brake INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2016 of 2395

SMA211A

Checking Exhaust SystemNBMA0019Check exhaust pipes, muffler and mounting for improper

attachment, leaks, cracks, damage, loose connections, chafing or

deterioration.

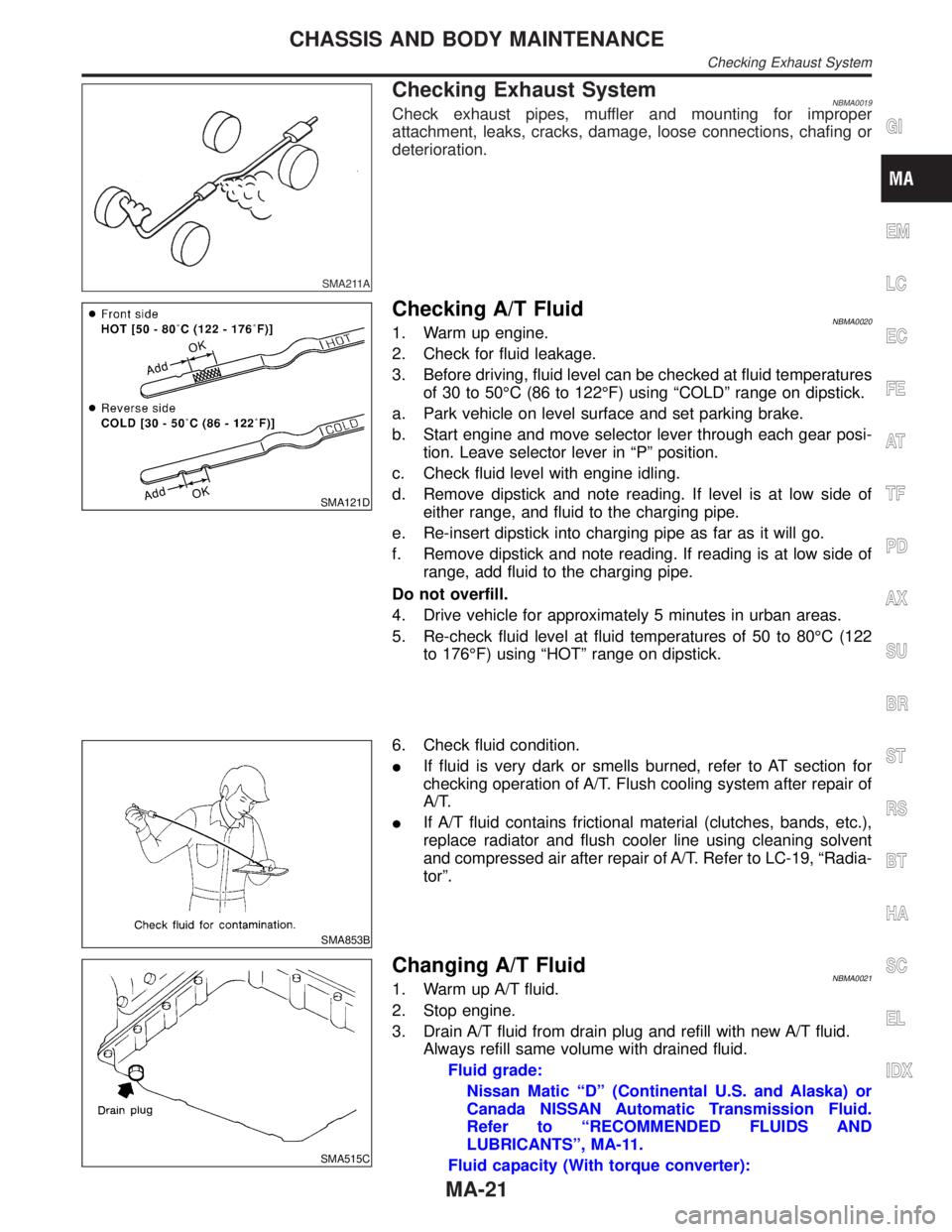

SMA121D

Checking A/T FluidNBMA00201. Warm up engine.

2. Check for fluid leakage.

3. Before driving, fluid level can be checked at fluid temperatures

of 30 to 50ÉC (86 to 122ÉF) using ªCOLDº range on dipstick.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in ªPº position.

c. Check fluid level with engine idling.

d. Remove dipstick and note reading. If level is at low side of

either range, and fluid to the charging pipe.

e. Re-insert dipstick into charging pipe as far as it will go.

f. Remove dipstick and note reading. If reading is at low side of

range, add fluid to the charging pipe.

Do not overfill.

4. Drive vehicle for approximately 5 minutes in urban areas.

5. Re-check fluid level at fluid temperatures of 50 to 80ÉC (122

to 176ÉF) using ªHOTº range on dipstick.

SMA853B

6. Check fluid condition.

IIf fluid is very dark or smells burned, refer to AT section for

checking operation of A/T. Flush cooling system after repair of

A/T.

