Wiring harness ISUZU KB P190 2007 Workshop Manual PDF

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2788 of 6020

Engine Mechanical – V6 Page 6A1–11

Page 6A1–11

Intake Manifold Assembly

Figure 6A1 – 3

Legend

1 PCV Hose

2 PCV Hose O-Ring Outer (larger)

3 PCV Hose O-Ring Inner (smaller)

4 Upper Intake Manifold

5 Lower Intake Manifold

6 Upper Intake Manifold Bolt – Long

7 Upper Intake Manifold Bolt – Short

8 Lower Intake Manifold to Upper Intake Manifold Guide Pin

9 Upper Intake Manifold to Lower Intake Manifold Gasket

10 Lower Intake Manifold to Cylinder Head Gasket

11 Lower Intake Manifold Bolt

12 Fuel Rail Bolt

13 Fuel Rail

14 Fuel Injector

15 Fuel Injector Retainer

16 Fuel Injector Upper O-ring 17 Fuel Injector Lower O-ring

18 Fuel Pressure Service Valve Cap

19 Fuel Pressure Service Valve

20 Ball Stud

21 Fuel Injector Wiring Harness

22 Throttle Body

23 Throttle Body Bolt

24 Throttle Body Gasket

25 Throttle Body Engine Wiring Harness Clip

26 EVAP Purge Solenoid

27 EVAP Purge Solenoid Bolt

28 EVAP Purge Solenoid Tube

29 EVAP Purge Solenoid Bracket

30 BARO Sensor Bolt

31 BARO Sensor

32 BARO Sensor O-Ring

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2847 of 6020

Engine Mechanical – V6 Page 6A1–70

Page 6A1–70

3.3 Oil Filter Adaptor

Remove

Disconnection of the battery affects

certain vehicle electronic systems, refer to

1.1 WARNING, CAUTION and NOTES before

disconnecting the battery.

