Connector a HONDA CIVIC 1996 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 991 of 2189

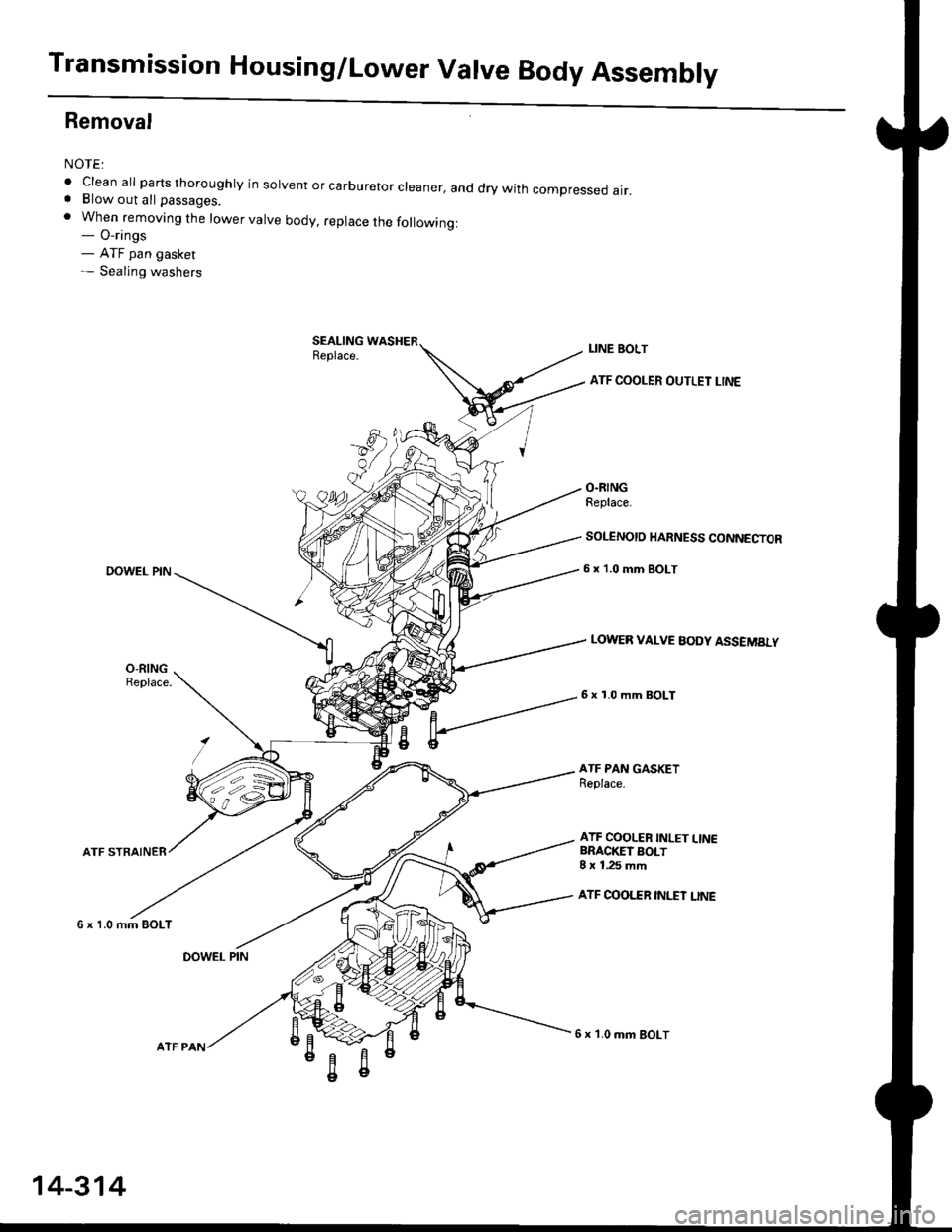

Transmission Housing/Lower Valve Body Assembty

Removal

NOTE:

. Clean all parts thoroughly in solvent or carburetor cleaner, and dry with compressed air.. Blow out all passages.

. When removing the lower valve body, replace the followingl- O-rings- ATF pan gasket- Sealing washers

DOWEL PIN

ATF STRAINER

6 x 1.0 mm BOLT

ATF PAN GASKETReplace.

ATF COOLER INLET LINEBRACKET BOLT8 x 1.25 mm

ATF COOI..ER INLET LINE

O.RINGReplace.

SOLENOIO HARNESS CONNECTOR

6 x'1.0 mm BOLT

LOWER VALVE BODY ASSEMBLY

6 x 1.0 mm BOLT

14-314

6 x 1.0 mm EOLT

Page 992 of 2189

l.

'1.

2.

5.

6.

7.

