belt Hyundai Getz 2008 Repair Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2008, Model line: Getz, Model: Hyundai Getz 2008Pages: 383, PDF Size: 9.23 MB

Page 326 of 383

VEHICLE MAINTENANCE REQUIREMENTS 5- 7

!

6ZF060A1-A

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

F060M01A-AAT

o Engine oil and filter

The engine oil and filter should be changed at the intervals specified inthe maintenance schedule. If the car is being driven in severe conditions, more frequent oil and filter changesare required. F060B01A-AAT

o Drive belts

Inspect all drive belts for evidence of cuts, cracks, excessive wear or oilsaturation and replace if necessary. Drive belts should be checked peri- odically for proper tension and ad-justed as necessary. F060C01A-GAT

o Fuel filter

A clogged filter can limit the speed at

which the vehicle may be driven, dam- age the emission system and cause hard starting. If an excessive amountof foreign matter accumulates in the fuel tank, the filter may require re- placement more frequently.

After installing a new filter, run the

engine for several minutes, and checkfor leaks at the connections.

F060D01TB-EAT

o Fuel lines, fuel hoses and con- nections

Check the fuel lines, fuel hoses and

connections for leakage and damage. Replace any damaged or leaking parts immediately. WARNING (Diesel only):

Never work on injection systemwith engine running or within 30 seconds after shutting off engine.High pressure pump, rail, injectors and high pressure pipes are sub- jected to high pressure even afterthe engine has been switched off. The fuel jet produced by fuel leaks may cause serious injury, if it con-tacts with the body. People using pacemakers should not move closer than 30cm to the ECU orwiring harness within the engine room with the engine running, since the high currents in the CommonRail system produce considerable magnetic fields.

Page 327 of 383

5- 8 VEHICLE MAINTENANCE REQUIREMENTS

F060H01A-AAT

o Air cleaner filter

A Genuine Hyundai air cleaner filter is recommended when filter is replaced. F060J01A-AAT

o Spark plugs

Make sure to install new spark plugs of the correct heat range.

F060G01A-EAT o Vapour hose and fuel filler cap The vapour hose and fuel filler cap should be inspected at those intervals specified in the maintenance sched- ule. Make sure that a new vapourhose or fuel filler cap is correctly re- placed. 6ZF060F1-A

o Vacuum, crankcase

ventilation hoses

Inspect the surface of hoses for evi- dence of heat and/or mechanical dam-age. Hard and brittle rubber, cracking, tears, cuts, abrasions, and excessive swelling indicate deterioration. Par-ticular attention should be paid to ex- amining those hose surfaces nearest to high heat sources, such as theexhaust manifold.Inspect the hose routing to assurethat the hoses do not come in contact with any heat source, sharp edges or moving component which might causeheat damage or mechanical wear. Inspect all hose connections, such as clamps and couplings, to make surethey are secure, and that no leaks are present. Hoses should be replaced immediately if there is any evidence ofdeterioration or damage. F060N01X-GAT

o Valve clearances (1.1 L)

Incorrect valve clearance will not onlyresult in unsteady engine operation, but will also cause excessive noise and reduced engine performance. In-spect valve clearance and adjust as required while the engine is hot. Valve-to-rocker arm clearance Intake valves ..... 0.2 mm (0.008 in.) Exhaust valves ... 0.25 mm (0.010 in.)

F060E01A-AAT o Timing belt Replace timimg belt and inspect all associated parts related for damage and deformation. Replace any dam- aged parts immediately.

Page 329 of 383

5- 10 VEHICLE MAINTENANCE REQUIREMENTS

F070P01HP-AAT

o Driveshafts and boots

Check the drive shafts, boots and

clamps for cracks, deterioration, or damage. Replace any damaged parts and, if necessary, repack the grease.

F070Q01A-AAT

o Air conditioning refrigerant

Check the air conditioning lines and

connections for leakage and damage. Check air conditioning performance according to the relevant shop manualif necessary.

F070J01A-AAT

o Brake pads, calipers and

rotors

Check the pads for excessive wear,discs for run out and wear, and cali-pers for fluid leakage. F070K01A-AAT

o Exhaust pipe and muffler

Visually inspect the exhaust pipes, muffler and hangers for cracks, dete- rioration, or damage. Start the engine and listen carefully for any exhaust gas leakage. Tighten connections or replace parts as necessary. F070L01A-AAT o Suspension mounting bolts Check the suspension connections for looseness or damage. Retightento the specified torque. F070M01O-AAT

o Steering gear box, linkage &

boots/lower arm ball joint

With the vehicle stopped and engineoff, check for excessive freeplay inthe steering wheel.Check the linkage for bends or dam-age. Check the dust boots and ball joints for deterioration, cracks, or dam- age. Replace any damaged parts. F070N01A-AAT

o Power steering pump, belt and

hoses

Check the power steering pump and hoses for leakage and damage. Re- place any damaged or leaking partsimmediately. Inspect the power steer- ing belt for evidence of cuts, cracks, excessive wear, oiliness and propertension. Replace or adjust it if neces- sary.

Page 330 of 383

6. Do-It-Yourself Maintenance

Engine compartment ........................................................................ 6-2

Daily operating checks ..................................................................... 6-5

Engine oil .......................................................................................... 6-6

Engine oil replenishment .................................................................. 6-8

Engine coolant Checking ................................................................. 6-9Changing the air cleaner filter ......................................................... 6-11

Windscreen Wiper Blades .............................................................. 6-12

Windscreen Washer Reservoir Replenishment ............................. 6-13

manual Transaxle Lubricant........................................................... 6-14

Automatic Transaxle fluid ............................................................... 6-15

Brake System Checking ................................................................ 6-17

Air conditioning System .................................................................. 6-18

Drive belts ...................................................................................... 6-20

Individual Circuit Fuses .................................................................. 6-21

Power steering fluid level ............................................................... 6-23

Replacing Light Bulbs .................................................................... 6-26

Fuse panel description ................................................................... 6-31

6

Page 334 of 383

DO-IT-YOURSELF MAINTENANCE 6- 5

!

G020D01TG-EAT MAINTENANCE PRECAUTIONS Improper or incomplete service may result in problems. This section givesinstructions only for the maintenance items that are easy to perform. Several procedures should be done byan authorised Hyundai dealer. NOTE: Improper owner maintenance dur- ing the warranty period may affectwarranty coverage. WARNING:

o Performing maintenance work on a vehicle can be dangerous. You can be seriously injured while performing some maintenanceprocedures. If you lack sufficient knowledge and experience or the proper tools and equipment to dothe work, have it done by an authorised Hyundai dealer.

o Working under the hood with the engine running is dangerous. Itbecomes even more dangerous when you wear jewelry or looseclothing. These can become en- tangled in moving parts and result in injury. Therefore, if you mustrun the engine while working un- der the hood, make certain that you remove all jewelry (especiallyrings, bracelets, watches, and necklaces) and all neckties, scarves, and similar loose cloth-ing before getting near the engine or cooling fans.

SG020B1-E DAILY OPERATING CHECKS The following items should be checked on a daily basis or whenever the vehicleis refuelled, whichever occurs sooner.

o Engine oil level.

o Engine coolant level.

o Power steering fluid level.

o Brake fluid level.

o Windscreen washer fluid level.

o Battery condition.

o Tyre condition and pressures.

o Operation and cleanliness of all light-

ing equipment.

o Windscreen wiper and washer opera- tion.

o Horn operation.

o Warning light operation.

o Adjustment and cleanliness of mir- rors.

o Seat and seat belt adjustment and operation.

o Fluid leakage. The vehicle must not be driven if the daily operating checks indicate that any item of equipment related to thesafety or roadworthiness of the vehicle is not functioning correctly.

Page 349 of 383

6- 20 DO-IT-YOURSELF MAINTENANCE

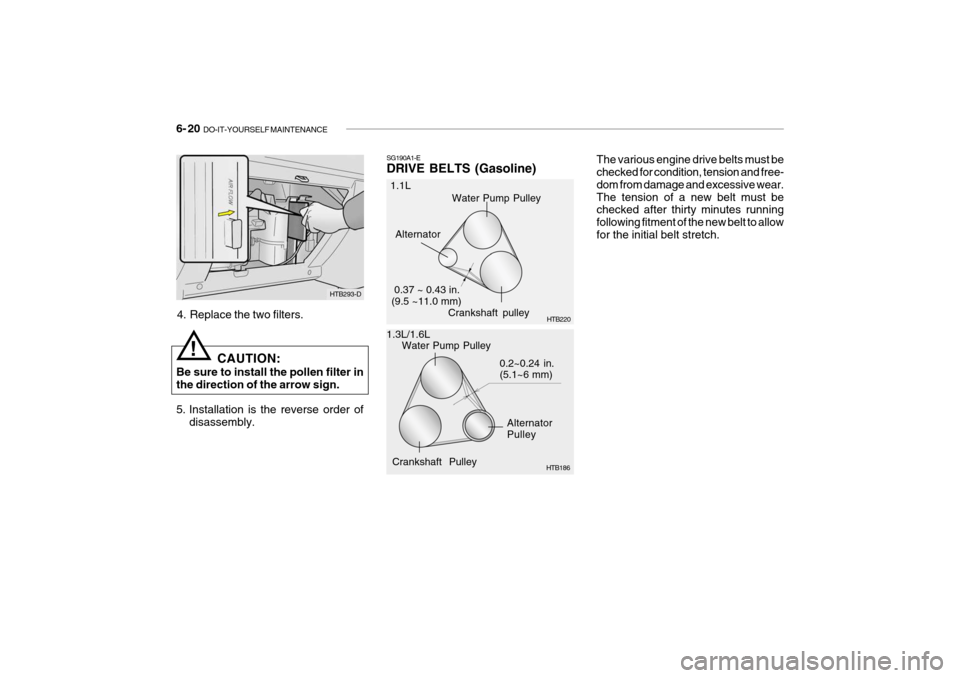

The various engine drive belts must be checked for condition, tension and free- dom from damage and excessive wear.The tension of a new belt must be checked after thirty minutes running following fitment of the new belt to allowfor the initial belt stretch.

Crankshaft Pulley

SG190A1-E DRIVE BELTS (Gasoline)

1.1L

1.3L/1.6L Alternator

0.37 ~ 0.43 in. (9.5 ~11.0 mm)

Water Pump Pulley

Alternator Pulley

0.2~0.24 in.(5.1~6 mm)

HTB186

Crankshaft pulley

HTB220

Water Pump Pulley

HTB293-D

4. Replace the two filters.

CAUTION:

Be sure to install the pollen filter in the direction of the arrow sign.

5. Installation is the reverse order of disassembly.

!

Page 350 of 383

DO-IT-YOURSELF MAINTENANCE 6- 21

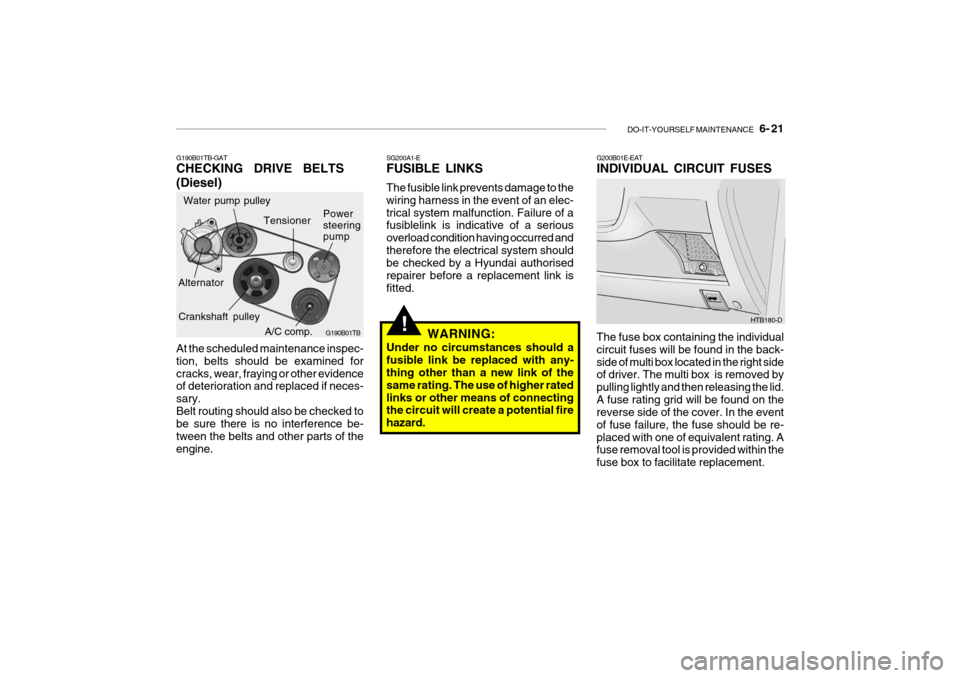

G190B01TB-GAT CHECKING DRIVE BELTS (Diesel) At the scheduled maintenance inspec- tion, belts should be examined forcracks, wear, fraying or other evidence of deterioration and replaced if neces- sary.Belt routing should also be checked to be sure there is no interference be- tween the belts and other parts of theengine.

!

SG200A1-E FUSIBLE LINKS The fusible link prevents damage to the wiring harness in the event of an elec-trical system malfunction. Failure of a fusiblelink is indicative of a serious overload condition having occurred andtherefore the electrical system should be checked by a Hyundai authorised repairer before a replacement link isfitted.

WARNING:

Under no circumstances should afusible link be replaced with any- thing other than a new link of the same rating. The use of higher ratedlinks or other means of connecting the circuit will create a potential fire hazard.G200B01E-EAT INDIVIDUAL CIRCUIT FUSES The fuse box containing the individual circuit fuses will be found in the back-side of multi box located in the right side of driver. The multi box is removed by pulling lightly and then releasing the lid.A fuse rating grid will be found on the reverse side of the cover. In the event of fuse failure, the fuse should be re-placed with one of equivalent rating. A fuse removal tool is provided within the fuse box to facilitate replacement. HTB180-D

A/C comp.

Water pump pulley

G190B01TB

Alternator Power steering pump

Tensioner

Crankshaft pulley

Page 378 of 383

10- 2 INDEX

A

ACTIVE HEADRESTS ................................................ 1-14

ADJUSTING ARMREST ............................................. 1-15

ADJUSTING HEAD RESTRAINTS............................. 1-13

AIR BAG ..................................................................... 1-34

AIR CONDITIONING SWI TCH .................................... 1-91

AIR CONDITIONI NG SYSTEM MAINTENANCE ........ 6-18

AIR CLEANER FILTER ............................................... 6-11

ANTENNA ................................................................... 1-96

ANTI-LOCK BRAKE SYSTEM .................................... 2-14

ANTI-THEFT ALARM SYSTEM ................................... 1-8

ASHTRAY ................................................................... 1-66

AUDIO REMOTE CONTROL SW ITCH ........................1-84

AUTOMATIC TRANSAXLE ......... ................................. 2-9

AUTOMATIC TRANSAXLE FLUID ..............................6-15

B

BATTERY MAINTENANCE ........................................ 6-22

BEFORE STARTING THE ENGINE ............................ 2-3

BONNET REL EASE ................................................... 1-75

BRAKE SYSTEM CHECKI NG .................................... 6-17

CCARE OF SEAT BELTS ............................................. 1-21

CARGO AREA COVER .............................................. 1-79CATALYTIC CONVERTOR OPERATING

PRECAUTIONS ....................................................... 7-3

CENTRAL DOOR LOCKS ............................................ 1-7

CHANGING A FLAT TYRE .......................................... 3-7

CHILD-PROOF REAR DOOR LOCK ............................ 1-8

CHILD RESTRAINT SYSTEM .................................... 1-25

CIGAR LIGHTER ........................................................ 1-64

COMBINATION IGNITION SWITCH AND STEERING LOCK ................................................... 2-3

CONSOLE TRAY ........................................................ 1-66

DDAILY OPERATING CHECKS ..................................... 6-5

DIGITAL CLOCK ......................................................... 1-64

DOOR LOCKS ............................................................. 1-6

DOOR WINDOWS ...................................................... 1-11

DRINK HOLDER ......................................................... 1-66

DRIVE BELTS ............................................................ 6-20

DRIVING FOR ECONOMY ......................................... 2-15

EEFFECTIVE BRA KING............................................. 2-13

ELECTRIC COOLING FANS ....................................... 6-23

ELECTRONIC STABILITY PROGRAM .......................2-14

EMERGENCY TOWING ............................................. 3-12

EMISSION CONTROL SYSTEM ................................. 7-2

Page 379 of 383

INDEX 10- 3

ENGINE COMPARTMENT . ......................................... 6-2

ENGINE COOLANT CHE CKING.................................. 6-9

ENGINE OIL CONS UMPTION ..................................... 6-9

ENGINE OIL REPLENISHMENT ................................. 6-8

ENGINE OIL ................................................................ 6-6 F FRONT ASHTRAY ...................................................... 1-66

FRONT SEAT ............................................................. 1-12

FRONT FOG LIGHT SWITCH ..................................... 1-63

FUEL ECONO MY ........................................................ 2-7

FUEL GAUGE ............................................................. 1-53

FUEL RECOMMENDATIONS ...................................... 1-2

FUSE PANEL DESCRI PTION .................................... 6-31

FUSIBLE LINKS ......................................................... 6-21

G

GLOVE BOX ............................................................... 1-71

HHATCHBACK DOOR .................................................. 1-78

HAZARD WARNING SYSTEM ................................... 1-62

HEADLIGHT AIMING ADJUSTEMENT.......................6-24

HEADLIGHT BULB ..................................................... 6-26

HEADLIGHT LEVELING DEVICE SYSTEM ...............1-67

HEATED REAR WINDOW .......................................... 1-63

HEATING AND COOLING CONTROL .........................1-85HEATING AND VENTILATION

...................................1-86

HEIGHT ADJUSTABLE FRONT SEAT SHOULDER BELT .................................................. 1-21

HORN ......................................................................... 1-83

HOW TO USE LUGGAGE ROOM ............................... 1-79

I

IF THE ENGINE CANNOT BE CRANKED ................... 3-2

IF THE ENGINE OVERHEATS .................................... 3-4

IF THE ENGINE WILL NOT START ............................ 3-2

IF THE EVENT OF A PUNCTURE ............................... 3-7

IMMOBILISER SYSTEM ............................................. 1-5

INDIVIDUAL CIRCUIT FUSES .................................... 6-21

INSTRUMENT CLUSTER AND INDICATORS............1-42

INTERIOR LIGHT ....................................................... 1-70

INTERIOR REAR VIEW MIRROR ............................... 1-74

JJUMP STARTING ....................................................... 3-3

KKEY POSITI ONS ......................................................... 2-4

Page 381 of 383

INDEX 10- 5

SEAT BELT PRECAUTIONS ......................................1-20

SEAT BELTS ............................................................. 1-22

SEAT POCKET .......................................................... 1-79

SEAT WARMER ......................................................... 1-19

SERVICE HISTORY .................................................... 5-2

SMOOTH CORNERING .............................................. 2-17

SNOW TYRES ............................................................. 8-4

SPARE TYRE .............................................................. 3-5

SPARE TYRE AND TOOLS ........................................ 8-6 SPARE WHEEL ........................................................... 3-6

SPECTACLE CASE .................................................... 1-71

SPEEDOMETER ........................................................ 1-53

SUPPLEMENTAL RESTRAINT (AIRBAG) SYSTEM ................................................................ 1-34

STARTING THE ENGINE ............................................ 2-5

STEERING WHEEL LOCK .......................................... 2-4STEERING WHEEL TILT LEVER ............................... 1-83

STEREO SOUND SYSTEM ....................................... 1-94

SUN-VISOR ................................................................ 1-82

SUNROOF .................................................................. 1-67

TTACHOMETER ........................................................... 1-54

TOWING ATTACHMENTS .......................................... 2-19

TRAILER AND CARAVAN TOWING ........................... 2-19TRIP ODOMETER

...................................................... 1-54

TRIP COMPUTER ...................................................... 1-55

TYPE PRESSURES .................................................... 8-3

TYRE BALANCING ...................................................... 8-5

TYRE CHAINS ............................................................. 8-4

TYRE REPLACEMENT ............................................... 8-5

TYRE ROTATION ........................................................ 8-4

UUNDERBODY COATINGS ........................................... 4-2

V VALETING ................................................................... 4-3

VEHICLE IDENTIFICATION NUMBER ........................ 8-2

VEHICLE SPECIFICATION ............ ............................. 9-2

VEHICLE TOWING OR RECOVERY .......................... 3-11

VENTILATION ............................................................ 1-85

W WHEEL REPLACEMENT ............................................ 8-6

WINDSCREEN WASHER RESERVOIR REPLENISHMENT ................................................. 6-13

WINDSCREEN WIPER BLADES ................................ 6-12

WINDSHIELD WIPER/WASHER SWITCH ..................1-59

WINTER MOTORING ................................................. 2-17