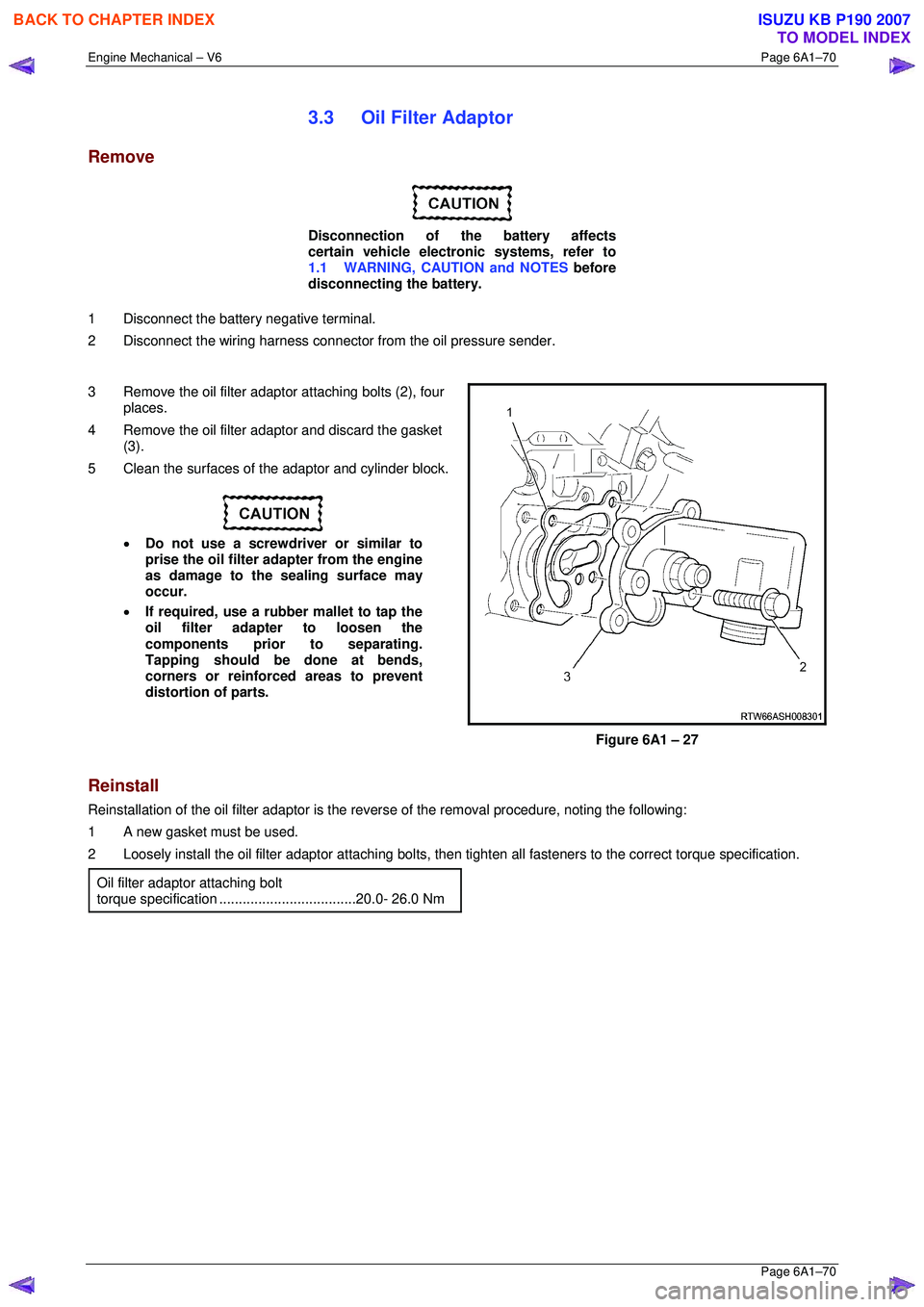

1 Disconnect the battery negative terminal.

2 Disconnect the wiring harness connecto r from the oil pressure sender.

3 Remove the oil filter adaptor attaching bolts (2), four

places.

4 Remove the oil filter adaptor and discard the gasket (3).

5 Clean the surfaces of t he adaptor and cylinder block.

• Do not use a screwdriver or similar to

prise the oil filter adapter from the engine

as damage to the sealing surface may

occur.

• If required, use a rubber mallet to tap the

oil filter adapter to loosen the

components prior to separating.

Tapping should be done at bends,

corners or reinforced areas to prevent

distortion of parts.

Figure 6A1 – 27

Reinstall

Reinstallation of the oil filter adaptor is the reverse of the remo val procedure, noting the following:

1 A new gasket must be used.

2 Loosely install the oil filter adaptor attaching bolts, then tighten all fast eners to the correct torque specification.