IIf A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer to LC-19, ªRadia-

torº.

SMA515C

Changing A/T FluidNBMA00211. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid from drain plug and refill with new A/T fluid.

Always refill same volume with drained fluid.

Fluid grade:

Nissan Matic ªDº (Continental U.S. and Alaska) or

Canada NISSAN Automatic Transmission Fluid.

Refer to ªRECOMMENDED FLUIDS AND

LUBRICANTSº, MA-11.

Fluid capacity (With torque converter):

GI

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CHASSIS AND BODY MAINTENANCE

Checking Exhaust System

MA-21

Page 2020 of 2395

SBR451D

Checking Brake Fluid Level and LeaksNBMA0030If fluid level is extremely low, check brake system for leaks.

SBR389C

Checking Brake Lines and CablesNBMA0031Check brake fluid lines and parking brake cables for improper

attachment, leaks, chafing, abrasions and deterioration.

SMA260A

Checking Disc BrakeNBMA0032ROTORNBMA0032S01Check condition and thickness.

Standard thickness:

28 mm (1.10 in)

Minimum thickness:

26 mm (1.02 in)

SMA922A

CALIPERNBMA0032S02Check for leakage.

SMA847B

PADNBMA0032S03Check wear or damage.

Standard thickness:

11 mm (0.43 in)

Minimum thickness:

2 mm (0.08 in)

GI

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CHASSIS AND BODY MAINTENANCE

Checking Brake Fluid Level and Leaks

MA-25

Page 2021 of 2395

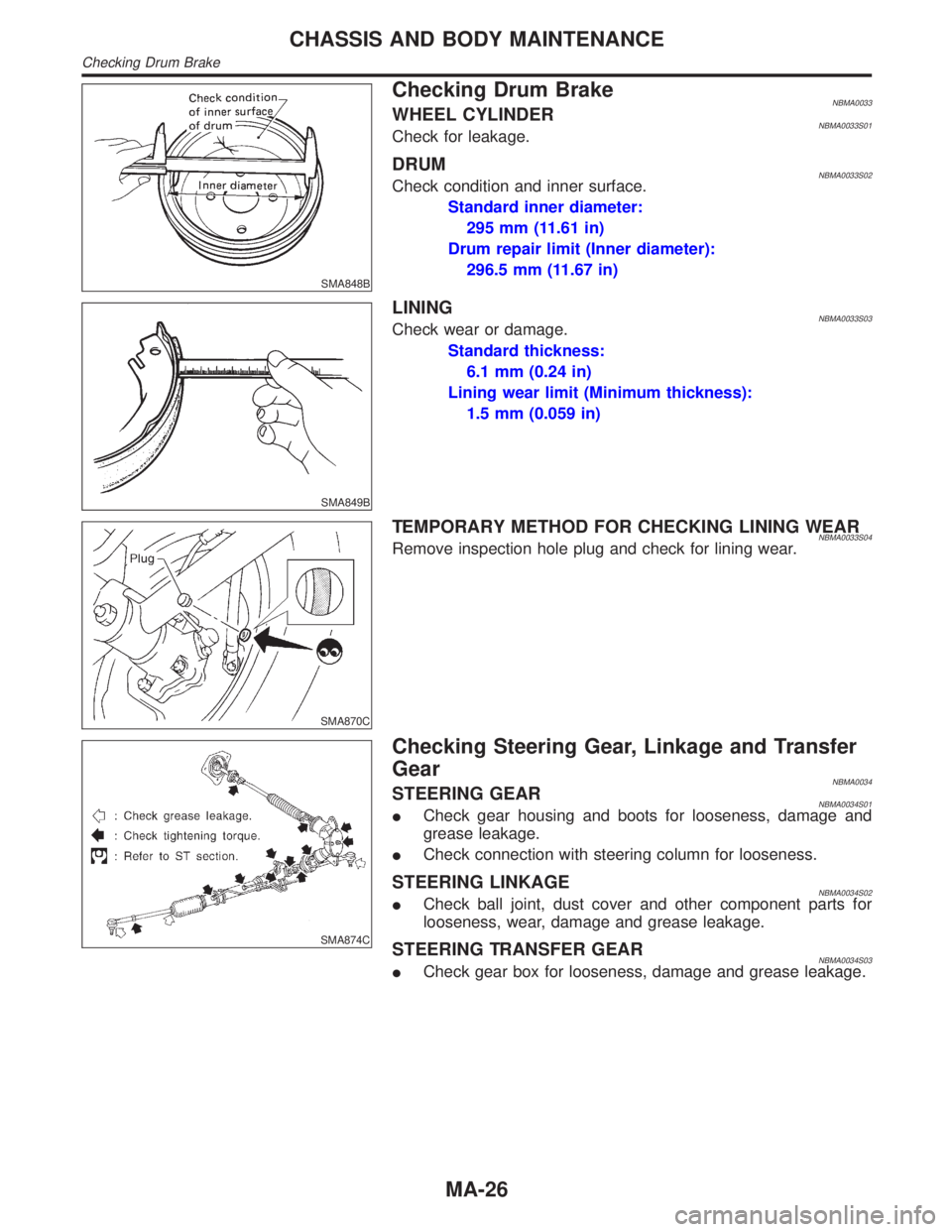

SMA848B

Checking Drum BrakeNBMA0033WHEEL CYLINDERNBMA0033S01Check for leakage.

DRUMNBMA0033S02Check condition and inner surface.

Standard inner diameter:

295 mm (11.61 in)

Drum repair limit (Inner diameter):

296.5 mm (11.67 in)

SMA849B

LININGNBMA0033S03Check wear or damage.

Standard thickness:

6.1 mm (0.24 in)

Lining wear limit (Minimum thickness):

1.5 mm (0.059 in)

SMA870C

TEMPORARY METHOD FOR CHECKING LINING WEARNBMA0033S04Remove inspection hole plug and check for lining wear.

SMA874C

Checking Steering Gear, Linkage and Transfer

Gear

NBMA0034STEERING GEARNBMA0034S01ICheck gear housing and boots for looseness, damage and

grease leakage.

ICheck connection with steering column for looseness.

STEERING LINKAGENBMA0034S02ICheck ball joint, dust cover and other component parts for

looseness, wear, damage and grease leakage.

STEERING TRANSFER GEARNBMA0034S03ICheck gear box for looseness, damage and grease leakage.

CHASSIS AND BODY MAINTENANCE

Checking Drum Brake

MA-26

Page 2028 of 2395

Noise, Vibration and Harshness (NVH)

Troubleshooting

=NBPD0049NVH TROUBLESHOOTING CHARTNBPD0049S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference pageÐ

Ð

Ð

Ð

PD-6

PD-6

PD-23, 47

PD-29, 56

PD-23, 47

PD-18, 43

Ð

Ð

Ð

Ð

AX-3

AX-3

SU-3

SU-3

SU-3

BR-6

ST-6

Possible cause and

SUSPECTED PARTS

Uneven rotation torque

Excessive center bearing axial end play

Center bearing mounting (insulator) cracks, damage or deterioration

Excessive joint angle

Rotation imbalance

Excessive runout

Rough gear tooth

Improper gear contact

Tooth surfaces worn

Incorrect backlash

Companion flange excessive runout

Improper gear oil

PROPELLER SHAFT

DIFFERENTIAL

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

STEERING

SymptomPROPEL-

LER

SHAFTNoise´´´´´´ ´´´´´´´´

Shake´ ´´´´´´´

Vibration´´´´´´ ´´´´ ´

DIFFER-

ENTIALNoise´´´´´´´ ´´´´´´´

´: Applicable

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PROPELLER SHAFT

Noise, Vibration and Harshness (NVH) Troubleshooting

PD-3

Page 2097 of 2395

SEAT BELT RETRACTOR ON-VEHICLE CHECKNBRS0029S03Emergency Locking Retractors (ELR) and Automatic Locking Retractors (ALR)NBRS0029S0301NOTE:

All seat belt retractors are of the Emergency Locking Retractors (ELR) type. In an emergency (sudden stop)

the retractor will lock and prevent the belt from extending any further. All 3-point type seat belt retractors except

the driver's seat belt also have an Automatic Locking Retractors (ALR) mode. The ALR mode (also called child

restraint mode) is used when installing child seats. The ALR mode is activated when the seat belt is fully

extended. When the belt is then retracted partially, the ALR mode automatically locks the seat belt in a spe-

cific position so the belt cannot be extended any further. To cancel the ALR mode, allow the seat belt to fully

wind back into the retractor.

Check the seat belt retractors using the following test(s) to determine if a retractor assembly is operating

properly.

ELR Function Stationary CheckNBRS0029S0302Grasp the shoulder belt and pull forward quickly. The retractor should lock and prevent the belt from extend-

ing further.

ALR Function Stationary CheckNBRS0029S03041. Pull out entire length of seat belt from retractor until a click is heard.

2. Retract the belt partially. A clicking noise should be heard as the belt retracts indicating that the retractor

is in the Automatic Locking Retractors (ALR) mode.

3. Grasp the seat belt and try to pull out the retractor. The belt must lock and not extend any further. If NG,

replace the retractor assembly.

4. Allow the entire length of the belt to retract to cancel the automatic locking mode.

ELR Function Moving CheckNBRS0029S0303WARNING:

Perform the following test in a safe, open area clear of other vehicles and obstructions (for example,

a large, empty parking lot). Road surface must be paved and dry. DO NOT perform the following test

on wet or gravel roads or on public streets and highways. This could result in an accident and seri-

ous personal injury. The driver and passenger must be prepared to brace themselves in the event the

retractor does not lock.

