brake system FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1822 of 2057

SECTION 307-01 Automatic Transmission/Transaxle

— Vehicles With: 5-Speed Automatic Transaxle - AW55 AWD

VEHICLE APPLICATION:2008.50 Kuga

PA G E

CONTENTS

SPECIFICATIONS

307-01-4

Specifications ........................................................................\

..............................................

DESCRIPTION AND OPERATION 307-01-5

Transmission Description (Component Location) ...............................................................

307-01-6

Transmission Description (Overview) ........................................................................\

.........

307-01-6

Components of the AW55 automatic transaxle ..................................................................

307-01-6

General overview ........................................................................\

....................................

307-01-8

Transaxle cooling ........................................................................\

....................................

307-01-8

External shift mechanism ........................................................................\

........................

307-01-9

Components of the electronic control ........................................................................\

.....

307-01-11

Overview of the brakes, clutches and one-way clutches ................................................

307-01-12

Input and output signals at the TCM ........................................................................\

.......

307-01-14

Knowing and Understanding Customer Concerns ..........................................................

307-01-14

Testing Possible Causes of Transmission Control Faults ...............................................

307-01-14

IDS Diagnosis ........................................................................\

.........................................

307-01-14

visual inspection ........................................................................\

.....................................

307-01-15

Towing the vehicle ........................................................................\

..................................

307-01-15

Push-starting the Vehicle ........................................................................\

........................

307-01-15

Jump-starting the Vehicle ........................................................................\

.......................

307-01-15

Selector Lever Emergency Release ........................................................................\

.......

307-01-16

Adjusting the Selector Lever Cable ........................................................................\

........

307-01-17

Transmission Fluid Level Check ........................................................................\

.............

307-01-17

Changing the Transmission Fluid ........................................................................\

...........

307-01-18

Diagnosis with IDS ........................................................................\

..................................

307-01-19

Resetting the counter for fluid change intervals. .............................................................

307-01-19

Programming the 'N' position of the TR sensor..............................................................

307-01-19

Resetting the values learned by the TCM .......................................................................

307-01-21

Transmission Description (System Operation and Component Description) .....................

307-01-21

System Operation ........................................................................\

.......................................

307-01-22

Functionality overview ........................................................................\

............................

307-01-24

Electronic Control System ........................................................................\

......................

307-01-24

Hydraulic Control System ........................................................................\

.......................

307-01-24

Type plate ........................................................................\

...............................................

307-01-25

Serial number of the transmission ........................................................................\

..........

307-01-25

Markings on the TCM ........................................................................\

.............................

307-01-25

Serial

number of the TCM ........................................................................\

.......................

307-01-25

Transmission Control ........................................................................\

..............................

307-01-27

Pin assignment for TCM connector 'C' (connection to transaxle) ...................................

307-01-28

Operation ........................................................................\

................................................

307-01-29

Gearshift control ........................................................................\

......................................

307-01-29

Adaptation ........................................................................\

...............................................

307-01-29

Shifting from 'P' to another transmission range ..............................................................

