power steering ISUZU AXIOM 2002 Service Workshop Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2002, Model line: AXIOM, Model: ISUZU AXIOM 2002Pages: 2100, PDF Size: 19.35 MB

Page 193 of 2100

2A±42

POWER±ASSISTED STEERING SYSTEM

WARNING: T H E I N F L AT O R M O D U L E S H O U L D

ALWAYS BE CARRIED WITH THE TRIM COVER

AWAY FROM YOUR BODY AND SHOULD ALWAYS

BE LAID ON A FLAT SURFACE WITH THE

URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE FREE SPACE IS PROVIDED TO ALLOW

THE AIR CUSHION TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT.

OTHERWISE, PERSONAL INJURY MAY RESULT.

827RW072

11. Remove steering column cover.

12. Disconnect the wiring harness connectors located

under the steering column.

13. Remove the combination switch assembly with SRS

coil.

825RW288

14. Remove snap ring.

15. Remove cushion rubber.

16. Remove shift lock cable (for A/T).

17. Disconnect the starter switch harness connector

located under the steering column then remove lock

cylinder assembly.

Installation

1. Install lock cylinder assembly.

2. Install shift lock cable (for A/T).

3. Install cushion rubber.

4. Install snap ring.

5. Install Combination switch and SRS coil assembly.

After installation of combination switch assembly,

connect the combination switch wiring harness

connector and the SRS 2-way connector located

under the steering column.

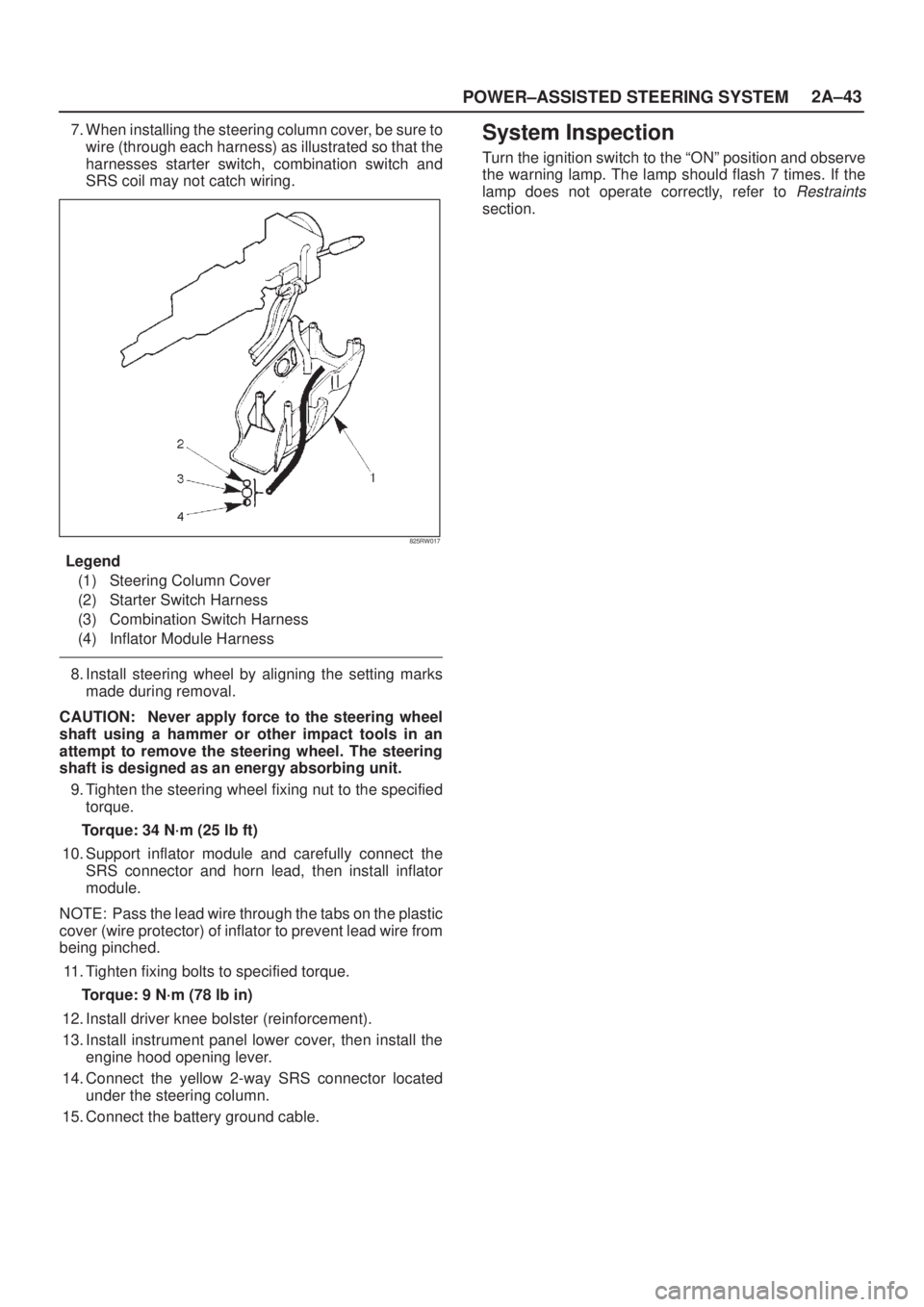

6. Turn the SRS coil counter clockwise to full, return

about 3 turns and align the neutral mark.

CAUTION: Turn the SRS coil counter clockwise

until some resistance is felt, or damage may occur to

the SRS coil.

825RW016

Page 194 of 2100

POWER±ASSISTED STEERING SYSTEM2A±43

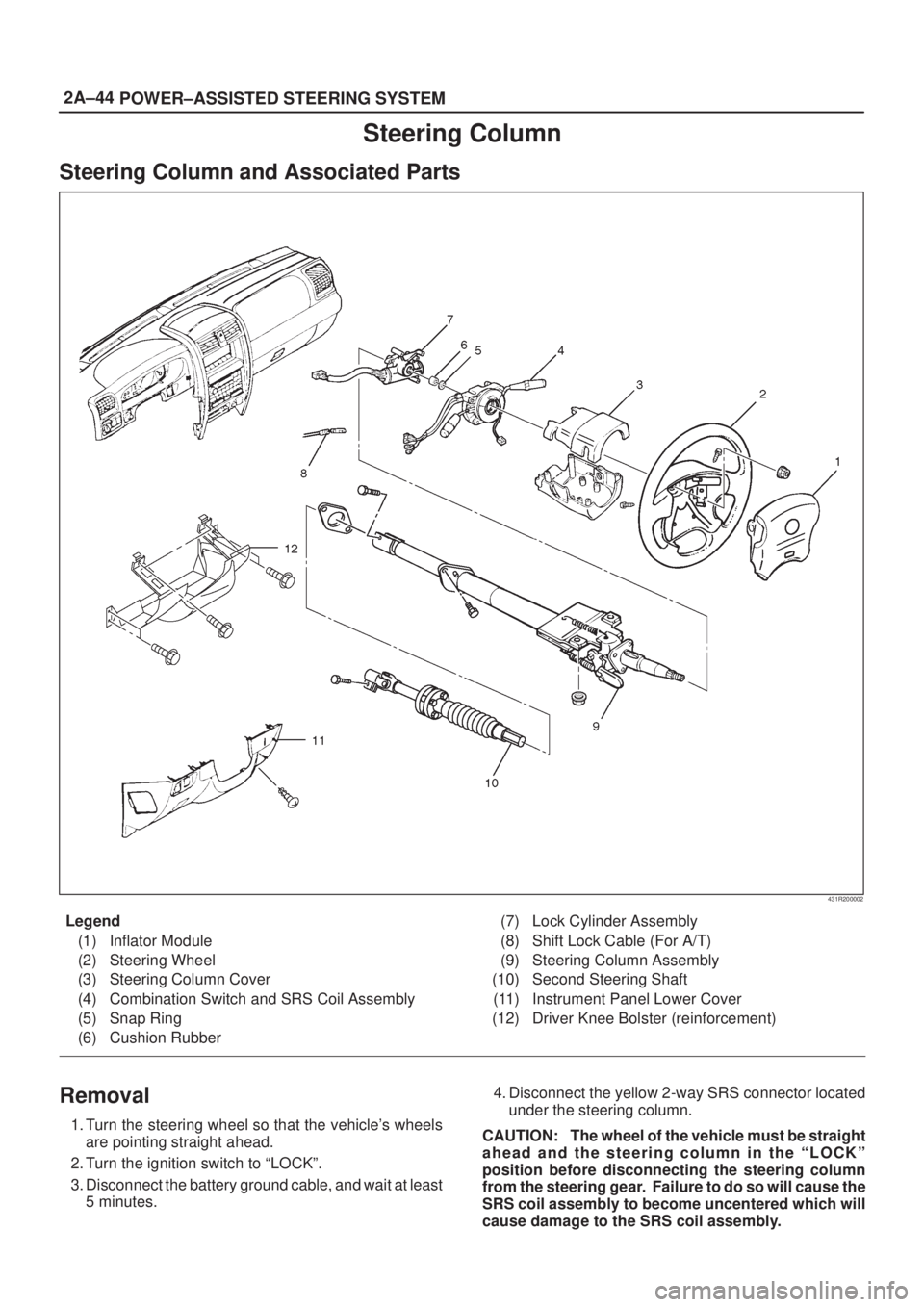

7. When installing the steering column cover, be sure to

wire (through each harness) as illustrated so that the

harnesses starter switch, combination switch and

SRS coil may not catch wiring.

825RW017

Legend

(1) Steering Column Cover

(2) Starter Switch Harness

(3) Combination Switch Harness

(4) Inflator Module Harness

8. Install steering wheel by aligning the setting marks

made during removal.

CAUTION: Never apply force to the steering wheel

shaft using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering

shaft is designed as an energy absorbing unit.

9. Tighten the steering wheel fixing nut to the specified

torque.

Torque: 34 N´m (25 lb ft)

10. Support inflator module and carefully connect the

SRS connector and horn lead, then install inflator

module.

NOTE: Pass the lead wire through the tabs on the plastic

cover (wire protector) of inflator to prevent lead wire from

being pinched.

11. Tighten fixing bolts to specified torque.

Torque: 9 N´m (78 lb in)

12. Install driver knee bolster (reinforcement).

13. Install instrument panel lower cover, then install the

engine hood opening lever.

14. Connect the yellow 2-way SRS connector located

under the steering column.

15. Connect the battery ground cable.

System Inspection

Turn the ignition switch to the ªONº position and observe

the warning lamp. The lamp should flash 7 times. If the

lamp does not operate correctly, refer to

Restraints

section.

Page 195 of 2100

2A±44

POWER±ASSISTED STEERING SYSTEM

Steering Column

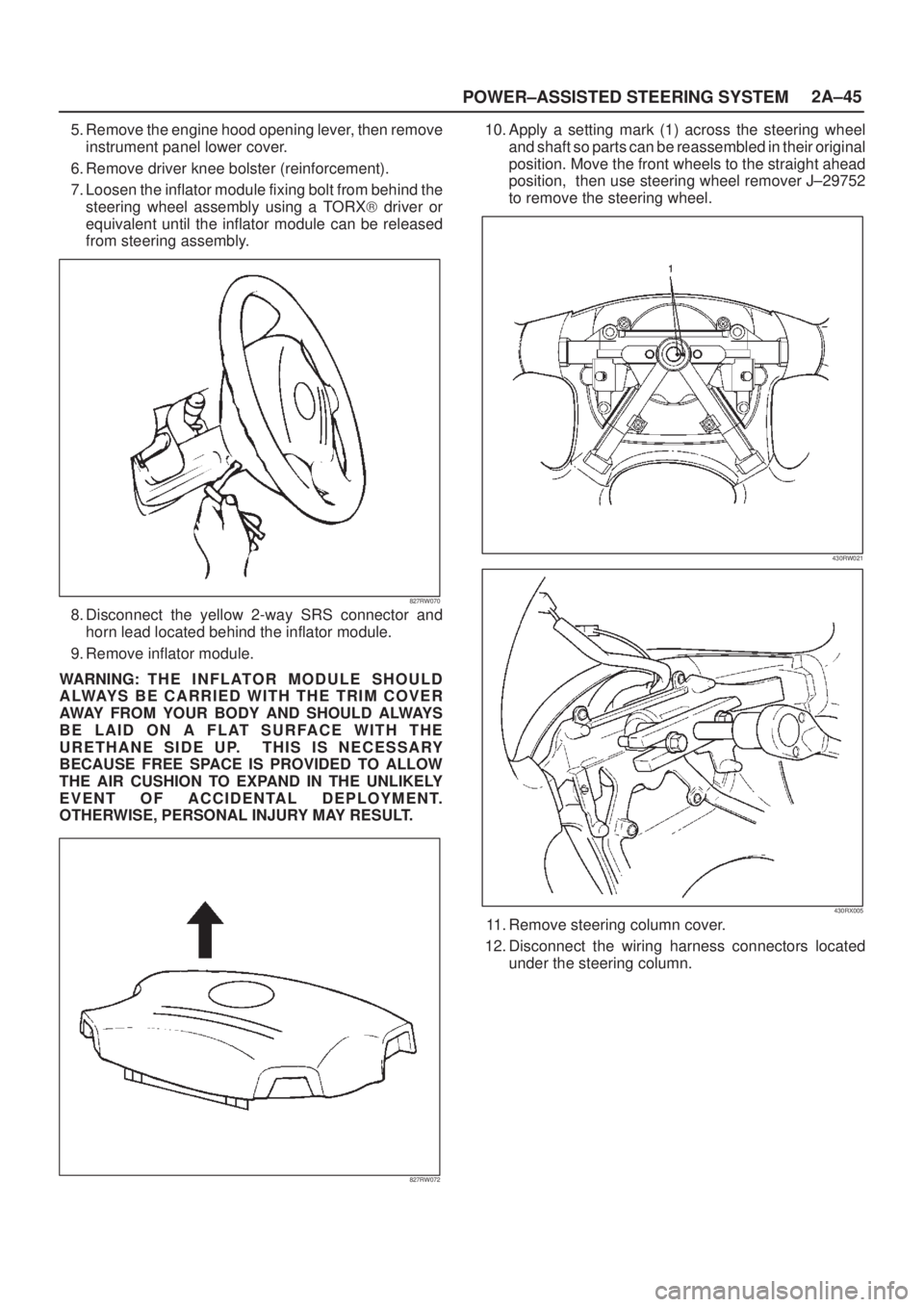

Steering Column and Associated Parts

431R200002

Legend

(1) Inflator Module

(2) Steering Wheel

(3) Steering Column Cover

(4) Combination Switch and SRS Coil Assembly

(5) Snap Ring

(6) Cushion Rubber(7) Lock Cylinder Assembly

(8) Shift Lock Cable (For A/T)

(9) Steering Column Assembly

(10) Second Steering Shaft

(11) Instrument Panel Lower Cover

(12) Driver Knee Bolster (reinforcement)

Removal

1. Turn the steering wheel so that the vehicle's wheels

are pointing straight ahead.

2. Turn the ignition switch to ªLOCKº.

3. Disconnect the battery ground cable, and wait at least

5 minutes.4. Disconnect the yellow 2-way SRS connector located

under the steering column.

CAUTION: The wheel of the vehicle must be straight

ahead and the steering column in the ªLOCKº

position before disconnecting the steering column

from the steering gear. Failure to do so will cause the

SRS coil assembly to become uncentered which will

cause damage to the SRS coil assembly.

Page 196 of 2100

POWER±ASSISTED STEERING SYSTEM2A±45

5. Remove the engine hood opening lever, then remove

instrument panel lower cover.

6. Remove driver knee bolster (reinforcement).

7. Loosen the inflator module fixing bolt from behind the

steering wheel assembly using a TORX) driver or

equivalent until the inflator module can be released

from steering assembly.

827RW070

8. Disconnect the yellow 2-way SRS connector and

horn lead located behind the inflator module.

9. Remove inflator module.

WARNING: T H E I N F L AT O R M O D U L E S H O U L D

ALWAYS BE CARRIED WITH THE TRIM COVER

AWAY FROM YOUR BODY AND SHOULD ALWAYS

BE LAID ON A FLAT SURFACE WITH THE

URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE FREE SPACE IS PROVIDED TO ALLOW

THE AIR CUSHION TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT.

OTHERWISE, PERSONAL INJURY MAY RESULT.

827RW072

10. Apply a setting mark (1) across the steering wheel

and shaft so parts can be reassembled in their original

position. Move the front wheels to the straight ahead

position, then use steering wheel remover J±29752

to remove the steering wheel.

430RW021

430RX005

11. Remove steering column cover.

12. Disconnect the wiring harness connectors located

under the steering column.

Page 197 of 2100

2A±46

POWER±ASSISTED STEERING SYSTEM

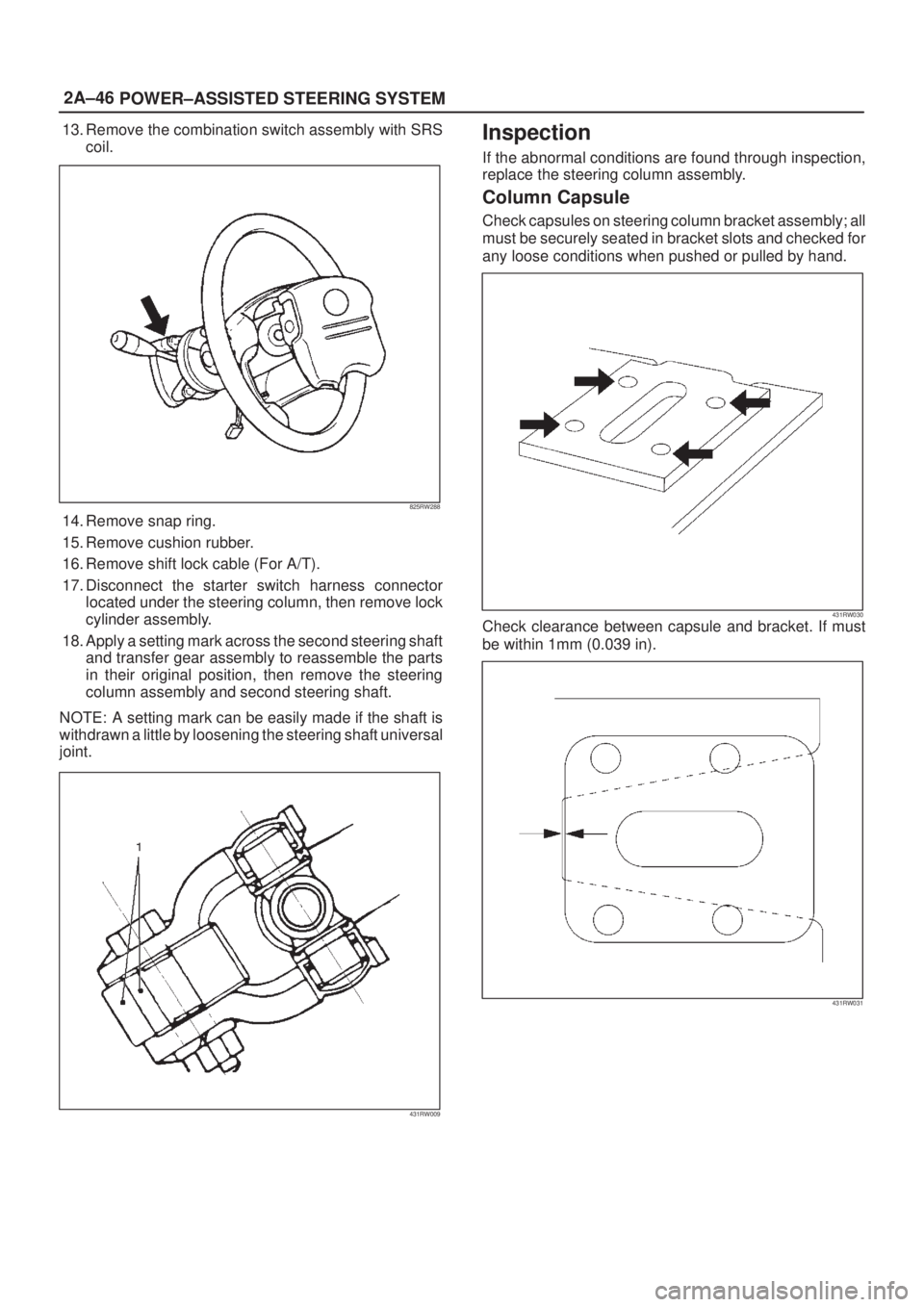

13. Remove the combination switch assembly with SRS

coil.

825RW288

14. Remove snap ring.

15. Remove cushion rubber.

16. Remove shift lock cable (For A/T).

17. Disconnect the starter switch harness connector

located under the steering column, then remove lock

cylinder assembly.

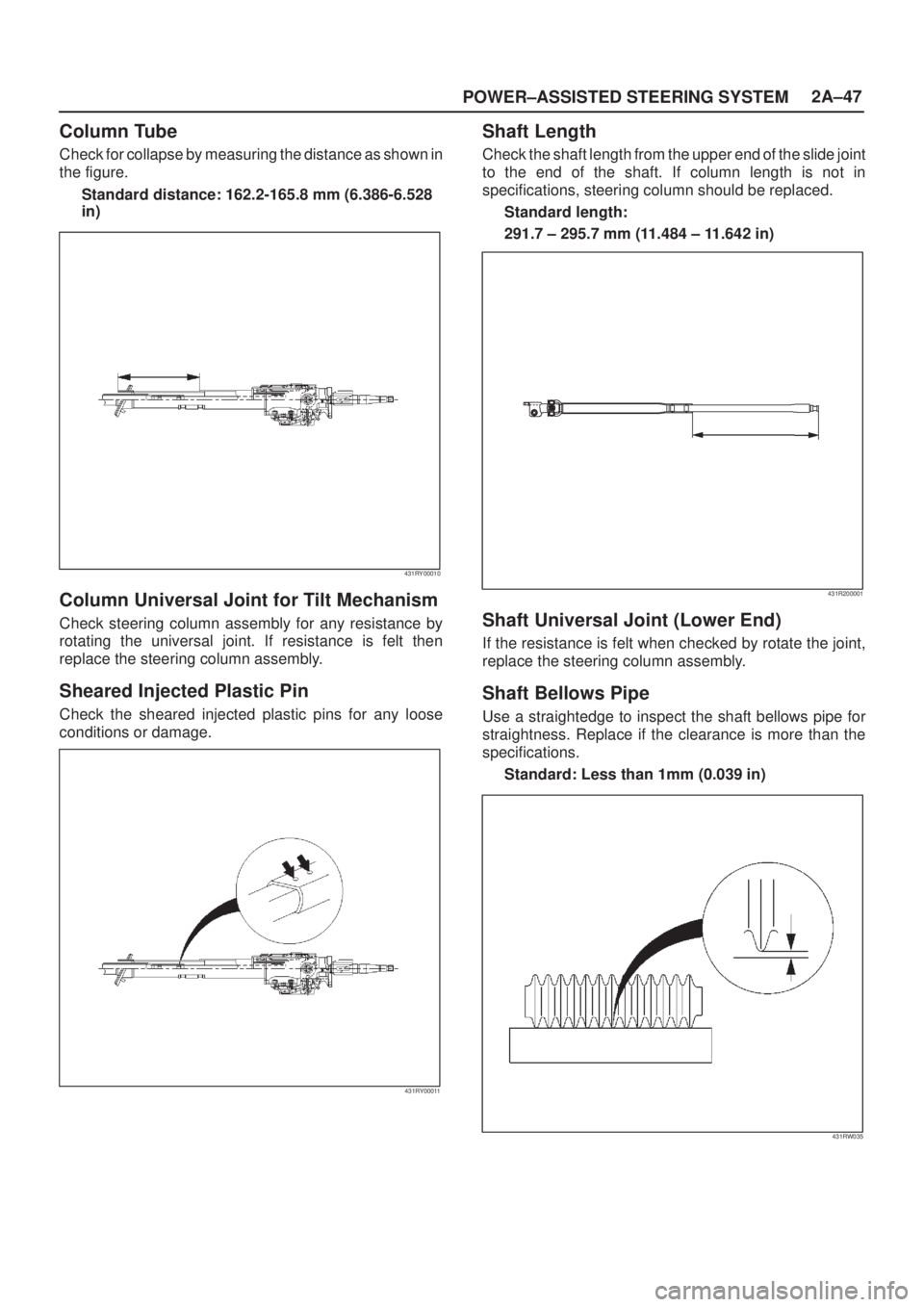

18. Apply a setting mark across the second steering shaft

and transfer gear assembly to reassemble the parts

in their original position, then remove the steering

column assembly and second steering shaft.

NOTE: A setting mark can be easily made if the shaft is

withdrawn a little by loosening the steering shaft universal

joint.

431RW009

Inspection

If the abnormal conditions are found through inspection,

replace the steering column assembly.

Column Capsule

Check capsules on steering column bracket assembly; all

must be securely seated in bracket slots and checked for

any loose conditions when pushed or pulled by hand.

431RW030Check clearance between capsule and bracket. If must

be within 1mm (0.039 in).

431RW031

Page 198 of 2100

POWER±ASSISTED STEERING SYSTEM2A±47

Column Tube

Check for collapse by measuring the distance as shown in

the figure.

Standard distance: 162.2-165.8 mm (6.386-6.528

in)

431RY00010

Column Universal Joint for Tilt Mechanism

Check steering column assembly for any resistance by

rotating the universal joint. If resistance is felt then

replace the steering column assembly.

Sheared Injected Plastic Pin

Check the sheared injected plastic pins for any loose

conditions or damage.

431RY00011

Shaft Length

Check the shaft length from the upper end of the slide joint

to the end of the shaft. If column length is not in

specifications, steering column should be replaced.

Standard length:

291.7 ± 295.7 mm (11.484 ± 11.642 in)

431R200001

Shaft Universal Joint (Lower End)

If the resistance is felt when checked by rotate the joint,

replace the steering column assembly.

Shaft Bellows Pipe

Use a straightedge to inspect the shaft bellows pipe for

straightness. Replace if the clearance is more than the

specifications.

Standard: Less than 1mm (0.039 in)

431RW035

Page 199 of 2100

2A±48

POWER±ASSISTED STEERING SYSTEM

Tilt Mechanism

Tilt mechanism should moves smoothly.

While locked the tilt mechanism, be sure the steering

column latch securely by pushing the steering wheel

upward and downward.

Installation

1. Pass through the steering column assembly to the

dash panel hole.

Temporary tightening the steering column bolt(cross

beam).

2. Tighten the steering column bolts(dash panel) to the

specified torque.

Torque: 20 N´m (14 lb ft)

3. Tighten the steering column nuts (cross beam) to the

specified torque.

Torque: 17 N´m (12 lb ft)

4. Install the universal joint assembly to the transfer

gear assembly align the setting marks made at

removal.

Then tighten the universal joint bolt.

Torque: 31 N´m (23 lb ft)

5. Install the second steering shaft to the universal joint

assembly, then tighten the universal joint bolt to the

specified torque.

Torque: 31 N´m (23 lb ft)

6. Install lock cylinder assembly.

7. Install shift lock cable (For A/T).

8. Install cushion rubber.

9. Install snap ring.

10. Install combination switch and SRS coil assembly.

After installation of combination switch assembly,

connect the combination switch wiring harness

connector and the SRS 2-way connector located

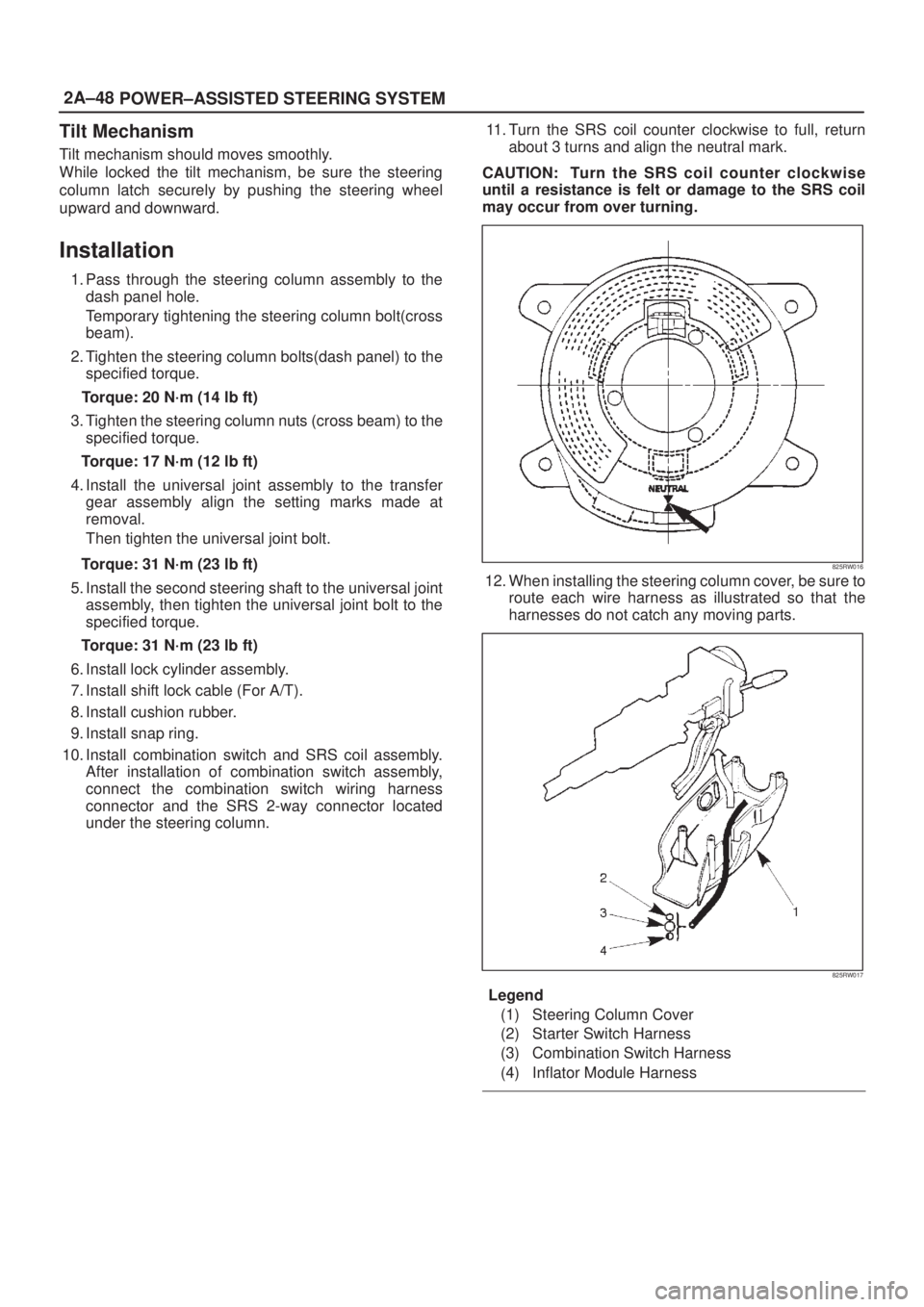

under the steering column.11. Turn the SRS coil counter clockwise to full, return

about 3 turns and align the neutral mark.

CAUTION: Turn the SRS coil counter clockwise

until a resistance is felt or damage to the SRS coil

may occur from over turning.

825RW016

12. When installing the steering column cover, be sure to

route each wire harness as illustrated so that the

harnesses do not catch any moving parts.

825RW017

Legend

(1) Steering Column Cover

(2) Starter Switch Harness

(3) Combination Switch Harness

(4) Inflator Module Harness

Page 200 of 2100

POWER±ASSISTED STEERING SYSTEM2A±49

13. Install steering wheel and align the setting marks

made when removing.

CAUTION: Never apply force to the steering wheel

shaft using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering

shaft is designed as an energy absorbing unit.

14. Tighten the steering wheel fixing nut to the specified

torque.

Torque: 34 N´m (25 lb ft)

15. Support the module and carefully connect the module

connector and horn lead, then install inflator module.

NOTE: Pass the lead wire through the tabs on the plastic

cover (wire protector) of inflator to prevent lead wire from

being pinched.

16. Tighten bolts to specified torque.

Torque: 9 N´m (78 lb in)

17. Install driver knee bolster (reinforcement).

18. Install instrument panel lower cover.

19. Install the engine hood opening lever.

20. Connect the yellow 2-way SRS connector and horn

lead located under the steering column.

21. Connect the battery ground cable.

System Inspection

Turn the ignition switch ªONº and observe if the warning

lamp flashes 7 times. If the warning lamp does not

operate correctly, refer to

Restraints section.

Page 201 of 2100

2A±50

POWER±ASSISTED STEERING SYSTEM

Supplemental Restraint System Steering Wheel & Column and

Associated Parts

Main Data and Specifications

Torque Specifications

430RY00002

Special Tools

ILLUSTRATIONTOOL NO.

TOOL NAME

J±29752

Steering wheel remover

Page 203 of 2100

3C±2FRONT SUSPENSION

General Description

The front suspension is designed to allow each wheel to

compensate for changes in the road surface level without

greatly affecting the opposite wheel. Each wheel is

independently connected to the frame by a steering

knuckle, ball joint assemblies, and upper and lower

control arms. The front wheels are held in proper

relationship to each other by two tie-rods which are

connected to steering arms on the knuckles, and to a

steering unit.

All models have a front suspension system consisting of

control arms, stabilizer bar, shock absorber and a torsion

bar. The front end of the torsion bar is attached to the

lower control arm. The rear of the torsion bar is mounted

into a height control arm at the crossmember. Vehicle trim

height is controlled by adjusting this arm.

Shock absorbers are mounted between the brackets on

the frame and the lower control arms. The lower portion ofeach shock absorber is attached to the lower control arm.

The upper portion of each shock absorber extends

through a frame bracket and is secured with two rubber

bushings, two retainers and a nut.

Ball joint assemblies are bolted to the outer end of the

upper and lower control arm and are attached to the

steering knuckle.

The inner ends of the upper control arm have pressed in

bushings. Bolts, passing through the bushing, attach the

control arm to the frame. The inner ends of the lower

control arm are attached to the frame by bolts passing

through the bushings.

Side roll of the front suspension is controlled by a spring

steel stabilizer bar. It is mounted in rubber bushings,

which are held to the frame by brackets. The ends of the

stabilizer bar are connected to the lower control arms by

links.

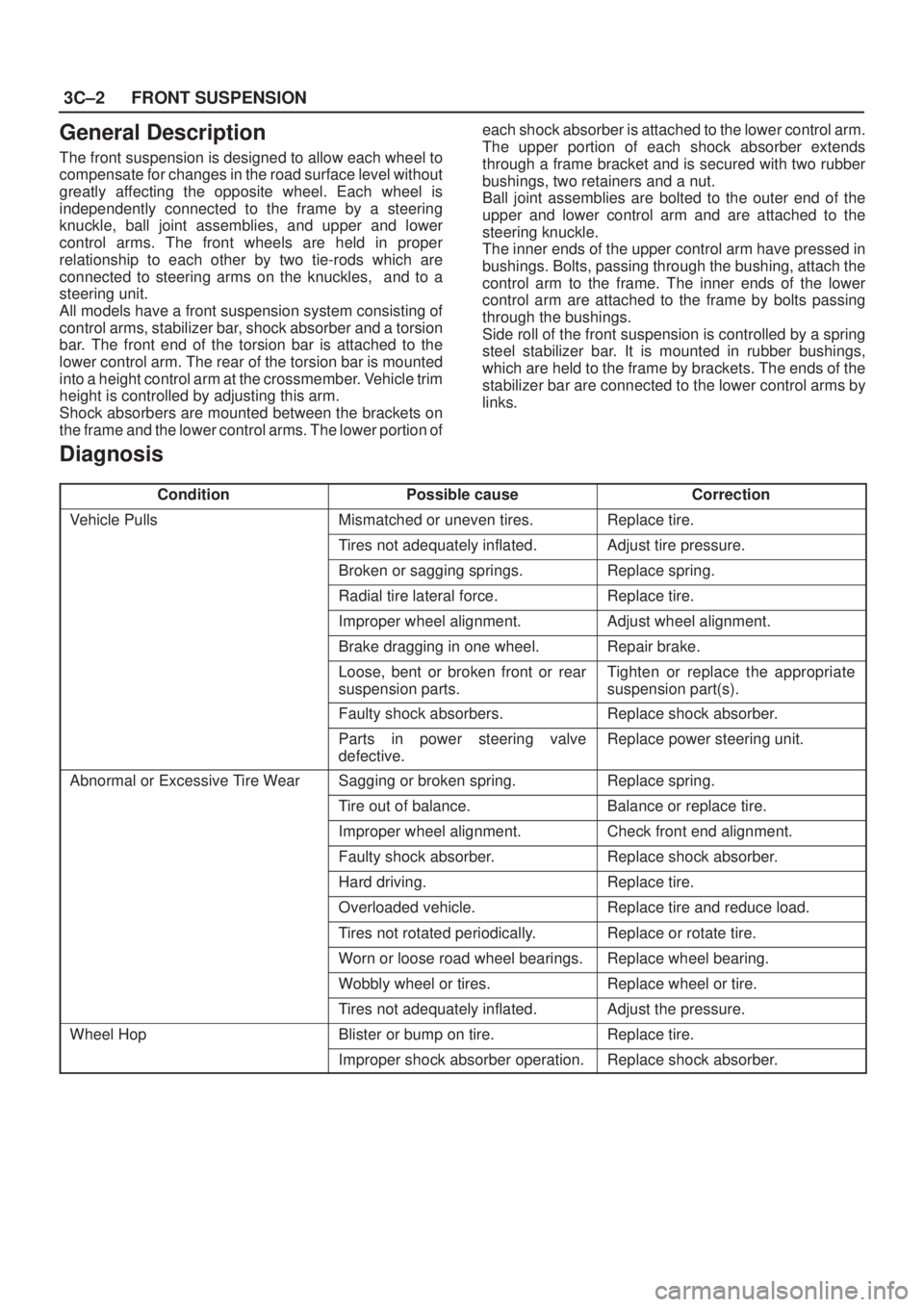

Diagnosis

ConditionPossible causeCorrection

Vehicle PullsMismatched or uneven tires.Replace tire.

Tires not adequately inflated.Adjust tire pressure.

Broken or sagging springs.Replace spring.

Radial tire lateral force.Replace tire.

Improper wheel alignment.Adjust wheel alignment.

Brake dragging in one wheel.Repair brake.

Loose, bent or broken front or rear

suspension parts.Tighten or replace the appropriate

suspension part(s).

Faulty shock absorbers.Replace shock absorber.

Parts in power steering valve

defective.Replace power steering unit.

Abnormal or Excessive Tire WearSagging or broken spring.Replace spring.

Tire out of balance.Balance or replace tire.

Improper wheel alignment.Check front end alignment.

Faulty shock absorber.Replace shock absorber.

Hard driving.Replace tire.

Overloaded vehicle.Replace tire and reduce load.

Tires not rotated periodically.Replace or rotate tire.

Worn or loose road wheel bearings.Replace wheel bearing.

Wobbly wheel or tires.Replace wheel or tire.

Tires not adequately inflated.Adjust the pressure.

Wheel HopBlister or bump on tire.Replace tire.

Improper shock absorber operation.Replace shock absorber.