1. Fasten driver's seat belt. Buckle a passenger into the seat for the belt that is to be tested.

2. Proceed to the designated safe area.

3. Drive the vehicle at approximately 16 km/h (10 MPH). Notify any passengers of a pending sudden stop

and the driver and passenger must be prepared to brace themselves in the event the retractor does not

lock, apply brakes firmly and make a very hard stop.

During stop, seat belts should lock and not be extended. If the seat belt retractor assembly does not lock,

perform the retractor off-vehicle check.

SEAT BELT RETRACTOR OFF-VEHICLE CHECKNBRS0029S041. Remove the seat belt retractor assembly.

2. Slowly pull out belt while tilting the retractor assembly forward from the mounted position without twisting

the retractor assembly as shown in the illustration.

15 degrees or less tilt: Belt can be pulled out.

35 degrees or more tilt: Belt locks and cannot be pulled out.

SEAT BELTS

Seat Belt Inspection (Cont'd)

RS-8

Page 2187 of 2395

NBST0043

NVH Troubleshooting ChartNBST0043S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference pageST-8

ST-9

ST-21

ST-21

ST-21

ST-8

ST-7

ST-9

MA-13

Ð

ST-13

ST-8

ST-13

ST-13

ST-17

PD-3

PD-3

AX-3

AX-3

SU-3

SU-3

SU-3

BR-6

Possible cause and

SUSPECTED PARTS

Fluid level

Air in hydraulic system

Tie-rod ball joint swinging force

Tie-rod ball joint rotating torque

Tie-rod ball joint end play

Steering gear fluid leakage

Steering wheel play

Steering gear rack sliding force

Drive belt looseness

Improper steering wheel

Improper installation or looseness or tilt lock lever

Mounting rubber deterioration

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

PROPELLER SHAFT

DIFFERENTIAL

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

Symp-

tomSTEERINGNoise´´´´´´´´´ ´´´´´´´´

Shake´´´ ´ ´´´´´´

Vibration´´´´´ ´ ´´´´

Shimmy´´´ ´ ´´´´´

Judder´ ´ ´´´´´

´: Applicable

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

ST-6

Page 2190 of 2395

CAUTION:

Do not hold the steering wheel in a locked position for more

than 15 seconds.

4. If fluid leakage at connectors is noticed, loosen flare nut and

then retighten.

Do not overtighten connector as this can damage O-ring,

washer and connector.

5. Check rack boots for accumulation of power steering fluid.

Bleeding Hydraulic SystemNBST00131. Raise front end of vehicle until wheels are clear of the ground.

2. Add fluid into oil tank to specified level. Then, quickly turn

steering wheel fully to right and left and lightly touch steering

stoppers.

Repeat steering wheel operation until fluid level no longer

decreases.

3. Start engine.

Repeat step 2 above.

IIncomplete air bleeding will cause the following to occur. When

this happens, bleed air again.

a) Air bubbles in reservoir tank

b) Clicking noise in oil pump

c) Excessive buzzing in oil pump

Fluid noise may occur in the valve or oil pump. This is common

when the vehicle is stationary or while turning steering wheel

slowly. This does not affect performance or durability of the system.

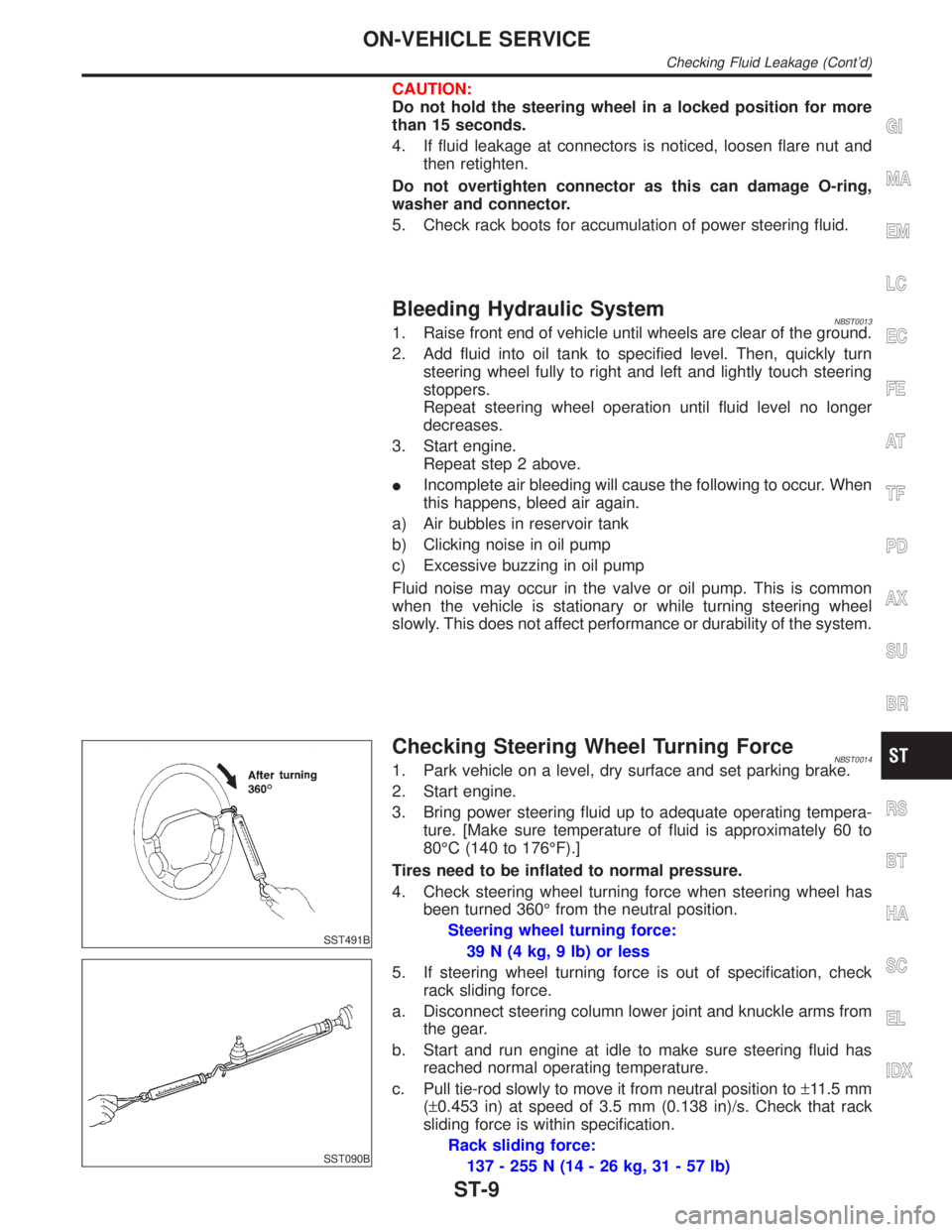

SST491B

SST090B

Checking Steering Wheel Turning ForceNBST00141. Park vehicle on a level, dry surface and set parking brake.

2. Start engine.

3. Bring power steering fluid up to adequate operating tempera-

ture. [Make sure temperature of fluid is approximately 60 to

80ÉC (140 to 176ÉF).]

Tires need to be inflated to normal pressure.

4. Check steering wheel turning force when steering wheel has

been turned 360É from the neutral position.

Steering wheel turning force:

39 N (4 kg, 9 lb) or less

5. If steering wheel turning force is out of specification, check

rack sliding force.

a. Disconnect steering column lower joint and knuckle arms from

the gear.

b. Start and run engine at idle to make sure steering fluid has

reached normal operating temperature.

c. Pull tie-rod slowly to move it from neutral position to±11.5 mm

(±0.453 in) at speed of 3.5 mm (0.138 in)/s. Check that rack

sliding force is within specification.

Rack sliding force:

137 - 255 N (14 - 26 kg, 31 - 57 lb)

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

ON-VEHICLE SERVICE

Checking Fluid Leakage (Cont'd)

ST-9

Page 2217 of 2395

SBR686C

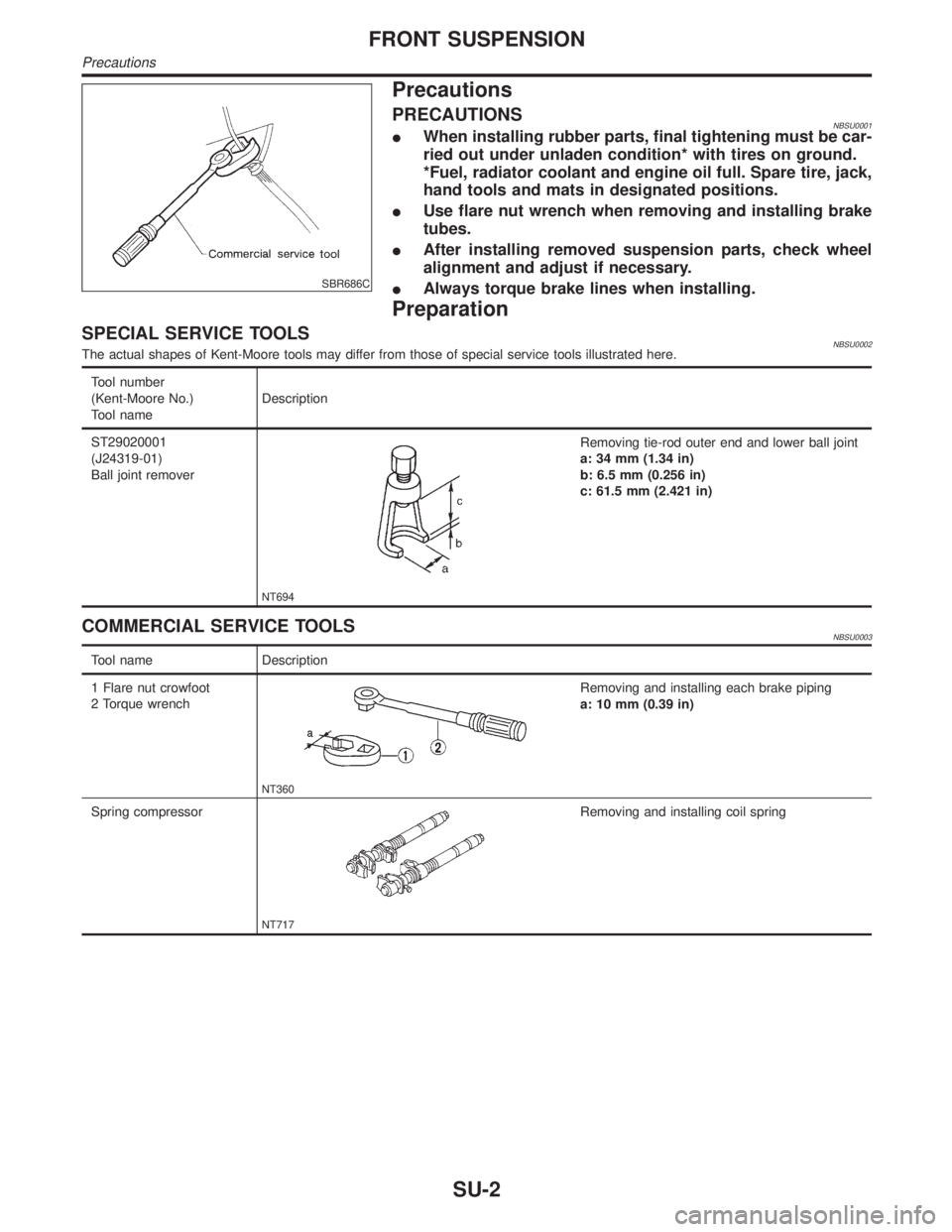

Precautions

PRECAUTIONSNBSU0001IWhen installing rubber parts, final tightening must be car-

ried out under unladen condition* with tires on ground.

*Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

IUse flare nut wrench when removing and installing brake

tubes.

IAfter installing removed suspension parts, check wheel

alignment and adjust if necessary.

IAlways torque brake lines when installing.

Preparation

SPECIAL SERVICE TOOLSNBSU0002The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

ST29020001

(J24319-01)

Ball joint remover

NT694

Removing tie-rod outer end and lower ball joint

a: 34 mm (1.34 in)

b: 6.5 mm (0.256 in)

c: 61.5 mm (2.421 in)

COMMERCIAL SERVICE TOOLSNBSU0003

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing each brake piping

a: 10 mm (0.39 in)

Spring compressor

NT717

Removing and installing coil spring

FRONT SUSPENSION

Precautions

SU-2

Page 2218 of 2395

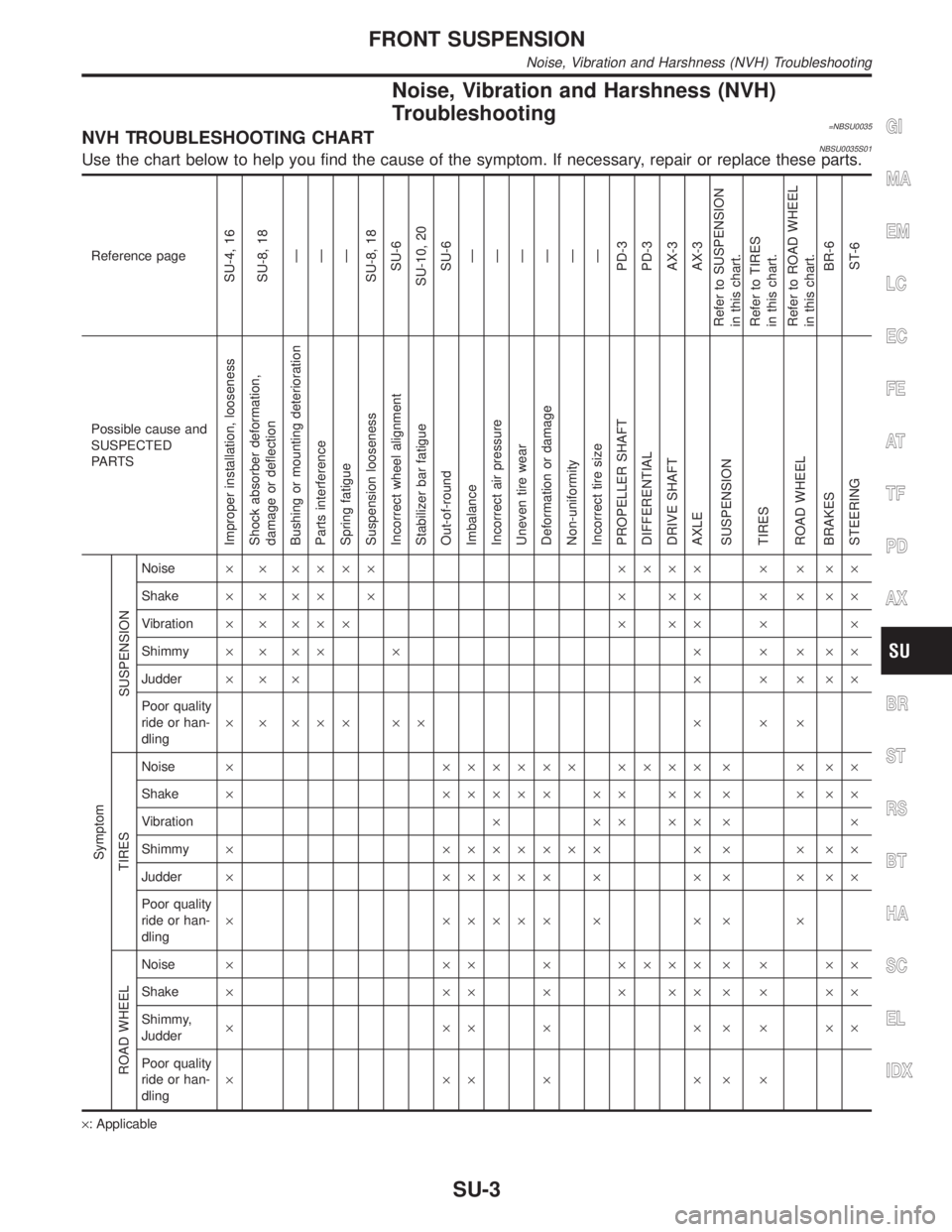

Noise, Vibration and Harshness (NVH)

Troubleshooting

=NBSU0035NVH TROUBLESHOOTING CHARTNBSU0035S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference page

SU-4, 16

SU-8, 18

Ð

Ð

Ð

SU-8, 18

SU-6

SU-10, 20

SU-6

Ð

Ð

Ð

Ð

Ð

Ð

PD-3

PD-3

AX-3

AX-3

Refer to SUSPENSION

in this chart.

Refer to TIRES

in this chart.

Refer to ROAD WHEEL

in this chart.

BR-6

ST-6

Possible cause and

SUSPECTED

PA R T S

Improper installation, looseness

Shock absorber deformation,

damage or deflection

Bushing or mounting deterioration

Parts interference

Spring fatigue

Suspension looseness

Incorrect wheel alignment

Stabilizer bar fatigue

Out-of-round

Imbalance

Incorrect air pressure

Uneven tire wear

Deformation or damage

Non-uniformity

Incorrect tire size

PROPELLER SHAFT

DIFFERENTIAL

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

STEERING Symptom

SUSPENSION

Noise´ ´ ´´´´ ´´´´ ´ ´ ´´

Shake´´´´´ ´´´ ´´´´

Vibration´ ´ ´´´ ´ ´´ ´ ´

Shimmy´´´´ ´ ´ ´ ´´´

Judder´´´ ´ ´ ´´´

Poor quality

ride or han-

dling´ ´ ´´´ ´´ ´ ´ ´

TIRES

Noise´ ´´´´´´ ´´´´ ´ ´ ´´

Shake´ ´´´´´ ´´ ´´ ´ ´ ´´

Vibration´´´´´´ ´

Shimmy´ ´´´´´´´ ´ ´ ´ ´´

Judder´ ´´´´´ ´ ´ ´ ´ ´´

Poor quality

ride or han-

dling´ ´´´´´ ´ ´ ´ ´

ROAD WHEEL

Noise´ ´´ ´ ´´´´ ´ ´ ´´

Shake´ ´´ ´ ´ ´´ ´ ´ ´´

Shimmy,

Judder´´´´´´´´´

Poor quality

ride or han-

dling´´´´´´´

´: Applicable

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT SUSPENSION

Noise, Vibration and Harshness (NVH) Troubleshooting

SU-3

Page 2220 of 2395

SMA525A

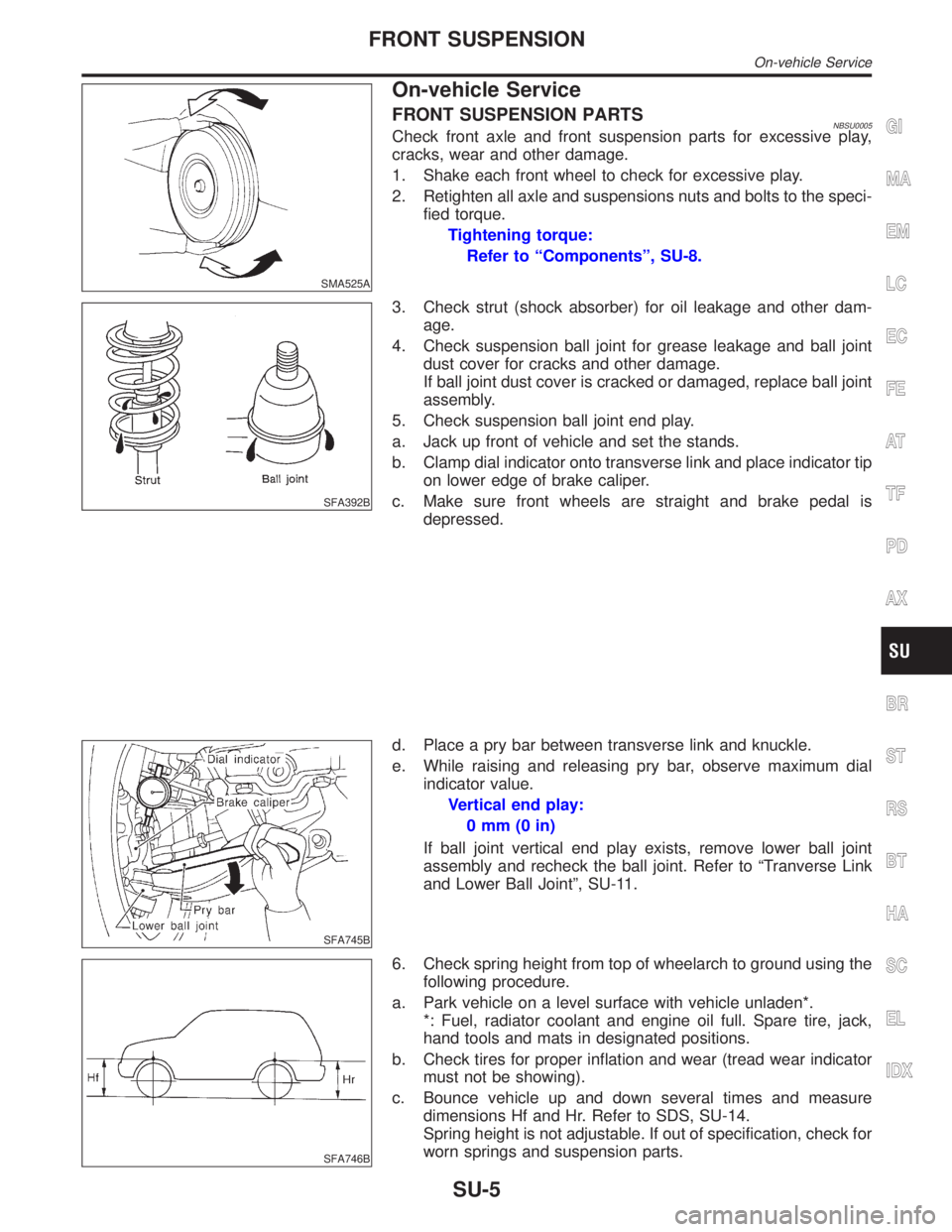

On-vehicle Service

FRONT SUSPENSION PARTSNBSU0005Check front axle and front suspension parts for excessive play,

cracks, wear and other damage.

1. Shake each front wheel to check for excessive play.

2. Retighten all axle and suspensions nuts and bolts to the speci-

fied torque.

Tightening torque:

Refer to ªComponentsº, SU-8.

SFA392B

3. Check strut (shock absorber) for oil leakage and other dam-

age.

4. Check suspension ball joint for grease leakage and ball joint

dust cover for cracks and other damage.

If ball joint dust cover is cracked or damaged, replace ball joint

assembly.

5. Check suspension ball joint end play.

a. Jack up front of vehicle and set the stands.

b. Clamp dial indicator onto transverse link and place indicator tip

on lower edge of brake caliper.

c. Make sure front wheels are straight and brake pedal is

depressed.

SFA745B

d. Place a pry bar between transverse link and knuckle.

e. While raising and releasing pry bar, observe maximum dial

indicator value.

Vertical end play:

0mm(0in)

If ball joint vertical end play exists, remove lower ball joint

assembly and recheck the ball joint. Refer to ªTranverse Link

and Lower Ball Jointº, SU-11.

SFA746B

6. Check spring height from top of wheelarch to ground using the

following procedure.

a. Park vehicle on a level surface with vehicle unladen*.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

b. Check tires for proper inflation and wear (tread wear indicator

must not be showing).

c. Bounce vehicle up and down several times and measure

dimensions Hf and Hr. Refer to SDS, SU-14.

Spring height is not adjustable. If out of specification, check for

worn springs and suspension parts.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT SUSPENSION

On-vehicle Service

SU-5