307-01-1

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 1

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

PAGE 1 OF 3 FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1832 of 2057

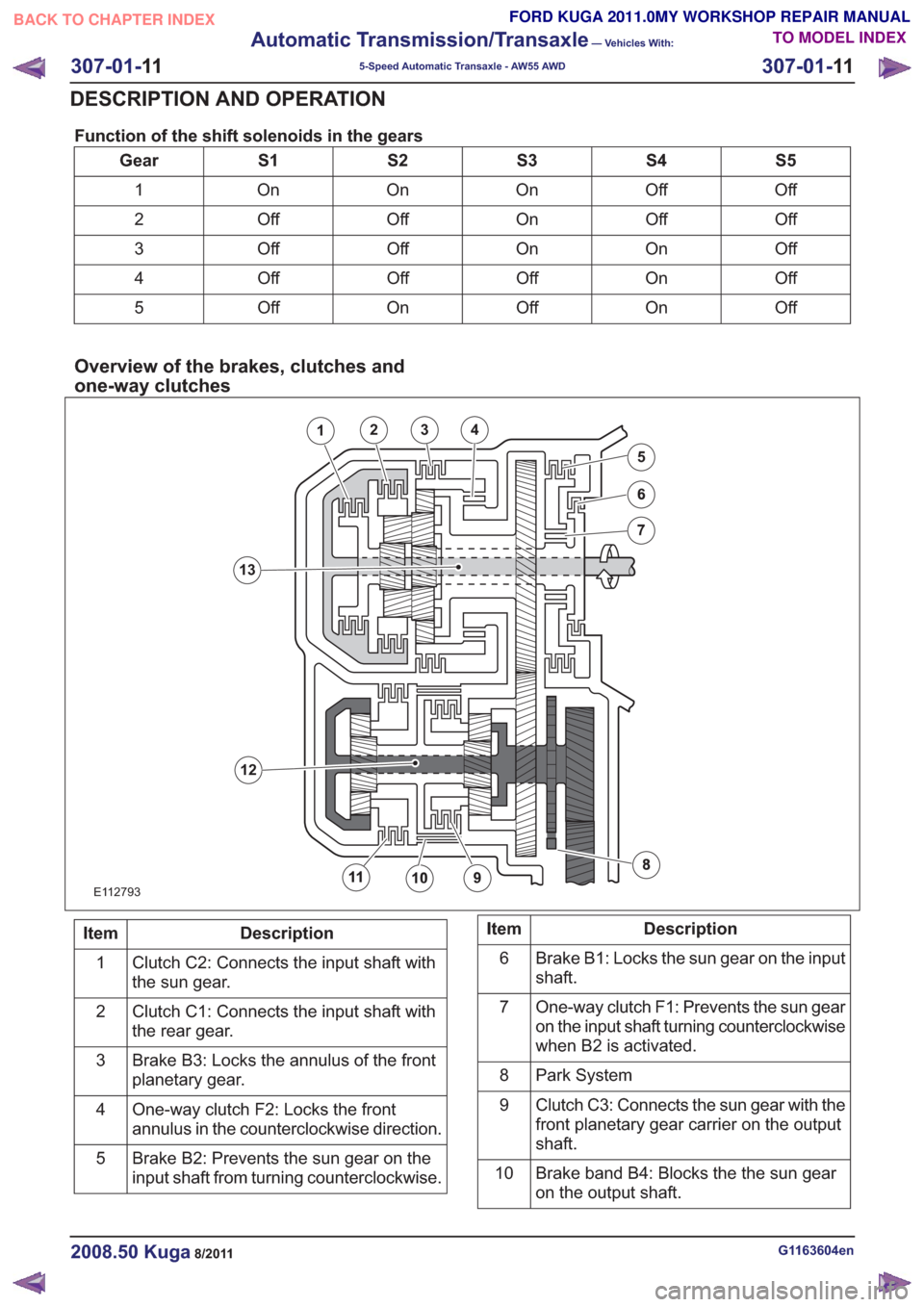

Function of the shift solenoids in the gears

S5

S4

S3

S2

S1

Gear

Off

Off

On

On

On

1

Off

Off

On

Off

Off

2

Off

On

On

Off

Off

3

Off

On

Off

Off

Off

4

Off

On

Off

On

Off

5

Overview of the brakes, clutches and

one-way clutches

E112793

1234

5

12

13

Description

Item

Clutch C2: Connects the input shaft with

the sun gear.

1

Clutch C1: Connects the input shaft with

the rear gear.

2

Brake B3: Locks the annulus of the front

planetary gear.

3

One-way clutch F2: Locks the front

annulus in the counterclockwise direction.

4

Brake B2: Prevents the sun gear on the

input shaft from turning counterclockwise.

5Description

Item

Brake B1: Locks the sun gear on the input

shaft.

6

One-way clutch F1: Prevents the sun gear

on the input shaft turning counterclockwise

when B2 is activated.

7

Park System

8

Clutch C3: Connects the sun gear with the

front planetary gear carrier on the output

shaft.

9

Brake band B4: Blocks the the sun gear

on the output shaft.

10

G1163604en2008.50 Kuga8/2011

307-01-

11

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 11

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1835 of 2057

Description

Item

ABS (anti-lock brake system)

5

Speed control

6

Select-shift switch module

7

PCM

8

Selector lever lock

9

PWM solenoid valve – shift pressure (SLS)

10

PWM solenoid valve for main line pressure

(SLT)

11

PWM- solenoid valve – TCC (SLU)

12Description

Item

Shift solenoid S1 (open when dormant)

13

Shift solenoid S2 (closed when dormant)

14

Shift solenoid S3 (closed when dormant)

15

Shift solenoid S4 (open when dormant)

16

Shift solenoid S5 (closed when dormant)

17

The TSS sensor

18

The OSS sensor

19

The TFT sensor

20

TR sensor in TCM

21

Knowing and Understanding Customer

Concerns

Knowing and understanding customer concerns is

necessary in order to perform diagnosis.

First of all, ask the customer under which operating

conditions the problem occurs. If possible, try to

reproduce the concern by road testing the vehicle

with the customer.

You should be familiar with the following operating

conditions:

• Engine operating state

– Cold, warm-up phase, or at operatingtemperature

• Ambient temperature – Below 0 °C (32 °F), 0 to 20 °C (32 to 68 °F),or above 20 °C (68 °F)

• Road conditions – Good, poor, or off-road

• Vehicle load status – Unloaded, loaded, or fully loaded

• Transaxle status in manual mode – Upshift, downshift, overrun or acceleration

Testing Possible Causes of Transmission

Control Faults

Before performing a symptom-based diagnosis,

first carry out checks to eliminate various other

potential causes of the fault.

These situations include:

• Battery state of charge

• Defective fuses • Loose or corroded cables or electrical

connectors

• Ground connections to the transmission

• Retrofitted add-on units which are not approved by Ford, such as air conditioning, car telephone,

cruise control

• Unapproved tire sizes

• Incorrect tire size programmed with IDS (Integrated Diagnostic System)

• Engine tuning

IDS Diagnosis

NOTE: Customer concerns relating to the transaxle

can also be caused by engine-related faults.

The transmission control system of the AW55 is

closely linked to the engine management system.

Faults in the engine management system may

affect the transmission control system.

Before repairing the transaxle, it should be ensured

that the fault is not caused by the engine

management system or other non-transaxle

components.

The diagnosis can be performed on the AW55 with

the aid of von IDS.

visual inspection

A thorough visual inspection of the transaxle is

necessary for successful diagnosis.

A visual inspection is made of the following

components:

