engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1984 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-367

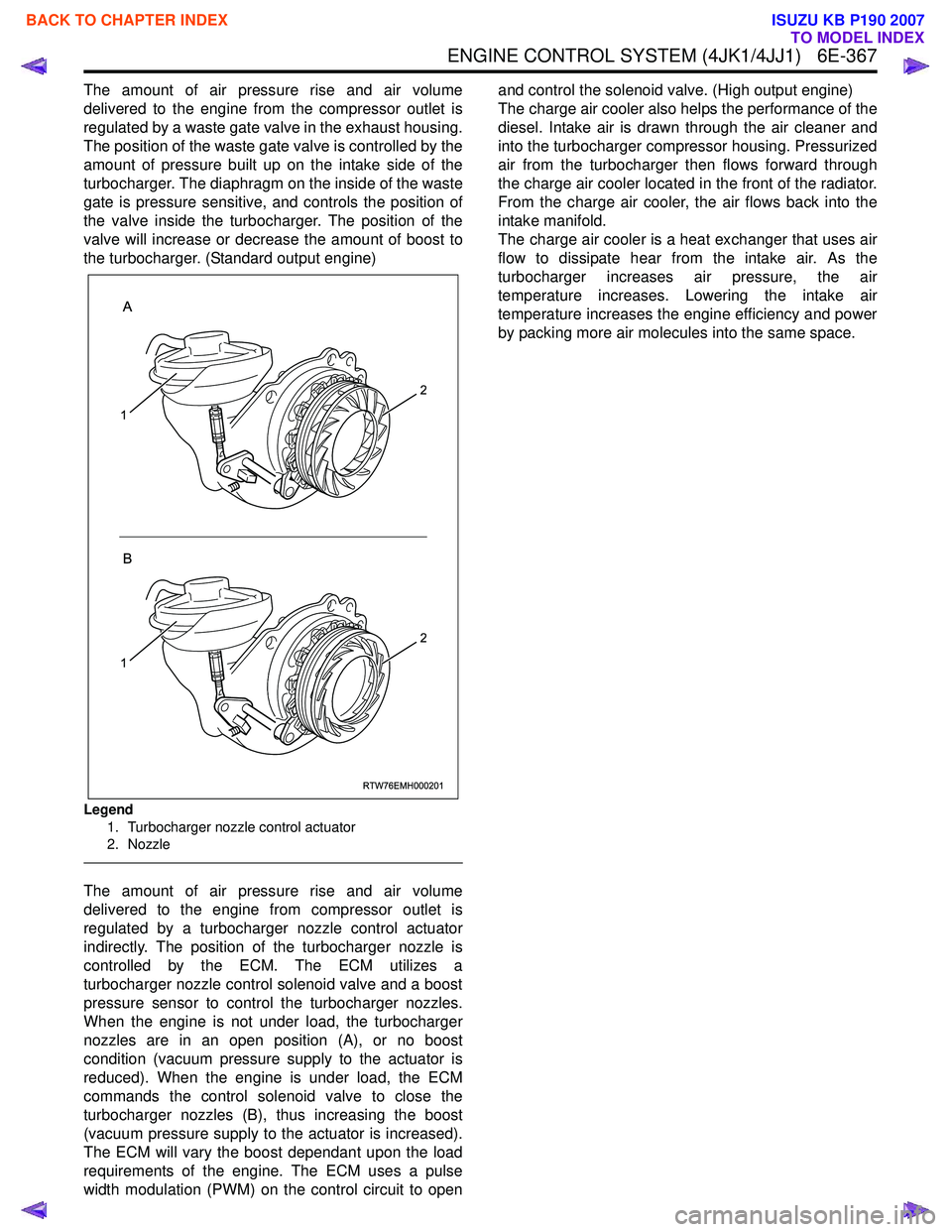

The amount of air pressure rise and air volume

delivered to the engine from the compressor outlet is

regulated by a waste gate valve in the exhaust housing.

The position of the waste gate valve is controlled by the

amount of pressure built up on the intake side of the

turbocharger. The diaphragm on the inside of the waste

gate is pressure sensitive, and controls the position of

the valve inside the turbocharger. The position of the

valve will increase or decrease the amount of boost to

the turbocharger. (Standard output engine)

Legend

1. Turbocharger nozzle control actuator

2. Nozzle

The amount of air pressure rise and air volume

delivered to the engine from compressor outlet is

regulated by a turbocharger nozzle control actuator

indirectly. The position of the turbocharger nozzle is

controlled by the ECM. The ECM utilizes a

turbocharger nozzle control solenoid valve and a boost

pressure sensor to control the turbocharger nozzles.

