4JH1 ISUZU KB P190 2007 Workshop Workshop Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 887 of 6020

6A – 82 ENGINE MECHANICAL

9. Compare the width of the Plastigage attached to either the

crankshaft or the bearing against the scale printed on the

Plastigage container.

If the measured value exceeds the limit, perform the

following additional steps.

1. Use a micrometer to measure the crankshaft outside diameter.

2. Use an inside dial indicator to measure the bearing inside diameter.

If the crankshaft journal and bearing clearance

exceeds the limit, the crankshaft and/or the bearing

must be replaced.

Crankshaft Journal and Bearing Clearance mm (in)

Standard Limit

0.032 - 0.077

(0.0013 - 0.0030) 0.110 (0.0043)

Crankpin and Bearing Clearance

1. Clean the crankshaft, the connecting rod, the bearing cap, and the bearings.

2. Install the bearing to the connecting rod and the bearing cap.

Do not allow the crankshaft to move when installing the

bearing cap.

3. Prevent the connecting rod from moving.

4. Attach the Plastigage to the crankpin. Apply engine oil to the Plastigage to keep it from falling.

5. Install the bearing cap and tighten it to the two step of anglar tihtening method.

Do not allow the connecting rod to move when installing

and tightening the bearing cap.

Connecting Rod Bearing Cap Bolt Torque

N·m (kg·m/Ib ft)

4JA1T (L), 4JA1TC 78-88 (8.0/57 – 9.0/65)

1st step ; 29.0–29.2 (3.00/22.0–3.01/22.2)4JH1TC

2nd step ; 45°-60 °

015LX129

015LX060

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 888 of 6020

ENGINE MECHANICAL 6A – 83

6. Remove the bearing cap.

7. Compare the width of the Plastigage attached to either the crankshaft or the bearing against the scale printed on the

Plastigage container.

If the measured value exceeds the specified limit, perform

the following additional steps.

1. Use a micrometer to measure the crankpin outside diameter.

2. Use an inside dial indicator to measure the bearing inside diameter.

If the crank pin and bearing clearance exceeds the

specified limit, the crankshaft and/or the bearing must

be replaced.

Crankpin and Bearing Clearance mm (in)

Standard Limit

4JA1T (L),

4JA1TC 0.029-0.066

(0.0011-0.0026) 0.100 (0.0039)

4JH1TC

0.029-0.083

(0.0011-0.0033) 0.100 (0.0039)

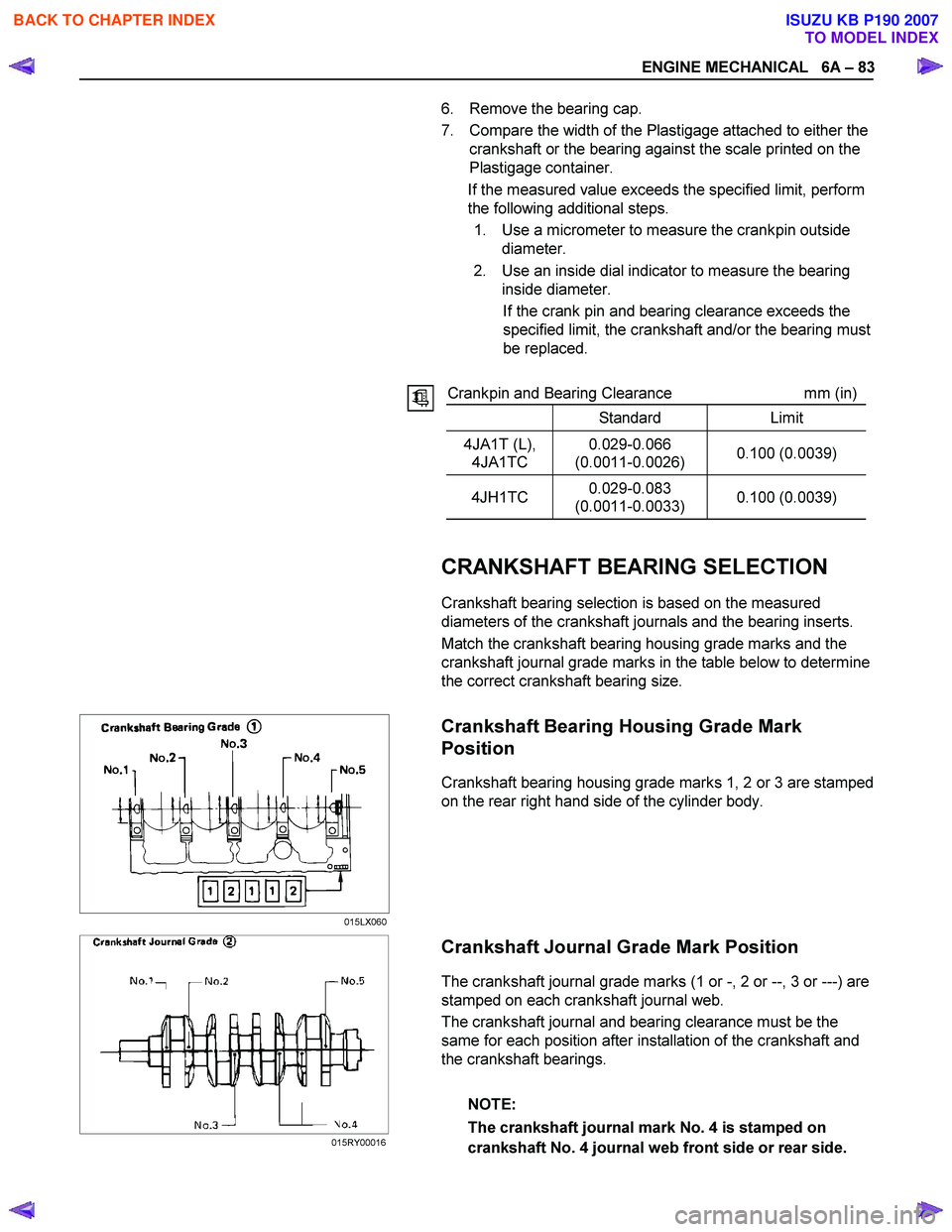

CRANKSHAFT BEARING SELECTION

Crankshaft bearing selection is based on the measured

diameters of the crankshaft journals and the bearing inserts.

Match the crankshaft bearing housing grade marks and the

crankshaft journal grade marks in the table below to determine

the correct crankshaft bearing size.

Crankshaft Bearing Housing Grade Mark

Position

Crankshaft bearing housing grade marks 1, 2 or 3 are stamped

on the rear right hand side of the cylinder body.

Crankshaft Journal Grade Mark Position

The crankshaft journal grade marks (1 or -, 2 or --, 3 or ---) are

stamped on each crankshaft journal web.

The crankshaft journal and bearing clearance must be the

same for each position after installation of the crankshaft and

the crankshaft bearings.

NOTE:

The crankshaft journal mark No. 4 is stamped on

crankshaft No. 4 journal web front side or rear side.

015LX060

015RY00016

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 889 of 6020

6A – 84 ENGINE MECHANICAL

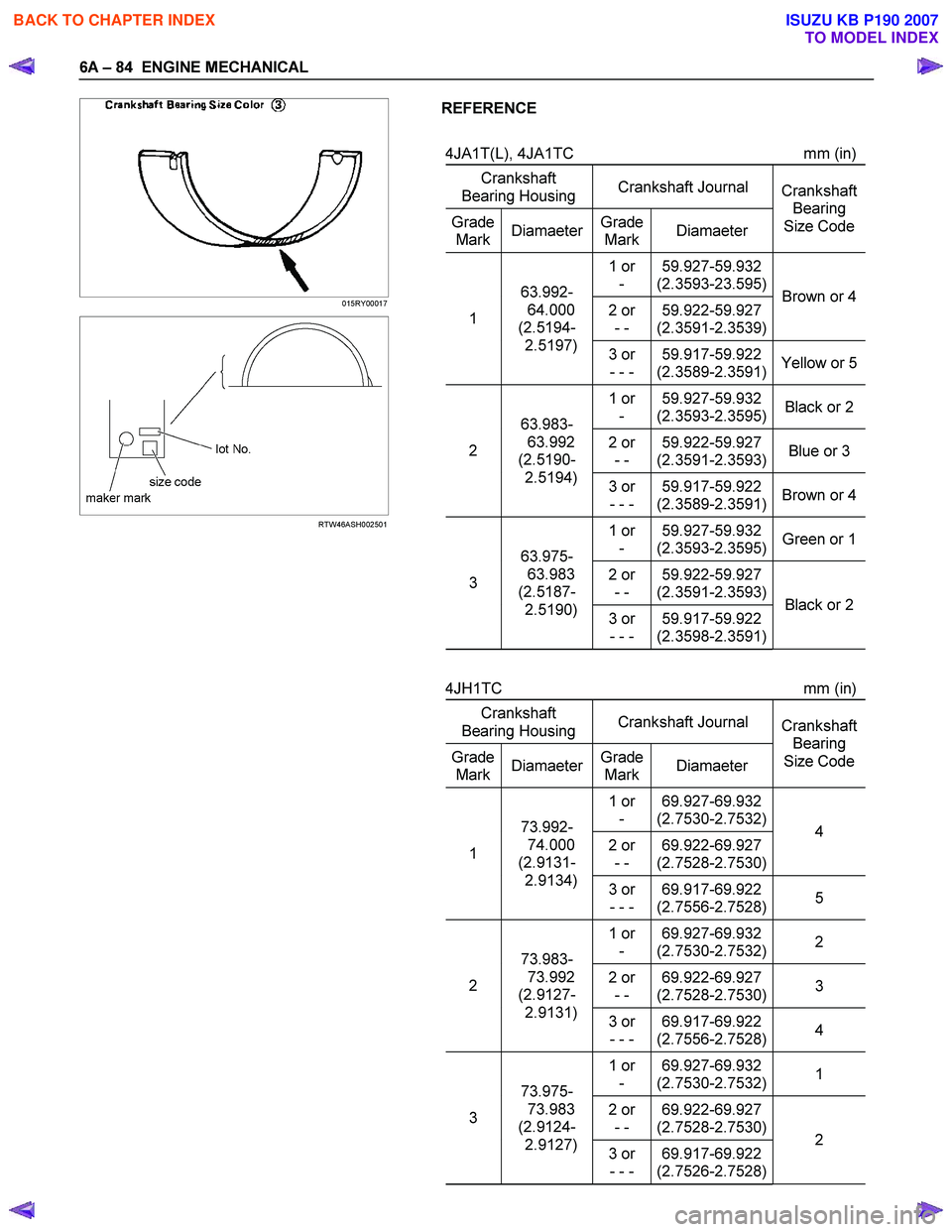

015RY00017

RTW46ASH002501

REFERENCE

4JA1T(L), 4JA1TC mm (in)

Crankshaft

Bearing Housing Crankshaft Journal

Grade

Mark Diamaeter

Grade

Mark Diamaeter Crankshaft

Bearing

Size Code

1 or - 59.927-59.932

(2.3593-23.595)

2 or - - 59.922-59.927

(2.3591-2.3539) Brown or 41

63.992-

64.000

(2.5194-

2.5197) 3 or

- - - 59.917-59.922

(2.3589-2.3591) Yellow or 5

1 or

- 59.927-59.932

(2.3593-2.3595) Black or 2

2 or

- - 59.922-59.927

(2.3591-2.3593) Blue or 3 2 63.983-

63.992

(2.5190-

2.5194) 3 or

- - - 59.917-59.922

(2.3589-2.3591) Brown or 4

1 or

- 59.927-59.932

(2.3593-2.3595) Green or 1

2 or

- - 59.922-59.927

(2.3591-2.3593)3 63.975-

63.983

(2.5187-

2.5190) 3 or

- - - 59.917-59.922

(2.3598-2.3591) Black or 2

4JH1TC mm (in)

Crankshaft

Bearing Housing Crankshaft Journal

Grade

Mark Diamaeter

Grade

Mark Diamaeter Crankshaft

Bearing

Size Code

1 or - 69.927-69.932

(2.7530-2.7532)

2 or - - 69.922-69.927

(2.7528-2.7530) 4 1

73.992-

74.000

(2.9131-

2.9134) 3 or

- - - 69.917-69.922

(2.7556-2.7528) 5

1 or

- 69.927-69.932

(2.7530-2.7532) 2

2 or

- - 69.922-69.927

(2.7528-2.7530) 3 2 73.983-

73.992

(2.9127-

2.9131) 3 or

- - - 69.917-69.922

(2.7556-2.7528) 4

1 or

- 69.927-69.932

(2.7530-2.7532) 1

2 or

- - 69.922-69.927

(2.7528-2.7530)3 73.975-

73.983

(2.9124-

2.9127) 3 or

- - - 69.917-69.922

(2.7526-2.7528) 2

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 890 of 6020

ENGINE MECHANICAL 6A – 85

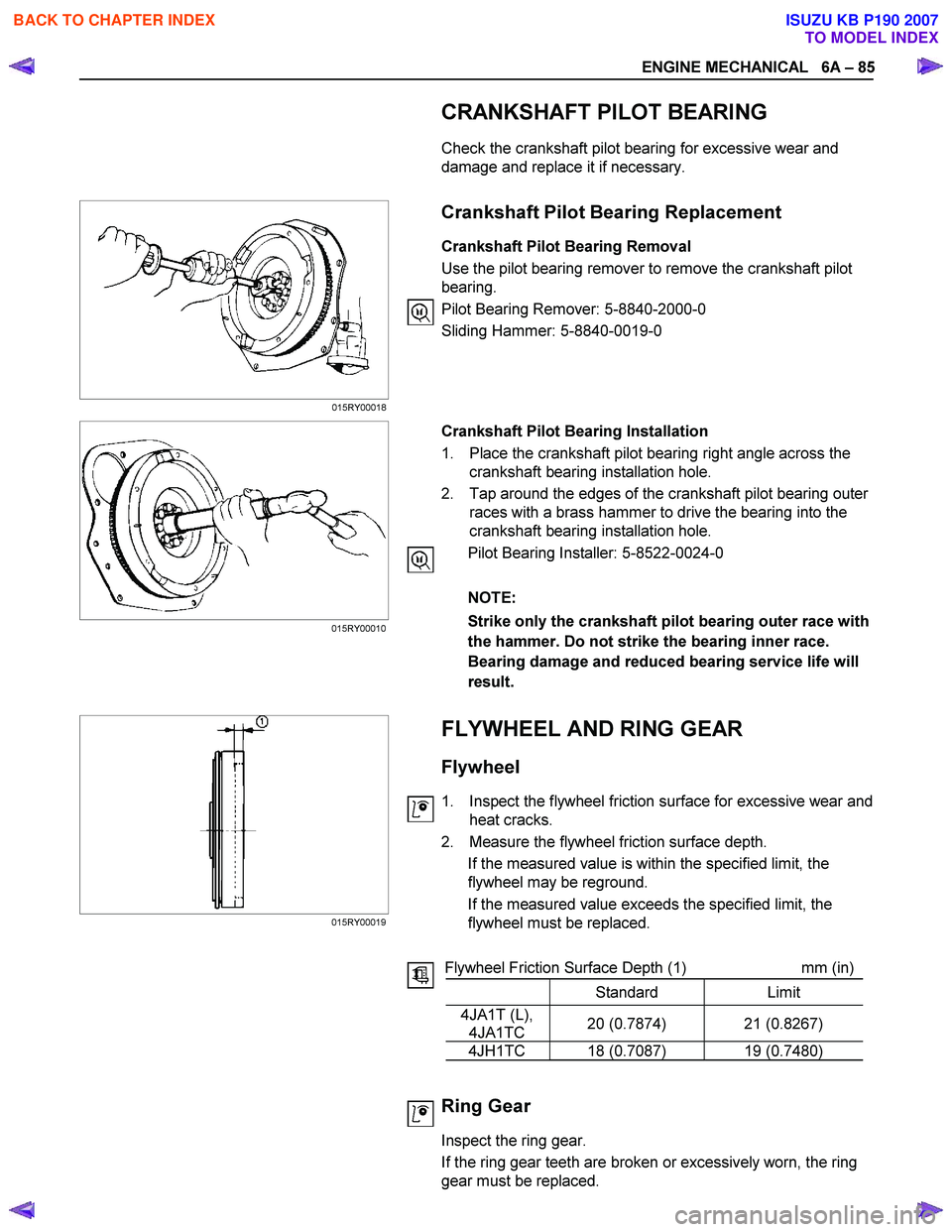

CRANKSHAFT PILOT BEARING

Check the crankshaft pilot bearing for excessive wear and

damage and replace it if necessary.

Crankshaft Pilot Bearing Replacement

Crankshaft Pilot Bearing Removal

Use the pilot bearing remover to remove the crankshaft pilot

bearing.

Pilot Bearing Remover: 5-8840-2000-0

Sliding Hammer: 5-8840-0019-0

Crankshaft Pilot Bearing Installation

1. Place the crankshaft pilot bearing right angle across the crankshaft bearing installation hole.

2. Tap around the edges of the crankshaft pilot bearing outer races with a brass hammer to drive the bearing into the

crankshaft bearing installation hole.

Pilot Bearing Installer: 5-8522-0024-0

NOTE:

Strike only the crankshaft pilot bearing outer race with

the hammer. Do not strike the bearing inner race.

Bearing damage and reduced bearing service life will

result.

FLYWHEEL AND RING GEAR

Flywheel

1. Inspect the flywheel friction surface for excessive wear and

heat cracks.

2. Measure the flywheel friction surface depth. If the measured value is within the specified limit, the

flywheel may be reground.

If the measured value exceeds the specified limit, the

flywheel must be replaced.

Flywheel Friction Surface Depth (1) mm (in)

Standard Limit

4JA1T (L),

4JA1TC 20 (0.7874) 21 (0.8267)

4JH1TC 18 (0.7087) 19 (0.7480)

Ring Gear

Inspect the ring gear.

If the ring gear teeth are broken or excessively worn, the ring

gear must be replaced.

015RY00010

015RY00019 015RY00018

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 892 of 6020

ENGINE MECHANICAL 6A – 87

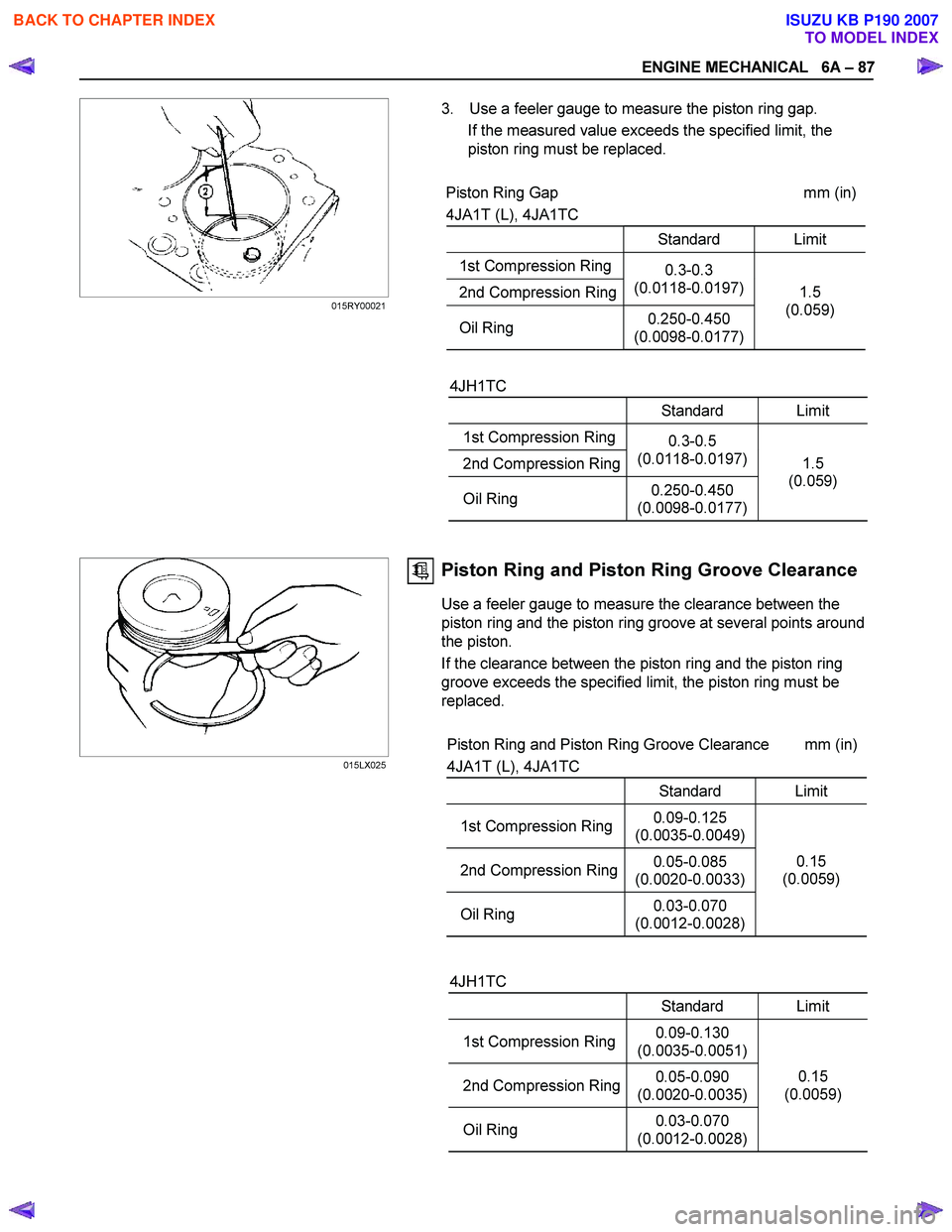

3. Use a feeler gauge to measure the piston ring gap. If the measured value exceeds the specified limit, the

piston ring must be replaced.

Piston Ring Gap mm (in)

4JA1T (L), 4JA1TC

Standard Limit

1st Compression Ring

2nd Compression Ring 0.3-0.3

(0.0118-0.0197)

Oil Ring 0.250-0.450

(0.0098-0.0177) 1.5

(0.059)

4JH1TC

Standard Limit

1st Compression Ring

2nd Compression Ring 0.3-0.5

(0.0118-0.0197)

Oil Ring 0.250-0.450

(0.0098-0.0177) 1.5

(0.059)

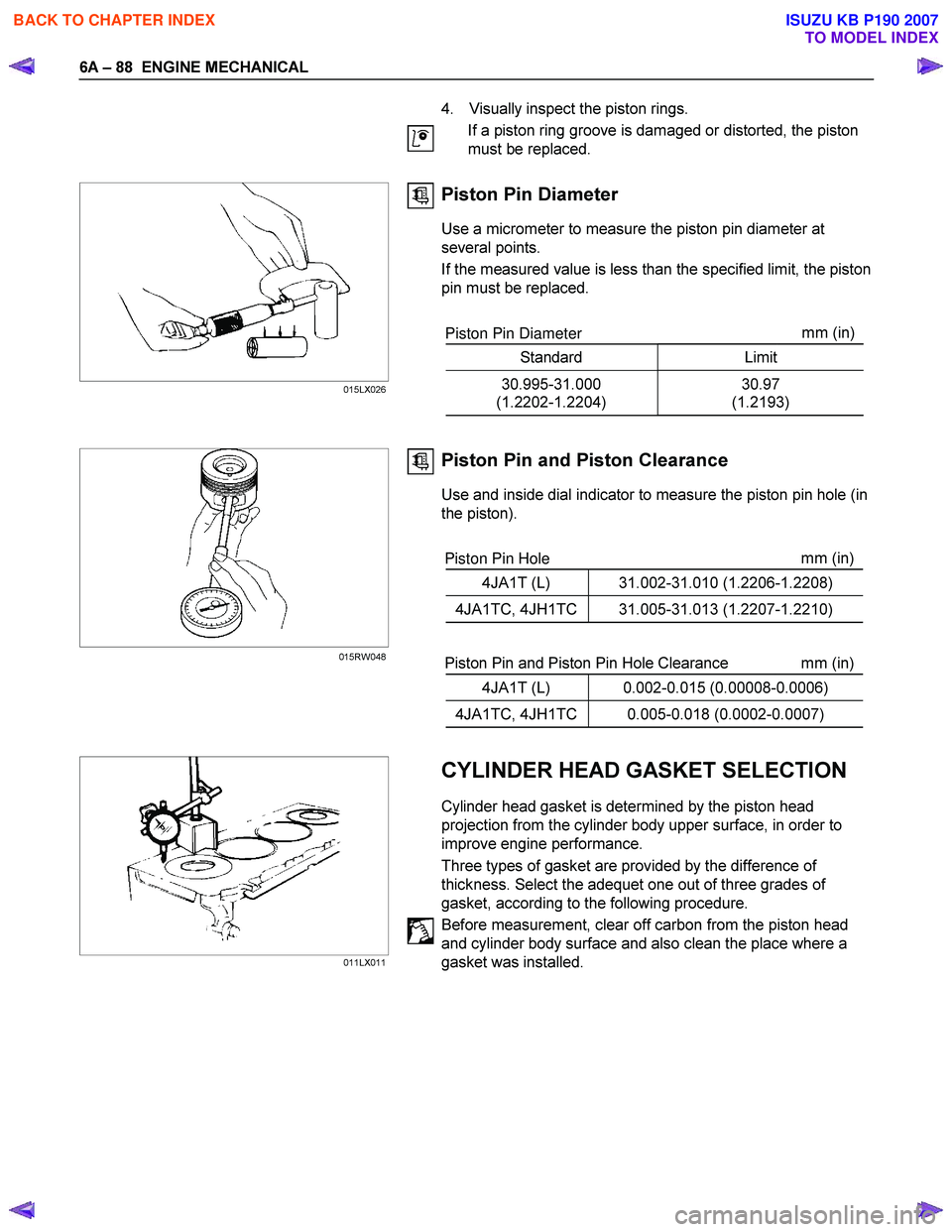

Piston Ring and Piston Ring Groove Clearance

Use a feeler gauge to measure the clearance between the

piston ring and the piston ring groove at several points around

the piston.

If the clearance between the piston ring and the piston ring

groove exceeds the specified limit, the piston ring must be

replaced.

Piston Ring and Piston Ring Groove Clearance mm (in)

4JA1T (L), 4JA1TC

Standard Limit

1st Compression Ring 0.09-0.125

(0.0035-0.0049)

2nd Compression Ring 0.05-0.085

(0.0020-0.0033)

Oil Ring 0.03-0.070

(0.0012-0.0028) 0.15

(0.0059)

4JH1TC

Standard Limit

1st Compression Ring 0.09-0.130

(0.0035-0.0051)

2nd Compression Ring 0.05-0.090

(0.0020-0.0035)

Oil Ring 0.03-0.070

(0.0012-0.0028) 0.15

(0.0059)

015RY00021

015LX025

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 893 of 6020

6A – 88 ENGINE MECHANICAL

4. Visually inspect the piston rings.

If a piston ring groove is damaged or distorted, the piston

must be replaced.

Piston Pin Diameter

Use a micrometer to measure the piston pin diameter at

several points.

If the measured value is less than the specified limit, the piston

pin must be replaced.

Piston Pin Diameter mm

(in)

Standard Limit

30.995-31.000

(1.2202-1.2204) 30.97

(1.2193)

Piston Pin and Piston Clearance

Use and inside dial indicator to measure the piston pin hole (in

the piston).

Piston Pin Hole mm

(in)

4JA1T (L) 31.002-31.010 (1.2206-1.2208)

4JA1TC, 4JH1TC 31.005-31.013 (1.2207-1.2210)

Piston Pin and Piston Pin Hole Clearance mm (in)

4JA1T (L) 0.002-0.015 (0.00008-0.0006)

4JA1TC, 4JH1TC 0.005-0.018 (0.0002-0.0007)

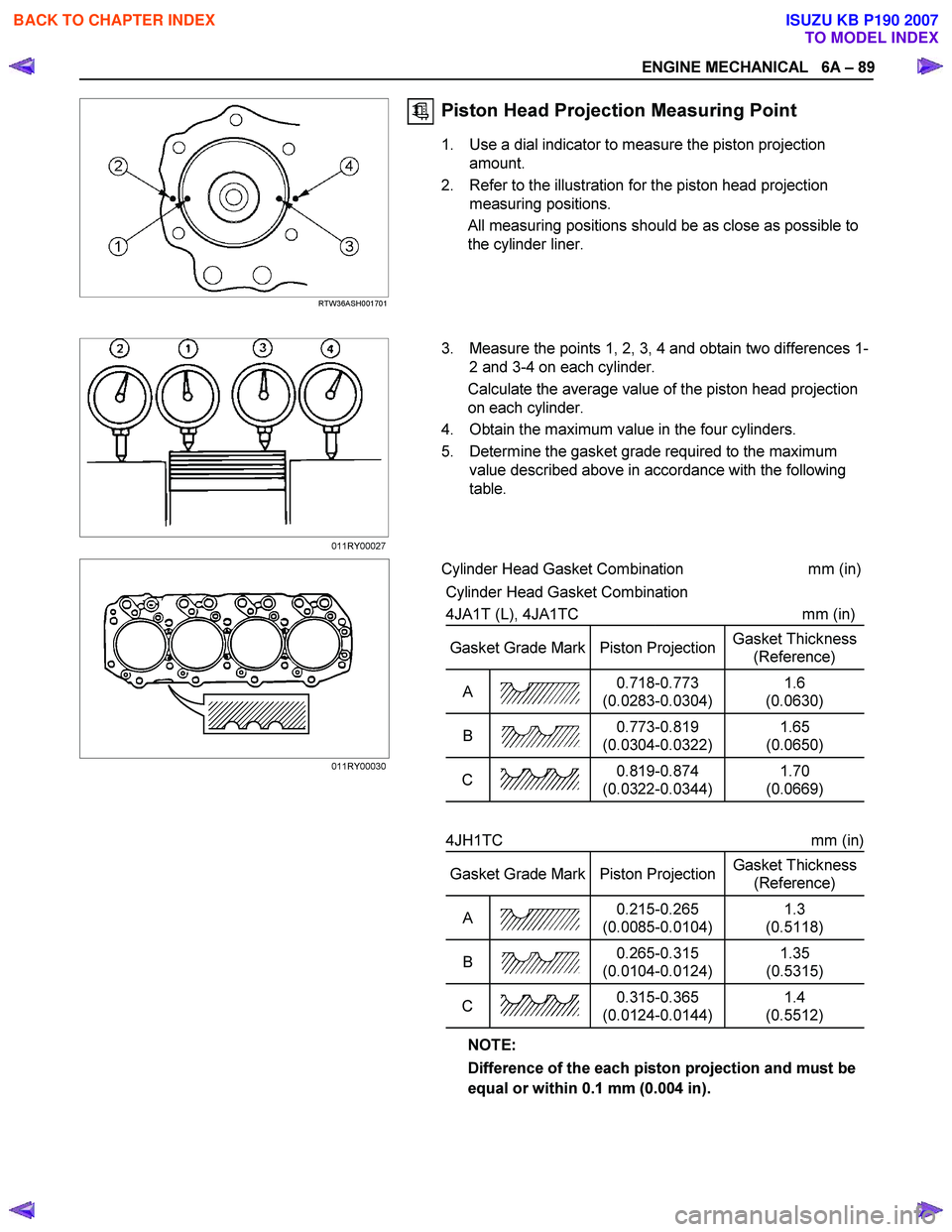

CYLINDER HEAD GASKET SELECTION

Cylinder head gasket is determined by the piston head

projection from the cylinder body upper surface, in order to

improve engine performance.

Three types of gasket are provided by the difference of

thickness. Select the adequet one out of three grades of

gasket, according to the following procedure.

Before measurement, clear off carbon from the piston head

and cylinder body surface and also clean the place where a

gasket was installed.

015LX026

015RW048

011LX011

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 894 of 6020

ENGINE MECHANICAL 6A – 89

RTW36ASH001701

Piston Head Projection Measuring Point

1. Use a dial indicator to measure the piston projection

amount.

2. Refer to the illustration for the piston head projection measuring positions.

All measuring positions should be as close as possible to

the cylinder liner.

3. Measure the points 1, 2, 3, 4 and obtain two differences 1- 2 and 3-4 on each cylinder.

Calculate the average value of the piston head projection

on each cylinder.

4. Obtain the maximum value in the four cylinders.

5. Determine the gasket grade required to the maximum value described above in accordance with the following

table.

Cylinder Head Gasket Combination mm (in)

Cylinder Head Gasket Combination

4JA1T (L), 4JA1TC mm (in)

Gasket Grade Mark Piston Projection Gasket Thickness

(Reference)

A 0.718-0.773

(0.0283-0.0304) 1.6

(0.0630)

B 0.773-0.819

(0.0304-0.0322) 1.65

(0.0650)

C 0.819-0.874

(0.0322-0.0344) 1.70

(0.0669)

4JH1TC mm (in)

Gasket Grade Mark Piston Projection Gasket Thickness

(Reference)

A 0.215-0.265

(0.0085-0.0104) 1.3

(0.5118)

B 0.265-0.315

(0.0104-0.0124) 1.35

(0.5315)

C 0.315-0.365

(0.0124-0.0144) 1.4

(0.5512)

NOTE:

Difference of the each piston projection and must be

equal or within 0.1 mm (0.004 in).

011RY00027

011RY00030

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 895 of 6020

6A – 90 ENGINE MECHANICAL

CONNECTING ROD

Connecting Rod Alignment

Use a connecting rod aligner to measure the distortion and the

parallelism between the connecting rod big end hole and the

connecting rod small end hole.

If either the measured distortion or parallelism exceed the

specified limit, the connecting rod must be replaced.

Connecting Rod Alignment Per Length of 100 mm (3.94 in)

mm (in)

Standard Limit

Distortion 0.08 (0.003) or Less 0.20 (0.008)

Parallelism 0.05 (0.002) or Less 0.15 (0.006)

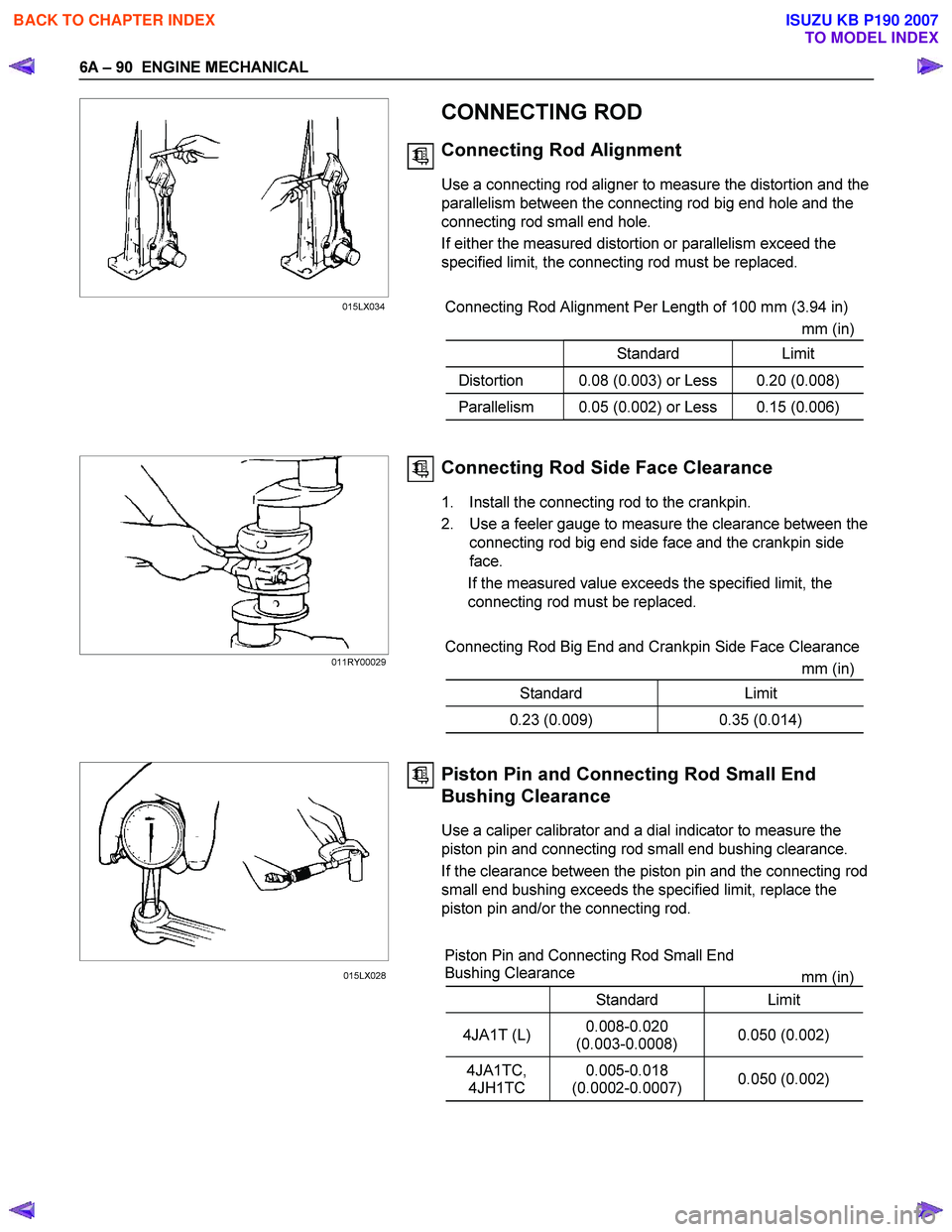

Connecting Rod Side Face Clearance

1. Install the connecting rod to the crankpin.

2. Use a feeler gauge to measure the clearance between the connecting rod big end side face and the crankpin side

face.

If the measured value exceeds the specified limit, the

connecting rod must be replaced.

Connecting Rod Big End and Crankpin Side Face Clearance

mm (in)

Standard Limit

0.23 (0.009) 0.35 (0.014)

Piston Pin and Connecting Rod Small End

Bushing Clearance

Use a caliper calibrator and a dial indicator to measure the

piston pin and connecting rod small end bushing clearance.

If the clearance between the piston pin and the connecting rod

small end bushing exceeds the specified limit, replace the

piston pin and/or the connecting rod.

Piston Pin and Connecting Rod Small End

Bushing Clearance mm (in)

Standard Limit

4JA1T (L) 0.008-0.020

(0.003-0.0008) 0.050 (0.002)

4JA1TC,

4JH1TC 0.005-0.018

(0.0002-0.0007) 0.050 (0.002)

015LX034

011RY00029 015LX028

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 913 of 6020

6A – 108 ENGINE MECHANICAL

10. Apply a coat of engine oil to the threads and setting

faces of each connecting rod cap bolt.

11. Tighten the connecting rod caps to the two step of anglar tigthen method.

Connecting Rod Bearing Cap Bolt Torque N·m (kg·m/Ib ft) 4JA1T (L), 4JA1TC 78-88 (8.0/57 – 9.0/65)

1st step; 29.0–29.2 (3.00/22.0–3.01/22.2) 4JH1TC

2nd step; 45°-60 °

13. Piston Cooling Oil Jet

1. Install the piston cooling oil jet to the cylinder body.

2. Tighten the oil jet bolts and relief valve to the specified torque.

Oil Jet Bolt Torque N·m(kg·m/lb ft)

M8 × 1.25 19 (1.9/14)

M6

× 1.00 8 (0.8/6)

Relief Valve Torque N·m(kg·m/lb ft)

29 (3.0/22)

NOTE:

Check that there is no interference between the piston

and the oiling jet by slowly rotating the crankshaft.

14. Oil Pump with Oil Pipe Apply a coat of the molybdenum disul fide and engine oil

enough on the pinion gear.

Install the oil pump with the oil pipe and tighten the bolts to

the specified torque.

Oil Pump Bolt Torque N·m(kg·m/lb ft)

19 (19/14)

NOTE:

Take care not to damage the O-rings when tightening

the oil pipe bolts.

15. Crankshaft Rear Oil Seal

Use a oil seal install to install the crankshaft rear oil seal.

Oil Seal Installer: 5-8840-2359-0

015LX130

015LX112

052LX010

051R100004

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 919 of 6020

6A – 114 ENGINE MECHANICAL

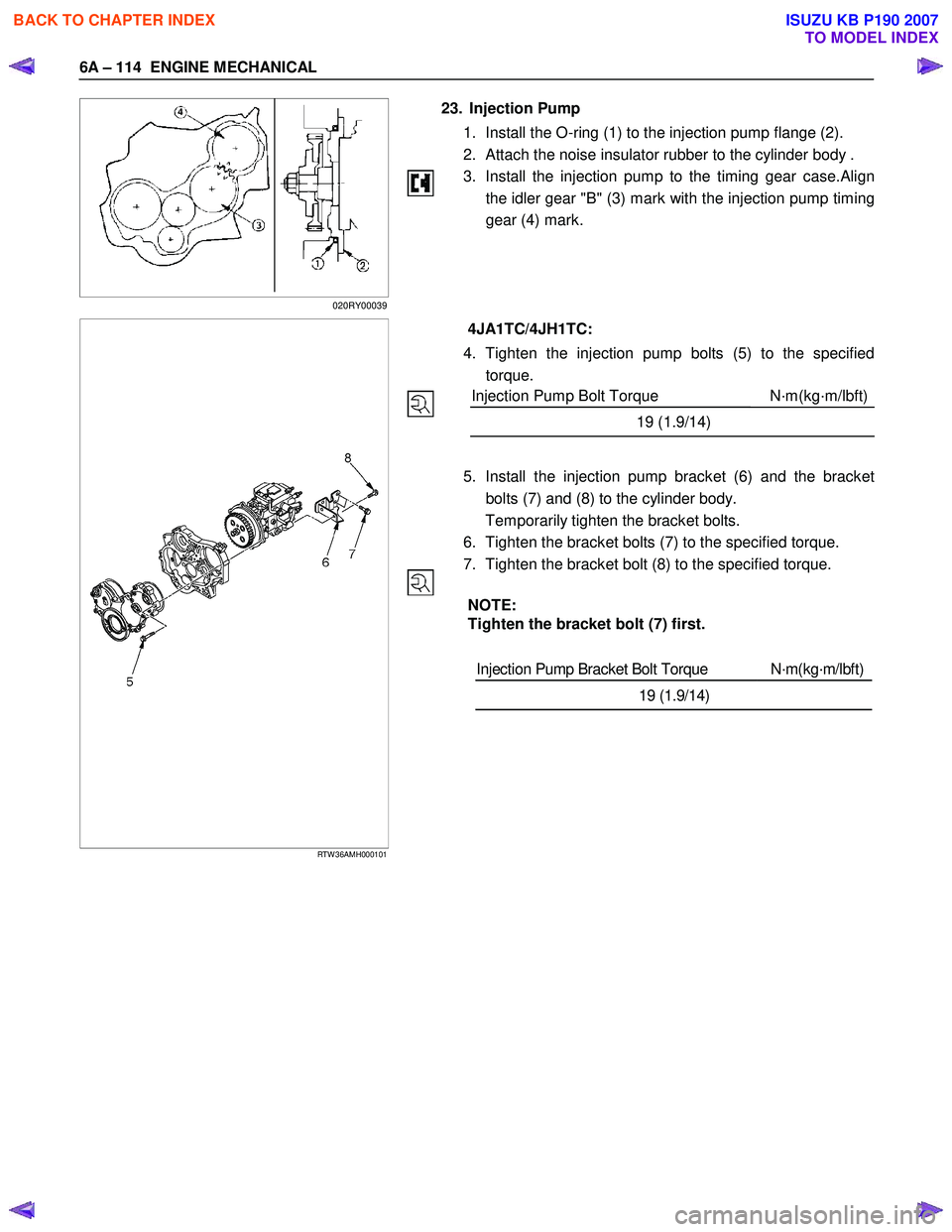

23. Injection Pump

1. Install the O-ring (1) to the injection pump flange (2).

2. Attach the noise insulator rubber to the cylinder body .

3. Install the injection pump to the timing gear case.Align the idler gear "B" (3) mark with the injection pump timing

gear (4) mark.

RTW 36AMH000101

4JA1TC/4JH1TC:

4. Tighten the injection pump bolts (5) to the specified torque.

Injection Pump Bolt Torque N·m(kg·m/lbft)

19 (1.9/14)

5. Install the injection pump bracket (6) and the bracket bolts (7) and (8) to the cylinder body.

Temporarily tighten the bracket bolts.

6. Tighten the bracket bolts (7) to the specified torque.

7. Tighten the bracket bolt (8) to the specified torque.

NOTE:

Tighten the bracket bolt (7) first.

Injection Pump Bracket Bolt Torque N·m(kg·m/lbft)

19 (1.9/14)

020RY00039

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007