• Connectors and plug connections

• Ease of operation of the selector lever

G1163604en2008.50 Kuga8/2011

307-01- 14

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 14

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1842 of 2057

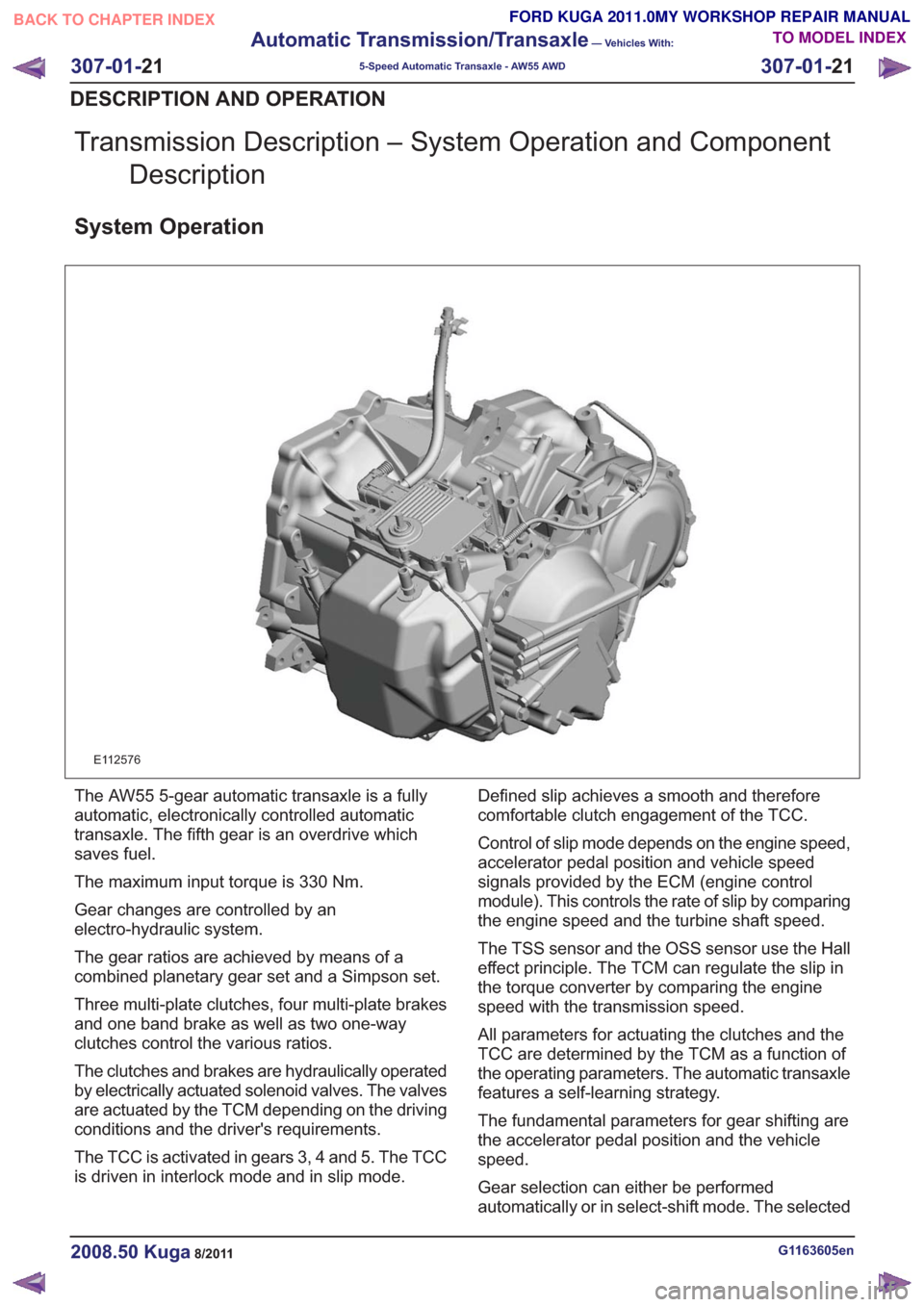

Transmission Description – System Operation and ComponentDescription

System Operation

E112576

The AW55 5-gear automatic transaxle is a fully

automatic, electronically controlled automatic

transaxle. The fifth gear is an overdrive which

saves fuel.

The maximum input torque is 330 Nm.

Gear changes are controlled by an

electro-hydraulic system.

The gear ratios are achieved by means of a

combined planetary gear set and a Simpson set.

Three multi-plate clutches, four multi-plate brakes

and one band brake as well as two one-way

clutches control the various ratios.

The clutches and brakes are hydraulically operated

by electrically actuated solenoid valves. The valves

are actuated by the TCM depending on the driving

conditions and the driver's requirements.

The TCC is activated in gears 3, 4 and 5. The TCC

is driven in interlock mode and in slip mode. Defined slip achieves a smooth and therefore

comfortable clutch engagement of the TCC.

Control of slip mode depends on the engine speed,

accelerator pedal position and vehicle speed

signals provided by the ECM (engine control

module). This controls the rate of slip by comparing

the engine speed and the turbine shaft speed.

The TSS sensor and the OSS sensor use the Hall

effect principle. The TCM can regulate the slip in

the torque converter by comparing the engine

speed with the transmission speed.

All parameters for actuating the clutches and the

TCC are determined by the TCM as a function of

the operating parameters. The automatic transaxle

features a self-learning strategy.

The fundamental parameters for gear shifting are

the accelerator pedal position and the vehicle

speed.

