spring FORD KUGA 2011 1.G Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1330 of 2057

Rear Halfshaft

Special Tool(s) / General Equipment308-759

Remover, Rear Driveshaft

E100143

Cable Ties

Special Tool(s) / General EquipmentTire Lever

Transmission Jack

Materials

Specification

Name

WSK-M2G349-A8 /

9U7J-M2G349-AA

Sealant LGN

Removal

1.

On both sides.

Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

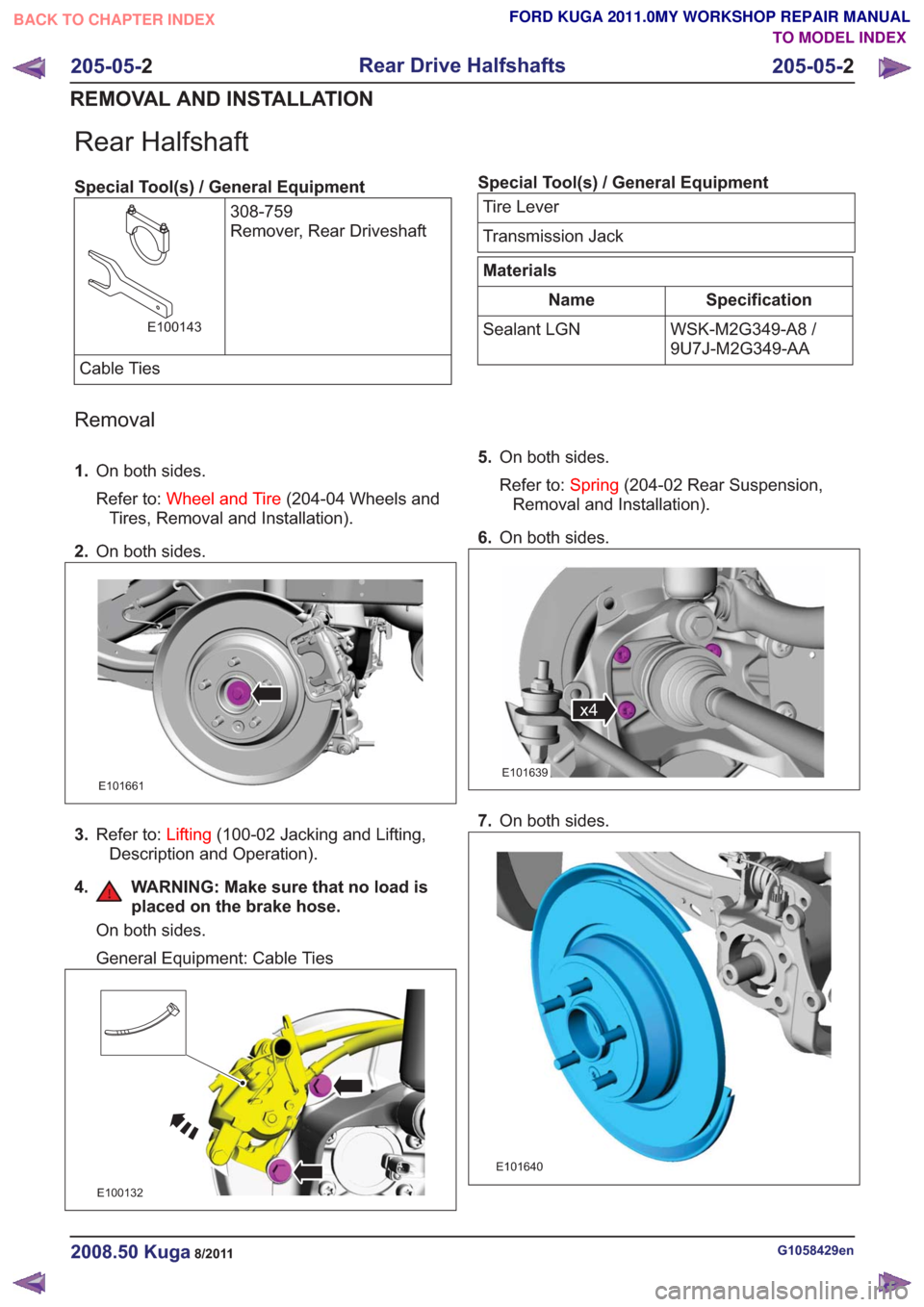

2. On both sides.

E101661

3.Refer to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

4. WARNING: Make sure that no load is placed on the brake hose.

On both sides.

General Equipment: Cable Ties

E100132

5.On both sides.

Refer to: Spring(204-02 Rear Suspension,

Removal and Installation).

6. On both sides.

x4x4

E101639

7.On both sides.

