radiator ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3158 of 6020

Engine Cooling – V6 Engine Page 6B1–23

1 W ith the engine off, remove the coolant filler cap on

the coolant outlet housing, located at the front left-

hand side of the engine.

Figure 6B1 – 19

2 If filling a completely empty cooling system for automatic transmission models, mix 5 litres of clean

water with 5 litres of the recommended coolant or

5.2 litres of each for manual transmission models.

3 Add coolant via the engine coolant filler neck on the coolant outlet housing.

NOTE

Do not replace the coolant filler cap before

starting the engine (in step 6). Leaving the filler

cap off allows the engine to warm up without

pressurising.

4 Reconnect battery ground lead. Refer to 6D1 – 3 Battery – V6.

5 Start the engine and set the HVAC controls to: • Full hot

• Low fan

Figure 6B1 – 20

6 Run the engine at approximately 2,000 rpm to warm up the engine.

7 W ait until the radiator fan switches on.

8 W hen the radiator fan has switched on, let the engine rpm drop back to idle.

9 Turn the engine off when the radiator fan switches off.

10 Top up the coolant until full.

11 Replace the coolant filler cap.

Do not loosen or remove the radiator filler cap

when the coolant temperature is high. Steam

or boiling coolant will gush out and you may

be burnt. To open the radiator filler cap, cover

the filler cap with a thick cloth when the

coolant has cooled, release the pressure by

slowly turning the filler cap, and remove the

cap.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3159 of 6020

Engine Cooling – V6 Engine Page 6B1–24

12 Open the coolant reservoir tank cap.

13 Top up the radiator coolant recovery reservoir to the MAX line.

14 Reinstall the coolant recovery reservoir cap.

NOTE

This condition only applies when the cooling

system is first being filled after a major loss of

coolant. The level of coolant in the reservoir

will then drop, once the engine is started and

normal operating temperature is reached. The

coolant level should then be maintained at the

correct level (between the MAX and MIN

Lines).

Figure 6B1 – 21

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3160 of 6020

Engine Cooling – V6 Engine Page 6B1–25

3.4 Cleaning Cooling System

NOTE

• Before carrying out reverse flushing

procedures, it is recommended that a

cleaning solution be used to loosen scale and

corrosion. Only use a Holden approved

radiator cleaner following the instructions on

the container label.

• This operation should only be carried out

when the engine and radiator are at ambient

temperature.

• When using specialised cooling system

flushing equipment, connect the equipment as

recommended by the manufacturer.

Cooling System Reverse Flush

Radiator

Refer to ‘

‘‘

‘

Environmental Issues ’

’’

’

in 3.1

Service Notes, before draining the coolant.

1 Drain the cooling system. Refer to 3.3 Draining and Filling Cooling System in this Section.

Always wear eye protection when working

with spring-type hose clamps. Failure to do

so may result in eye injury.

2 Remove the lower radiator outlet hose (1) at the coolant inlet pipe connection (2).

3 Remove the upper radiator inlet hose (3) at the coolant outlet housing connection (4).

4 Attach a lead-away hose to the open end of the upper radiator hose.

5 Attach a suitable piece of hose or adaptor between the flushing gun and the open end of the lower

radiator hose.

6 Connect and operate the flushing equipment as recommended by the manufacturer.

Apply air pressure gradually and not in

excess of 120 kPa, otherwise radiator

damage will result.

Figure 6B1 – 22

7 Continue flushing until the water from the lead-away hose runs clean and clear.

8 Install all disconnected hoses, ensuring that they are correctly positioned and securely clamped.

9 Fill the cooling system. Refer to 3.3 Draining and Filling Cooling System in this Section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3161 of 6020

Engine Cooling – V6 Engine Page 6B1–26

10 Pressure test the cooling system. Refer to 3.7 Pressure Testing in this Section.

Engine

Refer to ‘

‘‘

‘

Environmental Issues ’

’’

’

in 3.1

Service Notes, before draining the coolant.

1 Drain the cooling system. Refer to 3.3 Draining and Filling Cooling System in this Section.

Always wear eye protection when working

with spring-type hose clamps. Failure to do

so may result in eye injury.

2 Remove the upper and lower radiator hoses from the coolant outlet housing and coolant inlet pipe connections. Refer to Figure 6B1 – 22.

3 Remove the thermostat housing from the rear of the engine block. Refer to 6A1 Engine Mechanical – V6..

4 Remove the thermostat from the thermostat housing and reinstall the housing to the rear of the intake manifold. Refer to 3.8 Thermostat in this Section.

5 Remove both heater hoses (1) and (2) from their connections at the heater pipe assembly, noting

which hose was connected to which connection.

Seal the heater pipe assembly connections by

looping the heater inlet connection to the outlet

connection using a suitable piece of hose and two

hose clamps.

6 Install a lead-away hose to the coolant inlet pipe connection and a length of suitable hose between

the coolant outlet housing connection and the

flushing equipment.

7 Connect and operate the flushing equipment as recommended by the manufacturer.

Figure 6B1 – 23

8 Continue flushing until the water from the lead-away hose runs clear.

9 Remove the coolant recovery reservoir, flush it out with clean water and install. Refer to 3.9 Coolant Recovery Reservoir in this Section.

10 Install the thermostat. Refer to 3.8 Thermostat in this Section.

11 Install all disconnected hoses, ensuring that they are correctly positioned and securely clamped.

12 Fill the cooling system. Refer to 3.3 Draining and Filling Cooling System in this Section.

13 Pressure-test the cooling system. Refer to 3.7 Pressure Testing in this Section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3165 of 6020

Engine Cooling – V6 Engine Page 6B1–30

3.6 Coolant Hoses

Always wear protective safety glasses when

working with spring type hose clamps. Failure

to do so could result in eye injury.

Coolant hoses are installed as shown in the following illustrations, taking note that there are a number of variants,

depending on a specific vehicle specification.

Hose connections should be thoroughly cleaned before installing any new hose.

After all hoses are installed, always refill the cooling system with correct concentration of coolant, refer to 3.3 Draining

and Filling Cooling System and pressure test cooling system, refer to 3.7 Pressure Testing in this Section.

Figure 6B1 – 27

Legend

1 Radiator Hose – Upper

2 Radiator Hose – Lower

3 Hose Clamp – Upper Hose to Engine Outlet Housing 4 Hose Clamp – Upper Hose to Radiator Inlet

5 Hose Clamp – Lower Hose to Radiator Outlet

6 Hose Clamp – Lower Hose to Engine Coolant Inlet Pipe

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3168 of 6020

Engine Cooling – V6 Engine Page 6B1–33

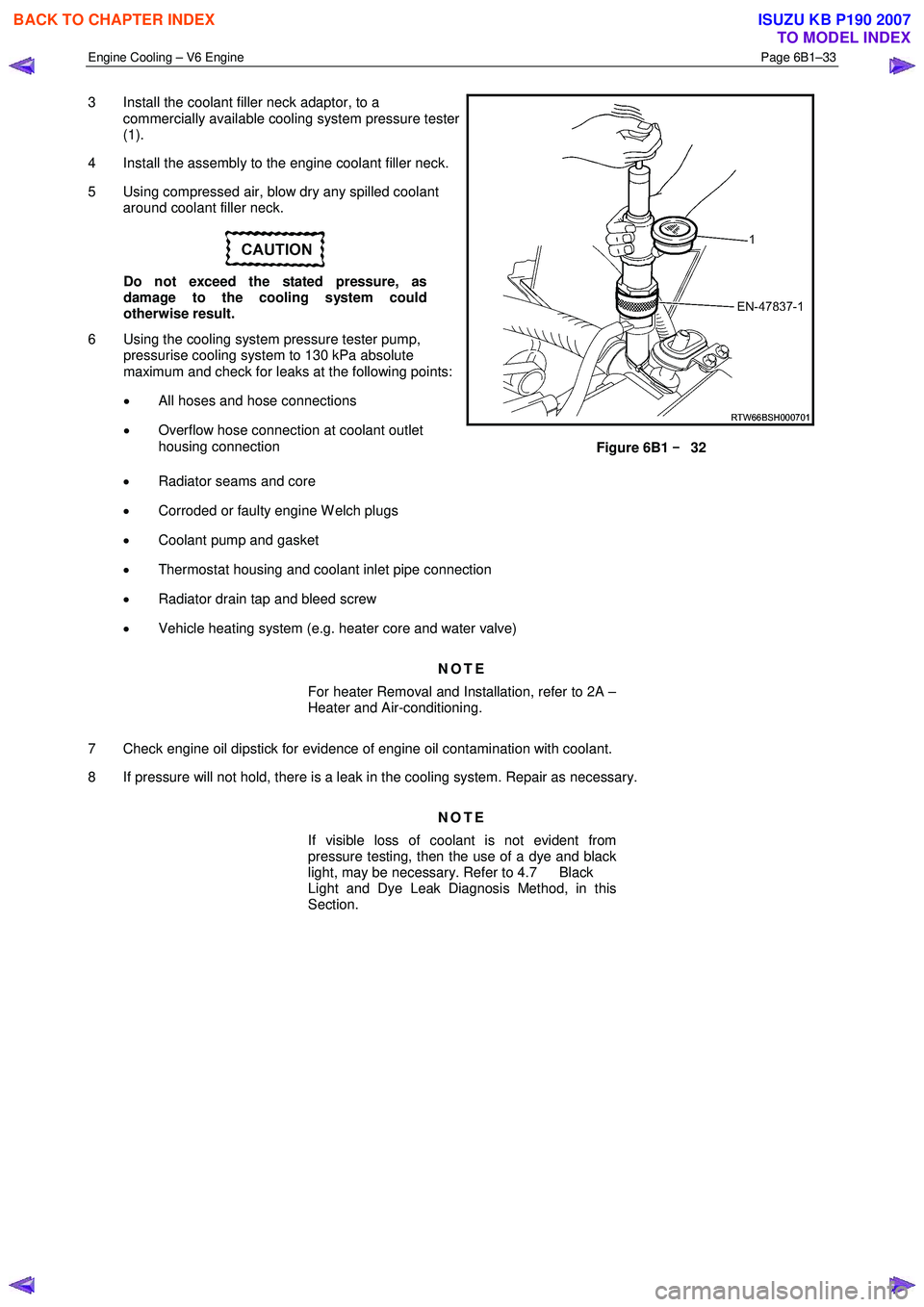

3 Install the coolant filler neck adaptor, to a

commercially available cooling system pressure tester

(1).

4 Install the assembly to the engine coolant filler neck.

5 Using compressed air, blow dry any spilled coolant around coolant filler neck.

Do not exceed the stated pressure, as

damage to the cooling system could

otherwise result.

6 Using the cooling system pressure tester pump, pressurise cooling system to 130 kPa absolute

maximum and check for leaks at the following points:

• All hoses and hose connections

• Overflow hose connection at coolant outlet

housing connection

Figure 6B1 –

––

–

32

• Radiator seams and core

• Corroded or faulty engine W elch plugs

• Coolant pump and gasket

• Thermostat housing and coolant inlet pipe connection

• Radiator drain tap and bleed screw

• Vehicle heating system (e.g. heater core and water valve)

NOTE

For heater Removal and Installation, refer to 2A –

Heater and Air-conditioning.

7 Check engine oil dipstick for evidence of engine oil contamination with coolant.

8 If pressure will not hold, there is a leak in the cooling system. Repair as necessary.

NOTE

If visible loss of coolant is not evident from

pressure testing, then the use of a dye and black

light, may be necessary. Refer to 4.7 Black

Light and Dye Leak Diagnosis Method, in this

Section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3173 of 6020

Engine Cooling – V6 Engine Page 6B1–38

Install

Always wear protective safety glasses when

working with spring-loaded devices. Failure to

do so could result in eye injury.

1 Install the thermostat into the housing (reverse to removal procedure).

2 Ensure that the engine block and thermostat housing mating surfaces are clean and dry.

3 Install a new gasket to the thermostat housing.

4 Install the thermostat housing to the engine block and secure with the attaching bolts (with rubber grommets installed). Tighten all bolts to the correct torque specification.

Thermostat housing to engine

block bolt torque specification ..............................10 N.m

5 Ensure that the heater pipe assembly and thermostat housing mating surfaces are clean and dry.

6 Install new O-rings to the heater pipe assembly.

7 Install heater pipe assembly to thermostat housing and secure with the attaching bolts. Tighten all bolts to the correct torque specification.

Heater pipe assembly to thermostat

housing bolt torque specification ..........................10 N.m

8 Install heater pipe assembly to right-hand cylinder head bolt. Tighten bolt to the correct torque specification. Heater pipe assembly to cylinder

head bolt torque specification ..............................35 N.m

Always wear protective safety glasses when

working with spring type hose clamps. Failure

to do so could result in eye injury.

9 Reinstall the engine wiring harness, securing the rear harness former to the rear of the engine with the two retaining bolts, tightened to the correct torque specification.

Rear engine harness former

retaining bolts torque specification .......................15 N.m

10 Reinstall the left side engine harness former to the two locating pegs, then push inward to secure.

11 Reinstall the bolt securing the engine harness ground terminal, to the left side of the cylinder block and tighten to the correct torque specification.

Engine harness ground terminal

attaching bolt torque specification ........................12 N.m

12 Reinstall each wiring harness connector to its correct location, ensuring that all security clips are installed correctly.

13 Connect the heater hoses to the heater pipe assembly.

14 Install the coolant inlet pipe. Refer to 3.12 Coolant Inlet Pipe in this Section.

15 Close the radiator drain tap on the lower LHS of the radiator and remove the piece of rubber tubing to the tap outlet.

16 Reinstall the complete intake manifold assembly. Refer to 6A1 Engine Mechanical.

17 Refill cooling system. Refer to 3.3 Draining and Filling Cooling System in this Section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3174 of 6020

Engine Cooling – V6 Engine Page 6B1–39

18 Check for coolant leaks. Refer to 3.7 Pressure Testing in this Section.

19 Install the radiator shroud.

20 Install the engine dress covers. Refer to 6A1 Engine Mechanical.

21 Reconnect battery ground lead. Refer to 8A_ Electrical Body & Chassis.

22 Road test the vehicle to check for correct operation.

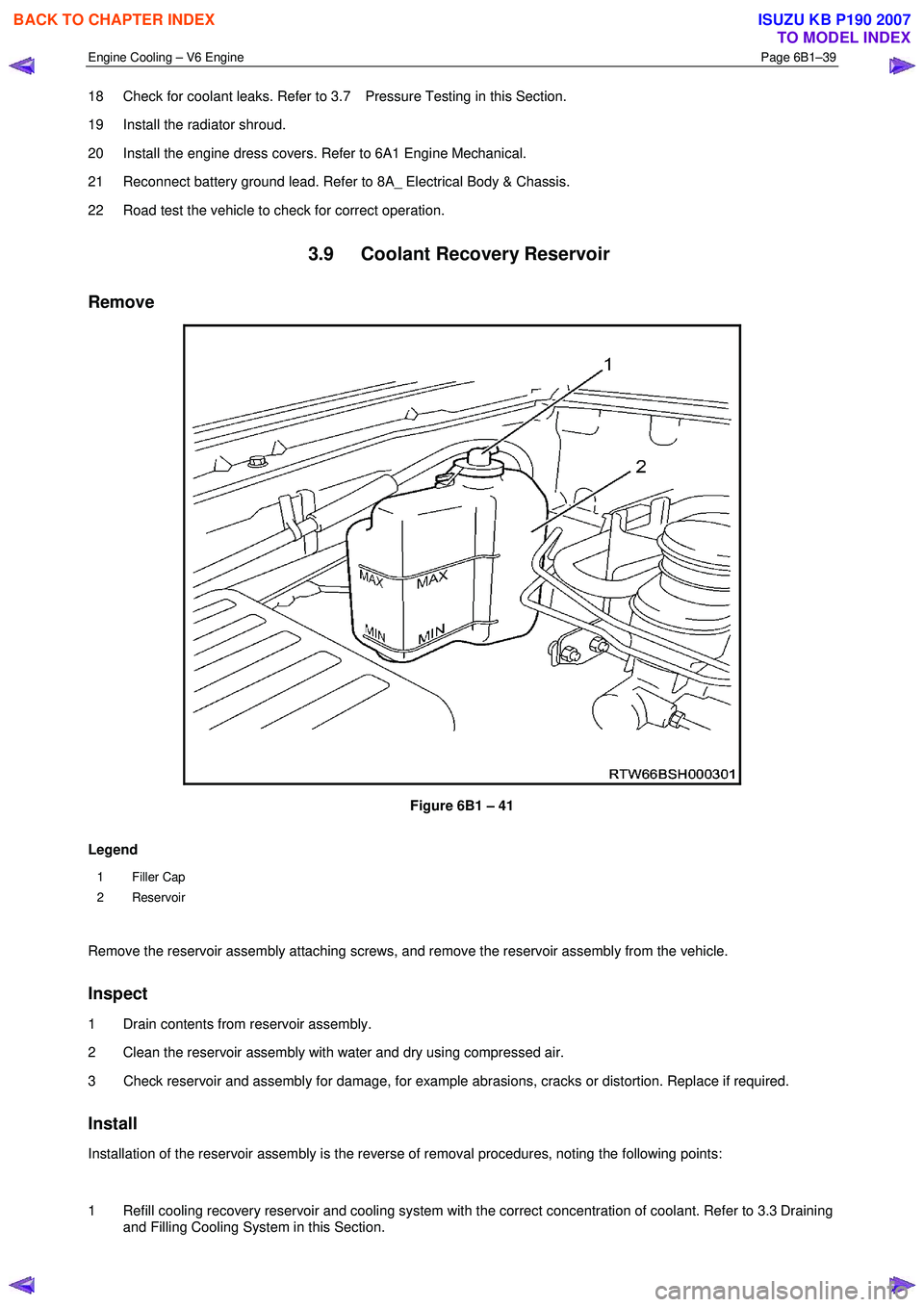

3.9 Coolant Recovery Reservoir

Remove

Figure 6B1 – 41

Legend

1 Filler Cap

2 Reservoir

Remove the reservoir assembly attaching screws, and remove the reservoir assembly from the vehicle.

Inspect

1 Drain contents from reservoir assembly.

2 Clean the reservoir assembly with water and dry using compressed air.

3 Check reservoir and assembly for damage, for example abrasions, cracks or distortion. Replace if required.

Install

Installation of the reservoir assembly is the reverse of removal procedures, noting the following points:

1 Refill cooling recovery reservoir and cooling system with the correct concentration of coolant. Refer to 3.3 Draining and Filling Cooling System in this Section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3179 of 6020

Engine Cooling – V6 Engine Page 6B1–44

5 Install coolant pump pulley and attaching bolts (1).

6 Install drive belt (reverse to removal procedures) and ensure that the drive belt is aligned with all accessory

pulleys and crankshaft balancer drive belt grooves.

NOTE

Refer to Figure 6B1 – 43, as required for the

correct drive belt routing.

7 Tighten coolant pump pulley attaching bolts (1) to the correct torque specification.

Coolant pump pulley to hub

bolt torque specification ...................................12 N.m

8 Close the radiator drain tap on the lower LHS of the radiator and remove the piece of rubber tubing to the

tap outlet.

Figure 6B1 – 49

9 Refill cooling system. Refer to 3.3 Draining and Filling Cooling System in this Section.

10 Check for coolant leaks. Refer to 3.7 Pressure Testing in this Section.

11 Install the radiator shroud.

12 Reconnect battery ground lead. Refer to 8A – Electrical Body & Chassis.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3180 of 6020

Engine Cooling – V6 Engine Page 6B1–45

3.11 Coolant Outlet Housing

Remove

Refer to 3.1 Service Notes in this Section, for

important safety items.

1 Allow engine to cool to ambient temperature (less than 50 ° C), and then remove the coolant filler cap (located at

the front left-hand side of the engine).

Disconnection of the battery affects certain

vehicle electronic systems. Refer to 1.1

WARNING, CAUTION and NOTES, before

removing the ground lead.

2 Disconnect the battery ground lead. Refer to 8A – Electrical Body & Chassis Battery.

3 Drain the coolant from the system. Refer to 3.3 Draining and Filling Cooling System.

4 Remove the complete intake manifold assembly. Refer to 6A1 Engine Mechanical.

Always wear protective safety glasses when

working with spring type hose clamps. Failure

to do so could result in eye injury.

5 Remove upper radiator hose clamp (1) at the coolant outlet housing connection (2), disconnect

hose from coolant outlet.

Figure 6B1 – 50

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007