Gear selection can either be performed

automatically or in select-shift mode. The selected

G1163605en2008.50 Kuga8/2011

307-01-

21

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 21

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1845 of 2057

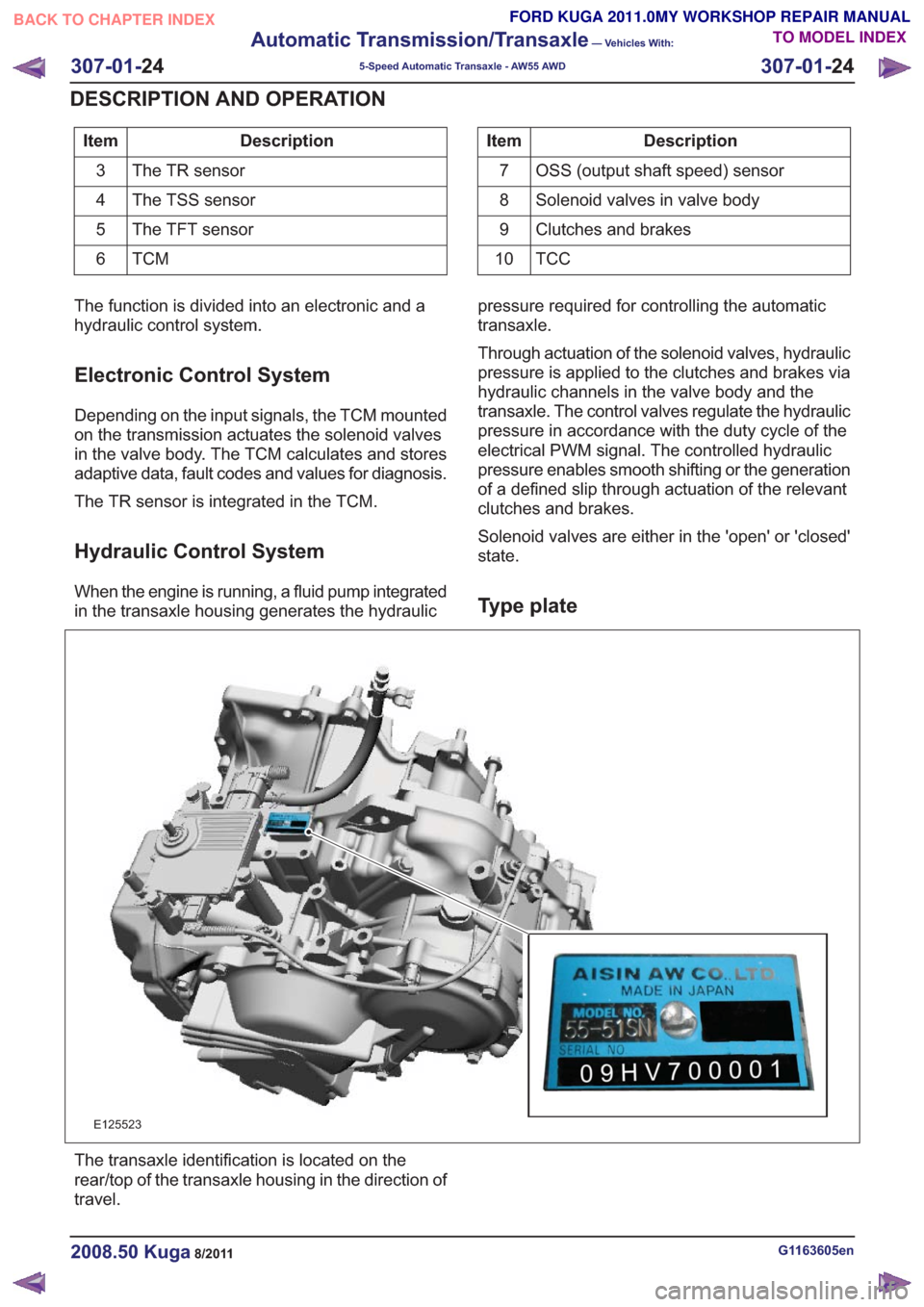

Description

Item

The TR sensor

3

The TSS sensor

4

The TFT sensor

5

TCM6Description

Item

OSS (output shaft speed) sensor

7

Solenoid valves in valve body

8

Clutches and brakes

9

TCC

10

The function is divided into an electronic and a

hydraulic control system.

Electronic Control System

Depending on the input signals, the TCM mounted

on the transmission actuates the solenoid valves

in the valve body. The TCM calculates and stores

adaptive data, fault codes and values for diagnosis.

The TR sensor is integrated in the TCM.

Hydraulic Control System

When the engine is running, a fluid pump integrated

in the transaxle housing generates the hydraulic pressure required for controlling the automatic

transaxle.

Through actuation of the solenoid valves, hydraulic

pressure is applied to the clutches and brakes via

hydraulic channels in the valve body and the

transaxle. The control valves regulate the hydraulic

pressure in accordance with the duty cycle of the

electrical PWM signal. The controlled hydraulic

pressure enables smooth shifting or the generation

of a defined slip through actuation of the relevant

clutches and brakes.

Solenoid valves are either in the 'open' or 'closed'

state.Type plate

E125523

The transaxle identification is located on the

rear/top of the transaxle housing in the direction of

travel.