E101640

G1058429en2008.50 Kuga8/2011

205-05- 2

Rear Drive Halfshafts

205-05- 2

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1335 of 2057

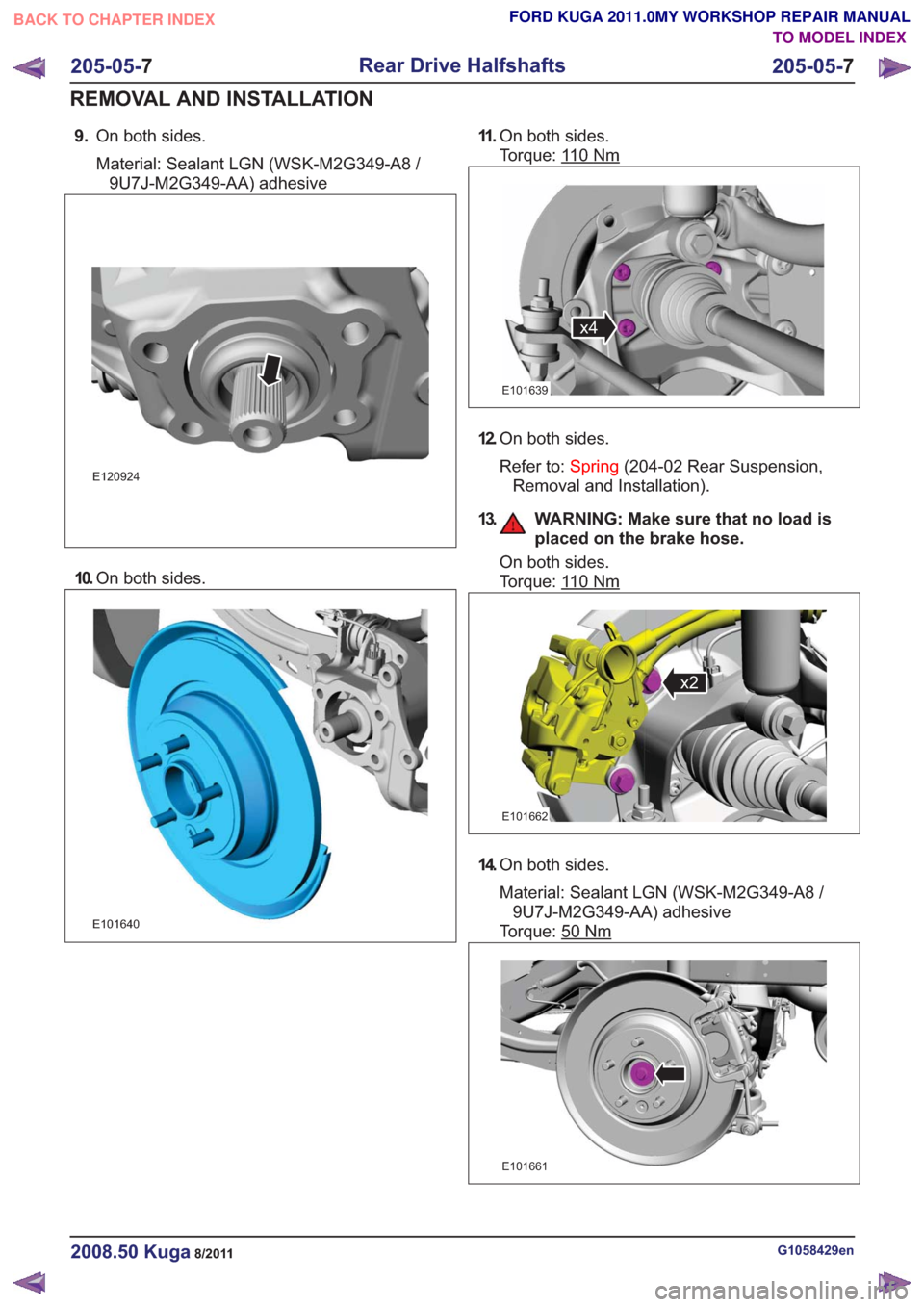

9.On both sides.

Material: Sealant LGN (WSK-M2G349-A8 /

9U7J-M2G349-AA) adhesive

E120924

10. On both sides.

E101640

11 .On both sides.

Torque: 1

10Nm

x4x4

E101639

12.On both sides.

Refer to: Spring(204-02 Rear Suspension,

Removal and Installation).

13. WARNING: Make sure that no load is placed on the brake hose.

On both sides.

Torque: 1

10Nm

x2x2

E101662

14.On both sides.

Material: Sealant LGN (WSK-M2G349-A8 /

9U7J-M2G349-AA) adhesive

Torque: 50

Nm

E101661

G1058429en2008.50 Kuga8/2011

205-05- 7

Rear Drive Halfshafts

205-05- 7

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1424 of 2057

Vehicles with ESP are equipped with an

opto-electronic steering wheel rotation sensor as

an integral part of the clockspring.

The following must be taken into account when

removing/installing or replacing the opto-electronic

steering wheel rotation sensor:

• If installing a new clockspring, remove theclockspring locking screw.

ESP switch

E99006

Stability assist can be deactivated via the menu in

the instrument cluster.

