FORD KUGA 2011 1.G User Guide

KUGA 2011 1.G

FORD

FORD

https://www.carmanualsonline.info/img/11/5478/w960_5478-0.png

FORD KUGA 2011 1.G User Guide

Page 1427 of 2057

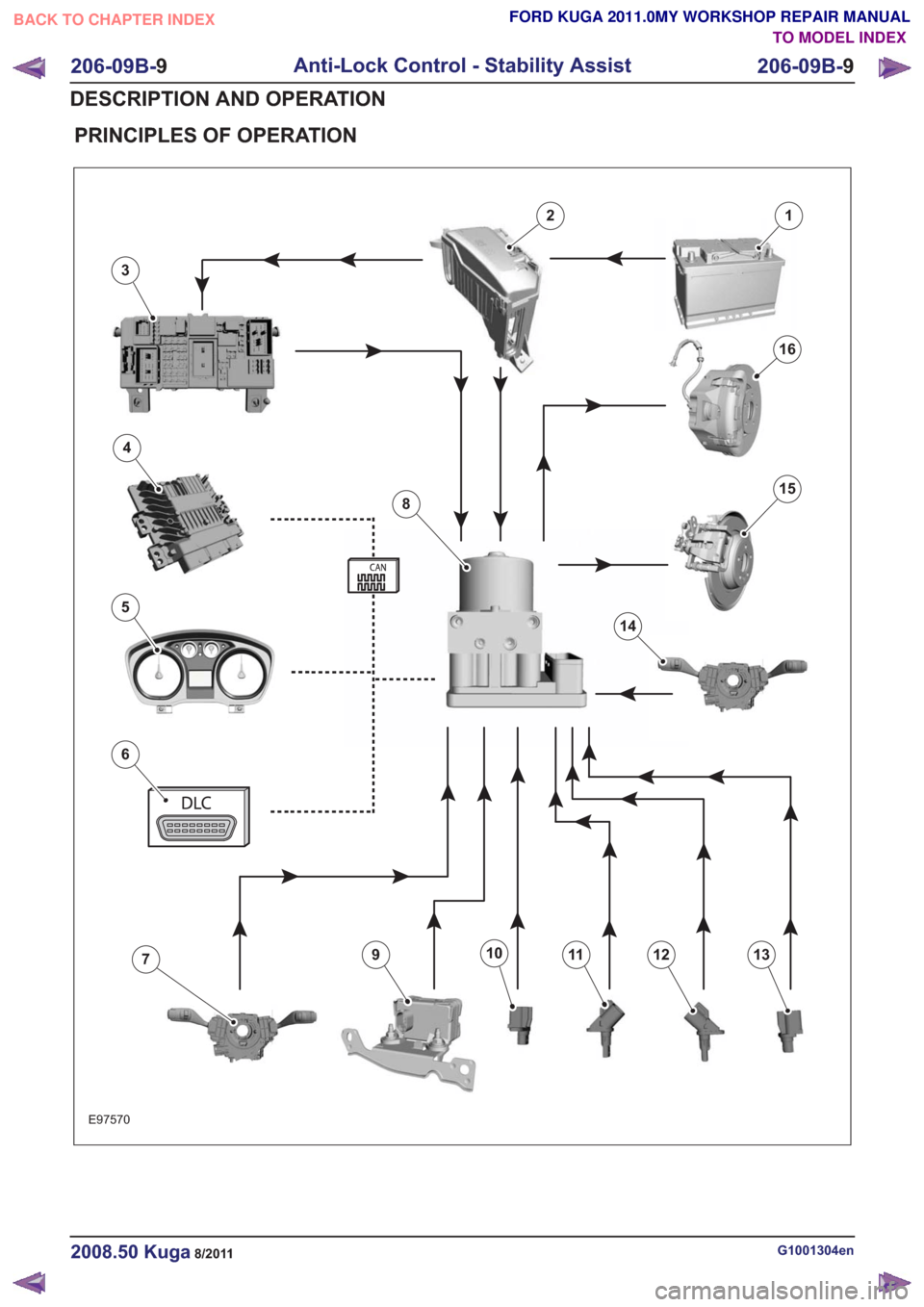

PRINCIPLES OF OPERATION

E97570

12

3

4

5

6

7910111213

815

16

14

G1001304en2008.50 Kuga8/2011

206-09B-9

Anti-Lock Control - Stability Assist

206-09B- 9

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1556 of 2057

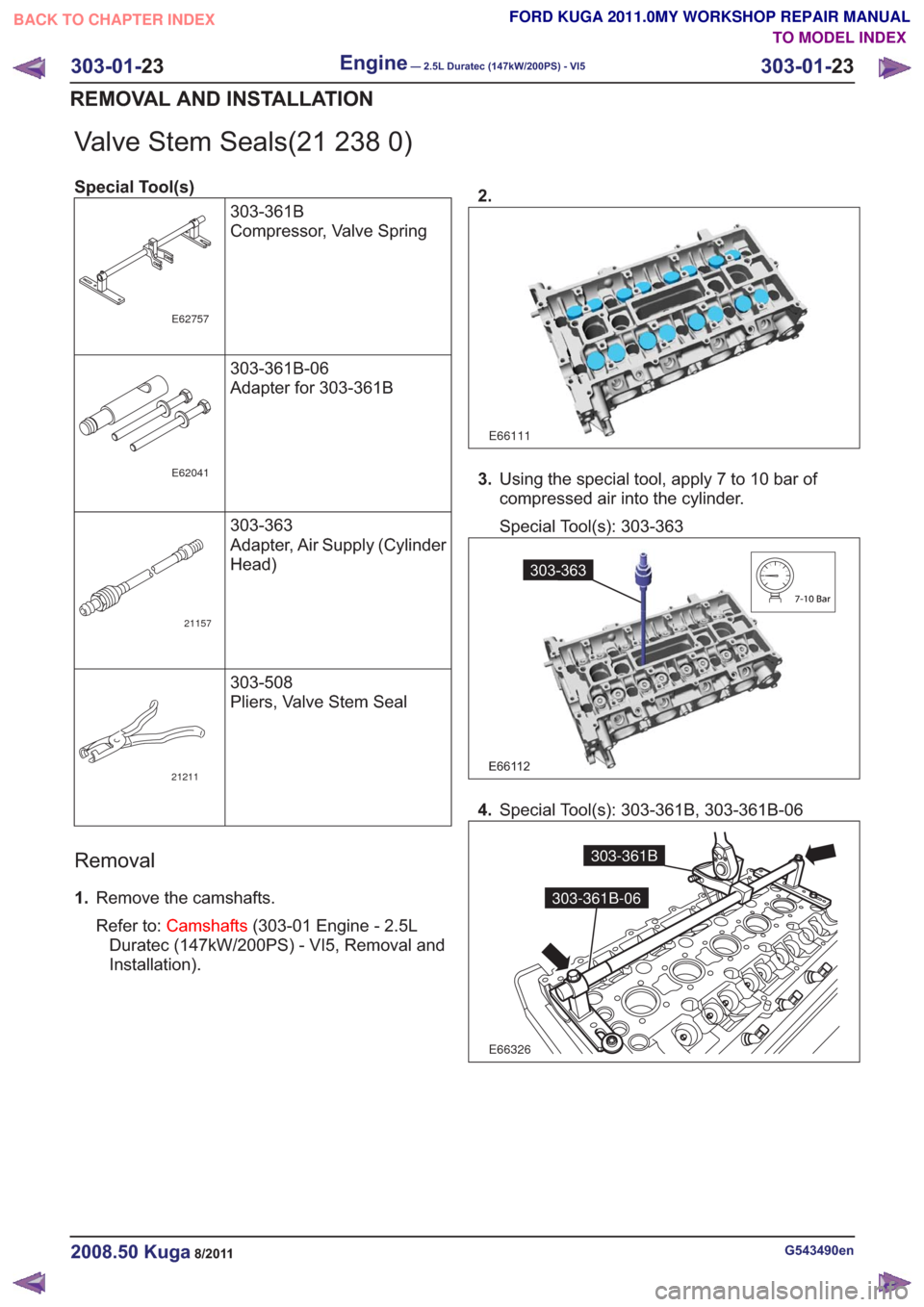

Valve Stem Seals(21 238 0)

Special Tool(s)303-361B

Compressor, Valve Spring

E62757

303-361B-06

Adapter for 303-361B

E62041

303-363

Adapter, Air Supply (Cylinder

Head)

21157

303-508

Pliers, Valve Stem Seal

21211

Removal

1.Remove the camshafts.

Refer to: Camshafts (303-01 Engine - 2.5L

Duratec (147kW/200PS) - VI5, Removal and

Installation). 2.

E66111

3.

Using the special tool, apply 7 to 10 bar of

compressed air into the cylinder.

