engine oil ISUZU KB P190 2007 Workshop Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 317 of 6020

3B-56 POWER-ASSISTED STEERING SYSTEM

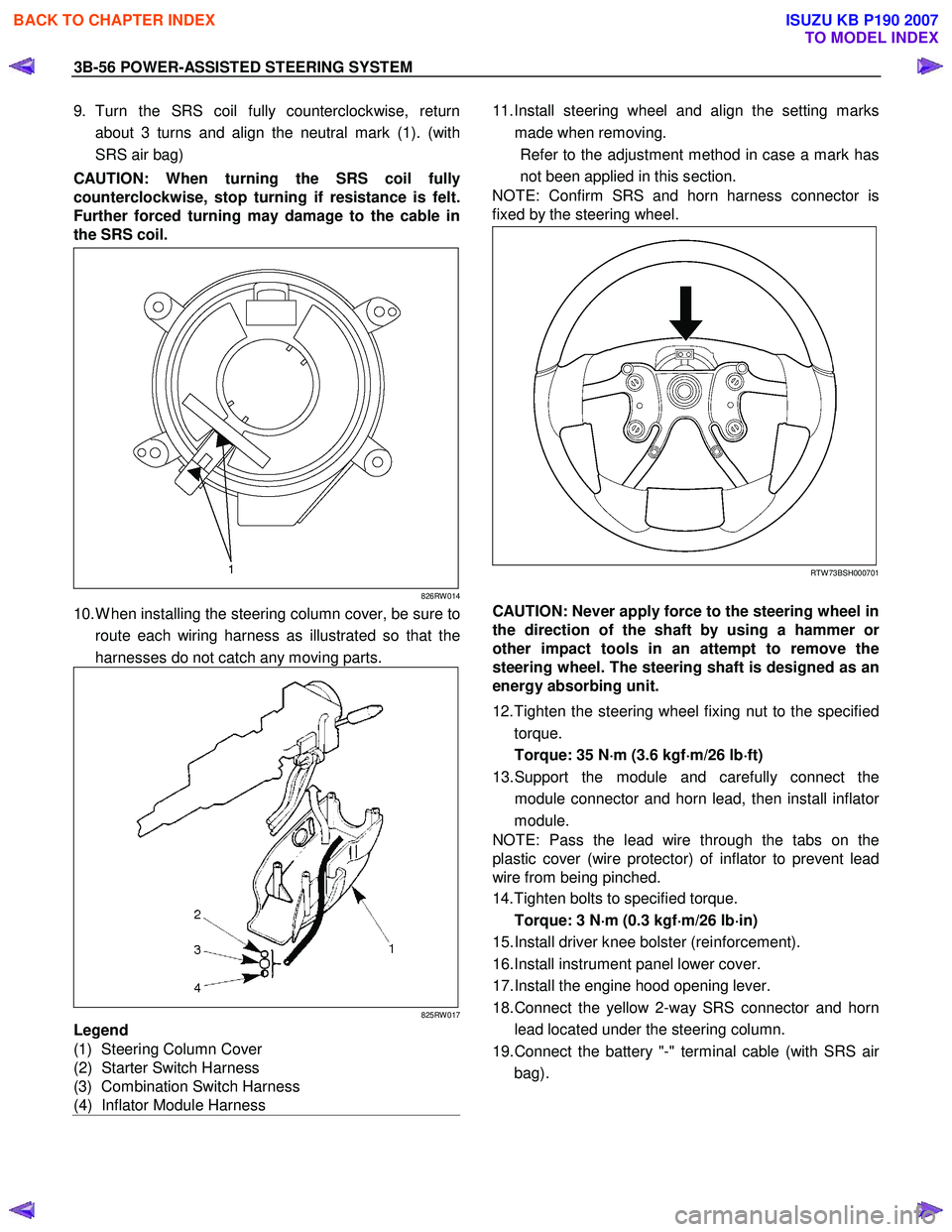

9. Turn the SRS coil fully counterclockwise, return

about 3 turns and align the neutral mark (1). (with

SRS air bag)

CAUTION: When turning the SRS coil fully

counterclockwise, stop turning if resistance is felt.

Further forced turning may damage to the cable in

the SRS coil.

826RW 014

10. W hen installing the steering column cover, be sure to

route each wiring harness as illustrated so that the

harnesses do not catch any moving parts.

825RW 017

Legend

(1) Steering Column Cover

(2) Starter Switch Harness

(3) Combination Switch Harness

(4) Inflator Module Harness

11. Install steering wheel and align the setting marks

made when removing. Refer to the adjustment method in case a mark has

not been applied in this section.

NOTE: Confirm SRS and horn harness connector is

fixed by the steering wheel.

RTW 73BSH000701

CAUTION: Never apply force to the steering wheel in

the direction of the shaft by using a hammer o

r

other impact tools in an attempt to remove the

steering wheel. The steering shaft is designed as an

energy absorbing unit.

12. Tighten the steering wheel fixing nut to the specified torque.

Torque: 35 N ⋅

⋅⋅

⋅

m (3.6 kgf ⋅

⋅⋅

⋅

m/26 lb ⋅

⋅⋅

⋅

ft)

13. Support the module and carefully connect the module connector and horn lead, then install inflato

r

module.

NOTE: Pass the lead wire through the tabs on the

plastic cover (wire protector) of inflator to prevent lead

wire from being pinched.

14. Tighten bolts to specified torque.

Torque: 3 N ⋅

⋅⋅

⋅

m (0.3 kgf ⋅

⋅⋅

⋅

m/26 lb ⋅

⋅⋅

⋅

in)

15. Install driver knee bolster (reinforcement).

16. Install instrument panel lower cover.

17. Install the engine hood opening lever.

18. Connect the yellow 2-way SRS connector and horn lead located under the steering column.

19. Connect the battery "-" terminal cable (with SRS ai

r

bag).

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 489 of 6020

REAR AXLE 4B-45

TROUBLESHOOTING

Refer to this Section to quickly diagnose and repai

r

rear axle problems.

Each troubleshooting chart has three headings

arranged from left to right.

(1) Checkpoint

(2) Trouble Cause

(3) Countermeasure

This Section is divided into five sub-sections:

1. Abnormal Rear Axle Noise 1) Noise when the engine is driving the vehicle

2) Noise when the vehicle is coasting

3) Intermittent noise

4) Noise when the vehicle is turning

5) Constant noise

2. Vibration

3. Oil Leakage 1) Differential carrier leakage

2) Axle case leakage

3) Axle case to inside hub leakage

4) Axle case to inside brake drum leakage

4. Power Not Being Transmitted to the W heels (Propeller Shaft Operation is Normal)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 490 of 6020

4B-46 REAR AXLE

1. ABNORMAL REAR AXLE NOISE

1) Noise when the Engine is Driving the Vehicle

Checkpoint Trouble Cause Countermeasure

Replenish the gear oilInsufficient gear oil

NG

Differential side bearingAdjust the differential side

bearing preload

Replace the drive pinion

bearings

Adjust the drive pinion bearing

preload

Replace the gear oil

Loose differential side

bearings

W orn drive pinion bearings

Loose drive pinion bearings

W rong or poor grade gear oil

Drive pinion to ring gear

backlash

Drive pinion end play

Adjust the backlashToo much or too little backlash

Continued on the next page OK

OK

NG

NG

NG

NG

NG

OK

OK

Rear axle gear oil

Replace the differential side

bearingsW orn differential side bearings

NG

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 724 of 6020

BRAKES 5C-25

Filling Master Cylinder Reservoir

CAUTION:

Use only specified brake fluid. Do not use any fluid which

contains a petroleum base. Do not use a container which

has been used for petroleum based fluids or a containe

r

which is wet with water. Petroleum based fluid will cause

swelling and distortion of rubber parts in the hydraulic

brake system. Water mixed with brake fluid lowers the

fluid boiling point. Keep all fluid containers capped to

prevent contamination.

Always fill the master cylinder reservoir when the engine

is cold.

Never allow the brake fluid to come in contact with the

painted surfaces.

The master cylinder reservoir must be kept properly filled

to ensure adequate reserve and to prevent air and

moisture from entering the hydraulic system. However,

because of expansion due to heat absorbed from the

brakes and the engine, the reservoir must not be

overfilled. Thoroughly clean reservoir cap before removal

to avoid getting dirt into reservoir. Add fluid as required to

bring level to the “MAX” mark on the reservoir tank. Use

“DOT 3” Hydraulic Brake Fluid.

Leakage of Brake Fluid

W ith engine idling, set shift lever in the neutral position and

continue to depress brake pedal at a constant pedal

application force.

Should the pedal stroke become deeper gradually, leakage

from the hydraulic pressure system is possible.

Make sure by visual check that there is no leak.

BLEEDING OF THE BRAKE HYDRAULIC

CIRCUIT

If air enters the bake lines, it will cause poor brake action.

Therefore, bleeding should be performed if the brakes have

been used with the level of brake fluid in the reservoi

r

excessively low or if brake pipes have been disconnected in

the course of brake servicing.

The bleeding operation calls for co-operative action of 2

persons.

• Set the parking brake firmly while bleeding.

• Perform bleeding operation with ENGINE RUNNING, to

prevent damage to push rod seal.

Make sure exhaust is suitably ventilated.

• Bleed the hydraulic system with the fluid reservoir filled to

the specified level.

• Bleed the system starting with the rear wheel cylinde

r

farthest from the master cylinder.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 761 of 6020

5C-62 BRAKES

360r300003

5. Vacuum Hose

The check valve (2) is built-in to the vacuum hose.

W hen installing the vacuum hose make sure that the arrow on

the hose is facing the engine (1).

Note:

• Do not apply oil to the vacuum hose.

• Installation direction is very important. The booster will not

operate if the vacuum hose is installed in the wrong

direction.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 786 of 6020

TROUBLESHOOTING 6 – 1

BASIC INSPECTION PROCEDURE....6– 2

1. HARD STARTING ............................6– 3

1-1.Starter Motor Inoperative ..........6– 3

1-2. Starter Motor Operates But

Engine Does Not Turn Over ...........6– 3

1-3. Engine Turns Over But Does

Not Start Engine ..............................6– 4

2. UNSTABLE IDLING .........................6– 5

3. INSUFFICIENT POWER ..................6– 6

4. EXCESSIVE FUEL

CONSUMPTION..................................6– 7

5. EXCESSIVE OIL CONSUMPTION ..6– 8

6. OVERHEATING ...............................6– 9

7. WHITE EXHAUST SMOKE..............6– 9

8. DARK EXHAUST SMOKE ...............6– 10

9. OIL PRESSURE DOES NOT RISE..6– 11

10. ABNORMAL ENGINE NOISE ........6– 12

10-1. Engine Knocking ....................6– 12

10-2. Gas Leakage Noise .................6– 12

10-3. Continuous Noise ...................6– 13

10-4. Slapping Noise ........................6– 13

10-5. Excessive Turbocharger

Noise ................................................6– 14

11. ROTATING PART WEAR OF

TURBOCHARGER.............................. 6– 14

12. OIL LEAKAGE FROM

TURBOCHRGER ................................ 6– 15

13. INSUFFICIENT ACCELERATION

AND/OR LACK OF POWER DUE

TO TURBOCHARGER........................ 6– 15

14. BATTERY CHARGING AND

NOISE PROBLEM .............................. 6– 16

14-1. Battery No Charging ............... 6– 16

14-2. Battery Overcharging ............. 6– 16

14-3. Battery Under Charging ......... 6– 17

14-4. Battery Unstable Charging

Current ............................................. 6– 17

14-5. Charging System Noise ......... 6– 18

15. STARTER MOTOR PROBLEM ..... 6– 19

15-1. Starter Motor Pinion Engages

to Ring Gear But Engine Does

Not Turn Over .................................. 6– 19

15-2. Incorrect Pinion And Ring

Gear Engagement ........................... 6– 19

15-3. Starter Motor Continues To

Run After The Starter Switch Is

Turned Off........................................ 6– 20

15-4. Excessive Commutator

Sparking .......................................... 6– 20

SECTION 6

TROUBLESHOOTING

TABLE OF CONTENTS

PAGE PAGE

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 787 of 6020

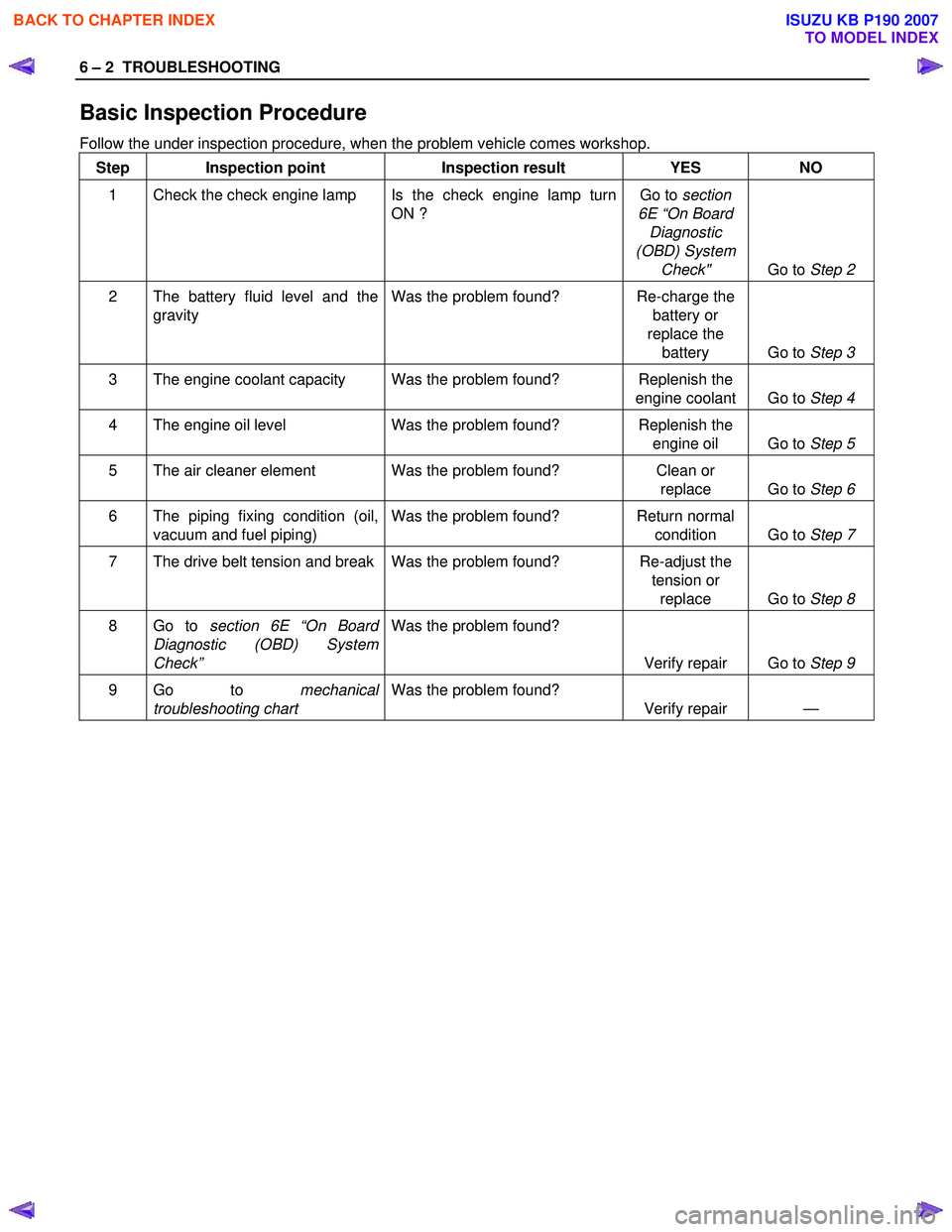

6 – 2 TROUBLESHOOTING

Basic Inspection Procedure

Follow the under inspection procedure, when the problem vehicle comes workshop. Step Inspection point Inspection result YES NO

1 Check the check engine lamp Is the check engine lamp turn ON ? Go to

section

6E “On Board Diagnostic

(OBD) System Check" Go to Step 2

2 The battery fluid level and the

gravity Was the problem found? Re-charge the

battery or

replace the battery Go to Step 3

3 The engine coolant capacity Was the problem found? Replenish the

engine coolant Go to Step 4

4 The engine oil level Was the problem found? Replenish the

engine oil Go to Step 5

5 The air cleaner element Was the problem found? Clean or

replace Go to Step 6

6 The piping fixing condition (oil,

vacuum and fuel piping) Was the problem found? Return normal

condition Go to Step 7

7 The drive belt tension and break Was the problem found? Re-adjust the

tension or replace Go to Step 8

8 Go to section 6E “On Board

Diagnostic (OBD) System

Check” Was the problem found?

Verify repair Go to Step 9

9 Go to mechanical

troubleshooting chart Was the problem found?

Verify repair —

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 794 of 6020

TROUBLESHOOTING 6 – 9

6. Overheating

Step Action Value(s) Yes No

1 Was the engine coolant level OK? —

Go to Step 2 Replenish the

coolant

2 Was the water leakage or the radiator restriction found? (Include radiator cap) —

Repair or

replace the

leakage part. Go to Step 3

3 Was the fan belt slippage found? — Tension or

replace the fan belt. Go to Step 4

4 Was the fan clutch working completely? —

Go to Step 5 Replace the fan

clutch

assembly.

5 Was the oil leakage found from fan clutch? — Replace the fan

clutch

assembly Go to Step 6

6 Was the thermostat working normally? —

Go to Step 7 Replace the

thermostat.

7 Was the water pump working OK? —

Go to Step 8 Replace the

water pump assembly.

8 Was the restriction by the foreign materials in the cooling system found? For example, clog the water

hose between the cylinder body and radiator etc.. —

Clean or

replace the clog part. Go to Step 9

9 Was the water leakage found from the sealing cap

on the cylinder body? —

Replace the

sealing cap or replace the

cylinder body. Go to Step 10

10 Are any DTC stored? — Go to indicated

DTC. Solved

7. White Exhaust Smoke

Step Action Value(s) Yes No

1 Was the compression pressure OK? 3.0 MPa

(31.0 kg/cm2,

441 psi) at 200 rpm

Go to Step 2 Readjust the

valve clearance or replace the cylinder head gasket or

cylinder liner or

piston or piston ring or valve and relation parts.

2 Was the PCV (Positive Crankcase Ventilation) valve working completely? —

Go to Step 3 Repair or

replace the

PCV valve.

3 Was the turbocharger working completely? —

Go to Step 4 Replace the

turbocharger.

4 Are any DTC stored? — Go to indicated

DTC Solved

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 799 of 6020

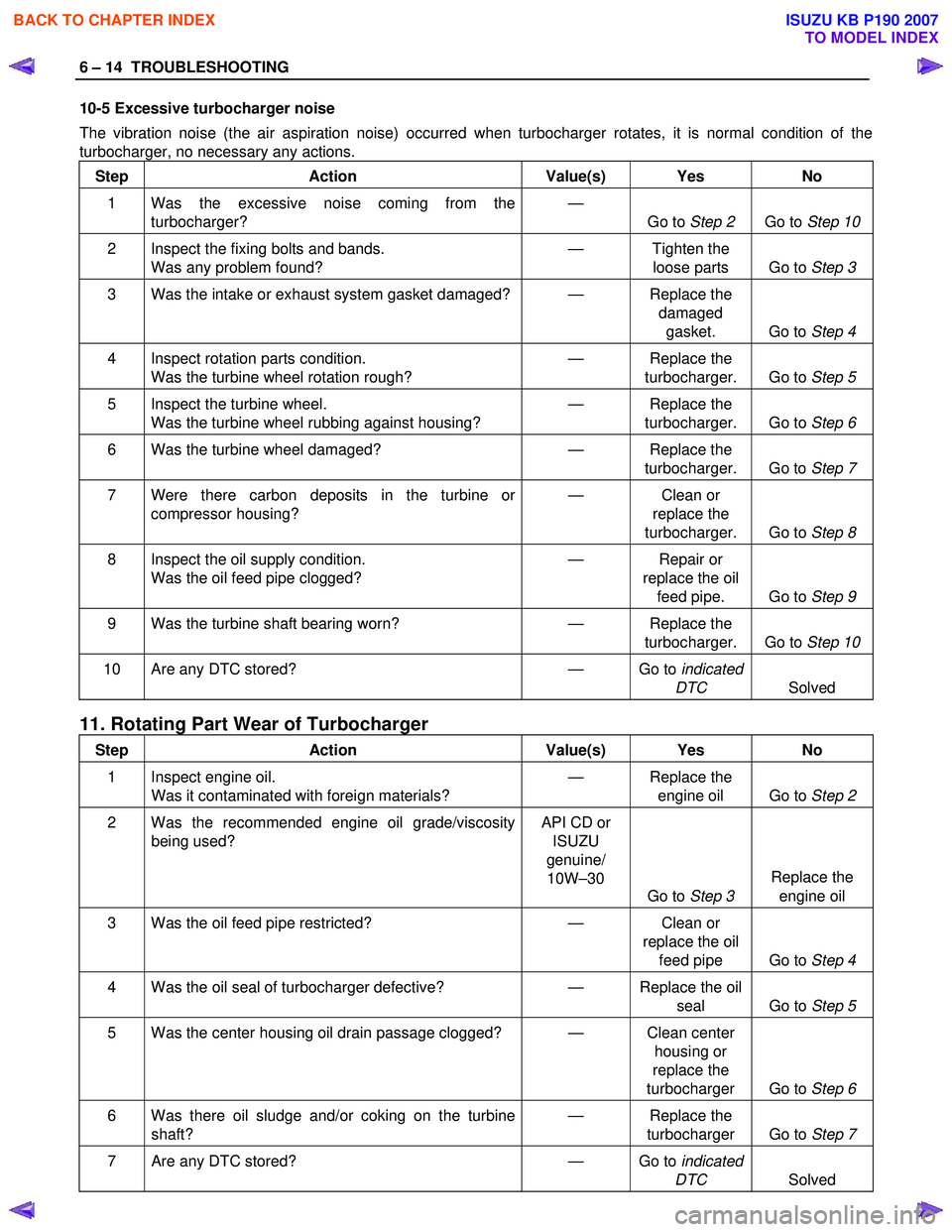

6 – 14 TROUBLESHOOTING

10-5 Excessive turbocharger noise

The vibration noise (the air aspiration noise) occurred when turbocharger rotates, it is normal condition of the

turbocharger, no necessary any actions.

Step Action Value(s) Yes No

1 Was the excessive noise coming from the turbocharger? —

Go to Step 2 Go to Step 10

2 Inspect the fixing bolts and bands.

Was any problem found? —

Tighten the

loose parts Go to Step 3

3 Was the intake or exhaust system gasket damaged? — Replace the

damaged gasket. Go to Step 4

4 Inspect rotation parts condition.

Was the turbine wheel rotation rough? —

Replace the

turbocharger. Go to Step 5

5 Inspect the turbine wheel.

Was the turbine wheel rubbing against housing? —

Replace the

turbocharger. Go to Step 6

6 Was the turbine wheel damaged? — Replace the

turbocharger. Go to Step 7

7 Were there carbon deposits in the turbine or

compressor housing? —

Clean or

replace the

turbocharger. Go to Step 8

8 Inspect the oil supply condition.

Was the oil feed pipe clogged? —

Repair or

replace the oil feed pipe. Go to Step 9

9 Was the turbine shaft bearing worn? — Replace the

turbocharger. Go to Step 10

10 Are any DTC stored? — Go to indicated

DTC Solved

11. Rotating Part Wear of Turbocharger

Step Action Value(s) Yes No

1 Inspect engine oil.

Was it contaminated with foreign materials? —

Replace the

engine oil Go to Step 2

2 Was the recommended engine oil grade/viscosity

being used? API CD or

ISUZU

genuine/ 10W –30

Go to Step 3 Replace the

engine oil

3 Was the oil feed pipe restricted? — Clean or

replace the oil feed pipe Go to Step 4

4 Was the oil seal of turbocharger defective? — Replace the oil

seal Go to Step 5

5 Was the center housing oil drain passage clogged? — Clean center

housing or

replace the

turbocharger Go to Step 6

6 Was there oil sludge and/or coking on the turbine

shaft? —

Replace the

turbocharger Go to Step 7

7 Are any DTC stored? — Go to indicated

DTC Solved

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 803 of 6020

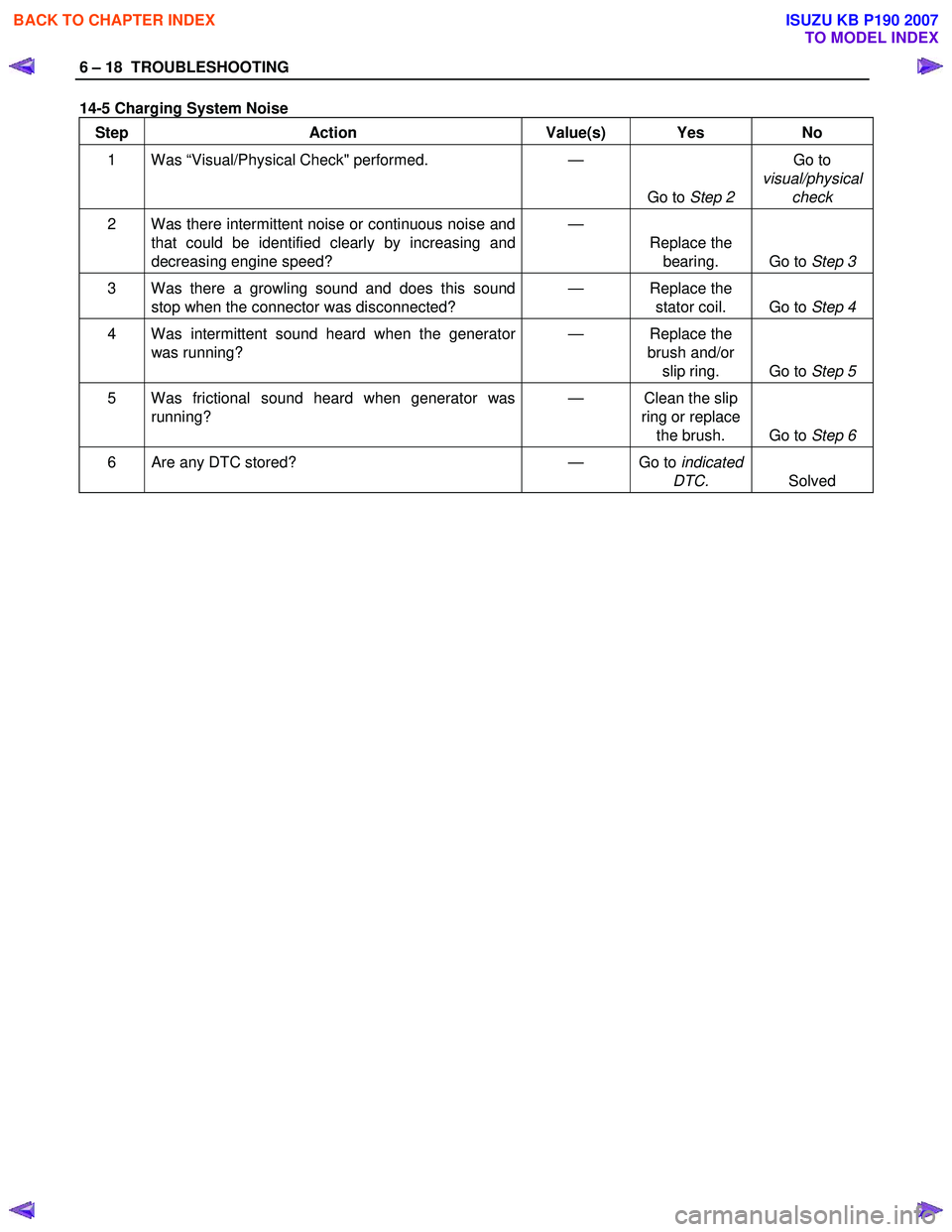

6 – 18 TROUBLESHOOTING

14-5 Charging System Noise Step Action Value(s) Yes No

1 Was “Visual/Physical Check" performed.

—

Go to Step 2 Go to

visual/physical check

2 Was there intermittent noise or continuous noise and

that could be identified clearly by increasing and

decreasing engine speed? —

Replace the bearing. Go to Step 3

3 Was there a growling sound and does this sound

stop when the connector was disconnected? —

Replace the

stator coil. Go to Step 4

4 Was intermittent sound heard when the generator

was running? —

Replace the

brush and/or slip ring. Go to Step 5

5 Was frictional sound heard when generator was

running? —

Clean the slip

ring or replace the brush. Go to Step 6

6 Are any DTC stored? — Go to indicated

DTC. Solved

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007