height ISUZU AXIOM 2002 Service Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2002, Model line: AXIOM, Model: ISUZU AXIOM 2002Pages: 2100, PDF Size: 19.35 MB

Page 267 of 2100

WHEEL AND TIRE SYSTEM3E±5

Condition CorrectionPossible cause

Erratic Steering When BrakingWorn wheel bearings.Replace wheel bearings.

Broken or sagging springs.Replace spring (pairs).

Leaking caliper.Repair or replace caliper.

Warped discs.Replace brake disc.

Badly worn brake pads.Replace brake pads.

Tires are inflated unequally.Inflate tires to proper pressure.

Low or Uneven Trim HeightBroken or sagging springs.Replace springs (In pairs).

Vehicle overloaded.Reduce load.

Incorrect springs.Adjust or replace torsion bar.

Suspension BottomsVehicle overloaded. Reduce load.

Faulty shock absorber.Replace shock absorber.

Incorrect, broken or sagging springs.Replace springs.

Body LeansLoose stabilizer bar.Tighten stabilizer bar bolts or replace

bushings.

Faulty shock absorber, struts or

mounting.Replace shock absorber.

Broken or sagging springs.Replace springs (In pairs).

Vehicle overloaded.Reduce load.

Cupped TiresWorn wheel bearings.Replace wheel bearing.

Excessive tire or wheel run out.Replace tire or wheel.

Worn ball joints.Replace ball joints.

Tire out of balance.Adjust tire balance.

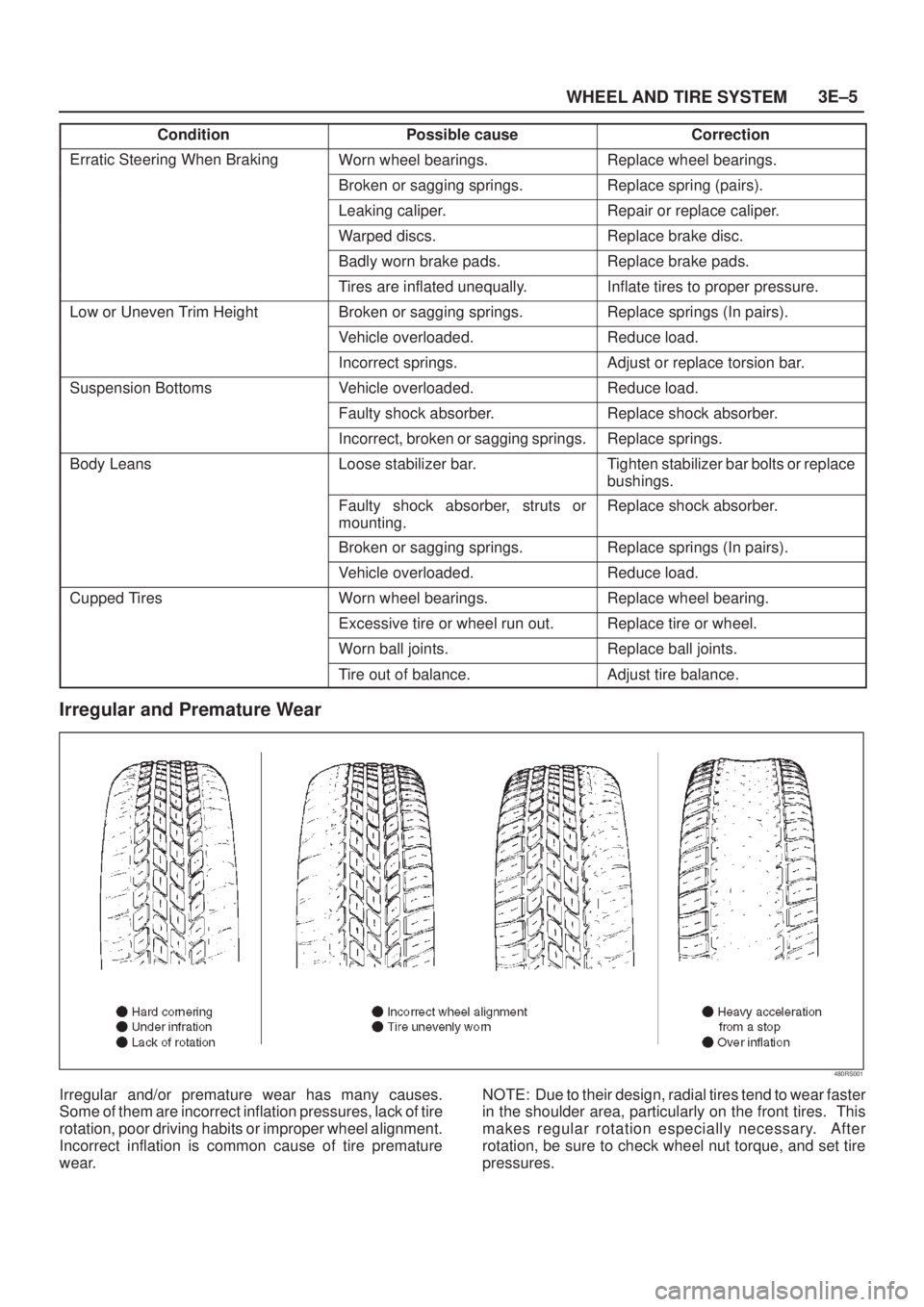

Irregular and Premature Wear

480RS001

Irregular and/or premature wear has many causes.

Some of them are incorrect inflation pressures, lack of tire

rotation, poor driving habits or improper wheel alignment.

Incorrect inflation is common cause of tire premature

wear.NOTE: Due to their design, radial tires tend to wear faster

in the shoulder area, particularly on the front tires. This

makes regular rotation especially necessary. After

rotation, be sure to check wheel nut torque, and set tire

pressures.

Page 319 of 2100

DIFFERENTIAL (FRONT) 4A1±6

Removal

1. Jack up the vehicle and support it using jack stand.

2. Remove the tire and wheel.

3. Remove the stone guard.

4. Remove the brake caliper fixing bolt and hang the

caliper. Refer to

Disc Brakes in Brake section.

5. Remove the antilock brake system speed sensor.

Refer to

Front Wheel Speed Sensor in Brake section.

6. Remove the hub and disc assembly.

Refer to

Front Hub and Disc in this section.

7. Remove the propeller shaft, refer to

Front Propeller

Shaft

in this section.

8. Loosen the height control arm of the torsion bar, then

remove the torsion bar from lower control arm.

Refer to

Torsion Bar in Suspension section.

9. Remove the suspension crossmember.

10. Remove the lower nut (1) of the stabilizer link.

11. Remove the lower bolt and nut (2) of the shock

absorber.

412RW057

12. Remove the tie-rod end from the knuckle. Refer to

Power Steering Unit in Steering Section.

13. Disconnect the hose of the shift on the fly.

14. Disconnect the actuator connector.

15. Remove the bolts and nuts of the lower control arm

(Frame side), then disconnect the lower control arm

from frame.

16. Disconnect between the right side upper control arm

and the knuckle, then remove the knuckle with lower

control arm.CAUTION: When removing the knuckle, be careful

not to damage the oil seal inside of the knuckle.

410RW008

17. Support the differential case by the jack.

18. Remove the front axle mounting bolts and nuts, lower

the jack slowly. Remove the left side drive shaft end

from the knuckle, then lower the axle assembly from

the vehicle.

CAUTION:

1. Make sure the axle assembly is supported

securely when performing repairs.

2. Do not damage the power steering unit when

performing the repairs.

3. Do not damage the shift±on±the fly hose bracket

when performing the repairs.

Installation

1. Support the differential case with a jack.

2. Jack up the front drive axle assembly, install the left

side drive shaft to the knuckle, then install the mount

bolts and nuts.

CAUTION:

1. Do not damage the power steering unit when

performing the repairs.

2. Do not damage the shift±on±the fly hose bracket

when performing the repairs.

3. When installing the drive shaft to the knuckle, be

careful not to damage the oil seal inside of the

knuckle.

Page 320 of 2100

4A1±7 DIFFERENTIAL (FRONT)

3. Tighten the mounting bolts and nuts to the specified

torque.

Torque: 168 N´m (124 lb ft)

412R200004

4. Install the right side knuckle with lower control arm to

the upper control arm.

Refer to

Knuckle in Suspension section.

CAUTION: Carefully insert the drive shaft into the

knuckle, to avoid damaging the oil seal.

5. Align the bolt hole of the lower control arm, then install

the bolts and nuts.

NOTE: Adjust the buffer clearance before tightening the

bolts and nuts of the lower control arm.

6. Install the hose of the shift on the fly.

7. Install the actuator connector of the shift on the fly.

8. Install the tie-rod end of the power steering unit to the

knuckle, tighten the nut to the specified torque.

Torque: 118 N´m (87 lb ft)

9. Install lower bolts and nuts of the shock absorber,

tighten it to the specified torque.

Torque: 93 N´m (69 lb ft)

10. Install lower nuts of the stabilizer link, tighten it to the

specified torque.

11. Install the suspension crossmember.

12. Install the torsion bar.

Refer to

Torsion Bar in Suspension section.

13. Install the front propeller shaft.

Refer to

Front Propeller Shaft in this section.

14. Install the hub and disc assembly and adjust the

bearing preload.

Refer to

Front Hub and Disc in this section.

15. Install the wheel speed sensor of the antilock brake

system.

16. Install the brake caliper. Tighten the bolt of the caliper

bracket to the specified torque.

Torque: 50 N´m (37 lb ft)

17. Install the stone guard.18. Install the tire and wheel.

19. Lower the vehicle, adjust the trim height.

Refer to

Trim Height Adjustment in Steering section.

20. Tighten the bolts and nuts of the lower control arm to

the specified torque.

Refer to

Lower Control Arm in Suspension section.

Page 681 of 2100

5C±1 POWER±ASSISTED BRAKE SYSTEM

AXIOM (Vehicles Produced Before July/31/2001)

BRAKES

POWER-ASSISTED BRAKE SYSTEM

CONTENTS

Service Precaution 5C±2. . . . . . . . . . . . . . . . . . . . . .

General Description 5C±2. . . . . . . . . . . . . . . . . . . . .

Diagnosis 5C±6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Diagnosis 5C±7. . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Brakes 5C±10. . . . . . . . . . . . . . . . . . . . . . . .

Filling Master Cylinder Reservoir 5C±10. . . . . . . .

Deterioration of Brake Fluid 5C±10. . . . . . . . . . . . .

Leakage of Brake Fluid 5C±10. . . . . . . . . . . . . . . . .

Bleeding Brake Hydraulic System 5C±10. . . . . . . .

Flushing Brake Hydraulic System 5C±11. . . . . . . .

Brake Pipes and Hoses 5C±11. . . . . . . . . . . . . . . .

Brake Hose Inspection 5C±11. . . . . . . . . . . . . . . . .

Front Caliper Brake Hose 5C±12. . . . . . . . . . . . . . . .

Front Caliper Brake Hose and Associated

Parts 5C±12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 5C±12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5C±12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Axle Brake Hose 5C±13. . . . . . . . . . . . . . . . . . .

Rear Axle Brake Hose and Associated

Parts 5C±13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 5C±13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5C±13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Pipe 5C±14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 5C±14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5C±14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

P & B (Proportioning and Bypass) Valve 5C±15. . . .

P & B (Proportioning and Bypass) Valve

Sectional View 5C±15. . . . . . . . . . . . . . . . . . . . . . . .

Removal 5C±15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5C±15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 5C±16. . . . . . . . . . . . .

Brake Pedal 5C±17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Pedal Height 5C±17. . . . . . . . . . . . . . . . .

Checking Pedal Travel 5C±17. . . . . . . . . . . . . . . . .

Brake Pedal and Associated Parts 5C±18. . . . . . .

Removal 5C±18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5C±18. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stoplight Switch 5C±19. . . . . . . . . . . . . . . . . . . . . . . . .

Parts Location 5C±19. . . . . . . . . . . . . . . . . . . . . . . .

Removal 5C±19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5C±19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 5C±20. . . . . . . . . . . . .

Fluid Reservoir Tank 5C±21. . . . . . . . . . . . . . . . . . . . .

Fluid Reservoir Tank and Associated Parts 5C±21Removal 5C±21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5C±21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Master Cylinder Assembly 5C±22. . . . . . . . . . . . . . . .

Master Cylinder Assembly and Associated

Parts 5C±22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 5C±22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 5C±22. . . . . . . . . . . . . . . . . .

Installation 5C±23. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 5C±24. . . . . . . . . . .

Special Tools 5C±24. . . . . . . . . . . . . . . . . . . . . . . . . .

Vacuum Booster Assembly 5C±25. . . . . . . . . . . . . . .

Vacuum Booster Assembly and Associated

Parts 5C±25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 5C±25. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 5C±26. . . . . . . . . . . . . . . . . .

Installation 5C±26. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exterior Components 5C±28. . . . . . . . . . . . . . . . . . . .

Exterior Components and Associated Parts 5C±28

Removal 5C±28. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 5C±29. . . . . . . . . . . . . . . . . .

Installation 5C±29. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vacuum Booster Overhaul 5C±29. . . . . . . . . . . . . . . .

Vacuum Booster 5C±29. . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 5C±30. . . . . . . . . . . . .

Special Tools 5C±31. . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Disc Brake Pads 5C±32. . . . . . . . . . . . . . . . . . .

Front Disc Brake Pads Inspection 5C±32. . . . . . . .

Front Disc Brake Pads and Associated

Parts 5C±32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 5C±33. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5C±33. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Disc Brake Rotor 5C±35. . . . . . . . . . . . . . . . . . .

Inspection 5C±35. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing Brake Rotors 5C±35. . . . . . . . . . . . . . . .

Refinishing Brake Rotors 5C±35. . . . . . . . . . . . . . .

Front Disc Brake Caliper Assembly 5C±36. . . . . . . .

Front Disc Brake Caliper Assembly and

Associated Parts 5C±36. . . . . . . . . . . . . . . . . . . . . .

Removal 5C±37. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5C±37. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Disc Brake Caliper 5C±39. . . . . . . . . . . . . . . . .

Front Disc Brake Caliper Disassembled

View 5C±39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 5C±39. . . . . . . . . . . . . . . . . . . . . . . . . .

Page 688 of 2100

5C±8

POWER±ASSISTED BRAKE SYSTEM

Condition CorrectionPossible cause

Excessive Brake Pedal TravelAir in hydraulic circuit.Bleed the hydraulic circuit.

Level of brake fluid in the reservoir

too low.Replenish brake fluid reservoir to

specified level and bleed hydraulic

circuit as necessary.

Master cylinder push rod clearance

excessive.Adjust

Leakage in hydraulic system.Correct or replace defective parts.

Brake DragMaster cylinder pistons not returning

correctly.Adjust the stop light switch and

vacuum booster push rod. If

necessary, rebuild.

Restricted brake pipes or hoses.Check for soft hoses or damaged

pipes, and replace with new hoses

and new double±walled steel brake

piping.

Parking brake maladjusted.Adjust

Parking brake lining clearance

insufficient.Adjust

Brake pedal free play insufficient.Adjust the brake pedal height or

power cylinder operating rod.

Piston in the master cylinder sticking.Replace

Piston in the disc brake caliper

sticking.Replace piston seals.

Brake pads sticking in caliper.Clean

Return spring weakened.Replace

Parking brake binding.Overhaul the parking brakes and

correct.

Front hub bearing preload incorrect.Adjust or replace.

Parking brake shoes not returning.Correct or replace the brake back

plate and brake shoe as necessary.

Obstructions in hydraulic circuit.Clean

Rotor warped excessively.Grind or replace.

Rear brake drum distorted.Grind or replace.

Parking cable sticking.Grind or replace.

Grabbing or Uneven Braking Action

(All conditions listed under ªPullsº)Malfunctioning vacuum booster.Check operation and correct as

necessary.

Binding brake pedal mechanism.Check and lubricate, if necessary.

Corroded caliper assembly.Clean and lubricate.

Brake NoisyBrake pads are worn.Replace

Brake pads are hardened.Replace

Brake pads are in poor contact with

rotor.Correct

Brake disc(s) warped, worn or

damaged.Grind or replace.

Disc brake anti±squeak shims

fatigued.Replace

Front hub bearings are loose or

preload is incorrect.Adjust or replace.

Brake disc is rusted.Grind or replace.

Page 697 of 2100

5C±17 POWER±ASSISTED BRAKE SYSTEM

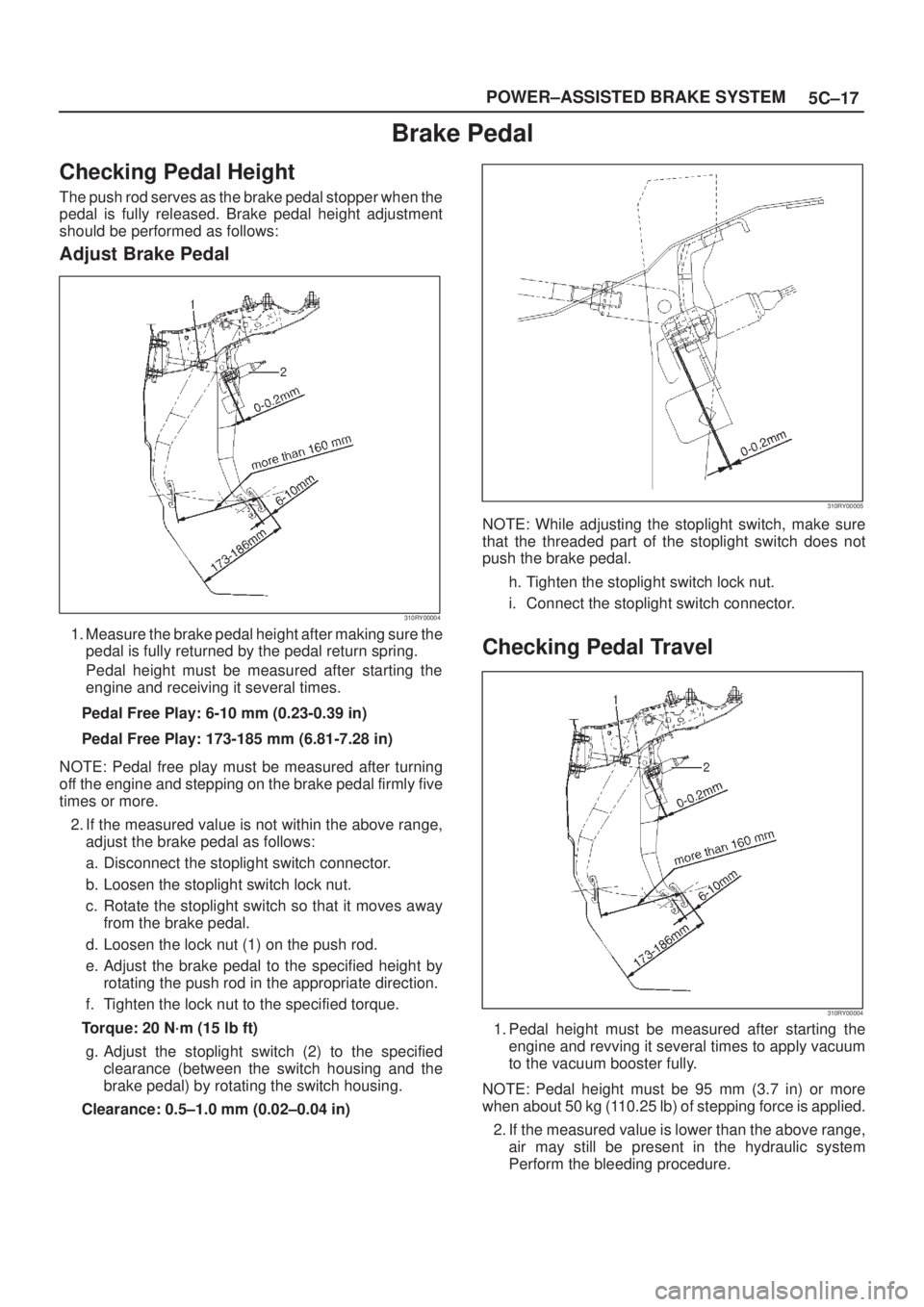

Brake Pedal

Checking Pedal Height

The push rod serves as the brake pedal stopper when the

pedal is fully released. Brake pedal height adjustment

should be performed as follows:

Adjust Brake Pedal

310RY00004

1. Measure the brake pedal height after making sure the

pedal is fully returned by the pedal return spring.

Pedal height must be measured after starting the

engine and receiving it several times.

Pedal Free Play: 6-10 mm (0.23-0.39 in)

Pedal Free Play: 173-185 mm (6.81-7.28 in)

NOTE: Pedal free play must be measured after turning

off the engine and stepping on the brake pedal firmly five

times or more.

2. If the measured value is not within the above range,

adjust the brake pedal as follows:

a. Disconnect the stoplight switch connector.

b. Loosen the stoplight switch lock nut.

c. Rotate the stoplight switch so that it moves away

from the brake pedal.

d. Loosen the lock nut (1) on the push rod.

e. Adjust the brake pedal to the specified height by

rotating the push rod in the appropriate direction.

f. Tighten the lock nut to the specified torque.

Torque: 20 N´m (15 lb ft)

g. Adjust the stoplight switch (2) to the specified

clearance (between the switch housing and the

brake pedal) by rotating the switch housing.

Clearance: 0.5±1.0 mm (0.02±0.04 in)

310RY00005

NOTE: While adjusting the stoplight switch, make sure

that the threaded part of the stoplight switch does not

push the brake pedal.

h. Tighten the stoplight switch lock nut.

i. Connect the stoplight switch connector.

Checking Pedal Travel

310RY00004

1. Pedal height must be measured after starting the

engine and revving it several times to apply vacuum

to the vacuum booster fully.

NOTE: Pedal height must be 95 mm (3.7 in) or more

when about 50 kg (110.25 lb) of stepping force is applied.

2. If the measured value is lower than the above range,

air may still be present in the hydraulic system

Perform the bleeding procedure.

Page 700 of 2100

5C±20

POWER±ASSISTED BRAKE SYSTEM

Main Data and Specifications

General Specifications

Pedal free play6±10 mm (0.23 ±0.39 in)

Pedal Height173±185 mm (6.81±7.28 in)

Torque Specifications

310RY00007

Page 741 of 2100

5C±61 POWER±ASSISTED BRAKE SYSTEM

AXIOM (Vehicles Produced After Aug./1/2001)

POWER-ASSISTED BRAKE SYSTEM

CONTENTS

Service Precaution 5C±62. . . . . . . . . . . . . . . . . . . . . .

General Description 5C±62. . . . . . . . . . . . . . . . . . . . .

Diagnosis 5C±66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Diagnosis 5C±67. . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Brakes 5C±70. . . . . . . . . . . . . . . . . . . . . . . .

Filling Master Cylinder Reservoir 5C±70. . . . . . . .

Deterioration of Brake Fluid 5C±70. . . . . . . . . . . . .

Leakage of Brake Fluid 5C±70. . . . . . . . . . . . . . . . .

Bleeding Brake Hydraulic System 5C±70. . . . . . . .

Flushing Brake Hydraulic System 5C±71. . . . . . . .

Brake Pipes and Hoses 5C±71. . . . . . . . . . . . . . . .

Brake Hose Inspection 5C±71. . . . . . . . . . . . . . . . .

Front Caliper Brake Hose 5C±72. . . . . . . . . . . . . . . .

Front Caliper Brake Hose and Associated

Parts 5C±72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 5C±72. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5C±72. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Axle Brake Hose 5C±73. . . . . . . . . . . . . . . . . . .

Rear Axle Brake Hose and Associated

Parts 5C±73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 5C±73. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5C±73. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Pipe 5C±74. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 5C±74. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5C±74. . . . . . . . . . . . . . . . . . . . . . . . . . . .

P & B (Proportioning and Bypass) Valve 5C±75. . . .

Removal 5C±75. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5C±75. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 5C±76. . . . . . . . . . . . .

Brake Pedal 5C±77. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Pedal Height 5C±77. . . . . . . . . . . . . . . . .

Checking Pedal Travel 5C±77. . . . . . . . . . . . . . . . .

Brake Pedal and Associated Parts 5C±78. . . . . . .

Removal 5C±78. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5C±78. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stoplight Switch 5C±79. . . . . . . . . . . . . . . . . . . . . . . . .

Parts Location 5C±79. . . . . . . . . . . . . . . . . . . . . . . .

Removal 5C±79. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5C±79. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 5C±80. . . . . . . . . . . . .

Master Cylinder Assembly 5C±81. . . . . . . . . . . . . . . .

Master Cylinder Assembly and Associated

Parts 5C±81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 5C±81. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 5C±81. . . . . . . . . . . . . . . . . . . . . . . . . . . . Master Cylinder Assembly 5C±82. . . . . . . . . . . . . . . .

Master Cylinder Assembly Desassembled

View 5C±82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Desassembly 5C±82. . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 5C±82. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 5C±83. . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5C±83. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 5C±84. . . . . . . . . . .

Vacuum Booster Assembly 5C±85. . . . . . . . . . . . . . .

Vacuum Booster Assembly and Associated

Parts 5C±85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 5C±85. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 5C±86. . . . . . . . . . . . . . . . . .

Exterior Components 5C±87. . . . . . . . . . . . . . . . . . . .

Exterior Components and Associated

Parts 5C±87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 5C±87. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 5C±88. . . . . . . . . . . . . . . . . .

Installation 5C±88. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vacuum Booster Overhaul 5C±88. . . . . . . . . . . . . . . .

Vacuum Booster 5C±88. . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 5C±89. . . . . . . . . . . . .

Front Disc Brake Pads 5C±90. . . . . . . . . . . . . . . . . . .

Front Disc Brake Pads Inspection 5C±90. . . . . . . .

Front Disc Brake Pads and Associated

Parts 5C±90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 5C±91. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5C±91. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Disc Brake Rotor 5C±93. . . . . . . . . . . . . . . . . . .

Inspection 5C±93. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing Brake Rotors 5C±93. . . . . . . . . . . . . . . .

Refinishing Brake Rotors 5C±93. . . . . . . . . . . . . . .

Front Disc Brake Caliper Assembly 5C±95. . . . . . . .

Front Disc Brake Caliper Assembly and

Associated Parts 5C±95. . . . . . . . . . . . . . . . . . . . . .

Removal 5C±95. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5C±96. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Disc Brake Caliper 5C±98. . . . . . . . . . . . . . . . .

Front Disc Brake Caliper Disassembled

View 5C±98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 5C±98. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 5C±99. . . . . . . . . . . . . . . . . .

Reassembly 5C±99. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 5C±100. . . . . . . . . . .

Rear Disc Brake Pads (4y4 Model) 5C±101. . . . . . . .

Page 748 of 2100

5C±68

POWER±ASSISTED BRAKE SYSTEM

Condition CorrectionPossible cause

Brake DragMaster cylinder pistons not returning

correctly.Adjust the stop light switch and

vacuum booster push rod. If

necessary, rebuild.

Restricted brake pipes or hoses.Check for soft hoses or damaged

pipes, and replace with new hoses

and new double±walled steel brake

piping.

Parking brake maladjusted.Adjust

Parking brake lining clearance

insufficient.Adjust

Brake pedal free play insufficient.Adjust the brake pedal height or

power cylinder operating rod.

Piston in the master cylinder sticking.Replace

Piston in the disc brake caliper

sticking.Replace piston seals.

Brake pads sticking in caliper.Clean

Return spring weakened.Replace

Parking brake binding.Overhaul the parking brakes and

correct.

Front hub bearing preload incorrect.Adjust or replace.

Parking brake shoes not returning.Correct or replace the brake back

plate and brake shoe as necessary.

Obstructions in hydraulic circuit.Clean

Rotor warped excessively.Grind or replace.

Rear brake drum distorted.Grind or replace.

Parking cable sticking.Grind or replace.

Grabbing or Uneven Braking Action

(All conditions listed under ªPullsº)Malfunctioning vacuum booster.Check operation and correct as

necessary.

Binding brake pedal mechanism.Check and lubricate, if necessary.

Corroded caliper assembly.Clean and lubricate.

Brake NoisyBrake pads are worn.Replace

Brake pads are hardened.Replace

Brake pads are in poor contact with

rotor.Correct

Brake disc(s) warped, worn or

damaged.Grind or replace.

Disc brake anti±squeak shims

fatigued.Replace

Front hub bearings are loose or

preload is incorrect.Adjust or replace.

Brake disc is rusted.Grind or replace.

Page 757 of 2100

5C±77 POWER±ASSISTED BRAKE SYSTEM

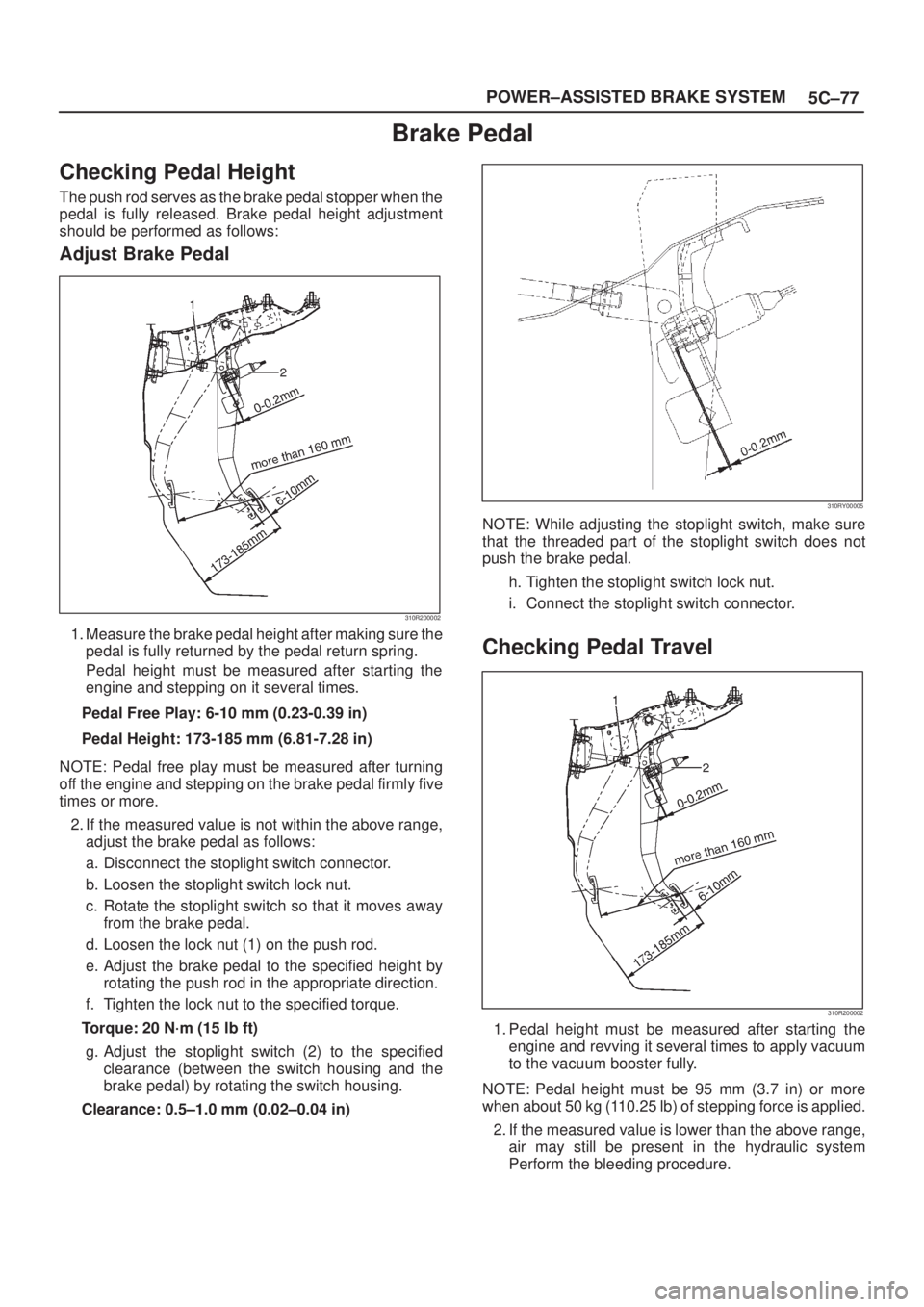

Brake Pedal

Checking Pedal Height

The push rod serves as the brake pedal stopper when the

pedal is fully released. Brake pedal height adjustment

should be performed as follows:

Adjust Brake Pedal

310R200002

1. Measure the brake pedal height after making sure the

pedal is fully returned by the pedal return spring.

Pedal height must be measured after starting the

engine and stepping on it several times.

Pedal Free Play: 6-10 mm (0.23-0.39 in)

Pedal Height: 173-185 mm (6.81-7.28 in)

NOTE: Pedal free play must be measured after turning

off the engine and stepping on the brake pedal firmly five

times or more.

2. If the measured value is not within the above range,

adjust the brake pedal as follows:

a. Disconnect the stoplight switch connector.

b. Loosen the stoplight switch lock nut.

c. Rotate the stoplight switch so that it moves away

from the brake pedal.

d. Loosen the lock nut (1) on the push rod.

e. Adjust the brake pedal to the specified height by

rotating the push rod in the appropriate direction.

f. Tighten the lock nut to the specified torque.

Torque: 20 N´m (15 lb ft)

g. Adjust the stoplight switch (2) to the specified

clearance (between the switch housing and the

brake pedal) by rotating the switch housing.

Clearance: 0.5±1.0 mm (0.02±0.04 in)

310RY00005

NOTE: While adjusting the stoplight switch, make sure

that the threaded part of the stoplight switch does not

push the brake pedal.

h. Tighten the stoplight switch lock nut.

i. Connect the stoplight switch connector.

Checking Pedal Travel

310R200002

1. Pedal height must be measured after starting the

engine and revving it several times to apply vacuum

to the vacuum booster fully.

NOTE: Pedal height must be 95 mm (3.7 in) or more

when about 50 kg (110.25 lb) of stepping force is applied.

2. If the measured value is lower than the above range,

air may still be present in the hydraulic system

Perform the bleeding procedure.