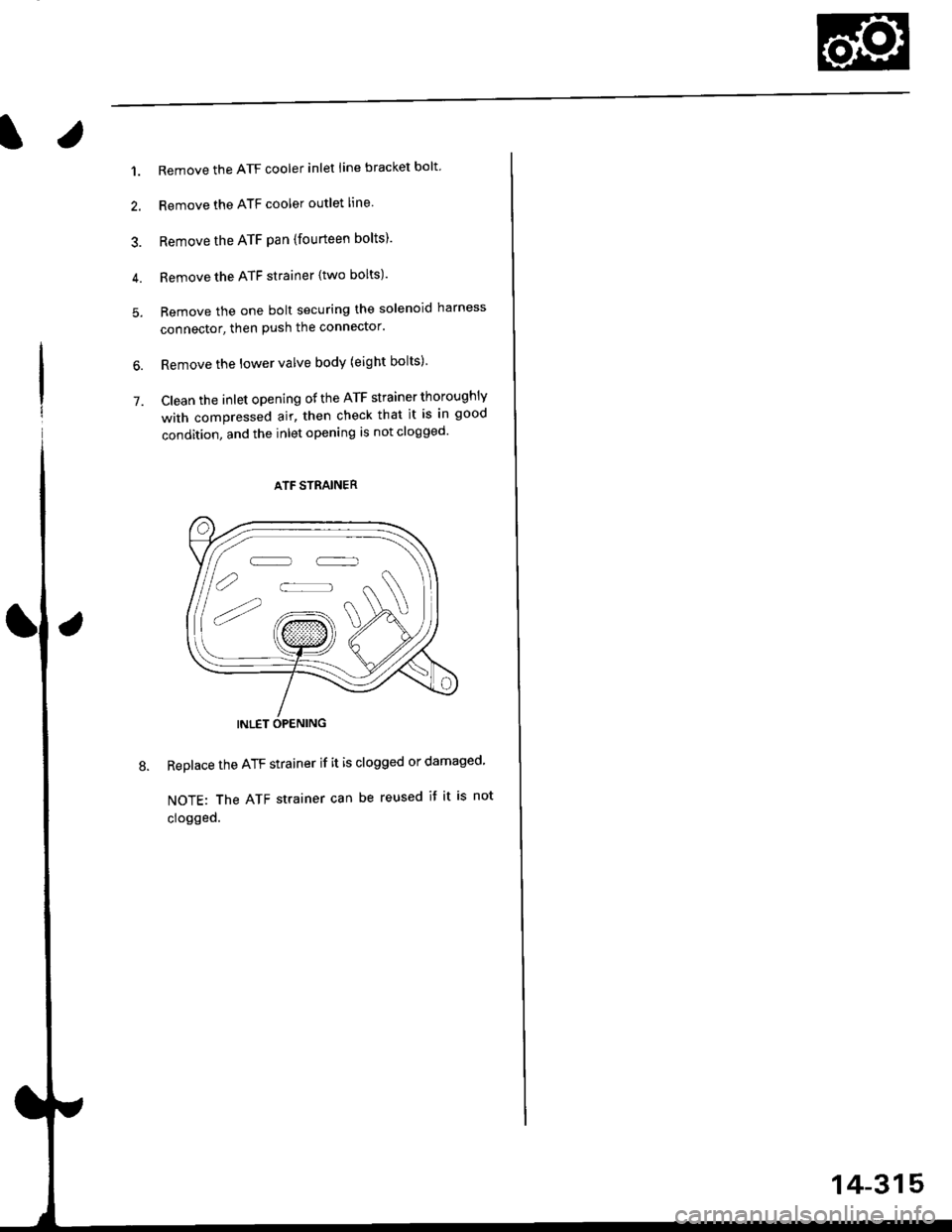

Remove the ATF cooler inlet iine bracket bolt'

Remove the ATF cooler outlet line

Remove the ATF pan (fourteen bolts).

Remove the ATF strainer {two bolts)

Remove the one bolt securing the solenoid harness

connector, then push the connector.

Remove the lower valve body (eight bolts)

Clean the inlet opening of the ATF strainer thoroughly

with compressed air, then check that it is in good

condition, and the inlet opening is not clogged'

ATF STRAINER

INLET OPENING

Replace the ATF strainer if it is clogged or damaged

NOTE: The ATF strainer can be reused it it is not

clogged.

2c'

c;2 ar\

14-315

Page 1021 of 2189

l.

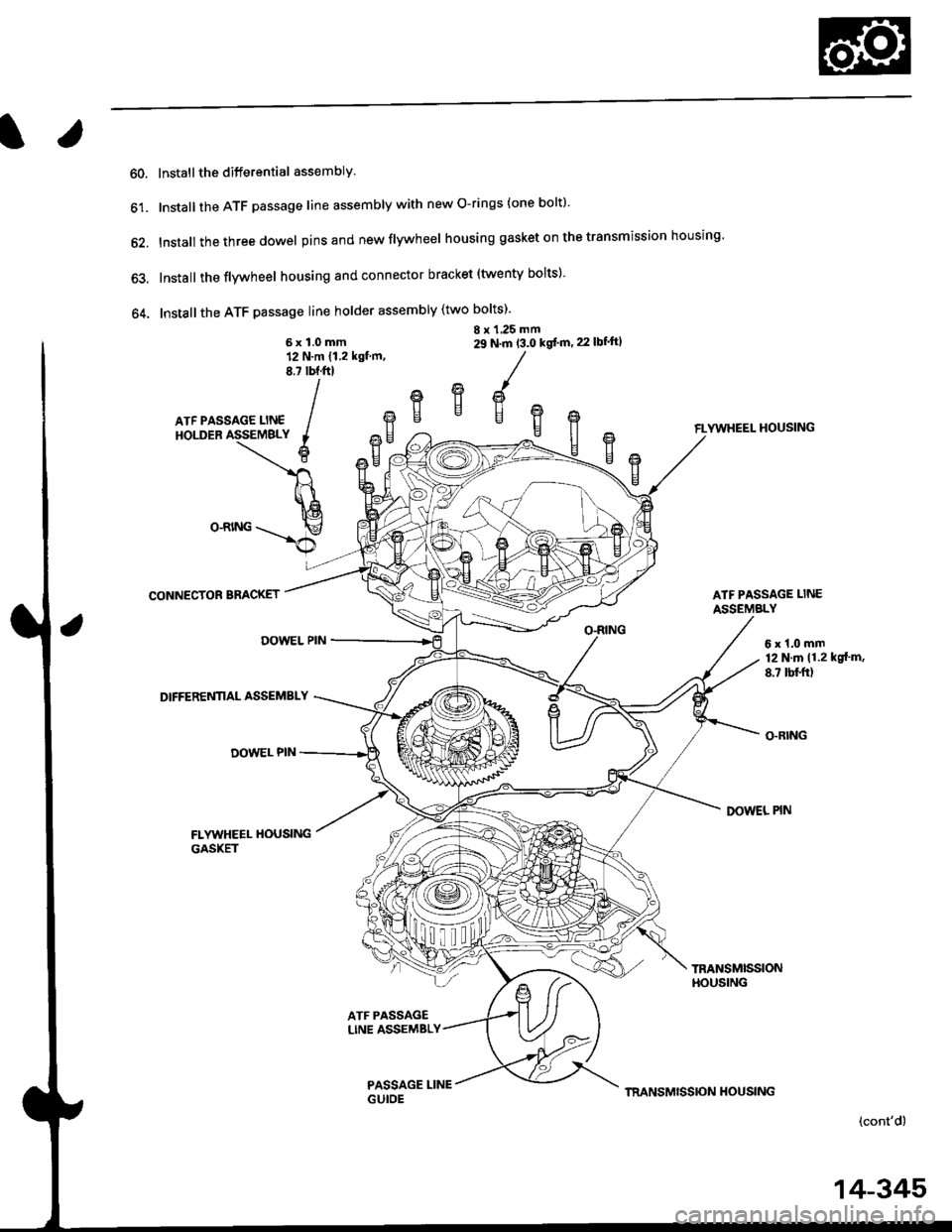

60. Install the ditferential assembly

61. Installthe ATF passage line assembly with new O-rings (one boltl'

62. Install thethreedowel pinsand new flywheel housing gasket on the transmission housing'

63. Install the flywheel housing and connector bracket (twenty bolts)'

64. Installthe ATF passage line holder assembly (two bolts)'

8 x 1.25 mm29 N.m t3.o kg['m, 22 lbf'ttl

IATF PASSAGE L|NE I"o.o.'o{

d

rm

\A

o-nrnc--.-..ff

FLYWHEEL HOUSINGGASKET

6x1.0mm12 N.m {1.2 ksf'm,

8.7 tbf.ftl/g

ugs llFLYWHEEL HOUSING

CONNECTOR BRACKET

DOWEL PIN

DIFFERENNAL ASSEMBLY

DOWEL PIN

ATF PASSAGE LINE

ASSEMALY

6x1.0mm12 N.m 11.2 kgd'm,

8.7 tbr.tr)

O.RING

DOWEL PIN

TRANSMISSIONItousrNG

ATF PASSAGELINE ASSEMBLY

PASSAGE LINEGUIOE

(cont'd)

TRANSMISSION HOUSING

14-345

Page 1022 of 2189

Transmission

Reassembly (cont'dl

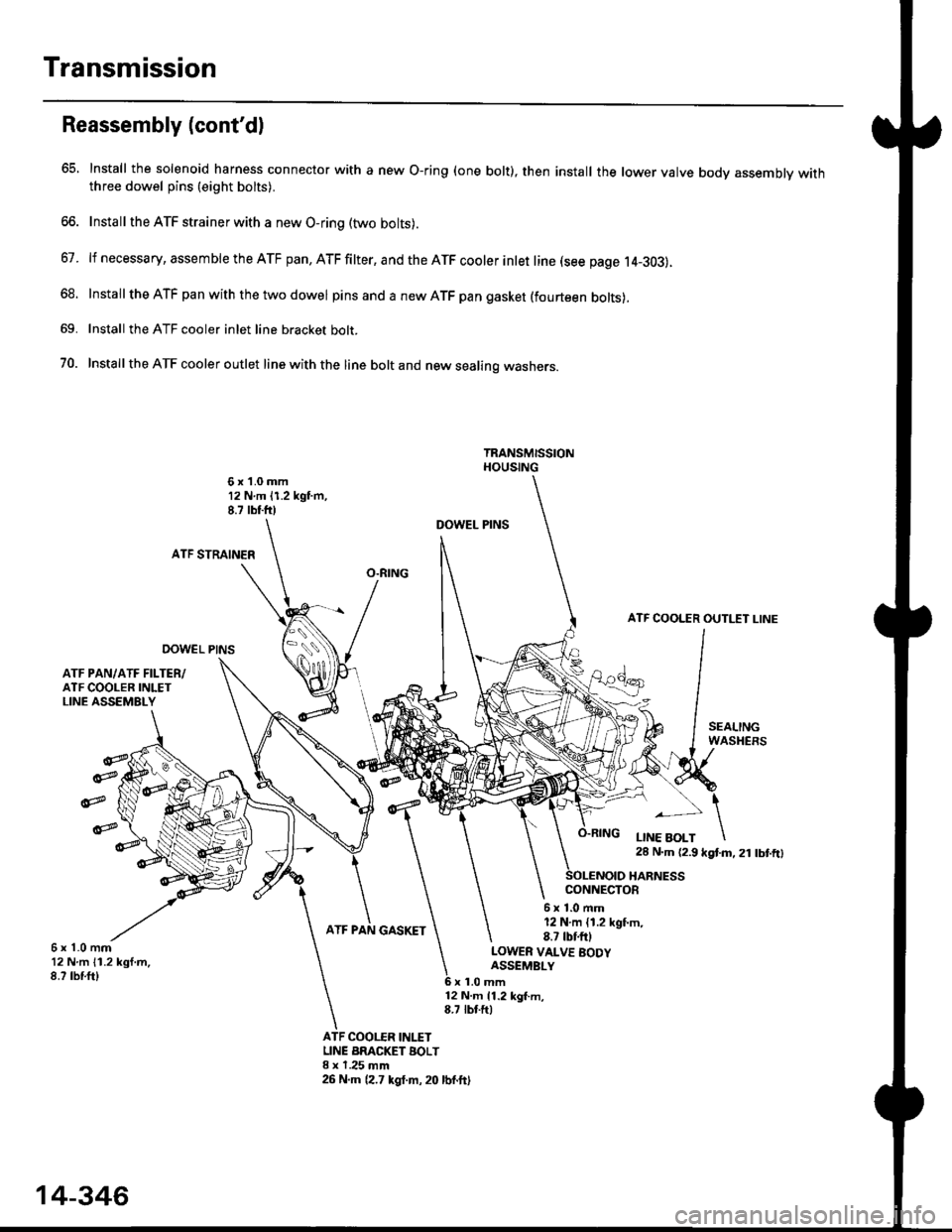

65 lnstall the solenoid harness connector with a new O-ring (one bolt), then install the lower valve body assembly withthree dowel pins (eight bolts).

66. Install the ATF strainer with a new O-ring (two bolts).

67. lf necessary, assemble the ATF pan, ATF filter, and the ATF cooler inlet line (see page 14_303).

68. Install the ATF pan with the two dowel pinsand a new ATF pan gasket (fourteen bolts).

69. Install the ATF cooler inlet line bracket bolt.

70. Installthe ATF cooler outlet line with the line bolt and new sealing washers.

6x1.0mm12 N.m 11.2 kgf.m,8.7 rbtft)DOWEL PINS

ATF STRAINER

DOWEL PINS

ATF PAN,/ATF FILTER/ATF COOLER INLETLINE ASSEMELY

@

@

C4

CONNECTOE

6x1.0mm12 N.m {1.2 kgf.m,8.7 tbtftl6x1.0mm12Nm11.2kgl.m,8.? tbf.ft)

LOWER VALVE BODYASSEMBLY

6x1.0mm12 N.m 11.2 kgf.m,8.7 tbt.ft)

ATF COOI.ER INI.ITLINE BRACKET BOLTI x 1.25 mm26 N.m (2.7 kgt.m, 20 lbf.ft)

ATF COOLER OUTI.IT LINE

14-346

Page 1026 of 2189

Transmission

17.

Installation (cont'd)

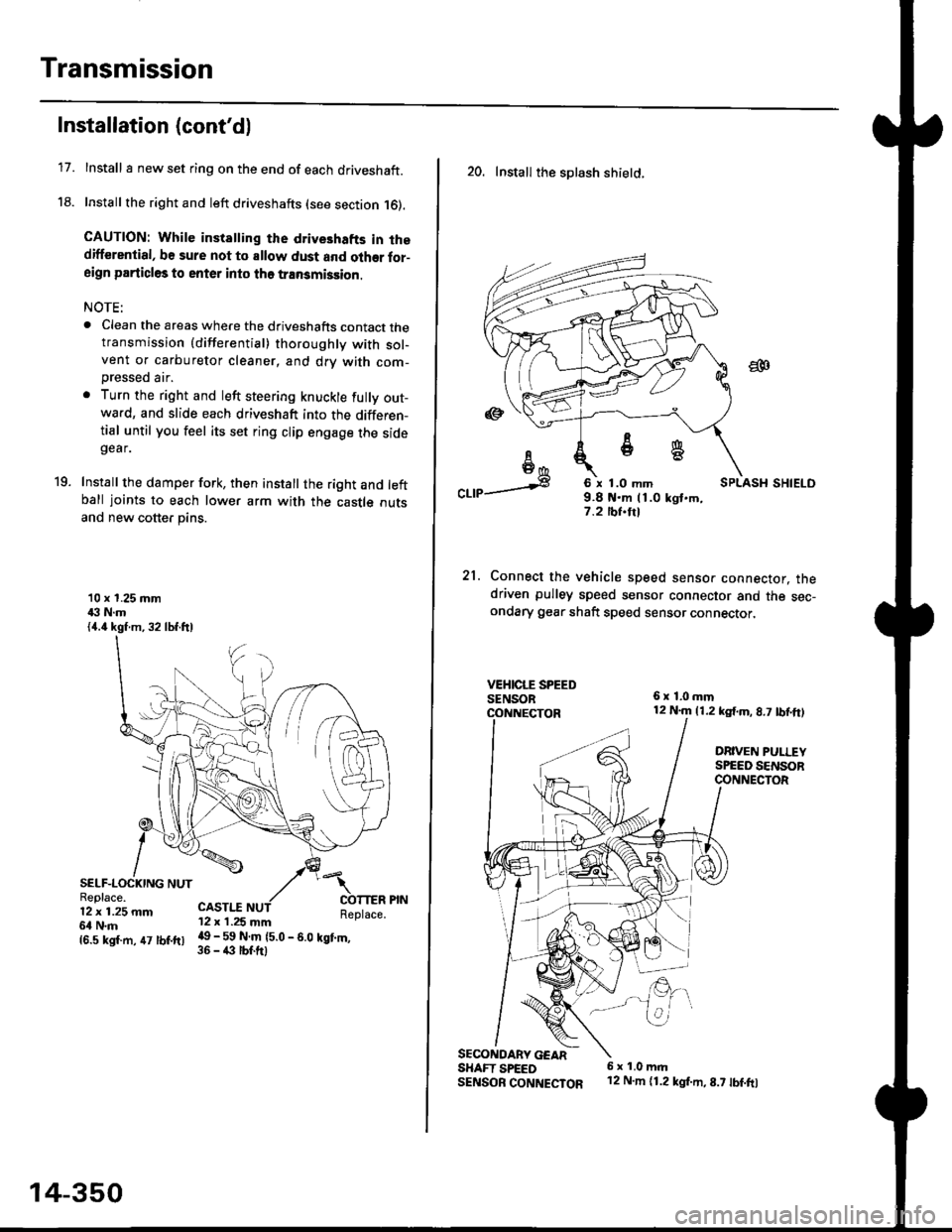

Install I new set ring on the end of each driveshaft.

Install the right and left driveshafts (see section 16).

CAUTION: While instatling the drive3hafts in thedifferential, be sure not to allow dust and olher for-aign particles to enter into tho transmission.

NOTE:

. Clean the areas where the driveshafts contact thetransmission {differential} thoroughly with sol-vent or carburetor cleaner, and drv with com-

Dressed air.

. Turn the right and left steering knuckle fully out-wa.d, and slide each driveshaft into the differen-tial until you feel its set ring clip engage the sidegear.

Install the damper fork, then install the right and leftball joints to each lower arm with the castle outsand new cotter pins.

19.

10 x 1.25 mm43 N.m{4.4 kgf.m, 32 lbf.ftl

SELF-LOCKING NUTReplace.12 x 1.25 mm6l N.m

CASTI.I'12 x 1.25 mm

{6.s ksr.m. 47 tbr.ftr l! _ ll ffiteo

- s.o tet'.,

14-350

20. Install the splash shietd.

aa

I6I6*

"a,a s

21.

SECONOARY GEARSHAFT SPEEDSENSOB CONNECTOR

6 x 1.0 mm9.8 t{.m 11.0 kgt.m,7.2 tbf.trl

Connect the vehicle speed senso. connector. thedriven pulley speed sensor connector and the sec-ondary gear shaft speed sensor connector,

6x1,0mm12 N.m {1.2 kg{.m, 8.7 tbf,ft)

DRIVEN PULLEYSPEED SENSORCONNECTOR

E.

6 x 1.0 m.rl'12 N.m {1.2 kg{.m,8.7 tbf.fo

Page 1027 of 2189

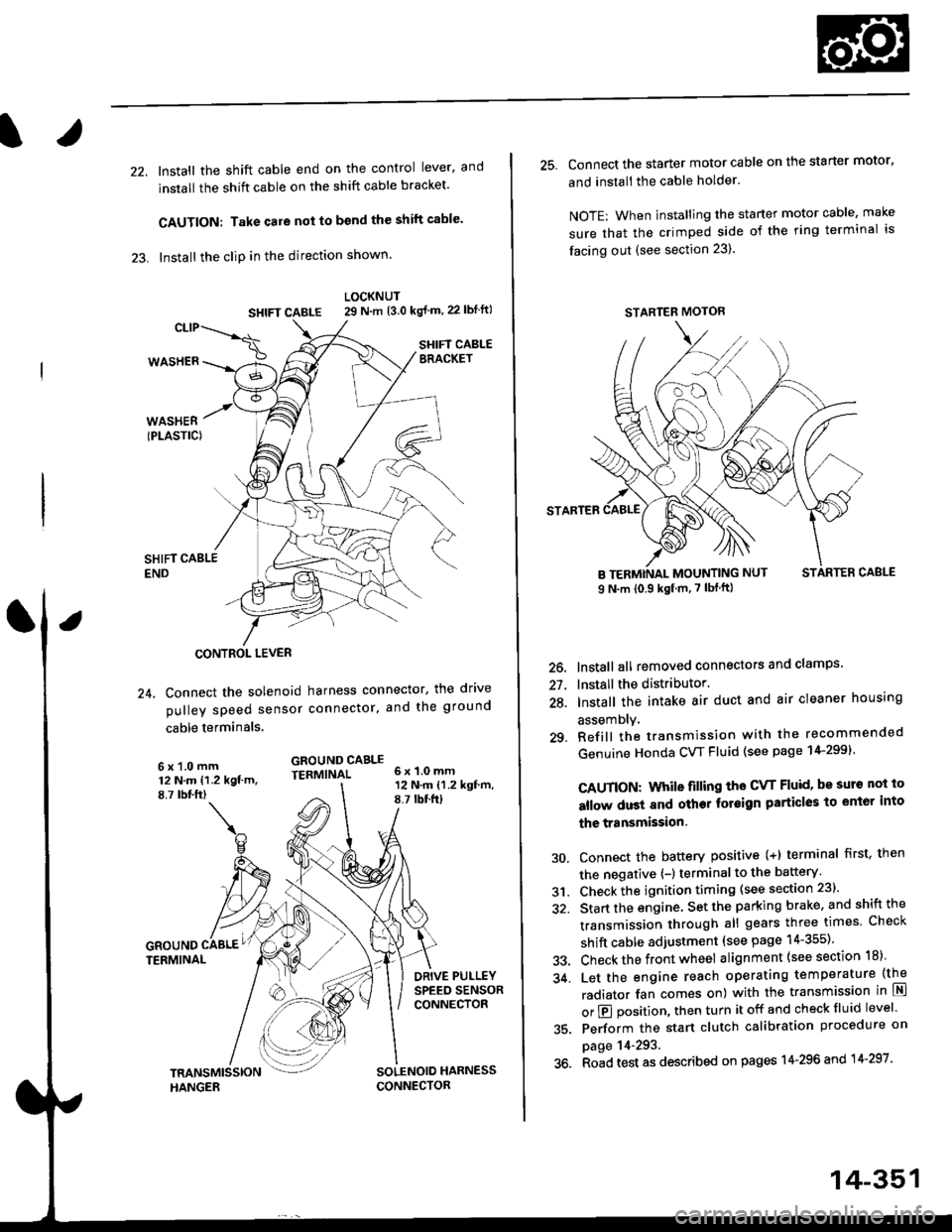

22. Install the shift cable end on the control lever, and

install the shift cable on the shift cable bracket'

CAUTION: Take care not to bend the shift cable'

23. lnstall the clip in the direction shown.

LOCKNUT

SHIFI CABLE 29 N m {3.0 kg{ m, 22lblftl

SHIFT CABLEERACKET

WASHERIPLASTIC)

CONTROL LEVER

24, Connect the solenoid harness connector. the drive

pulley speed sensor connector. and the ground

cable terminals.

6x1.0mm12 N.m {1.2 kgf.m.8,7 rbtft)

GROUND CABLETERMINAL 6x1.0mm

GROUNDTERMINAL

12 N.m {1.2 kgf'm,8.7lbtfrl

DRIVE PULLEYSPEED SENSORCONNECTOR

SOLENOID HARNESS

CONNECTOR

25. Connect the starter motor cable on the starter motor.

and install the cable holder.

NOTE: When installing the staner motor cable. make

sure that the crimped side of the ring terminal is

facing out (see section 23).

STARTEB

BMOUNTING NUT

9 N.m (0.9 kgf m,7 lbf ft)

26. Install all removed connectors and clamps'

27. Install the distributor.

28. Install the intake air duct and air cleaner housing

29.

assemDly.

Refill the transmission with the recommended

Genuine Honda CVT Fluid (see page 14-2991

CAUTION: While filling the CvT Fluid, bs surs not io

allow dust and other fotoign particles to entor into

the transmission.

Connect the battery positive (+) terminal first, then

the negative (-l terminal to the battery'

Check the ignition timing (see section 23).

Start the engine. Set the parking brake, and shift the

transmission through all gears three times Check

shift cable adjustment (see page 14-355).

Check the front wheel alignment (see section 18)

Let the engine reach operating temperature (the

radiator fan comes on) with the transmission in lXl

or E position, then turn it off and check fluid level'

Perform the start clutch calibration procedure on

page 14-293.

Road test as described on pages 14-296 and 14-297

30.

31.

34.

36.