G1163605en2008.50 Kuga8/2011

307-01-

24

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 24

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1847 of 2057

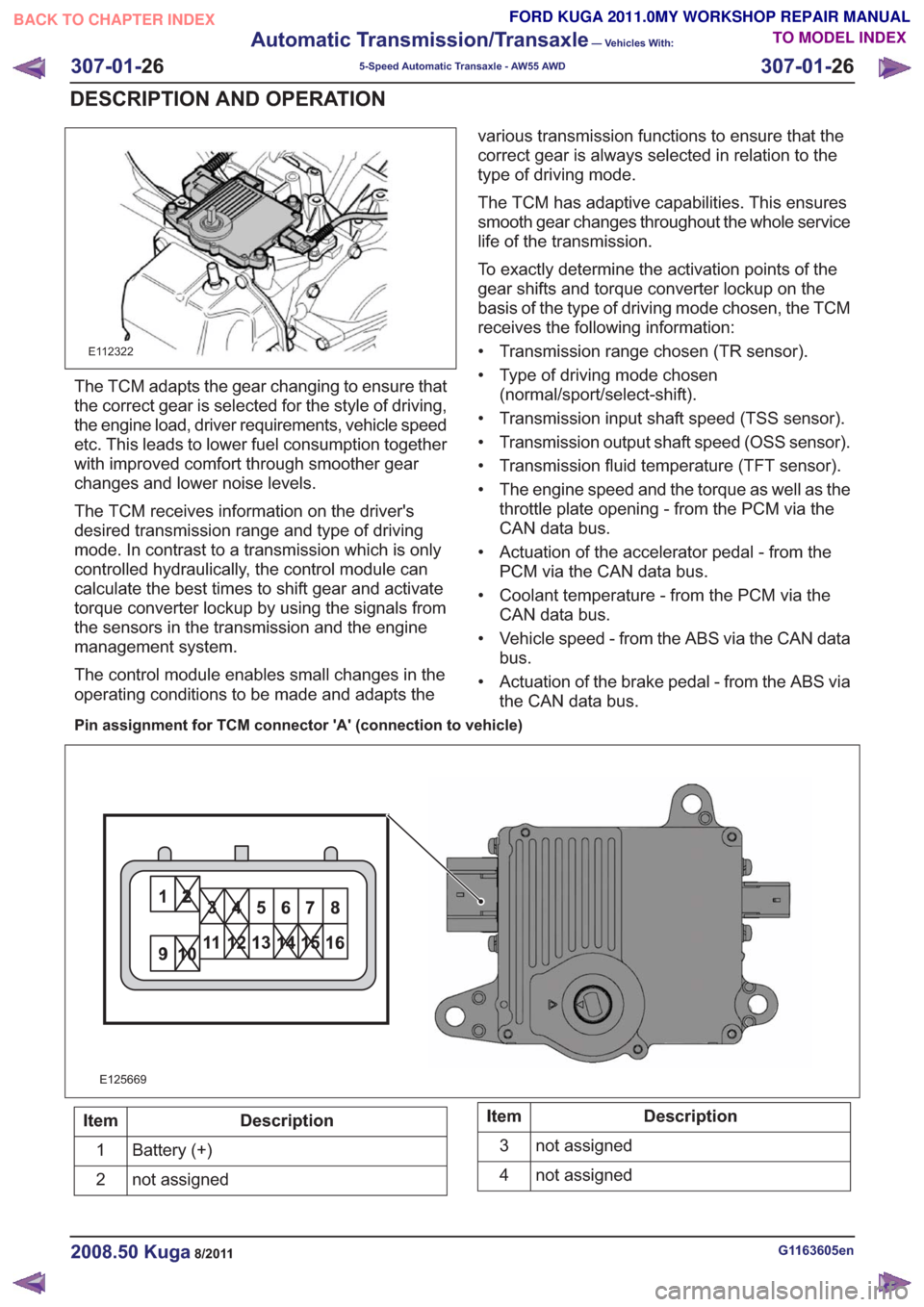

E112322

The TCM adapts the gear changing to ensure that

the correct gear is selected for the style of driving,

the engine load, driver requirements, vehicle speed

etc. This leads to lower fuel consumption together

with improved comfort through smoother gear

changes and lower noise levels.

The TCM receives information on the driver's

desired transmission range and type of driving

mode. In contrast to a transmission which is only

controlled hydraulically, the control module can

calculate the best times to shift gear and activate

torque converter lockup by using the signals from

the sensors in the transmission and the engine

management system.

The control module enables small changes in the

operating conditions to be made and adapts thevarious transmission functions to ensure that the

correct gear is always selected in relation to the

type of driving mode.

The TCM has adaptive capabilities. This ensures

smooth gear changes throughout the whole service

life of the transmission.

To exactly determine the activation points of the

gear shifts and torque converter lockup on the

basis of the type of driving mode chosen, the TCM

receives the following information:

• Transmission range chosen (TR sensor).

• Type of driving mode chosen

(normal/sport/select-shift).

• Transmission input shaft speed (TSS sensor).

• Transmission output shaft speed (OSS sensor).

• Transmission fluid temperature (TFT sensor).

• The engine speed and the torque as well as the throttle plate opening - from the PCM via the

CAN data bus.

• Actuation of the accelerator pedal - from the PCM via the CAN data bus.

• Coolant temperature - from the PCM via the CAN data bus.

• Vehicle speed - from the ABS via the CAN data bus.

• Actuation of the brake pedal - from the ABS via the CAN data bus.

Pin assignment for TCM connector 'A' (connection to vehicle)

11

E125669

Description

Item

Battery (+)