G1001303en2008.50 Kuga8/2011

206-09B- 6

Anti-Lock Control - Stability Assist

206-09B- 6

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1443 of 2057

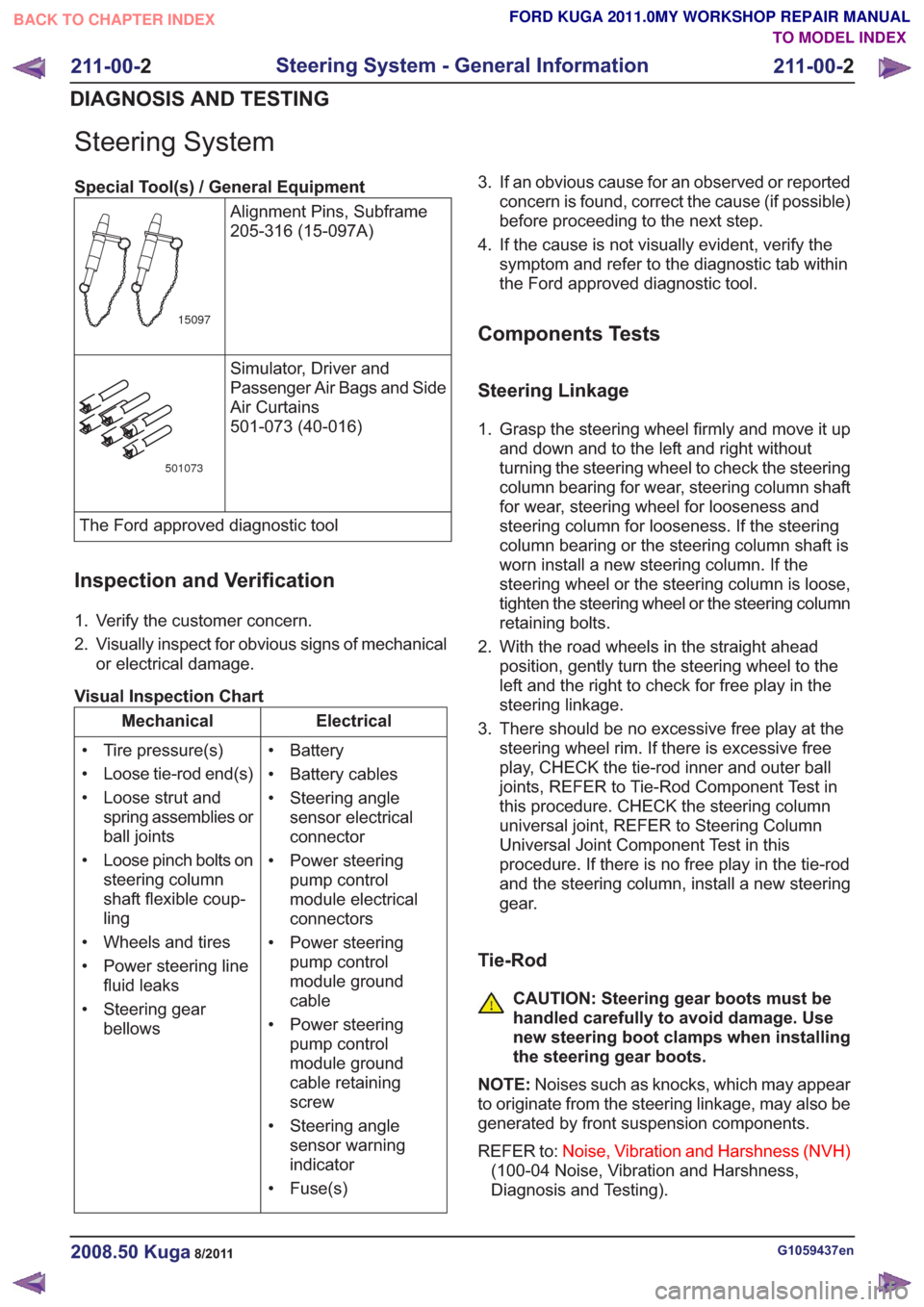

Steering System

Special Tool(s) / General EquipmentAlignment Pins, Subframe

205-316 (15-097A)

15097

Simulator, Driver and

Passenger Air Bags and Side

Air Curtains

501-073 (40-016)

501073

The Ford approved diagnostic tool

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanicalor electrical damage.

Visual Inspection Chart

Electrical

Mechanical

• Battery

• Battery cables

• Steering anglesensor electrical

connector

• Power steering pump control

module electrical

connectors

• Power steering pump control

module ground

cable

• Power steering pump control

module ground

cable retaining

screw

• Steering angle sensor warning

indicator

• Fuse(s)

• Tire pressure(s)

• Loose tie-rod end(s)

• Loose strut and

spring assemblies or

ball joints

• Loose pinch bolts on steering column

shaft flexible coup-

ling

• Wheels and tires

• Power steering line fluid leaks

• Steering gear bellows 3. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the diagnostic tab within

the Ford approved diagnostic tool.

Components Tests

Steering Linkage

1. Grasp the steering wheel firmly and move it upand down and to the left and right without

turning the steering wheel to check the steering

column bearing for wear, steering column shaft

for wear, steering wheel for looseness and

steering column for looseness. If the steering

column bearing or the steering column shaft is

worn install a new steering column. If the

steering wheel or the steering column is loose,

tighten the steering wheel or the steering column

retaining bolts.

2. With the road wheels in the straight ahead position, gently turn the steering wheel to the

left and the right to check for free play in the

steering linkage.

3. There should be no excessive free play at the steering wheel rim. If there is excessive free

play, CHECK the tie-rod inner and outer ball

joints, REFER to Tie-Rod Component Test in

this procedure. CHECK the steering column

universal joint, REFER to Steering Column

Universal Joint Component Test in this

procedure. If there is no free play in the tie-rod

and the steering column, install a new steering

gear.

Tie-Rod

CAUTION: Steering gear boots must be

handled carefully to avoid damage. Use

new steering boot clamps when installing

the steering gear boots.

NOTE: Noises such as knocks, which may appear

to originate from the steering linkage, may also be

generated by front suspension components.

