check oil ISUZU KB P190 2007 Workshop Manual PDF

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 802 of 6020

TROUBLESHOOTING 6 – 17

14-3 Battery Under Charging

Step Action Value(s) Yes No

1 Was “Visual/Physical Check" performed.

—

Go to Step 2 Go to

visual/physical check

2 Inspect the brush contact condition on the generator.

Was there intermittent contact between the brush

and the slip ring? —

Repair or

replace the

brush holder assembly. Go to Step 3

3 Inspect the rotor coil on the generator.

Was there a short circuit in the rotor coil? —

Repair or

replace the rotor coil. Go to Step 4

4 Inspect the stator coil on the generator.

Was there an open circuit or the short circuit on the

stator coil? —

Repair or

replace the stator coil. Go to Step 5

5 Inspect the rectifier on the generator.

Was the rectifier defective? —

Replace the

rectifier Go to Step 6

6 Inspect the IC regulator on the generator.

Was the IC regulator defective? —

Replace the IC

regulator. Go to Step 7

7 Was the electrical load excessive? — Replace more

higher capacity generator. Go to Step 8

8 Are any DTC stored? — Go to indicated

DTC. Solved

14-4 Battery Unstable Charging Current

Step Action Value(s) Yes No

1 Was “Visual/Physical Check" performed.

—

Go to Step 2 Go to

visual/physical check

2 Inspect the brush contact condition on the generator.

Was there poor contact between the brush and the

slip ring? —

Repair or

replace the

brush and/or the slip ring. Go to Step 3

3 Inspect the rotor coil on the generator.

Was there the short circuit or an open circuit in the

rotor coil? —

Repair or

replace the rotor coil. Go to Step 4

4 Inspect the stator coil on the generator.

Was there an open circuit or the short circuit in the

stator coil? —

Repair or

replace the stator coil. Go to Step 5

5 Inspect the connection between the rectifier and

stator coil on the generator.

Was there a loose connection between the rectifier

and stator coil ? —

Repair the loose

connection. Go to Step 6

6 Inspect the IC regulator on the generator.

Was the IC regulator defective? —

Replace the IC

regulator. Go to Step 7

7 Are any DTC stored? — Go to indicated

DTC. Solved

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 803 of 6020

6 – 18 TROUBLESHOOTING

14-5 Charging System Noise Step Action Value(s) Yes No

1 Was “Visual/Physical Check" performed.

—

Go to Step 2 Go to

visual/physical check

2 Was there intermittent noise or continuous noise and

that could be identified clearly by increasing and

decreasing engine speed? —

Replace the bearing. Go to Step 3

3 Was there a growling sound and does this sound

stop when the connector was disconnected? —

Replace the

stator coil. Go to Step 4

4 Was intermittent sound heard when the generator

was running? —

Replace the

brush and/or slip ring. Go to Step 5

5 Was frictional sound heard when generator was

running? —

Clean the slip

ring or replace the brush. Go to Step 6

6 Are any DTC stored? — Go to indicated

DTC. Solved

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 804 of 6020

TROUBLESHOOTING 6 – 19

15. Starter Motor Problem

Visual/physical check the following items before diagnosis.

The battery terminals connection condition.

The ground connection condition.

The starter motor or the battery fastener condition.

The battery fluid level and specific gravity.

15-1 Starter motor pinion engages to ring gear but engine does not turn over

Step Action Value(s) Yes No

1 Was “Visual/Physical Check" performed.

—

Go to Step 2 Go to

visual/physical check

2 Check the contact condition between the brush and

the commutator.

Was the brush and the commutator contact

intermittent? —

Replace the

brush or repair the

commutator. Go to Step 3

3 Were the brush and the commutator contact faces

dirty?

—

Clean contact face Go to Step 4

4 Was the pinion clutch slipped? — Replace the

pinion clutch Go to Step 5

5 Inspect the armature field coil.

Was there an open circuit or a short circuit in the

armature field coil? —

Repair or

replace the

armature field coil. Go to Step 6

6 Are any DTC stored? — Go to indicated

DTC. Solved

15-2 Incorrect pinion and ring gear engagement

Step Action Value(s) Yes No

1 Was “Visual/Physical Check" performed.

—

Go to Step 2 Go to

visual/physical check

2 Inspect the pinion and the ring gear teeth.

Were the pinion and/or the ring gear teeth worn or

broken? —

Replace the wron parts. Go to Step 3

3 Inspect the pinion gear return movement.

Was the pinion gear return movement incorrect? —

Adjust or

replace the movement parts. Go to Step 4

4 Are any DTC stored? — Go to indicated

DTC. Solved

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 829 of 6020

6A – 24 ENGINE MECHANICAL

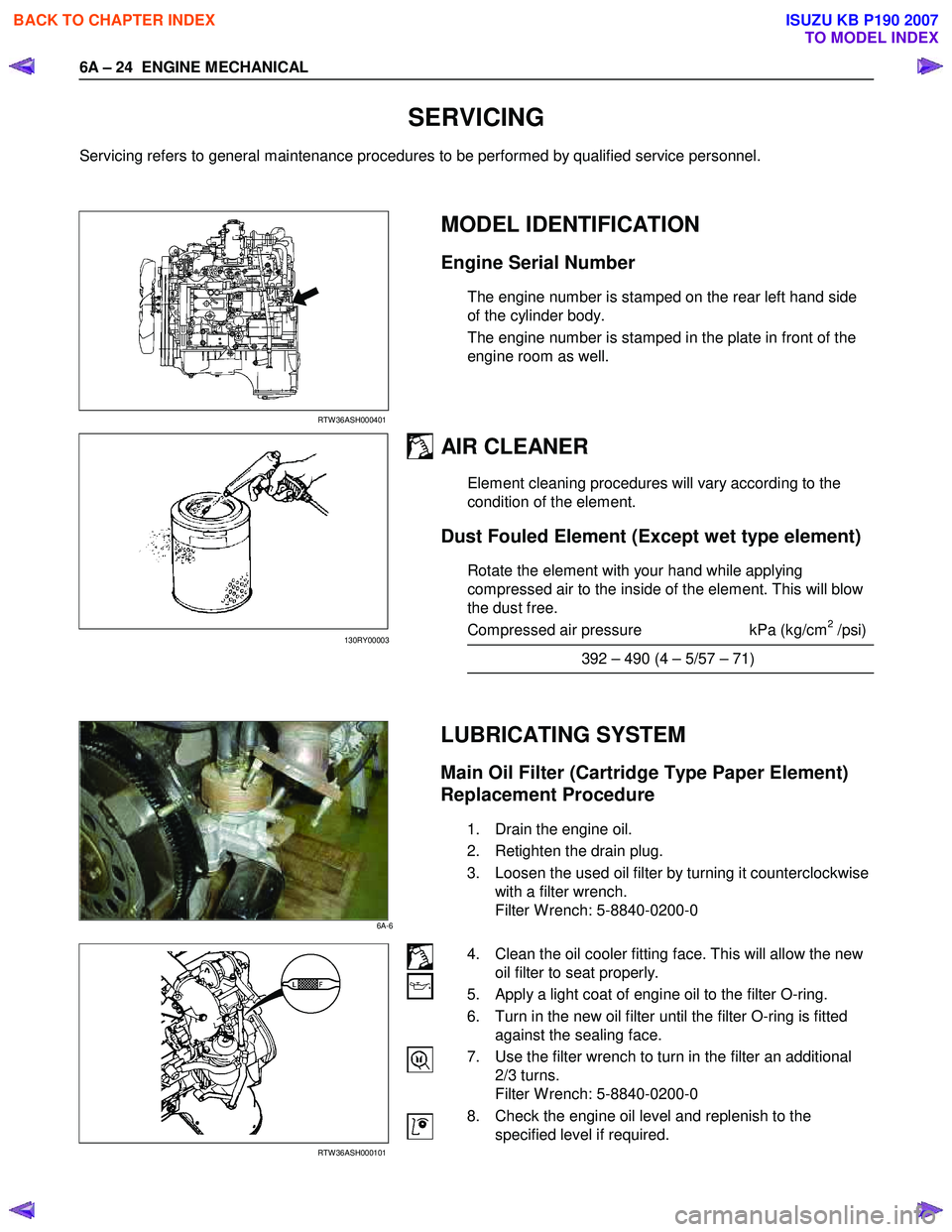

SERVICING

Servicing refers to general maintenance procedures to be performed by qualified service personnel.

RTW 36ASH000401

MODEL IDENTIFICATION

Engine Serial Number

The engine number is stamped on the rear left hand side

of the cylinder body.

The engine number is stamped in the plate in front of the

engine room as well.

AIR CLEANER

Element cleaning procedures will vary according to the

condition of the element.

Dust Fouled Element (Except wet type element)

Rotate the element with your hand while applying

compressed air to the inside of the element. This will blow

the dust free.

Compressed air pressure kPa (kg/cm

2 /psi)

392 – 490 (4 – 5/57 – 71)

LUBRICATING SYSTEM

Main Oil Filter (Cartridge Type Paper Element)

Replacement Procedure

1. Drain the engine oil.

2. Retighten the drain plug.

3. Loosen the used oil filter by turning it counterclockwise with a filter wrench.

Filter W rench: 5-8840-0200-0

RTW 36ASH000101

4. Clean the oil cooler fitting face. This will allow the new oil filter to seat properly.

5. Apply a light coat of engine oil to the filter O-ring.

6. Turn in the new oil filter until the filter O-ring is fitted against the sealing face.

7. Use the filter wrench to turn in the filter an additional 2/3 turns.

Filter W rench: 5-8840-0200-0

8. Check the engine oil level and replenish to the specified level if required.

130RY00003

6A-6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 830 of 6020

ENGINE MECHANICAL 6A – 25

Replenished Engine Oil MAX lit (US/UK gal)

Condition

Model Engine Dry

W ith oil filter

replacement W ithout oil

filter

replacement

4 × 2

4 × 4

(4JA1L/TC)6.2 (1.64/1.36) 5.2 ∼ 4.2

(1.37 ∼ 1.11

/ 1.14 ∼ 0.92) 4.5

∼ 3.5

(1.19 ∼ 0.93

/ 0.99 ∼ 0.77)

4 × 2

(4JH1TC)

6.2 (1.64/1.36) 5.2

∼ 4.2

(1.37 ∼ 1.11

/ 1.14 ∼ 0.92) 4.5

∼ 3.5

(1.19 ∼ 0.93

/ 0.99 ∼ 0.77)

4 × 4

(4JH1TC) 7.0 (1.85/1.54) 6.2 ∼ 5.2

(1.64 ∼ 1.37

/ 1.36 ∼ 1.14) 5.3

∼ 4.3

(1.72 ∼ 1.14

/ 1.17 ∼ 0.95)

9. Start the engine and check for oil leakage from the

main oil filter.

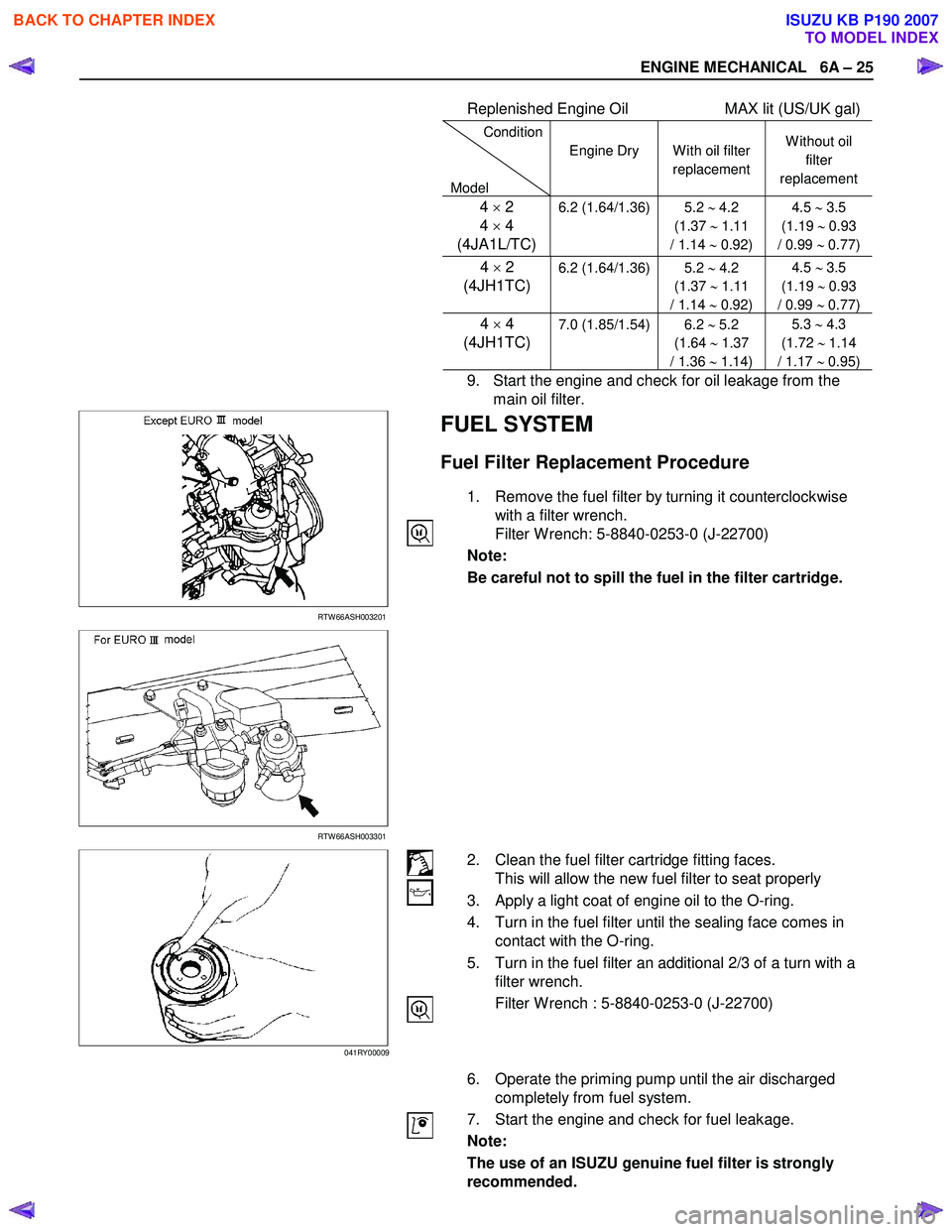

RTW 66ASH003201

FUEL SYSTEM

Fuel Filter Replacement Procedure

1. Remove the fuel filter by turning it counterclockwise with a filter wrench.

Filter W rench: 5-8840-0253-0 (J-22700)

Note:

Be careful not to spill the fuel in the filter cartridge.

RTW 66ASH003301

2. Clean the fuel filter cartridge fitting faces. This will allow the new fuel filter to seat properly

3. Apply a light coat of engine oil to the O-ring.

4. Turn in the fuel filter until the sealing face comes in contact with the O-ring.

5. Turn in the fuel filter an additional 2/3 of a turn with a filter wrench.

Filter W rench : 5-8840-0253-0 (J-22700)

6. Operate the priming pump until the air discharged completely from fuel system.

7. Start the engine and check for fuel leakage.

Note:

The use of an ISUZU genuine fuel filter is strongly

recommended.

041RY00009

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 832 of 6020

ENGINE MECHANICAL 6A – 27

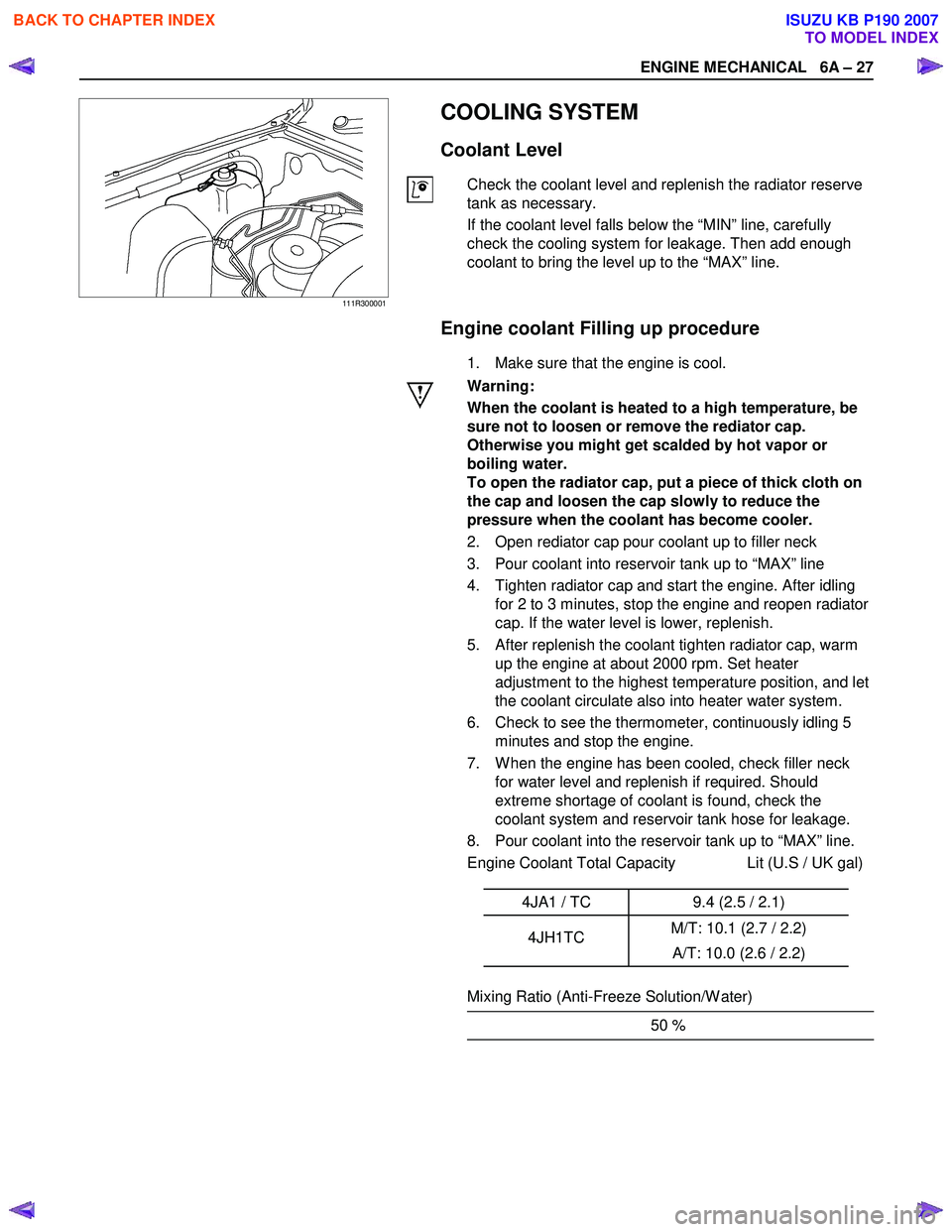

111R300001

COOLING SYSTEM

Coolant Level

Check the coolant level and replenish the radiator reserve

tank as necessary.

If the coolant level falls below the “MIN” line, carefully

check the cooling system for leakage. Then add enough

coolant to bring the level up to the “MAX” line.

Engine coolant Filling up procedure

1. Make sure that the engine is cool.

Warning:

When the coolant is heated to a high temperature, be

sure not to loosen or remove the rediator cap.

Otherwise you might get scalded by hot vapor or

boiling water.

To open the radiator cap, put a piece of thick cloth on

the cap and loosen the cap slowly to reduce the

pressure when the coolant has become cooler.

2. Open rediator cap pour coolant up to filler neck

3. Pour coolant into reservoir tank up to “MAX” line

4. Tighten radiator cap and start the engine. After idling for 2 to 3 minutes, stop the engine and reopen radiator

cap. If the water level is lower, replenish.

5. After replenish the coolant tighten radiator cap, warm up the engine at about 2000 rpm. Set heater

adjustment to the highest temperature position, and let

the coolant circulate also into heater water system.

6. Check to see the thermometer, continuously idling 5 minutes and stop the engine.

7. W hen the engine has been cooled, check filler neck for water level and replenish if required. Should

extreme shortage of coolant is found, check the

coolant system and reservoir tank hose for leakage.

8. Pour coolant into the reservoir tank up to “MAX” line.

Engine Coolant Total Capacity Lit (U.S / UK gal)

4JA1 / TC 9.4 (2.5 / 2.1)

4JH1TC M/T: 10.1 (2.7 / 2.2)

A/T: 10.0 (2.6 / 2.2)

Mixing Ratio (Anti-Freeze Solution/W ater)

50 %

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 834 of 6020

ENGINE MECHANICAL 6A – 29

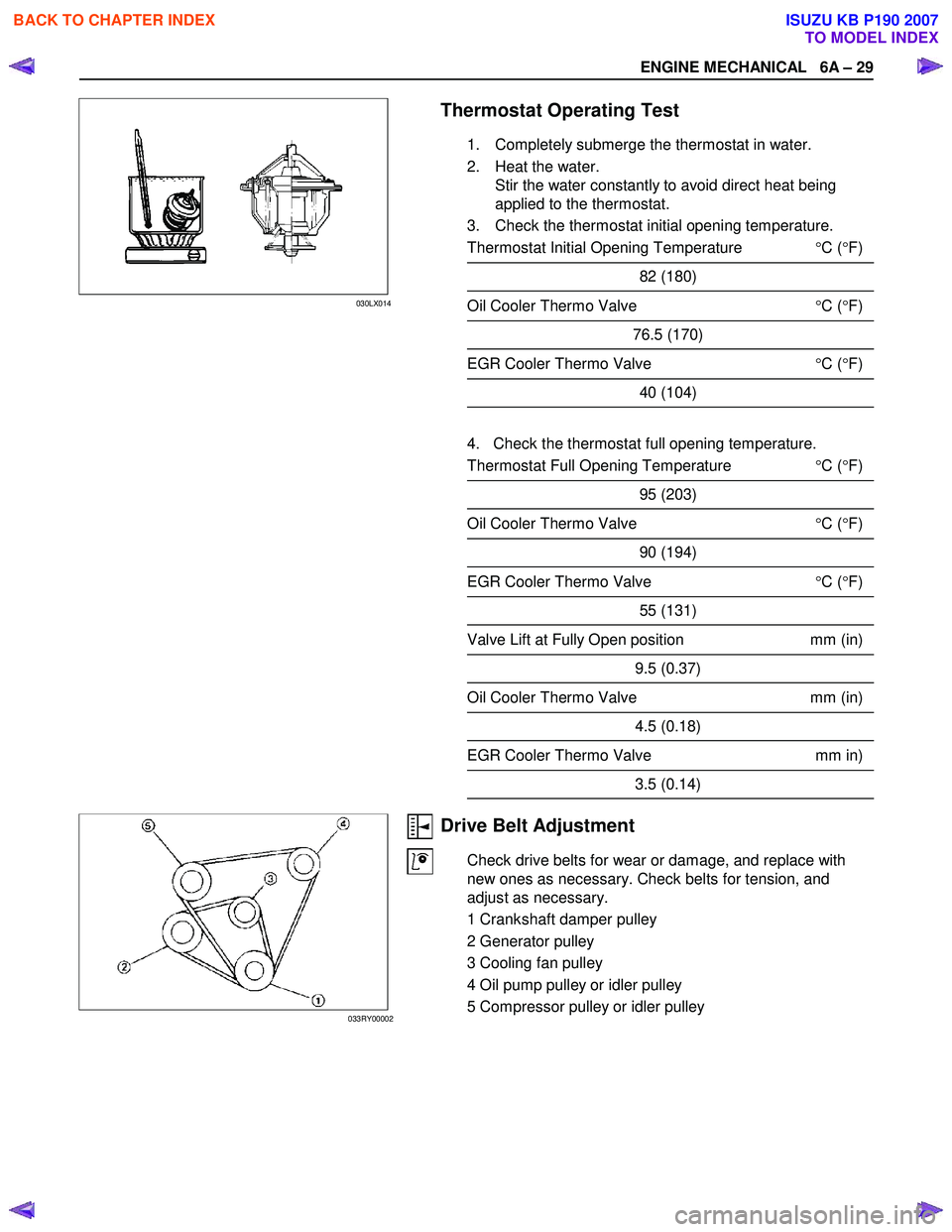

Thermostat Operating Test

1. Completely submerge the thermostat in water.

2. Heat the water. Stir the water constantly to avoid direct heat being

applied to the thermostat.

3. Check the thermostat initial opening temperature.

Thermostat Initial Opening Temperature °C ( °F)

82 (180)

Oil Cooler Thermo Valve °C ( °F)

76.5 (170)

EGR Cooler Thermo Valve °C ( °F)

40 (104)

4. Check the thermostat full opening temperature.

Thermostat Full Opening Temperature °C ( °F)

95 (203)

Oil Cooler Thermo Valve °C ( °F)

90 (194)

EGR Cooler Thermo Valve °C ( °F)

55 (131)

Valve Lift at Fully Open position mm (in)

9.5 (0.37)

Oil Cooler Thermo Valve mm (in)

4.5 (0.18)

EGR Cooler Thermo Valve mm in)

3.5 (0.14)

Drive Belt Adjustment

Check drive belts for wear or damage, and replace with

new ones as necessary. Check belts for tension, and

adjust as necessary.

1 Crankshaft damper pulley

2 Generator pulley

3 Cooling fan pulley

4 Oil pump pulley or idler pulley

5 Compressor pulley or idler pulley

030LX014

033RY00002

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 846 of 6020

ENGINE MECHANICAL 6A – 41

Coolant Replenishment

Warning:

When the coolant is heated to a high temperature, be

sure not to loosen or remove the rediator cap.

Otherwise you might get scalded by hot vapor or

boiling water.

To open the radiator cap, put a piece of thick cloth on

the cap and loosen the cap slowly to reduce the

pressure when the coolant has become cooler.

1. Open rediator cap pour coolant up to filler neck

2. Pour coolant into reservoir tank up to "MAX" line

3. Tighten radiator cap and start the engine. After idling for 2 to 3 minutes, stop the engine and reopen radiator

cap. If the water level is lower, replenish.

4. After replenish the coolant tighten radiator cap, warm up the engine at about 2000 rpm. Set heater

adjustment to the highest temperature position, and let

the coolant circulate also into heater water system.

5. Check to see the thermometer, continuously idling 5 minutes and stop the engine.

6. W hen the engine has been cooled, check filler neck for water level and replenish if required. Should extreme

shortage of coolant is found, check the coolant system

and reservoir tank hose for leakage.

7. Pour coolant into the reservoir tank up to "MAX" line.

Coolant Capacity lit (US/UK gal)

4JA1 / TC 9.4 (2.5 / 2.1)

4JH1TC M/T: 10.1 (2.7 / 2.2)

A/T: 10.0 (2.6 / 2.2)

Engine Warm-Up

After completing the required maintenance procedures,

start the engine and allow it to idle until it is warm.

Check the following:

1. Engine idling speed.

2. Engine noise level.

3. Engine lubricating system and cooling system. Carefully check for oil and coolant leakage.

4. Clutch engagement.

5. Transmission operation.

6. Indicator warning light operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 874 of 6020

ENGINE MECHANICAL 6A – 69

3. Check that the rocker arm oil port is free of obstructions. If necessary, use compressed air to clean the rocker arm

oil port.

Rocker Arm Correction

Inspect the rocker arm valve stem contact surfaces for step

wear (1) and scoring (2).

If the contact surfaces have light step wear or scoring, they

may be honed with an oil stone.

If the step wear or scoring is severe, the rocker arm must be

replaced.

CYLINDER BODY

Cylinder Body Upper Face Warpage

1. Remove the cylinder body dowel.

2. Remove the cylinder liner. Refer to "Cylinder Liner Replacement".

3. Use a straight edge (1) and a feeler gauge (2) to measure

the four sides and the two diagonals of the cylinder body

upper face.

If the measured values exceeds the limit, the cylinder body

must be replaced.

Cylinder Body Upper Face Warpage mm (in)

Standard Limit

0.05 (0.002) or less 0.20 (0.008)

Cylinder Body Height (H) (Reference) mm (in)

Standard

4JA1T(L), 4JA1TC : 244.945-245.055 (9.6435-9.6478)

4JH1TC : 269.945-270.055 (10.6277-10.6320)

4. Reinstall the cylinder liner. Refer to "Cylinder Liner Replacement".

5. Reinstall the cylinder body dowel.

014RY00024

012R100001

012RY00009 014RY00023

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 878 of 6020

ENGINE MECHANICAL 6A – 73

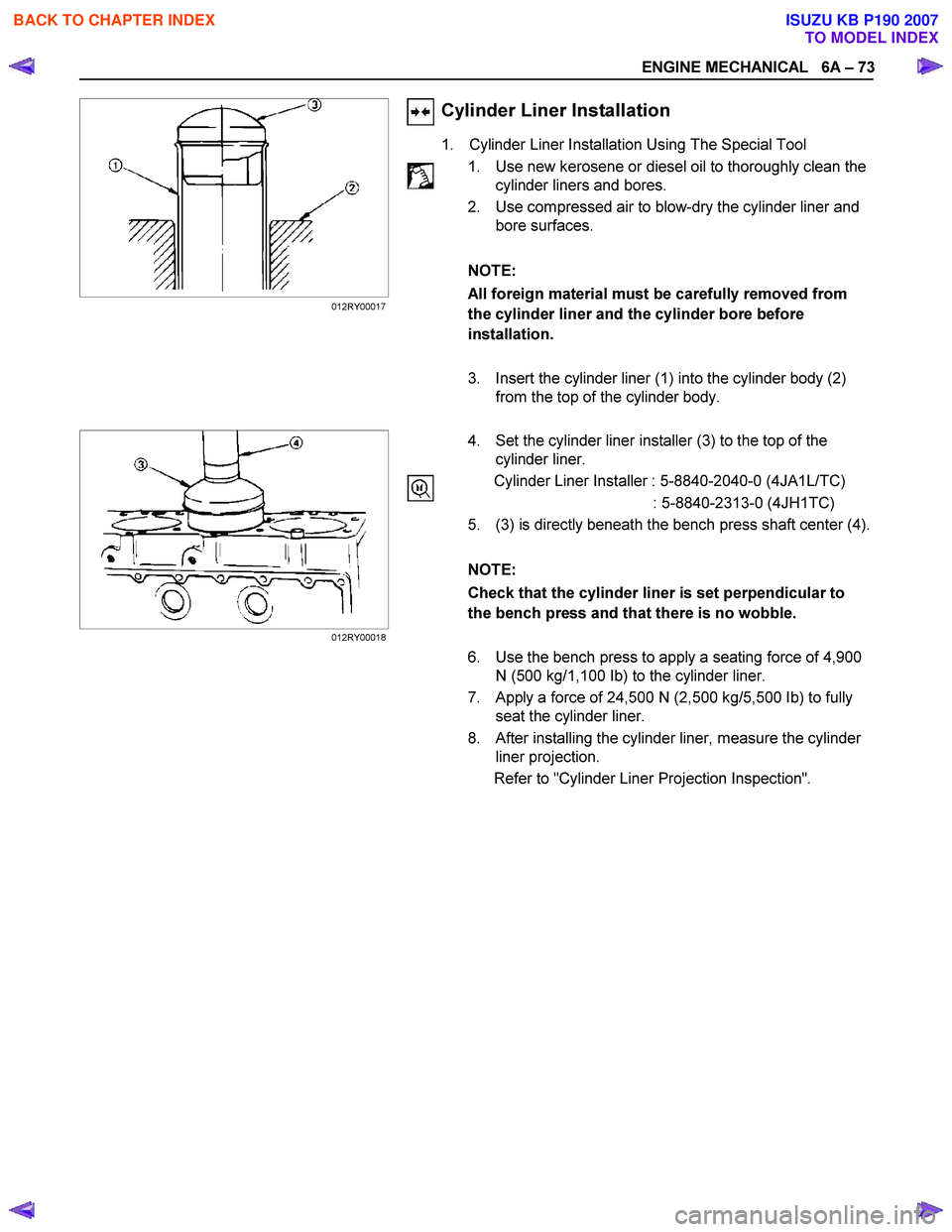

Cylinder Liner Installation

1. Cylinder Liner Installation Using The Special Tool

1. Use new kerosene or diesel oil to thoroughly clean the cylinder liners and bores.

2. Use compressed air to blow-dry the cylinder liner and bore surfaces.

NOTE:

All foreign material must be carefully removed from

the cylinder liner and the cylinder bore before

installation.

3. Insert the cylinder liner (1) into the cylinder body (2) from the top of the cylinder body.

4. Set the cylinder liner installer (3) to the top of the

cylinder liner.

Cylinder Liner Installer : 5-8840-2040-0 (4JA1L/TC)

: 5-8840-2313-0 (4JH1TC)

5. (3) is directly beneath the bench press shaft center (4).

NOTE:

Check that the cylinder liner is set perpendicular to

the bench press and that there is no wobble.

6. Use the bench press to apply a seating force of 4,900 N (500 kg/1,100 Ib) to the cylinder liner.

7. Apply a force of 24,500 N (2,500 kg/5,500 Ib) to fully seat the cylinder liner.

8. After installing the cylinder liner, measure the cylinder liner projection.

Refer to "Cylinder Liner Projection Inspection".

012RY00017

012RY00018

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007