When the engine is not under load, the turbocharger

nozzles are in an open position (A), or no boost

condition (vacuum pressure supply to the actuator is

reduced). When the engine is under load, the ECM

commands the control solenoid valve to close the

turbocharger nozzles (B), thus increasing the boost

(vacuum pressure supply to the actuator is increased).

The ECM will vary the boost dependant upon the load

requirements of the engine. The ECM uses a pulse

width modulation (PWM) on the control circuit to open and control the solenoid valve. (High output engine)

The charge air cooler also helps the performance of the

diesel. Intake air is drawn through the air cleaner and

into the turbocharger compressor housing. Pressurized

air from the turbocharger then flows forward through

the charge air cooler located in the front of the radiator.

From the charge air cooler, the air flows back into the

intake manifold.

The charge air cooler is a heat exchanger that uses air

flow to dissipate hear from the intake air. As the

turbocharger increases air pressure, the air

temperature increases. Lowering the intake air

temperature increases the engine efficiency and power

by packing more air molecules into the same space.

RTW76EMH000201

A

B

1

2

1

2

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1985 of 6020

6E-368 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

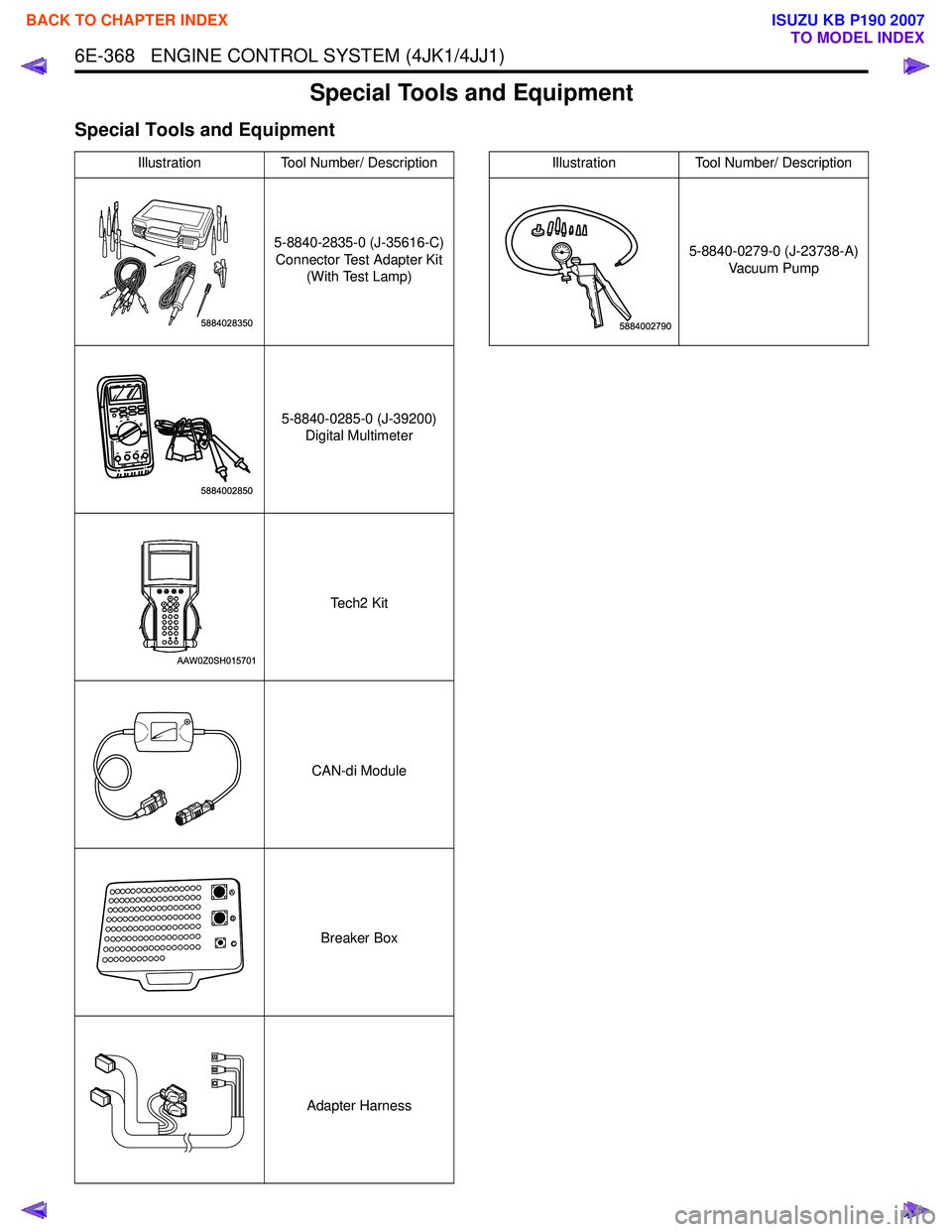

Special Tools and Equipment

Special Tools and Equipment

IllustrationTool Number/ Description

5-8840-2835-0 (J-35616-C) Connector Test Adapter Kit (With Test Lamp)

5-8840-0285-0 (J-39200) Digital Multimeter

Te c h 2 K i t

CAN-di Module Breaker Box

Adapter Harness

5884028350

5884002850

AAW0Z0SH015701

1851110030

A

B C

ABC

5-8840-0279-0 (J-23738-A) Vacuum Pump

Illustration Tool Number/ Description

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1994 of 6020

EXHAUST SYSTEM (4JK1/4JJ1) 6F-9

Removal

1. Drain the coolant.

2. Remove the intercooler.

3. Remove the heat protector.

4. Disconnect the water hoses from the EGR coole

r

water pipes.

5. Remove the EGR cooler.

Installation (Standard Output)

1. Gasket

2. EGR Cooler

3. Nuts and Bolts

RTW 56FSH000201

• Temporary tightening order

1 – 2 – 4 – 5 - 3

• Fully tightening order

4 – 5 – 1 – 2 - 3

Tighten the nuts and bolts to the specified torque.

Tightening torque: 27 N ⋅

⋅⋅

⋅

m (2.8 kg ⋅

⋅⋅

⋅

m / 20 lb ft)

4. W ater hose

5. Heat protector • Tighten the bolts to the specified torque.

Tightening torque: 10 N ⋅

⋅⋅

⋅

m (1.0 kg ⋅

⋅⋅

⋅

m / 87 lb in)

RTW 56ASH014601

6. Replenish the engine coolant.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1995 of 6020

6F-10 EXHAUST SYSTEM (4JK1/4JJ1)

Installation (High Output)

1. Gasket

2. EGR Cooler

3. Nuts and Bolts

6

543

1

2

RTW 76FSH000201

• Temporary tightening order

1 →2→ 3→ 4→ 5→ 6

• Fully tightening order

3 →4→ 5→ 1→ 2→ 6

Tighten the nuts and bolts to the specified torque.

Tightening torque: Nuts and bolts 1-5: 27 N ⋅

⋅⋅

⋅

m (2.8 kg ⋅

⋅⋅

⋅

m / 20 lb ft)

Bolt 6: 52 N⋅

⋅⋅

⋅

m (5.3 kg ⋅

⋅⋅

⋅

m / 38 lb ft)

4. W ater hose

5. Heat protector • Tighten the bolts to the specified torque.

Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m / 18 lb ft)

RTW 76FSH000101

6. Replenish the engine coolant.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1998 of 6020

ENGINE SPEED CONTROL SYSTEM (4JK1/4JJ1) 6H-1

SECTION 6H

ENGINE SPEED CONTROL SYSTEM

CONTENTS

Accelerator Pedal Position (APP) Sensor ......... 6H-2

Removal .......................................................... 6H-2

Installation ....................................................... 6H-2

How to adjust for APP Sensor......................... 6H-2

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1999 of 6020

6H-2 ENGINE SPEED CONTROL SYSTEM (4JK1/4JJ1)

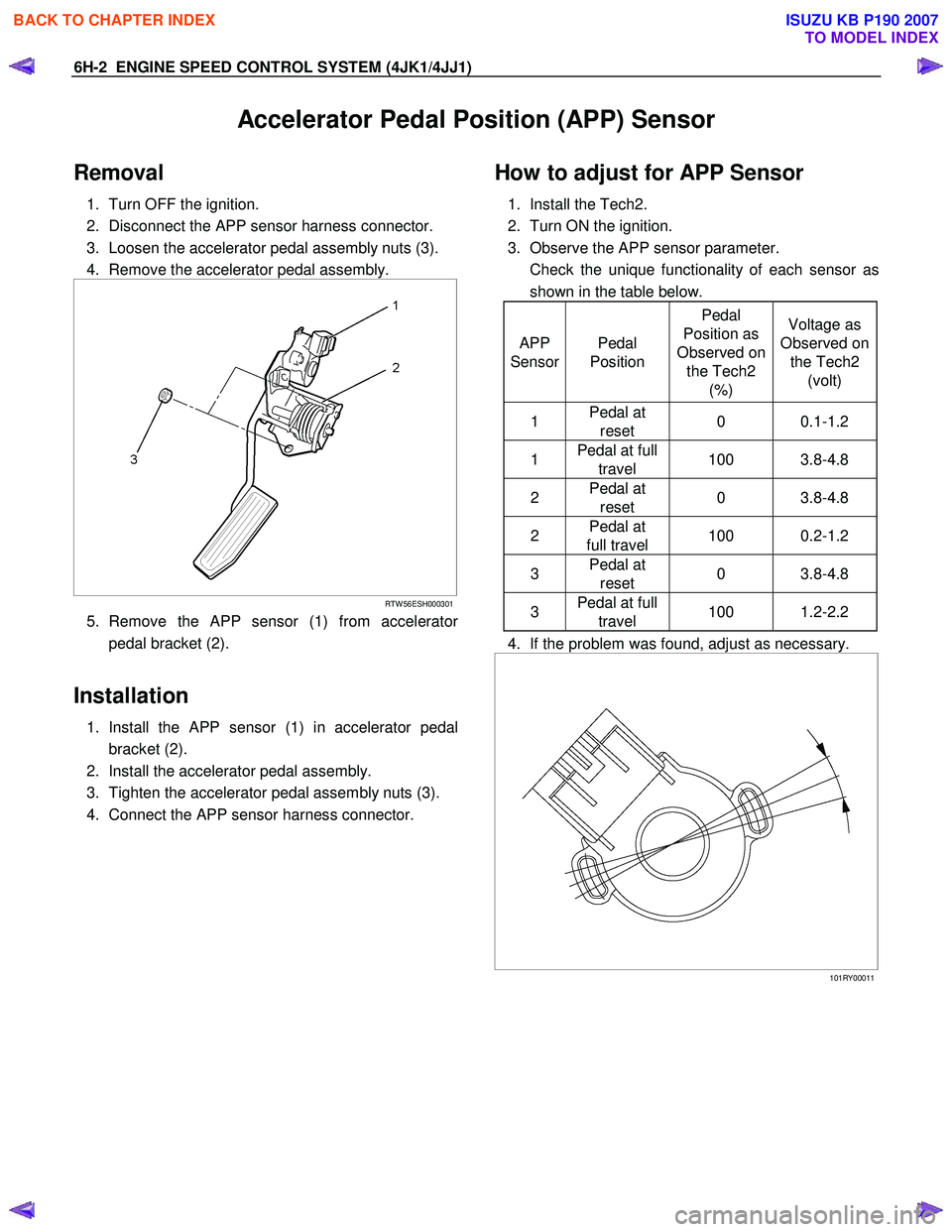

Accelerator Pedal Position (APP) Sensor

Removal

1. Turn OFF the ignition.

2. Disconnect the APP sensor harness connector.

3. Loosen the accelerator pedal assembly nuts (3).

4. Remove the accelerator pedal assembly.

RTW 56ESH000301

5. Remove the APP sensor (1) from accelerator

pedal bracket (2).

Installation

1. Install the APP sensor (1) in accelerator pedal

bracket (2).

2. Install the accelerator pedal assembly.

3. Tighten the accelerator pedal assembly nuts (3).

4. Connect the APP sensor harness connector.

How to adjust for APP Sensor

1. Install the Tech2.

2. Turn ON the ignition.

3. Observe the APP sensor parameter.

Check the unique functionality of each sensor as shown in the table below.

APP

Sensor Pedal

Position Pedal

Position as

Observed on the Tech2 (%) Voltage as

Observed on the Tech2 (volt)

1 Pedal at

reset 0 0.1-1.2

1 Pedal at full

travel 100 3.8-4.8

2 Pedal at

reset 0 3.8-4.8

2 Pedal at

full travel 100 0.2-1.2

3 Pedal at

reset 0 3.8-4.8

3 Pedal at full

travel 100 1.2-2.2

4. If the problem was found, adjust as necessary.

101RY00011

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2000 of 6020

Section 6 Engine Diagnosis .......................................................................................... 2001 PAGE

Section 6A Engine Mechanical .................................................................................... 2015

Section 6B Engine Cooling .......................................................................................... 2105

Section 6C Fuel System .......................................................................... ..................... 2119

Section 6D Engine Electrical ....................................................................................... 2137

Section 6E Engine Driveability and Emissions .......................................................... 2171

Section 6F Exhaust System ........................................................................................ 2450

SECTION 6

ENGINE

TA BLE OF CONTENTS

C24SE MODEL

EN G IN E (C 24SE) 6

Section 6 G En gine L ubri ca tio n.................................................................................... 24 65

Section 6H Engine Speed Control System ................................................................ 2472

Section 6J Induction ................................................................................................... 2476

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2001 of 6020

ENGINE DIAGNOSIS (C24SE) 6-1

SECTION 6

ENGINE DIAGNOSIS

TABLE OF CONTENTS

PAGE

Engine Diagnosis .............................................................................................................. 6- 2

Hard Starting ................................................................................................................. 6- 2

Engine Compression Test Procedure ......................................................................... 6- 3

Rough Engine Idling or Engine Stalling...................................................................... 6- 4

Rough Engine Running ................................................................................................ 6- 5

Hesitation ..................................................................................................................... . 6- 6

Engine Lacks Power ..................................................................................................... 6- 7

Engine Noisy ................................................................................................................. 6 - 8

Abnormal Noise Due to Hydraulic Lash Adjustor ...................................................... 6- 9

Troubleshooting Procedure ......................................................................................... 6- 9

Abnormal Combustion ................................................................................................. 6-11

Engine Oil Consumption Excessive............................................................................ 6-12

Fuel Consumption Excessive ...................................................................................... 6-13

Oil Problems.................................................................................................................. 6-13

Engine Oil Pressure Check .......................................................................................... 6-13

Malfunction Indicator Lamp ......................................................................................... 6-14

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2002 of 6020

6-2 ENGINE DIAGNOSIS (C24SE)

Engine Diagnosis

Hard Starting

1.Starting Motor Does Not Turn Over

Trouble Shooting Procedure

Turn on headlights and starter switch.

Condition Possible cause Correction

Headlights go out or dim

considerably Battery run down or under

charged Recharge or replace battery

Terminals poorly connected Clean battery posts and terminals

and connect properly

Starting motor coil circuit shorted Overhaul or replace

Starting motor defective Overhaul or replace

2.Ignition Trouble - Starting Motor Turns Over But Engine Does Not Start

Spark Test Disconnect a high tension cable from any spark plug.

Connect the spark plug tester (use commercially

available tool), crank the engine, and check if a spark is

generated in the spark plug tester. Before cranking the

engine, make sure that the spark plug tester is properly

grounded. To avoid electrical shock, do not touch the

high tension cable while the engine is running.

Condition Possible cause Correction

Spark jumps across gap Spark plug defective Clean, adjust spark gap or replace

Spark plug wire in correct Connect properly or replace

Ignition timing incorrect Refer to Ignition System

Fuel not reaching fuel injector(s)

or engine Refer to item 3 (Trouble in fuel

system)

Valve timing incorrect Adjust

Engine lacks compression Refer to item 4 (Engine lacks

compression)

No sparking takes place Ignition coil disconnected or

broken Connect properly or replace

Electronic Ignition System with

module Replace

Poor connections in engine

harness Correct

Engine Control Module cable

disconnected or defective Correct or replace

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2003 of 6020

ENGINE DIAGNOSIS (C24SE) 6-3

3.Trouble in Fuel System Condition Possible cause Correction

Starting motor turns over and

spark occurs but engine does not

start. Fuel tank empty Fill

Water in fuel system Clean

Fuel filter clogged Replace filter

Fuel pipe clogged Clean or replace

Fuel pump defective Replace

Fuel pump circuit open Correct or replace

Evaporative Emission Control

system circuit clogged Correct or replace

Multiport Fuel Injection System

faulty Refer to "Electronic Fuel Injection"

section

4.Engine Lacks Compression

Condition Possible cause Correction

Engine lacks compression Spark plug loosely fitted or spark

plug gasket defective Tighten to specified torque or

replace gasket

Spark plug wire incorrect Connect properly or replace

Valve timing incorrect Adjust

Cylinder head gasket defective Replace gasket

Valve incorrectly seated Lap valve

Valve stem seized Replace valve and valve guide

Valve spring weakened Replace

Cylinder or piston rings worn Overhaul engine

Piston ring seized Overhaul engine.

Engine Compression Test Procedure

1. Start and run the engine until the engine

reaches normal operating temperature.

2. Turn the engine off.

3. Remove all the spark plugs.

4. Remove ignition coil fuse (15A) and disable the ignition system.

5. Remove the fuel pump relay from the relay and fuse box. 6. Engage the starter and check that the cranking

speed is approximately 300 rpm.

7. Install cylinder compression gauge into spark plug hole.

8. With the throttle valve opened fully, keep the starter engaged until the compression gauge

needle reaches the maximum level. Note the

reading.

9. Repeat the test with each cylinder. The pressure difference between the individual

cylinders should not exceed 100kPa (14.5 psi).

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007