REFER to: Noise, Vibration and Harshness (NVH)

(100-04 Noise, Vibration and Harshness,

Diagnosis and Testing).

G1059437en2008.50 Kuga8/2011

211-00- 2

Steering System - General Information

211-00- 2

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1504 of 2057

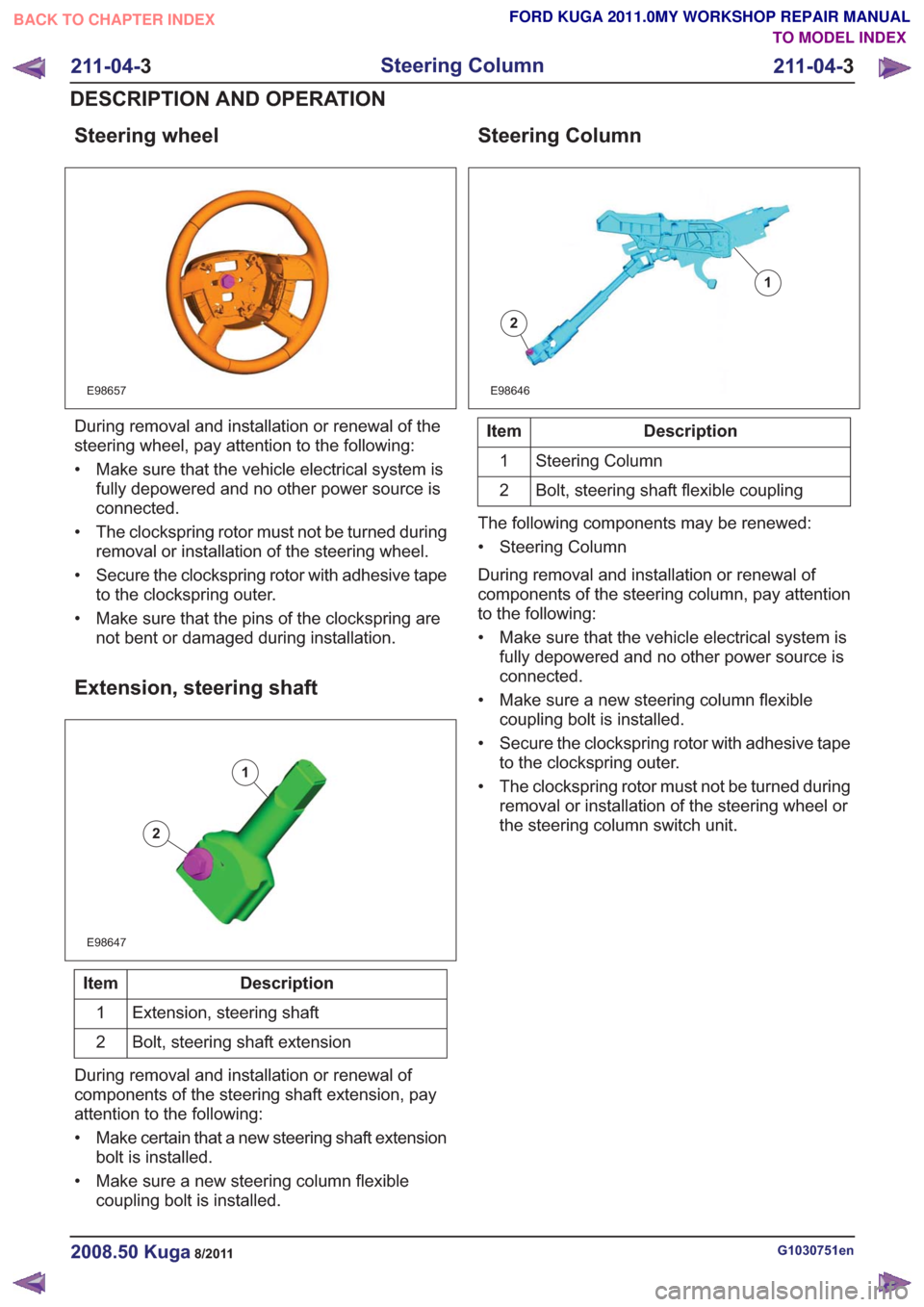

Steering wheel

E98657

During removal and installation or renewal of the

steering wheel, pay attention to the following:

• Make sure that the vehicle electrical system isfully depowered and no other power source is

connected.

• The clockspring rotor must not be turned during removal or installation of the steering wheel.

• Secure the clockspring rotor with adhesive tape to the clockspring outer.

• Make sure that the pins of the clockspring are not bent or damaged during installation.

Extension, steering shaft

E98647

1

2

Description

Item

Extension, steering shaft

1

Bolt, steering shaft extension

2

During removal and installation or renewal of

components of the steering shaft extension, pay

attention to the following:

• Make certain that a new steering shaft extension bolt is installed.

• Make sure a new steering column flexible coupling bolt is installed.

Steering Column

E98646

1

2

Description

Item

Steering Column

1

Bolt, steering shaft flexible coupling

2

The following components may be renewed:

• Steering Column

During removal and installation or renewal of

components of the steering column, pay attention

to the following:

• Make sure that the vehicle electrical system is fully depowered and no other power source is

connected.

• Make sure a new steering column flexible coupling bolt is installed.

• Secure the clockspring rotor with adhesive tape to the clockspring outer.

• The clockspring rotor must not be turned during removal or installation of the steering wheel or

the steering column switch unit.