1

not assigned

2Description

Item

not assigned

3

not assigned

4

G1163605en2008.50 Kuga8/2011

307-01- 26

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 26

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1872 of 2057

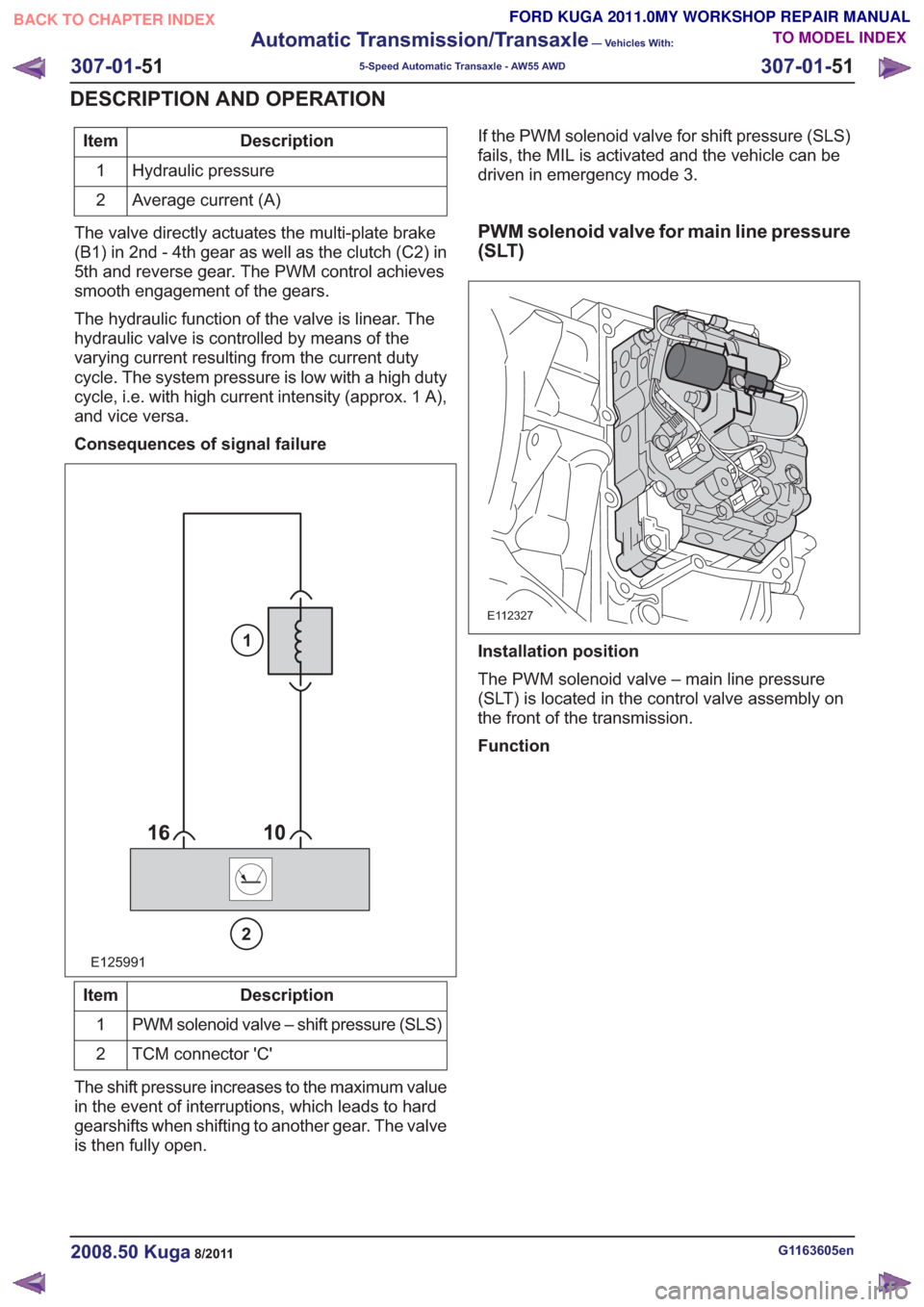

Description

Item

Hydraulic pressure

1

Average current (A)

2

The valve directly actuates the multi-plate brake

(B1) in 2nd - 4th gear as well as the clutch (C2) in

5th and reverse gear. The PWM control achieves

smooth engagement of the gears.

The hydraulic function of the valve is linear. The

hydraulic valve is controlled by means of the

varying current resulting from the current duty

cycle. The system pressure is low with a high duty

cycle, i.e. with high current intensity (approx. 1 A),

and vice versa.

Consequences of signal failure

E125991

2

1

Description

Item

PWM solenoid valve – shift pressure (SLS)

1

TCM connector 'C'

2

The shift pressure increases to the maximum value

in the event of interruptions, which leads to hard

gearshifts when shifting to another gear. The valve

is then fully open. If the PWM solenoid valve for shift pressure (SLS)

fails, the MIL is activated and the vehicle can be

driven in emergency mode 3.

PWM solenoid valve for main line pressure

(SLT)

E112327

Installation position

The PWM solenoid valve – main line pressure

(SLT) is located in the control valve assembly on

the front of the transmission.

Function

G1163605en2008.50 Kuga8/2011

307-01-

51

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 51

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1970 of 2057

Fuel System — Vehicles With: Fuel Additive Tank

General EquipmentFord diagnostic equipment

Principles of Operation

WARNINGS:

This procedure involves fuel additive

handling. Be prepared for fuel additive

spillage at all times and always observe

fuel handling precautions. Failure to follow

these instructions may result in personal

injury.

Eye, hand, ear protection and protective

clothing are required to be worn during

any general service or removal and

installation service procedure of fuel

additive system components. Failure to

follow this instruction may result in

personal injury.

In case of fuel additive fluid contact with

the skin or the eyes, flush immediately with

water for a minimum of 15 minutes and

seek prompt medical attention. Failure to

follow these instructions may result in

personal injury.

If fuel additive fluid is swallowed, call a

physician immediately. Rinse mouth

immediately with water, do not induce

vomiting. Failure to follow these

instructions may result in personal injury.

Always provide adequate ventilation when

working on the fuel additive fluid system

or related components. Failure to follow

these instructions may result in personal

injury.

Do not smoke or carry lighted tobacco or

open flame of any type when working on

or near any fuel related components.

Highly flammable vapors are always

present and may ignite. Failure to follow

these instructions may result in personal

injury.

CAUTION: Make sure the workshop area

in which the vehicle is being worked on is

as clean and as dust free as possible.

Foreign matter from working on clutches,

brakes or from machining or welding

operations can contaminate the fuel

system and may result in later malfunction. The fuel additive system is an on-board system

that allows the injection of an additive at each

refueling operation by the customer. The additive

quantity is proportional to the fuel quantity that has

been added. The fuel additive system module

controls the amount of additive fluid entering the

fuel tank at each refueling, A switch mounted on

the fuel filler flap is used to detect the start of the

refueling event and the fuel gauge that is mounted

within the fuel tank informs the fuel additive tank

module the quantity of actual fuel added.

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of leakage

and mechanical or electrical damage.

