maintenance GEELY FC 2008 Workshop Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: FC, Model: GEELY FC 2008Pages: 419, PDF Size: 13.87 MB

Page 3 of 419

Preface

Geely “FC” is an automobile with high performance/price ratio and it meets the requirement

of national safety, energy saving, emission regulations and personal use. This automobile is

a completely new and excellent model produced by Zhejiang Geely Automobile Co., Ltd with

development in self-reliance of Geely group and with self-dominated intellectual property

right. It characterizes elegant appearance,

energy conservation and environmental protection,

safety and comfort. “FC” is a product opening a completely new viewpoint of automobile

selection, because it is developed on the basis of creative design thinking that breaks through

all established customs and it features perfectly balanced performance of power, space,

safety, manipulation and comfort. “FC” is a competitive product for Geely developing brand

and exploring mid-level automobile market, which takes over the company philosophy “make

good cars that common people can afford, and let Geely cars go to the whole world” of Geely

automobile. “FC” is combination of creativity and intelligence of quite a large number of

automobile experts, who have been developing and searching with great concentration for

more than 30 months, and it fully embodies persistent Geely style of fashion appearance

and high performance/price ratio.

“FC” is equipped with engine JL4G18 completely developed and produced by Geely group.

Engine JL4G18 applies the following advanced technology such as VVT, full aluminum cylin-

der body, plastic intake manifold, completely new VVT inside seal method, completely new

OCV valve filtering method etc. with M7.9.7 electric injection system of BOSCH, and its

index on power efficiency, economical efficiency, and safety efficiency etc. reaches leading

level of national model with the same type. This engine features strong power, low fuel

consumption, low noise and high power per liter etc.

We start to compile “FC” Automobile Maintenance Manual, which is divided into 27 sec-

tions with detailed description of overall structure and maintenance of engine 4G18.VVT;

inspection and repair of engine BOSCH M7.9.7 electric control fuel injection system; struc-

ture and maintenance of chassis; structure and maintenance of FC electrical equipment;

structure and maintenance of ABS anti-lock brake system; structure and maintenance of

SRS air bag; structure and maintenance of auto air conditioning system; structure and main-

tenance of vehicle body etc. Information is detailed and accurate, contents are in systematic

coherence and description is concise and comprehensive.

This manual is compiled from structure, which prompts “FC” service personnel to master

Page 4 of 419

necessary maintenance, repair and malfunction knowledge on the basis of understanding

main structure characteristics and simple principle of vision automobile. Electric control sys-

tem of “FC” automobile is particularly described with detail, and detailed steps and methods

are given for trouble shooting process. All kinds of malfunction could be eliminated quickly

and efficiently within the shortest time as long as you detect as the repair steps of this manual.

In addition, this manual is compiled with the following characteristics: in proper sequence,

clear demarcations, easy to understand, excellent in picture and its accompanying essay,

simple and clear, which is very applicable for a quite large number of “FC” automobile main-

tenance technicians and service personnel to refer to.

This manual is mainly compiled by Geely International Corporation; Geely Automobile En-

gine No. 2 Plant and engineering technicians of service corporation help complete this work.

Defects and mistakes are inevitable in this manual for limited level of compiler and limited

time, please contact Geely International Corporation if you find mistakes and careless omis-

sions in using and we can correct in time and reverse in next version.

Geely International Corporation

Nov. 2007

Page 5 of 419

This manual is mainly for qualified vehicle technicians, but it does not in-

clude all items on repair and maintenance.

In order to avoid personnel injury and vehicle damage caused by dangerous

operation, please observe the following regulations.

�zPlease read this manual carefully, and particularly fully master all con-

tents in “Precautions”.

�zMaintenance methods described in the manual are quite useful for vehicle

maintenance. Please adopt specified or recommended tools in maintain-

ing vehicle as steps described in this manual; maintaining vehicle with

tools or methods not specified or recommended in this manual will cause

personnel injury or vehicle damage. Therefore, please consider ensuring

the safety of technicians and vehicle at first before performing maintenance.

�zIf it is necessary to replace parts, please replace with parts of the same or

similar size with original ones. It is forbidden to use inferior parts.

�zIn order to effectively avoid technician injury and vehicle damage and hid-

den danger caused by incorrect operation, it is very important to observe

“Warning” and “Notes” in this manual. It particularly needs to mention that

not all precautions on safety are included in “Warning” and “Notes” etc. in

this manual. Therefore, please fully realize that perform maintenance not

as regulations will cause dangerous consequences.

