change time ISUZU KB P190 2007 Workshop Owners Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4920 of 6020

7D1-46 TRANSFER CONTROL SYSTEM

Diagnosis

Before determining a trouble (Non-trouble mode)

1. When shifting from 2H to 4H:

1-1-1 When the flashing frequency of the 4WD indicator is changed from 2Hz to 4Hz (Shift on the fly) If the load is too large to shift the gears synchronously, the operation is repeated up to 3 times. If the shifting

is not effected after being repeated 3 times, the indicator frequency is changed from 2Hz to 4Hz. At the same

time, the actuator condition is changed to 2H, indicator flashes at 4Hz for 10 seconds, and then goes out.

Cause of excessive synchronous shifting load

• Extremely low temperature (the oil viscosity of the front differential increases requiring a large load for

synchronization).

• High speed (since the difference of relative revolutions of gears to be shifted synchronously is too large,

required work load per unit time becomes larger).

Step 1-1-1:

Stop the vehicle or decrease the speed and operate as required again.

1-1-2 When the flashing frequency of the 4WD indicator is changed from 2Hz to 4Hz (Rigid and free wheel

Hub) / Block out of meshing spline in transfer case.

Step 1-1-2:

Run the vehicle forward and backward several meters and operate as required again.

1-2 When the flashing of 4WD indicator at 2Hz continues more than 11.5 seconds (repetition of 3 times of

above No.1 is counted) (Shift on the fly)

If there is difference of revolutions and phases between the front wheel and the axle, connecting the front

wheel and axle is difficult.

Until shifting in the transfer and connection of the front wheel and axle are completed

∗, the indicator flashes at

a frequency of 2Hz. In the above case, the indicator continues flashing at a frequency of 2Hz until the

connection of the front axle is completed. (If the shifting in the transfer is not completed, the flashing

frequency is changed to 4Hz (above No.1).)

By correcting the difference of relative revolutions and deviation of phases, the shifting can be completed.

Step 1-2:

While the vehicle is running, check it is safe around the vehicle and then accelerate or decelerate the

vehicle while going straight.

When the vehicle is at a stop, run the vehicle forward and backward several meters.

2. When shifting from 4H to 2H

2-1 When 4WD indicator continues flashing at 2Hz

W hen shifting from 4H to 2H, the 4W D indicator continues flashing at 2Hz until separation in the transfer and

the separation of the front wheel axle are completed∗. W hen torsional torque is accumulated in the drive

system, separation in the transfer and separation of the front axle∗ is difficult. In such a case, they can be

separated by removing the torsional torque of the drive system.

Step 2-1:

While the vehicle is running, check it is safe around the vehicle and then accelerate or decelerate the

vehicle while going straight.

When the vehicle is in stop, run the vehicle several meters forward and backward.

∗: Shift on the fly only.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5300 of 6020

8A-362 ELECTRICAL-BODY AND CHASSIS

Tachometer Off-Vehicle Inspection

Remove the tachometer from the meter assembly and

measure the resistance value and the current consumption

between each terminal.

SELF DIAGNOSTIC FUNCTION

Check that the speedometer, tachometer, fuel gauge, and

temperature gauge operate properly.

821R300033

Entering the self-diagnostic mode

1. Push in and hold the “Change Indicator and Reset” knob.

2. Turn the ignition ON.

3. W hen the LCD odometer turns ON, release the “Change Indicator and Reset” knob.

4. Push in and release the “Change Indicator and Reset” knob three times in quick succession.

The meter cluster is now in “Self-diagnostic” mode.

NOTE: Steps 2-4 must be performed within 7 seconds.

The meter cluster will not enter “Self-diagnostic” mode if any of

the following conditions occur:

1. The “Change Indicator and Reset” knob is not depressed when the ignition is turned ON.

2. The “Change Indicator and Reset” knob is released within 600ms of turning the ignition ON.

3. The “Change Indicator and Reset” knob is not depressed and released three times within 7 seconds.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5649 of 6020

9A-14 SUPPLEMENTAL RESTRAINT SYSTEM

Component Description

SRS Control Unit

WARNING: DURING SERVICE PROCEDURES, BE

VERY CAREFUL WHEN HANDLING A SRS

CONTROL UNIT. NEVER STRIKE OR JAR THE SRS

CONTORL UNIT. NEVER POWER UP THE SRS

WHEN THE SRS CONTROL UNIT IS NOT RIGIDLY

ATTACHED TO THE VEHICLE. ALL SRS CONTROL

UNIT AND MOUNTING BRACKET FASTENERS

MUST BE CAREFULLY TORQUED AND THE

ARROW MUST BE POINTED TOWARD THE FRONT

OF THE VEHICLE TO ENSURE PROPER

OPERATION OF THE SRS. THE SRS CONTROL

UNIT COULD BE ACTIVATED WHEN POWERED

WHILE NOT RIGIDLY ATTACHED TO THE

VEHICLE WHICH COULD CAUSE DEPLOYMENT

AND RESULT IN PERSONAL INJURY.

The SRS control unit is designed to perform the

following functions in the SRS:

1. Energy Reserve — The SRS control unit maintains 30–Volt Loop Reserve (30VLR) energy supply to

provide deployment energy when ignition voltage is

lost in a frontal crash.

2. Frontal Crash Detection — The SRS control unit monitors vehicle velocity changes to detect frontal

crashes which are severe enough to warrant

deployment.

3. Air Bag Deployment — W hen a frontal crash o

f

sufficient force is detected, the SRS control unit

will cause enough current to flow through the ai

r

bag assembly to deploy the air bag.

4. Malfunction Detection — The SRS control unit performs diagnostic monitoring of SRS electrical

components and sets a diagnostic trouble code

when a malfunction is detected.

5. Frontal Crash Recording — The SRS control unit records information regarding SRS status during

frontal crash.

6. Malfunction Diagnosis — The SRS control unit displays SRS diagnostic trouble codes and system

status information through the use of a scan tool.

7. Driver Notification — The SRS control unit warns the vehicle driver of SRS malfunctions b

y

controlling the “SRS” warning lamp.

The SRS control unit is connected to the SRS wiring

harness by a 52–pin connector. This harness

connector uses a shorting clip across certain terminals

in the contact area. This shorting clip connects the

“SRS” warning lamp to ground when the SRS control

unit harness connector is disconnected or CP

A

(Connector Position Assurance) is not inserted even i

f

completely connected. This will cause the “SRS”

warning lamp to come “ON” steady whenever the

ignition switch is at the ON or START positions with

the SRS control unit disconnected.

RTW 79ASH000401

Legend

(1) SRS Control Unit

(2) SRS Harness

“SRS” Warning Lamp

Ignition voltage is applied to the “SRS” warning lamp

when the ignition switch is at the ON or START

positions. The SRS control unit controls the lamp b

y

providing ground with a lamp driver. The “SRS”

warning lamp is used in the SRS to do the following:

1. Verify lamp and SRS control unit operation b

y

flashing SEVEN (7) times when the ignition switch

is first turned “ON”.

2. W arn the vehicle driver of SRS electrical system malfunctions which could potentially affect the

operation of the SRS. These malfunctions could

result in nondeployment in case of a frontal crash

or deployment for conditions less severe than

intended.

The “SRS “ warning lamp is the key to drive

r

notification of SRS malfunctions. For proper lamp

operation, refer to the “SRS Diagnostic System Check”

in this section.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5887 of 6020

11A-36 IMMOBILIZER CONTROL SYSTEM (4JK1/4JJ1/HFV6)

Resetting and Programming

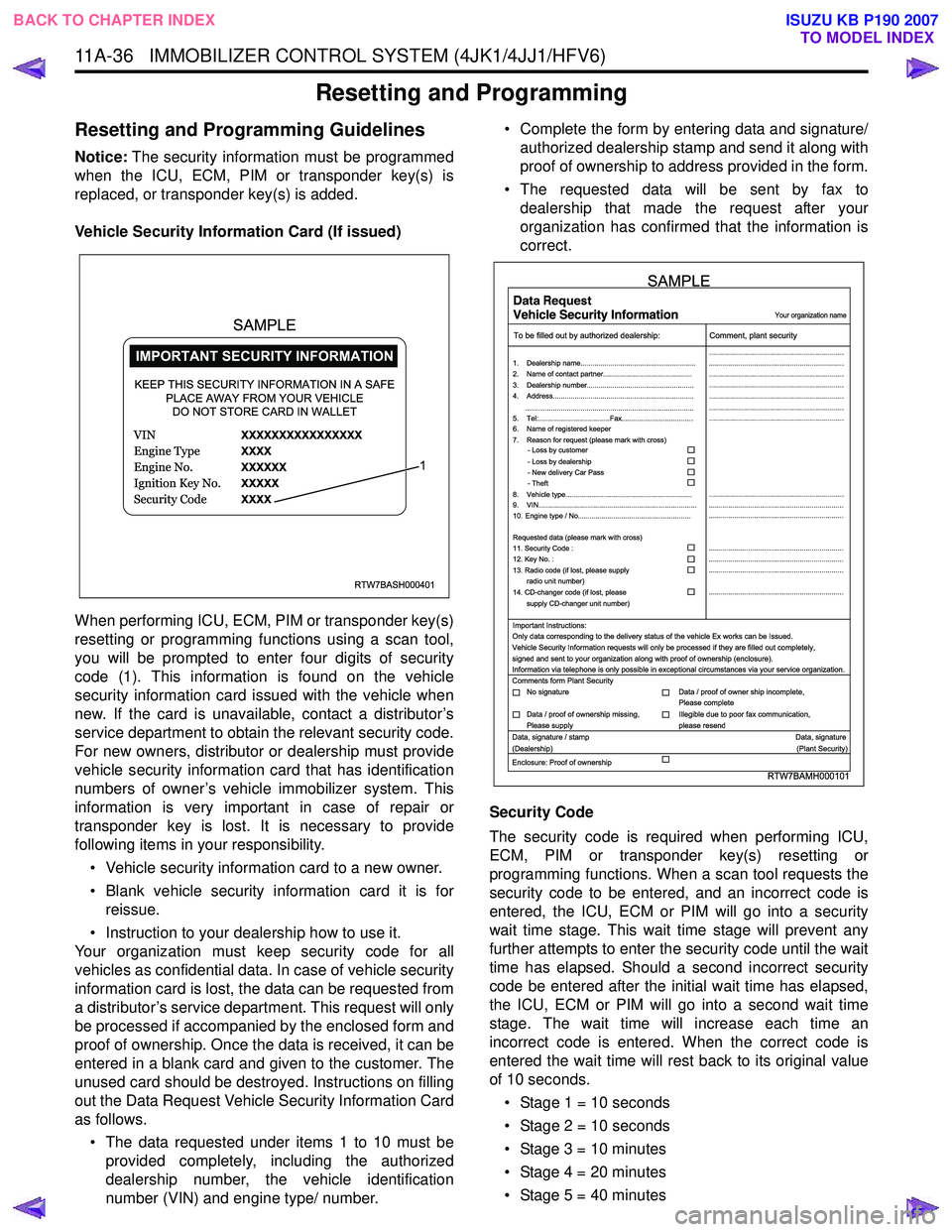

Resetting and Programming Guidelines

Notice:The security information must be programmed

when the ICU, ECM, PIM or transponder key(s) is

replaced, or transponder key(s) is added.

Vehicle Security Information Card (If issued)

When performing ICU, ECM, PIM or transponder key(s)

resetting or programming functions using a scan tool,

you will be prompted to enter four digits of security

code (1). This information is found on the vehicle

security information card issued with the vehicle when

new. If the card is unavailable, contact a distributor’s

service department to obtain the relevant security code.

For new owners, distributor or dealership must provide

vehicle security information card that has identification

numbers of owner’s vehicle immobilizer system. This

information is very important in case of repair or

transponder key is lost. It is necessary to provide

following items in your responsibility.

• Vehicle security information card to a new owner.

• Blank vehicle security information card it is for reissue.

• Instruction to your dealership how to use it.

Your organization must keep security code for all

vehicles as confidential data. In case of vehicle security

information card is lost, the data can be requested from

a distributor’s service department. This request will only

be processed if accompanied by the enclosed form and

proof of ownership. Once the data is received, it can be

entered in a blank card and given to the customer. The

unused card should be destroyed. Instructions on filling

out the Data Request Vehicle Security Information Card

as follows.

• The data requested under items 1 to 10 must be provided completely, including the authorized

dealership number, the vehicle identification

number (VIN) and engine type/ number. • Complete the form by entering data and signature/

authorized dealership stamp and send it along with

proof of ownership to address provided in the form.

• The requested data will be sent by fax to dealership that made the request after your

organization has confirmed that the information is

correct.

Security Code

The security code is required when performing ICU,

ECM, PIM or transponder key(s) resetting or

programming functions. When a scan tool requests the

security code to be entered, and an incorrect code is

entered, the ICU, ECM or PIM will go into a security

wait time stage. This wait time stage will prevent any

further attempts to enter the security code until the wait

time has elapsed. Should a second incorrect security

code be entered after the initial wait time has elapsed,

the ICU, ECM or PIM will go into a second wait time

stage. The wait time will increase each time an

incorrect code is entered. When the correct code is

entered the wait time will rest back to its original value

of 10 seconds.

• Stage 1 = 10 seconds

• Stage 2 = 10 seconds

• Stage 3 = 10 minutes

• Stage 4 = 20 minutes

• Stage 5 = 40 minutes

RTW7BASH000401

KEEP THIS SECURITY INFORMATION IN A SAFE PLACE AWAY FROM YOUR VEHICLEDO NOT STORE CARD IN WALLET

1

SAMPLE

RTW7BAMH000101

Your organization name

To be filled out by authorized dealership: Comment, plant security

1. Dealership name.......................................................... ....................................................................

....................................................................

....................................................................

....................................................................

....................................................................

....................................................................

....................................................................

....................................................................

.................................................................... ....................................................................

....................................................................

....................................................................

....................................................................

....................................................................

2. Name of contact partner.............................................

6. Name of registered keeper

7. Reason for request (please mark with cross)

3. Dealership number......................................................

4. Address.......................................................................

8. Vehicle type................................................................

9. VIN................................................................................

10. Engine type / No.........................................................

11. Security Code :

12. Key No. :

13. Radio code (if lost, please supply radio unit number)

14. CD-changer code (if lost, please

supply CD-changer unit number)

Requested data (please mark with cross)

5. Tel:....................................Fax....................................

.....................................................................................

- Loss by customer

- Loss by dealership

- New delivery Car Pass

- Theft

Important Instructions:

Comments form Plant Security

Data, signature / stamp Data, signature

(Dealership) (Plant Security)

Enclosure: Proof of ownership Only data corresponding to the delivery status of the vehicle Ex works can be Issued.

Vehicle Security Information requests will only be processed if they are filled out completely,

signed and sent to your organization along with proof of ownership (enclosure).

Information via telephone is only possible in exceptional circumstances via your service organization.

No signature Data / proof of owner ship incomplete,

Please complete

Data / proof of ownership missing,

Please supply Illegible due to poor fax communication,

please resend

SAMPLE

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5915 of 6020

IMMOBILIZER SYSTEM (C24SE, 4JA1-T) 11A-17

lmportant information on Programming

Security code

The security code protects the immobilizer control unit

against unauthorized programming and data access

from Tech-2. The security code consists of a 4 digit

code number and is programmed into the immobilize

r

control unit and Engine Control Module (ECM).

New control units are not programmed with a securit

y

code.

If the control units are replaced, the security code

entered in the car pass, transponder lD, etc.

Must be programmed into the new control unit with

Tech-2.

The security code can only be programmed with Tech-2

once and must therefore be performed with great care.

Once programmed, the security code cannot be

overwritten. An already used immobilizer can be reused

in a different car by initializing the immobilizer. After that

you can program the security code again. For initializing

command you need the current security code.

If the immobilizer control unit is returned, always

enclosed the security code that is allocated to that

control unit. If this is not done, we can not process the

case and the warranty will not be recognized.

Entering a code

If the Tech-2 display requests that the

• security code

• mechanical key number

• Vehicle Identification No.

be entered, process as follows;

To input a digit you need to use the up and down

buttons of the Tech-2. By using the numeric buttons the

according digit will be displayed at the current position

and the cursor will move to the next position.

For letters you need to use the up and down buttons o

f

the Tech-2. The up and down key might be used for

digits as well. By using the up and down buttons the

displayed digit or letter will be increased or decreased.

To move to the next position you need to use the move-

to-right-button.

W ith the two buttons, move-to-right and move-to-left

you can select the position of number you want to

change.

This will allow you to correct a wrong number.

After the number is completed you need to press the

Enter button to accept the number. Correction is now no

longer possible.

Use the OKAY soft key to program the number and the

NOT OKAY soft key to abort the programming.

Transponder (Key)

•

••

•

If a transponder key is lost:

If a transponder key is lost, all transponder keys in the

immobilizer control system must be erased.

Transponder keys can be ordered via the "Your prope

r

organization name such as part and accessory

department" as previously by providing the mechanical

key number.

The mechanical key number is provided on the car pass

card.

Thereafter, existing and new transponder keys are

programmed consecutively using Tech-2. The vehicle

can then no longer be started using lost key.

•

••

•

5 transponder keys can be provided:

Each transponder has different Identifications. If a

customer wants more than 2 transponder keys,

maximum 5 transponder keys can be provided b

y

additional programming by Tech-2.

•

••

•

lf a new ignition key with different mechanical key

number needs to be installed:

If installation of an ignition lock with a different

mechanism key number is necessary (an ignition lock

which belongs to the mechanical key number has to be

ordered first), all transponder keys must first be erased

and the two transponder keys which belong to the

ignition lock that is now installed must be programmed.

The new mechanical key number must be programmed

now into the immobilizer. The mechanical key numbe

r

in the car pass is to be changed as well.

Important:

After successful programming, the engine control can

only be used for vehicles with immobilizer and

transponder.

Faults that occur in connection with the immobilize

r

control unit are recognized by the engine control unit

and as long as "IMMOBILOZER" is not programmed,

are indicated by a flashing of the check engine lamp.

If the immobilizer and engine control unit are replaced

at the same time, the immobilizer control unit must be

programmed first before the "IMMOBILIZER" function in

the engine control unit can be activated.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5919 of 6020

IMMOBILIZER SYSTEM (C24SE, 4JA1-T) 11A-21

•

••

•

CAUTION

060R200286

•

••

•

Erase

060R200285

4. See programming result on display.

Programming Immobilizer Function

Caution:

1) Do not replace ICU and ECM at the same time

2) Change ICU at first or ECM and other one

change follows.

1. Select "Body" and "immobilizer".

2. Select "Programming" on Tech-2 display.

3. Check the display, then press the "Confirm" key.

LTW 3BASH000401

4. Install the "Hardware Key" on PC.

5. Connect RS232 cable to the PC and Tech2.

6. Turn on the PC, then start software "TIS 2000".

7. Select "Security Access" in the TIS 2000 screen.

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5958 of 6020

11B-4 ANTITHEFT SYSTEM

Transmitter (into remote key) power

The transmitted power is less than 10 m W .

Battery life time for transmitter power

The minimum life time of battery is 2 years with 15

lock/unlock cycles per day.

W hile the battery is changed, the data retention will be

at least 3 minutes without pressing a button.

Super lock

(Mechanical anti-theft locking system)

To Lock:

All doors must be closed; press the lock button on the

remote control unit again within 10 seconds after

locking or turn key in driver's door lock towards rear of

vehicle again within 10 seconds after locking, then turn

it back to the vertical position and remove.

Lock buttons on all doors are positioned such that doors

cannot be opened.

To unlock:

Press unlock button on remote key or turn key in

driver's door lock towards front of vehicle, then turn it

back to the vertical position and remove. If the key is

used, antitheft alarm sound operate which continues

until ignition switch turn ON. If a problem is found, open

the driver door as necessary.

No proper transmitter is available, what

should be done for the system?

W hen any proper transmitter is not available, a new

transmitter should be programmed. Up to 5 transmitters

can be provided with a scan tool (Tech-2) and by proper

procedure.

In addition to the absence of proper transmitter, it may

happen particular secret code to the particular vehicle is

missing. ln this case, the secret code must be provided

by your organization.

Otherwise transmitter cannot be programmed in any

way.

lf the essential for a scan tool (Tech-2) for programming

and proper software for Tech-2 are not available, there

is no permanent way to fix system. Temporary replace

with new ACU, new ICU and new transmitter without

any secret code can make the system be deactivated,

but it does not last long. Such a replacement does not

solve any condition. Even after replacement, the system

is activated automatically in short time and then no

operation of the vehicle can be made in any way.

Tech-2 should be provided in your organization.

• Security code management

Your organization must keep security codes for all

vehicles as confidential data. Once the security codes

are lost, anybody who have the security code can

access antitheft system. Your organization has

responsibility of any missing vehicles caused by stolen

security code.

• Essential tool (Scan tool: Tech-2)

Your dealership must have Tech-2, and Tech-2 updated

software for immobilizer system.

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5990 of 6020

11B-36 ANTITHEFT SYSTEM

Diagnosis

Diagnostic procedure

• Once the cause of DTC is repaired or gone,

engine can be operated normally, and present

DTC becomes history code.

• History code is canceled by no repeat failure on 25

consequence ignition key on afterward.

• History code cannot be canceled by batter

y

connector disconnected.

Clearing Diagnostic Trouble Codes

IMPORTANT: Do not clear DTCs unless directed to do

so by the service information provided for each

diagnostic procedure. W hen DTCs are cleared, the

Failure Record data which may help diagnose an

intermittent fault will also be erased from memory.

Verifying Vehicle Repair

Verification of vehicle repair will be more

comprehensive for vehicles with immobilizer system

diagnostic. Following a repair, the technician should

perform the following steps:

1. Review and record the Fail Records for the DTC which has been diagnosed.

2. Clear DTC (s).

3. Operate the vehicle within conditions noted in the Fail Records.

4. Monitor the DTC status information for the DTC which has been diagnosed until the diagnostic test

associated with that DTC runs.

Following these steps are very important in verifying

repairs on immobilizer systems. Failure to follow these

steps could result in unnecessary repairs.

Diagnostic Aids

An intermittent may be caused by the following:

• Poor connections.

• Miss routed harness.

• Rubbed through wire insulation.

• Broken wire inside the insulation.

Check for the following conditions:

• Poor connection at ACU-Inspect harness

connectors for backed out terminals, imprope

r

mating, broken locks, improperly formed or

damaged terminals, and poor terminal to wire

connection.

• Damaged harness-Inspect the wiring harness fo

r

damage.

If the harness appears to be OK, observe the data

display on the Tech2 while moving connectors and

wiring harnesses related to the switch or actuator.

A change in the display will indicate the location of

the fault.

If DTC cannot be duplicated, the information included in the Failure Records data can be useful

in determined vehicle mileage since the DTC was

last set.

If it is determined that the DTC occurs intermittently, performing the DTC Diagnostic

Chart may isolate the cause of the fault.

NOTE: Breakage of antitheft fuse does not operate

antitheft system. Check LED lamp flashes at this time.

Check the Electro-Magnetic Interference (EMI)

• Location of vehicle check

Move the vehicle to a new location and perform

the check again.

• Non-OEM Parts.

Switch is “OFF” or remove the Non-OEM parts and

perform the check again.

• Other

Remove the accessory and another key from key.

Check the other items.

• Battery voltage is low.

• Antitheft programming functions.

Must be programmed antitheft system.

• Registration for security code, antitheft control unit

parts number.

• Key switch operation.

Antitheft system may detect a history DTC by the

timing of ON-OFF of a key switch.

• Active the antitheft system.

• Keyless entry system is malfunction.

• Immobilizer system is malfunction.

Check the operation

Check the operation "Lock / unlock" by using transmitter

(key) on the vehicle.

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007