Visual Inspection Chart

Electrical

Mechanical

– Fuse(s)

– Fuel filler switch andmagnet

– Wiring harness(s)

– Electrical connector(s)

– Fuel additive system module

– Fuel additive tank module

– Instrument cluster

– Powertrain Control Module (PCM)

– Fuel level sensor

– Fuel additive tank

– Fuel additive tank

line(s)

– Fuel additive tank pipe(s)

– Fuel additive tank connector(s)

– Fuel tank filler cap

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step

4. If the cause is not visually evident, REFER to the Ford diagnostic equipment.

G1080718en2008.50 Kuga8/2011

310-00- 2

Fuel System - General Information

310-00- 2

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2006 of 2057

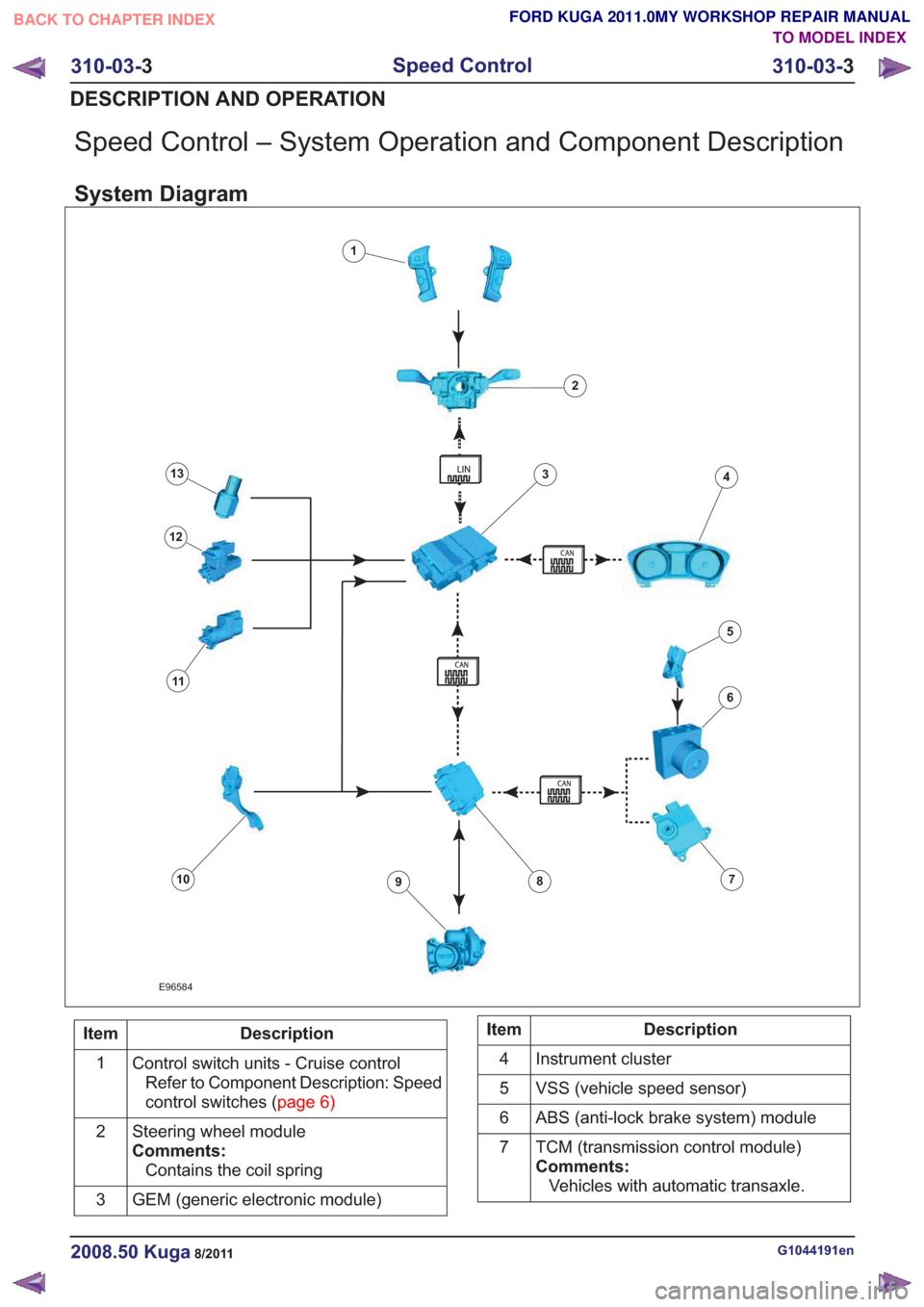

Speed Control – System Operation and Component Description

System Diagram

E96584

1

2

34

6

78910

11

12

13

5

Description

Item

Control switch units - Cruise controlRefer to Component Description: Speed

controlswitches(page6)

1

Steering wheel module

Comments:Contains the coil spring

2

GEM (generic electronic module)

3Description

Item

Instrument cluster

4

VSS (vehicle speed sensor)

5

ABS (anti-lock brake system) module

6

TCM (transmission control module)

Comments:Vehicles with automatic transaxle.

7

G1044191en2008.50 Kuga8/2011

310-03-

3

Speed Control

310-03- 3

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2007 of 2057

Description

Item

PCM

8

Throttle body

Comments:Contains the TP (throttle position) sensor

9

The APP (accelerator pedal position)

sensor.

10Description

Item

CPP (clutch pedal position) switch

Comments:Vehicles with manual transaxle.

11

BPP (brake pedal position) switch

12

Reverse gear solenoid

Comments:Vehicles with manual transaxle.

