ISUZU KB P190 2007 Workshop Repair Manual

Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 271 of 6020

3B-10 POWER-ASSISTED STEERING SYSTEM

Torque Specification

N⋅m (kgf ⋅m/Ib ⋅ft)

RTW 53BLF001001

Special Tools

ILLUSTRATION

TOOL NO.

TOOL NAME

ILLUSTRATION

TOOL NO.

TOOL NAME

5-8840-0135-0

(J-29877-A) Tester;

Power steering 5-8840-2297-0

(J-39213) Adapter;

Power steering tester

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 272 of 6020

POWER-ASSISTED STEERING SYSTEM 3B-11

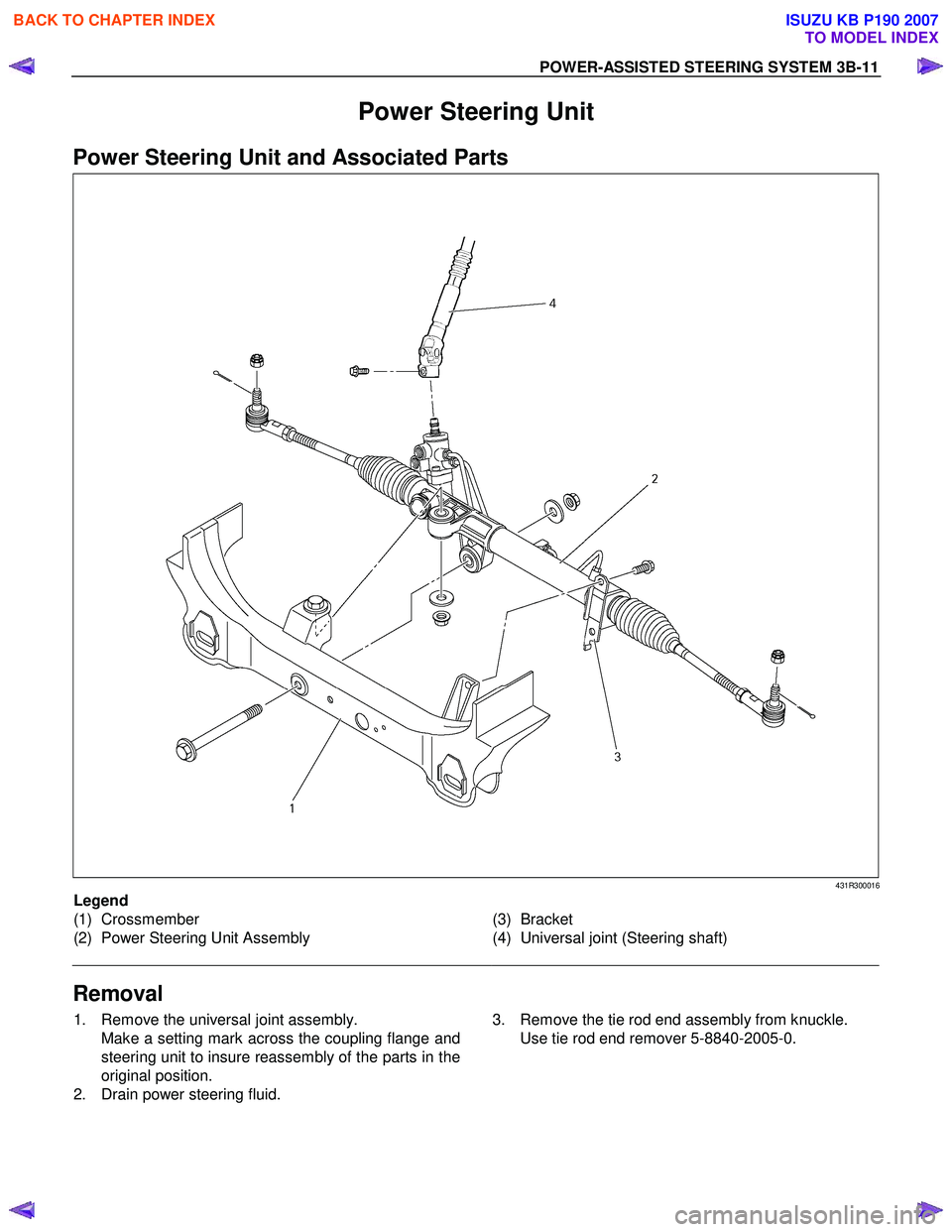

Power Steering Unit

Power Steering Unit and Associated Parts

431R300016

Legend

(1) Crossmember

(2) Power Steering Unit Assembly

(3) Bracket

(4) Universal joint (Steering shaft)

Removal

1. Remove the universal joint assembly. Make a setting mark across the coupling flange and

steering unit to insure reassembly of the parts in the

original position.

2. Drain power steering fluid.

3. Remove the tie rod end assembly from knuckle.

Use tie rod end remover 5-8840-2005-0.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 273 of 6020

3B-12 POWER-ASSISTED STEERING SYSTEM

901RW 270

4. Disconnect the feed line and return line from

steering unit.

Remove the clips on the crossmember and frame.

W ire the power steering line to frame.

NOTE: Take care to prevent foreign matter from

entering when disconnecting the power steering line.

5. Remove the power steering unit from the crossmember.

Installation

1. Install power steering unit on crossmember.

Tighten fixing bolt and nut to specified torque.

Torque:

116 N ⋅

⋅⋅

⋅

m (11.8 kgf ⋅

⋅⋅

⋅

m/85 lb ⋅

⋅⋅

⋅

ft)

Torque:

220 N ⋅

⋅⋅

⋅

m (22.4 kgf ⋅

⋅⋅

⋅

m/162 lb ⋅

⋅⋅

⋅

ft)

2. Connect the feed line and return line. Torque:

25 N ⋅

⋅⋅

⋅

m (2.5 kgf ⋅

⋅⋅

⋅

m/18 lb ⋅

⋅⋅

⋅

ft)

3. Install tie-rod end assembly on knuckle. Torque:

98 N ⋅

⋅⋅

⋅

m (10 kgf ⋅

⋅⋅

⋅

m/72 lb ⋅

⋅⋅

⋅

ft)

4.

Align the setting marks on the universal joint

(applied at disassembly) with the setting marks on

the power steering unit. Connect the universal joint

assembly to the power steering unit.

5. Tighten the universal joint bolt to the specified torque.

Torque:

31 N ⋅

⋅⋅

⋅

m (3.2 kgf ⋅

⋅⋅

⋅

m/23 lb ⋅

⋅⋅

⋅

ft)

6. Install the stone guard.

7. Bleed the system. Refer to Bleeding the Power Steering System in this

section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 274 of 6020

POWER-ASSISTED STEERING SYSTEM 3B-13

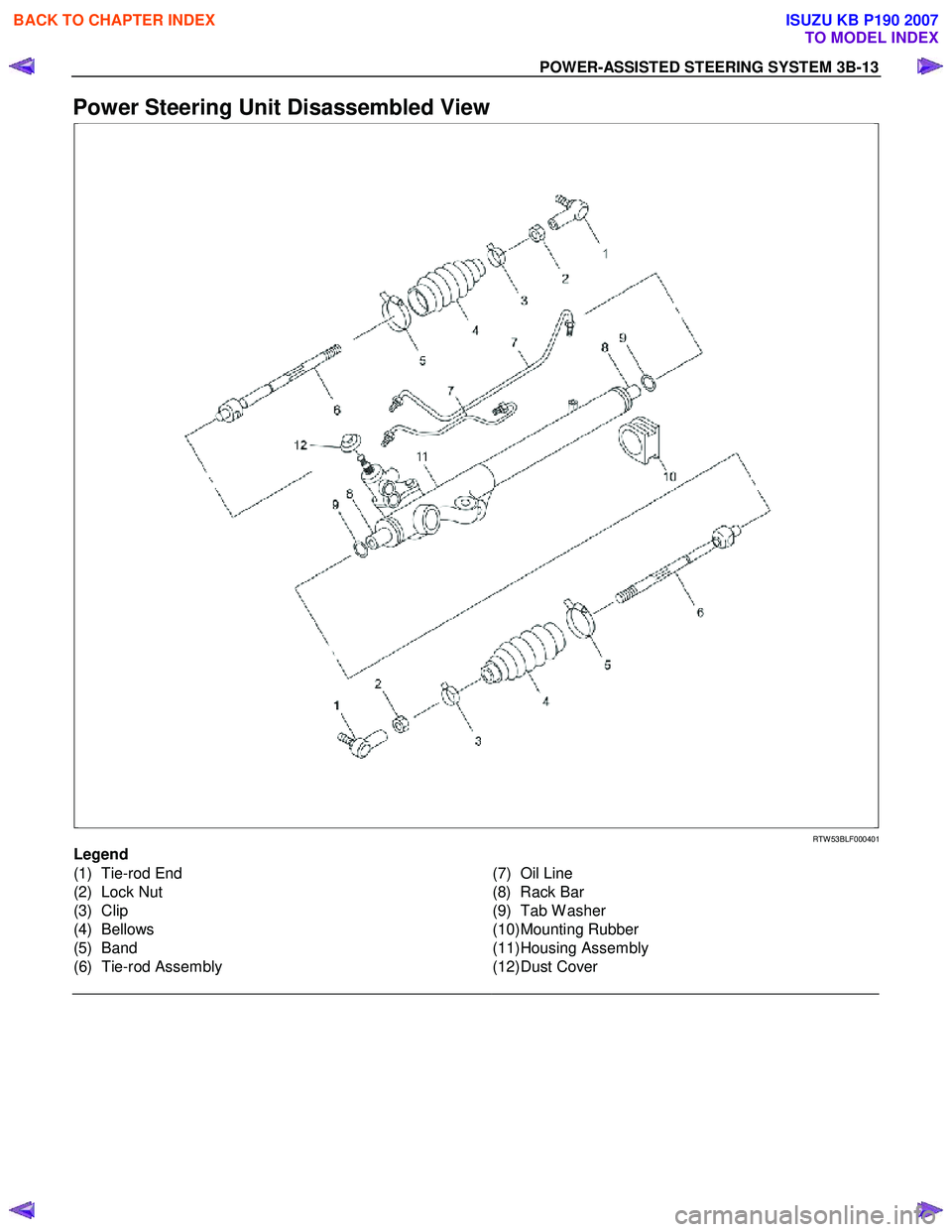

Power Steering Unit Disassembled View

RTW 53BLF000401

Legend

(1) Tie-rod End

(2) Lock Nut

(3) Clip

(4) Bellows

(5) Band

(6) Tie-rod Assembly

(7) Oil Line

(8) Rack Bar

(9) Tab W asher

(10) Mounting Rubber

(11) Housing Assembly

(12) Dust Cover

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 275 of 6020

3B-14 POWER-ASSISTED STEERING SYSTEM

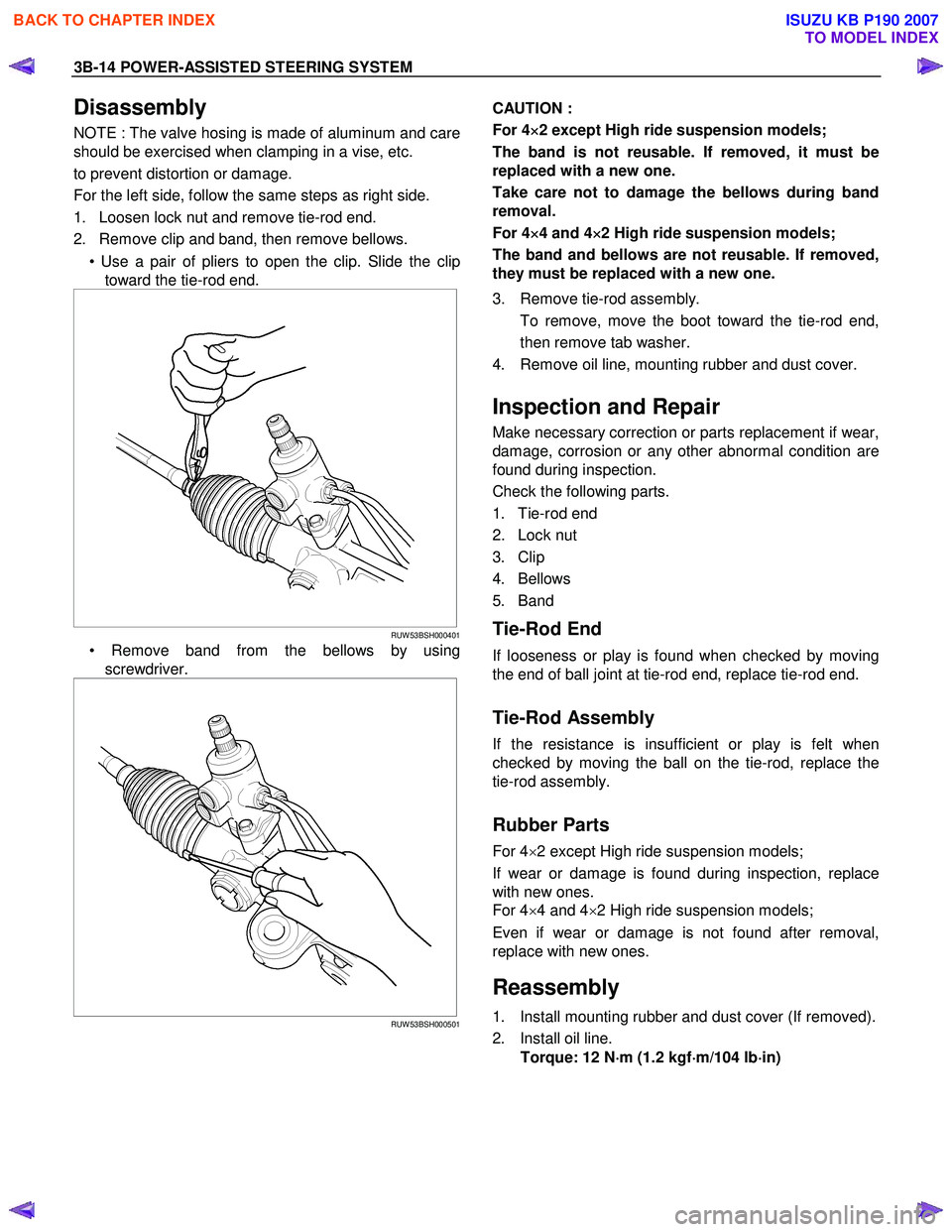

Disassembly

NOTE : The valve hosing is made of aluminum and care

should be exercised when clamping in a vise, etc.

to prevent distortion or damage.

For the left side, follow the same steps as right side.

1. Loosen lock nut and remove tie-rod end.

2. Remove clip and band, then remove bellows.

• Use a pair of pliers to open the clip. Slide the cliptoward the tie-rod end.

RUW 53BSH000401

• Remove band from the bellows by using

screwdriver.

RUW 53BSH000501

CAUTION :

For 4 ×

××

×

2 except High ride suspension models;

The band is not reusable. If removed, it must be

replaced with a new one.

Take care not to damage the bellows during band

removal.

For 4 ×

××

×

4 and 4 ×

××

×

2 High ride suspension models;

The band and bellows are not reusable. If removed,

they must be replaced with a new one.

3. Remove tie-rod assembly.

To remove, move the boot toward the tie-rod end, then remove tab washer.

4. Remove oil line, mounting rubber and dust cover.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition are

found during inspection.

Check the following parts.

1. Tie-rod end

2. Lock nut

3. Clip

4. Bellows

5. Band

Tie-Rod End

If looseness or play is found when checked by moving

the end of ball joint at tie-rod end, replace tie-rod end.

Tie-Rod Assembly

If the resistance is insufficient or play is felt when

checked by moving the ball on the tie-rod, replace the

tie-rod assembly.

Rubber Parts

For 4 ×2 except High ride suspension models;

If wear or damage is found during inspection, replace

with new ones.

For 4 ×4 and 4 ×2 High ride suspension models;

Even if wear or damage is not found after removal,

replace with new ones.

Reassembly

1. Install mounting rubber and dust cover (If removed).

2. Install oil line. Torque: 12 N ⋅

⋅⋅

⋅

m (1.2 kgf ⋅

⋅⋅

⋅

m/104 lb ⋅

⋅⋅

⋅

in)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 276 of 6020

POWER-ASSISTED STEERING SYSTEM 3B-15

3. Install tie-rod assembly with tab washer, then tighten

to specified torque. For 4 ×2 except High ride suspension models;

Torque: 83 N ⋅

⋅⋅

⋅

m (8.5 kgf ⋅

⋅⋅

⋅

m/61 lb ⋅

⋅⋅

⋅

ft)

For 4 ×4 and 4 ×2 High ride suspension models;

Torque: 108 N ⋅

⋅⋅

⋅

m (11.0 kgf ⋅

⋅⋅

⋅

m/80 lb ⋅

⋅⋅

⋅

ft)

After tightening, bend tab washer against width

across flat of inner ball joint.

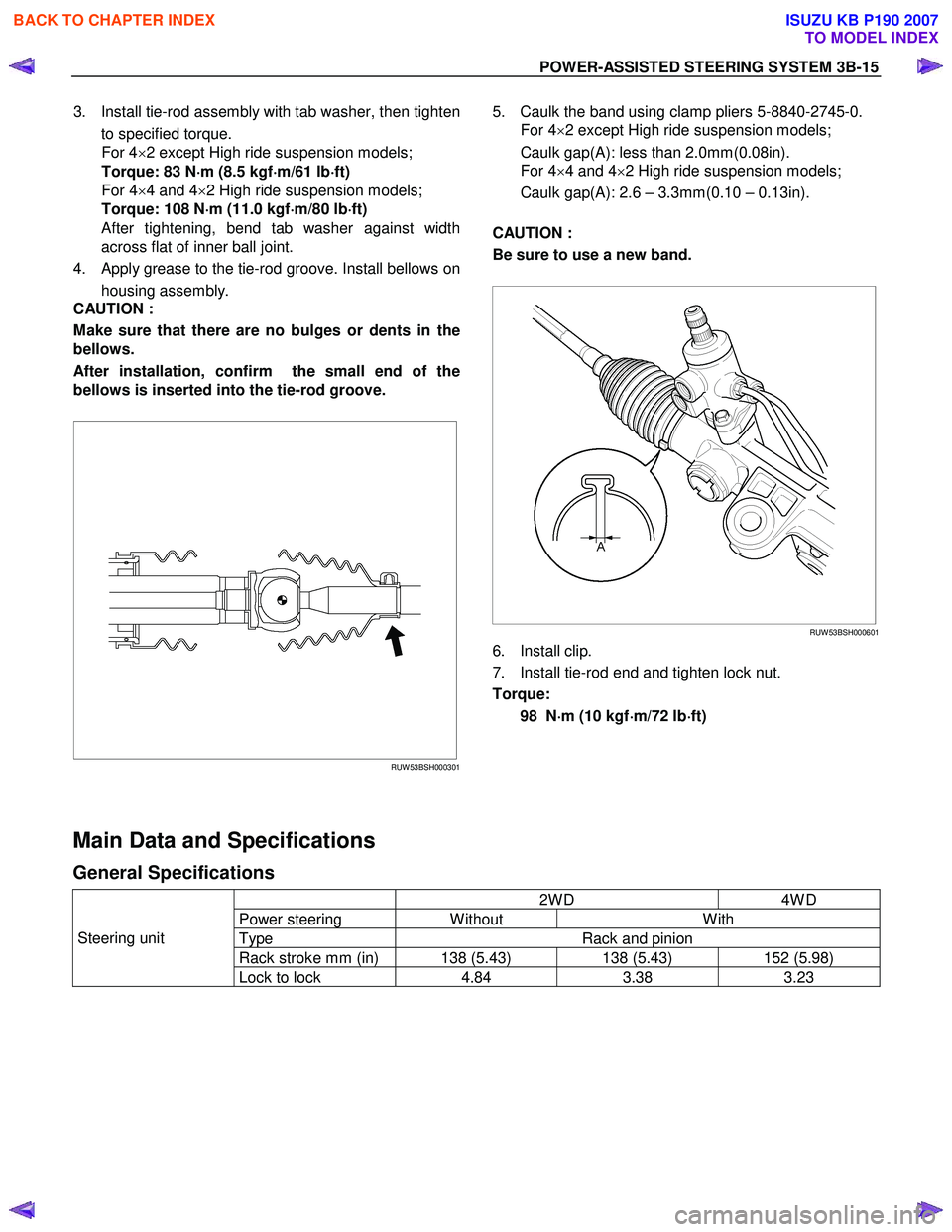

4. Apply grease to the tie-rod groove. Install bellows on housing assembly.

CAUTION :

Make sure that there are no bulges or dents in the

bellows.

After installation, confirm the small end of the

bellows is inserted into the tie-rod groove.

RUW 53BSH000301

5. Caulk the band using clamp pliers 5-8840-2745-0.

For 4 ×2 except High ride suspension models;

Caulk gap(A): less than 2.0mm(0.08in).

For 4 ×4 and 4 ×2 High ride suspension models;

Caulk gap(A): 2.6 – 3.3mm(0.10 – 0.13in).

CAUTION :

Be sure to use a new band.

RUW 53BSH000601

6. Install clip.

7. Install tie-rod end and tighten lock nut.

Torque:

98 N ⋅

⋅⋅

⋅

m (10 kgf ⋅

⋅⋅

⋅

m/72 lb ⋅

⋅⋅

⋅

ft)

Main Data and Specifications

General Specifications

2W D 4W D

Power steering W ithout W ith

Type Rack and pinion

Rack stroke mm (in) 138 (5.43) 138 (5.43) 152 (5.98)

Steering unit

Lock to lock 4.84 3.38 3.23

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 277 of 6020

3B-16 POWER-ASSISTED STEERING SYSTEM

Torque Specifications

N⋅m (kgf ⋅m/Ib ⋅ft)

RTW 73BLF000801

Special Tools

ILLUSTRATION

TOOL NO.

TOOL NAME

ILLUSTRATION

TOOL NO.

TOOL NAME

5-8840-2005-0

(J-29107)

Tie rod end remover

5-8840-2745-0 Clamp plier

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 278 of 6020

POWER-ASSISTED STEERING SYSTEM 3B-17

Power Steering Pump (4JH1-TC, 4JA1-T)

Power Steering Pump and Associated Parts

RTW 53BMF000401

Legend (1) Pump Assembly

(2) Suction Hose

(3) Flexible Hose

(4) Bolt

(5) Bracket

Removal

1. Remove the drive belt.

2. Remove the pulley

3. Place a drain pan below the pump.

4. Disconnect the suction hose.

5. Disconnect the flexible hose.

6. Remove the power steering fixing bolt and remove the pump assembly.

Installation

1. Install the pump assembly to the pump braket,

tighten the fixing bolt to the specified torque.

Torque: 40 N·m (4.1 kgf·m/30 lb·ft)

2. Install the flexible hose.

Tighten the nut to specified torque.

Torque: 20 N·m (2.0 kgf·m/14 lb·ft)

3. Install the pulley and tighten the bolt to the specified torque.

Torque: 28 N·m (2.9 kgf·m/21 lb·ft)

4. Install the drive belt.

5. Connect the suction hose, then fill and bleed system.

Refer to Bleeding the Power Steering System in this section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 279 of 6020

3B-18 POWER-ASSISTED STEERING SYSTEM

Power Steering Pump Disassembled View

RTW 63BLF000301

Legend

(1) Bolt

(2) Suction Pipe

(3) O-ring

(4) Shaft Assembly

(5) Oil Seal

(6) Front Housing

(7) O-ring

(8) O-ring

(9) Side Plate

(10) Rotor and Vane

(11) Cam

(12) Pump Cartridge Assembly

(13) O-ring

(14) Snap Ring

(15) Rear Housing

(16) Bolt

(17) Spring

(18) Relief Valve

(19) O-ring

(20) Connector

(21) Bush

(22) Pulley

(23) O-ring

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 280 of 6020

POWER-ASSISTED STEERING SYSTEM 3B-19

Disassembly

1. Clean the oil pump with solvent (plug the discharge

and suction ports to prevent the entry of solvent).

Be careful not to expose the oil seal of shaft

assembly to solvent.

2. Remove the bolt, suction pipe and O-ring.

3. Remove the connector, O-ring, relief valve and spring.

4. Remove the bolt, rear housing and O-ring.

5. Remove the snap ring.

6. Remove the shaft assembly.

7. Remove the oil seal.

CAUTION: When removing the oil seal, be careful

not to damage the housing.

8. Remove the pump cartridge assembly from the front housing.

9. Remove two O-rings.

Inspection and Repair

Make all necessary adjustments, repairs, and part

replacements if wear, damage, or other problems are

discovered during inspection.

Rotor

442RS002

Check that the groove in the vane is free from excessive

wear and that the vane slides smoothly. W hen part

replacement becomes necessary, the pump cartridge

should be replaced as a subassembly.

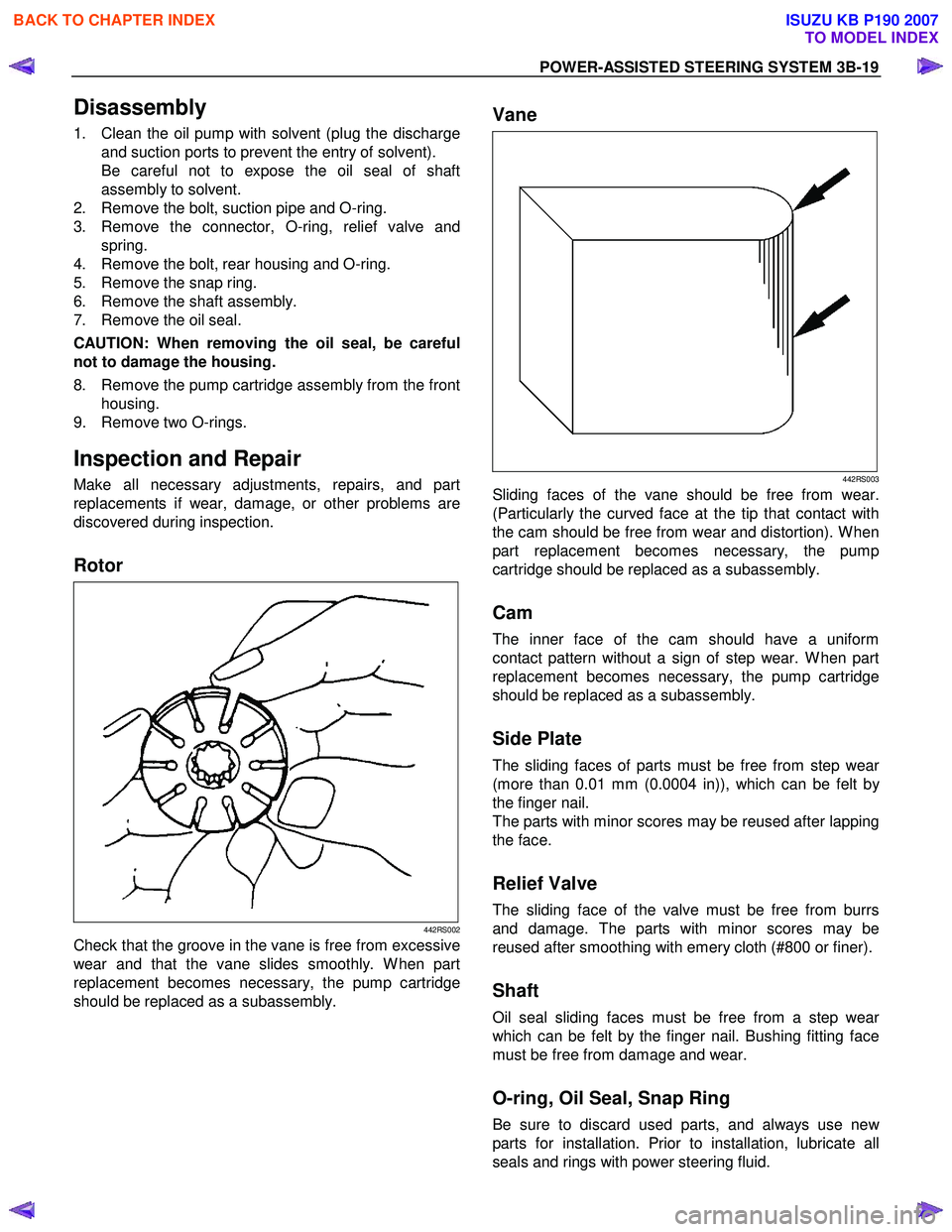

Vane

442RS003

Sliding faces of the vane should be free from wear.

(Particularly the curved face at the tip that contact with

the cam should be free from wear and distortion). W hen

part replacement becomes necessary, the pump

cartridge should be replaced as a subassembly.

Cam

The inner face of the cam should have a uniform

contact pattern without a sign of step wear. W hen part

replacement becomes necessary, the pump cartridge

should be replaced as a subassembly.

Side Plate

The sliding faces of parts must be free from step wear

(more than 0.01 mm (0.0004 in)), which can be felt b

y

the finger nail.

The parts with minor scores may be reused after lapping

the face.

Relief Valve

The sliding face of the valve must be free from burrs

and damage. The parts with minor scores may be

reused after smoothing with emery cloth (#800 or finer).

Shaft

Oil seal sliding faces must be free from a step wear

which can be felt by the finger nail. Bushing fitting face

must be free from damage and wear.

O-ring, Oil Seal, Snap Ring

Be sure to discard used parts, and always use new

parts for installation. Prior to installation, lubricate all

seals and rings with power steering fluid.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007