel supply line.

steering pump pulley.

For additional information, refer to: Quick

Discard the power steering pump pulley. Release Coupling (310-00 Fuel System - - - - -

General information, General procedures).

,'-

', .

29. Detach the power steering pump to steering

gearpressurelinefromthepowersteering 32. Raiseands~pportthevehicle~For

Pumpm additional information, refer to: (I 00-02

Jacking and Lifting)

Jacking (Description and Operation),

Lifting (Description and Operation).

33. Remove the air cleaner resonator support

bracket.

2006.0 Fiesta 1212006 G451290en

procarmanuals.com

Page 813 of 1226

Fuel Charging and Controls - 2.OL

303-04B-5 Duratec-HE (M14) 303-04B-5

DIAGNOSIS AND TESTING

Fuel Charging and Controls

General Equipment

Wgnostic System (WDS) I

Principles of Operation

Ethanol equipped vehicles

Ethanol, is derived from cellulose waste. A large

proportion of Ethanol is distilled from corn, wheat

and sugar cane crops. The product that is to be

used in this vehicle is called Ethanol E85. E85 is

a mixture of 15% gasoline and 85% Ethanol.

Ethanol is a clear liquid and when fully burnt the

combustion gasses remaining are Carbon Dioxide

and water. This makes the use of Ethanol a good

environmental proposition. One drawback with pure

Ethanol is that it is corrosive to certain rubber and

plastic materials. The

introduction of Ethanol E85 has required some

major internal changes to the fuel supply and

delivery system. Some earlier vehicles used an

Ethanol mixture called Ethanol

El 5. This fuel was

made up of 15% Ethanol and 85% gasoline. At this

mixture ratio, no changes to the fuel charging or

delivery system where required, as no degradation

would occur with the cylinder head valves or

material content of the components, although some

performance loss would be noticeable.

The components used by vehicles running Ethanol

appear to be the same in construction as those

that use unleaded fuel only. The changes are

mainly to do with the materials used and increases

in fuel flow rates.

Ethanol has a much higher octane rating than

standard fuel which means that the ignition and

fuel injection calibrations for a vehicle that is

capable of using Ethanol E85 must be adapted

suitably.

