park assist GREAT WALL HOVER 2006 Service Repair Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 17 of 425

Brake system

The front wheel brake is ventilation coil type, the rear wheel brake is disk and drum type. The service brake type is that the double-

loop vacuum assist hydraulic brake is applied on the front and rear disc brake. The parking brake is mechanical dragline acting on the

drum brake of the rear wheel.

The free stroke of brake pedal is 20mm

30mm, and the operating stroke of the pedal is 120mm. The operating stroke of the brake

handle is 17

(3 teeth)30(8 teeth).

1. The adjustment of brake pedal

Measure the operating stroke of the brake pedal, the standard value is 120mm. When the eighth is no in compliance with the

requirement, make adjustment according to the following procedures:

a. Separate the brake lamp switch wire connector, loosen the blocking nut, and turn the brake lamp switch to the position that the

stopper is not touched;

b. Unscrew the blocking nut of the operation connecting rod, use the thinnose pliers to turn the operation connecting rod, adjust

the brake pedal height to standard value, after reaching the standard value, tighten the lock nut;

c. Turn the brake lamp switch to the position that the stopper of brake pedal is just touched, continue the turning for 1/2

1 circle,

and tighten the blocking nut;

d. Connect the brake lamp switch wire connector;

e. The brake lamp should not be light when the brake pedal is in release status.

2. Standard value of brake pedal free stroke: 20-30 mm

a. Under the stopping status of the engine, step on the brake pedal for 2

3 times, clear the influence of brake assistor, then use

hand to push the brake pedal to the position that there is resistance, measure the amount of movement (free stroke). It shall

be in compliance with the regulation of standard value;

b. If the gap is less than the regulation value, check to see whether the gap between the carrier rod of brake lamp switch and the

brake pedal is in compliance with the regulation. If this gap is exceeding the regulation, it means that the gap between the drive

rod clevis pin and the brake pedal arm is exceeding the regulated value.

3. Start the engine, step down the brake pedal with a force of about 700N,ehck the main brake pump, whether there is oil

leakage on the connection positions of the brake pipeline. If there is, maintain it.

4. Operating status test of brake assistor

Conduct the operation status test of the brake assistor according to the following methods:

a. Start the engine, stop if after operating for 1

2 minutes. Step on the brake pedal for several times with normal force. Expect

that the pedal can be fully stepped down a the first stepping, the height of the brake pedal shall be raised on and on with the

stepping, thus means that the brake assistor operates normally, if the height of the pedal is not changed, it means that the brake

assistor is damaged;

b. Under the stopping status of the engine, step on the brake pedal for several times, confirms that the height of brake pedal is

elevated on and on, under the status that the brake pedal is stepped down, start the engine. At this time, the brake pedal will

move down a bit, it means that the brake assistor is working normally. If the brake pedal is moving upwards, it means that the

brake assistor is damaged;

c. Under the operation status of the engine, step down the brake pedal to stop the operation of the engine. AT this time, the there

shall be no change of the height of brake pedal within 30 seconds, it means that the brake assistor is working normally. If the

brake pedal is moving upwards, it means that the brake pedal assistor is damaged.

5. Adjustment of the parking brake system:

a.For positioning, pull the brake bar to the limit position for over 3 times, use a force of about 400N to pull the brake parking

lever, count the number of knocking teeth. The standard value of stroke of parking brake : 17

(3 teeth) 30(8 teeth);

b.If the stroke of brake parking lever is too big and not in compliance with the requirement, adjust it with the following methods:

Loosen the brake parking lever, unscrew the adjusting nut.

Remove the adjuster hole cap from the brake assembly, use screwdriver to turn the adjustor in the arrow direction to the limit

that the brake drum cannot turn.

Rotate 5 teeth in the counter arrow direction.

Rotate the adjusting nut, adjust the brake parking lever stroke to the standard value.

c. If the stroke is less than the standard value, unscrew the adjusting nut to make it reach the standard value.

d. Check to see whether the adjusting nut and the rod are loosened, whether the adjusting nut is fixed in the fixed seat.

e. After adjustment, jack up the rear part of the car. Loosen the brake parking lever, the brake disc shall not be dragged when

checking the rear wheel.

f. The breaking in of the parking brake: use the force of about 200-250N to pull the brake parking lever,drive the car for about

400m with a speed of about 60km/h, repeat for 2-3 times, then test on the slope of 30%, the car shall be able to be parked.