Special Tool(s): 303-363

E66112

303-363

4.Special Tool(s): 303-361B, 303-361B-06

E66326

303-361B

303-361B-06

G543490en2008.50 Kuga8/2011

303-01- 23

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

23

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1567 of 2057

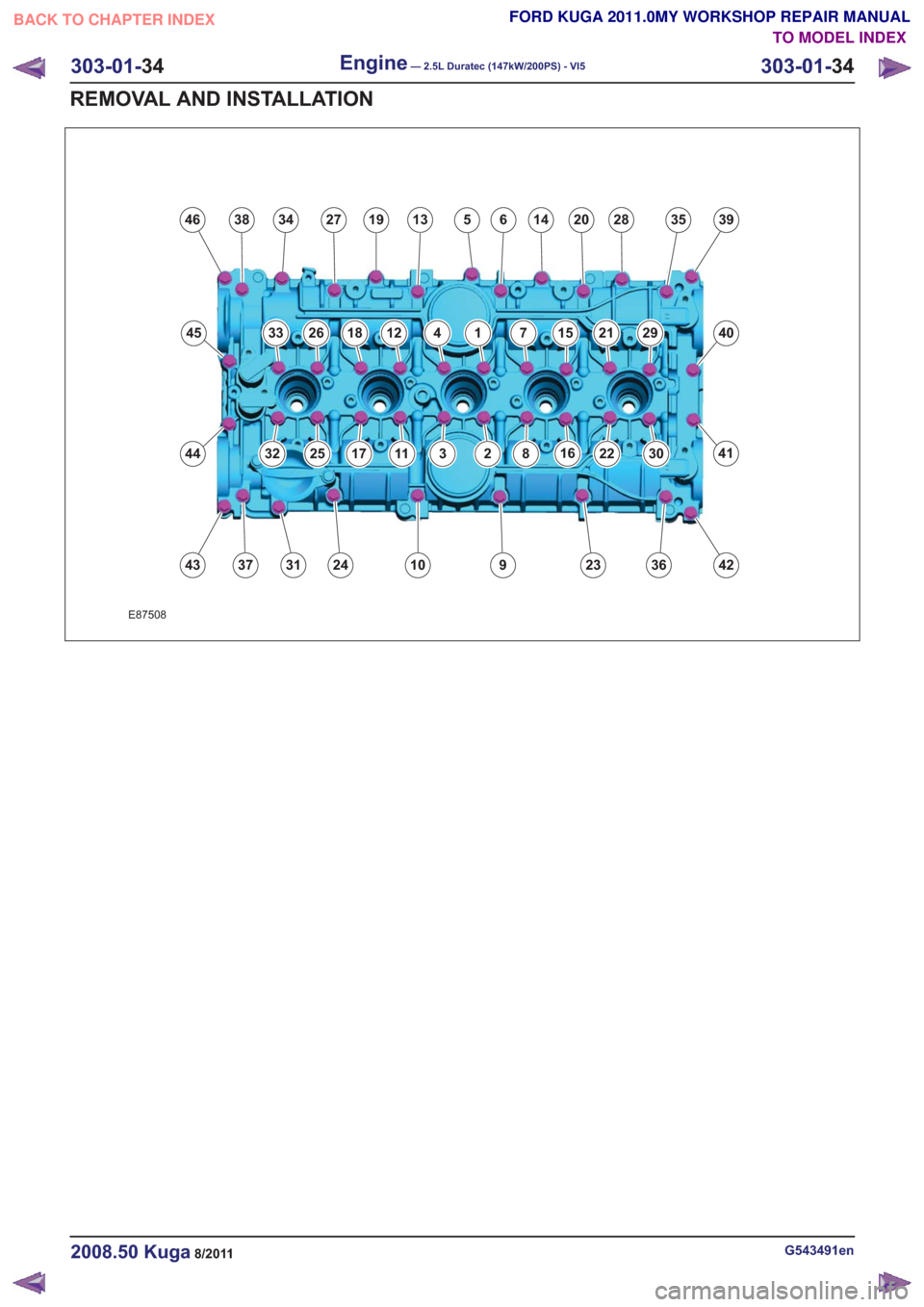

E87508

46

45

44

43

3834271913514202839

40

41

423623910243137

635

29211571412182633

30221682311172532

G543491en2008.50 Kuga8/2011

303-01-34

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

34

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1587 of 2057

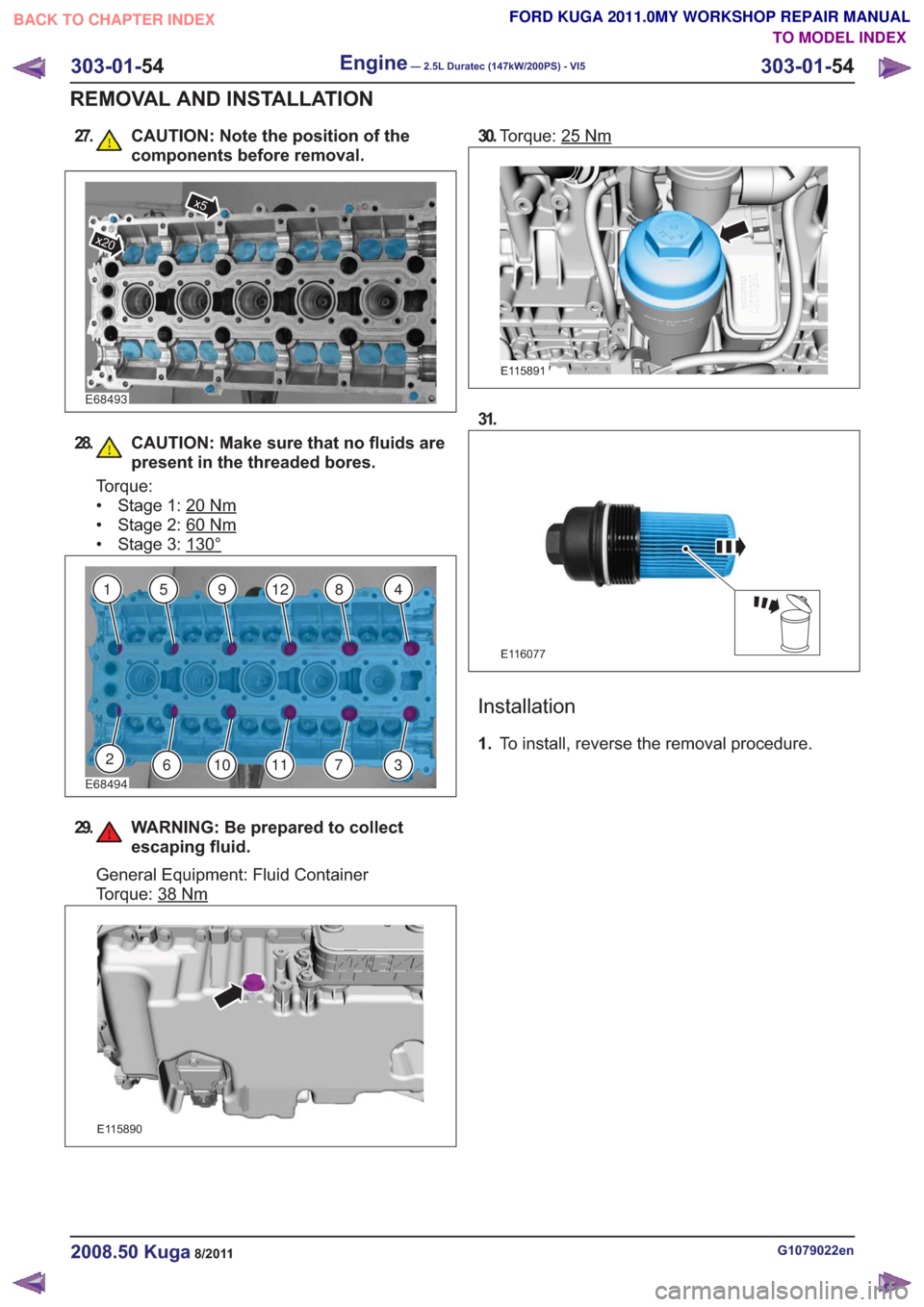

27. CAUTION: Note the position of thecomponents before removal.

E68493

x20

x5

28. CAUTION: Make sure that no fluids arepresent in the threaded bores.

Torque:

• Stage 1: 20

Nm

• Stage 2: 60Nm

• Stage 3: 130°

E68494

1591284

37111062

29. WARNING: Be prepared to collectescaping fluid.

General Equipment: Fluid Container

Torque: 38

Nm

E115890

30.Torque: 25Nm

E115891

31.

E116077

Installation

1.To install, reverse the removal procedure.

G1079022en2008.50 Kuga8/2011

303-01- 54

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

54

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

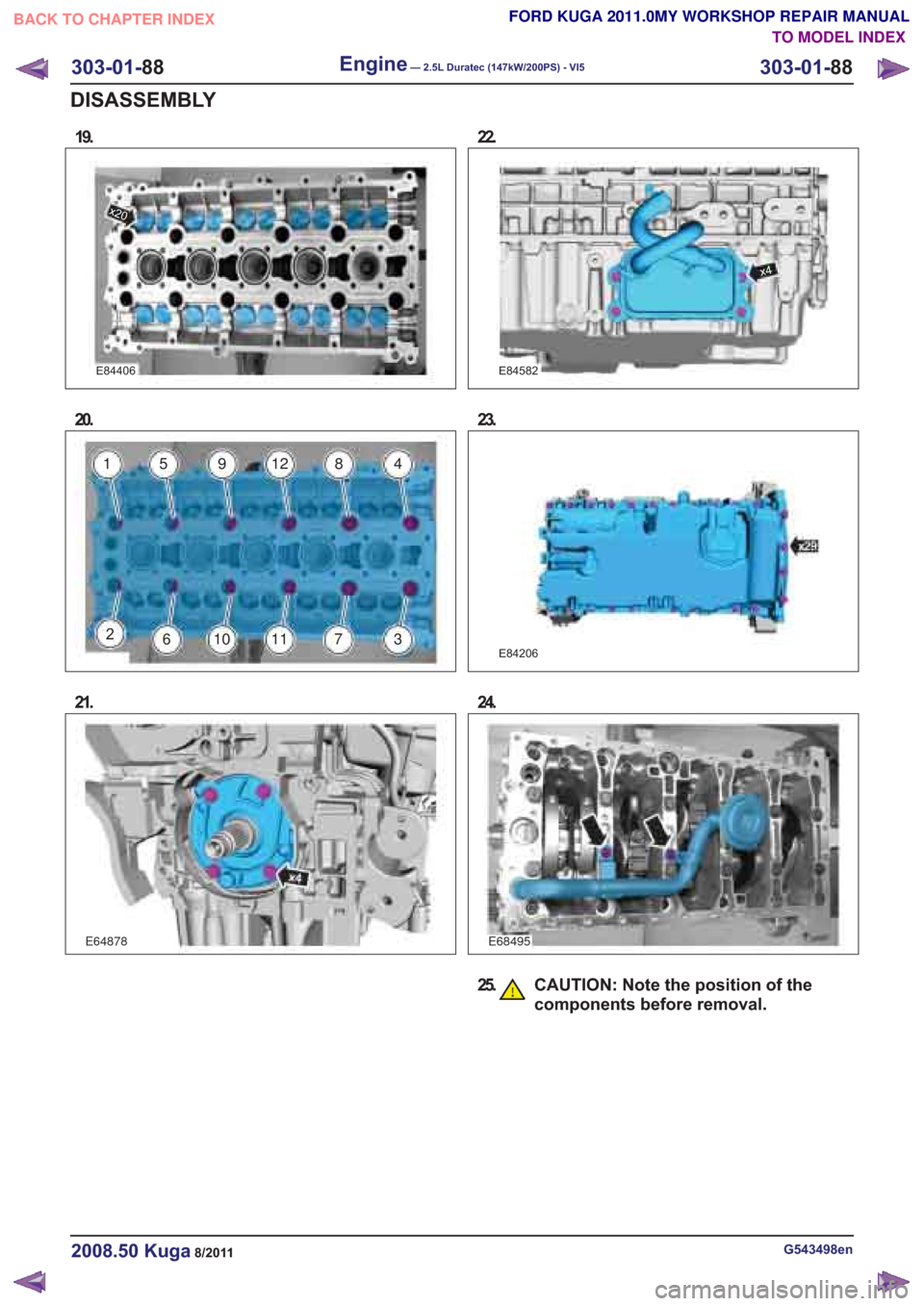

Page 1621 of 2057

E84406

x20

20.

21.

22.

x4

23.

E84206

24.

25. CAUTION: Note the position of thecomponents before removal.

G543498en2008.50 Kuga8/2011

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALBACK TO CHAPTER INDEX

TO MODEL INDEX

1591284

3711106

2

E64878E68495

19.