Oil filter adaptor attaching bolt

torque specificatio n ...................................20.0- 26.0 Nm

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2848 of 6020

Engine Mechanical – V6 Page 6A1–71

Page 6A1–71

3.4 Oil Level Indicator Tube

Remove

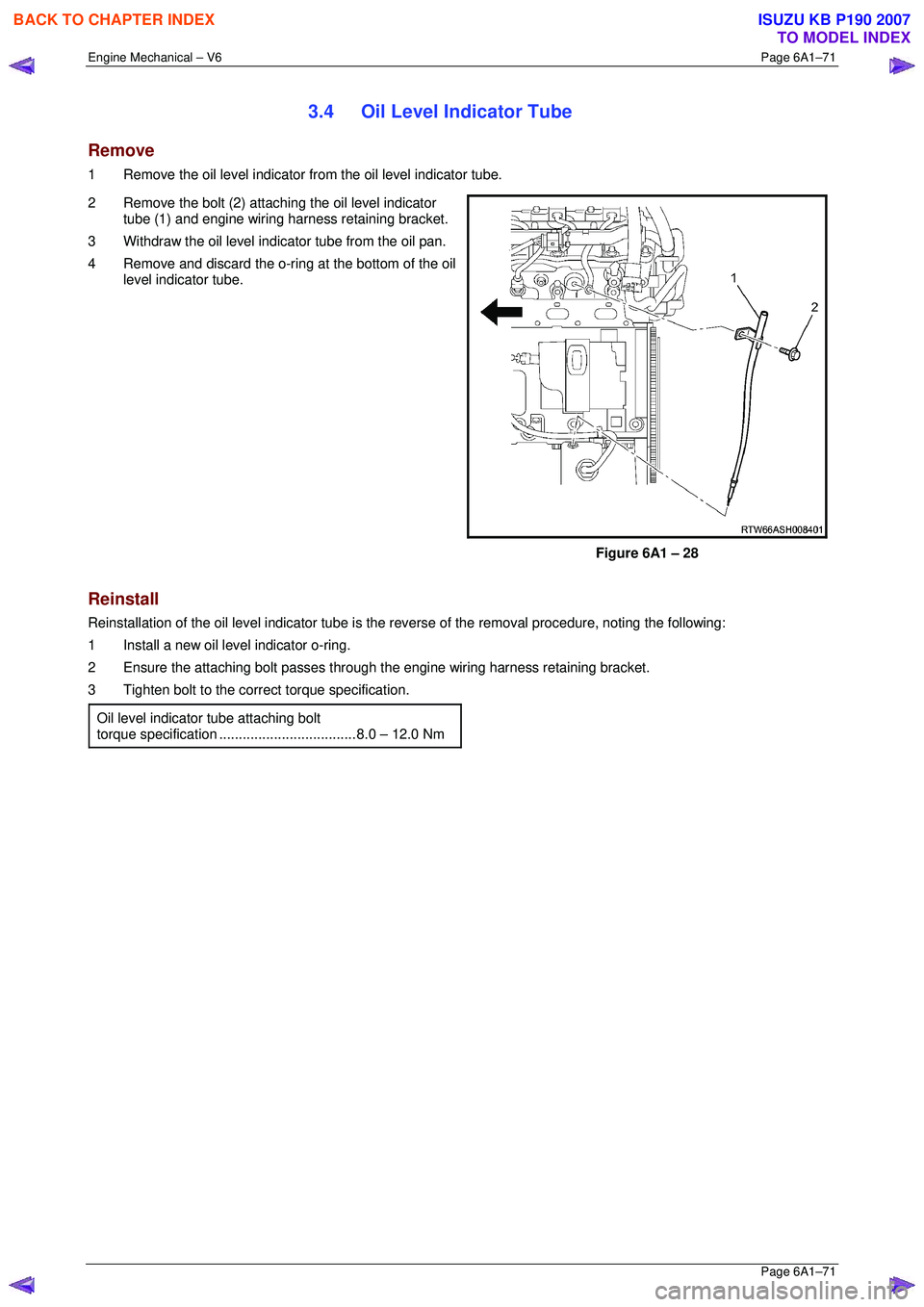

1 Remove the oil level indicator from the oil level indicator tube.

2 Remove the bolt (2) attaching the oil level indicator tube (1) and engine wiring harness retaining bracket.

3 Withdraw the oil level indi cator tube from the oil pan.

4 Remove and discard the o-ring at the bottom of the oil level indicator tube.

Figure 6A1 – 28

Reinstall

Reinstallation of the oil level indicator tube is the reverse of the removal procedure, noting the following:

1 Install a new oil level indicator o-ring.

2 Ensure the attaching bolt passes through the engine wiring harness retaining bracket.

3 Tighten bolt to the correct torque specification.

Oil level indicator tube attaching bolt

torque specificatio n ................................... 8. 0 – 12.0 Nm

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2855 of 6020

Engine Mechanical – V6 Page 6A1–78

Page 6A1–78

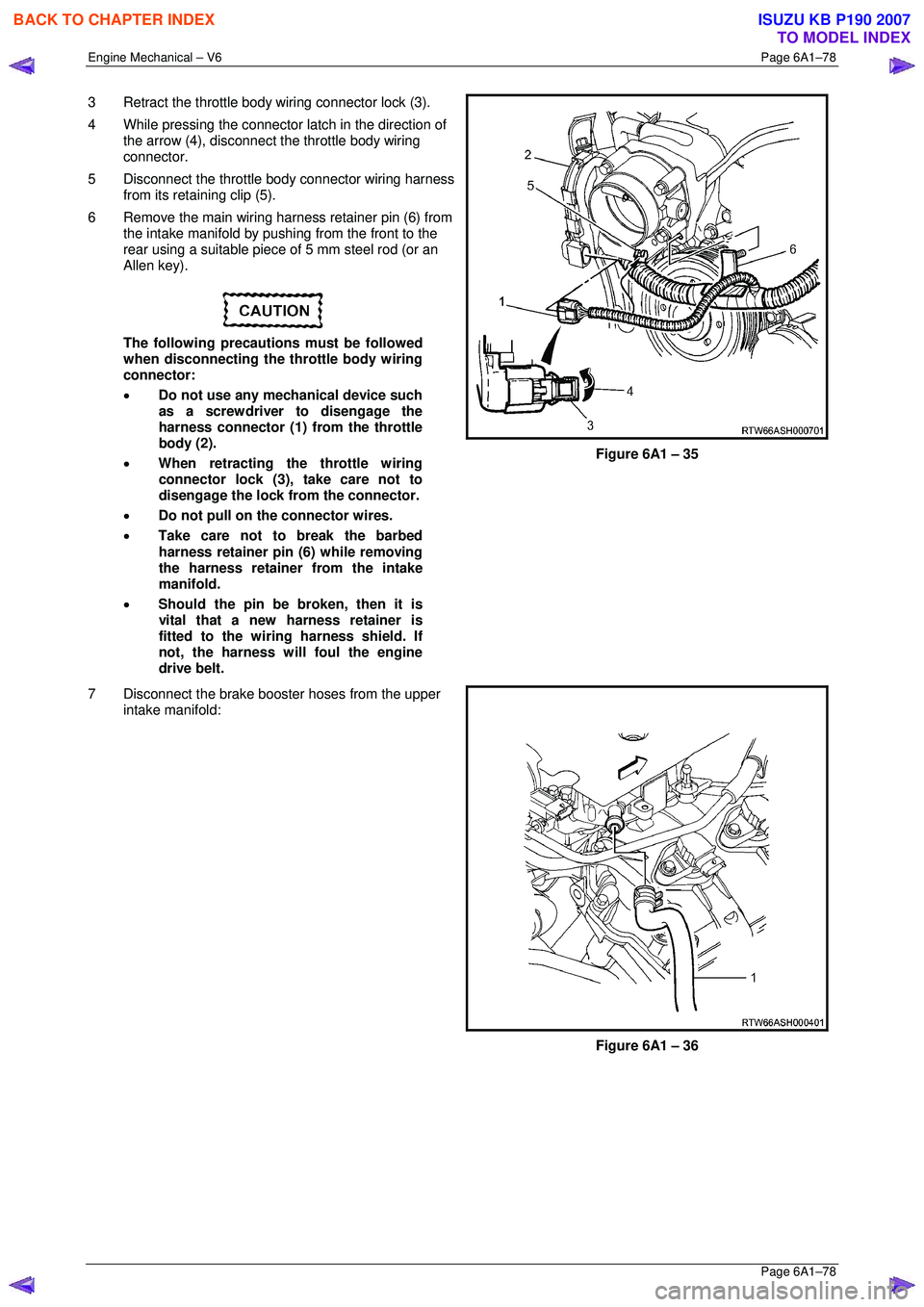

3 Retract the throttle body wiring connector lock (3).

4 While pressing the connector latch in the direction of

the arrow (4), disconnect the throttle body wiring

connector.

5 Disconnect the throttle body connector wiring harness from its retaining clip (5).

6 Remove the main wiring harness retainer pin (6) from the intake manifold by pushing from the front to the

rear using a suitable piece of 5 mm steel rod (or an

Allen key).

The following precautions must be followed

when disconnecting the throttle body wiring

connector:

• Do not use any mechanical device such

as a screwdriver to disengage the

harness connector (1) from the throttle

body (2).

• When retracting the throttle wiring

connector lock (3), take care not to

disengage the lock from the connector.

• Do not pull on the connector wires.

• Take care not to break the barbed

harness retainer pin (6) while removing

the harness retainer from the intake

manifold.

• Should the pin be broken, then it is

vital that a new harness retainer is

fitted to the wiring harness shield. If

not, the harness will foul the engine

drive belt.

Figure 6A1 – 35

7 Disconnect the brake booster hoses from the upper intake manifold:

Figure 6A1 – 36

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2856 of 6020

Engine Mechanical – V6 Page 6A1–79

Page 6A1–79

8 Disconnect the wiring harness connector from the

barometric (BARO) pressure sensor (1).

Figure 6A1 – 37

9 Disconnect the PCV tube connector (1) from the upper intake manifold assembly.

Figure 6A1 – 38

10 Remove the bolt (3) attaching the EVAP valve and the fuel injector wiring harness connector mounting

bracket to the upper inta ke manifold assembly.

11 Move the EVAP valve and the fuel injector wiring harness connector mounting br acket clear of the upper

intake manifold assembly.

12 Disconnect the PCV fresh air tube (1) from its upper intake manifold mounting clip (2).

Figure 6A1 – 39

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2859 of 6020

Engine Mechanical – V6 Page 6A1–82

Page 6A1–82

Reinstall

Reinstallation of the upper intake manifold and the upper and lower intake manifold assembly is the reverse of the

removal procedure, noting the following:

1 Only new gaskets are to be fitted betw een the upper and lower intake manifolds.

CAUTION

Tighten the intake manifold bolts in a circular

pattern starting at the centre bolt and moving

outward.

2 Ensure that all fasteners are tightened to the correct torque specification.

Upper intake manifold to lower

intake manifold attaching bolt

torque specificat ion ............................................ 23.0 Nm

Upper intake manifold to

cylinder head attaching bolt

torque specification ............................................ 23.0 Nm

Incorrect wiring connector installation may

cause component malfunction or component

damage.

3 Ensure all wiring connectors are fully engaged and if applicable, locked in place.

4 Ensure all wiring harnesses are correctly routed and attached securely in their retaining clips.

5 Ensure that all hoses and pipes ar e routed correctly and that any retaining clips are correctly installed.

6 Start and run the engine to c heck for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2861 of 6020

Engine Mechanical – V6 Page 6A1–84

Page 6A1–84

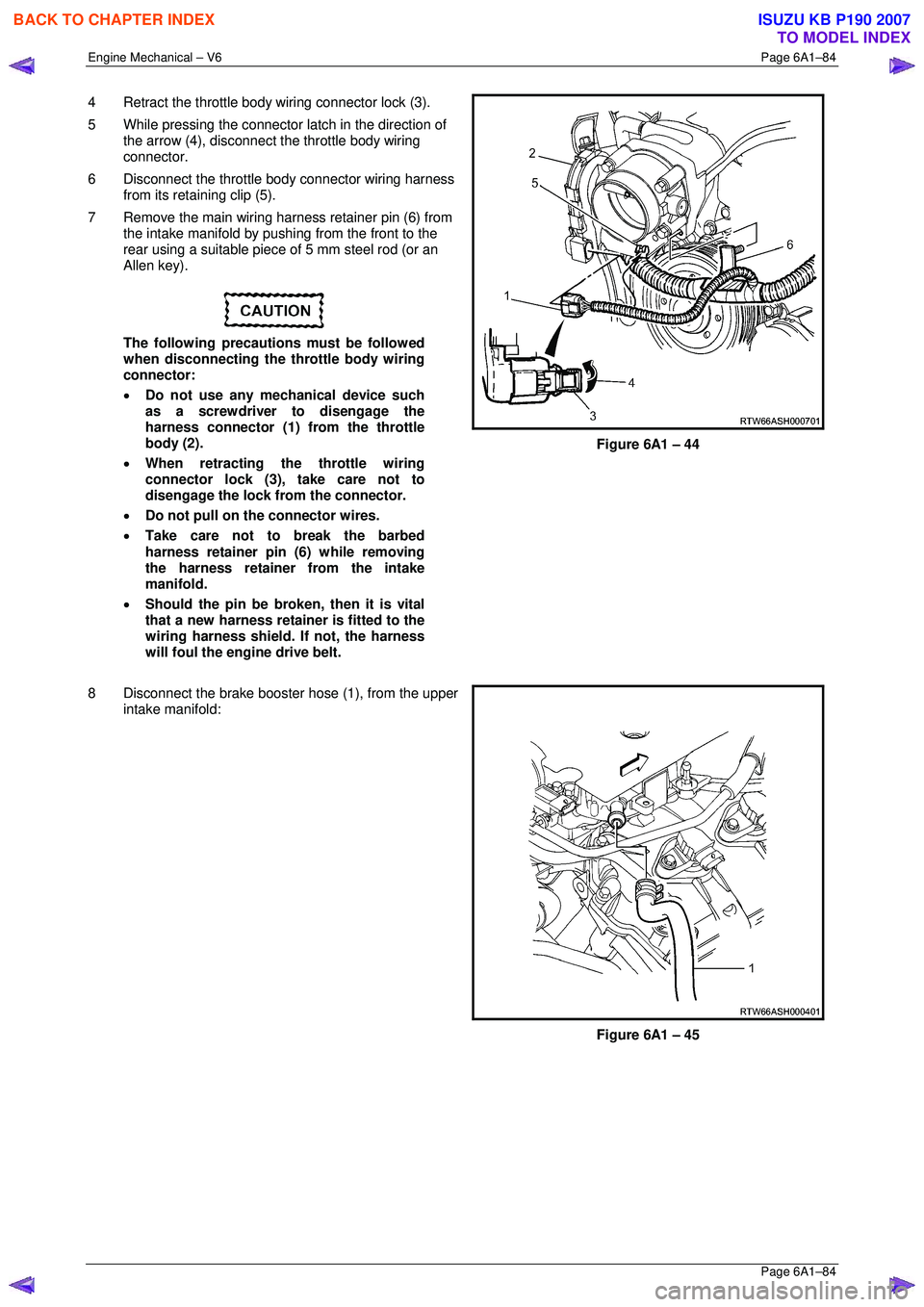

4 Retract the throttle body wiring connector lock (3).

5 While pressing the connector latch in the direction of

the arrow (4), disconnect the throttle body wiring

connector.

