INFINITI FX35 2006 Service Manual

FX35 2006

INFINITI

INFINITI

https://www.carmanualsonline.info/img/42/57019/w960_57019-0.png

INFINITI FX35 2006 Service Manual

Page 3890 of 4462

PG-38

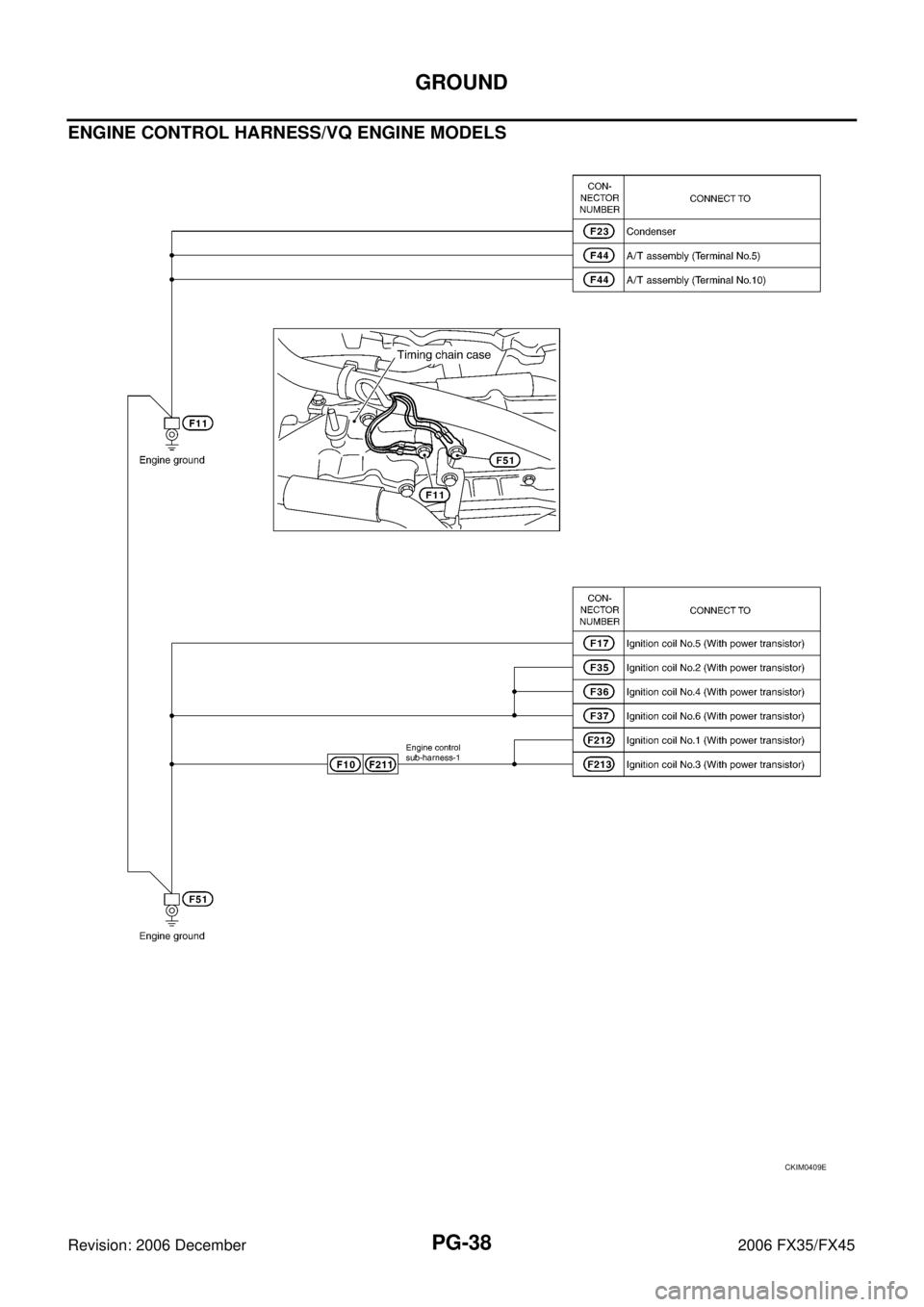

GROUND

Revision: 2006 December 2006 FX35/FX45

ENGINE CONTROL HARNESS/VQ ENGINE MODELS

CKIM0409E

Page 3896 of 4462

PG-44

HARNESS

Revision: 2006 December 2006 FX35/FX45

HARNESS PFP:00011

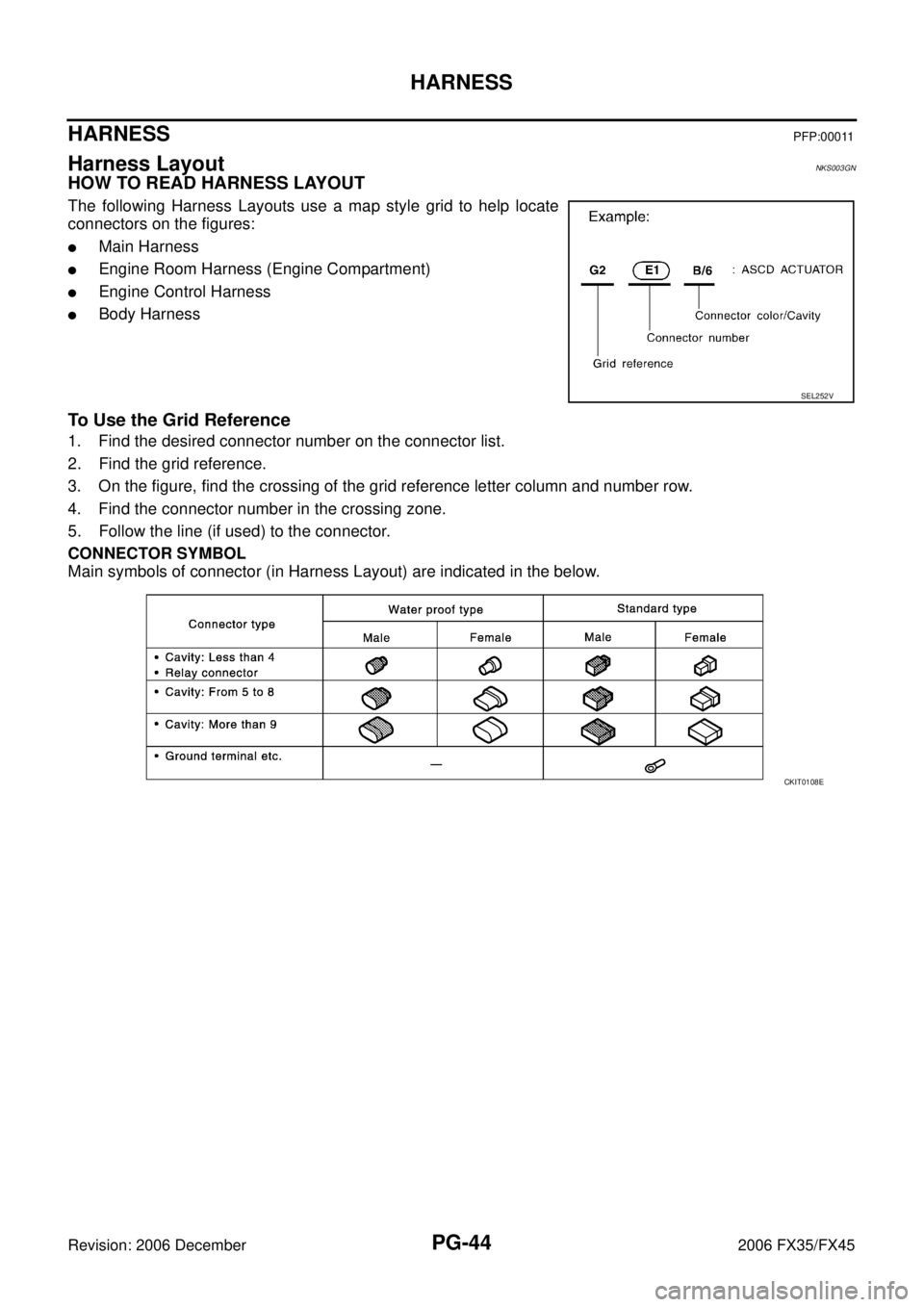

Harness Layout NKS003GN

HOW TO READ HARNESS LAYOUT

The following Harness Layouts use a map style grid to help locate

connectors on the figures:

�Main Harness

�Engine Room Harness (Engine Compartment)

�Engine Control Harness

�Body Harness

To Use the Grid Reference

1. Find the desired connector number on the connector list.

2. Find the grid reference.

3. On the figure, find the crossing of the grid reference letter column and number row.

4. Find the connector number in the crossing zone.

5. Follow the line (if used) to the connector.

CONNECTOR SYMBOL

Main symbols of connector (in Harness Layout) are indicated in the below.

SEL252V

CKIT0108E

Page 3901 of 4462

HARNESS PG-49

C

D E

F

G H

I

J

L

M A

B

PG

Revision: 2006 December 2006 FX35/FX45

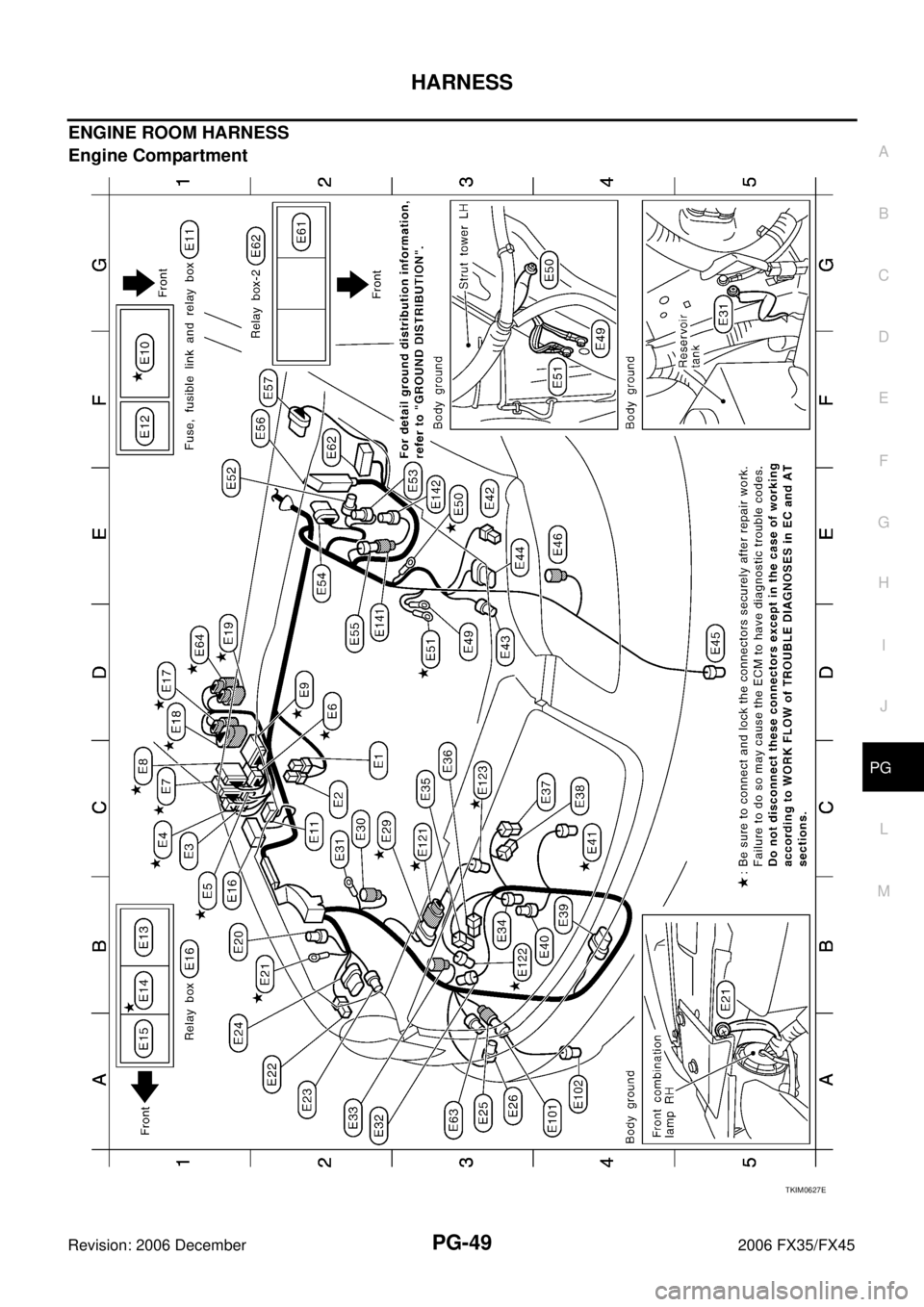

ENGINE ROOM HARNESS

Engine Compartment

TKIM0627E

Page 3904 of 4462

PG-52

HARNESS

Revision: 2006 December 2006 FX35/FX45

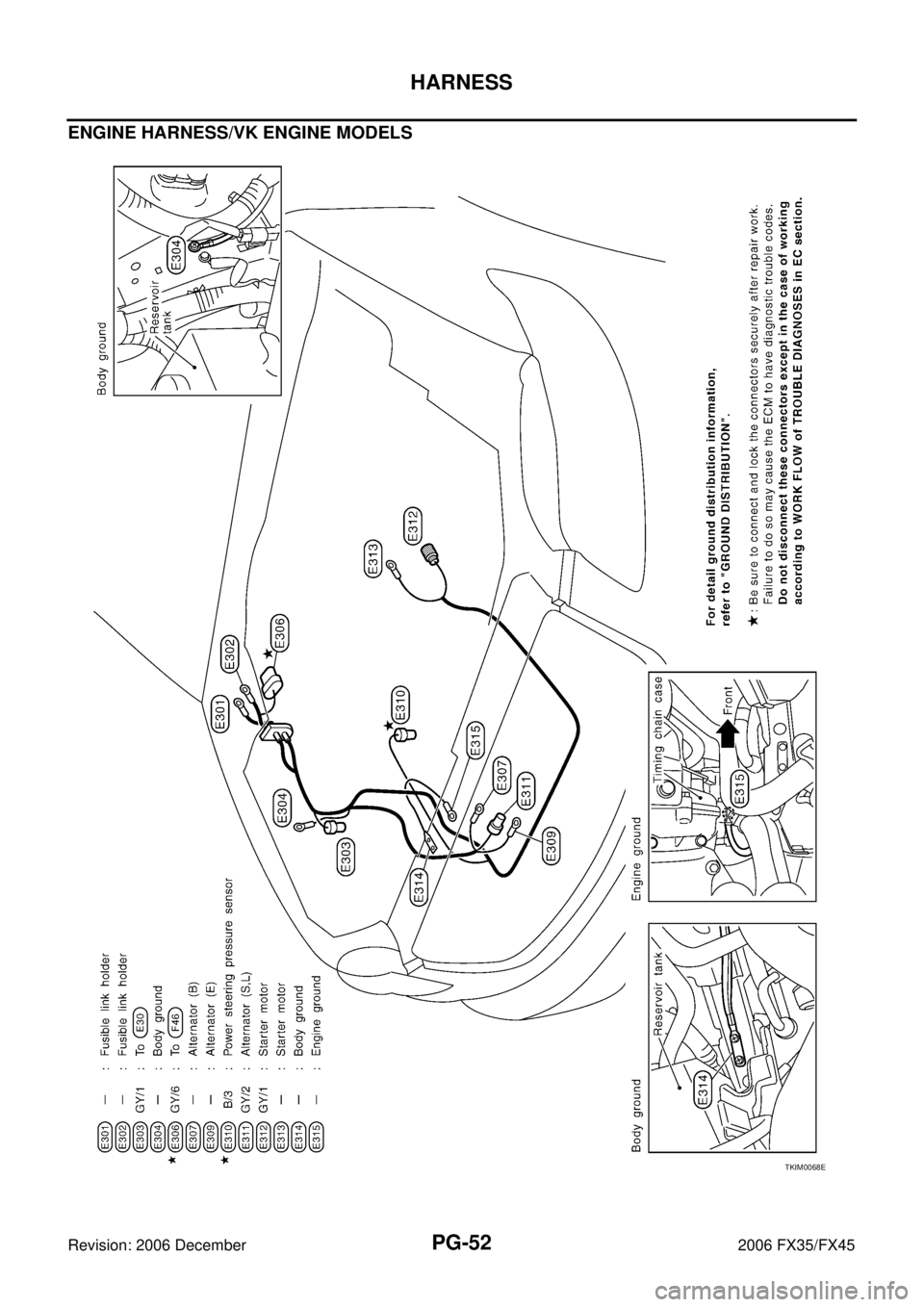

ENGINE HARNESS/VK ENGINE MODELS

TKIM0068E

Page 3905 of 4462

HARNESS PG-53

C

D E

F

G H

I

J

L

M A

B

PG

Revision: 2006 December 2006 FX35/FX45

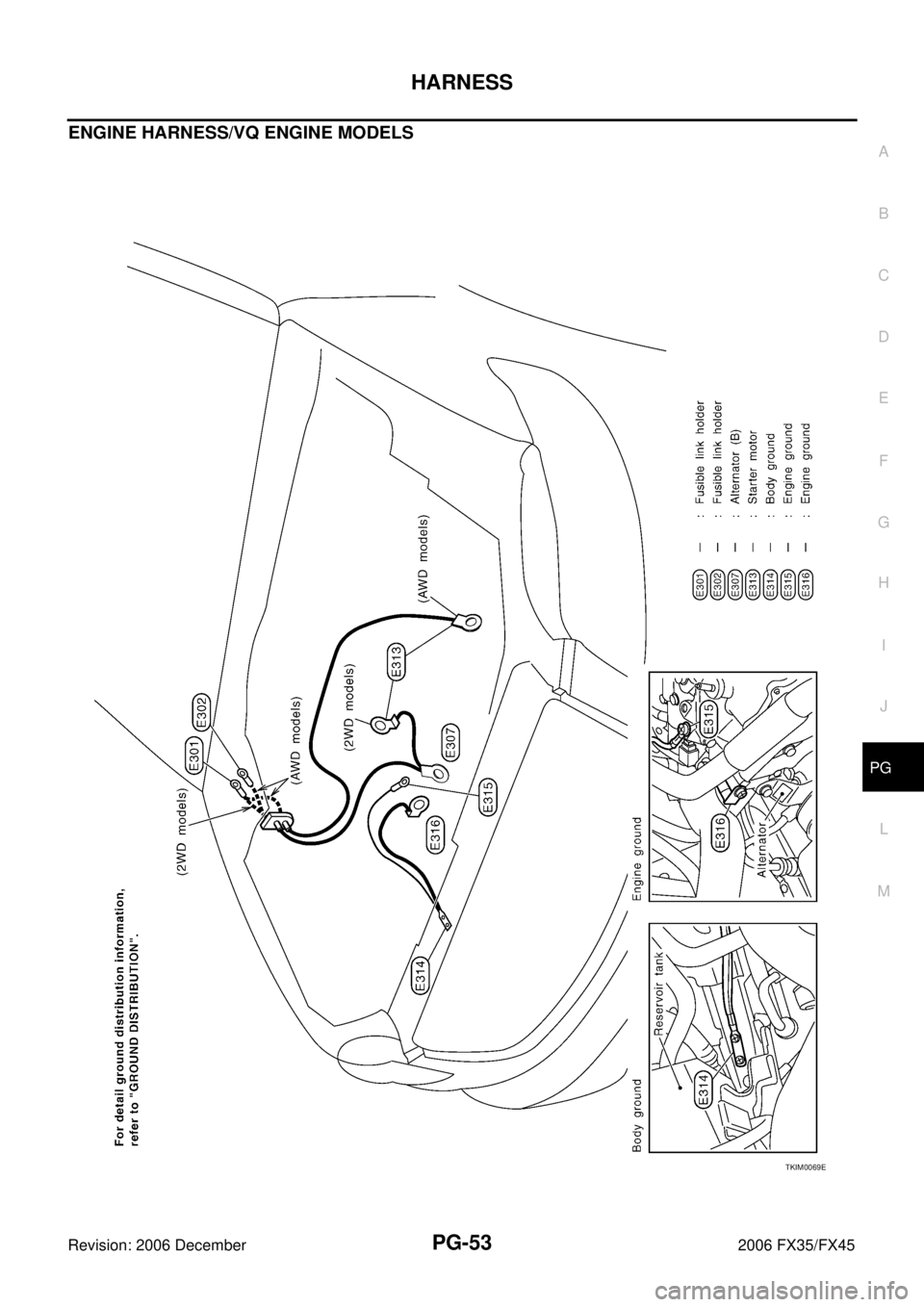

ENGINE HARNESS/VQ ENGINE MODELS

TKIM0069E

Page 3906 of 4462

PG-54

HARNESS

Revision: 2006 December 2006 FX35/FX45

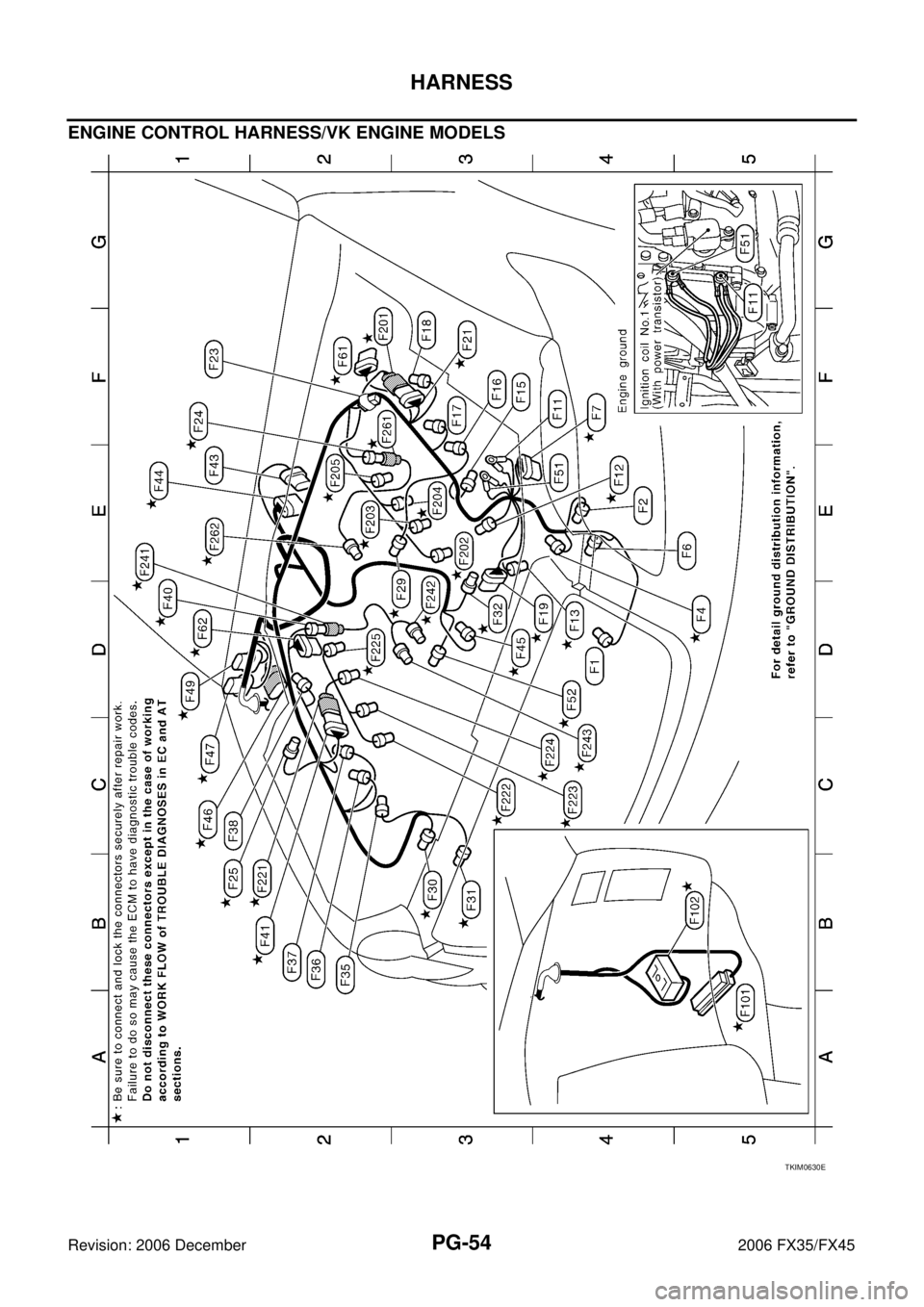

ENGINE CONTROL HARNESS/VK ENGINE MODELS

TKIM0630E

Page 3908 of 4462

PG-56

HARNESS

Revision: 2006 December 2006 FX35/FX45

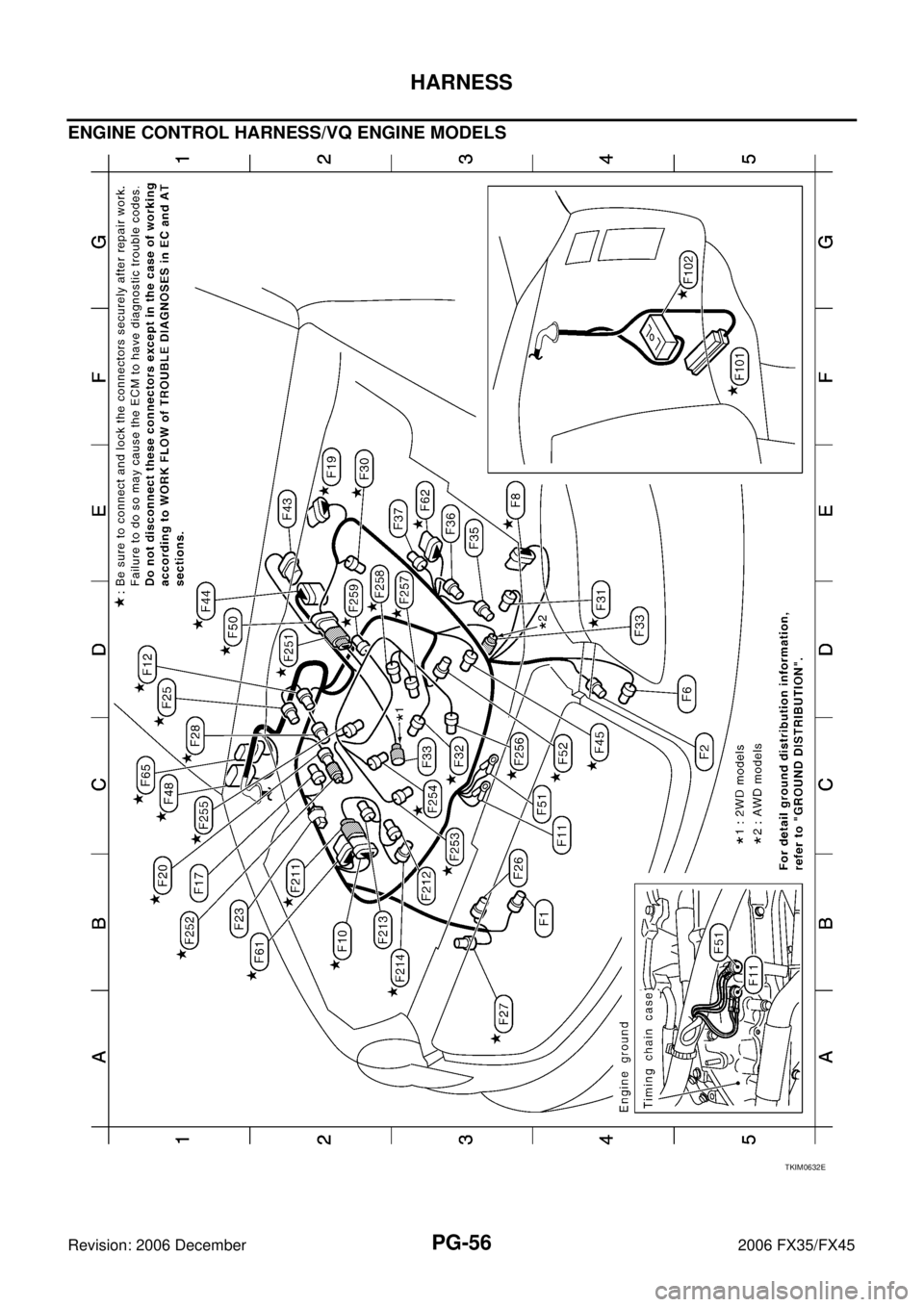

ENGINE CONTROL HARNESS/VQ ENGINE MODELS

TKIM0632E

Page 3917 of 4462

HARNESS PG-65

C

D E

F

G H

I

J

L

M A

B

PG

Revision: 2006 December 2006 FX35/FX45

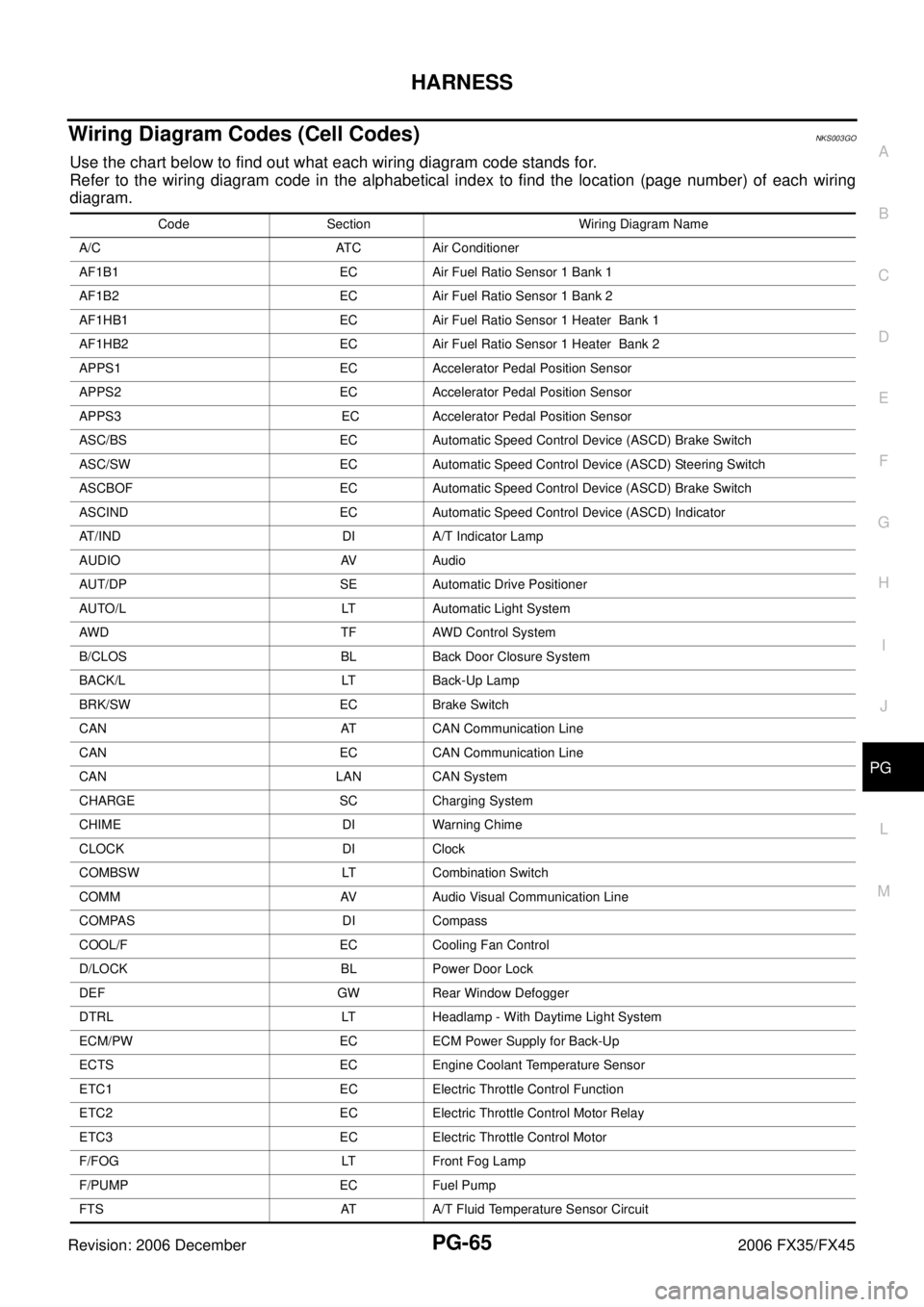

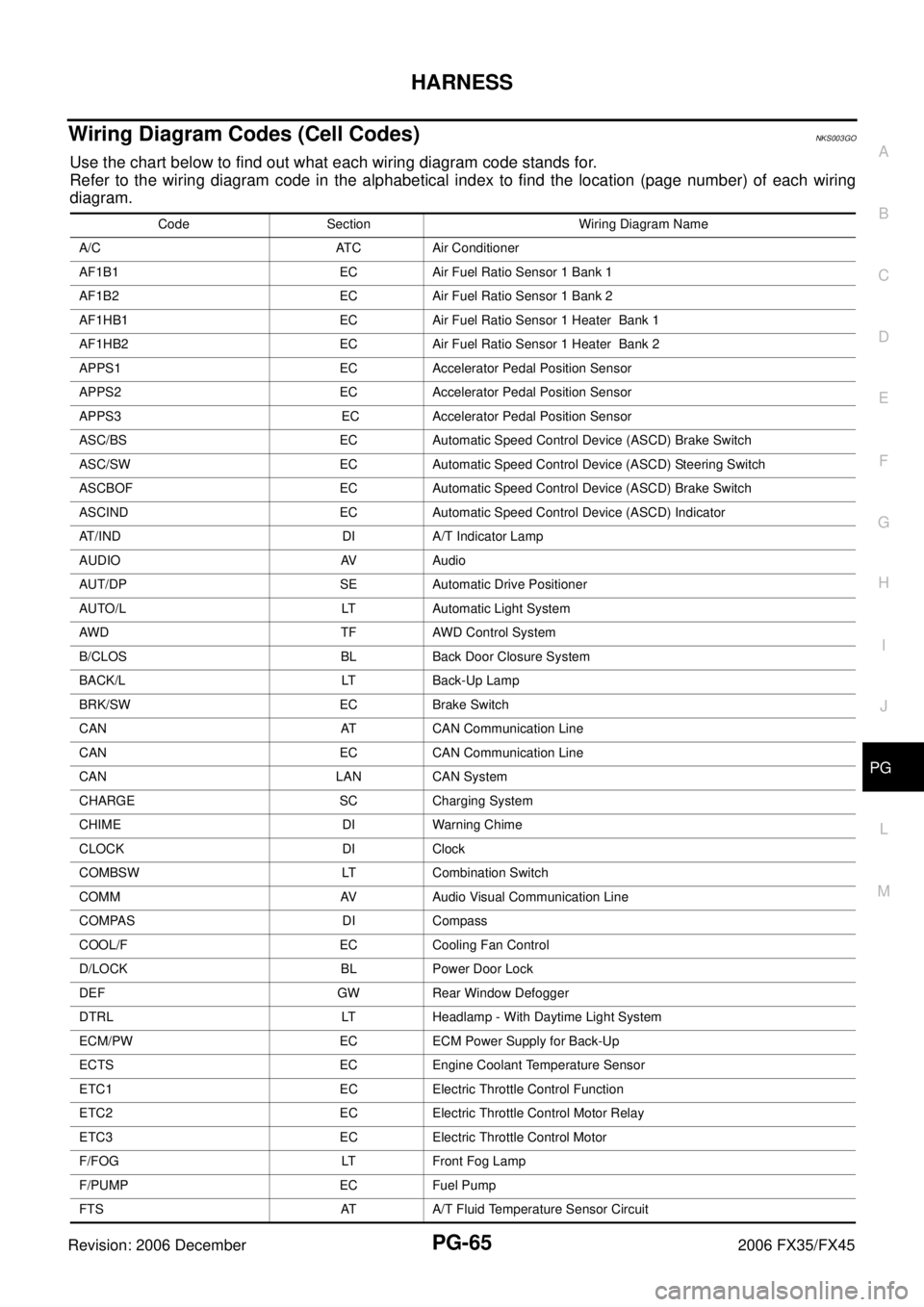

Wiring Diagram Codes (Cell Codes) NKS003GO

Use the chart below to find out what each wiring diagram code stands for.

Refer to the wiring diagram code in the alphabetical index to find the location (page number) of each wiring

diagram.

Code Section Wiring Diagram Name

A/C ATC Air Conditioner

AF1B1 EC Air Fuel Ratio Sensor 1 Bank 1

AF1B2 EC Air Fuel Ratio Sensor 1 Bank 2

AF1HB1 EC Air Fuel Ratio Sensor 1 Heater Bank 1

AF1HB2 EC Air Fuel Ratio Sensor 1 Heater Bank 2

APPS1 EC Accelerator Pedal Position Sensor

APPS2 EC Accelerator Pedal Position Sensor

APPS3 EC Accelerator Pedal Position Sensor

ASC/BS EC Automatic Speed Control Device (ASCD) Brake Switch

ASC/SW EC Automatic Speed Control Device (ASCD) Steering Switch

ASCBOF EC Automatic Speed Control Device (ASCD) Brake Switch

ASCIND EC Automatic Speed Control Device (ASCD) Indicator

AT/IND DI A/T Indicator Lamp

AUDIO AV Audio

AUT/DP SE Automatic Drive Positioner

AUTO/L LT Automatic Light System

AWD TF AWD Control System

B/CLOS BL Back Door Closure System

BACK/L LT Back-Up Lamp

BRK/SW EC Brake Switch

CAN AT CAN Communication Line

CAN EC CAN Communication Line

CAN LAN CAN System

CHARGE SC Charging System

CHIME DI Warning Chime

CLOCK DI Clock

COMBSW LT Combination Switch

COMM AV Audio Visual Communication Line

COMPAS DI Compass

COOL/F EC Cooling Fan Control

D/LOCK BL Power Door Lock

DEF GW Rear Window Defogger

DTRL LT Headlamp - With Daytime Light System

ECM/PW EC ECM Power Supply for Back-Up

ECTS EC Engine Coolant Temperature Sensor

ETC1 EC Electric Throttle Control Function

ETC2 EC Electric Throttle Control Motor Relay

ETC3 EC Electric Throttle Control Motor

F/FOG LT Front Fog Lamp

F/PUMP EC Fuel Pump

FTS AT A/T Fluid Temperature Sensor Circuit

Page 3920 of 4462

PG-68

ELECTRICAL UNITS LOCATION

Revision: 2006 December 2006 FX35/FX45

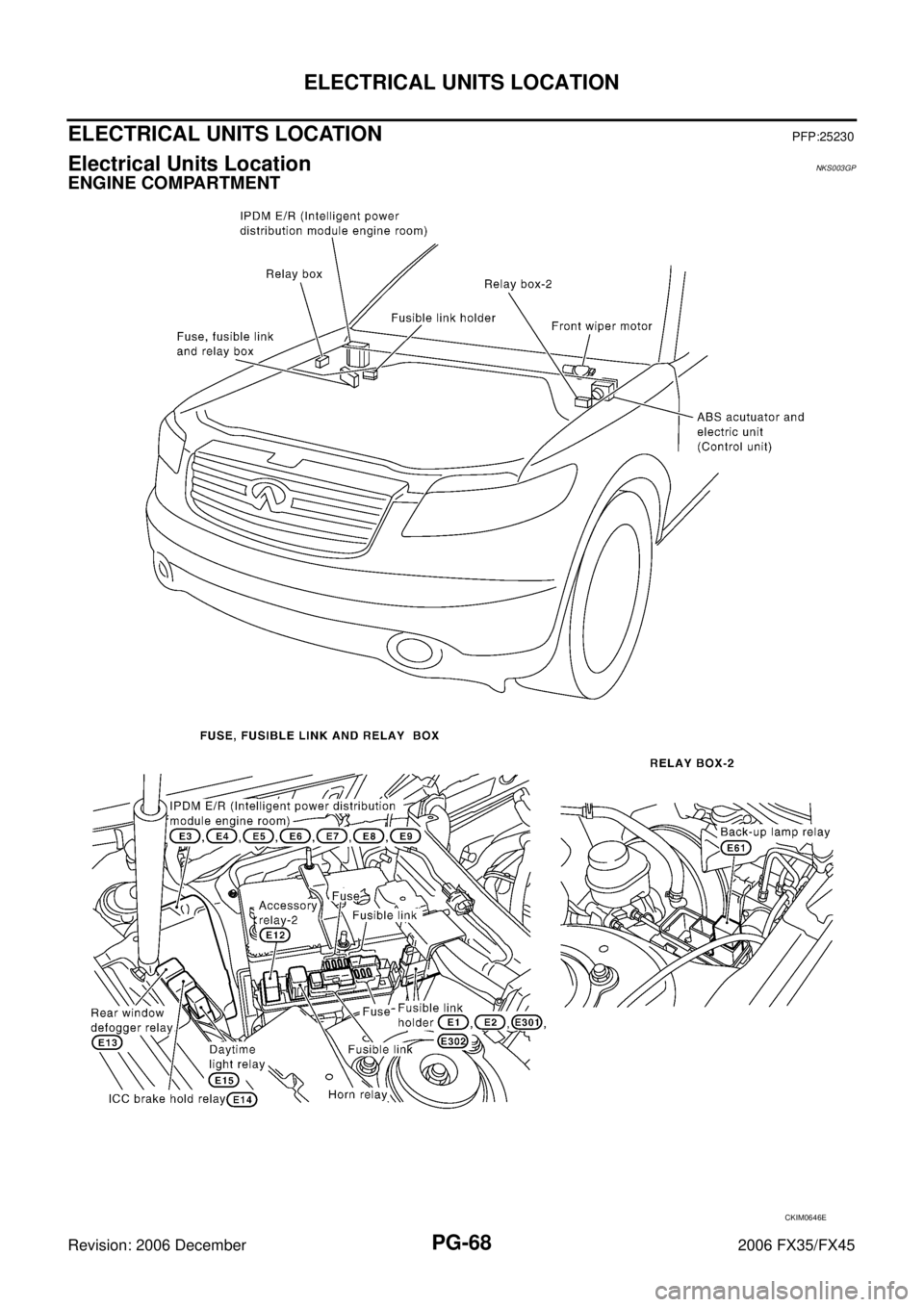

ELECTRICAL UNITS LOCATIONPFP:25230

Electrical Units Location NKS003GP

ENGINE COMPARTMENT

CKIM0646E

Page 3939 of 4462

FRONT PROPELLER SHAFT PR-5

C E F

G H

I

J

K L

M A

B

PR

Revision: 2006 December 2006 FX35/FX45

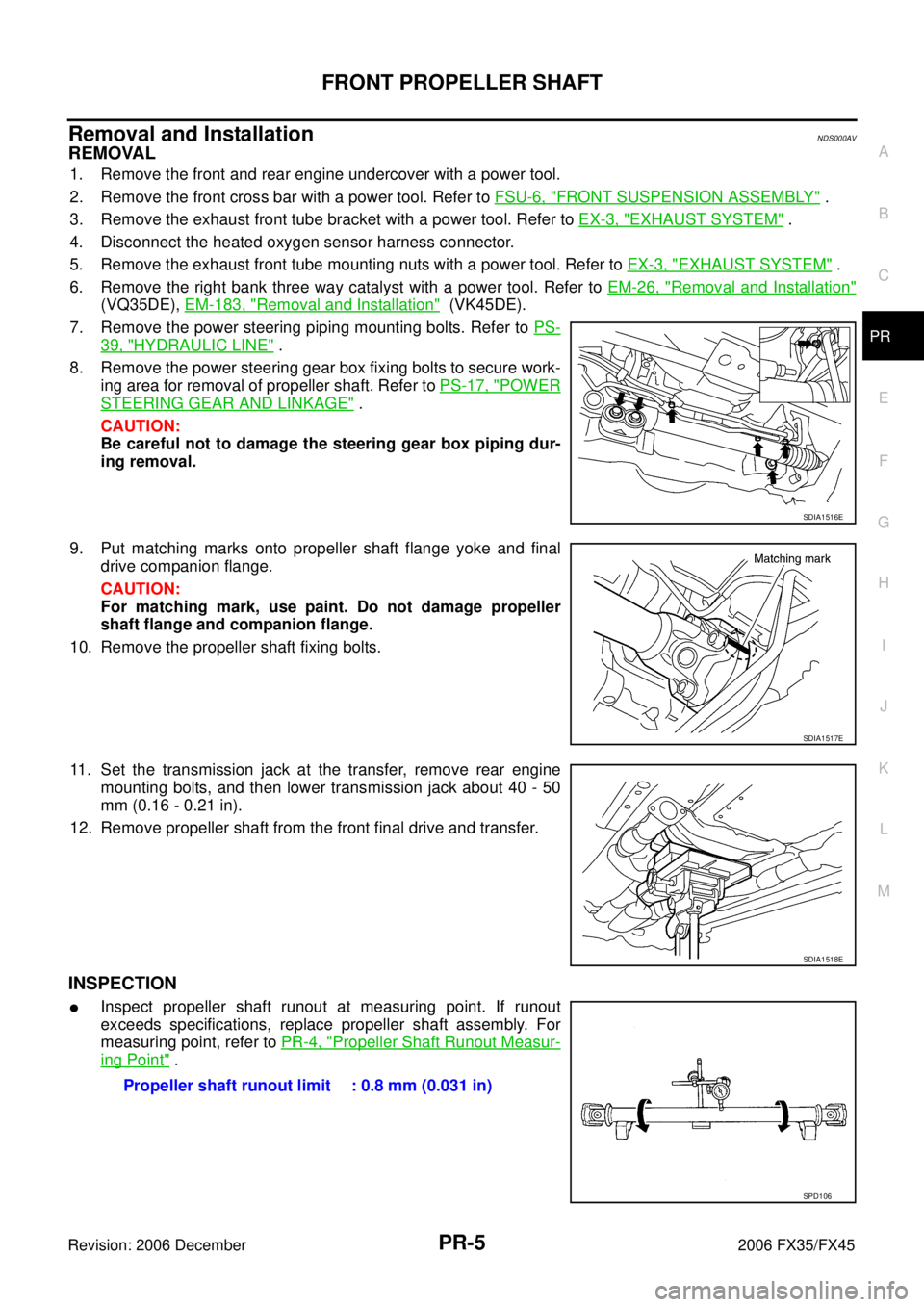

Removal and InstallationNDS000AV

REMOVAL

1. Remove the front and rear engine undercover with a power tool.

2. Remove the front cross bar with a power tool. Refer to FSU-6, "

FRONT SUSPENSION ASSEMBLY" .

3. Remove the exhaust front tube bracket with a power tool. Refer to EX-3, "

EXHAUST SYSTEM" .

4. Disconnect the heated oxygen sensor harness connector.

5. Remove the exhaust front tube mounting nuts with a power tool. Refer to EX-3, "

EXHAUST SYSTEM" .

6. Remove the right bank three way catalyst with a power tool. Refer to EM-26, "

Removal and Installation"

(VQ35DE), EM-183, "Removal and Installation" (VK45DE).

7. Remove the power steering piping mounting bolts. Refer to PS-

39, "HYDRAULIC LINE" .

8. Remove the power steering gear box fixing bolts to secure work- ing area for removal of propeller shaft. Refer to PS-17, "

POWER

STEERING GEAR AND LINKAGE" .

CAUTION:

Be careful not to damage the steering gear box piping dur-

ing removal.

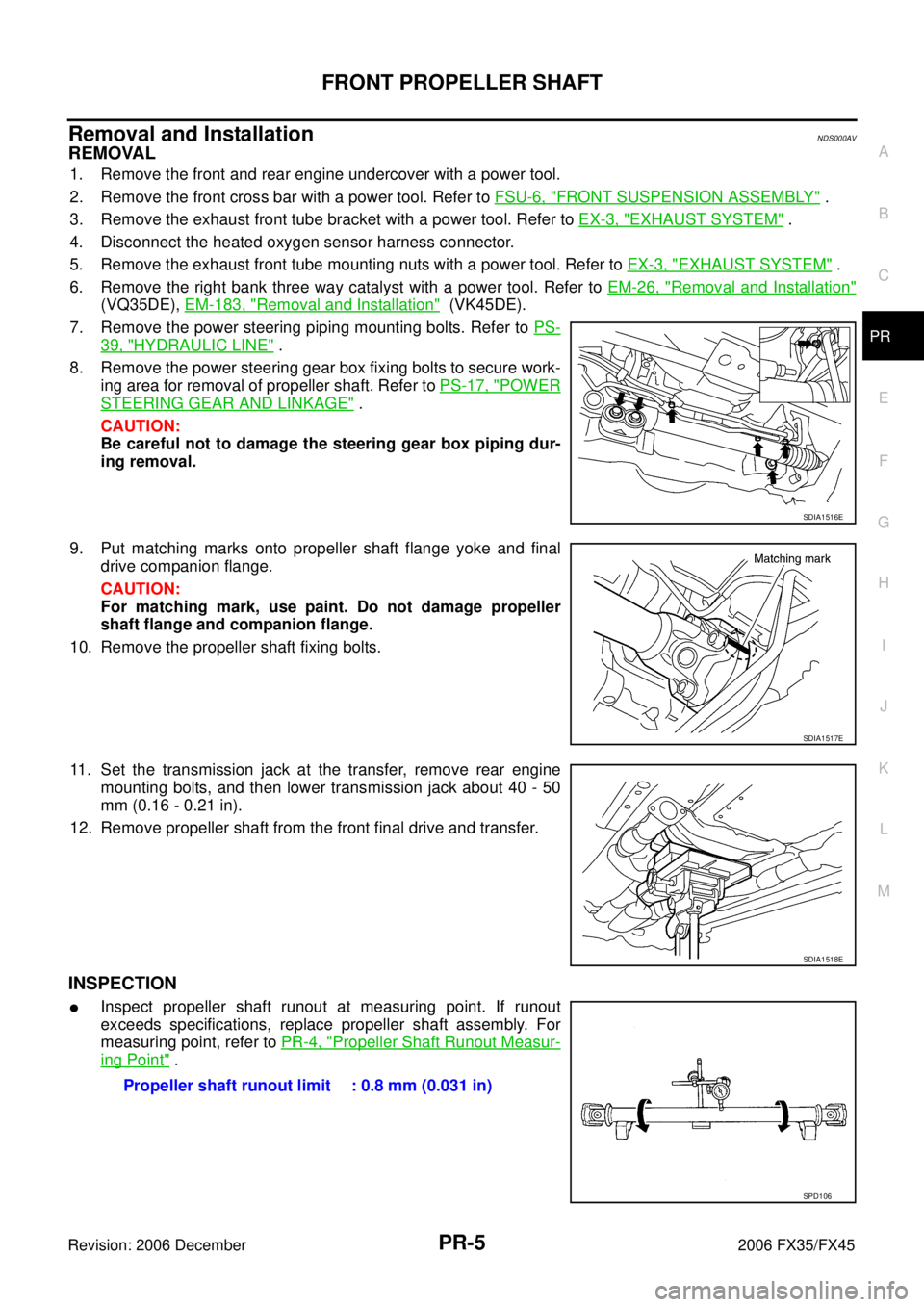

9. Put matching marks onto propeller shaft flange yoke and final drive companion flange.

CAUTION:

For matching mark, use paint. Do not damage propeller

shaft flange and companion flange.

10. Remove the propeller shaft fixing bolts.

11. Set the transmission jack at the transfer, remove rear engine mounting bolts, and then lower transmission jack about 40 - 50

mm (0.16 - 0.21 in).

12. Remove propeller shaft from the front final drive and transfer.

INSPECTION

�Inspect propeller shaft runout at measuring point. If runout

exceeds specifications, replace propeller shaft assembly. For

measuring point, refer to PR-4, "

Propeller Shaft Runout Measur-

ing Point" .

SDIA1516E

SDIA1517E

SDIA1518E

Propeller shaft runout limit : 0.8 mm (0.031 in)

SPD106