E84582

303-01-

88

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

88

DISASSEMBLY

Page 1638 of 2057

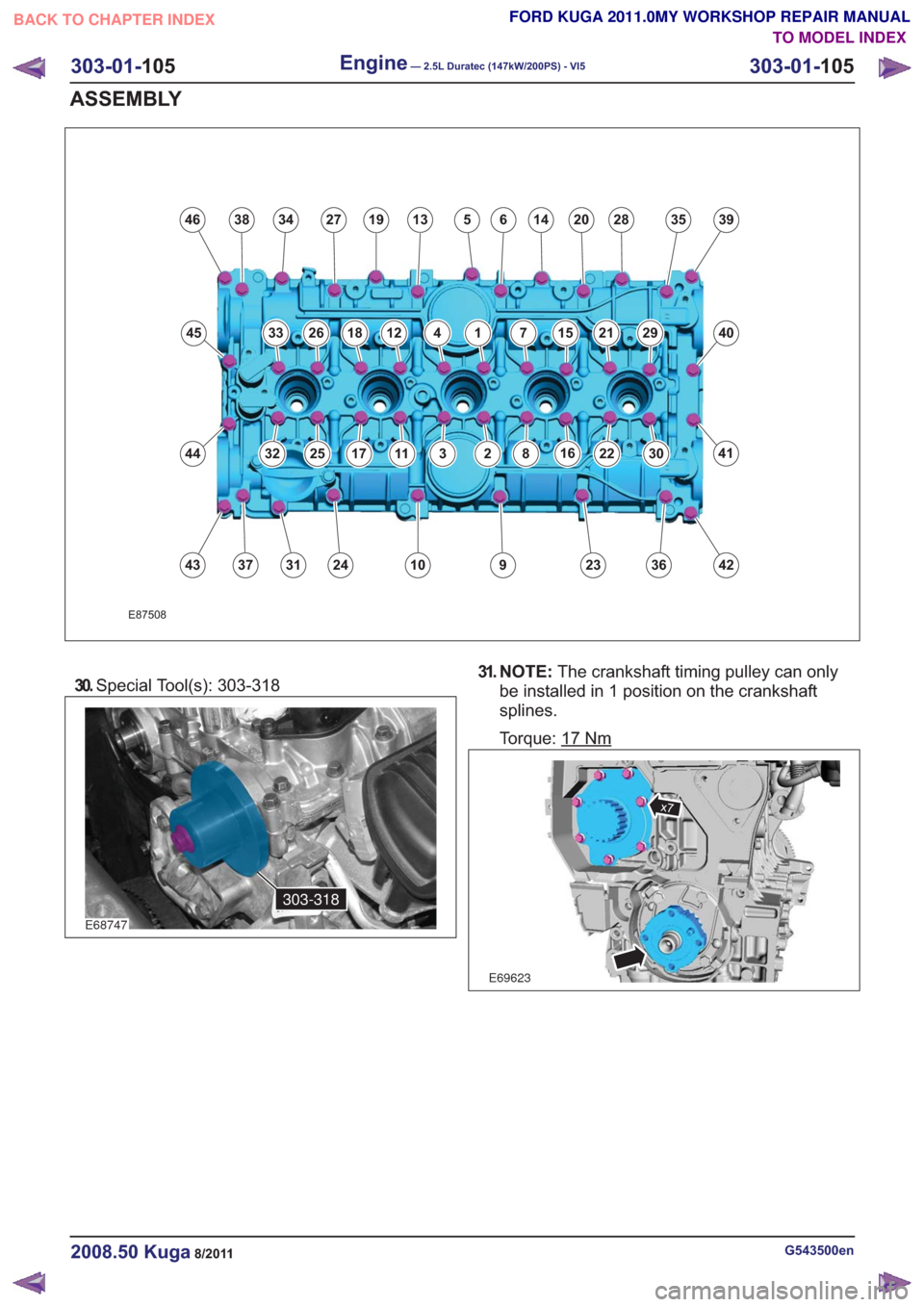

E87508

46

45

44

43

3834271913514202839

40

41

423623910243137

635

29211571412182633

30221682311172532

30.Special Tool(s): 303-318

E68747

303-318

31. N O T E : The crankshaft timing pulley can only

be installed in 1 position on the crankshaft

splines.

Torque: 17

Nm

E69623

x7

G543500en2008.50 Kuga8/2011

303-01- 105

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

105

ASSEMBLY

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1644 of 2057

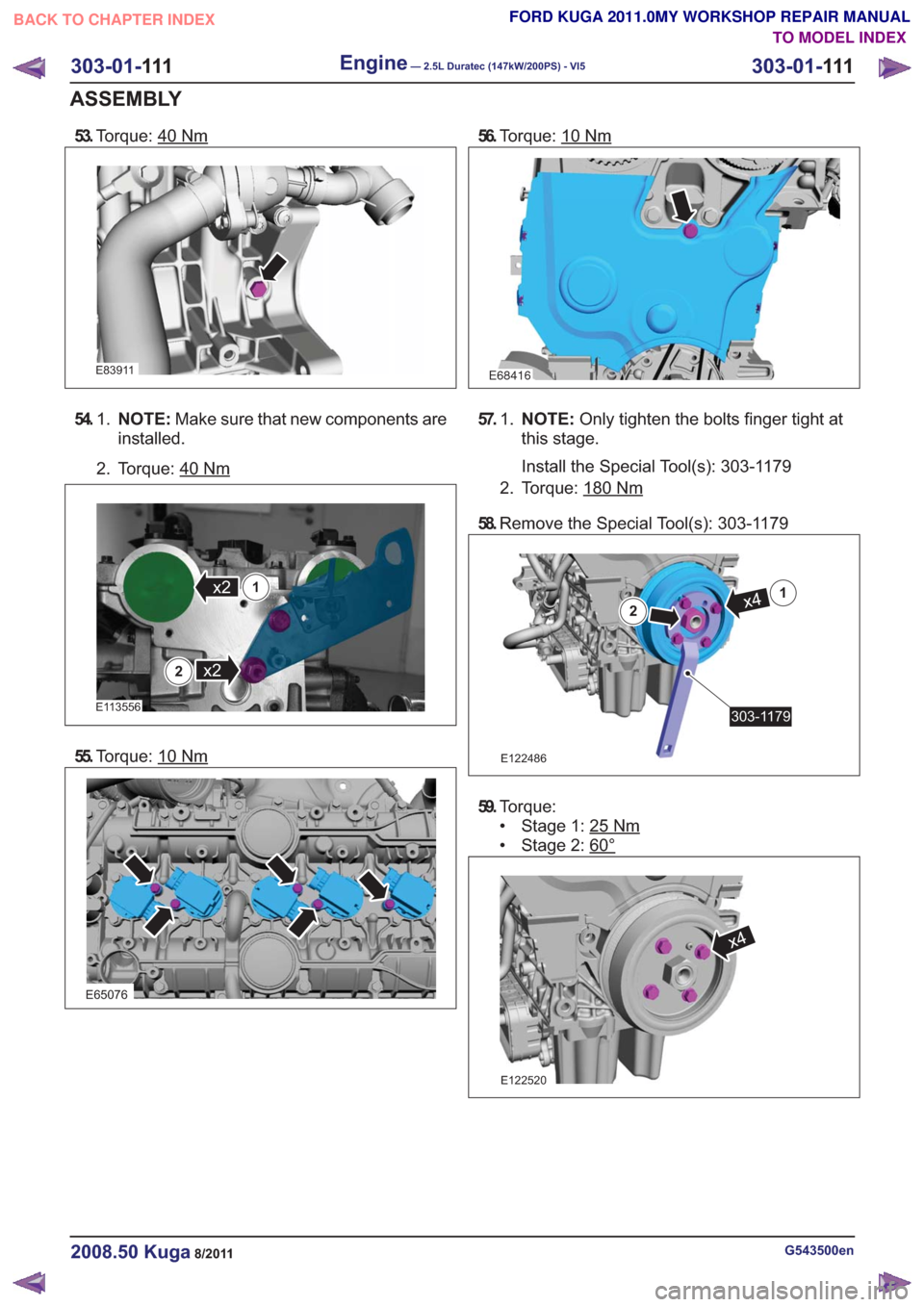

53.Torque: 40Nm

E83911

54. N O T E : Make sure that new components are

installed.

1.

2. Torque: 40

Nm

E113556

x21

x22

55.

Torque: 10Nm

E65076

56.Torque: 10Nm

E68416

57. N O T E : Only tighten the bolts finger tight at

this stage.

Install the Special Tool(s): 303-1179

1.

2. Torque: 180

Nm

58.

Remove the Special Tool(s): 303-1179

E122486

x41

2

303-1179

59.Torque:

• Stage 1: 25

Nm

• Stage 2: 60°

E122520

x4

G543500en2008.50 Kuga8/2011

303-01- 111

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

111

ASSEMBLY

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1751 of 2057

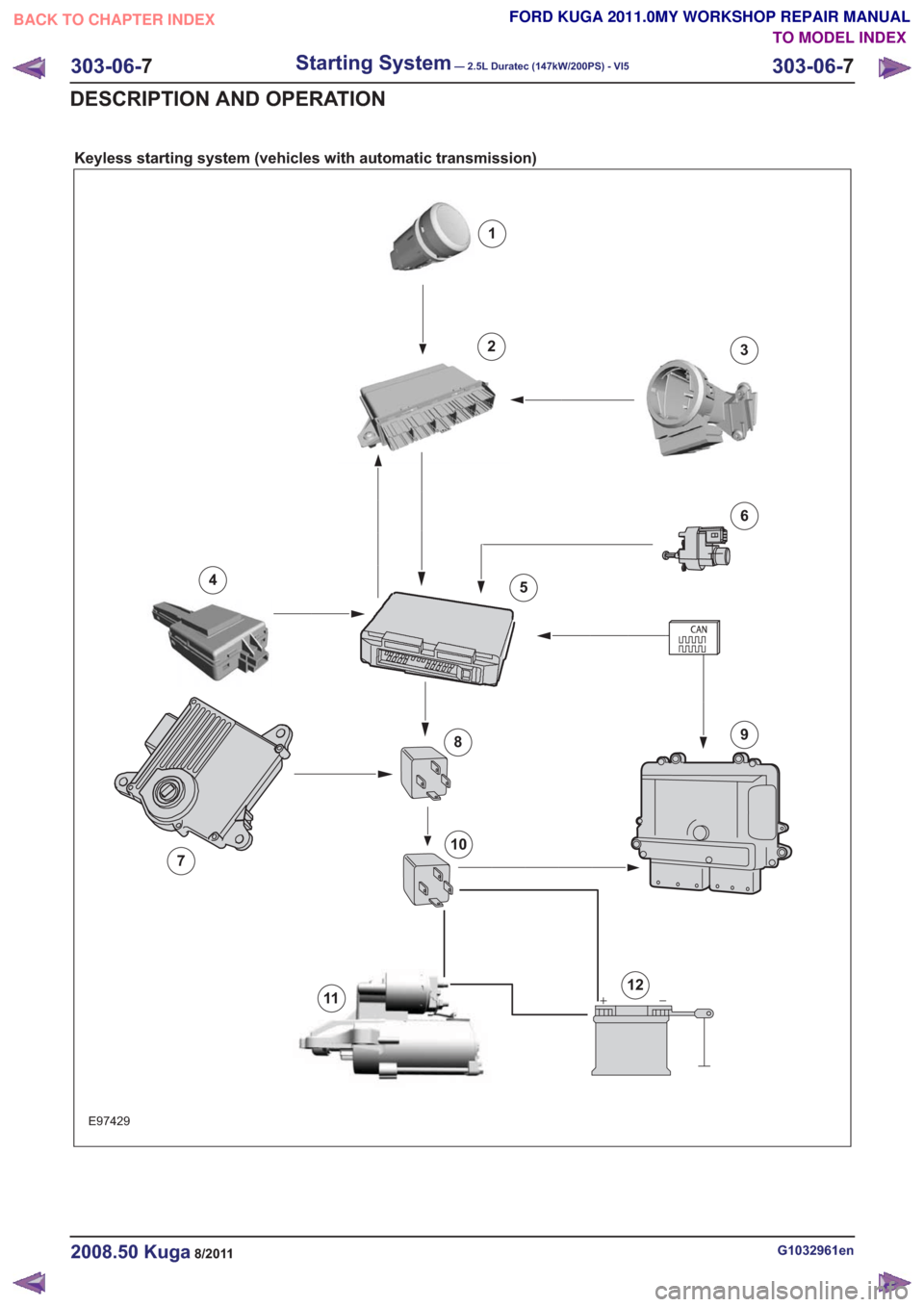

Keyless starting system (vehicles with automatic transmission)

E97429

1

23

45

6

7

89

10

1112

G1032961en2008.50 Kuga8/2011

303-06-7

Starting System— 2.5L Duratec (147kW/200PS) - VI5303-06-

7

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1880 of 2057

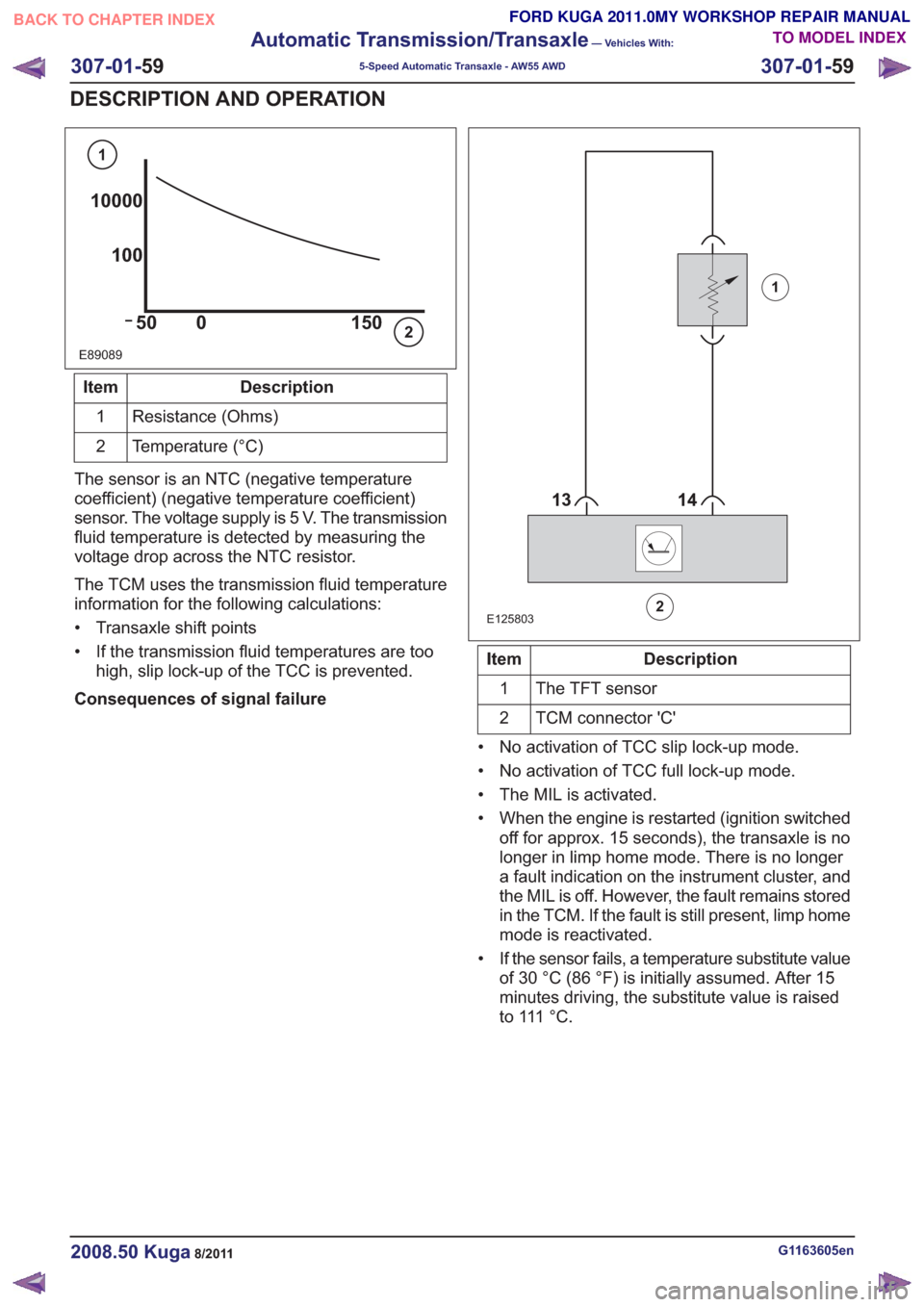

E89089

10000100

50 0 150

1

2

Description

Item

Resistance (Ohms)

1

Temperature (°C)

2

The sensor is an NTC (negative temperature

coefficient) (negative temperature coefficient)

sensor. The voltage supply is 5 V. The transmission

fluid temperature is detected by measuring the

voltage drop across the NTC resistor.