Note

Page 6 of 419

Brief introduction on Geely model “FC”

Basic parameters...................................................

1

Maintenance period

Regular maintenance items...................................

4

Table on maintenance period at normal conditions5

Table on maintenance period at severe conditions..

7

Engine control system

EFI system.............................................................

8

On-vehicle inspection........................................

8

Inspection..........................................................

9

Throttle body assembly........................................

13Removing, installing and disassembling, assembling...13

Fuel

Fuel system..........................................................

14

Precautions......................................................

14

On-vehicle inspection......................................

16

Inspection........................................................

17

Injection nozzle assembly....................................

18

Replacement...................................................

18

Fuel pump assembly...........................................

20Removing, installing and disassembling, assembling....20

Fuel tank assembly.............................................

21Removing, installing and disassembling, assembling.....21

Exhaust gas control

Exhaust gas control system...............................

23

On-vehicle inspection......................................

23

Inspection........................................................

25

Engine mechanism

Engine assembly..................................................

26Inspection........................................................

26

Drive belt..............................................................

29

Replacement...................................................

29

Valve clearance....................................................

30

Adjustment......................................................

30

Engine assembly.................................................

36

Replacement...................................................

36

Timing chain assembly.......................................

45

Replacement...................................................

45

Camshaft.............................................................

52

Replacement...................................................

52

Crankshaft front oil seal assembly.....................

60

Replacement...................................................

60

Crankshaft rear oil seal assembly......................

62

Replacement...................................................

62

Cylinder cover gasket components.....................

63

Replacement...................................................

63

Exhaust

Exhaust pipe assembly........................................

65Removing, installing and disassembling, assembling.....65

Cooling

Cooling system....................................................

66

On-vehicle inspection......................................

66

Inspection........................................................

66

Cooling fan system..............................................

68

On-vehicle inspection......................................

68

Inspection........................................................

68

Water pump assembly........................................

69

Replacement...................................................

69

Temperature regulator components...................

71

Replacement...................................................

71

Radiator with electronic fan assembly................

72Contents

Page 15 of 419

Your precious automobile should be maintained according to maintenance period

at normal conditions (see table on maintenance period at normal conditions)If your precious automobile is mainly driven under one or more of the following conditions, some

maintenance items must be performed more frequently (see table on maintenance period at severe

conditions).A. Road conditions1. Driving on rugged, muddy or melting snow road.

2. Driving on dusty road.B. Driving conditions1. Towing tail vehicle, equipped with camp frame or top storage racks.

2. Repeated on short-distance driving within 8 km and the temperature is below 0.

3. Vehicles driven for long distance under idle speed or low speed over a long period of time,

such as police car, taxi or delivery truck.

4. Continuously driving at high speed for more than 2 hours frequently. (With 80% of max. ve-

hicle speed)

5. Vehicles driven with idle speed or low speed over a long period of time or frequently acceler-

ated or decelerated, such as training car of driving training class.Maintenance period-Regular maintenance itemsMaintenance periodRegular maintenance items 4

Page 16 of 419

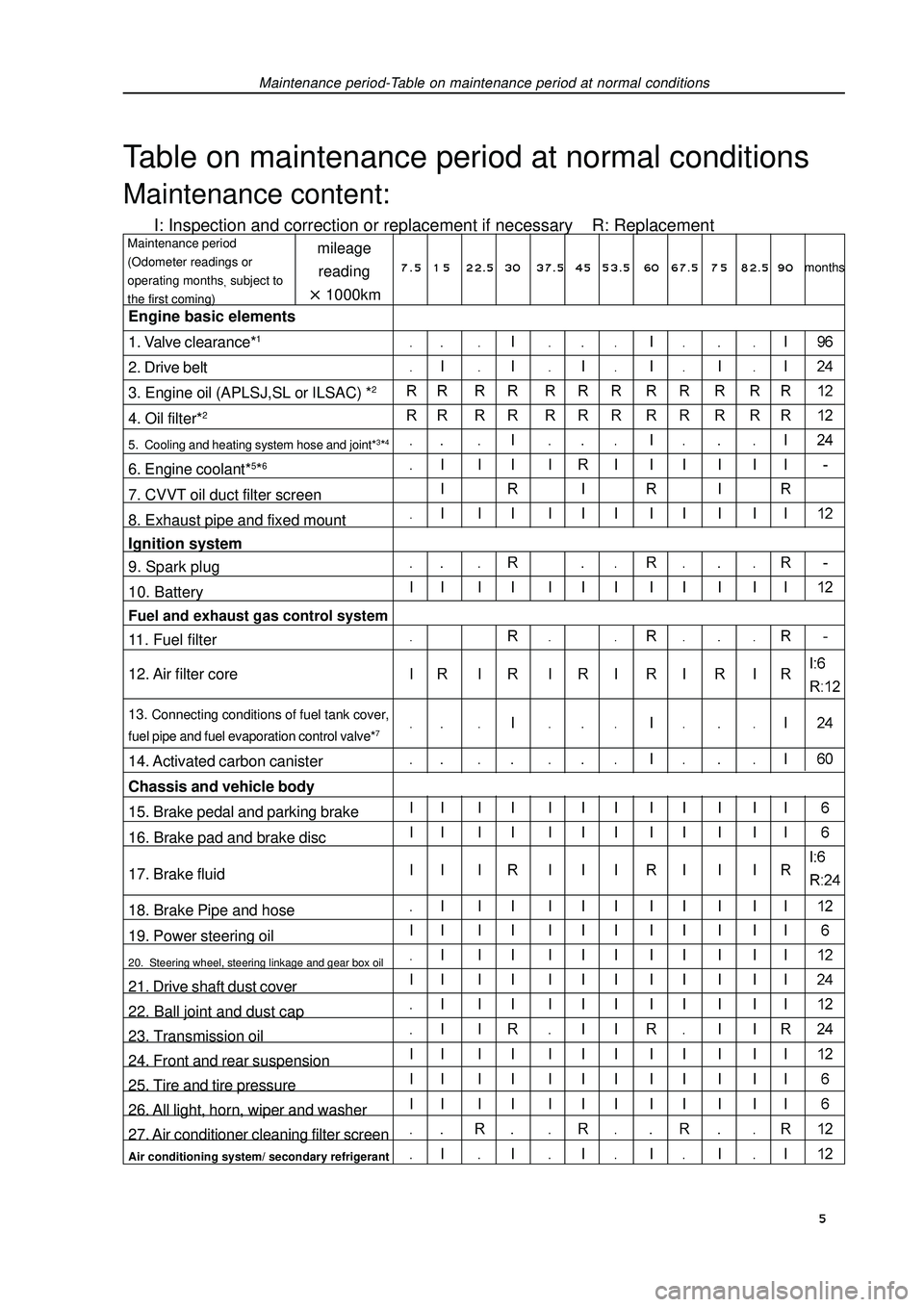

Maintenance period-Table on maintenance period at normal conditionsTable on maintenance period at normal conditionsMaintenance content:I: Inspection and correction or replacement if necessary R: Replacementmileage

reading1000kmMaintenance period

(Odometer readings or

operating monthssubject to

the first coming)Engine basic elements

1. Valve clearance*12. Drive belt

3. Engine oil (APLSJ,SL or ILSAC) *24. Oil filter*25. Cooling and heating system hose and joint*3*46. Engine coolant*5*67. CVVT oil duct filter screen

8. Exhaust pipe and fixed mount

Ignition system

9. Spark plug

10. BatteryFuel and exhaust gas control system11. Fuel filter

12. Air filter core13. Connecting conditions of fuel tank cover,

fuel pipe and fuel evaporation control valve*714. Activated carbon canister

Chassis and vehicle body

15. Brake pedal and parking brake

16. Brake pad and brake disc

17. Brake fluid

18. Brake Pipe and hose

19. Power steering oil20. Steering wheel, steering linkage and gear box oil21. Drive shaft dust cover

22. Ball joint and dust cap

23. Transmission oil

24. Front and rear suspension

25. Tire and tire pressure

26. All light, horn, wiper and washer

27. Air conditioner cleaning filter screenAir conditioning system/ secondary refrigerant7 . 5 1 5 22.5 3037.5 4553.5 60 67.5 7 582.5 90months 5

Page 17 of 419

Note: *1 Indicating that check valve noise and engine vibration condition, and adjust them if necessary.*2 It is suggested that see operating modes on page 116 of operating instruction to perform.*3 Indicating that check once every 20000km or 12 moths after 80000km or 48 months.*4 Indicating that check water tank and condenser are blocked by leaves, dust or insects, and clean

hose connections.*5 Replace at initial 60000km, and replace every 30000km in future.*6 Only “Geely genuine ultra-long engine coolant” or equivalent high-quality ethylene glycol engine

coolant without silicate, amines, nitrite, borate and with long-life compound organic acid technology

are allowed to use, and coolant should be repeated several times until it is filled up.*7 Indicating that check once every 20000km or 12 moths after 80000km or 48 months.Maintenance period-Table on maintenance period at normal conditions 6

Page 18 of 419

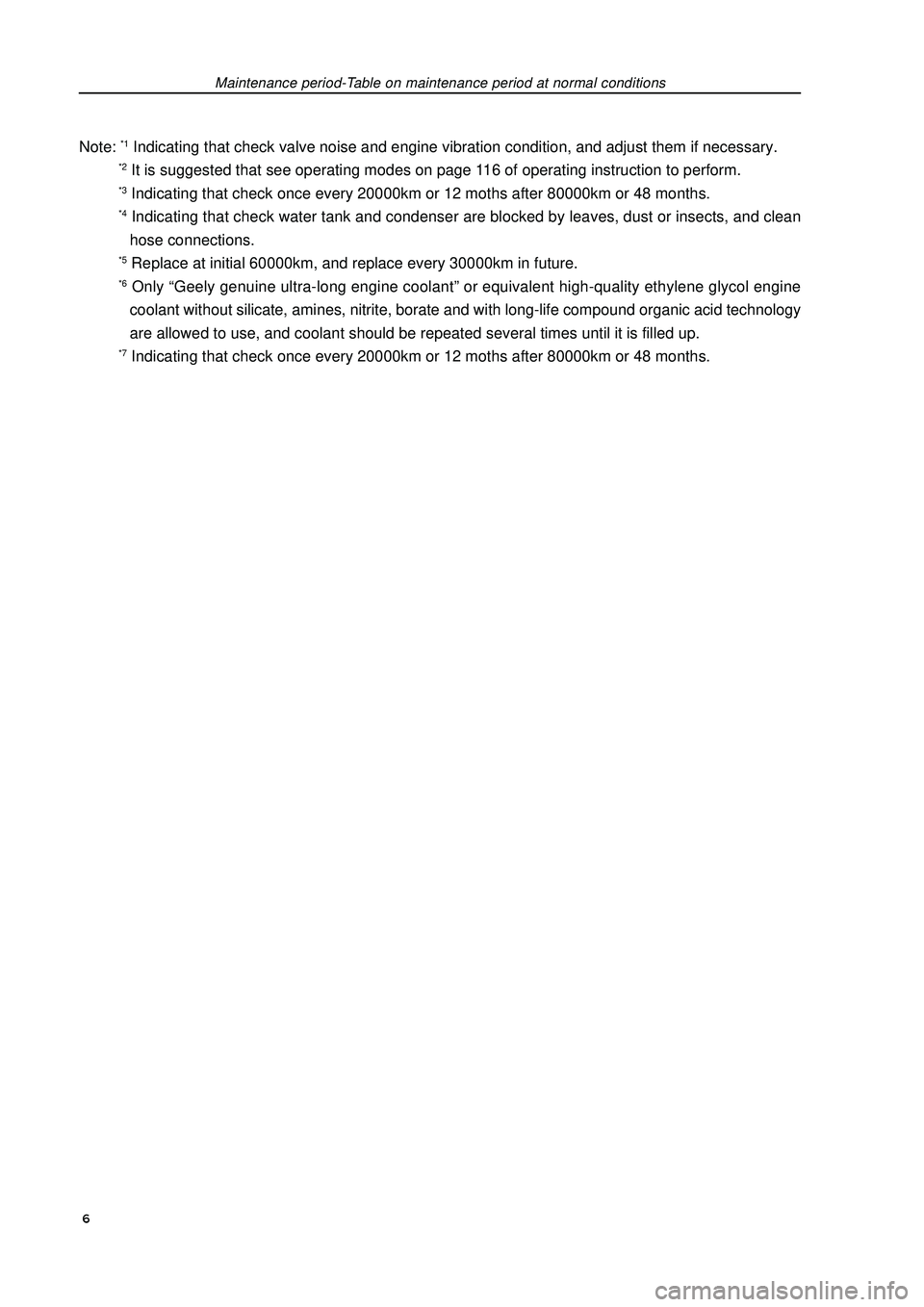

Maintenance period-Table on maintenance period at severe conditionsTable on maintenance period at severe conditionsAccording to the driving conditions listed below, maintenance should be performed to the items that

should be maintained more frequently (for other items not listed, please see Table on maintenance

period at normal conditions) 7 A-1: Driving on rugged, muddy or melting snow road Inspection of brake pad and brake disc Every 5,000 km or 3 moths Inspection of brake pipeline and hose Every 10,000 km or 6 moths Inspection of ball joint and dust cover Every 10,000 km or 6 moths Inspection of drive shaft dust cover Every 10,000 km or 12 moths Inspection of the steering wheel, steering linkage and gear box oilEvery 5,000 km or 3 moths Check of front and rear suspension Every 10,000 km or 6 moths

A-2: Driving on dusty road Replacement of engine oil Every 5,000 km or 6 moths Replacement of engine oil filter Every 5,000 km or 6 moths Inspection or replacement of air filter core I: Every 2,500 km or 3 moths

R: Every 10,000 km or 6 moths Inspection of brake block and brake disc Every 5,000 km or 3 moths Replacement of air conditioner cleaning filter screen Every 15,000 km

B-1: Towing tail vehicle, equipped with camp frame or top storage racks Replacement of engine oil Every 5,000 km or 6 moths Replacement of engine oil filter Every 5,000 km or 6 moths Inspection of brake pad and brake disc Every 5,000 km or 3 moths Inspection or replacement of transmission oil Every 60,000 km or 24 moths Inspection of front and rear suspension Every 10,000 km or 6 moths Screwing down the bolts and nuts of the chassis and vehicle bodyEvery 10,000 km or 6 moths

B-2: Repeated on short-distance driving within 8 km and the temperature is below 0 °C Replacement of engine oil Every 5,000 km or 6 moths Replacement of engine oil filter Every 5,000 km or 6 moths

B-3: Vehicles driven for long distance under idle speed or low speed over a long period of time, such as police car, taxi or deliverytruck. Replacement of engine oil Every 5,000 km or 6 moths Replacement of engine oil filter Every 5,000 km or 6 moths Inspection of PCV valve and pipelines Every 5,000 km or 6 moths Inspection of brake block and brake disc Every 5,000 km or 3 moths

B-4: Continuously driving at high speed for more than 2 hours frequently (With 80% of max. vehicle speed) Replacement of transmission oil Every 40,000 km or 12 moths

B-5: Vehicles driven with idle speed or low speed over a long period of time or frequently accelerated or

decelerated, such as student car of driving training class. Replacement of engine oil Every 3,000 km or 3 moths Replacement of engine oil filter Every 3,000 km or 3 moths Inspection of PCV valve and pipelines Every 3,000 km or 3 moths

Page 23 of 419

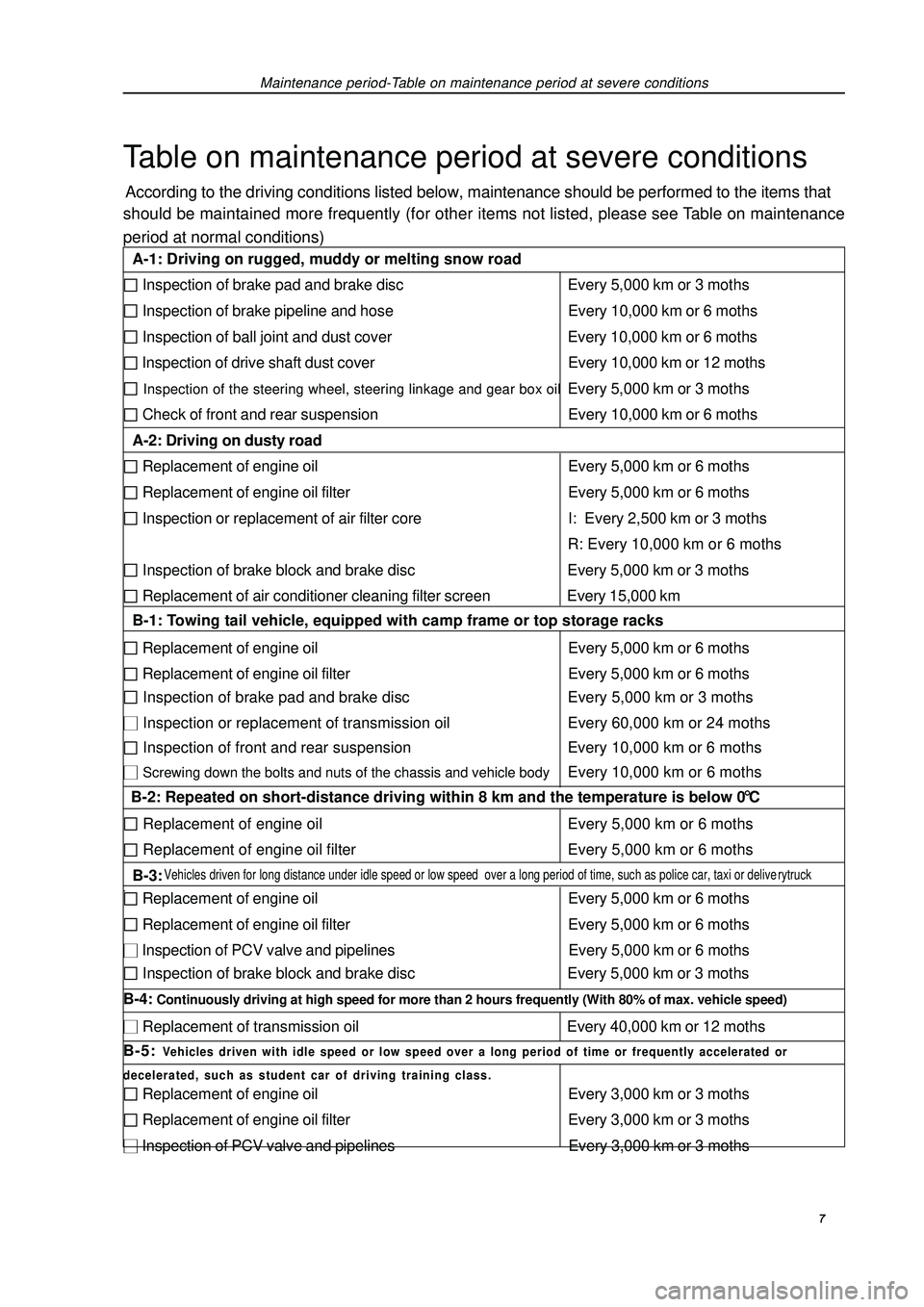

Pins: Pin A is connected to ECU No. 65 pin

Pin B is connected to ECU No. 66 pin

Pin C is connected to ECU No. 67 pin

Pin D is connected to ECU No. 64 pin

Maintenance precautions:

1. It is not allowed to apply any force at axial direction with the purpose of pressing into or pulling out the

axle;

2. Before idle speed regulator with stepping motor is mounted into throttle body, its shaft must be at fully

retractive position;

3. Pay attention to clean and maintain bypass air passage frequently;

4. After removing battery or ECU, pay attention to self-teach stepping motor in time.

Self-teach method of M7 system: turn on ignition switch but not start engine immediately, and start it

after 5 seconds. If engine idle speed is found bad at the moment, it is

necessary to repeat the above steps.

Simple measuring method:(removing the joint) place digital universal meter at ohm gear, and connect