Page 288 of 425

Brake-2

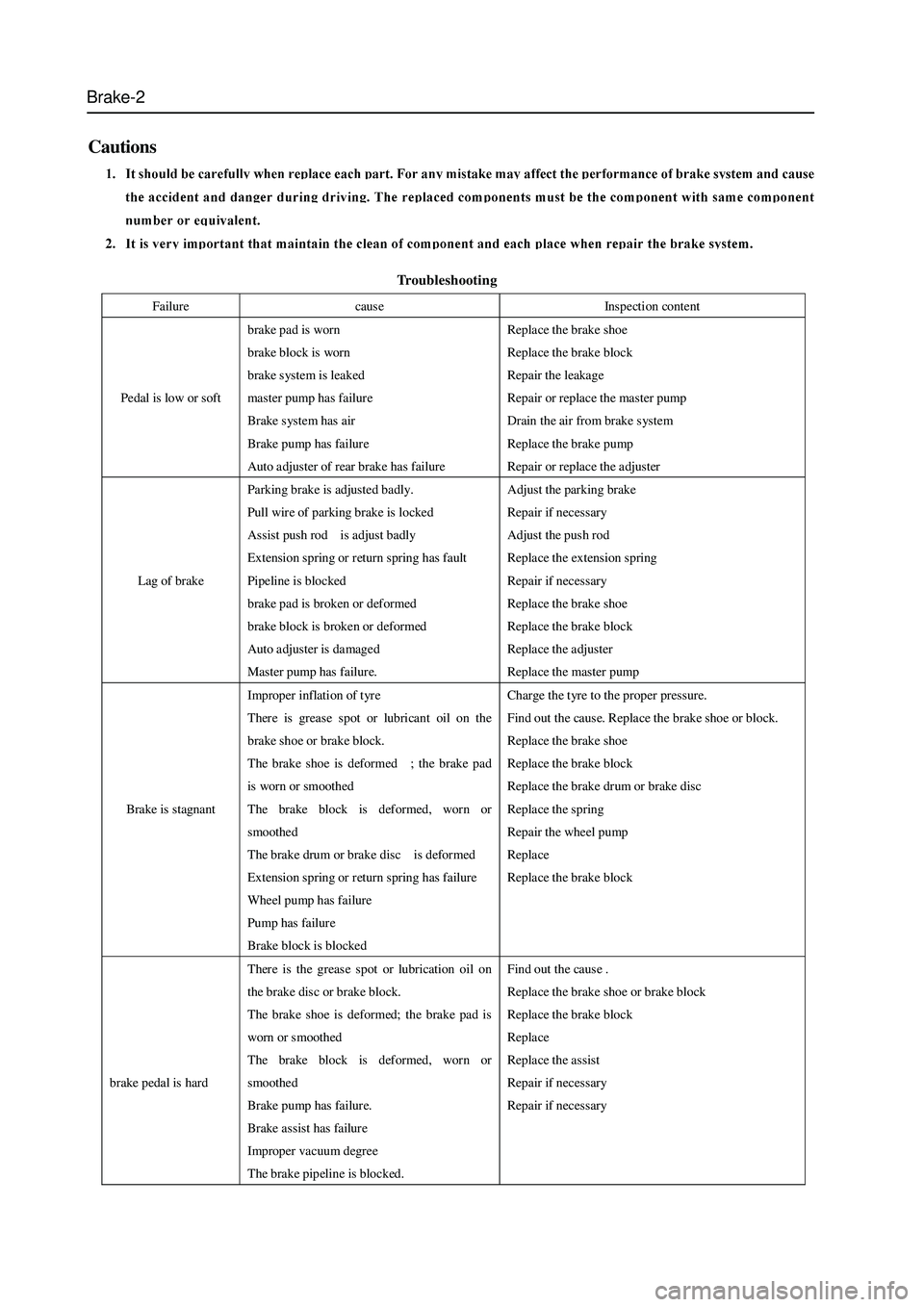

Troubleshooting

Cautions

Failure cause Inspection content

Pedal is low or soft brake pad is worn

brake block is worn

brake system is leaked

master pump has failure

Brake system has air

Brake pump has failure

Auto adjuster of rear brake has failure Replace the brake shoe

Replace the brake block

Repair the leakage

Repair or replace the master pump

Drain the air from brake system

Replace the brake pump

Repair or replace the adjuster

Lag of brake Parking brake is adjusted badly.