13

System Operation

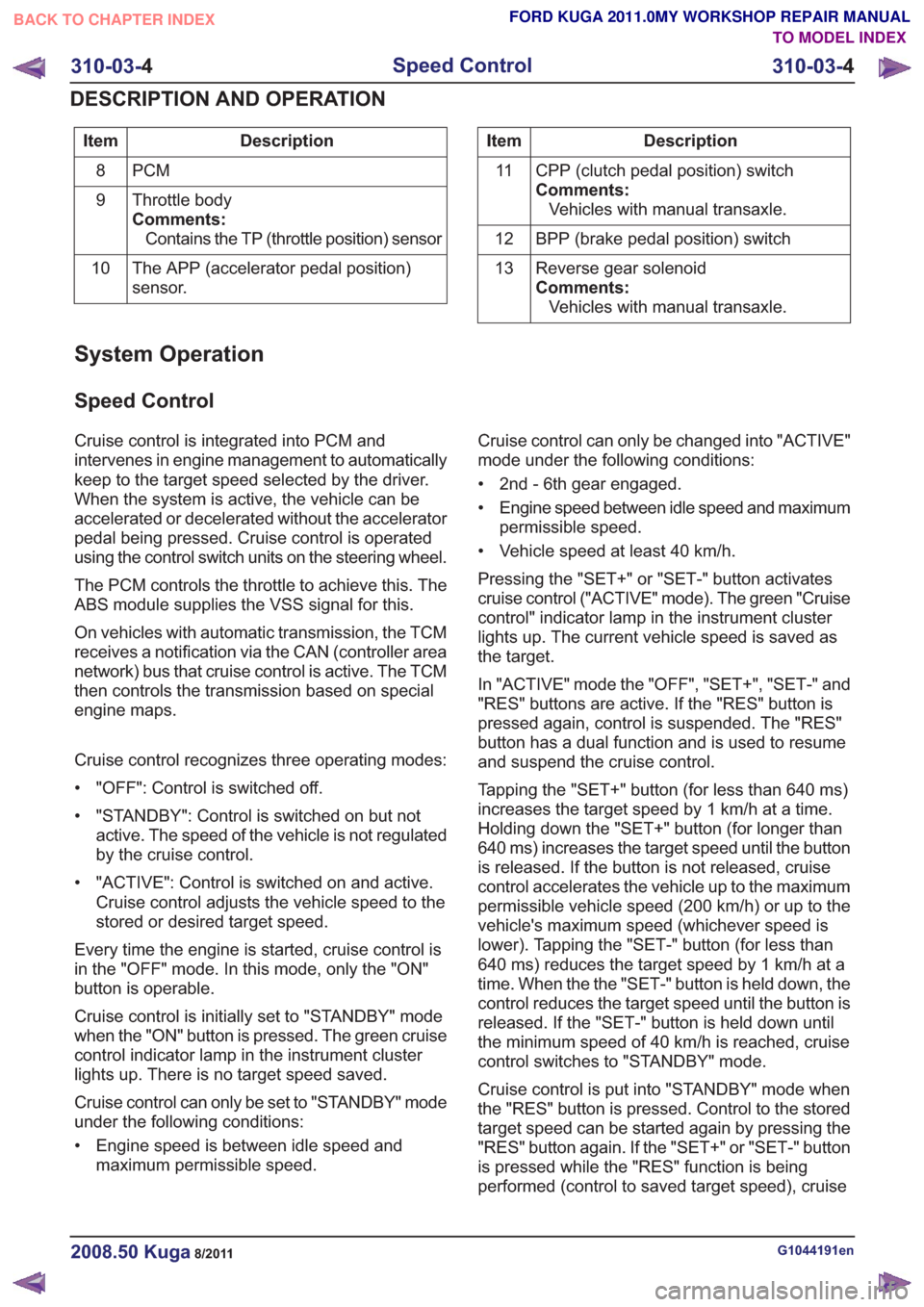

Speed Control

Cruise control is integrated into PCM and

intervenes in engine management to automatically

keep to the target speed selected by the driver.

When the system is active, the vehicle can be

accelerated or decelerated without the accelerator

pedal being pressed. Cruise control is operated

using the control switch units on the steering wheel.

The PCM controls the throttle to achieve this. The

ABS module supplies the VSS signal for this.

On vehicles with automatic transmission, the TCM

receives a notification via the CAN (controller area

network) bus that cruise control is active. The TCM

then controls the transmission based on special

engine maps.

Cruise control recognizes three operating modes:

• "OFF": Control is switched off.

• "STANDBY": Control is switched on but not

active. The speed of the vehicle is not regulated

by the cruise control.

• "ACTIVE": Control is switched on and active. Cruise control adjusts the vehicle speed to the

stored or desired target speed.

Every time the engine is started, cruise control is

in the "OFF" mode. In this mode, only the "ON"

button is operable.

Cruise control is initially set to "STANDBY" mode

when the "ON" button is pressed. The green cruise

control indicator lamp in the instrument cluster

lights up. There is no target speed saved.

Cruise control can only be set to "STANDBY" mode

under the following conditions:

• Engine speed is between idle speed and maximum permissible speed. Cruise control can only be changed into "ACTIVE"

mode under the following conditions:

• 2nd - 6th gear engaged.

• Engine speed between idle speed and maximum

permissible speed.

• Vehicle speed at least 40 km/h.

Pressing the "SET+" or "SET-" button activates

cruise control ("ACTIVE" mode). The green "Cruise

control" indicator lamp in the instrument cluster

lights up. The current vehicle speed is saved as

the target.

In "ACTIVE" mode the "OFF", "SET+", "SET-" and

"RES" buttons are active. If the "RES" button is

pressed again, control is suspended. The "RES"

button has a dual function and is used to resume

and suspend the cruise control.

Tapping the "SET+" button (for less than 640 ms)

increases the target speed by 1 km/h at a time.

Holding down the "SET+" button (for longer than

640 ms) increases the target speed until the button

is released. If the button is not released, cruise

control accelerates the vehicle up to the maximum

permissible vehicle speed (200 km/h) or up to the

vehicle's maximum speed (whichever speed is

lower). Tapping the "SET-" button (for less than

640 ms) reduces the target speed by 1 km/h at a

time. When the the "SET-" button is held down, the

control reduces the target speed until the button is

released. If the "SET-" button is held down until

the minimum speed of 40 km/h is reached, cruise

control switches to "STANDBY" mode.

Cruise control is put into "STANDBY" mode when

the "RES" button is pressed. Control to the stored

target speed can be started again by pressing the

"RES" button again. If the "SET+" or "SET-" button

is pressed while the "RES" function is being

performed (control to saved target speed), cruise

G1044191en2008.50 Kuga8/2011

310-03- 4

Speed Control

310-03- 4

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL