clutch ISUZU KB P190 2007 Workshop Service Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 954 of 6020

6B – 10 ENGINE COOLING

WATER PUMP

REMOVAL AND INSTALLATION

Read this Section carefully before performing any removal and installation procedure. This Section gives you

important points as well as the order of operation. Be sure that you understand everything in this Section before you

begin.

Removal

1. Radiator Upper Hose 1) Partially drain the engine coolant.

2) Remove the radiator upper hose.

031R300003

2. Water Outlet Pipe

1) Disconnect the turbocharger-cooling pipe from outlet pipe.

2) Loosen the fixing bolt and remove the water outlet bolt.

3. Thermostat

Remove the thermostat from the thermostat housing.

Take care not to damage the thermostat.

4. Upper Fan Shroud

5. Fan and Fan Clutch 1) Loosen the fan clutch nuts.

2) Remove the fan together with the fan clutch. Take care not to damage the radiator core.

6. Fan Drive Belt and Pulley

1) Loosen the tension adjust bolt on the generator.

2) Remove the fan drive belt with the fan pulley.

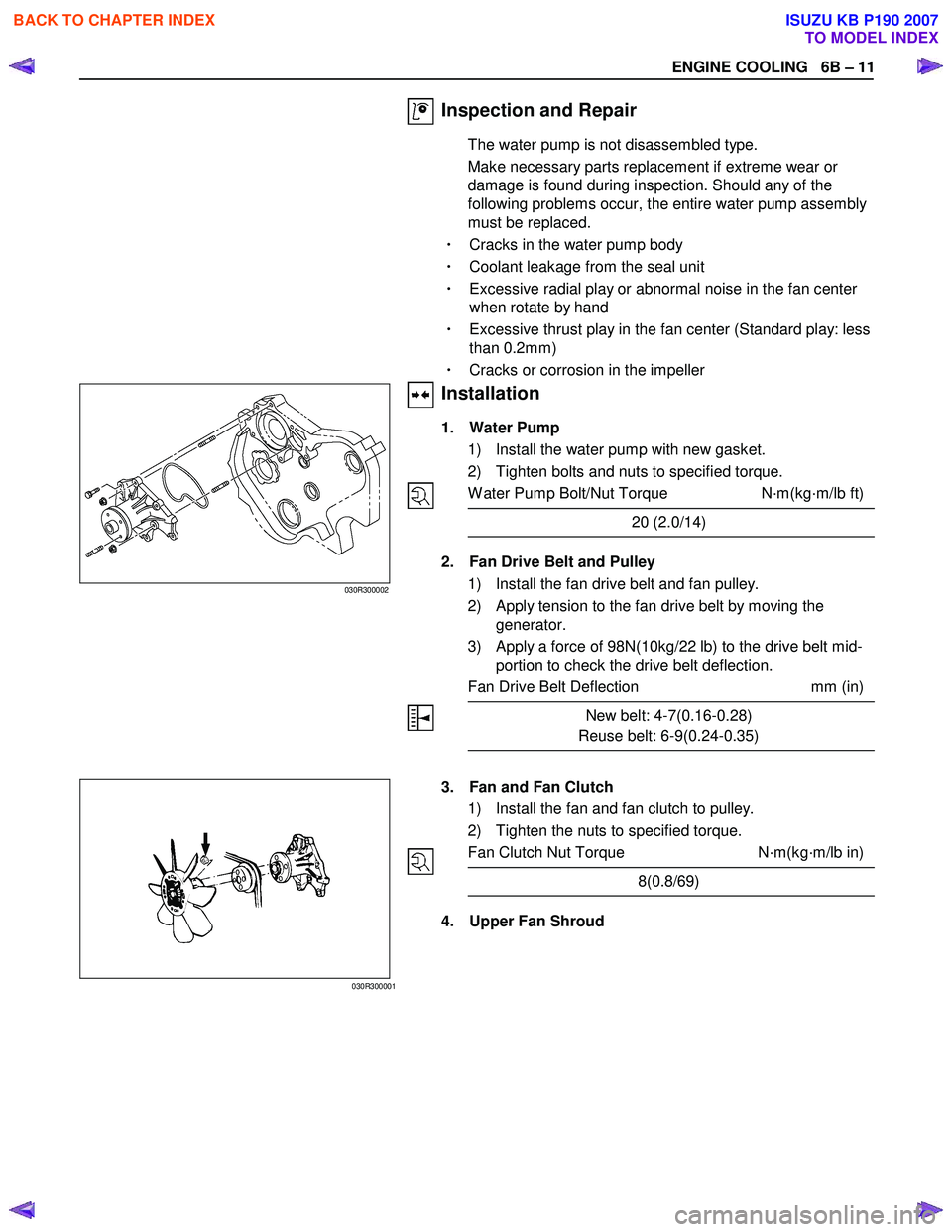

030R300001 7. Water Pump

1) Remove the water pump bolts.

2) Remove the water pump.

030R300002

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 955 of 6020

ENGINE COOLING 6B – 11

Inspection and Repair

The water pump is not disassembled type.

Make necessary parts replacement if extreme wear or

damage is found during inspection. Should any of the

following problems occur, the entire water pump assembly

must be replaced.

・ Cracks in the water pump body

・ Coolant leakage from the seal unit

・ Excessive radial play or abnormal noise in the fan center

when rotate by hand

・ Excessive thrust play in the fan center (Standard play: less

than 0.2mm)

・ Cracks or corrosion in the impeller

Installation

1. Water Pump

1) Install the water pump with new gasket.

2) Tighten bolts and nuts to specified torque.

W ater Pump Bolt/Nut Torque N·m(kg·m/lb ft)

20 (2.0/14)

2. Fan Drive Belt and Pulley

1) Install the fan drive belt and fan pulley.

2) Apply tension to the fan drive belt by moving the generator.

3) Apply a force of 98N(10kg/22 lb) to the drive belt mid- portion to check the drive belt deflection.

Fan Drive Belt Deflection mm (in)

New belt: 4-7(0.16-0.28)

Reuse belt: 6-9(0.24-0.35)

030R300002

030R300001

3. Fan and Fan Clutch

1) Install the fan and fan clutch to pulley.

2) Tighten the nuts to specified torque.

Fan Clutch Nut Torque N·m(kg·m/lb in)

8(0.8/69)

4. Upper Fan Shroud

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 964 of 6020

6B – 20 ENGINE COOLING

FAN CLUTCH WITH COOLING FAN

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear, damage or any other abnormal condition are found through

inspection.

033R300001

Visually inspect for damage, leak (sillicon grease) or other

abnormal conditions.

1. Inspection (on-vehicle)

1) Turn the fan clutch by hand when in a low temperature condition before starting the engine, and confirm that it

can be turned readily.

2) Start the engine to warm it up until the temperature at the fan clutch portion gets to around 80 °C. Then stop

the engine and confirm that the fan clutch can be

turned with considerable effort (clutch torque) when

turned by hand.

If the fan clutch rotates more readily, however, this indicates that the silicone grease is leaking internally.

Replace the fan clutch with a new one.

033RY00011

2. Inspection (in unit)

W arm up the bimetal of the fan clutch by using the heat

gun until the temperature gets to about 80 °C when

measured with the thermistor. Then confirm that the fan

clutch can be turned with considerable effort (clutch

torque).

If the fan clutch retates more readily at this time, this

indicates that the silicone grease is leaking internally.

Replace the fan clutch with a new one.

SPECIAL TOOLS

Illustration Tool Number Tool Name

5-8840-0277-0 Cap tester

5-8840-2663-0 Adapter

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1024 of 6020

ENGINE ELECTRICAL 6D – 23

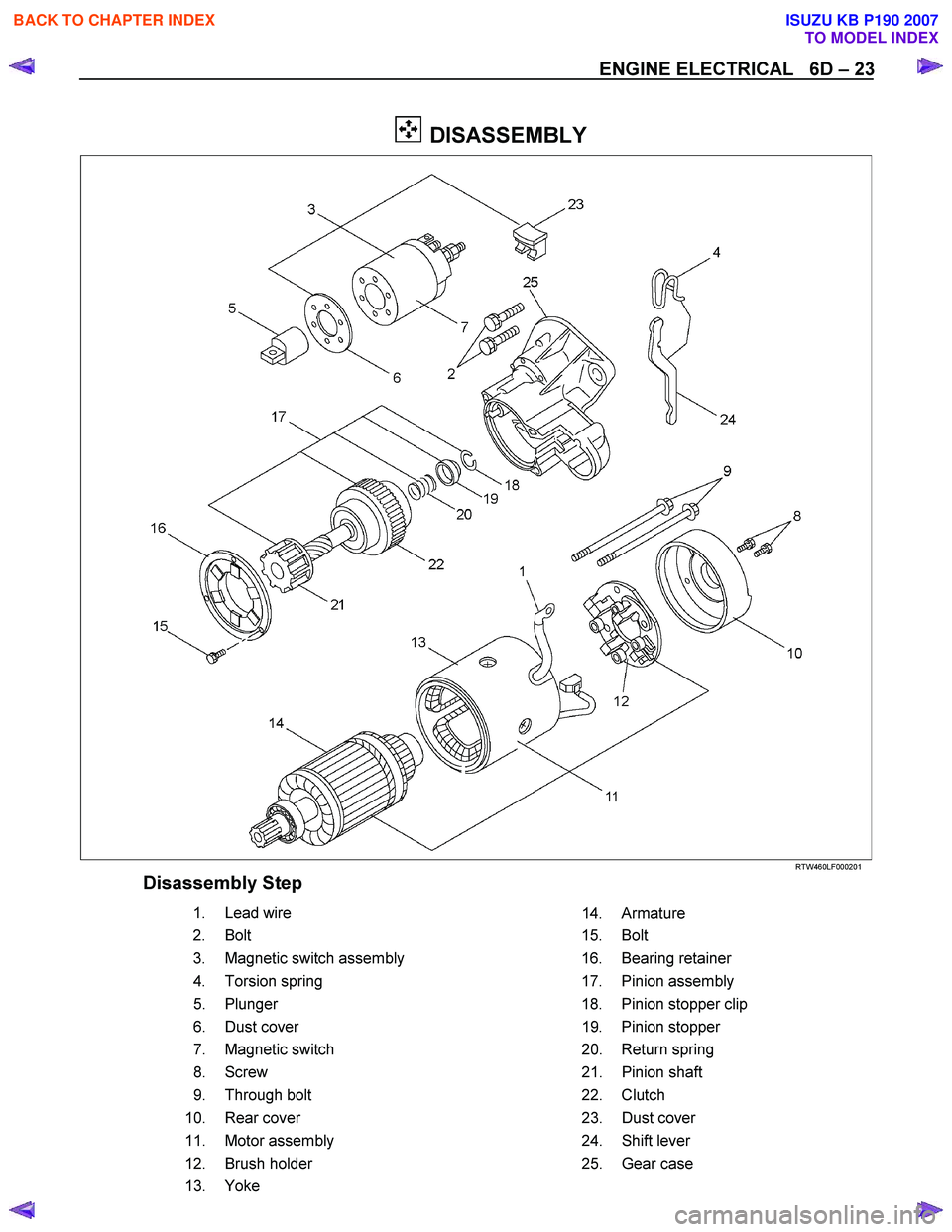

DISASSEMBLY

RTW460LF000201

Disassembly Step

1.

Lead wire

14. Armature

2.

Bolt 15. Bolt

3.

Magnetic switch assembly 16. Bearing retainer

4.

Torsion spring 17. Pinion assembly

5.

Plunger 18. Pinion stopper clip

6.

Dust cover 19. Pinion stopper

7.

Magnetic switch 20. Return spring

8.

Screw 21. Pinion shaft

9.

Through bolt 22. Clutch

10.

Rear cover 23. Dust cover

11.

Motor assembly 24. Shift lever

12.

Brush holder 25. Gear case

13.

Yoke

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1029 of 6020

6D – 28 ENGINE ELECTRICAL

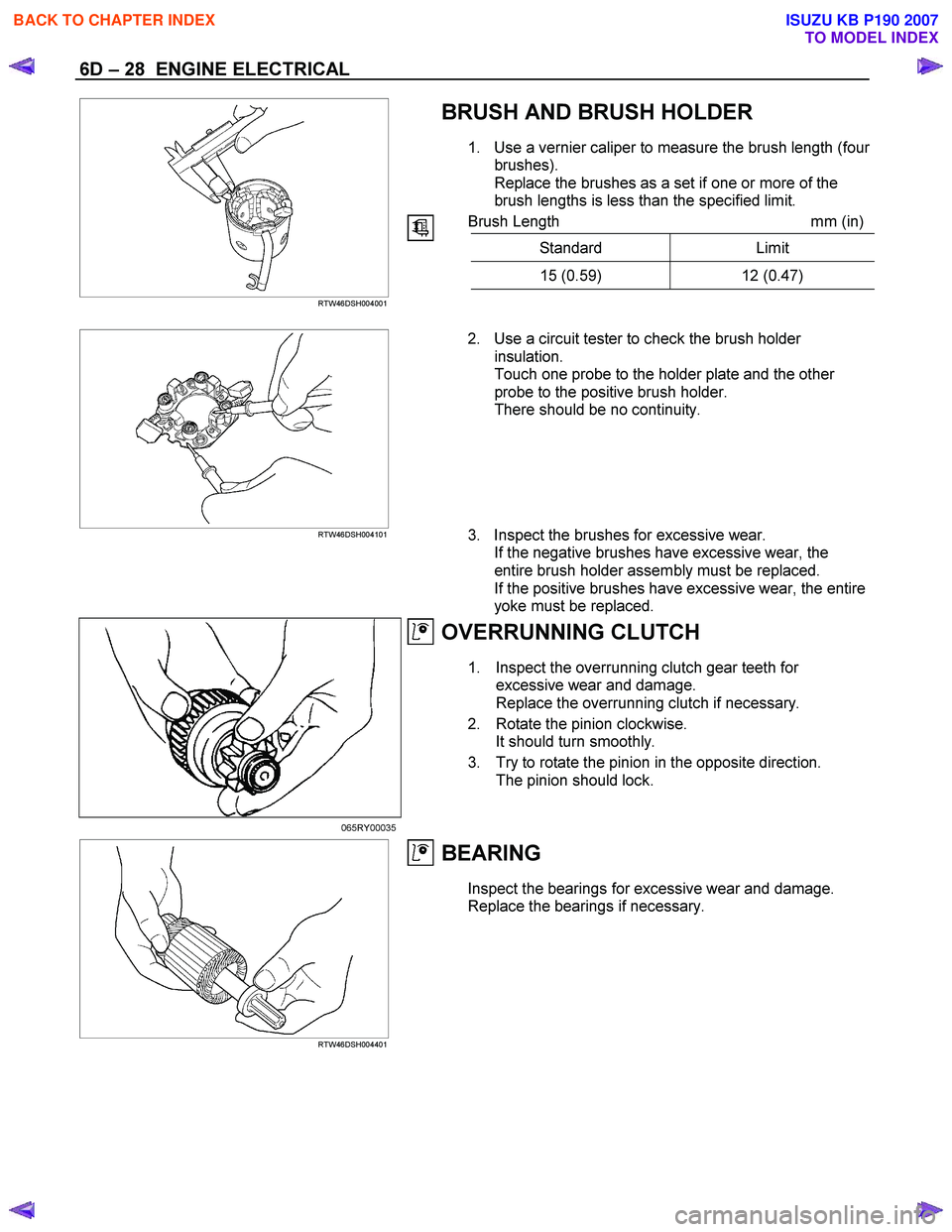

BRUSH AND BRUSH HOLDER

1. Use a vernier caliper to measure the brush length (four

brushes).

Replace the brushes as a set if one or more of the

brush lengths is less than the specified limit.

Brush Length mm (in)

Standard Limit

15 (0.59) 12 (0.47)

RTW46DSH004001

RTW46DSH004101

2. Use a circuit tester to check the brush holder

insulation.

Touch one probe to the holder plate and the other

probe to the positive brush holder.

There should be no continuity.

3. Inspect the brushes for excessive wear. If the negative brushes have excessive wear, the

entire brush holder assembly must be replaced.

If the positive brushes have excessive wear, the entire

yoke must be replaced.

OVERRUNNING CLUTCH

1. Inspect the overrunning clutch gear teeth for excessive wear and damage.

Replace the overrunning clutch if necessary.

2. Rotate the pinion clockwise. It should turn smoothly.

3. Try to rotate the pinion in the opposite direction. The pinion should lock.

065RY00035

RTW46DSH004401

BEARING

Inspect the bearings for excessive wear and damage.

Replace the bearings if necessary.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1030 of 6020

ENGINE ELECTRICAL 6D – 29

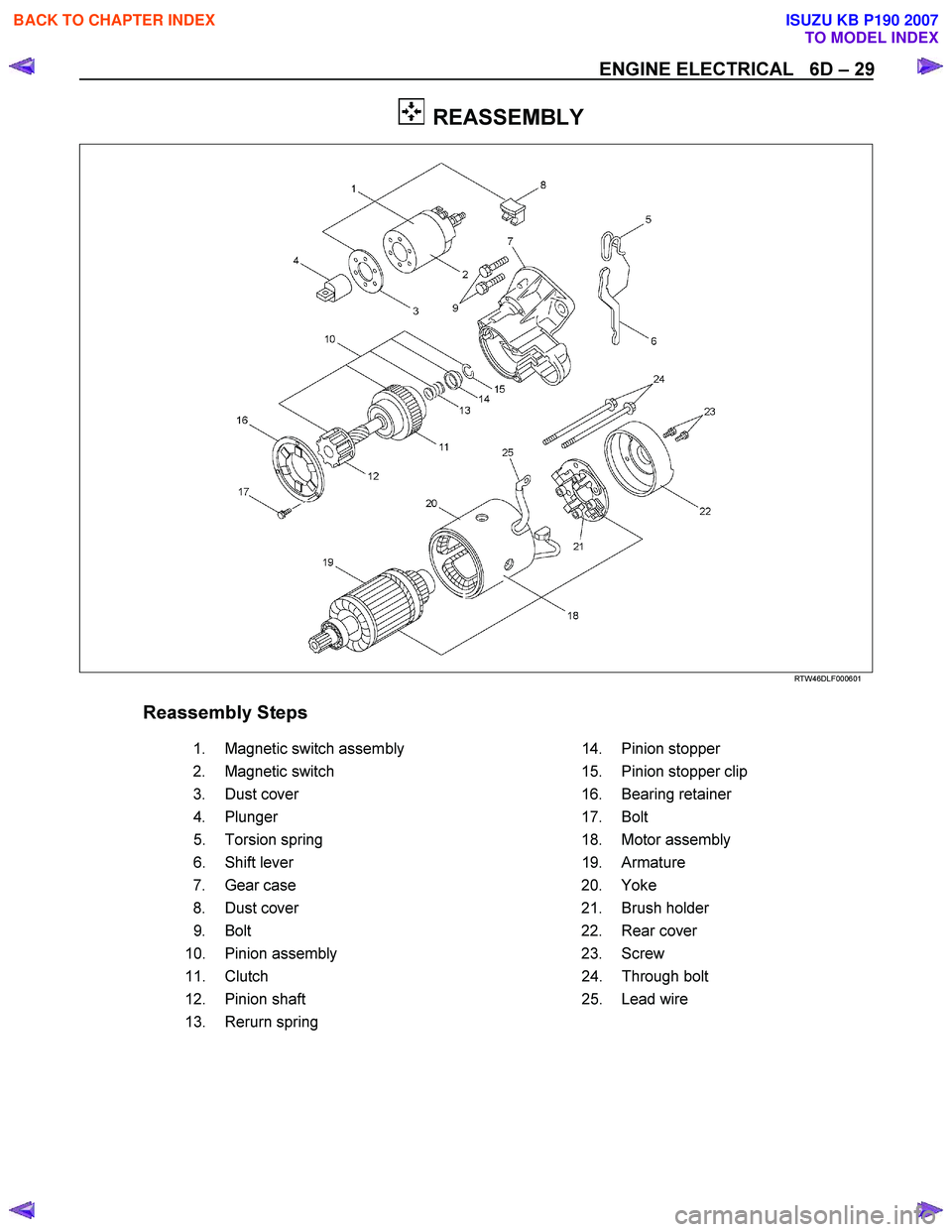

REASSEMBLY

RTW46DLF000601

Reassembly Steps

1.

Magnetic switch assembly

14. Pinion stopper

2.

Magnetic switch 15. Pinion stopper clip

3.

Dust cover 16. Bearing retainer

4.

Plunger 17. Bolt

5.

Torsion spring 18. Motor assembly

6.

Shift lever

19. Armature

7.

Gear case 20. Yoke

8.

Dust cover 21. Brush holder

9.

Bolt 22. Rear cover

10.

Pinion assembly 23. Screw

11.

Clutch 24. Through bolt

12.

Pinion shaft 25. Lead wire

13.

Rerurn spring

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1033 of 6020

6D – 32 ENGINE ELECTRICAL

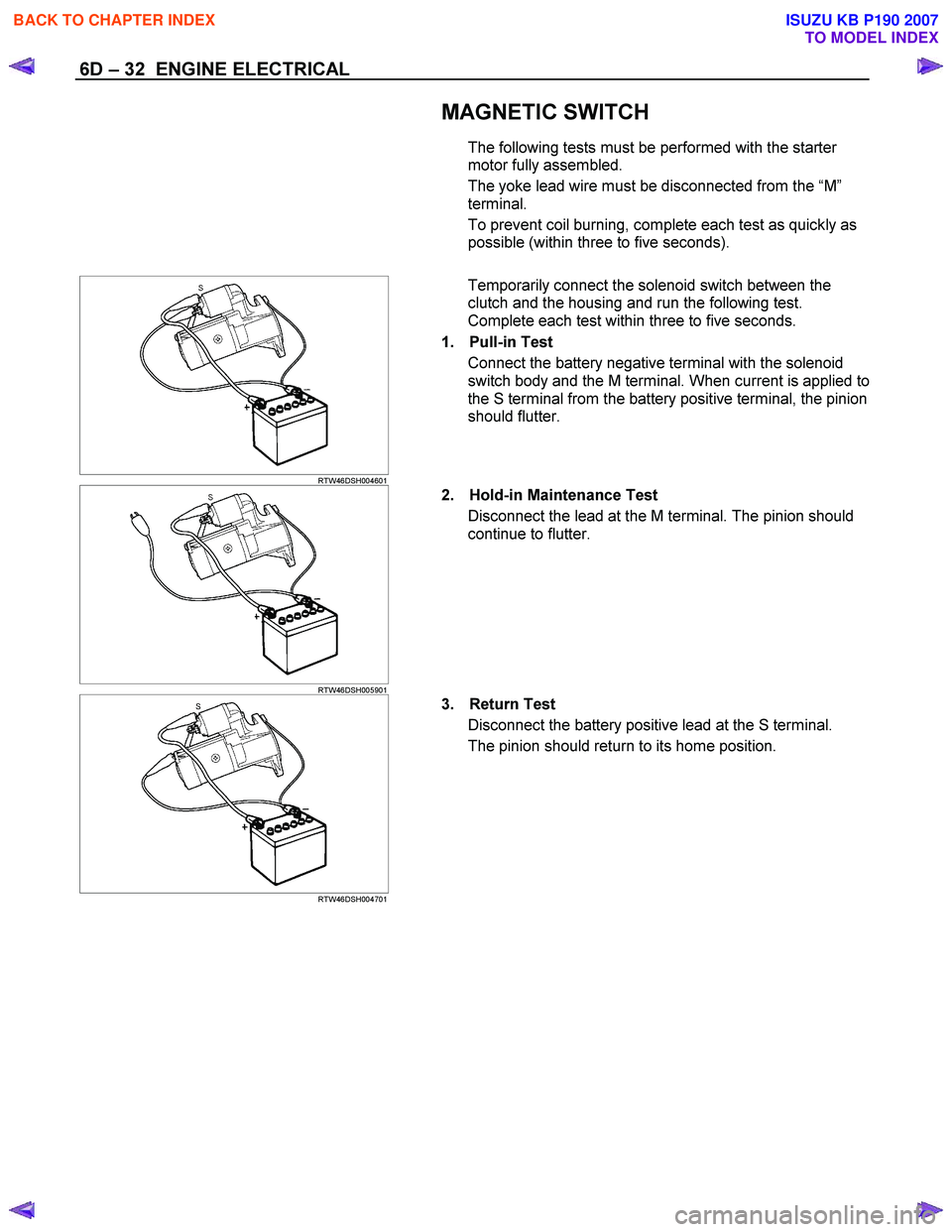

MAGNETIC SWITCH

The following tests must be performed with the starter

motor fully assembled.

The yoke lead wire must be disconnected from the “M ”

terminal.

To prevent coil burning, complete each test as quickly as

possible (within three to five seconds).

RTW46DSH004601

Temporarily connect the solenoid switch between the

clutch and the housing and run the following test.

Complete each test within three to five seconds.

1. Pull-in Test Connect the battery negative terminal with the solenoid

switch body and the M terminal. When current is applied to

the S terminal from the battery positive terminal, the pinion

should flutter.

RTW46DSH005901

2. Hold-in Maintenance Test

Disconnect the lead at the M terminal. The pinion should

continue to flutter.

RTW46DSH004701

3. Return Test

Disconnect the battery positive lead at the S terminal.

The pinion should return to its home position.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1051 of 6020

Engine Control System (4JH1) 6E-17

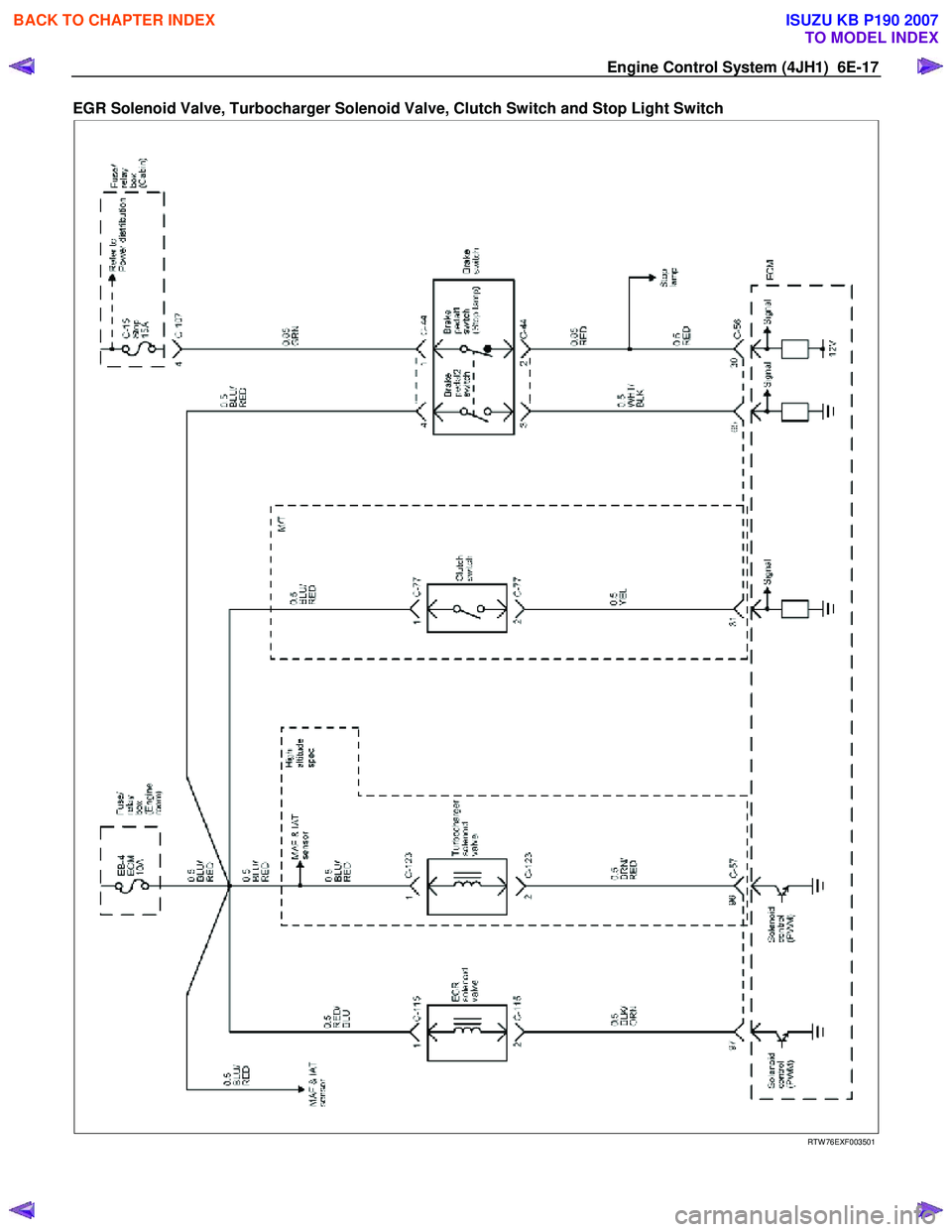

EGR Solenoid Valve, Turbocharger Solenoid Valve, Clutch Switch and Stop Light Switch

RTW 76EXF003501

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1054 of 6020

6E-20 Engine Control System (4JH1)

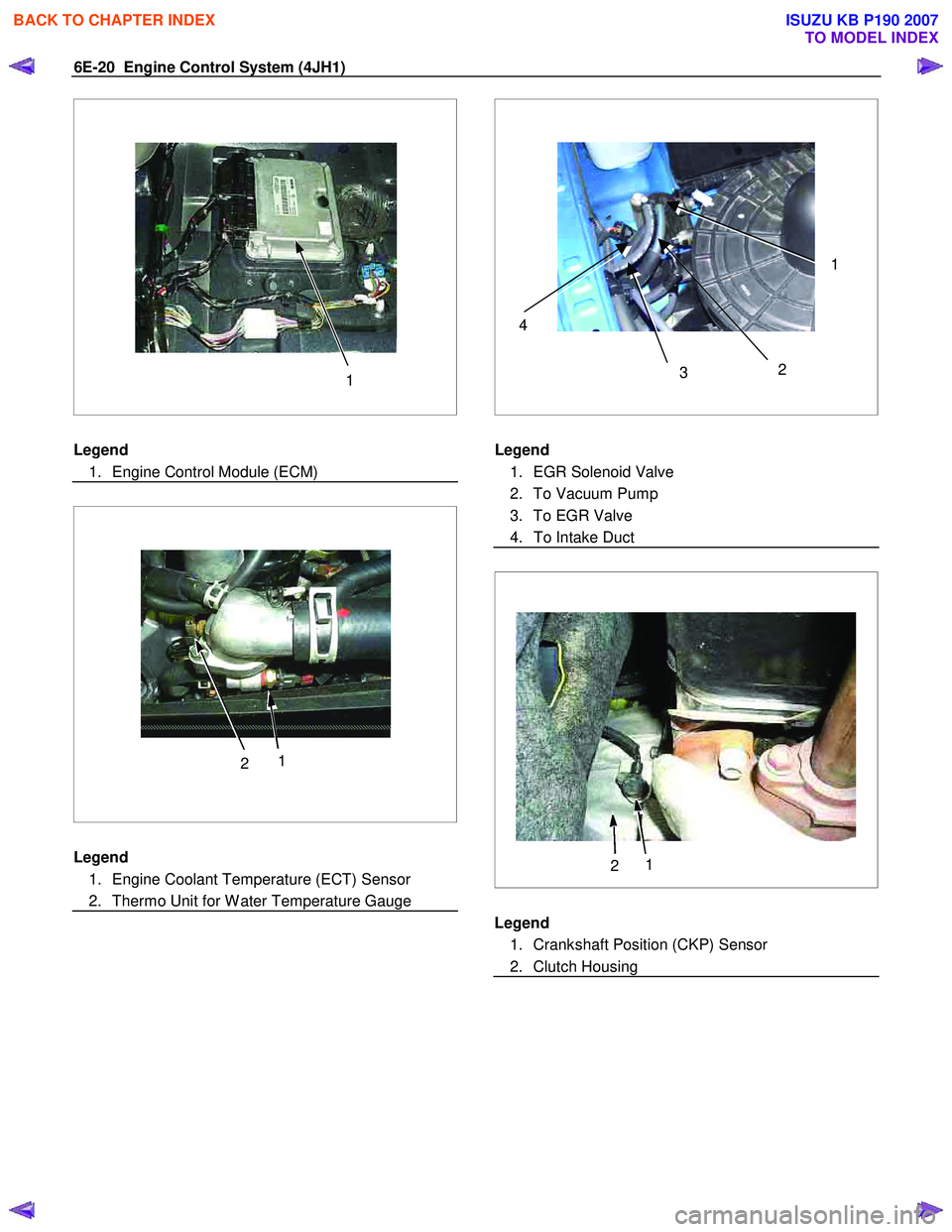

1

Legend

1. Engine Control Module (ECM)

2 1

Legend

1. Engine Coolant Temperature (ECT) Sensor

2. Thermo Unit for W ater Temperature Gauge

2

3 14

Legend

1. EGR Solenoid Valve

2. To Vacuum Pump

3. To EGR Valve

4. To Intake Duct

2 1

Legend

1. Crankshaft Position (CKP) Sensor

2. Clutch Housing

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1056 of 6020

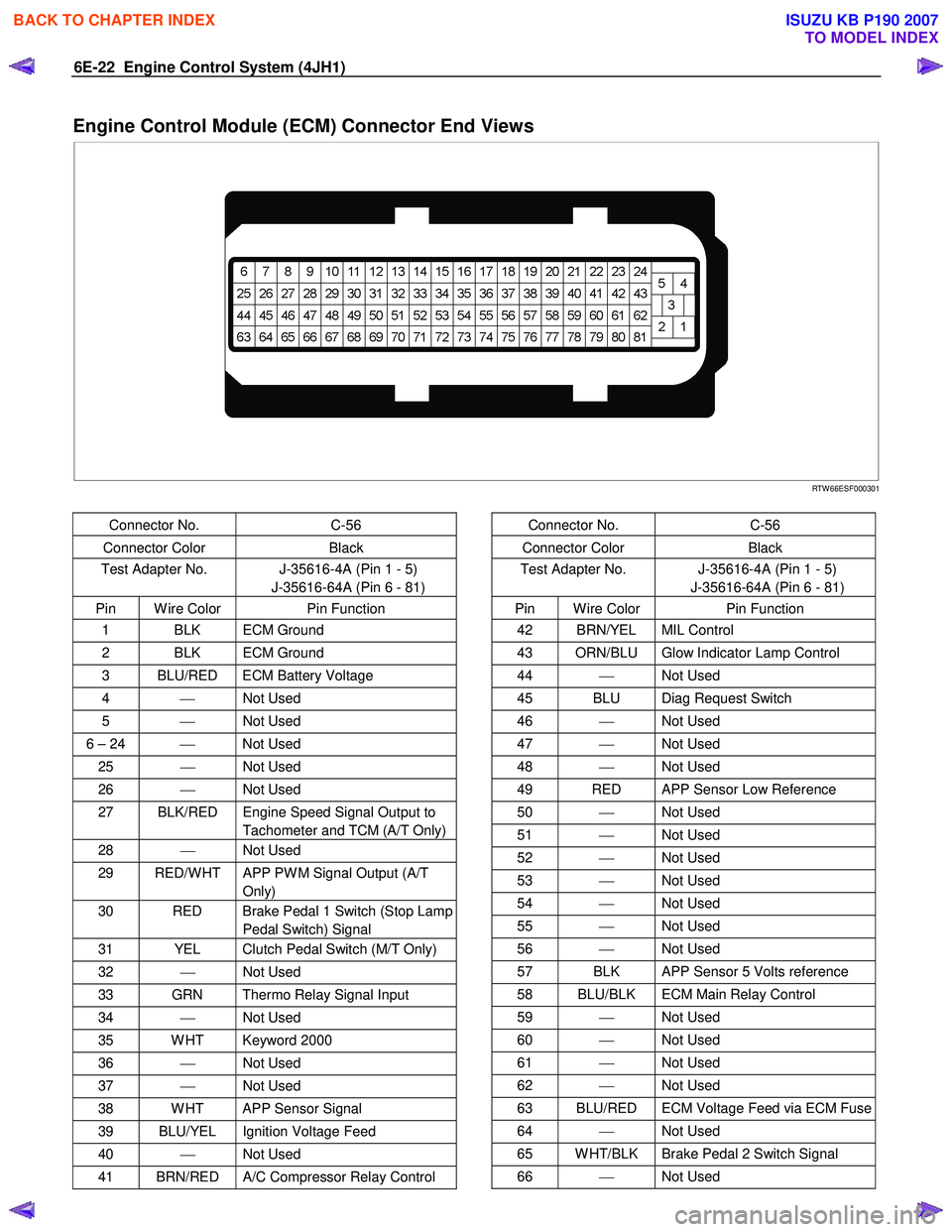

6E-22 Engine Control System (4JH1)

Engine Control Module (ECM) Connector End Views

RTW 66ESF000301

Connector No. C-56

Connector Color Black

Test Adapter No. J-35616-4A (Pin 1 - 5)

J-35616-64A (Pin 6 - 81)

Pin W ire Color Pin Function

1 BLK ECM Ground

2 BLK ECM Ground

3 BLU/RED ECM Battery Voltage

4 Not Used

5 Not Used

6 – 24 Not Used

25 Not Used

26 Not Used

27 BLK/RED Engine Speed Signal Output to

Tachometer and TCM (A/T Only)

28 Not Used

29 RED/W HT APP PW M Signal Output (A/T

Only)

30 RED Brake Pedal 1 Switch (Stop Lamp Pedal Switch) Signal

31 YEL Clutch Pedal Switch (M/T Only)

32 Not Used

33 GRN Thermo Relay Signal Input

34 Not Used

35 W HT Keyword 2000

36 Not Used

37 Not Used

38 W HT APP Sensor Signal

39 BLU/YEL Ignition Voltage Feed

40 Not Used

41 BRN/RED A/C Compressor Relay Control

Connector No. C-56

Connector Color Black

Test Adapter No. J-35616-4A (Pin 1 - 5)

J-35616-64A (Pin 6 - 81)

Pin W ire Color Pin Function

42 BRN/YEL MIL Control

43 ORN/BLU Glow Indicator Lamp Control

44 Not Used

45 BLU Diag Request Switch

46 Not Used

47 Not Used

48 Not Used

49 RED APP Sensor Low Reference

50 Not Used

51 Not Used

52 Not Used

53 Not Used

54 Not Used

55 Not Used

56 Not Used

57 BLK APP Sensor 5 Volts reference

58 BLU/BLK ECM Main Relay Control

59 Not Used

60 Not Used

61 Not Used

62 Not Used

63 BLU/RED ECM Voltage Feed via ECM Fuse

64 Not Used

65 W HT/BLK Brake Pedal 2 Switch Signal

66 Not Used

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007