G1030751en2008.50 Kuga8/2011

211-04- 3

Steering Column

211-04- 3

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1505 of 2057

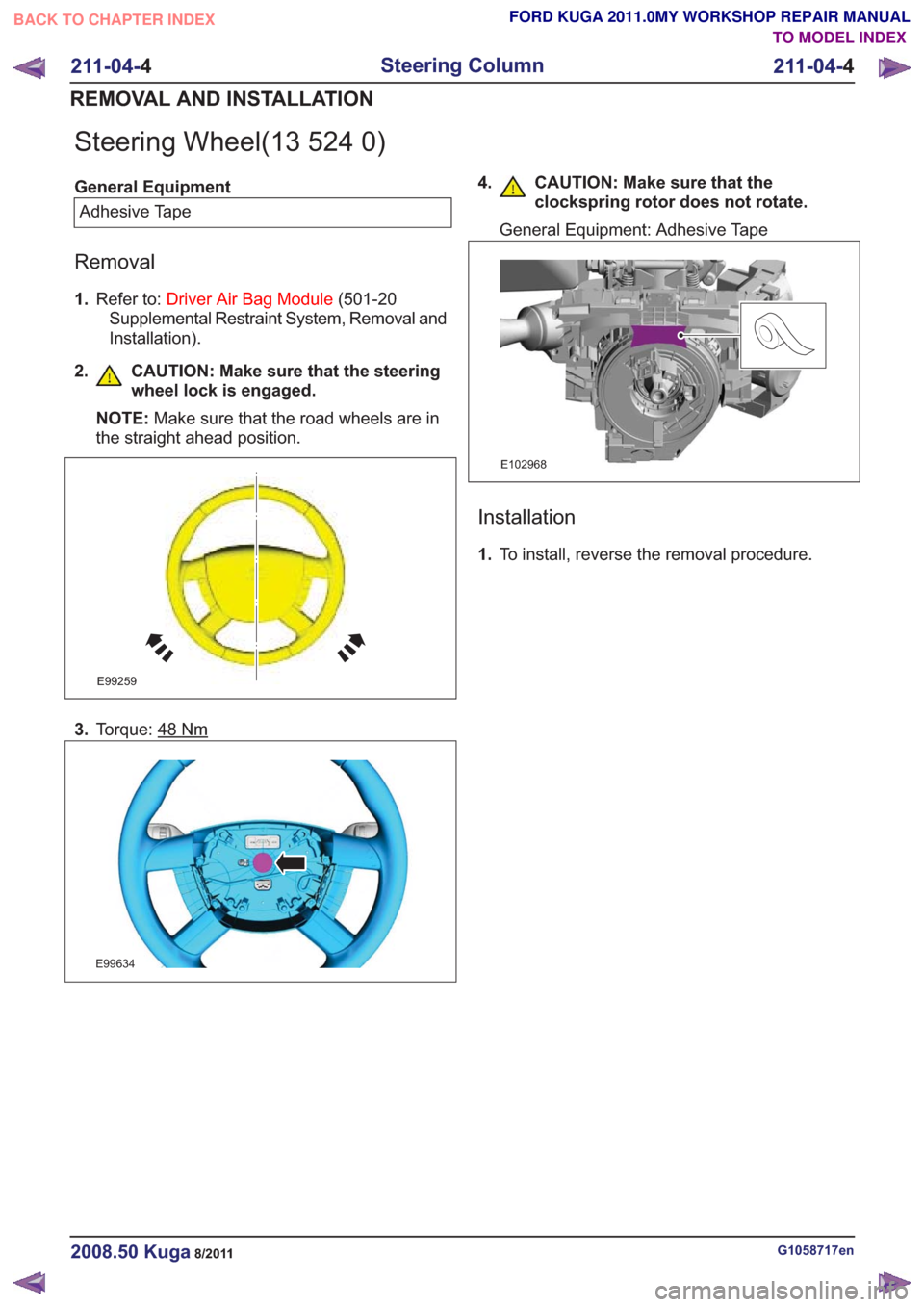

Steering Wheel(13 524 0)

General EquipmentAdhesive Tape

Removal

1. Refer to: Driver Air Bag Module (501-20

Supplemental Restraint System, Removal and

Installation).

2. CAUTION: Make sure that the steering wheel lock is engaged.

NOTE: Make sure that the road wheels are in

the straight ahead position.

E99259

3. Torque: 48Nm

E99634

4. CAUTION: Make sure that the

clockspring rotor does not rotate.

General Equipment: Adhesive Tape

E102968

Installation

1.To install, reverse the removal procedure.

G1058717en2008.50 Kuga8/2011

211-04- 4

Steering Column

211-04- 4

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1508 of 2057

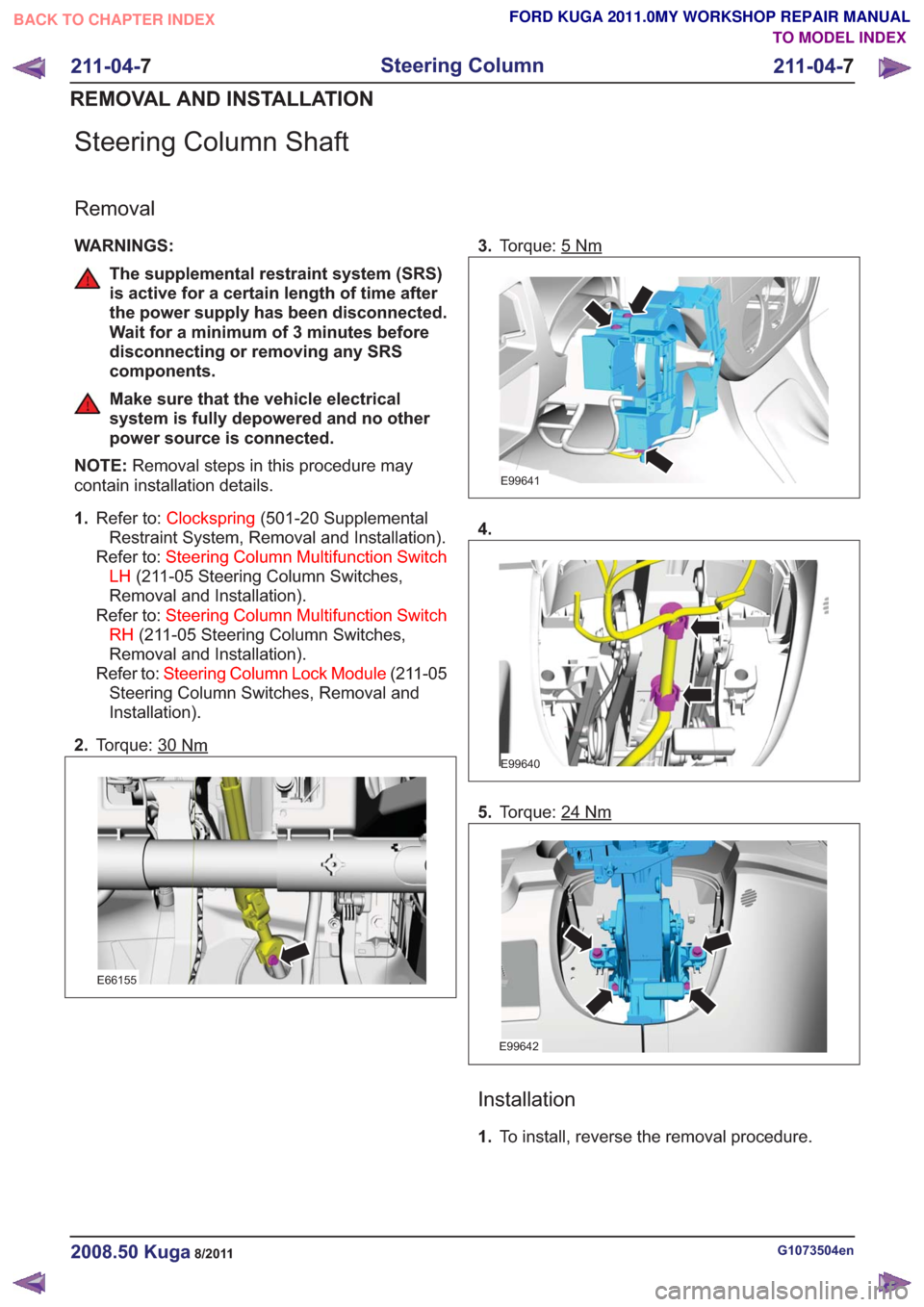

Steering Column Shaft

Removal

WARNINGS:

The supplemental restraint system (SRS)

is active for a certain length of time after

the power supply has been disconnected.

Wait for a minimum of 3 minutes before

disconnecting or removing any SRS

components.

Make sure that the vehicle electrical

system is fully depowered and no other

power source is connected.

NOTE: Removal steps in this procedure may

contain installation details.

1. Refer to: Clockspring (501-20 Supplemental

Restraint System, Removal and Installation).

Refer to: Steering Column Multifunction Switch

LH (211-05 Steering Column Switches,

Removal and Installation).

Refer to: Steering Column Multifunction Switch

RH (211-05 Steering Column Switches,

Removal and Installation).

Refer to: Steering Column Lock Module (211-05

Steering Column Switches, Removal and

Installation).

2. Torque: 30

Nm

E66155

3.Torque: 5Nm

E99641

4.

E99640

5.Torque: 24Nm

E99642

Installation

1.To install, reverse the removal procedure.

G1073504en2008.50 Kuga8/2011

211-04- 7

Steering Column

211-04- 7

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1509 of 2057

SECTION 211-05 Steering Column Switches

VEHICLE APPLICATION:2008.50 Kuga

PA G E

CONTENTS

DESCRIPTION AND OPERATION

211-05-2

Steering Column Switches (Component Location) .............................................................

211-05-3

Steering Column Switches (Overview) ........................................................................\

.......

211-05-3

Switch unit, steering column ........................................................................\

.......................

211-05-3

Clockspring ........................................................................\

.................................................

REMOVAL AND INSTALLATION 211-05-4

Steering Column Lock Module ........................................................................\

...................

211-05-6

Steering Column Multifunction Switch LH ........................................................................\

..

211-05-7

Steering Column Multifunction Switch RH ........................................................................\

..