The TCM uses the transmission fluid temperature

information for the following calculations:

• Transaxle shift points

• If the transmission fluid temperatures are too high, slip lock-up of the TCC is prevented.

Consequences of signal failure

88

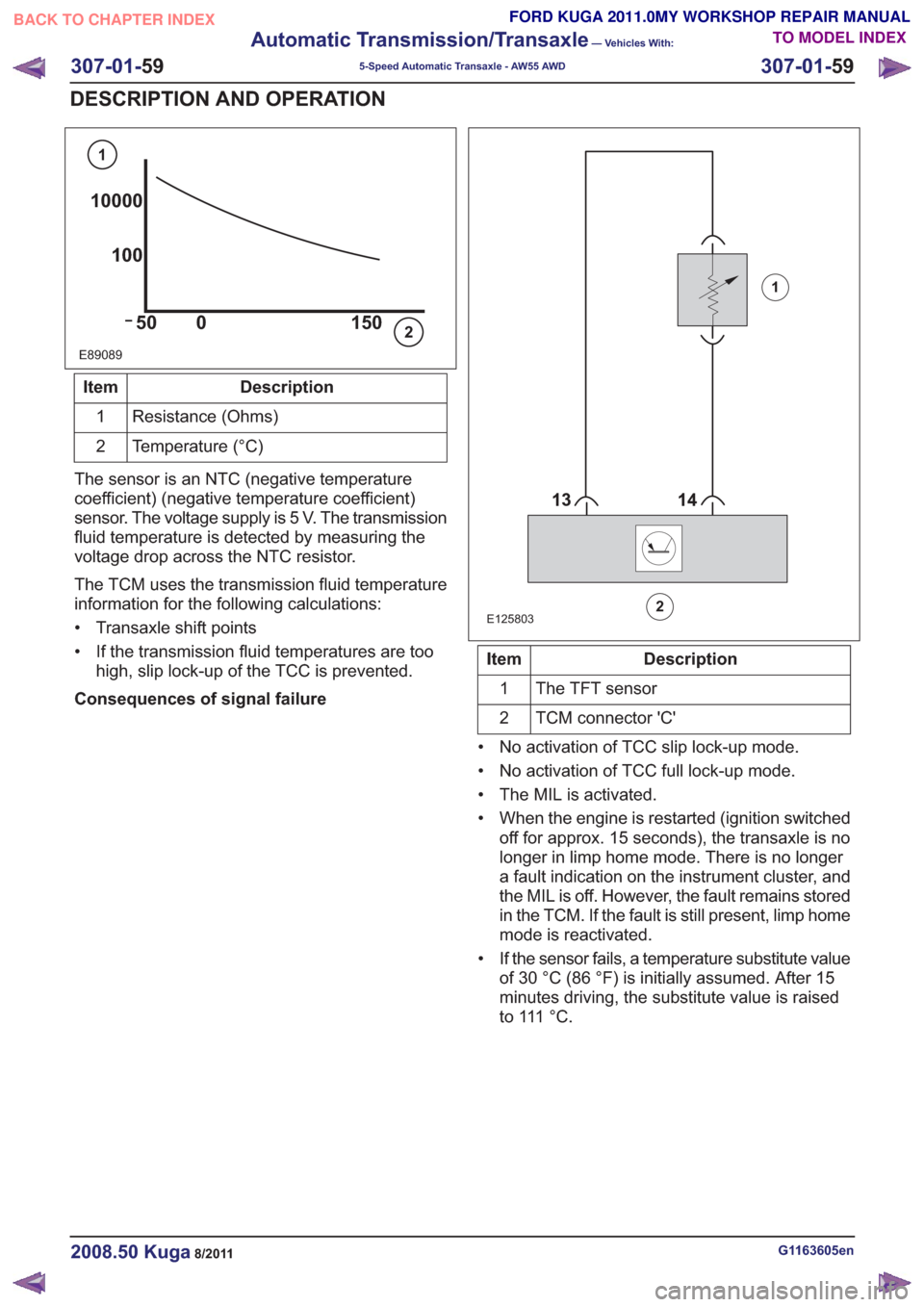

E125803

1

2

Description

Item

The TFT sensor

1

TCM connector 'C'

2

• No activation of TCC slip lock-up mode.

• No activation of TCC full lock-up mode.

• The MIL is activated.

• When the engine is restarted (ignition switched off for approx. 15 seconds), the transaxle is no

longer in limp home mode. There is no longer

a fault indication on the instrument cluster, and

the MIL is off. However, the fault remains stored

in the TCM. If the fault is still present, limp home

mode is reactivated.

• If the sensor fails, a temperature substitute value of 30 °C (86 °F) is initially assumed. After 15

minutes driving, the substitute value is raised

t o 111 ° C .

G1163605en2008.50 Kuga8/2011

307-01- 59

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 59

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL