radiator HONDA INTEGRA 1998 4.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 1010 of 1681

.J

5.

6.

7.

8.

Remove the dashboard (see section 2O).

Remove the heater duct (see page 21 20) or the

evaporator lsee page 22-261.

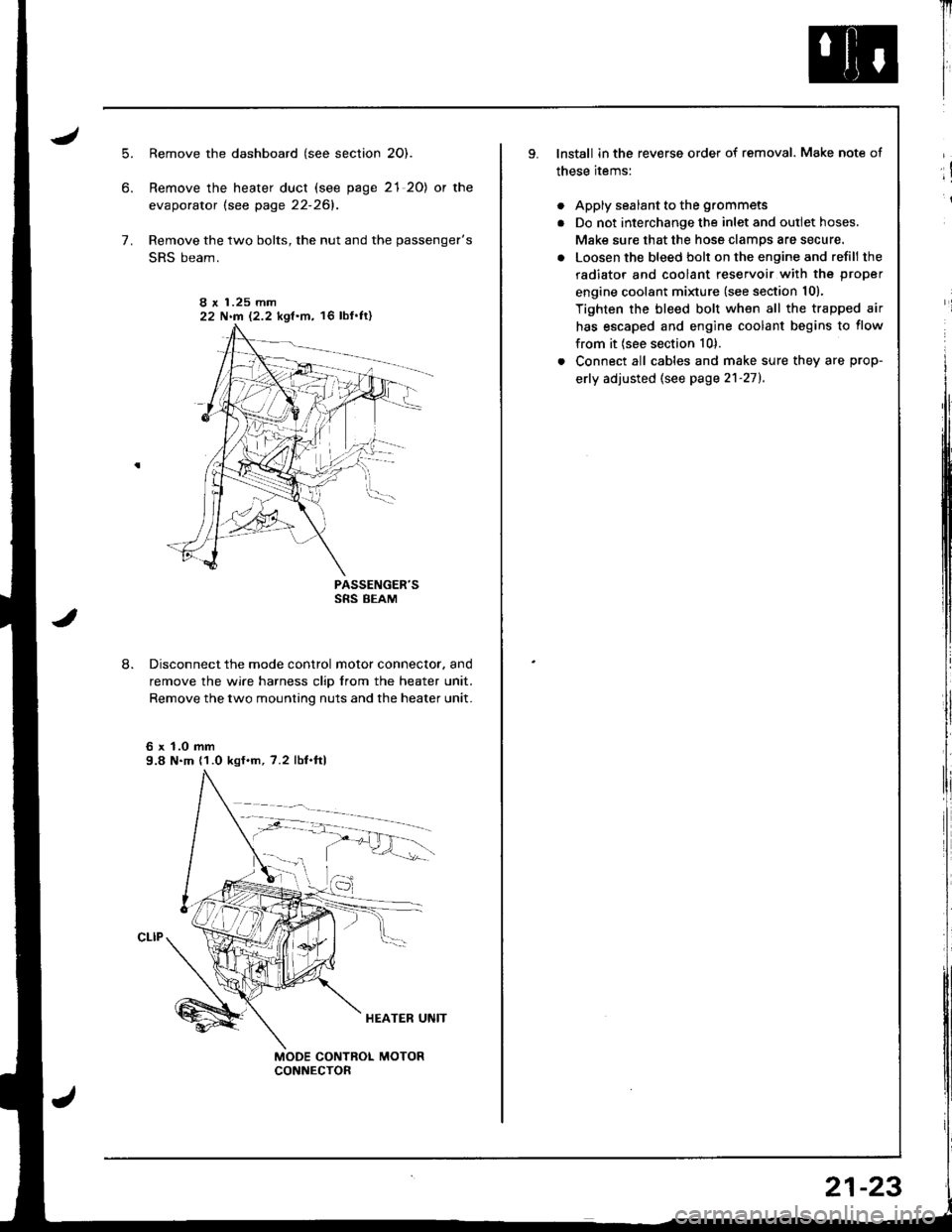

Remove the two bolts, the nut and the passenger's

SRS beam.

PASSENGER'SSRS BEAM

Disconnect the mode control motor connector. and

remove the wire harness clip from the heater unit.

Remove the two mounting nuts and the heater unit.

6 x 1.0 mm9.8 N.m (1.0 kgf.m, 7.2 lbf.ftl

I r 1.25 mm22 N.m 12.2 kgf.m, 16 lbf'ft)

Il

I

I

lnstall in the reverse order of removal. Make note of

these items:

. Apply sealant to the grommets

. Do not interchange the inlet and outlet hoses.

Make sure that the hose clamps are secure.

. Loosen the bleed bolt on the engine and refill the

radiator and coolant reservoir with the proper

engine coolant minure (see section 10).

Tighten the bleed bolt when all the trapped air

has escaped and engine coolant begins to flow

from it (see section 10).

. Connect all cables and make sure they are prop-

erly adjusted (see page 2'l-271.

;!

i

21-23

Page 1022 of 1681

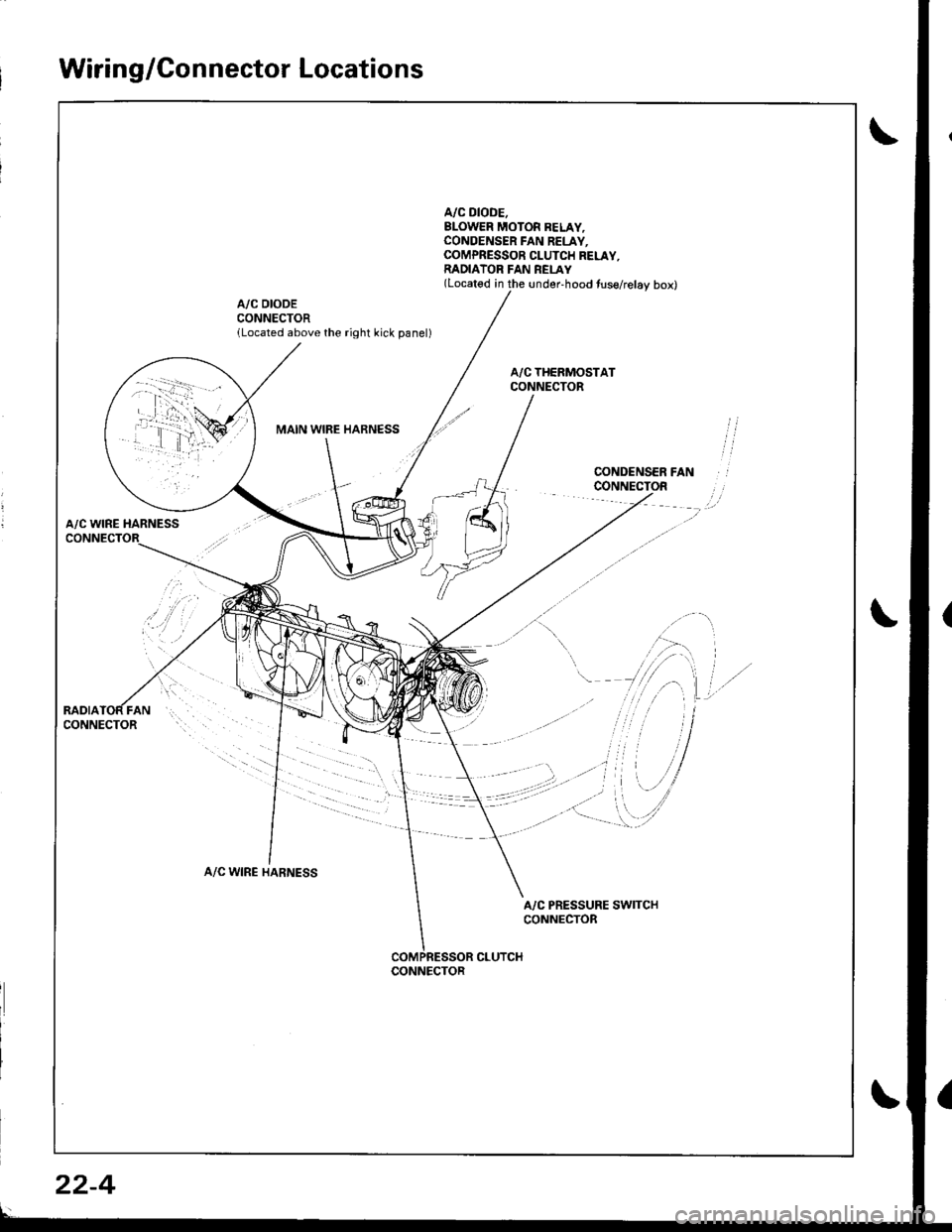

Wiring/Connector Locations

A/C DIODE.BLOWER MOTOR BELAY,CONOENSER FAN RELAY.COMPRESSOR CLUTCH RELAY,RADIATOR FAN REI-AY(Located in the under-hood tuse/relay box)

A/C DIODECONNECTORlLocated above the right kick panel)

MAIN WIBE HARNESS

A/C WINE HARNESS

A/C WIRE HARNESS

A/C PRESSURE SWITCHCONNECTOR

CLUTCHCONNECTOR

22-4

Page 1025 of 1681

J

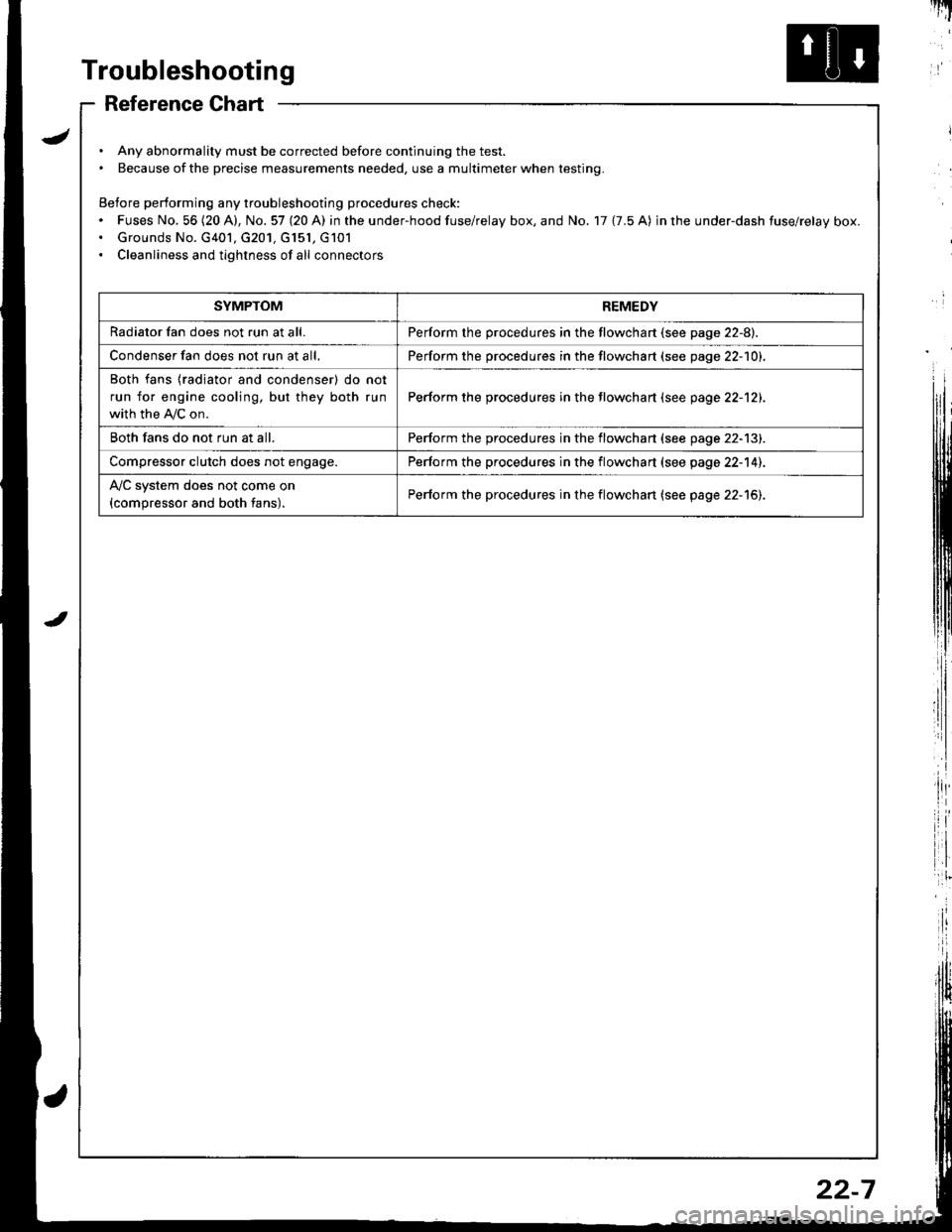

Troubleshooting

Reference Chart

. Any abnormality must be corrected before continuing the test.. Because of the precise measurements needed, use a multimeter when testing.

Before performing any troubleshooting procedures check:. Fuses No, 56 (20 A), No. 57 (20 A) in the under-hood fuse/relay box, and No. 17 {7.5 A) in rhe under-dash fuse/relay box.. Grounds No. G401, G201, G151, G101. Cleanliness and tightness of all connectors

I'IT

I

I

SYMPTOMREMEDY

Radiator fan does not run at all.Perform the procedures in the flowchart {see page 22-8).

Condenser fan does not run at all,Perform the procedures in the flowchart (see page 22-1O1.

Both fans {radiator and condenser) do not

run for engine cooling, but they both run

with the IVC on.

Perform the procedures in the tlowchart (see page 22-12).

Both fans do not run at all.Perform the procedures in the flowchart (see page 22-13).

Compressor clutch does not engage.Perform the procedures in the flowchart (see page 22-14).

l'lc system does not come on

{compressor and both fans).Perform the procedures in the flowchart (see page 22-15).

22-7

Page 1026 of 1681

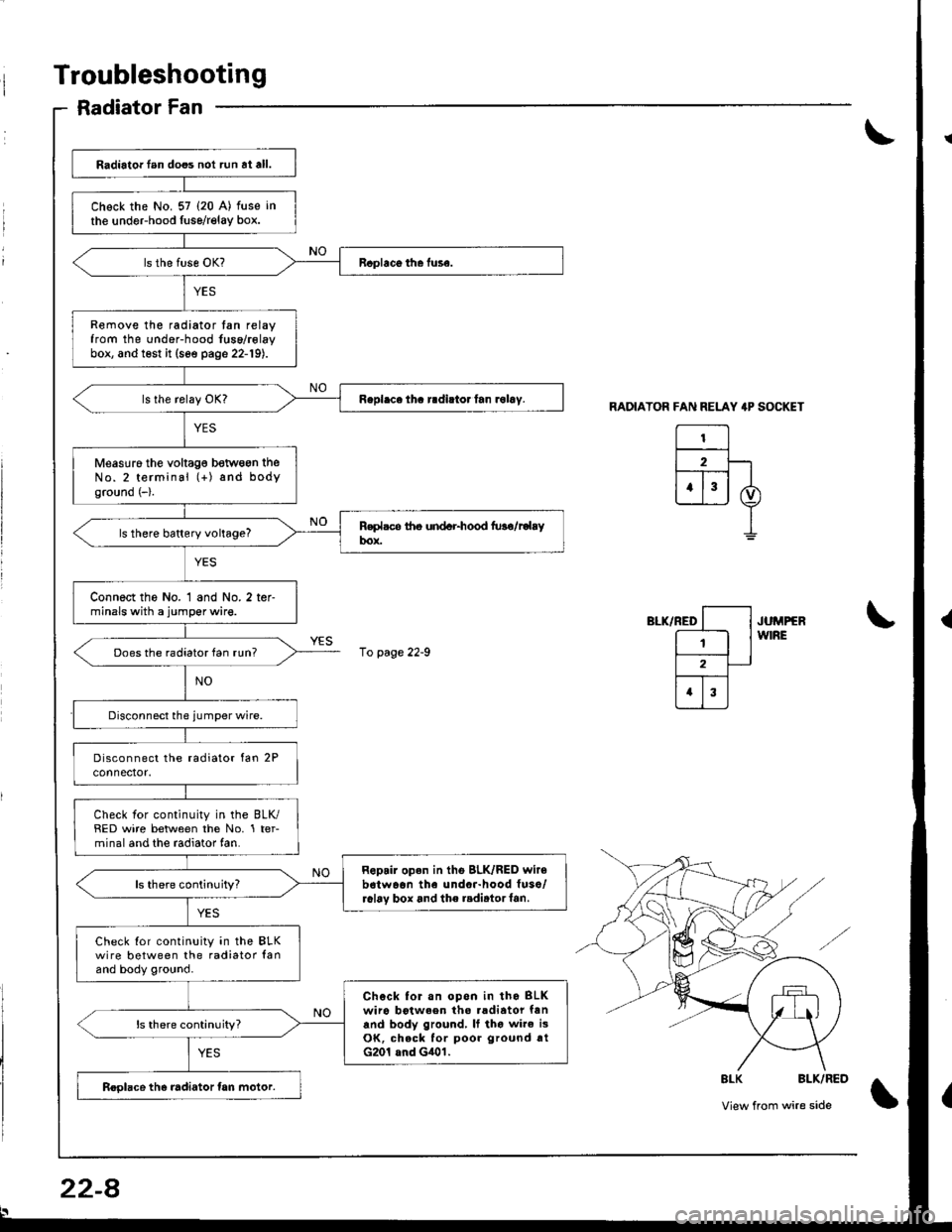

Troubleshooting

Radiator Fan

RADIATOR FAN RELAY 4P SOCKET

El2F-lt--T-- |

ujj I

I

",-*rrro [--l .u^rrrr

E lw'RE

l2-

trI

\

\

8LK BLK/RED

View from wire side\

Radiator lan does not run at all.

Chock the No. 57 (20 A) fuse in

the undeFhood fuse/relay box.

Remove the radiator tan relayfrom the under-hood fuse/rolaybox, and test it (see page 22-19).

Measuro the voltag€ betwogn theNo.2 terminal (+) and bodyground (-).

ls there battery voltage?

Connect the No. 1 and No. 2 ter-minals with a jumper wire.

Does the radiator fan run?

Check for continuity in the BLK/RED wire between the No. 1 ter-minal and the radiator fan.

Repair open in tho BLK/RED wir6b6twaon the undor-hood fuso/r6l6v box and the radirtorf6n.ls there continuity?

Check Ior continuity in the BLKwire between the radiator lanand body ground.

Chock for.n opon in tho BLKwiro botween tho .adiator fanand body ground, It tho wire i3OK, check for poor ground rtG201 and G401.

ls there continuity?

Roolace the radiator tan motor.

10 page 22-9

22-8

Page 1027 of 1681

![HONDA INTEGRA 1998 4.G Service Manual From page 22 8

RADIATORFAN RELAY

l---l

| 2 |

[T;]

I BrK/YEt

o)

I

RELAY 4P SOCKET

Disconnect the,umper wire andturn the ignition switch ON (II).

Measure the voltage between theNo. 4 terminal (+i and b HONDA INTEGRA 1998 4.G Service Manual From page 22 8

RADIATORFAN RELAY

l---l

| 2 |

[T;]

I BrK/YEt

o)

I

RELAY 4P SOCKET

Disconnect the,umper wire andturn the ignition switch ON (II).

Measure the voltage between theNo. 4 terminal (+i and b](/img/13/6069/w960_6069-1026.png)

From page 22 8

RADIATORFAN RELAY

l-'--l

| 2 |

[T;]

I BrK/YEt

o)

I

RELAY 4P SOCKET

Disconnect the,umper wire andturn the ignition switch ON (II).

Measure the voltage between theNo. 4 terminal (+i and bodyground ( ).

Ropair op€n in the GRN wire be-tween the undor-hood Iuse/.elay box and the A/C diode.

ls there battery voltage?

Repair open in the BLK/YEL wirebotwean the under-hood tuse/relay box snd the under-daahfuso/relay box,

22-9

Page 1030 of 1681

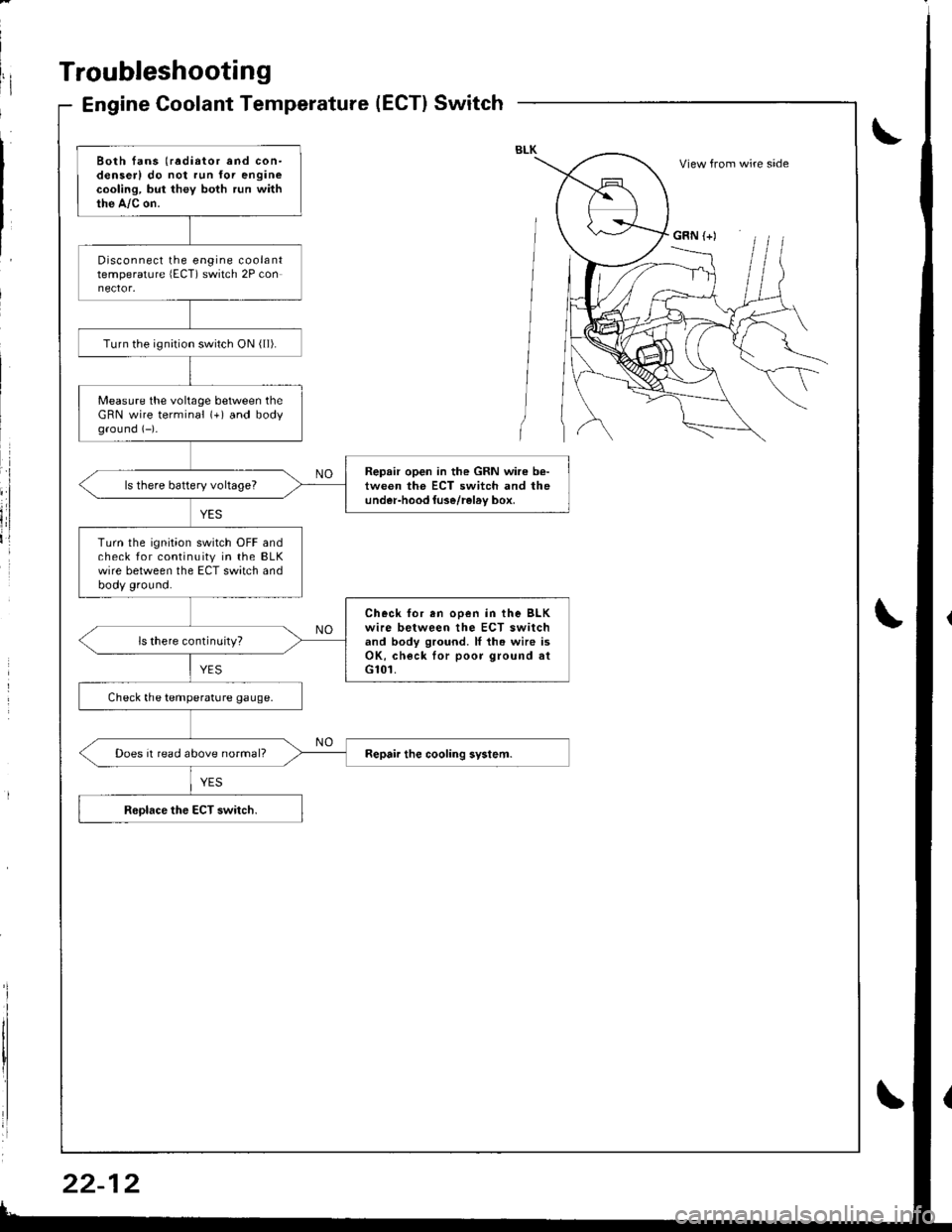

Troubleshooting

Engine Coolant Temperature(ECT}Switch

Both fans (radiator and con-denserl do not run for enginecooling, but they both run withthe A,/c on.

Disconnect the engine coolanttemperature lECT) switch 2P con

Turn the ignirion switch ON ( ll).

Measure the voltage between theGRN wire terminal (+) and bodyground (-)-

Repair open in the GRN wire b€-tween the ECT switch and theunder-hood luse/rel6v box,ls there battery voltageT

Turn the ignition switch OFF andcheck for continuity in the BLKwire between the ECT switch andbody ground.

Check for en ooen in the BLKwire between the ECT switchand body ground. ll th. wire isOK, check lor poor ground atG101.

ls there continuity?

Check the temperature gauge.

Does it read above normal?

View from wire side

GRN (+)

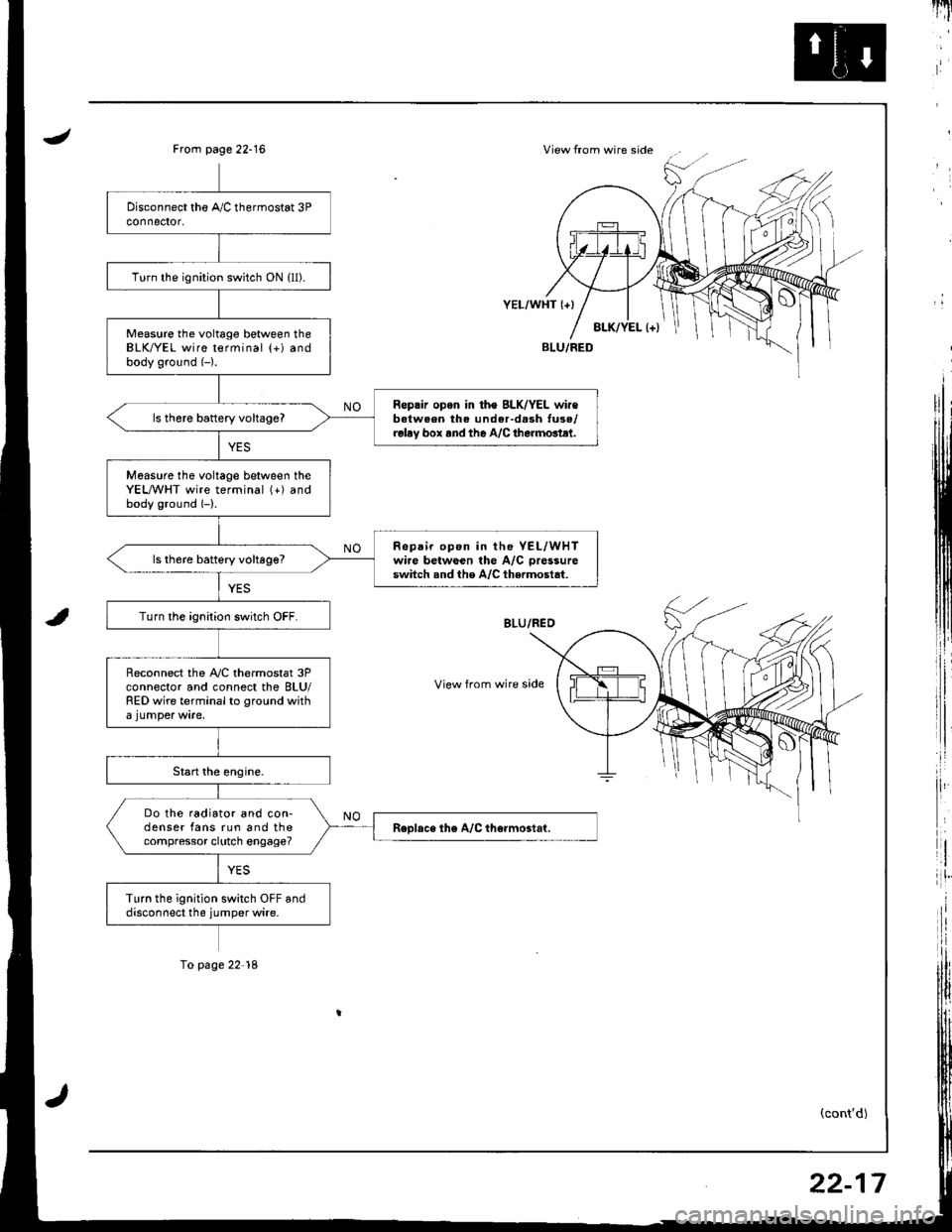

Page 1035 of 1681

JView from wire sideFrom page 22-16

i,:,

il

rlt'

8LK/YEL l+)

YEL/WHT {+}

View from wire side

BLU/FED

(cont'd)

Turn the ignition switch ON {ll).

Measure the voltago between theBLK/YEL wire terminal (+) andbody ground (-).

Reprir opon in th€ BLK/YEL wir€batween the under-d.sh tuse/relay box rnd the A/C therm6tlt.

ls there battery vohageT

Moasure tho voltage between theYEL,A/VHT wire terminal (+) andbody ground (-).

Repair op6n in the YEL/WHTwire betwGen the A/C pressure

switch snd the A/C thermostat.ls th6re battery voltage?

Turn the ignition switch OFF.

Reconnect the A,/C thermostat 3Pconnector and connect the BLU/RED wire terminal to ground with

Do the radiator and con-denser fans run and thecompressor clutch engage?

Turn the ignition switch OFF anddisconnect the jumper wire.

To page 22'18

22-17

Page 1037 of 1681

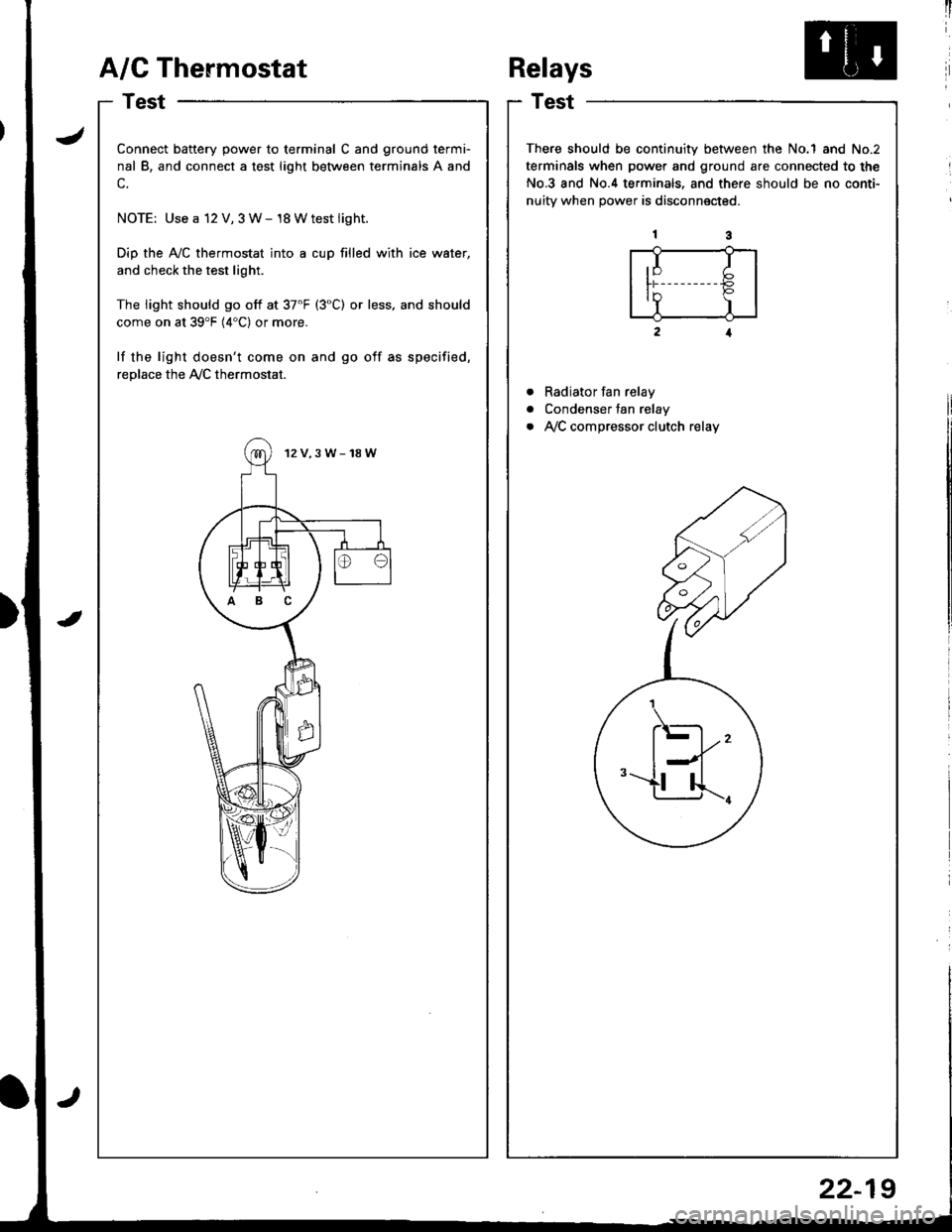

A/G Thermostat

I

I

a

a

a

t)

Connect battery power to terminal C and ground termi-

nal B, and connect a test light between terminals A and

c.

NOTE: Use a 12 V, 3 W- 18 Wtest light.

Dip the Ay'C thermostat into a cup filled with ice water,

and check the test light.

The light should go off at 37'F (3"C) or less. and should

come on at 39'F (4"C) or more.

lf the light doesn't come on and go off as specified,

replace the Ay'C thermostat.

12V,3W-18W

ABC

Relays

Test

There should be continuity between the No.1 and No.2

terminals when power and ground are connected to the

No.3 and No.4 terminals, and there should be no conti-

nuitv when Dower is disconnected.

Radiator fan relay

Condenser fan relay

Ay'C compressor clutch relay

,I I

ln P'Y )

.\-

l--l''-u...r.

22-19

Page 1041 of 1681

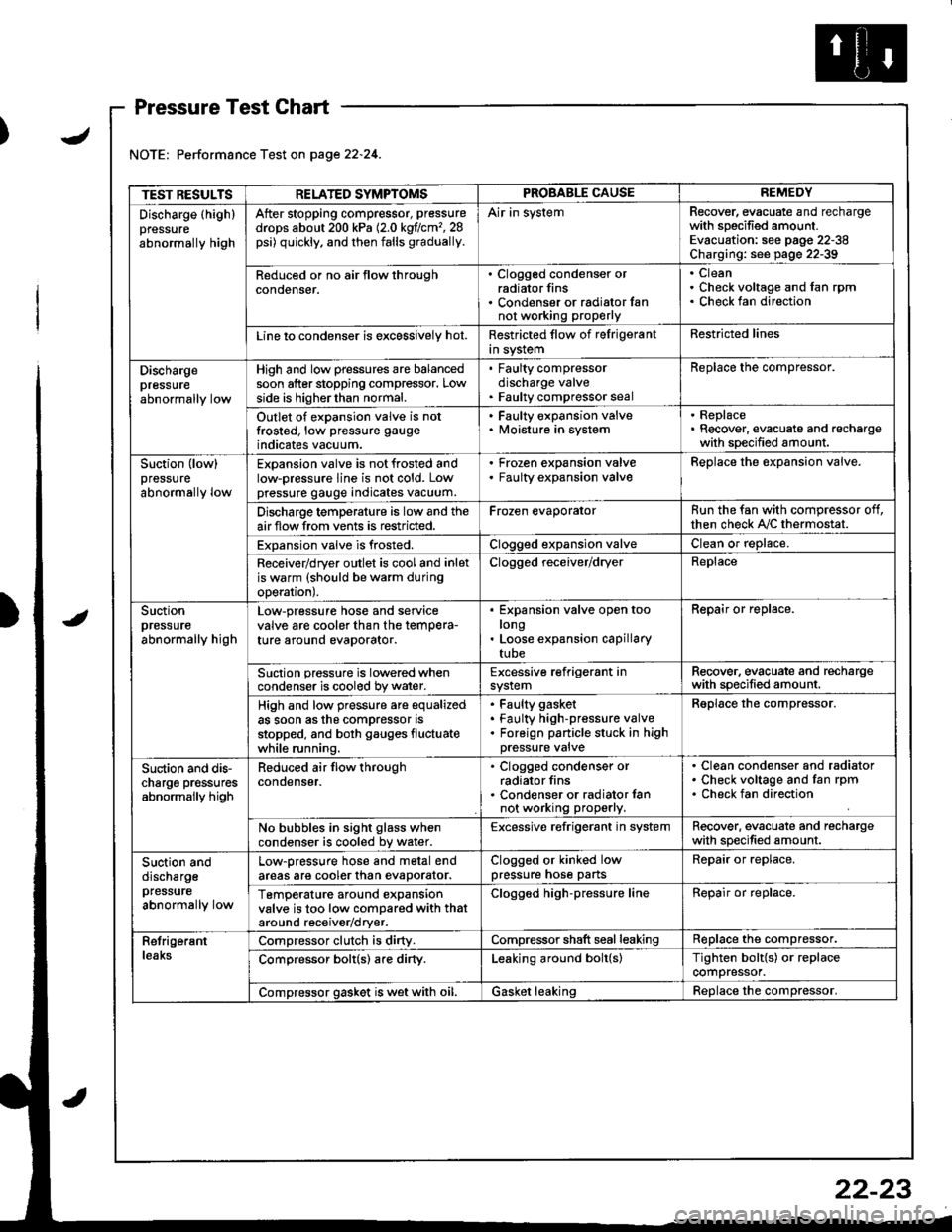

J

Pressure Test Chart

Performance Test on page 22.24.

TEST RESULTSRELATED SYMPTOMSPROBABLE CAUSEREMEDY

Discharge (highlpressure

abnormally high

After stopping compressor, pressure

drops about 200 kPa (2.0 kgflcm'�,28psi) quickly, and then falls gradually.

Air in systemRecover, evacuate and rechargewith specified amount.Evacuation: see pag€ 22-38Charging: see page 22-39

Reduced or no air tlow throughconoenser.

. Clogged condenser orradiator fins. Condenser or radialor fannot working proPerly

CleanCheck voltage and fan rpmCheck fan direction

Line lo condenser is excessively hot.Restricted flow of felrigerantin systemRestricted lines

Dischargepressureabnormally low

High and low pressures are balancedsoon after stopping compressor. Lowside is higherthan normal.

. Faulty compressordischarge valve. Faulty compressor seal

Replace the compressor.

Outlet of expansion valve is notfrosted, low pressure gauge

indicates vacuum.

. Faulty expansion valve. lvloisture in system

. Replace. Recover, evacuate and rechargewith specified amount.

Suction (low)pressure

abnormally low

Expansion valve is not frosted andlow-pressure line is not cold. Lowpressure gauge indicates vacuum.

Frozen expansion valveFaulty expansion valveReplace the expansion valve.

Discharge temperature is low and theairflow from vents is restricted.Frozen evaporatorRun the fan with compressor off,then check A,/C thermostat.

Expansion valve is frosted.Clogged expansion valveClean or replace.

Receiver/dryer outlet is cool and inletis warm (should be warm duringoperal|onJ.

Clogged receiver/dryerReplace

Suctionpressureabnormally high

Low-pressure hose and seryicevalve are cooler than the temPera-ture around evaporator.

Expansion valve open toolongLoose expansion capillarytube

Repair or replace.

Suction pressure is lowered whencondenser is cooled by water.Excessive refrigerant insystemRecover. evacuate and rechargewith specified amount.

High and low pressure are equalizedas soon asthe compressor asstopped, and both gauges fluctuatewhile running.

Faulty gasket

Faulty high-pressure valveForeign panicle stuck in highpressure valve

Reolace the comDressor.

Suction and dis-charge pr€ssuresabnormally high

Reduced air flow throughcondenser.

. Clogged condenser orradiator fins. Condenser or radiator lannot working properly.

Clean condenser and radiatorCheck voltage and fan rpmCheck fan direction

No bubbles in sight glass whencondenser is cooled bv water.Excessive refrigerant in systemRecover. evacuate and rechargewith specified amount.

Suction anddischargepfessure

abnormally low

Low-pressure hose and metal endareas are cooler than evaDorator.Clogged or kinked lowpressure hose partsRepair or replace.

TemP€rature around expansionvalve is too low compared with thataround receiv€r/dryer.

Clogged high-pressure lineRepair or replace.

RetrigerantleaksCompressor clutch is dirty.Compressor shaft seal leakingReplace the compressor.

Comoressor bolt(s) are dirty.Leaking around bolt(s)Tighten bolt{s) or replacecompressor.

Compressor gasket is wet with oil.Gasket leakingReolace the comoressor.

22-23

Page 1048 of 1681

Compressor

Replacement

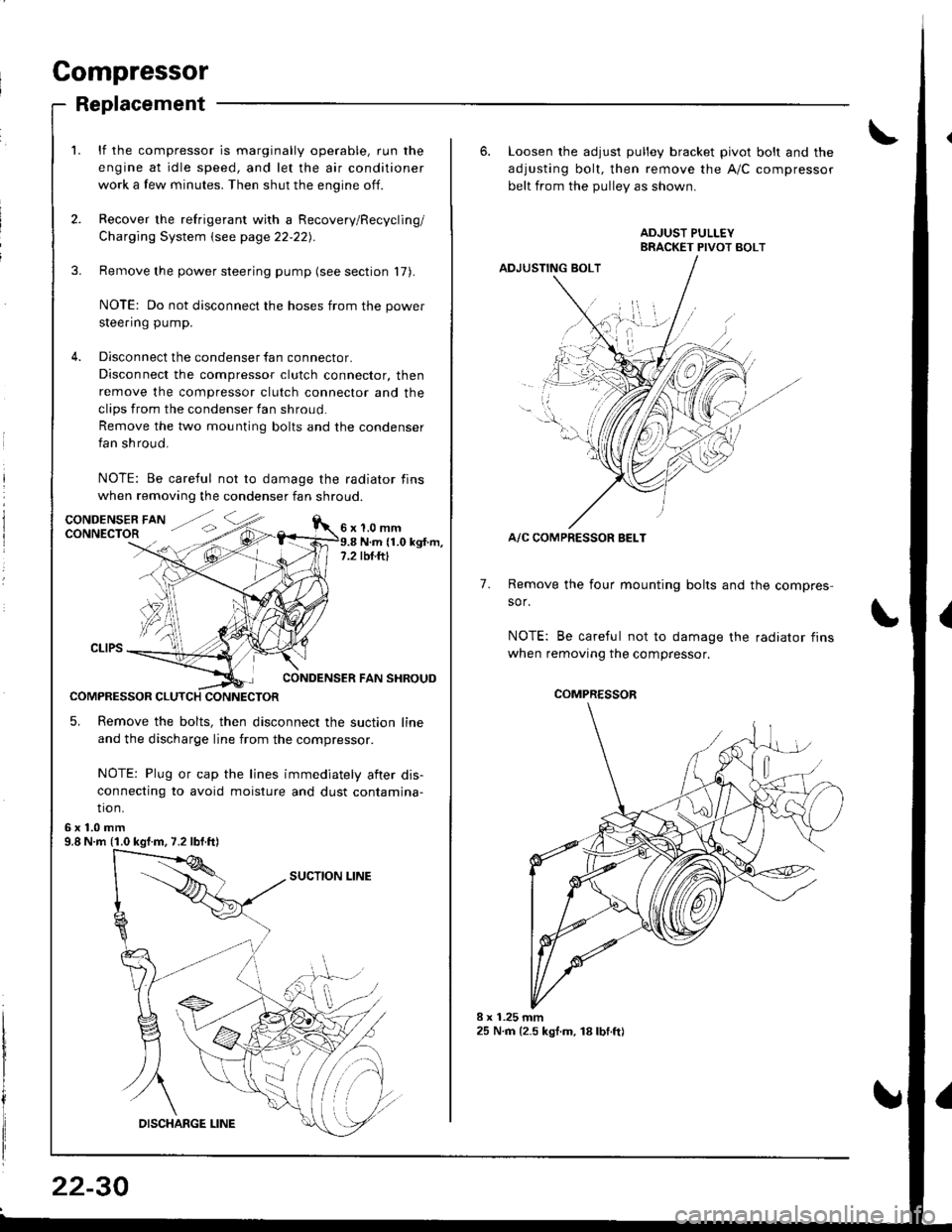

lf the compressor is marginally operable, run the

engine at idle speed, and let the air conditioner

work a few minutes. Then shut the engine off.

Recover the refrigerant with a Recovery/Recycling/

Charging System \see page 22-22).

Remove the power steering pump (see section 17).

NOTE: Do not disconnect the hoses from the power

steering pump.

Disconnect the condenser fan connector.

Disconnect the compressor clutch connector, then

remove the compressor clutch connector and the

clips from the condenser fan shroud

Remove the two mounting bolts and the condenser

fan shroud.

NOTE: Be careful not to damage the radiator fins

when removing the condenser fan shroud.

1.0 mmN.m (1.0 kgt.m,rbf.ftt

CONDENSER FAN SHROUD

COMPRESSOR CLUTCH CONNECTOR

5. Remove the bolts, then disconnect the suction line

and the discharge line from the compressor.

NOTE: Plug or cap the lines immediately aiter dis-

connecting to avoid moisture and dust contamina-

tio n.

6x1.0mm9.8 N.m (1.0 kgf.m, 7.2 lbf.ft)

22-30

6. Loosen the adjusl pulley bracket pivot bolt and the

adjusting bolt, then remove the A/C compressor

belt from the Dullev as shown.

ADJUSTING BOLT

A/C COMPRESSOR BELT

Remove the four mounting bolts and the compres-

sor.

NOTE: Be careful not to damage the radiator fins

when removing the compressor.

7.

./.,

COMPRESSOR