211-05-1

Steering Column Switches

211-05- 1

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1511 of 2057

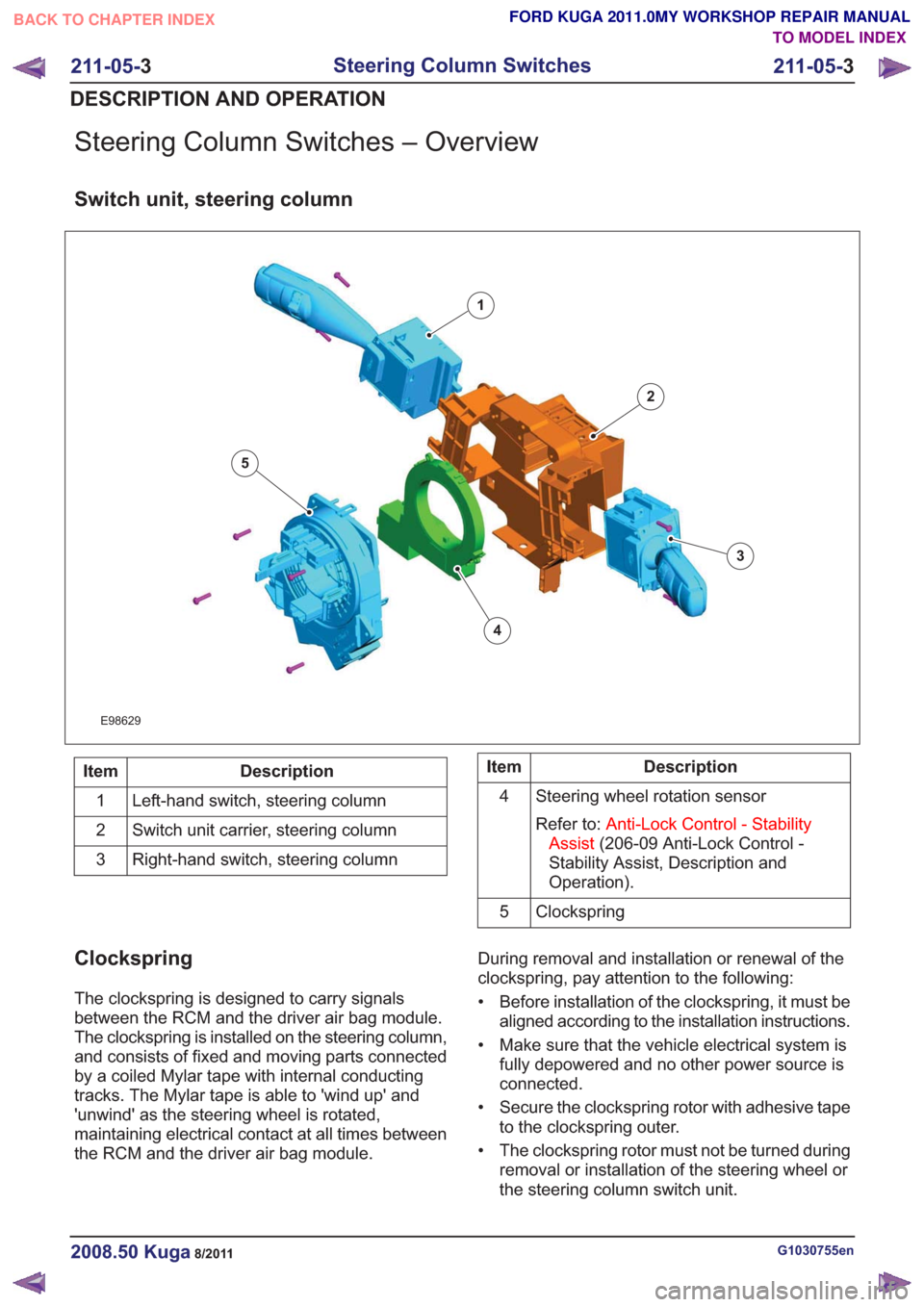

Steering Column Switches – Overview

Switch unit, steering column

E98629

1

2

3

4

5

Description

Item

Left-hand switch, steering column

1

Switch unit carrier, steering column

2

Right-hand switch, steering column

3Description

Item

Steering wheel rotation sensor

Refer to: Anti-Lock Control - Stability

Assist (206-09 Anti-Lock Control -

Stability Assist, Description and

Operation).

4

Clockspring

5

Clockspring

The clockspring is designed to carry signals

between the RCM and the driver air bag module.

The clockspring is installed on the steering column,

and consists of fixed and moving parts connected

by a coiled Mylar tape with internal conducting

tracks. The Mylar tape is able to 'wind up' and

'unwind' as the steering wheel is rotated,

maintaining electrical contact at all times between

the RCM and the driver air bag module. During removal and installation or renewal of the

clockspring, pay attention to the following:

• Before installation of the clockspring, it must be

aligned according to the installation instructions.

• Make sure that the vehicle electrical system is fully depowered and no other power source is

connected.

• Secure the clockspring rotor with adhesive tape to the clockspring outer.

• The clockspring rotor must not be turned during removal or installation of the steering wheel or

the steering column switch unit.

G1030755en2008.50 Kuga8/2011

211-05- 3

Steering Column Switches

211-05- 3

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1546 of 2057

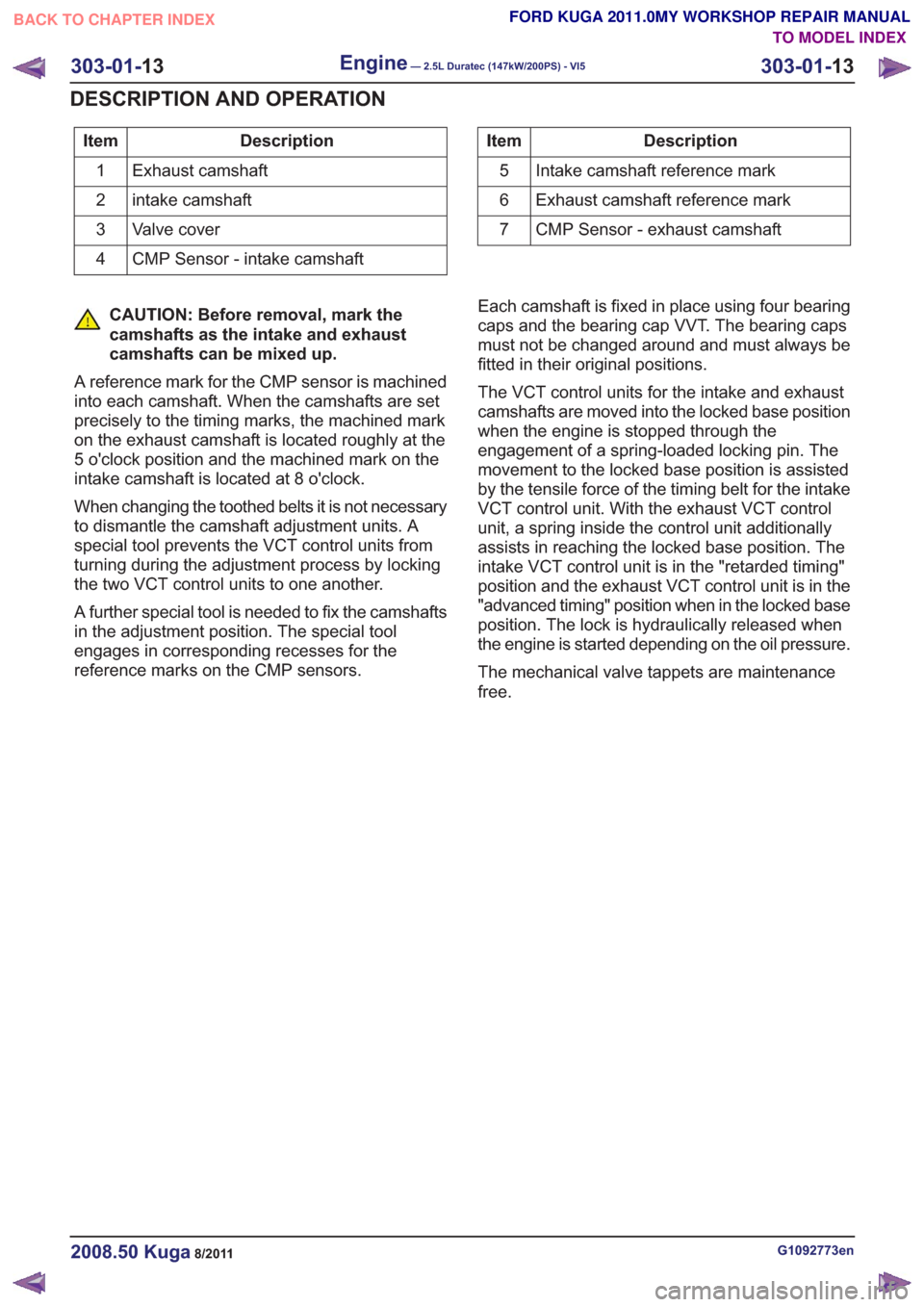

Description

Item

Exhaust camshaft

1

intake camshaft

2

Valve cover

3

CMP Sensor - intake camshaft

4Description

Item

Intake camshaft reference mark

5

Exhaust camshaft reference mark

6

CMP Sensor - exhaust camshaft

7

CAUTION: Before removal, mark the

camshafts as the intake and exhaust

camshafts can be mixed up.

A reference mark for the CMP sensor is machined

into each camshaft. When the camshafts are set

precisely to the timing marks, the machined mark

on the exhaust camshaft is located roughly at the

5 o'clock position and the machined mark on the

intake camshaft is located at 8 o'clock.

When changing the toothed belts it is not necessary

to dismantle the camshaft adjustment units. A

special tool prevents the VCT control units from

turning during the adjustment process by locking

the two VCT control units to one another.

A further special tool is needed to fix the camshafts

in the adjustment position. The special tool

engages in corresponding recesses for the

reference marks on the CMP sensors. Each camshaft is fixed in place using four bearing

caps and the bearing cap VVT. The bearing caps

must not be changed around and must always be

fitted in their original positions.

The VCT control units for the intake and exhaust

camshafts are moved into the locked base position

when the engine is stopped through the

engagement of a spring-loaded locking pin. The

movement to the locked base position is assisted

by the tensile force of the timing belt for the intake

VCT control unit. With the exhaust VCT control

unit, a spring inside the control unit additionally

assists in reaching the locked base position. The

intake VCT control unit is in the "retarded timing"

position and the exhaust VCT control unit is in the

"advanced timing" position when in the locked base

position. The lock is hydraulically released when

the engine is started depending on the oil pressure.

The mechanical valve tappets are maintenance

free.

G1092773en2008.50 Kuga8/2011

303-01-

13

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

13

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL