fuel cap HONDA CIVIC 2003 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 360 of 1139

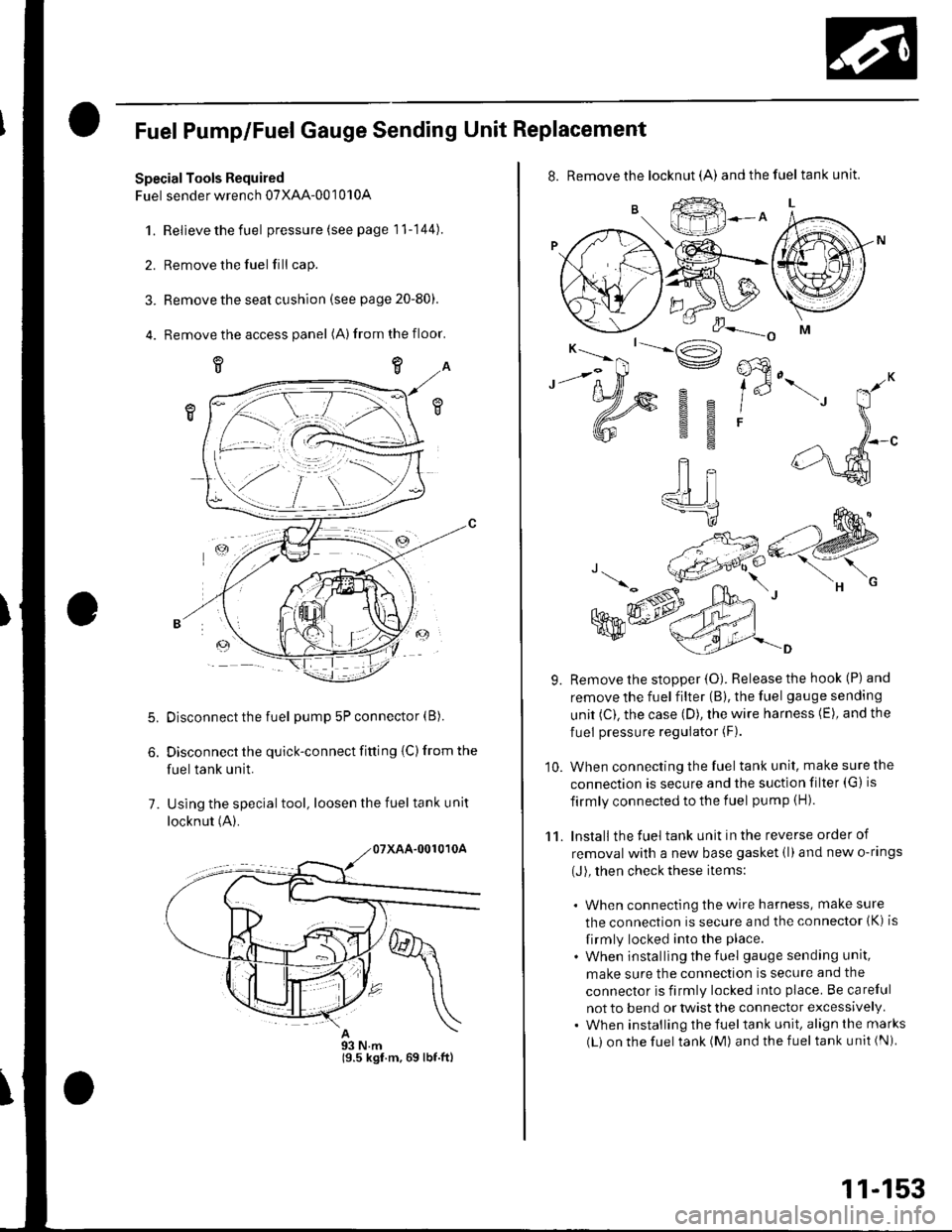

Fuel Pump/Fuel Gauge Sending Unit Replacement

SpecialTools Required

Fuel sender wrench 07XAA-001010A

1.Relieve the fuel pressure (see page 11-144).

Remove the fuel fill cap.

Remove the seat cushion (see page 20-80).

Remove the access panel (A)from the floor.

5.

7.

Disconnect the fuel pump 5P connector (B).

Disconnect the quick-connect fitting {C) from the

fuel tank unit.

Using the special tool, loosen the fuel tank unit

locknut (A).

93 N.m19.5 kgf.m,69 lbf.ftl

11-153

8. Remove the locknut (A) andthefuel tankunit.

9. Remove the stopper {O). Release the hook (P) and

remove the fuel filter (B), the fuel gauge sending

unit (C). the case (D), the wire harness (E), and the

fuel pressure regulator (F).

10. When connecting the fuel tank unit, make sure the

connection is secure and the suction filter (G) is

firmly connected to the f uel pump (H).

11. Install the fuel tank unit in the reverse order of

removal with a new base gasket (l)and new o-rings

(J), then check these items:

. When connecting the wire harness, make sure

the connection is secure and the connector (K) is

firmly locked into the place.

. When installing the f uel gauge sending unit,

make sure the connection is secure and the

connector is firmly locked into place. Be careful

not to bend or twist the connector excessively.. When installing the fueltank unit, align the marks

(L) on the fuel tank (M) and the fuel tank unit (Ni

Page 364 of 1139

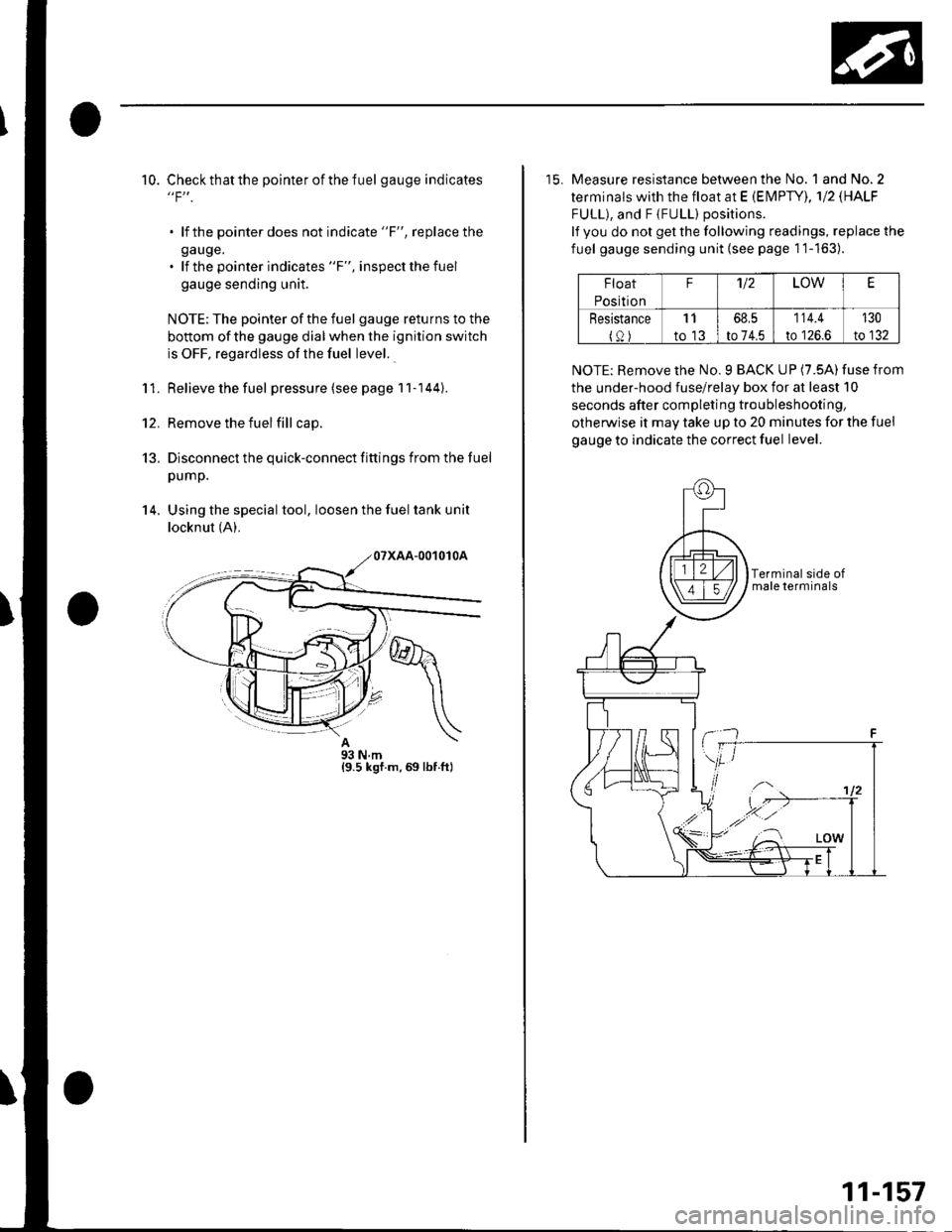

10. Checkthatthe pointerof thefuel gauge indicates"F".

. lf the pointer does not indicate "F", replace the

ga uge.. lf the pointer indicates "F", inspect the fuel

gauge sending unit.

NOTE: The pointer of the fuel gauge retu rns to the

bottom of the gauge dial when the ignition switch

is OFF, regardless of the fuel level. -

11. Relieve the fuel pressure (see page 11-144\.

12. Remove the fuelfill cap.

13. Disconnect the quick-connect fittings from the fuel

pump.

14. Using the special tool, loosen the fuel tank unit

locknut (A).

A93Nm{9.5 ksf.m,69 lbf.ft}

15. Measure resistance between the No. 1 and No.2

terminals with the float at E (EN4PTY), 'l12 \HALF

FULL), and F {FULL) positions.

lf you do not get the following readings, replace the

fuel gauge sending unit {see page 1'1-163).

Float

Position

F'U2LOWE

Resistance

{0)

11

to 13

68,5

to 74.5

114.4

to 126.6

130

to 132

NOTE: Remove the No. 9 BACK UP (7.5A) fuse from

the under-hood fuse/relay box for at least 10

seconds after completing troubleshooting,

otherwise it may take up to 20 minutes for the fuel

gauge to indicate the correct fuel level.

11-157

Page 378 of 1139

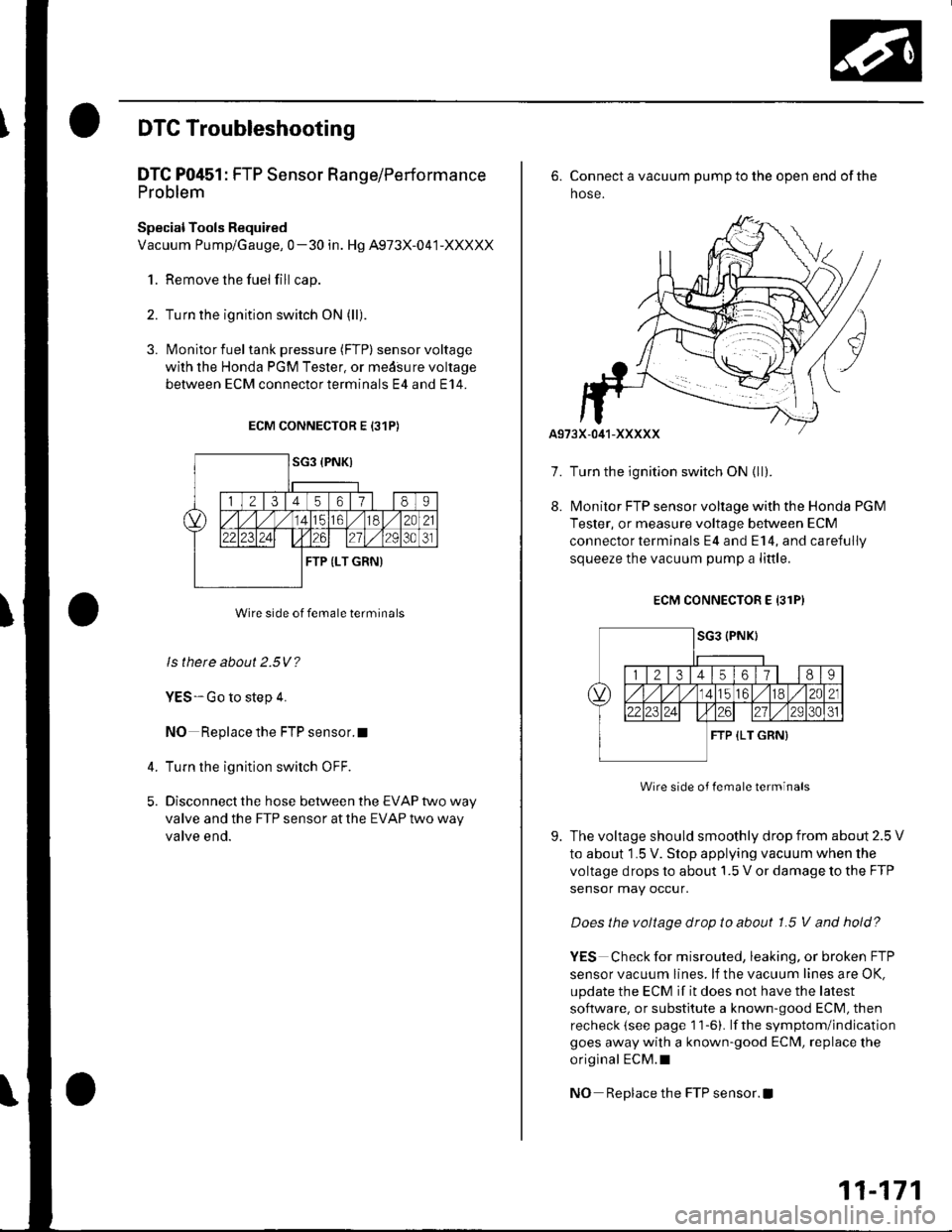

DTC Troubleshooting

DTC P0451: FTP Sensor Range/Performa nce

Problem

Special Tools Required

Vacuum Pump/Gauge, 0-30 in. Hg A973X-041-XXXXX

1. Remove the fuel fill cap.

2. Turn the ignition switch ON (ll)

3. l\4onitor fuel tank pressure (FTP) sensorvoltage

with the Honda PGM Tester, or medsure voltage

between ECM connectorterminals E4 and E14.

ECM CONNECTOR E 131P)

Wire side of female terminals

ls there about 2.5V?

YES-Go to step 4.

NO Replace the FTP sensor.I

Turn the ignition switch OFF.

Disconnect the hose between the EVAP two way

valve and the FTP sensor at the EVAP two way

valve end.

4.

5.

7.

8.

6. Connect a vacuum pump to the open end of the

hose.

Turn the ignition switch ON {ll).

l\4onitor FTP sensor voltage with the Honds PGM

Tester, or measure voltage between ECM

connector terminals E4 and E14, and carefully

squeeze the vacuum pump a little.

ECM CONNECTOR E 13lPI

Wire side of lemale terminals

The voltage should smoothly drop from about 2.5 V

to about 1.5 V. Stop applying vacuum when the

voltage drops to about 1.5 V or damage to the FTP

sensor may occur.

Does the voltage drop to about 1.5 V and hold?

YES Check for misrouted, leaking, or broken FTP

sensor vacuum lines. lf the vacuum lines are OK,

update the ECM if it does not have the latest

software. or substitute a known-good ECM, then

recheck (see page 1 1-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I

NO Replace the FTP sensor. !

9.

11-171

Page 379 of 1139

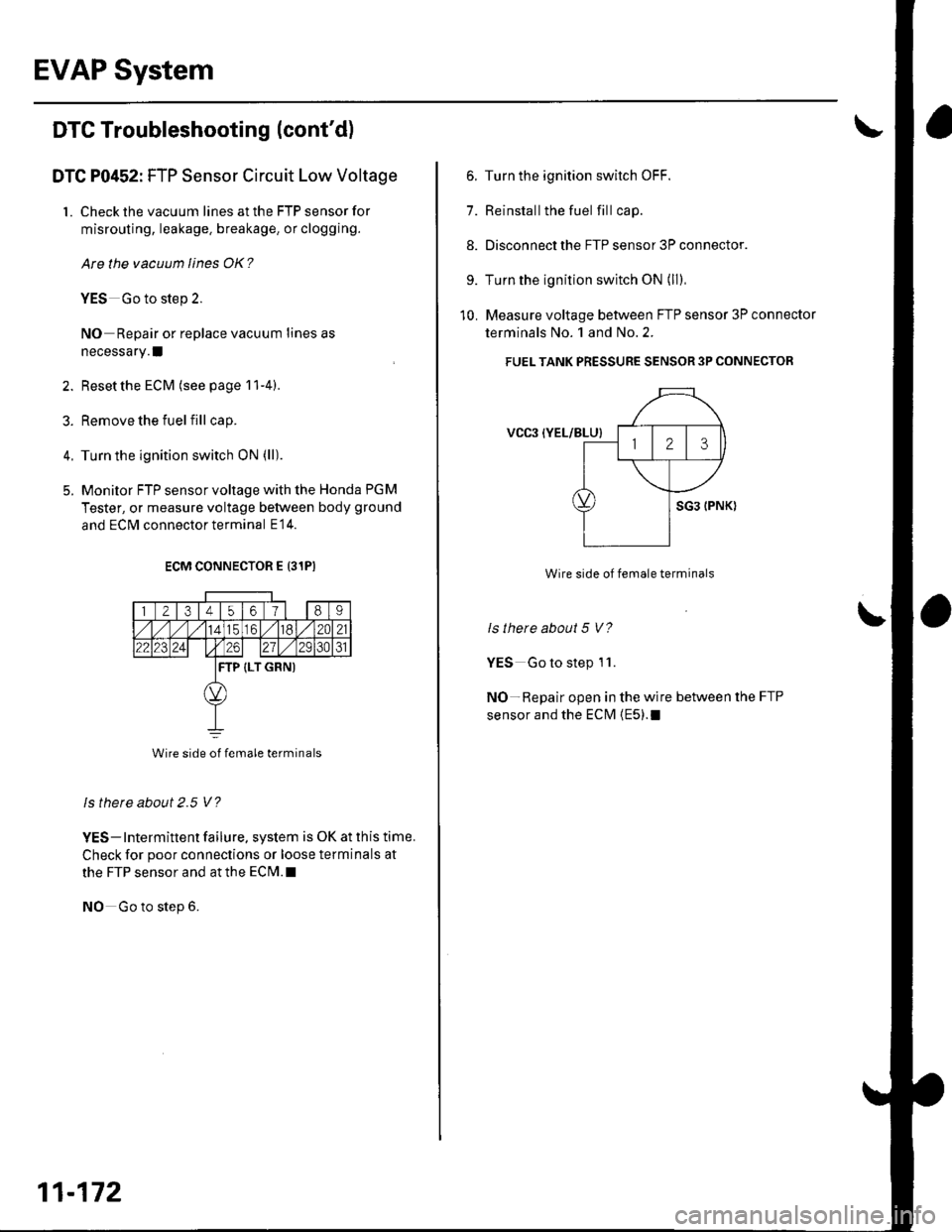

EVAP System

DTC Troubleshooting (cont'd)

DTC P0452: FTP Sensor Circuit Low Voltage

1. Check the vacuum lines at the FTP sensor for

misrouting, leakage. breakage, or clogging.

Are the vacuum lines OK?

YES Go to step 2.

NO Repair or replace vacuum lines as

necessary. I

2. Reset the ECM (see page 11-4).

3. Remove the fuelfill cap.

4. Turn the ignition switch ON (ll)

5. Monitor FTP sensor voltage with the Honda PGM

Tester, or measure voltage between body ground

and ECM connector terminal E14.

ECM CONNECTOR E 131PI

1 2t3t45o/89

././114tc61./182C21

22123241 t26271/ 2931

TP (LT GRN)

Wire side of female terminals

ls thete about 2.5 V?

YES- Intermittent failure, system is OK at this time.

Check for poor connections or loose terminals at

the FTP sensor and at the ECrM.l

NO Go to step 6.

11-172

6. Turn the ignition switch OFF.

7. Reinstallthe fuel fill cap.

8. Disconnect the FTP sensor 3P connector.

9. Turn the ignition switch ON (ll)

10. Measure voltage between FTP sensor 3P connector

terminals No. 1 and No.2.

FUEL TANK PRESSURE SENSOR 3P CONNECTOR

VCgl {YEL/BLU}

Wire side of female terminals

ls there about 5 V?

YES Go to step 1 '1.

NO-Repair open in the wire between the FTP

sensor and the ECM {E5).1

Page 380 of 1139

't2.

13.

14.

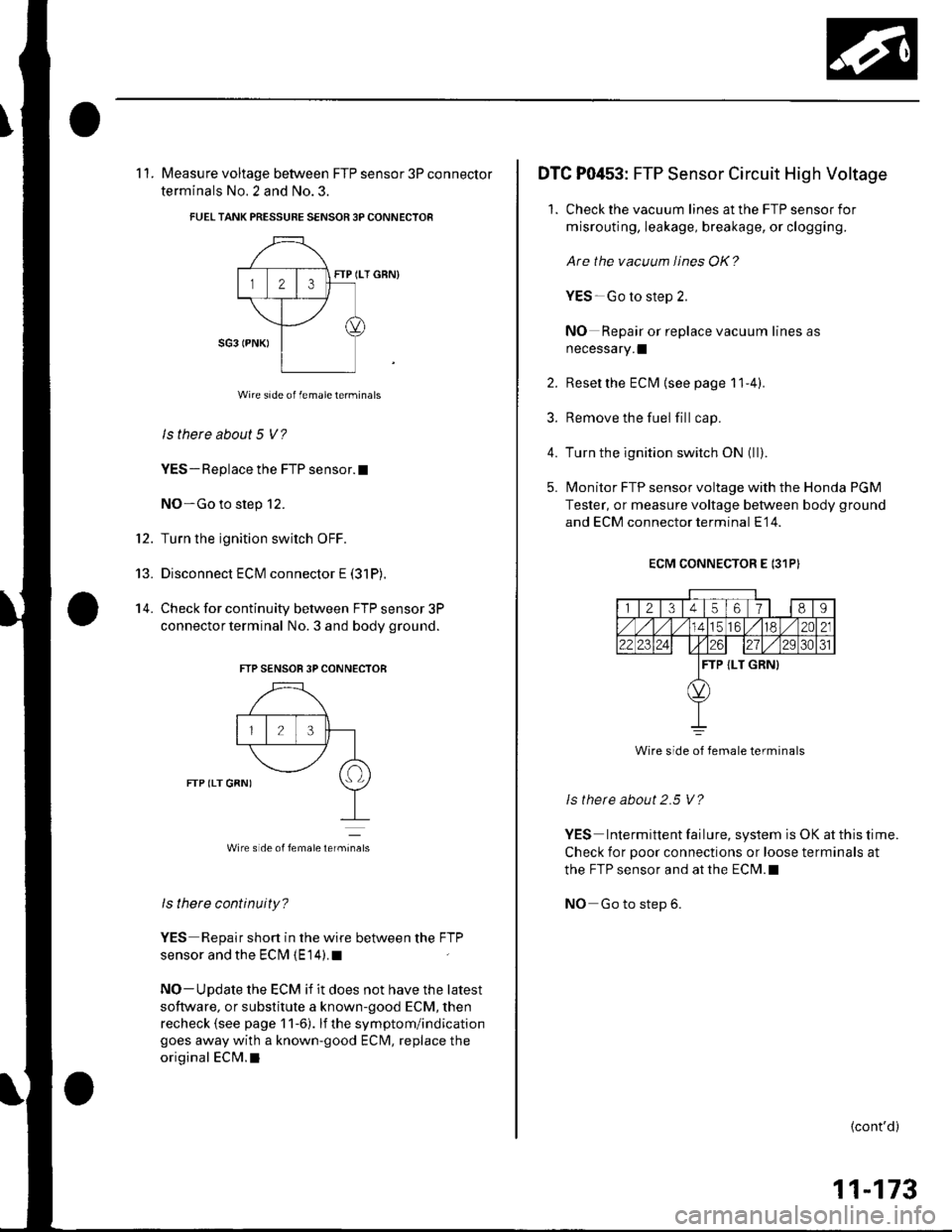

11. Measure voltage between FTP sensor 3P connector

terminals No. 2 and No.3.

FUELTANK PRESSUBE SENSOR 3P CONNECTOR

FTP (LT GBN)

Wire side of femaleterminals

ls there about 5 V?

YES - Replace the FTP sensor. t

NO-Go to step 12.

Turn the ignition switch OFF.

Disconnect ECM connector E (31P),

Check for continuity between FTP sensor 3P

connector terminal No. 3 and body ground.

FTP SENSOR 3P CONNECTOB

FTP (LT GRNI

Wire side of femalelerminats

ls there continuity?

YES Repair short in the wire between the FTP

sensor and the ECI\4 {E14).I

NO-Update the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck (see page 1 1-6). lf the symptom/indicationgoes away with a known-good EClvl, replace the

original ECM.I

DTC P0453: FTP Sensor Circuit High Voltage

1. Check the vacuum lines at the FTP sensor for

misrouting, leakage, breakage, or clogging.

Are the vacuum lines OK?

YES-Go to step 2.

NO Repair or replace vacuum lines as

necessary.I

2. Reset the ECM {see page 11'4).

3. Remove the fuel fill cap.

4. Turn the ignition switch ON (ll).

5. lvlonitor FTP sensor voltage with the Honda PGM

Tester, or measure voltage between body ground

and ECM connector terminal E'14.

ECM CONNECTOR E 131PI

112134567I9

56/ t182C21

242il./29 3031

TP {LT GRN}

Wire side of female terminals

Is there about 2.5 V?

YES Intermittent failure, system is OK at this time.

Check for poor connections or loose terminals at

the FTP sensor and at the ECM.I

NO Go to step 6.

{cont'd)

11-173

Page 381 of 1139

EVAP System

DTC Troubleshooting (cont'dl

6. Turn the ignition switch OFF.

7. Reinstall lhe fuel fill cap.

8. Disconnect the FTP sensor 3P connector.

9. Turn the ignition switch ON (ll).

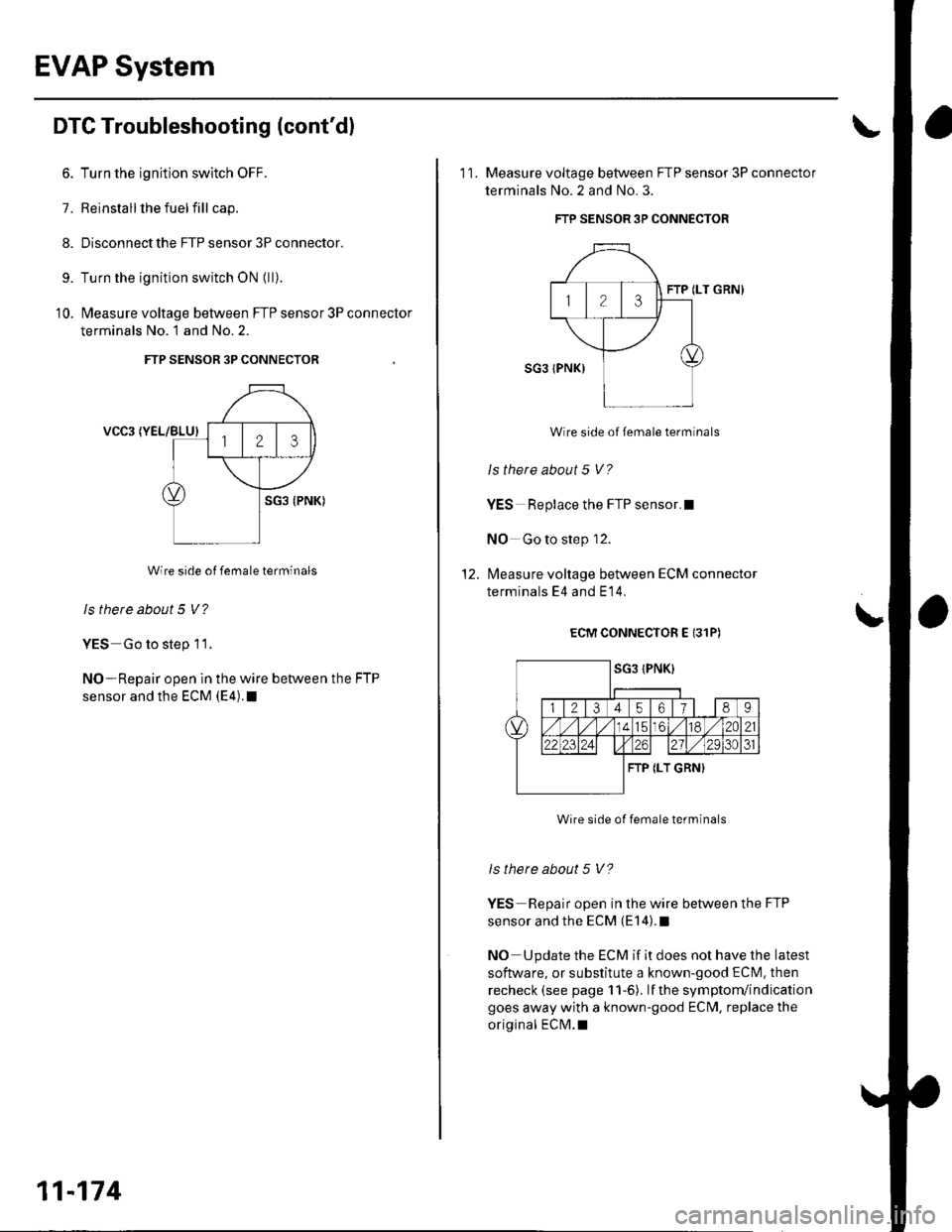

'10. l\4easure voltage between FTP sensor 3P connector

terminals No. 1 and No.2.

FTP SENSOR 3P CONNECTOR

VCC3 (YEL/BLU)

Wire side of female terminals

ls there about 5 V?

YES Go to step 11.

NO-Repair open in the wire between the FTP

sensor and the ECM (E4). !

11-174

11, Measure voltage between FTP sensor 3P connector

terminals No.2 and No.3.

FTP SENSOR 3P CONNECTOR

FTP ILT GRN}

Wire side of female terminals

ls there about 5 V?

YES Replace the FTP sensor.l

NO Go to step 12.

l\4easure voltage between ECM connector

terminals E4 and E 14,

ECM CONNECTOR E (31P)

Wire side of female terminals

ls there about 5 V?

YES Repair open in the wire between the FTP

sensor and the ECM (E14).I

NO Update the ECM if it does not have the latest

software, or substitute a known-good ECN4. then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I

\

Page 382 of 1139

DTC Pl456: EVAP Control(Fuel Tank Svstem)

System Leakage

The fuel system is designed to allow specified

maximum vacuum and pressure conditions. Do not

deviate from the vacuum and pressure tests as

indicated in these procedures. Excessive pressure/

vacuum would damage the EVAP components or cause

eventual fuel tank failure.

Special Tools Required

Vacuum Pump/Gauge, 0-30 in. Hg A973X-041-XXXXX

This is a two-trip code. Once cleared, it cannot be

reproduced in one trip. Also, cenain specific driving

and ambient conditions must occur before the ECM will

complete the system checks. Additional test drives may

still not meet the specific conditions needed to

reproduce the code.

Follow these troubleshooting procedures carefully to

ensure the integrity of the system and to confirm the

cause of the problem or code.

NOTE: Fresh fuel has a higher volatility that createsgreater pressure/vacuum. The optimum condltlon for

testing is fresh fuel, and must be less than a full tank. lf

possible, to assist in leak detection, add 1 gallon of

fresh fuel to the tank (as long as it will not fill the tank).just before starting these procedures.

Fuel Fill Cap Check

1. Check the fuel fill cap (the cap must say "lf not

tightened 3 clicks check engine light may come

on" ).

ls the proper luel till cap installed and properly

tightened?

YES Go to step 2.

NO- Replace or tighten the cap.I

2. Check the fuel fill cap seal.

ls the tuel fill cap seal missing or damaged?

YES- Replace the fuel fill cap.I

NO The fuelfill cap is OK. Go to step 3.

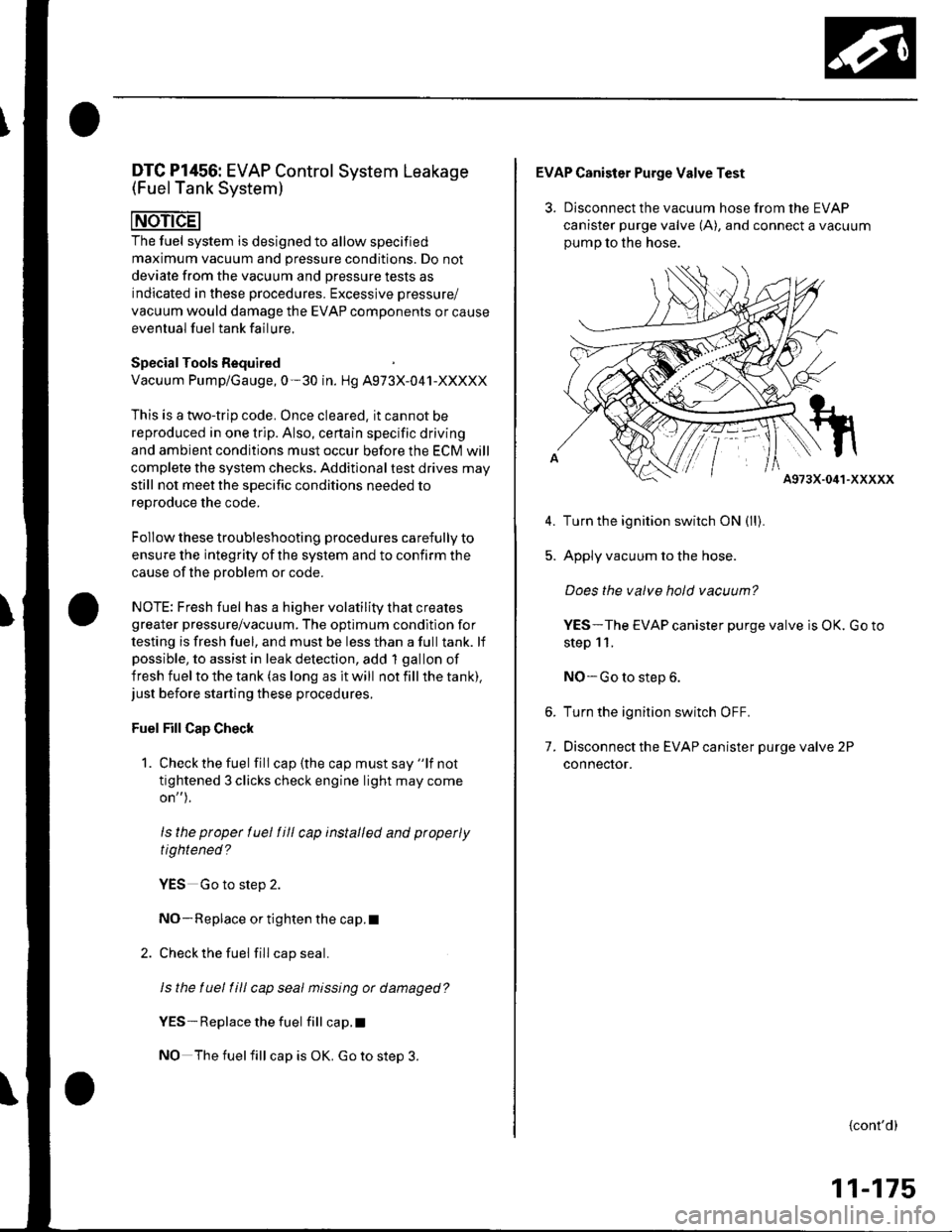

EVAP Canister Purge Valve Test

3. Disconnect the vacuum hose from the EVAP

canister purge valve (A), and connect a vacuum

oumo to the hose.

A973X-041-XXXXX

Turn the ignition switch ON (ll).

Apply vacuum to the hose.

Does the valve hold vacuum?

YES-The EVAP canister purge valve is OK. Go to

step 11.

NO-Go to step 6.

Turn the ignition switch OFF.

Disconnect the EVAP canister purge valve 2P

connecror.

5.

7.

{cont'd)

11-175

Page 386 of 1139

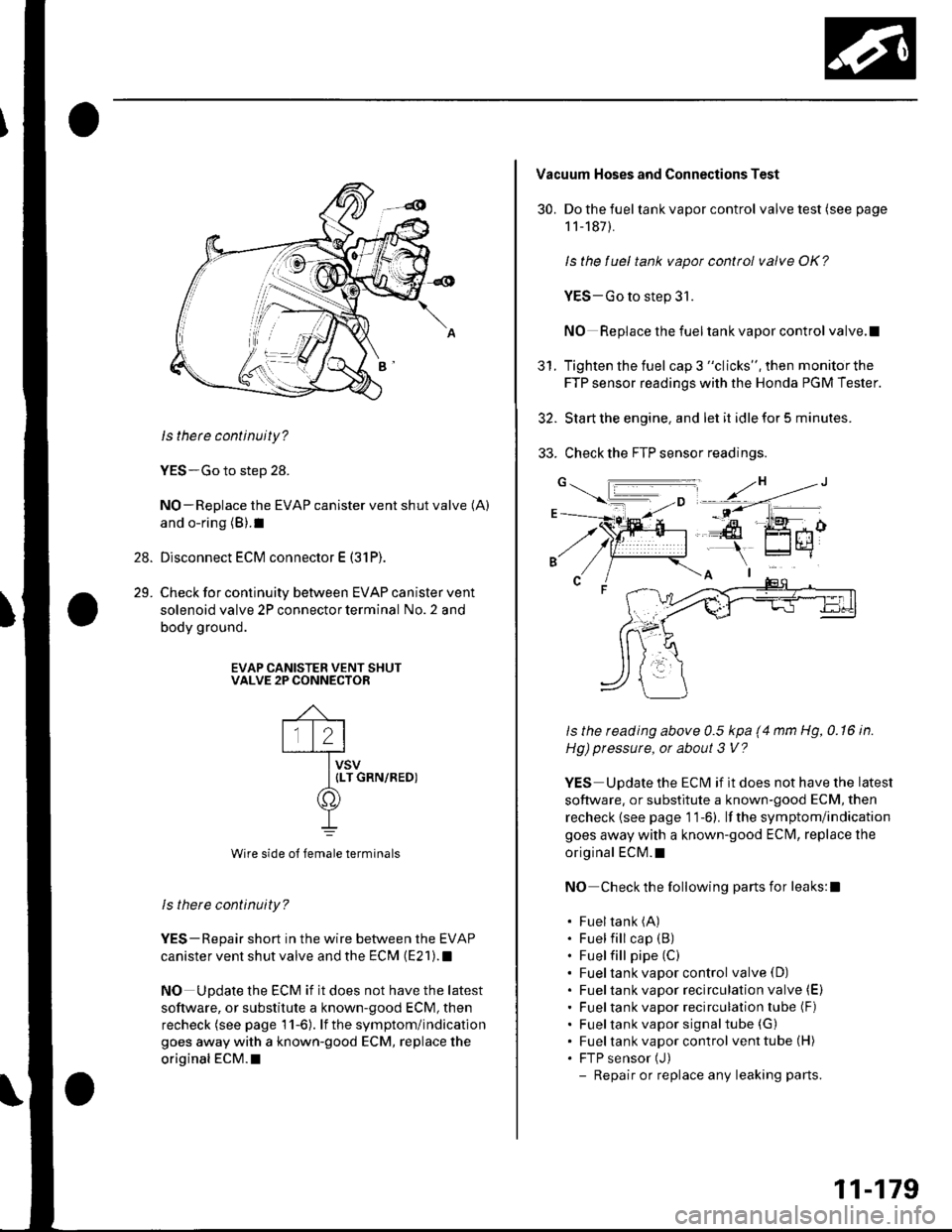

28.

29.

ls thete continuity?

YES-Go to step 28.

NO-Replace the EVAP canister vent shut valve (A)

and o-ring (B).1

Disconnect ECM connector E (31P).

Check for continuity between EVAP canister vent

solenoid valve 2P connector terminal No. 2 and

body ground.

EVAP CANISTER VENT SHUTVALVE 2P CONNECTOR

Wire side o{ female terminals

ls there continuity?

YES-Repair short in the wire between the EVAP

canister vent shut valve and the ECM (E21).1

NO Update the ECM if it does not have the latest

soflware, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I

30.

Vacuum Hoses and Connections Test

Do the fuel tank vapor control valve test (see page

1 1-187).

ls the fuel tank vapot control valve OK?

YES-Go to step 31.

NO Replace the fueltank vapor control valve.l

Tighten the fuel cap 3 "clicks", then monitorthe

FTP sensor readings with the Honda PGM Tester.

Start the engine. and let it idle for 5 minutes.

Check the FTP sensor readings.

ls the reading above 0.5 kpa (4 mm Hg, 0.16 in.

Hg) pressure, or about 3 V?

YES Update the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck {see page 1 1-6). lf the symptom/indication

goes away with a known-good ECfvl, replace the

original ECM.t

NO Check the following parts for leaks:l

. Fueltank (A)

. Fuel fill cap (B)

. Fuel fill pipe (C)

. Fueltank vapor control valve(D). Fueltank vapor recirculation valve (E)

. Fueltank vapor recirculation tube (F)

. Fueltank vapor signaltube (G)

. Fueltank vapor control venttube(H). FTP sensor (J)

- Repair or replace any leaking parts.

5t.

11-179

Page 393 of 1139

EVAP System

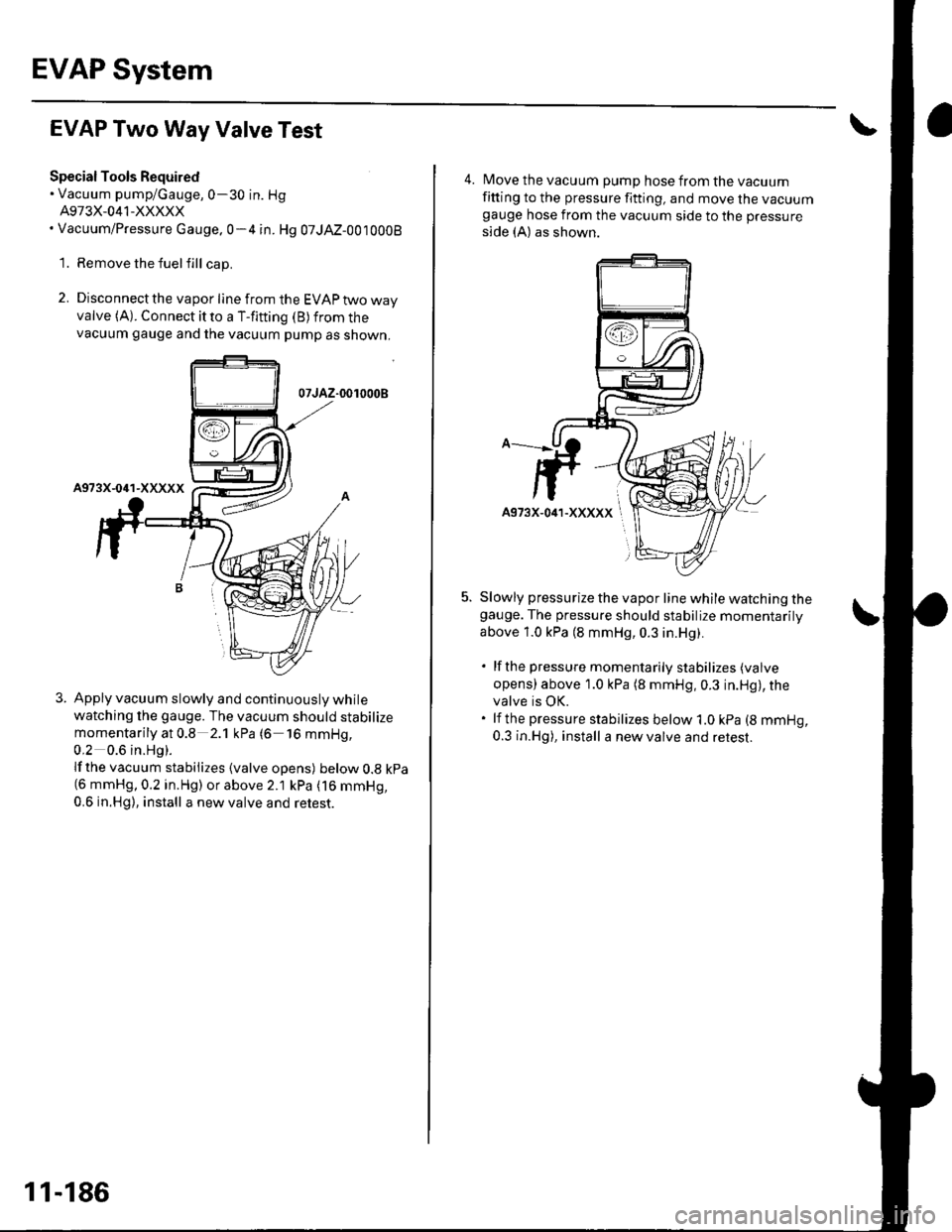

EVAP Two Way Valve Test

Special Tools Required. Vacuum pump/Gauge,0-30 in. Hg

A973X-041-XXXXX. Vacuum/Pressure cauge.0-4 in. Hg 07JAZ-0010008

1. Remove the fuelfill cap.

2. Disconnect the vapor line from the EVAP two wayvalve (A). Connect it to a T-fitting (B) from thevacuum gauge and the vacuum pump as shown,

07JAZ-0010008

Apply vacuum slowly and continuously while

watching the gauge. The vacuum should stabilize

momentarily at 0.8 2.1 kPa (6 16 mmHg,

0,2 0.6 in.Hg).

lf the vacuum stabilizes {valve opens) below 0.8 kpa(6 mmHg,0.2 in.Hg) or above 2.1 kPa (16 mmHg,

0.6 in.Hg), install a new valve and retest.

11-186

4. Move the vacuum pump hose from the vacuumfitting to the pressure fitting, and move the vacuumgauge hose from the vacuum side to the pressure

side (A) as shown.

Slowly pressurize the vapor line while watching thegauge. The pressure should stabilize momentarilV

above 1.0 kPa (8 mmHg, 0.3 in.Hg).

. lfthe pressure momentarily stabilizes (valve

opens) above 1.0 kPa (8 mmHg,0.3 in.Hg), thevalve is OK.. lf the pressure stabilizes below 1.0 kPa (8 mmHg,

0.3 in.Hg), install a new valve and retest.

Page 394 of 1139

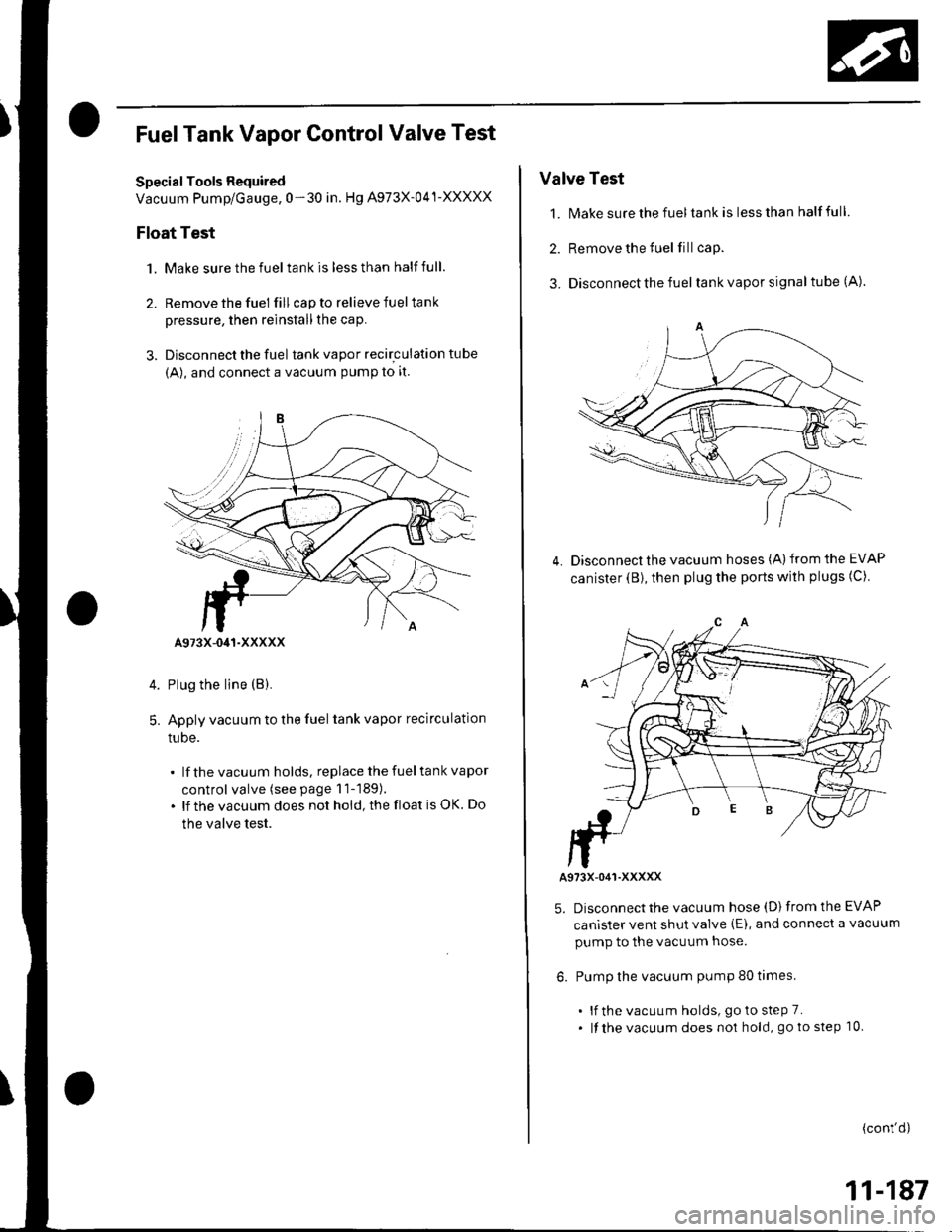

FuelTank Vapor Control Valve Test

Special Tools Required

Vacuum Pump/Gauge, 0-30 in. Hg A973X-041-XXXXX

Float Test

1. Make sure the fuel tank is less than half full.

2. Remove the fuel fill cap to relieve fuel tank

pressure, then reinstall the cap.

3. Disconnect the fuel tank vapor recirculation tube

{A), and connect a vacuum PumP to it.

Plug the line (B).

Apply vacuum to the fuel tank vapor recirculation

tuDe.

lf the vacuum holds, replace the fuel tank vapor

control valve (see page 11-189).

lf the vacuum does not hold, the float is OK. Do

the valve test.

5.

A973X-041-XXXXX

Valve Test

1. N4ake sure the fuel tank is less than half full

2. Remove the fuel fill cap.

3. Disconnect the fuel tank vapor signal tube (A).

Disconnect the vacuum hoses (A) from the EVAP

canister (B), then plug the ports with plugs (C)4.

A973X-O41-XXXXX

5. Disconnect the vacuum hose (D) from the EVAP

canister vent shut valve (E), and connect a vacuum

pump to the vacuum hose.

6. Pump the vacuum pump 80 times.

. lf the vacuum holds, goto steP 7.. lf the vacuum does no1 hold, go to step 10.

(cont'd)

11-187