2 terminals respectively to Ad pin and BC pin of regulator, and rated resis-

tance at Engine control system·- EFI systemElectrical

wiring

diagram

on step-

ping motor

of idle

speed

actuator12

Page 26 of 419

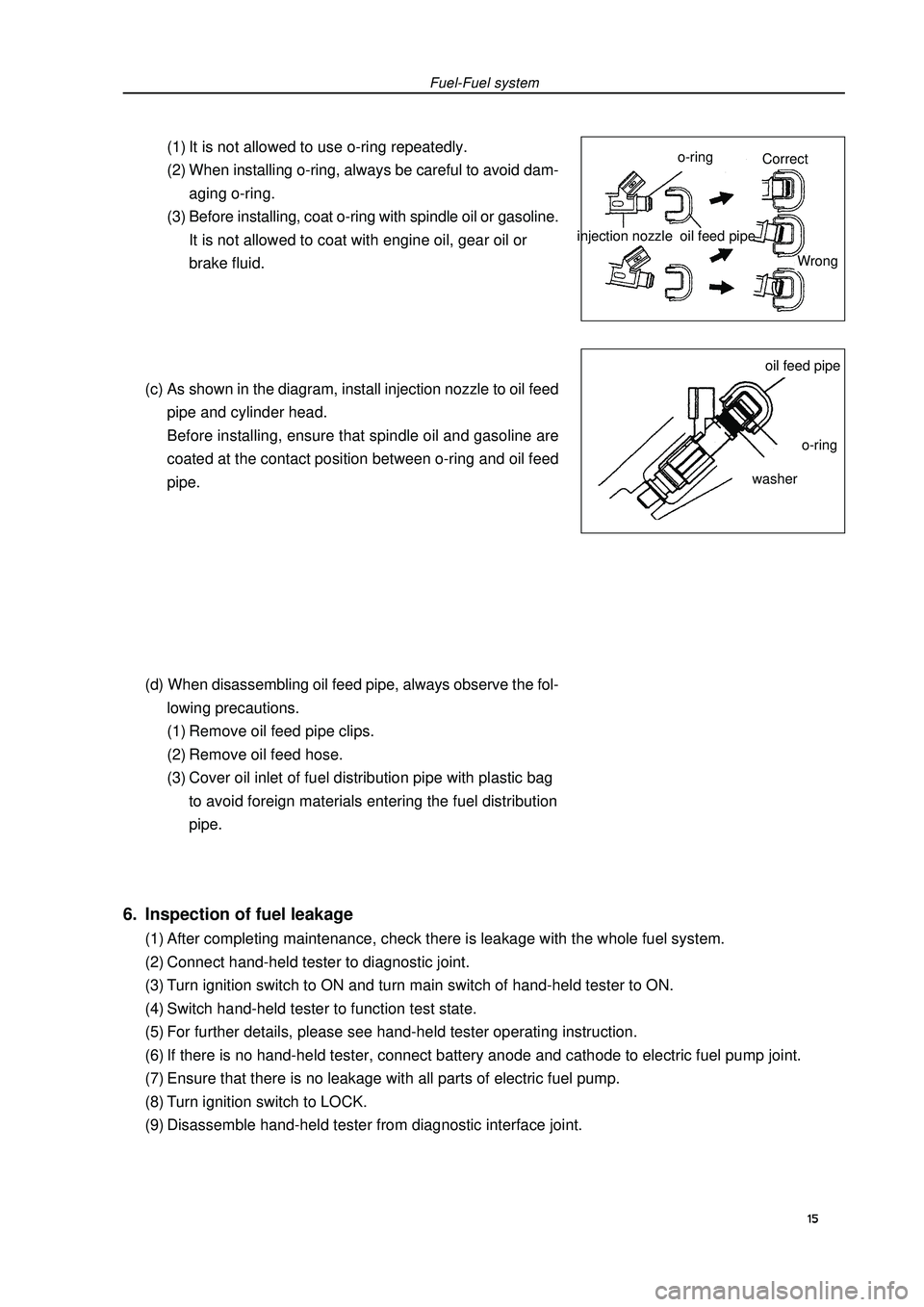

Fuel-Fuel system(1) It is not allowed to use o-ring repeatedly.

(2) When installing o-ring, always be careful to avoid dam-

aging o-ring.

(3) Before installing, coat o-ring with spindle oil or gasoline.

It is not allowed to coat with engine oil, gear oil or

brake fluid.

(c) As shown in the diagram, install injection nozzle to oil feed

pipe and cylinder head.

Before installing, ensure that spindle oil and gasoline are

coated at the contact position between o-ring and oil feed

pipe.

(d) When disassembling oil feed pipe, always observe the fol-

lowing precautions.

(1) Remove oil feed pipe clips.

(2) Remove oil feed hose.

(3) Cover oil inlet of fuel distribution pipe with plastic bag

to avoid foreign materials entering the fuel distribution

pipe.injection nozzle6. Inspection of fuel leakage(1) After completing maintenance, check there is leakage with the whole fuel system.

(2) Connect hand-held tester to diagnostic joint.

(3) Turn ignition switch to ON and turn main switch of hand-held tester to ON.

(4) Switch hand-held tester to function test state.

(5) For further details, please see hand-held tester operating instruction.

(6) If there is no hand-held tester, connect battery anode and cathode to electric fuel pump joint.

(7) Ensure that there is no leakage with all parts of electric fuel pump.

(8) Turn ignition switch to LOCK.

(9) Disassemble hand-held tester from diagnostic interface joint.15o-ringoil feed pipeoil feed pipeo-ringwasherCorrect

Wrong