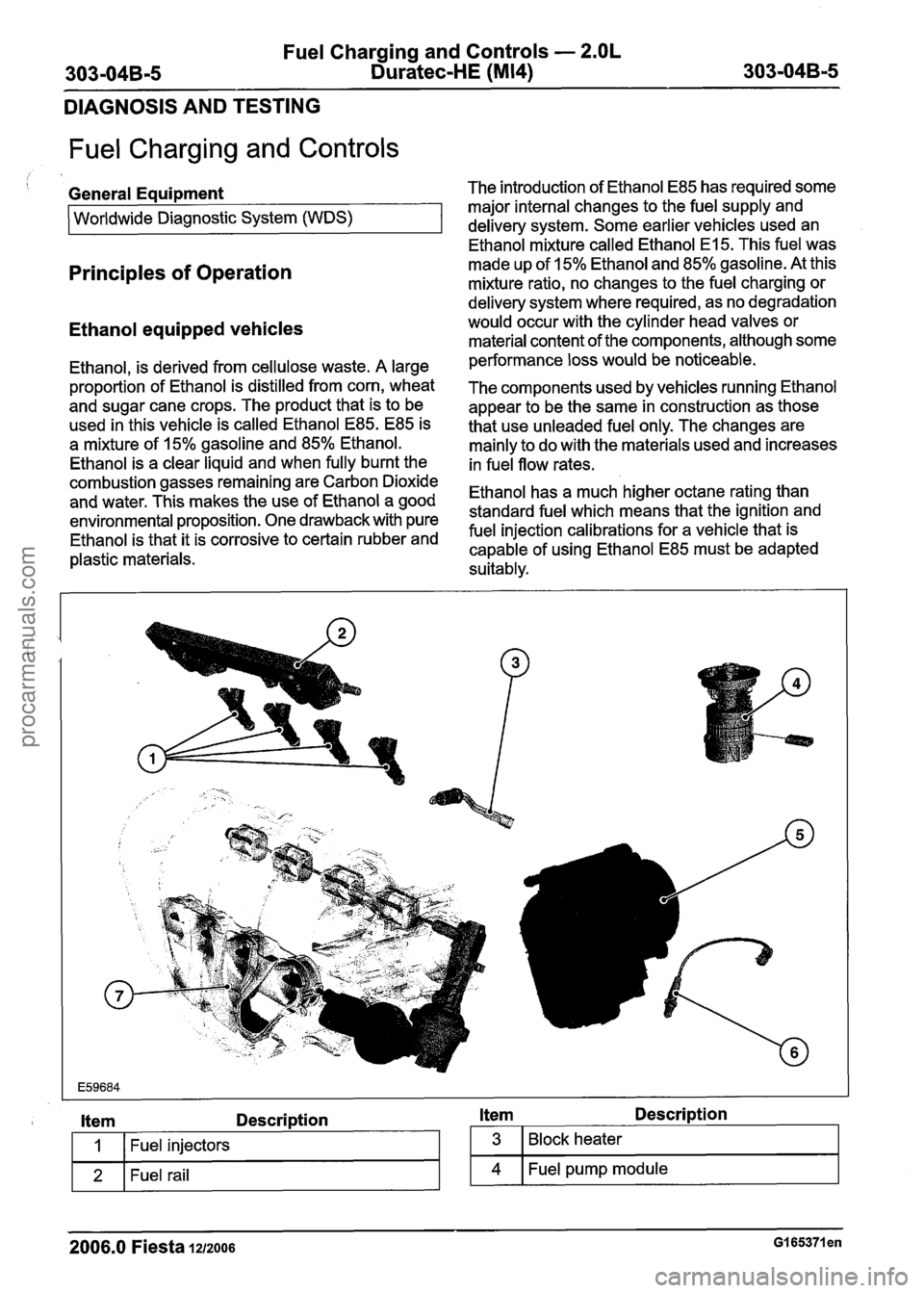

I Item Description

I 1 I Fuel injectors

1ue1 rail I

2006.0 Fiesta 1212006 GI 65371 en

Item Description

3

4

Block heater

Fuel pump module

procarmanuals.com

Page 814 of 1226

Fuel Charging and Controls - 2.OL

303-04B-6 Duratec-HE (M14) 303-04B-6

DIAGNOSIS AND TESTING

1 6 1 Heated Oxygen sensor (H02s) I

Item Description Fuel supply

1 7 1 Intake manifold I

5

Fuel injectors

Throttle body

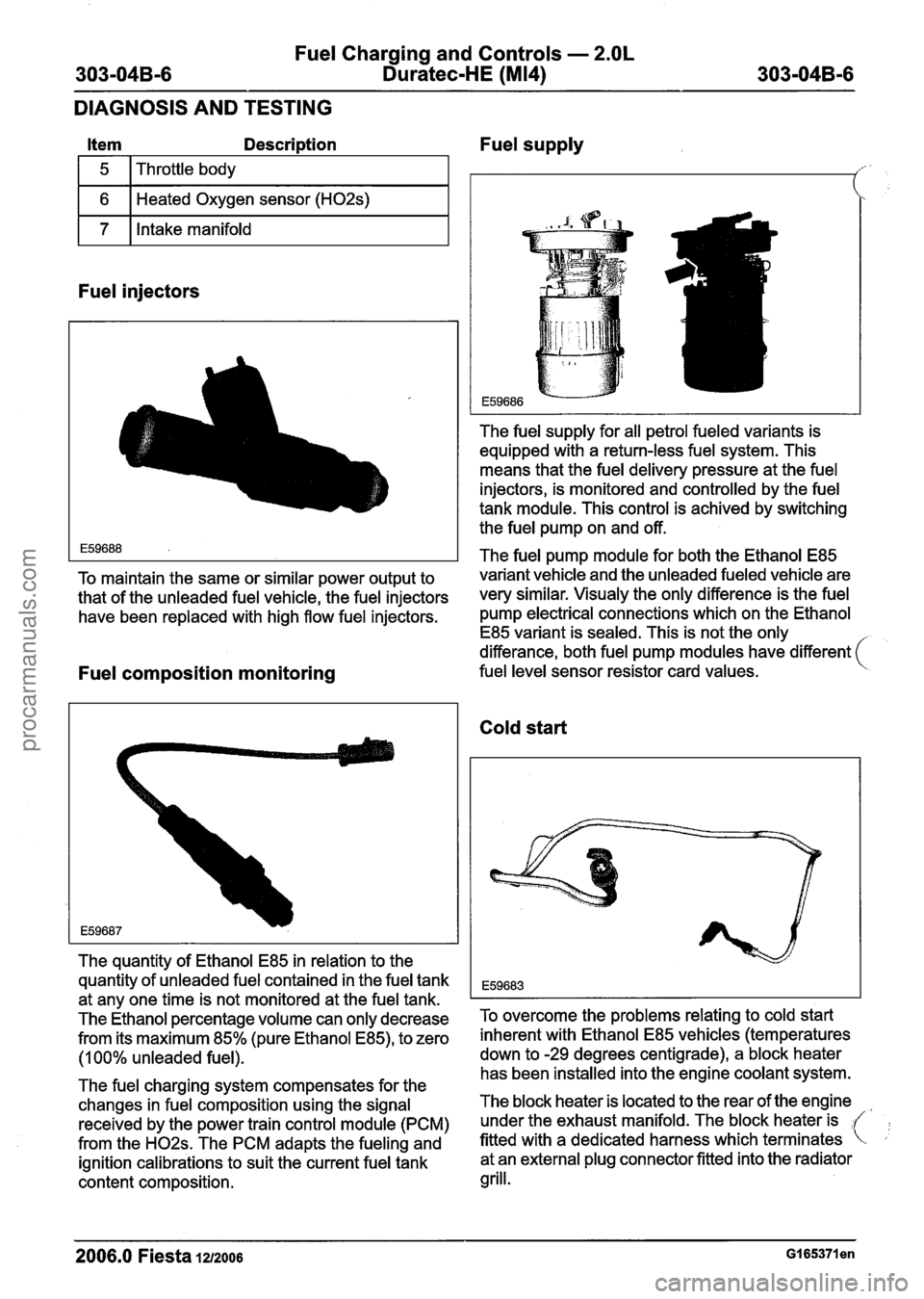

The fuel supply for all petrol fueled variants is

equipped with a return-less fuel system. This

means that the fuel delivery pressure at the fuel

injectors, is monitored and controlled by the fuel

tank module. This control is achived by switching

the fuel pump on and off.

The fuel pump module for both the Ethanol E85

TO maintain the same or similar power output to variant vehicle and the unleaded fueled vehicle are

that of the unleaded fuel vehicle, the fuel injectors

very similar, visual^ the only difference is the fuel

have been replaced with high flow fuel injectors. pump electrical connections which on the Ethanol

E85 variant is sealed. This is not the only

differance, both fuel pump modules have different

(

Fuel composition monitoring fuel level sensor resistor card values.

The quantity of Ethanol E85 in relation to the

quantity of unleaded fuel contained in the fuel tank

at any one time is not monitored at the fuel tank.

The Ethanol percentage volume can only decrease

from its maximum 85% (pure Ethanol

E85), to zero

(1 00% unleaded fuel).

The fuel charging system compensates for the

changes in fuel composition using the signal

received by the power train control module (PCM)

from the

H02s. The PCM adapts the fueling and

ignition calibrations to suit the current fuel tank

content composition.

Cold start

To overcome the problems relating to cold start

inherent with Ethanol E85 vehicles (temperatures

down to -29 degrees centigrade), a block heater

has been installed into the engine coolant system.

The block heater is located to the rear of the engine

under the exhaust manifold. The block heater is

fitted with a dedicated harness which terminates at an external plug connector fitted into the radiator

grill.

2006.0 Fiesta 1212006

procarmanuals.com