Pull wire of parking brake is locked

Assist push rod is adjust badly

Extension spring or return spring has fault

Pipeline is blocked

brake pad is broken or deformed

brake block is broken or deformed

Auto adjuster is damaged

Master pump has failure. Adjust the parking brake

Repair if necessary

Adjust the push rod

Repla ce the extension spring

Repair if necessary

Replace the brake shoe

Replace the brake block

Repla ce the a djuster

Repla ce the master pump

Brake is stagnant Improper inflation of tyre

There is grease spot or lubricant oil on the

brake shoe or brake block.

The brake shoe is deformed ; the brake pad

is worn or smoothed

The brake block is deformed, worn or

smoothed

The brake drum or brake disc is deformed

Extension spring or return spring has failure

Wheel pump has failure

Pump has failure

Brake block is blocked Charge the tyre to the proper pressure.

Find out the cause. Replace the brake shoe or block.

Replace the brake shoe

Replace the brake block

Replace the brake drum or brake disc

Repla ce the spring

Repair the wheel pump

Replace

Replace the brake block

brake pedal is hard There is the grease spot or lubrication oil on

the brake disc or brake block.

The brake shoe is deformed; the brake pad is

worn or s moothed

The brake block is deformed, worn or

smoothed

Brake pump has failure.

Brake assist has failure

Improper vacuum degree

The brake pipeline is blocked. Find out the caus e .

Replace the brake shoe or brake block

Replace the brake block

Replace

Replace the assist

Repair if necessary

Repair if necessary

Page 291 of 425

Brake-5

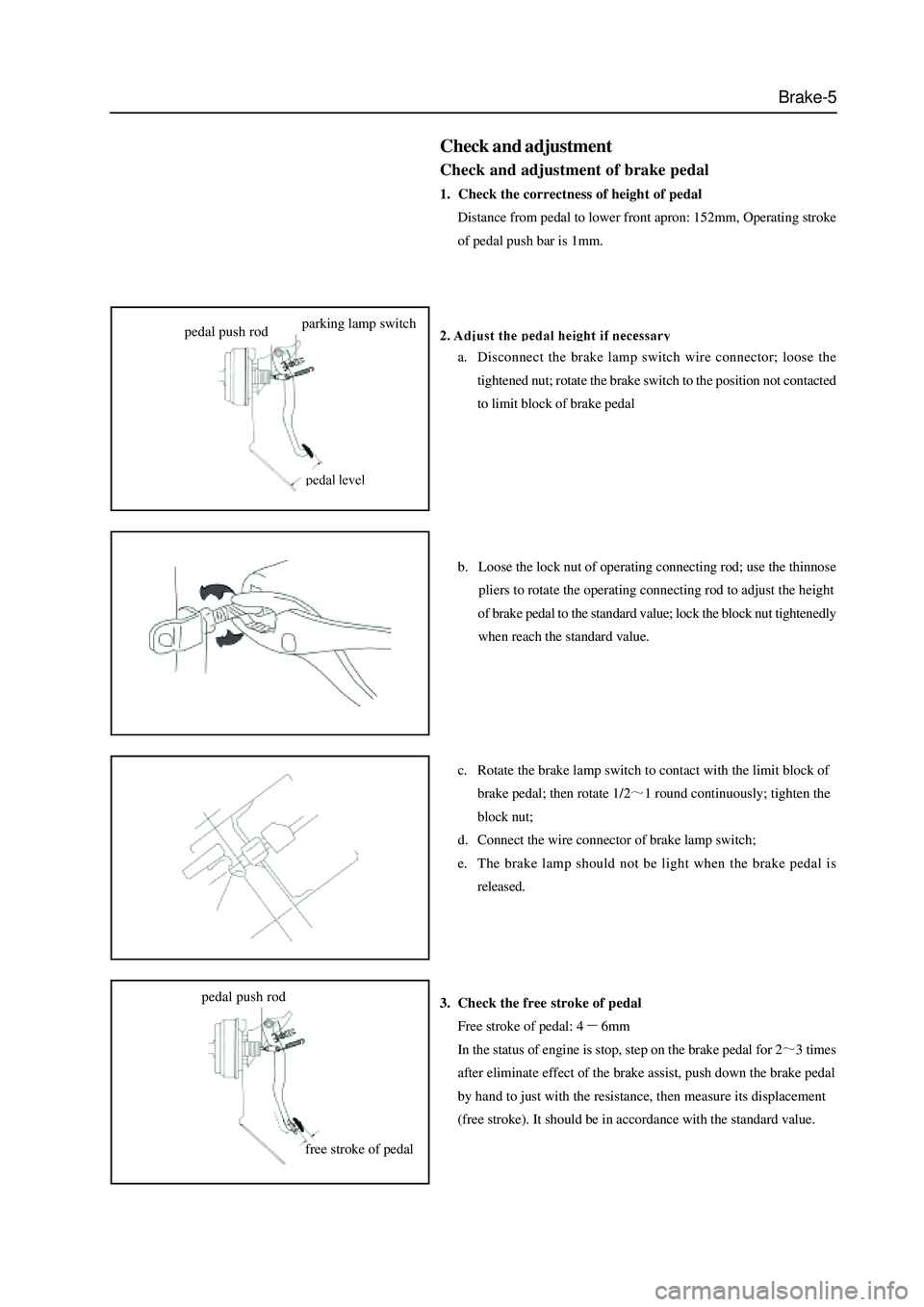

Check and adjustment

Check and adjustment of brake pedal

1. Check the correctness of height of pedal

Distance from pedal to lower front apron: 152mm, Operating stroke

of pedal push bar is 1mm.

a. Disconnect the brake lamp switch wire connector; loose the

tightened nut; rotate the brake switch to the position not contacted

to limit block of brake pedal

b. Loose the lock nut of operating connecting rod; use the thinnose

pliers to rotate the operating connecting rod to adjust the height

of brake pedal to the standard value; lock the block nut tightenedly

when reach the standard value.

c. Rotate the brake lamp switch to contact with the limit block of

brake pedal; then rotate 1/2

1 round continuously; tighten the

block nut;

d. Connect the wire connector of brake lamp switch;

e. The brake lamp should not be light when the brake pedal is

released.

3. Check the free stroke of pedal

Free stroke of pedal: 4

6mm

In the status of engine is stop, step on the brake pedal for 2

3 times

after eliminate effect of the brake assist, push down the brake pedal

by hand to just with the resistance, then measure its displacement

(free stroke). It should be in accordance with the standard value.

pedal push rodparking lamp switch

free stroke of pedal pedal push rod

Page 319 of 425

Brake-32

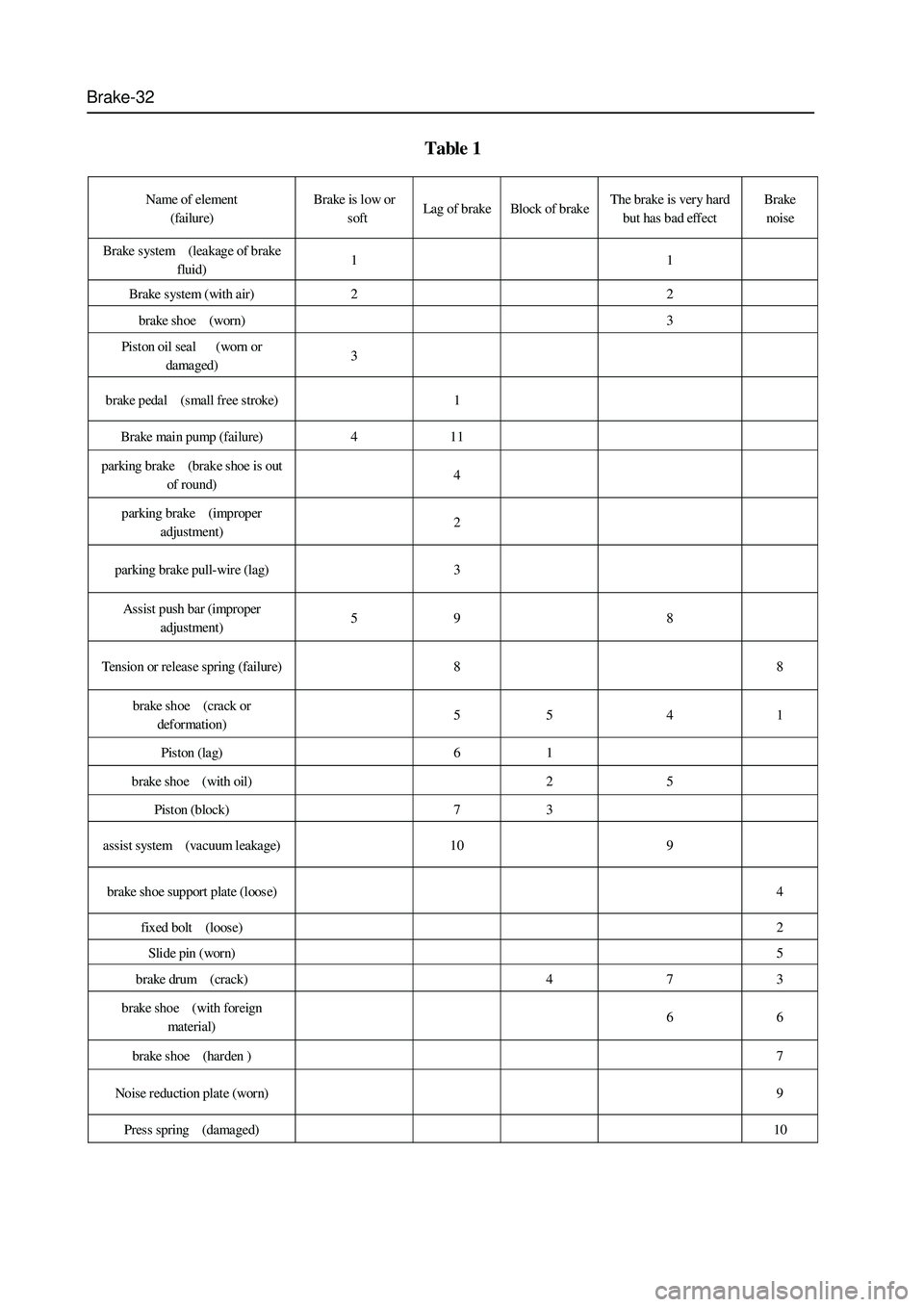

Table 1

Name of element

(failure) Brake is low or

soft Lag of brake Block of brake The brake is very hard

but has bad eff ect Brake

noise

Brake system (leakage of brake

fluid) 1 1

Brake system (with air) 2 2

brake shoe (worn) 3

Piston oil seal (worn or

damaged) 3

brake pedal (small free stroke) 1

Brake mai n p ump (fai lur e) 4 1 1

parking brake (brake shoe is out

of round) 4

parking brake (improper

adjustment) 2

parking brake pull-wire (lag) 3

Assist push bar (improper

adjustment) 5 9 8

Tension or release spring (failure) 8 8

brake shoe (crack or

deformation) 5 5 4 1

Piston (lag) 6 1

brake shoe (with oil) 2 5

Piston (block) 7 3

assist system (vacuum leakage) 10 9

brake shoe support plate (loose) 4

fixed bolt (loose) 2

Slide pin (worn) 5

brake drum (crack) 4 7 3

brake shoe (with foreign

mater ial) 6 6

brake shoe (harden ) 7

Noise reduction plate (worn) 9

Press spring (damaged) 10