radiator ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3777 of 6020

Automatic Transmission – 4L60E – General Information Page 7C1–17

7 Transmission Specifications

7.1 General

Type

Hydra-matic 4L60E

Special Features

Electronically controlled shift pattern, feel and torque

Converter clutch operation

Overdrive 4th speed range

Selector Location ..................................................................................Floor mounted console

Gear Ratios Park (P) ....................................................................................................................... ........... –

Reverse (R) .................................................................................................................... ... 2.29

Neutral (N) .............................................................................................................................. –

Drive (D – 4) .................................................................................................................. ...... 0.7

Drive (D – 3) .................................................................................................................. ...... 1.0

Second (2) ......................................................................................................................... 1.63

First (1) ...................................................................................................................... ........ 3.06

Shift Speeds Refer to 7C3 Automatic Transmission – 4L60E – Hydraulic and Mechanical Diagnosis

Oil Pressure

Refer to 7C3 Automatic Transmission – 4L60E – Hydraulic and Mechanical Diagnosis

Torque Converter

Number of Elements .................................................................. 3 plus torque converter clutch

Torque Converter Diameter and End Play

HFV6 ........................................................................................................................... 258 mm

End Play .............................................................................................................. 0.1 – 0.5 mm

Lubricant

Type recommended ................................................................................................ Dexron

® III

Capacity......................... Nominal only. Check when transmission is at operating temperature

Service Refill ............................................................................................................... 4. 8 litres

Total (Dry)................................................................................................................... 8 .8 litres

Fluid Cooling.....................................Transmission fluid to engine coolant in one radiator tank

Clutches and Band 2 – 4 Band:

Type........................................................................................... Composition lined, steel band

Operation: ..................................................................................................................... .. Servo

Adjustment: ................................................................................................ Selective Apply Pin

Pin Size and Identification.

65.82 – 66.12 mm ...................................................................................................... 1 Groove

67.23 – 67.53 mm ...................................................................................................... 2 Groove

68.64 – 68.94 mm ....................................................................................................No Groove

Reverse Input Clutch Type................................................................................................................Multiple we t disc

Backing plate ........................................................................................................ (1) Select ive

Clutch plate (numbers):

Steel ....................................................................................................................................... 4

Composition............................................................................................................................ 4

Belleville ..................................................................................................................... ............ 1

Backing Plate ........................................................................................................ 1 (Selecti ve)

Backing plate, identification and thickness:

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3819 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–33

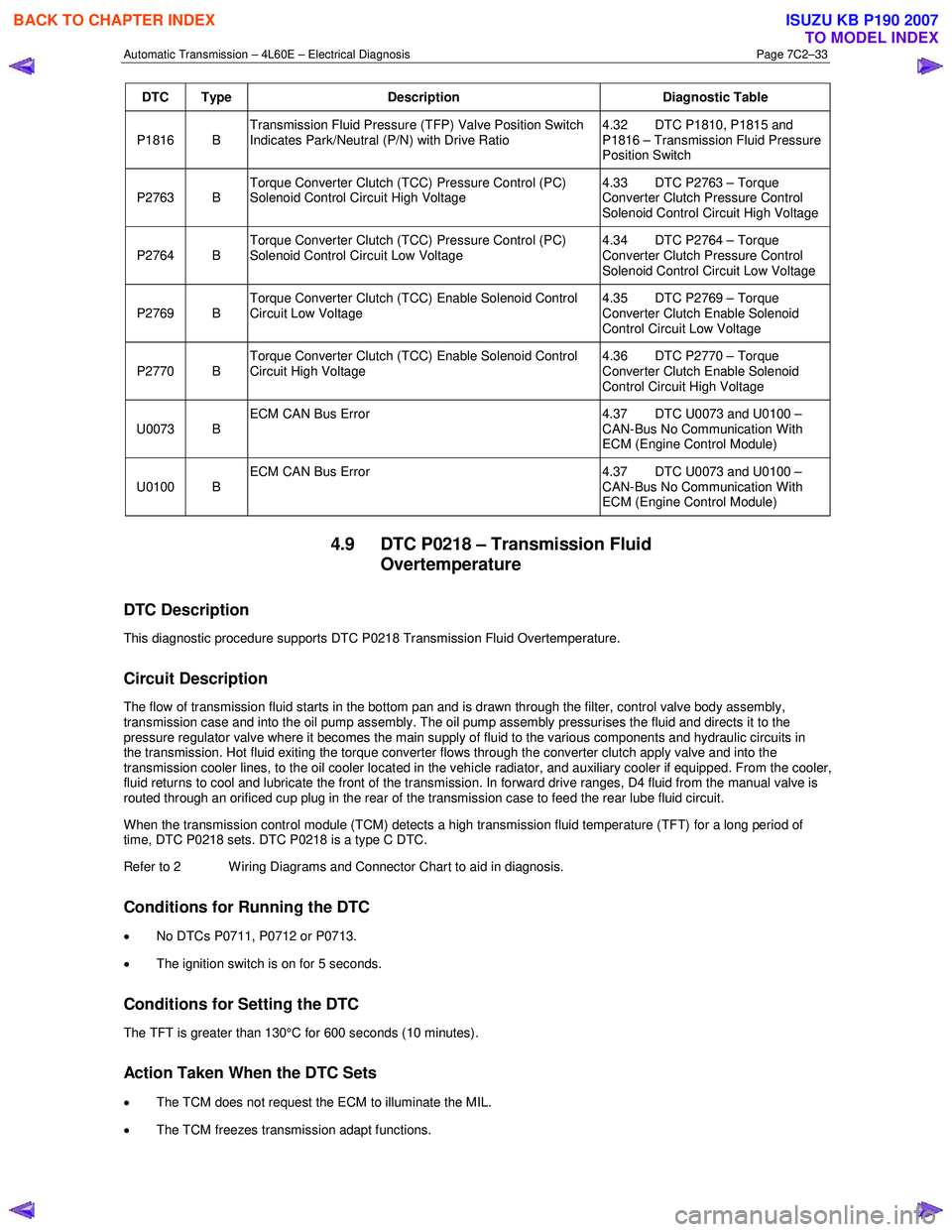

DTC Type Description Diagnostic Table

P1816 B Transmission Fluid Pressure (TFP) Valve Position Switch

Indicates Park/Neutral (P/N) with Drive Ratio 4.32 DTC P1810, P1815 and

P1816 – Transmission Fluid Pressure

Position Switch

P2763 B Torque Converter Clutch (TCC) Pressure Control (PC)

Solenoid Control Circuit High Voltage 4.33 DTC P2763 – Torque

Converter Clutch Pressure Control

Solenoid Control Circuit High Voltage

P2764 B Torque Converter Clutch (TCC) Pressure Control (PC)

Solenoid Control Circuit Low Voltage 4.34 DTC P2764 – Torque

Converter Clutch Pressure Control

Solenoid Control Circuit Low Voltage

P2769 B Torque Converter Clutch (TCC) Enable Solenoid Control

Circuit Low Voltage 4.35 DTC P2769 – Torque

Converter Clutch Enable Solenoid

Control Circuit Low Voltage

P2770 B Torque Converter Clutch (TCC) Enable Solenoid Control

Circuit High Voltage 4.36 DTC P2770 – Torque

Converter Clutch Enable Solenoid

Control Circuit High Voltage

U0073 B ECM CAN Bus Error

4.37 DTC U0073 and U0100 –

CAN-Bus No Communication With

ECM (Engine Control Module)

U0100 B ECM CAN Bus Error

4.37 DTC U0073 and U0100 –

CAN-Bus No Communication With

ECM (Engine Control Module)

4.9 DTC P0218 – Transmission Fluid Overtemperature

DTC Description

This diagnostic procedure supports DTC P0218 Transmission Fluid Overtemperature.

Circuit Description

The flow of transmission fluid starts in the bottom pan and is drawn through the filter, control valve body assembly,

transmission case and into the oil pump assembly. The oil pump assembly pressurises the fluid and directs it to the

pressure regulator valve where it becomes the main supply of fluid to the various components and hydraulic circuits in

the transmission. Hot fluid exiting the torque converter flows through the converter clutch apply valve and into the

transmission cooler lines, to the oil cooler located in the vehicle radiator, and auxiliary cooler if equipped. From the cooler ,

fluid returns to cool and lubricate the front of the transmission. In forward drive ranges, D4 fluid from the manual valve is

routed through an orificed cup plug in the rear of the transmission case to feed the rear lube fluid circuit.

When the transmission control module (TCM) detects a high transmission fluid temperature (TFT) for a long period of

time, DTC P0218 sets. DTC P0218 is a type C DTC.

Refer to 2 W iring Diagrams and Connector Chart to aid in diagnosis.

Conditions for Running the DTC

• No DTCs P0711, P0712 or P0713.

• The ignition switch is on for 5 seconds.

Conditions for Setting the DTC

The TFT is greater than 130°C for 600 seconds (10 minutes).

Action Taken When the DTC Sets

•

The TCM does not request the ECM to illuminate the MIL.

• The TCM freezes transmission adapt functions.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3844 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–58

Conditions for Running the DTC

• No DTCs P0722, P0723, P0742, P2763 or P2764.

• The IMS range is D2, D3 or D4.

• Ignition voltage is 8 – 18 V.

• The transmission fluid temperature is greater than 20°C.

• The engine torque is 108 – 881 Nm.

• The throttle position is greater than 10 percent.

• The gear ratio is within the following ranges:

• 1.41:1 – 1.56:1 — 2nd gear,

• 0.95:1 – 1.05:1 — 3rd gear.

• The TCC is commanded on 0.1 seconds.

• The TCC duty cycle is greater than 60 percent for more than 3 seconds.

Conditions for Setting the DTC

The TCM commands the TCC on, and the TCC slip is greater than 250 r.p.m. for 3 seconds.

Action Taken When the DTC Sets

•

The TCM requests the ECM to illuminate the MIL during the second consecutive drive trip in which the conditions

for setting the DTC are met.

• The TCM inhibits TCC.

• The TCM inhibits 4th gear if the transmission is in Hot Mode.

• The TCM commands elevated line pressure.

• The TCM freezes transmission adaptive functions.

• At the time of the first failure, the TCM records the operating conditions when the conditions for setting the DTC are

met. The TCM stores this information as a Failure Record.

• At the time of the second failure, the ECM records the operating conditions when the conditions for setting the DTC

are met. The ECM stores this information as a Freeze Frame.

• The TCM stores DTC P0741 in TCM history.

Conditions for Clearing the DTC

• The ECM turns off the MIL after the sixth consecutive drive trip in which the TCM does not send a MIL illumination

request.

• Tech 2 can clear the DTC.

• The TCM clears the DTC from TCM history if the vehicle completes 40 warm-up cycles without a non-emission

related diagnostic fault occurring.

• The TCM cancels the default actions when the ignition is off long enough to power down the TCM.

Diagnostic Aids

• Inspect the transmission fluid lines to the radiator. The lines may be pinched, blocked or twisted.

• Contamination may cause the TCC apply valve to stick in the valve body.

• Internal damage to the torque converter may prevent TCC application.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3916 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–3

1 General Information

This Section describes the removal and reinstallation procedures of the four speed 4L60E hydra-matic automatic

transmission as well as the service operations which can be performed with the transmission still fitted to the vehicle.

1.1 General Service Information

Description

The shift selector mechanism is linked to the transmission manual shaft with a selector cable. A heat protector is fitted

over the neutral start and back-up switch and manual shaft select lever.

For rear wheel drive (RWD) vehicles an extension housing is fitted to the rear of the transmission case.

Four wheel drive (4W D) vehicles have an adaptor housing and transfer case fitted to the rear of the transmission case,

for description and service operation refer to 7D Transfer Case and Adaptor Housing.

The four speed 4L60E hydra-matic automatic transmission is fitted with a filler tube, a breather hose and a vent pipe for

hot fluid overflow.

The transmission fluid is driven through a cooler within the radiator via the cooler line/hose assemblies to maintain

normal operating temperature.

Service Information

Throughout the service operations within this

Section, when handling retaining clips, using

compressed air or cleaning fluids, wear safety

equipment to avoid personal injury.

Refer to 7C1 Automatic Transmission – 4L60E – General Information for the following:

• information relating to mechanical and electrical operations,

• abbreviations, transmission specifications, special tools and torque wrench specifications,

• servicing, cleaning and inspection procedure recommendations.

It is essential to read and understand the General Information, W arnings, Cautions and Service Notes contained in that

same Section, before any service operation is performed on the four speed 4L60E hydra-matic automatic transmission or

any associated components.

Failure to comply with the procedures and service notes can affect the reliable and efficient operation of this automatic

transmission.

1.2 WARNINGS, CAUTIONS and NOTES

This Section contains various W ARNINGS, CAUTIONS and NOTE statements that you must observe carefully to reduce

the risk of death or injury during service, repair procedures or vehicle operation. Incorrect service or repair procedures

may damage the vehicle or cause operational faults. W ARNINGS, CAUTION and NOTE statements are not exhaustive.

GM HOLDEN LTD can not possibly warn of all the potentially hazardous consequences of failure to follow these

instructions.

Definition of WARNING, CAUTION and NOTE Statements

Diagnosis and repair procedures in this Section contain both general and specific W ARNING, CAUTION and NOTE

statements. GM HOLDEN LTD is dedicated to the presentation of service information that helps the technician to

diagnose and repair the systems necessary for proper operation of the vehicle. Certain procedures may present a hazard

to the technician if they are not followed in the recommended manner. W ARNING, CAUTION and NOTE statements are

designed to help prevent these hazards from occurring, but not all hazards can be foreseen.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3919 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–6

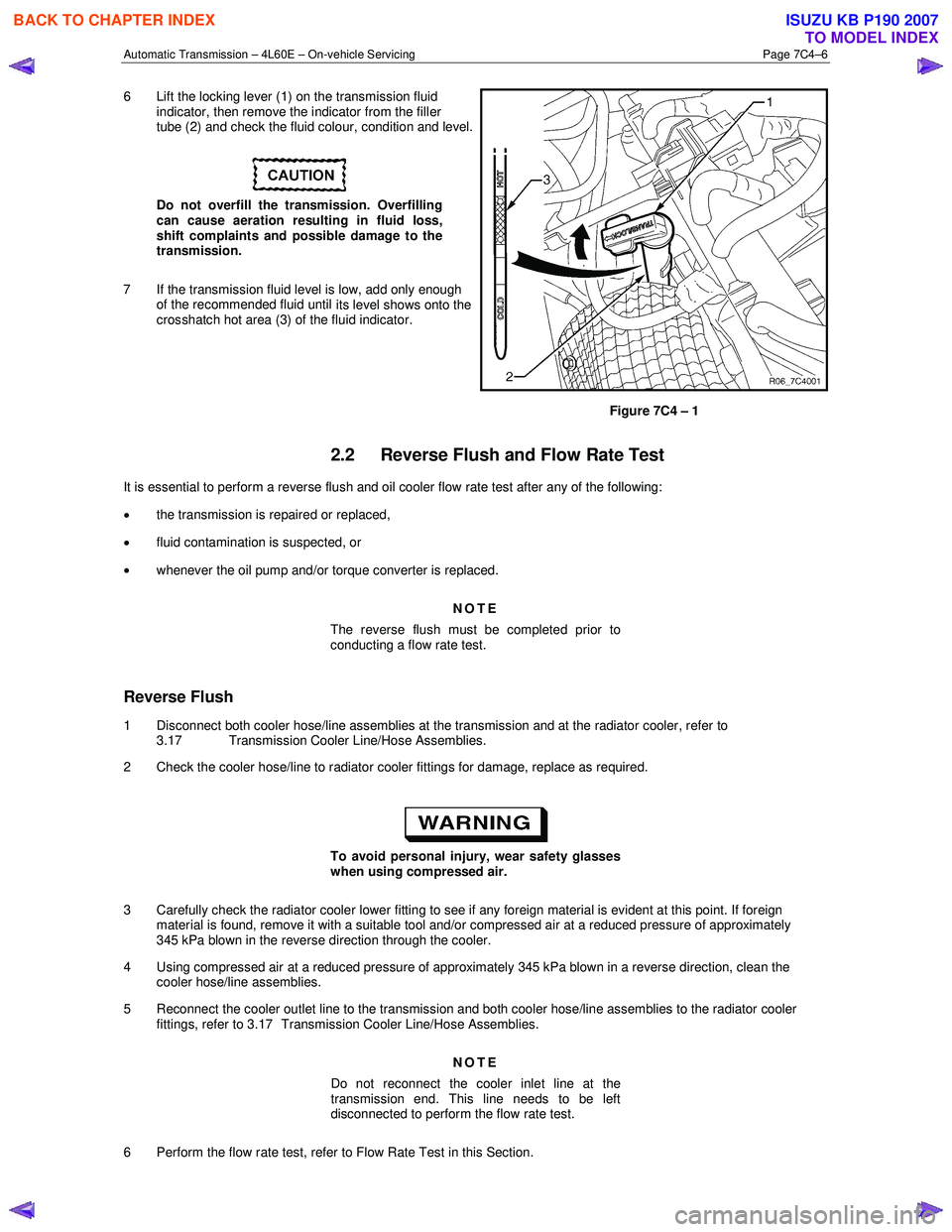

6 Lift the locking lever (1) on the transmission fluid

indicator, then remove the indicator from the filler

tube (2) and check the fluid colour, condition and level.

Do not overfill the transmission. Overfilling

can cause aeration resulting in fluid loss,

shift complaints and possible damage to the

transmission.

7 If the transmission fluid level is low, add only enough of the recommended fluid until

its level shows onto the

crosshatch hot area (3) of the fluid indicator.

Figure 7C4 – 1

2.2 Reverse Flush and Flow Rate Test

It is essential to perform a reverse flush and oil cooler flow rate test after any of the following:

• the transmission is repaired or replaced,

• fluid contamination is suspected, or

• whenever the oil pump and/or torque converter is replaced.

NOTE

The reverse flush must be completed prior to

conducting a flow rate test.

Reverse Flush

1 Disconnect both cooler hose/line assemblies at the transmission and at the radiator cooler, refer to 3.17 Transmission Cooler Line/Hose Assemblies.

2 Check the cooler hose/line to radiator cooler fittings for damage, replace as required.

To avoid personal injury, wear safety glasses

when using compressed air.

3 Carefully check the radiator cooler lower fitting to see if any foreign material is evident at this point. If foreign material is found, remove it with a suitable tool and/or compressed air at a reduced pressure of approximately

345 kPa blown in the reverse direction through the cooler.

4 Using compressed air at a reduced pressure of approximately 345 kPa blown in a reverse direction, clean the cooler hose/line assemblies.

5 Reconnect the cooler outlet line to the transmission and both cooler hose/line assemblies to the radiator cooler fittings, refer to 3.17 Transmission Cooler Line/Hose Assemblies.

NOTE

Do not reconnect the cooler inlet line at the

transmission end. This line needs to be left

disconnected to perform the flow rate test.

6 Perform the flow rate test, refer to Flow Rate Test in this Section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3920 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–7

NOTE

This will also flush the cooler hose/line

assemblies and cooler with transmission fluid.

7 If the flow rate is satisfactory, reconnect the cooler inlet line to the transmission, refer to 3.17 Transmission Cooler Line/Hose Assemblies.

8 Lower the vehicle, check and top up the transmission fluid to the correct level as required, refer to 2.1 Transmission Fluid.

Flow Rate Test

Do not run the engine any longer than

absolutely necessary, as a fluid level too low

can cause aeration and foaming.

1 Ensure the transmission fluid is at the recommended level or slightly above, refer to 2.1 Transmission Fluid.

2 Disconnect the cooler inlet line at the transmission quick-connect fitting, refer to 3.17 Transmission Cooler Line/Hose Assemblies.

3 Place a suitable size container underneath the disconnected cooler inlet line.

4 W ith the selector lever in the P position, start the engine and observe the fluid flow into the container after all the air bubbles have ceased and a steady flow is evident. Measure the flow rate over 20 seconds and ensure it is within

the specification.

Transmission fluid flow rate specification per 20 Seconds:

Temperature: Ambient ............................................................ 0.7 Litres 86° – 93° C ...................................................... 1.2 Litres

5 If the flow rate is less than the specification, the cause of the low flow rate must be located and rectified. Possible cause could include:

• restricted cooler within the radiator tank,

• kinked or damaged transmission cooler hose/line assemblies, or

• internal transmission fault such as a faulty pump.

6 Reinstall the cooler inlet line to the transmission quick-connect fitting, refer to 3.17 Transmission Cooler Line/Hose Assemblies.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3954 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–41

3.17 Transmission Cooler Line/Hose

Assemblies

Remove

1 Disconnect the transmission cooler hose/line assemblies from the radiator quick connect fittings as

follows:

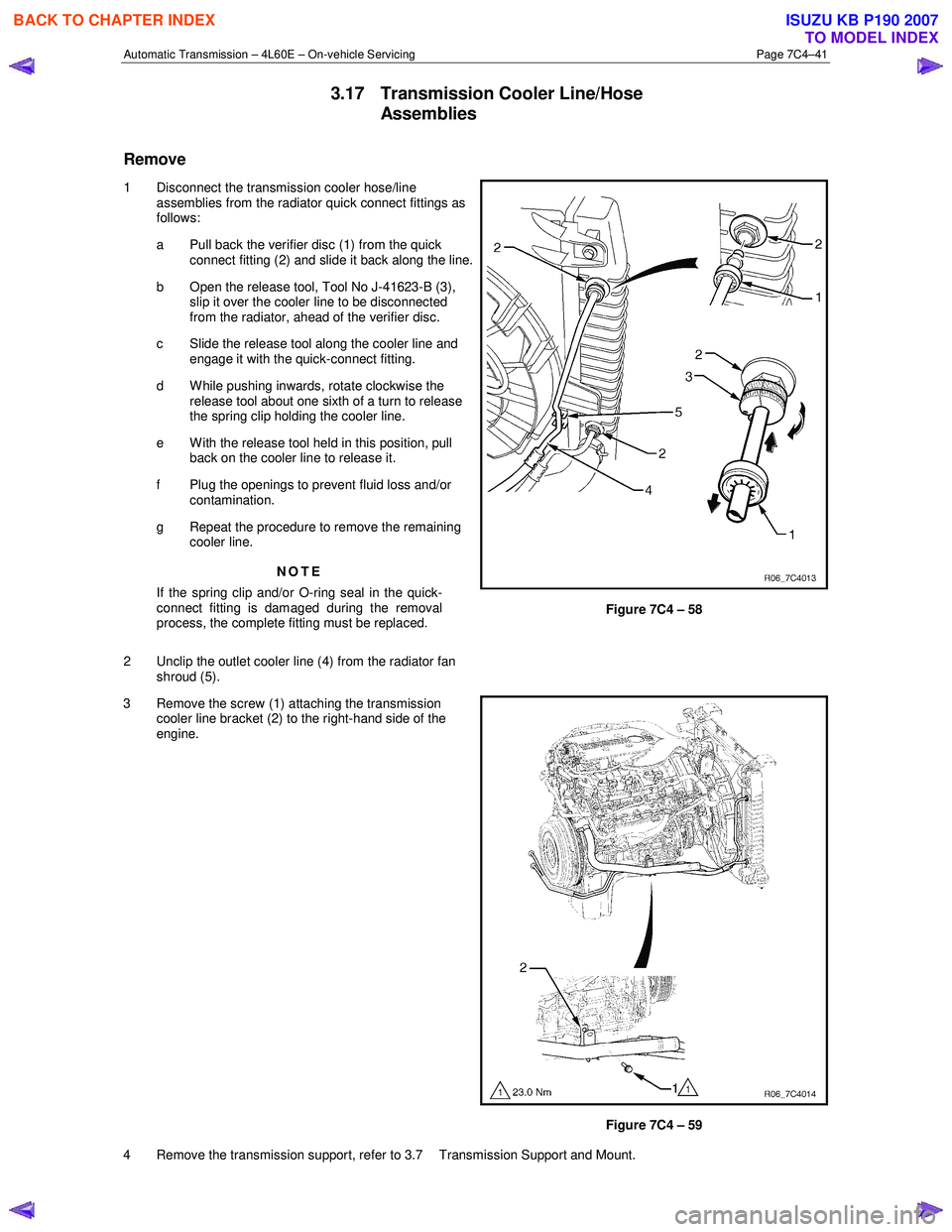

a Pull back the verifier disc (1) from the quick connect fitting (2) and slide it back along the line.

b Open the release tool, Tool No J-41623-B (3), slip it over the cooler line to be disconnected

from the radiator, ahead of the verifier disc.

c Slide the release tool along the cooler line and engage it with the quick-connect fitting.

d W hile pushing inwards, rotate clockwise the release tool about one sixth of a turn to release

the spring clip holding the cooler line.

e With the release tool held in this position, pull back on the cooler line to release it.

f Plug the openings to prevent fluid loss and/or contamination.

g Repeat the procedure to remove the remaining cooler line.

NOTE

If the spring clip and/or O-ring seal in the quick-

connect fitting is damaged during the removal

process, the complete fitting must be replaced.

2 Unclip the outlet cooler line (4) from the radiator fan shroud (5).

Figure 7C4 – 58

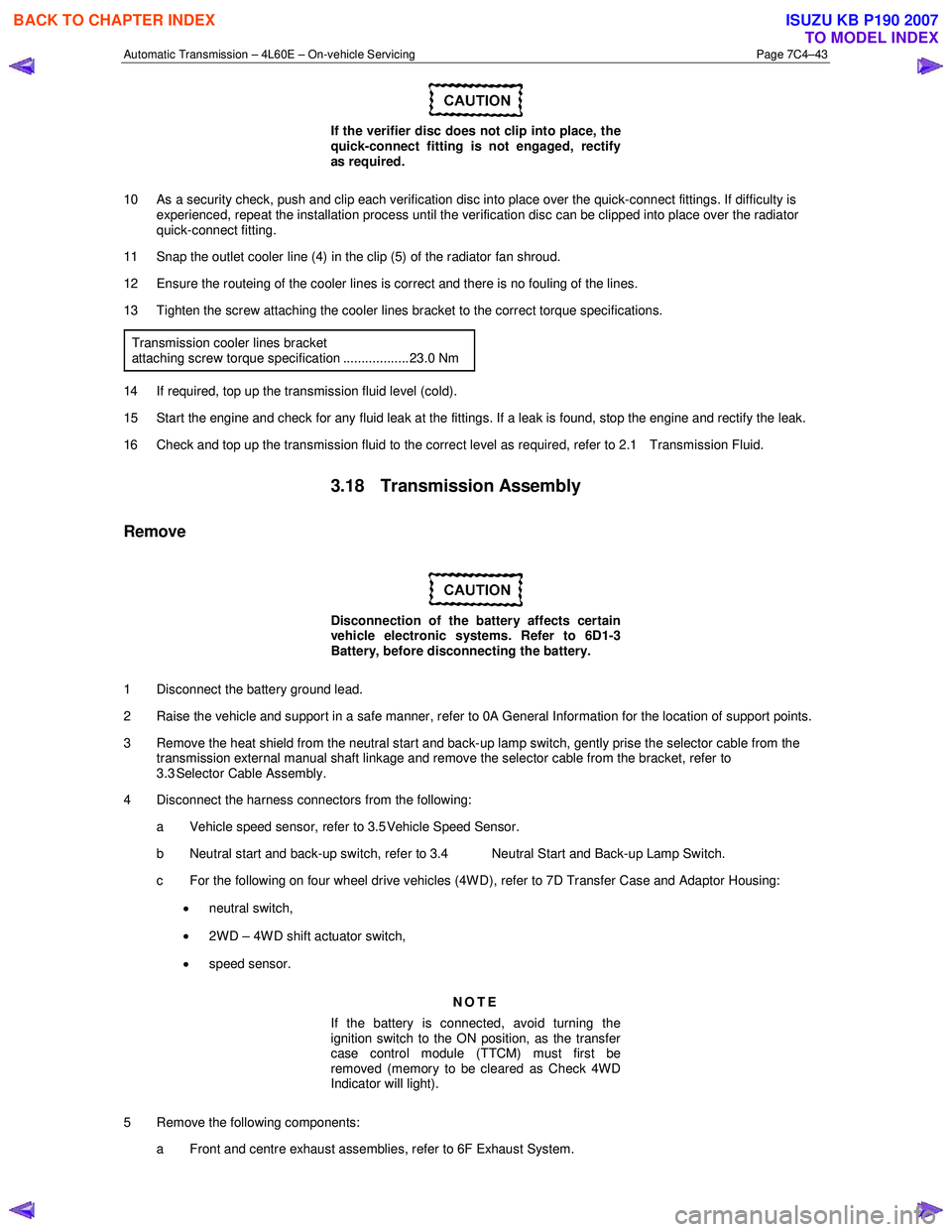

3 Remove the screw (1) attaching the transmission cooler line bracket (2) to the right-hand side of the

engine.

Figure 7C4 – 59

4 Remove the transmission support, refer to 3.7 Transmission Support and Mount.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3955 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–42

5 Carefully lower the rear of the transmission sufficiently to get access to the cooler lines.

6 Place a suitable sized drip tray underneath the transmission.

7 W ith the rear of the transmission lowered, disconnect the cooler lines from the transmission, as follows:

a Pull back the verifier disc (1) to release it and slide it back along the cooler line (2).

b Open the release tool, Tool No J-41623-B (3), slip it over the cooler line to be disconnected

from the transmission, ahead of the verifier disc.

c Slide the release tool along the cooler line and engage it with the quick-connect fitting (4).

d W hile pushing inwards, rotate clockwise the release tool about one sixth of a turn to release

the spring clip holding the cooler line.

e With the release tool held in this position, pull back on the cooler line to release it.

f Plug all openings to prevent fluid loss and/or contamination.

g Repeat this process with the remaining cooler line.

NOTE

If the spring clip and/or O-ring seal in the quick-

connect fitting is damaged during the removal

process, the complete fitting must be replaced.

Figure 7C4 – 60

8 Carefully remove the two cooler lines from the vehicle.

9 As required, separate the two cooler lines by removing the bracket and the two clips.

Reinstall

1 On the transmission end, ensure the spring clip and/or O-ring seal in each quick-connect fitting is not damaged, replace the complete fitting if required.

2 If required, fit the bracket and the two clips to attach the transmission two cooler lines together.

3 Position the cooler lines in place, attach the cooler line bracket (2) with the screw (1) hand tight to the right-hand side of the engine, refer to Figure 7C4 – 59.

4 Remove the plugs from the cooler lines and transmission fittings and wipe all exposed parts clean.

5 At the transmission end, smear the fluid lines rear fittings with clean automatic transmission fluid and push the quick-connect fittings together.

If the verifier disc does not clip into place, the

quick-connect fitting is not engaged, rectify

as required.

6 As a security check, push and clip each verification disc into place over the quick-connect fittings. If difficulty is experienced, repeat the installation process until the verification disc can be clipped into place over the

transmission quick-connect fitting.

7 Reinstall the transmission support, refer to 3.7 Transmission Support and Mount.

8 Remove the plugs from the cooler lines and radiator fittings and wipe all exposed parts clean.

9 At the radiator end, smear the fluid lines fittings with clean automatic transmission fluid and push the quick-connect fittings together, refer to Figure 7C4 – 58.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3956 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–43

If the verifier disc does not clip into place, the

quick-connect fitting is not engaged, rectify

as required.

10 As a security check, push and clip each verification disc into place over the quick-connect fittings. If difficulty is experienced, repeat the installation process until the verification disc can be clipped into place over the radiator

quick-connect fitting.

11 Snap the outlet cooler line (4) in the clip (5) of the radiator fan shroud.

12 Ensure the routeing of the cooler lines is correct and there is no fouling of the lines.

13 Tighten the screw attaching the cooler lines bracket to the correct torque specifications.

Transmission cooler lines bracket

attaching screw torque specification .................. 23.0 Nm

14 If required, top up the transmission fluid level (cold).

15 Start the engine and check for any fluid leak at the fittings. If a leak is found, stop the engine and rectify the leak.

16 Check and top up the transmission fluid to the correct level as required, refer to 2.1 Transmission Fluid.

3.18 Transmission Assembly

Remove

Disconnection of the battery affects certain

vehicle electronic systems. Refer to 6D1-3

Battery, before disconnecting the battery.

1 Disconnect the battery ground lead.

2 Raise the vehicle and support in a safe manner, refer to 0A General Information for the location of support points.

3 Remove the heat shield from the neutral start and back-up lamp switch, gently prise the selector cable from the transmission external manual shaft linkage and remove the selector cable from the bracket, refer to

3.3 Selector Cable Assembly.

4 Disconnect the harness connectors from the following:

a Vehicle speed sensor, refer to 3.5 Vehicle Speed Sensor.

b Neutral start and back-up switch, refer to 3.4 Neutral Start and Back-up Lamp Switch.

c For the following on four wheel drive vehicles (4W D), refer to 7D Transfer Case and Adaptor Housing:

• neutral switch,

• 2WD – 4WD shift actuator switch,

• speed sensor.

NOTE

If the battery is connected, avoid turning the

ignition switch to the ON position, as the transfer

case control module (TTCM) must first be

removed (memory to be cleared as Check 4W D

Indicator will light).

5 Remove the following components: a Front and centre exhaust assemblies, refer to 6F Exhaust System.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4243 of 6020

7A1-4 CONSTRUCTION AND FUNCTION

MAIN DATA AND SPECIFICATION

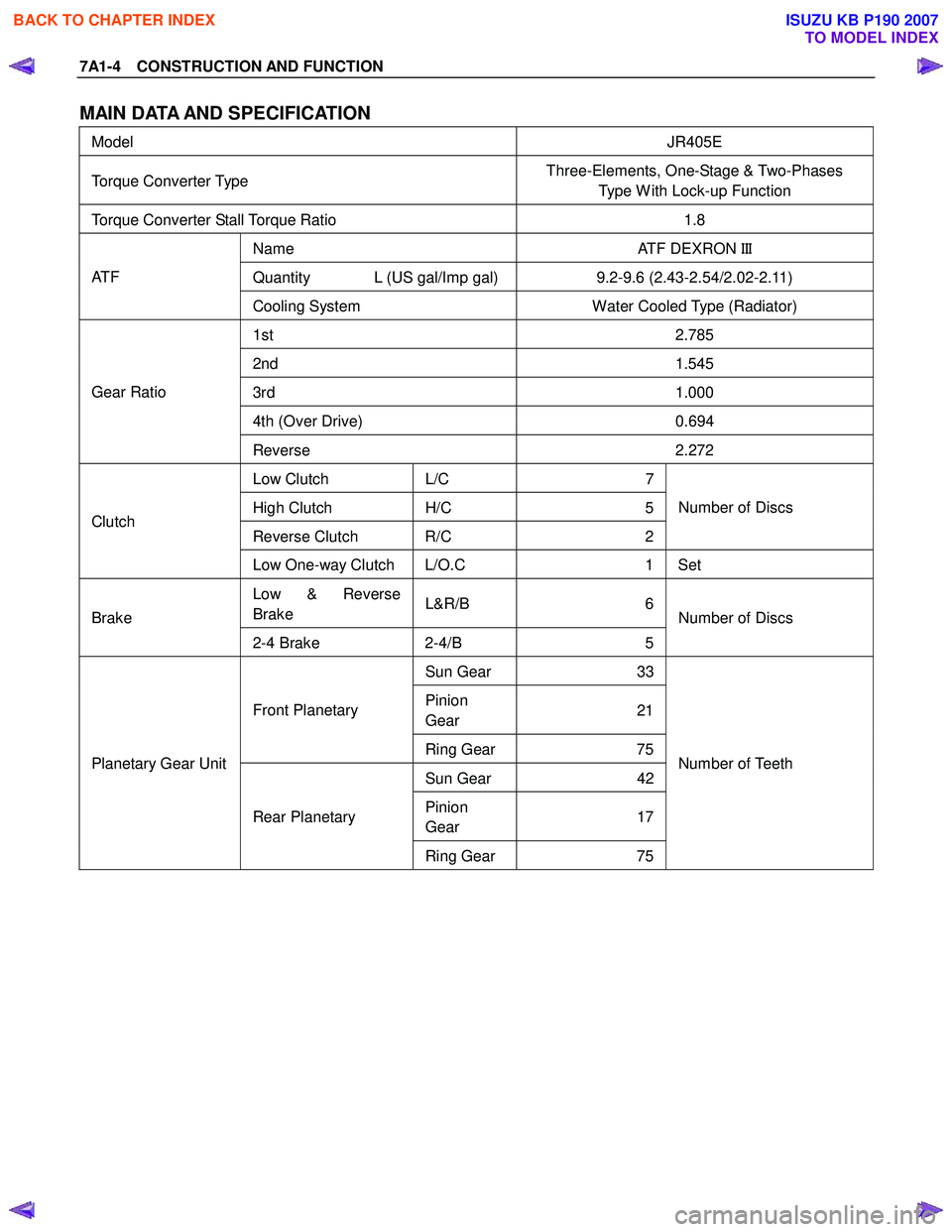

Model JR405E

Torque Converter Type Three-Elements, One-Stage & Two-Phases

Type W ith Lock-up Function

Torque Converter Stall Torque Ratio 1.8

Name ATF DEXRON III

Quantity L (US gal/Imp gal) 9.2-9.6 (2.43-2.54/2.02-2.11) AT F

Cooling System Water Cooled Type (Radiator)

1st 2.785

2nd 1.545

3rd 1.000

4th (Over Drive) 0.694

Gear Ratio

Reverse 2.272

Low Clutch L/C 7

High Clutch H/C 5

Reverse Clutch R/C 2Number of Discs Clutch

Low One-way Clutch L/O.C 1 Set

Low & Reverse

Brake L&R/B 6

Brake

2-4 Brake 2-4/B 5 Number of Discs

Sun Gear

33

Pinion

Gear 21Front Planetary

Ring Gear 75

Sun Gear 42

Pinion

Gear 17

Planetary Gear Unit

Rear Planetary Ring Gear 75 Number of Teeth

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007