STARTER MOTOR

14-351

Page 1082 of 2189

Troubleshooting

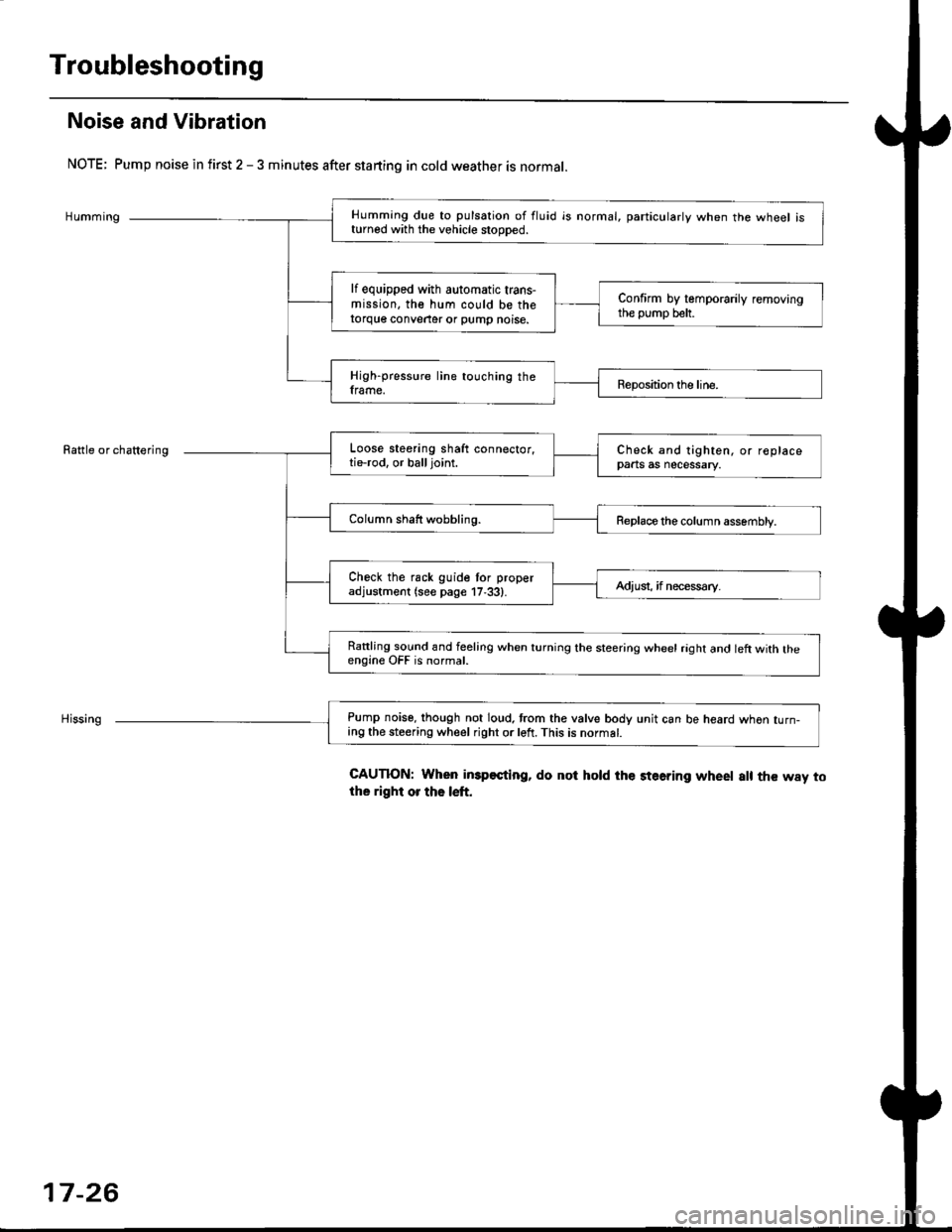

Noise and Vibration

NOTE; Pump noise in first 2 - 3 minutes after starting in cold weather is normal.

Humming

Rattle or chattering

Humming due to pulsation of fluid is normal, particularlv when the wheel isturned with the vehicle stooDed.

lf equipped with automatic trans-mission, the hum could be thetorque conveater or pump noise.

Confirm by temporarily removingthe pump belt.

High-pressure line touching theframe.Reposition the line.

Loose steering shaft connector,tie-rod. or balljoint.Check and tighten, or replacepaats as necessary.

Column shaft wobbling.Replace the column assembly.

Check the rack guide tor properadjustment (see page 17,33).Adiusi, if necess€ry.

Rattling sound and feeling when turning the steering wheel raght and left with theengine OFF is normal.

Pump noise, though not loud. trom the valve body unit can be heard whon turn-ing the steering wheel right or left. This is normat.

CAUTION: When imp€sting, do not hold the steering wheet a[ the way tothe right or the left.

17-26

Page 1084 of 2189

Troubleshooting

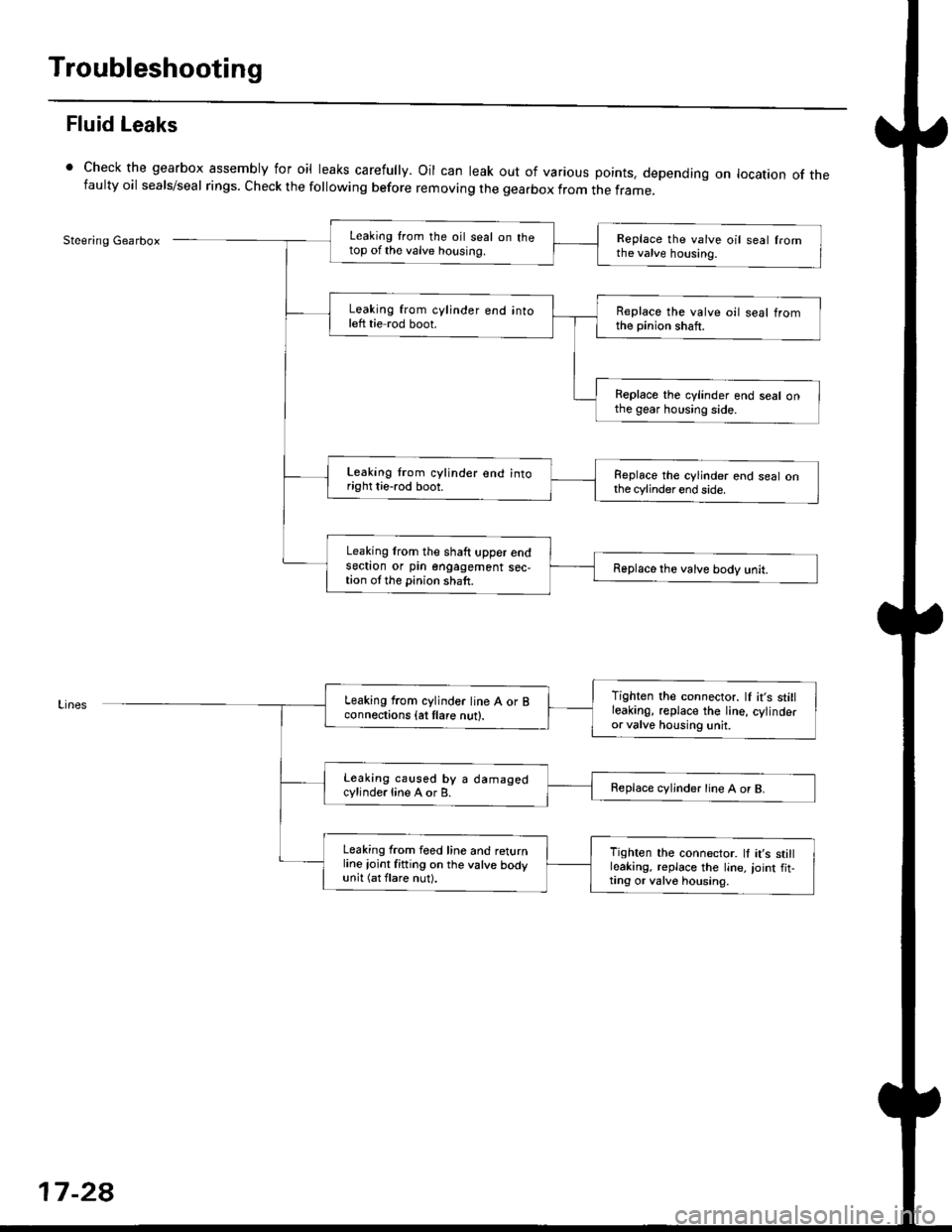

Fluid Leaks

Check the gearbox assembly for oil leaks carefully. Oil can leak out of various points. depending on location of thefaulty oil seals/seal rings. Check the following before removing the gearbox from the frame_

Steering GearboxLeaking from the oil seal on thetop of the valve housing.Replace the valve oil seal fromthe valve housing.

Leaking from cylinder end intoleft tie rod boot.Replace the valve oil seal tromthe pinion shaft.

Replace the cylinder end seal onthe gear housing side.

Leaking lrom cylinder end intoright tie-rod boot.Replace the cylinder end seal onthe cylinder end side.

Leaking lrom the shaft upper endsectron or pin engagement sec,tion ol the pinion shaft.Replace the valve body unit.

Tighten the connector. lf it's stillleakinO, replace the Iine, cylinderor valve housing unit.

Leaking from cylinder line A or Bconnections {at tlare nut}.

Leaking caused by a damagedcylinde.line A or B.Replace cvljnder line A or B.

Leaking from feed line and returnline ioint fitting on the valve bodyunit (at flare nut).

Tighten the connector. ll it's stillleaking, replace the line,,oint fit,ting or valv6 housing.

17-2a

Page 1091 of 2189

Steering Wheel

l,/

Removal

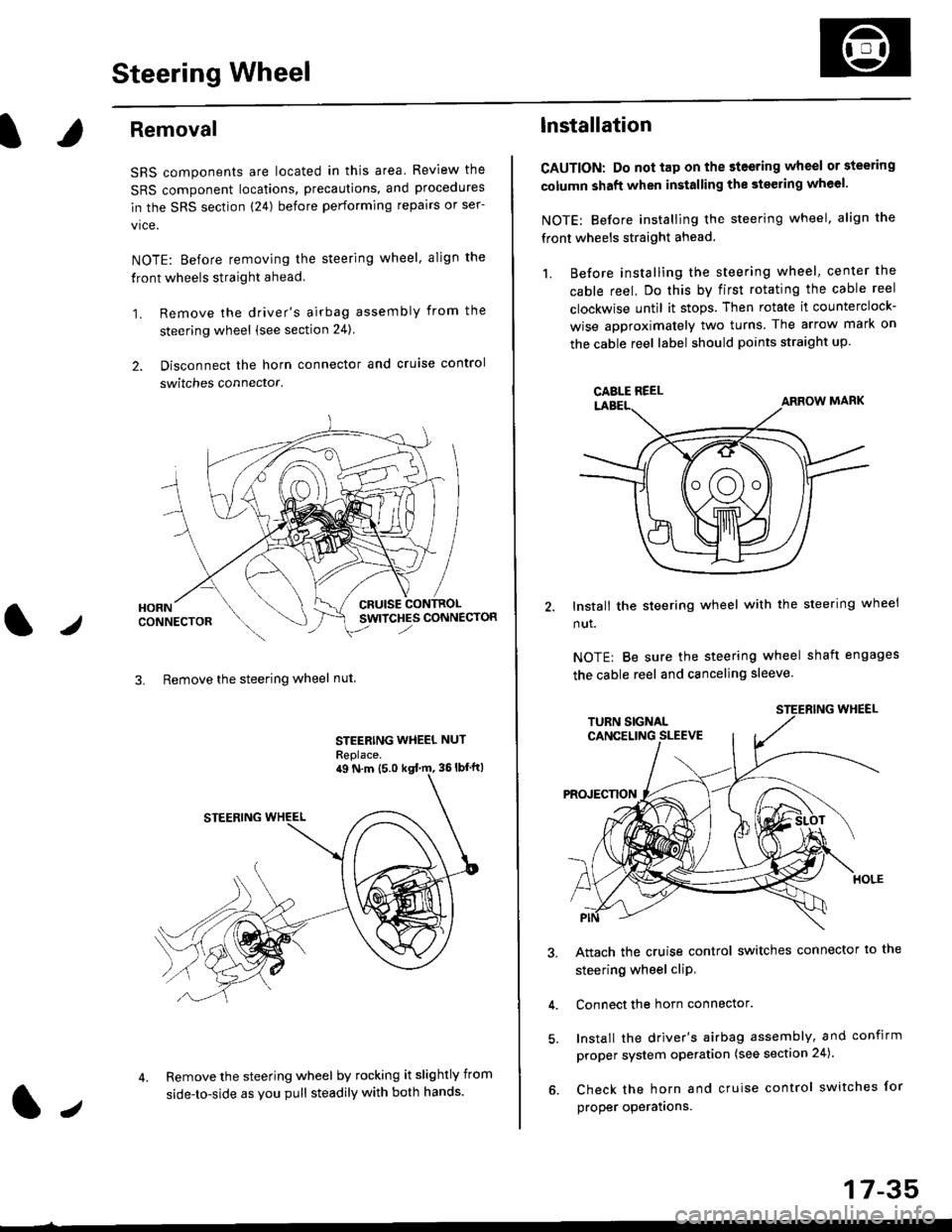

SRS components are located in this area Review the

SRS component locations, precautions, and procedures

in the SRS section (24) before performing repairs or ser-

vice.

NOTE: Before removing the steering wheel. align the

front wheels straight ahead.

1. Remove the driver's airbag assembly from the

steering wheel (see section 24)

2. Disconnect the horn connector and cruise control

switches connector.

CRUISESWITCHES CONNECTOR

3. Remove the steering wheel nut

STEERING WHEEL NUT

Replace.

Remove the steering wheel by rocking it slightly from

side-to-side as you pull steadily with both hands.

ag N.m {5.0 kgt rn, 36lbfft)

1.,

17-35

lnstallation

CAUTION: Do not tap on the steering wheel or steering

column shaft when installing the stsering wheel.

NOTE: Before installing the steering wheel, align the

front wheels straight ahead.

1. Before installing the steering wheel, center the

cable reel, Do this by first rotating the cable reel

clockwise until it stops. Then rotate it counterclock-

wise approximately two turns The arrow mark on

the cable reel label should points straight up.

Install the steering wheel with the steering wheel

nut.

NOTE: Be sure the steering wheel shaft engages

the cable reel and canceling sleeve.

Attach the cruise control switches connector io the

steering wheel cliP,

Connect the horn connector.

Install the driver's airbag assembly, and confirm

proper system operation (see section 24).

Check the horn and cruise control switches for

proper operatrons.

CAELE REEL

Page 1093 of 2189

Steering Column

I

Removal/lnstallation

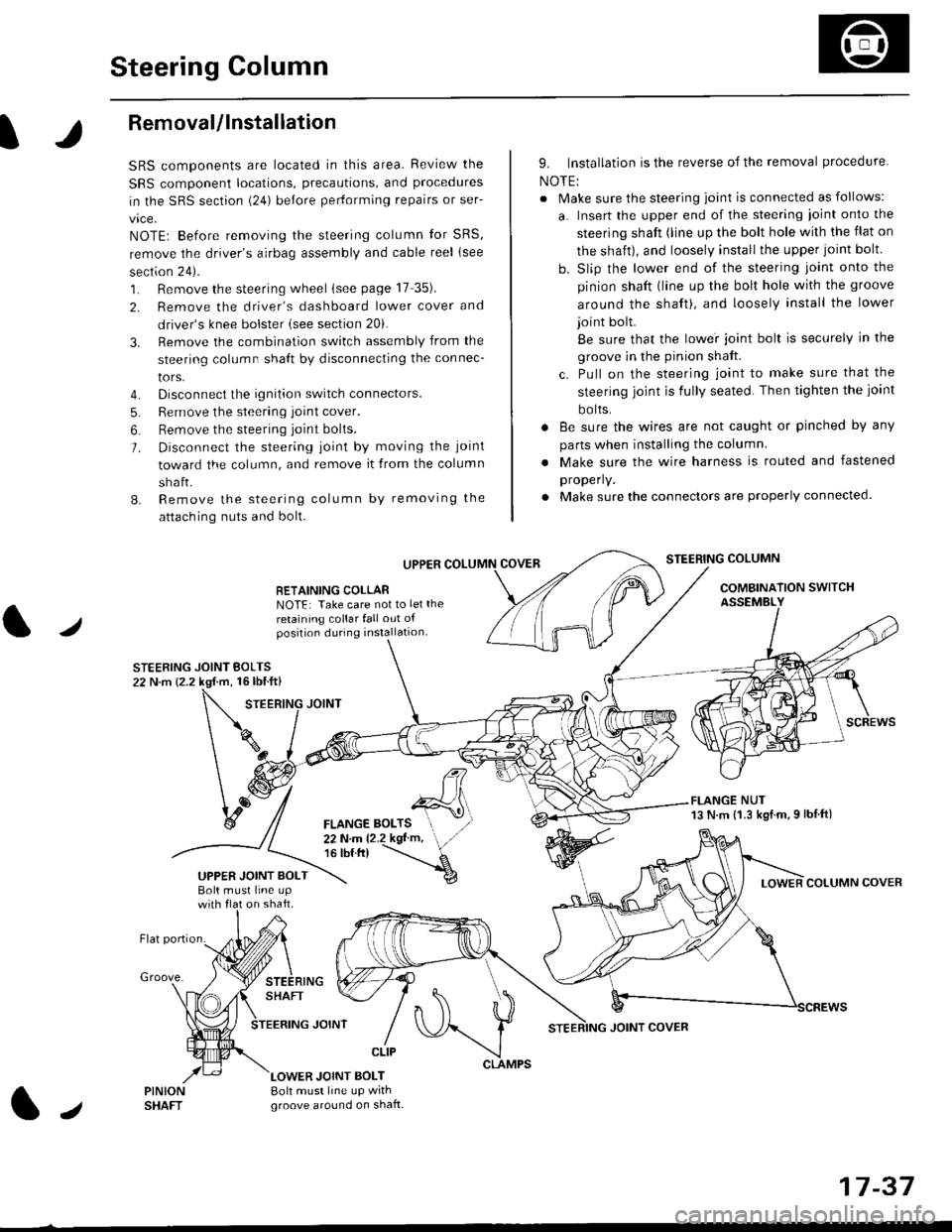

SRS components are located in this area. Review the

SRS component locations, precautions, and proceclures

in the SRS sectron (24) before pertorming repairs or ser-

vice.

NOTE: Before removing the steering column for SRS,

remove the driver's airbag assembly and cable reel lsee

section 24).

1. Remove the steering wheel (see page 17 35).

2. Remove the driver's dashboard lower cover and

driver's knee bolster (see section 20).

3. Remove the combination switch assembly from the

steering column sha{t by disconnecting the connec-

tors.

4. Disconnect the ignition switch connectors.

5. Remove the steering joint cover.

6. Bemove the steering joint bolls.

7. Disconnect the steering ioint by moving the joint

toward the column, and remove it from the column

shaft.

8. Remove the steering column by removing the

attaching nuts and bolt.

UPPER

RETAINING COLLABNOTE: Take care not to let the

retaining collar fall out ofposition during installation.

STEERING JOINT BOLTS22 N.m {2.2 kgf.m, 16lbtft}

9. Installation is the reverse of the removal procedure

NOTE:

. Make sure the steering joint is connected as follows:

a. Insert the upper end of the steering ioint onto the

steering shaft (line up the bolt hole with the flat on

the shait), and loosely install the upper joint bolt.

b. Slip the lower end of the steering joint onto the

pinion shaft (line up the bolt hole with the groove

around the shaft), and loosely install the lower

joint bolt.

Be sure that the lowei joint bolt is securely in the

groove in the pinion shaft.

c. Pull on the steering joint to make sure that the

steering joint js fully seated. Then tighten the ioint

bolts.

. 8e sure the wires are not caught or pinched by any

parts when installing the column

. Make sure the wire harness is routed and fastened

properly.

. Make sure the connectors are properly connected.

STEERING COLUMN

COMBINATION SWITCHASSEMBLY

FLANGE NUT13 N.m {1.3 kgl.m.9 lbf ft)

COLUMN COVER

FLANGE BOLTS22Nm12.2kgl'm,16 tbt.tr)

UPPER JOINT BOLTBolt musl line upon shaft.

Groove.

LOWER JOINT BOLT8oh must line up wrthgroove around on shaft.

CLIP

J

JOINT COVER

17-37