6 Disconnect the throttle body connector wiring harness from its retaining clip (5).

7 Remove the main wiring harness retainer pin (6) from the intake manifold by pushing from the front to the

rear using a suitable piece of 5 mm steel rod (or an

Allen key).

The following precautions must be followed

when disconnecting the throttle body wiring

connector:

• Do not use any mechanical device such

as a screwdriver to disengage the

harness connector (1) from the throttle

body (2).

• When retracting the throttle wiring

connector lock (3), take care not to

disengage the lock from the connector.

• Do not pull on the connector wires.

• Take care not to break the barbed

harness retainer pin (6) while removing

the harness retainer from the intake

manifold.

• Should the pin be broken, then it is vital

that a new harness retainer is fitted to the

wiring harness shield. If not, the harness

will foul the engine drive belt.

Figure 6A1 – 44

8 Disconnect the brake booster hose (1), from the upper

intake manifold:

Figure 6A1 – 45

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2862 of 6020

Engine Mechanical – V6 Page 6A1–85

Page 6A1–85

9 Disconnect the wiring harness connector from the

barometric (BARO) pressure sensor (1).

Figure 6A1 – 46

10 Disconnect the PCV tube connector (1) from the upper intake manifold assembly.

Figure 6A1 – 47

11 Disconnect the fuel feed hose from the fuel rail (1).

12 Pull out the release bar (2) (broad arrow) of the fuel

injector harness wiring connector (3).

13 Disconnect the fuel injector harness wiring connector from the fuel injector wiring harness (4).

Plug the fuel feed hose opening after

removal to prevent dirt and other

contaminants from entering the fuel system.

Figure 6A1 – 48

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2863 of 6020

Engine Mechanical – V6 Page 6A1–86

Page 6A1–86

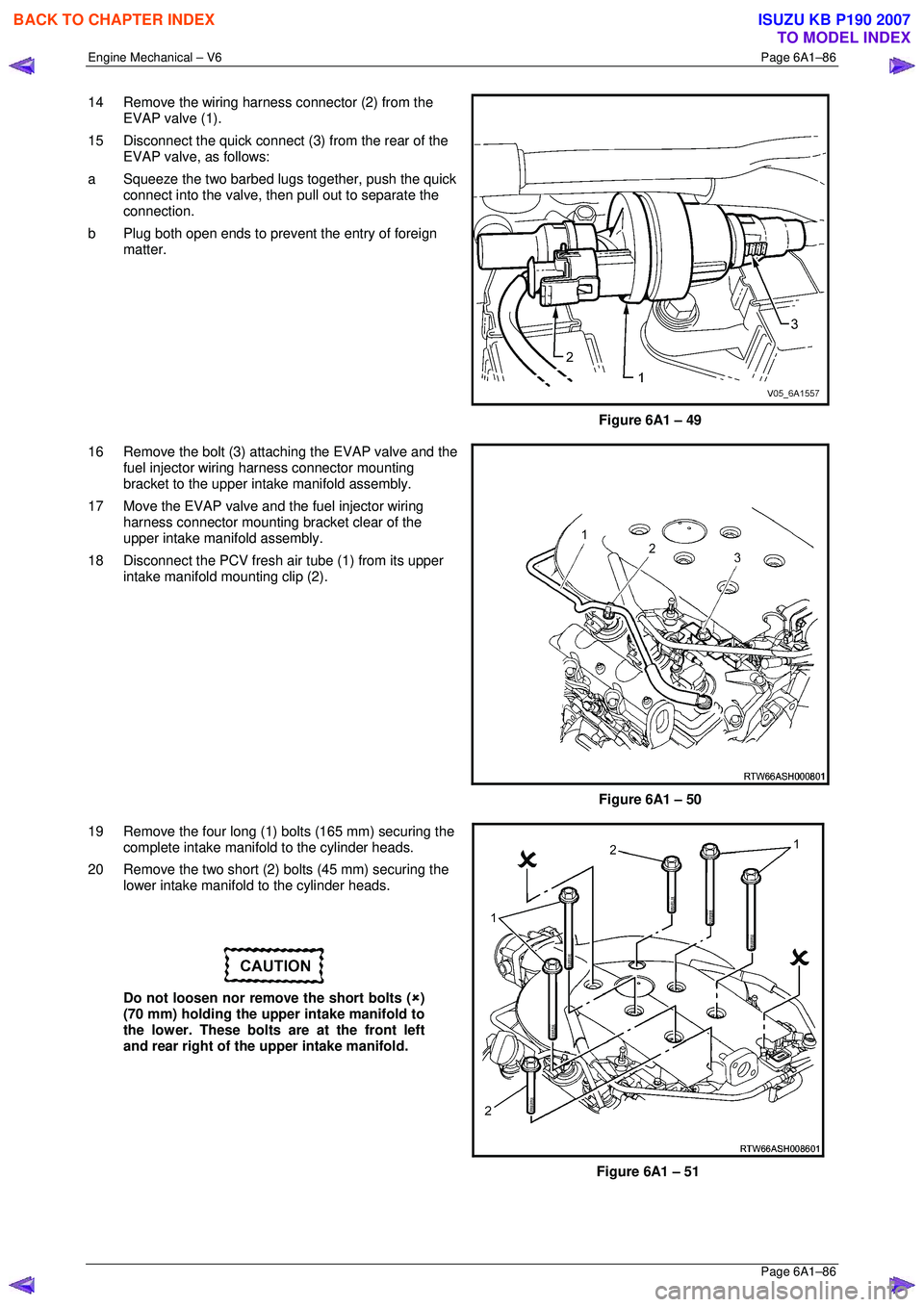

14 Remove the wiring harness connector (2) from the

EVAP valve (1).

15 Disconnect the quick connect (3 ) from the rear of the

EVAP valve, as follows:

a Squeeze the two barbed lugs together, push the quick

connect into the valve, t hen pull out to separate the

connection.

b Plug both open ends to prevent the entry of foreign

matter.

Figure 6A1 – 49

16 Remove the bolt (3) attaching the EVAP valve and the fuel injector wiring harness connector mounting

bracket to the upper inta ke manifold assembly.

17 Move the EVAP valve and the fuel injector wiring harness connector mounting bracket clear of the

upper intake manifold assembly.

18 Disconnect the PCV fresh air tube (1) from its upper intake manifold mounting clip (2).

Figure 6A1 – 50

19 Remove the four long (1) bolts (165 mm) securing the complete intake manifo ld to the cylinder heads.

20 Remove the two short (2) bolts (45 mm) securing the lower intake manifold to the cylinder heads.

Do not loosen nor remove the short bolts ( �8)

(70 mm) holding the upper intake manifold to

the lower. These bolts are at the front left

and rear right of the upper intake manifold.

Figure 6A1 – 51

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2866 of 6020

Engine Mechanical – V6 Page 6A1–89

Page 6A1–89

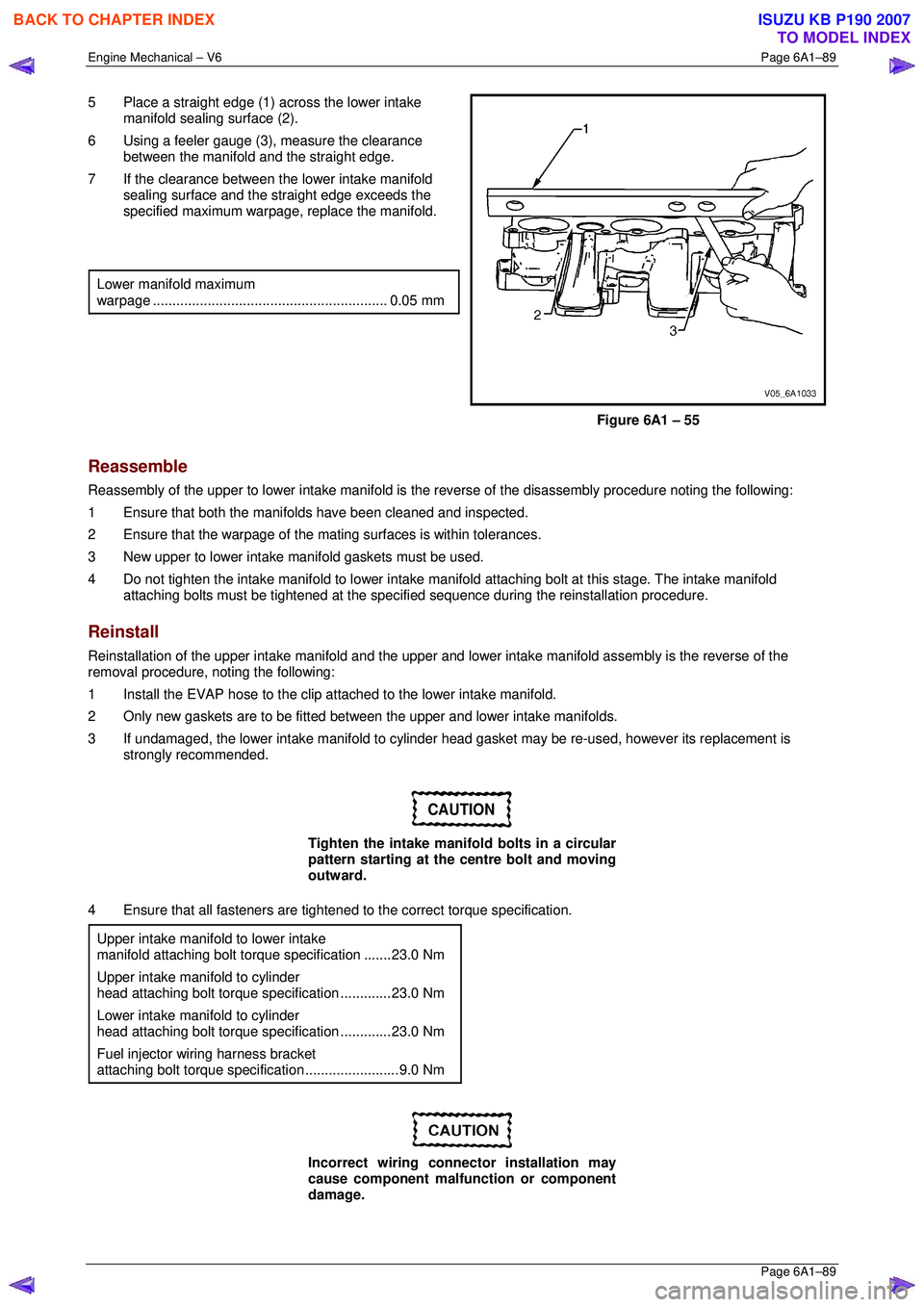

5 Place a straight edge (1) across the lower intake

manifold sealing surface (2).

6 Using a feeler gauge (3), measure the clearance

between the manifold and the straight edge.

7 If the clearance between the lower intake manifold sealing surface and the straight edge exceeds the

specified maximum warpage, replace the manifold.

Lower manifold maximum

warpage ............................................................ 0.05 mm

Figure 6A1 – 55

Reassemble

Reassembly of the upper to lower intake manifold is the reverse of the disassembly procedure noting the following:

1 Ensure that both the manifo lds have been cleaned and inspected.

2 Ensure that the warpage of the mati ng surfaces is within tolerances.

3 New upper to lower intake m anifold gaskets must be used.

4 Do not tighten the intake manifold to lower intake manifold attaching bolt at this stage. The intake manifold

attaching bolts must be tightened at the specif ied sequence during the reinstallation procedure.

Reinstall

Reinstallation of the upper intake manifold and the upper and lower intake manifo ld assembly is the reverse of the

removal procedure, noting the following:

1 Install the EVAP hose to the clip atta ched to the lower intake manifold.

2 Only new gaskets are to be fitted betw een the upper and lower intake manifolds.

3 If undamaged, the lower intake manifold to cylinder head gasket may be re-used, however its replacement is

strongly recommended.

CAUTION

Tighten the intake manifold bolts in a circular

pattern starting at the centre bolt and moving

outward.

4 Ensure that all fasteners are tightened to the correct torque specification.

Upper intake manifold to lower intake

manifold attaching bolt torq ue specification .......23.0 Nm

Upper intake manifold to cylinder

head attaching bolt torque specification .............23.0 Nm

Lower intake manifold to cylinder

head attaching bolt torque specification .............23.0 Nm

Fuel injector wiring harness bracket

attaching bolt torque specification ........................9.0 Nm

Incorrect wiring connector installation may

cause component malfunction or component

damage.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007