fuel ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4071 of 6020

TRANSMISSION CONTROL SYSTEM (AW30–40LE) 7A2-105

DTC P2769 or P2770 (Flash Code 33)

RTW 77ALF001501

Circuit Description

The lock-up solenoid SL of the torque converter clutch

(TCC) controls the lock-up clutch by a signal according

to the lock-up position judgment of the TCM when the

vehicle runs.

This function can improve the fuel consumption to

almost the same extent as the manual transmission.

The lock-up solenoid SL is put into B+ by the TCM, so

that the solenoid is actuated with the result of lock-up.

Condition For Running The DTC

All of the following conditions are met.

(1) All of the following conditions are met for 2 seconds or more continuously.

• The supply voltage is more than 10.2 volts and

less than 15.5 volts.

(2) Not emergency mode.

(3) 0.025 seconds or more passed after the state o

f

energized solenoid is changed.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4117 of 6020

7A3-32 ON-VEHICLE SERVICE (AW30–40LE)

Shift Solenoid and Lock-Up Solenoid

Removal

Preparation:

• Disconnect negative (–) battery cable.

• Drain the fluid.

Refer to ATF REPLACEMENT in this section.

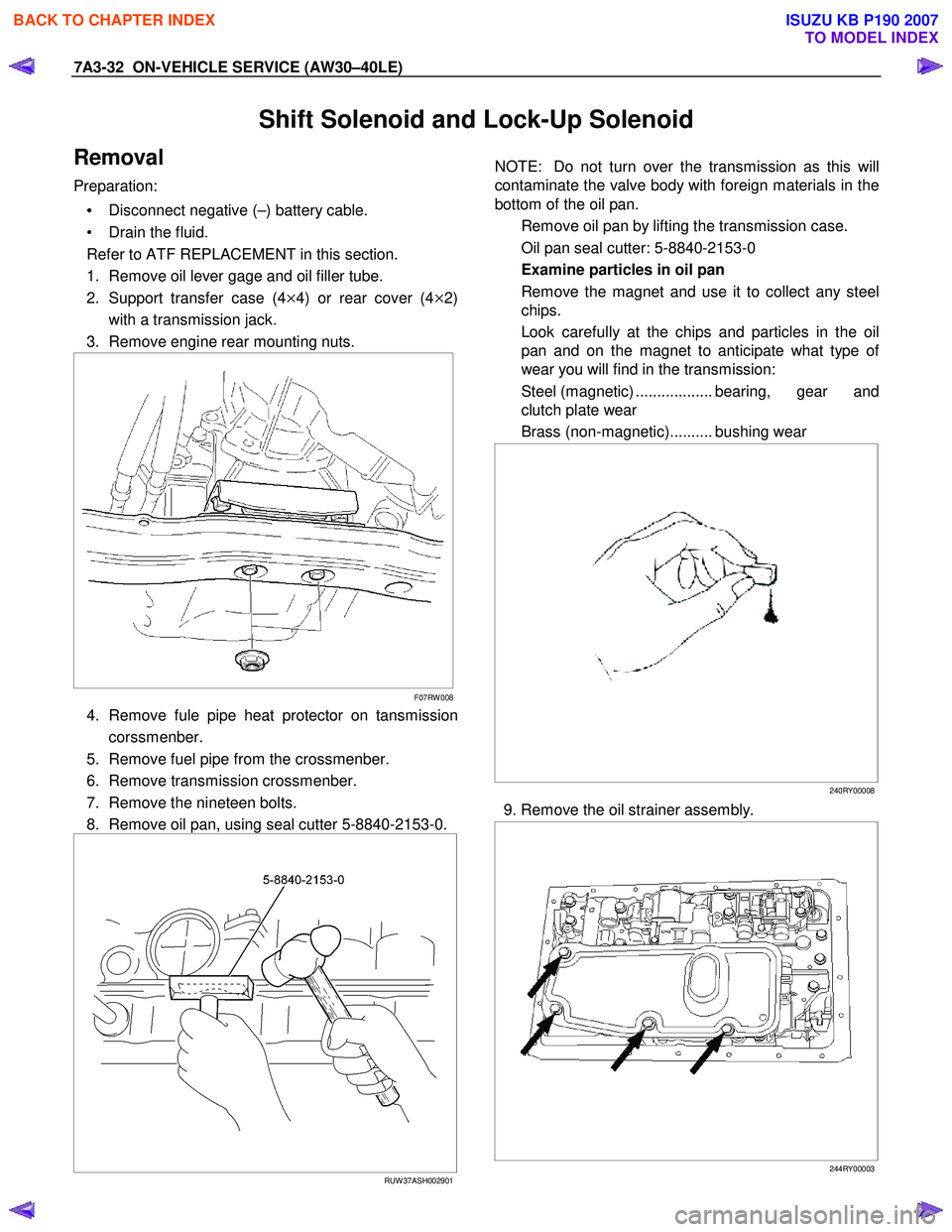

1. Remove oil lever gage and oil filler tube.

2. Support transfer case (4

×4) or rear cover (4×2)

with a transmission jack.

3. Remove engine rear mounting nuts.

F07RW 008

4. Remove fule pipe heat protector on tansmission

corssmenber.

5. Remove fuel pipe from the crossmenber.

6. Remove transmission crossmenber.

7. Remove the nineteen bolts.

8. Remove oil pan, using seal cutter 5-8840-2153-0.

RUW 37ASH002901

NOTE: Do not turn over the transmission as this will

contaminate the valve body with foreign materials in the

bottom of the oil pan.

Remove oil pan by lifting the transmission case.

Oil pan seal cutter: 5-8840-2153-0

Examine particles in oil pan

Remove the magnet and use it to collect any steel

chips.

Look carefully at the chips and particles in the oil

pan and on the magnet to anticipate what type o

f

wear you will find in the transmission:

Steel (magnetic) .................. bearing, gear and

clutch plate wear

Brass (non-magnetic).......... bushing wear

240RY00008

9. Remove the oil strainer assembly.

244RY00003

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4124 of 6020

ON-VEHICLE SERVICE (AW30–40LE) 7A3-39

Transmission Assembly

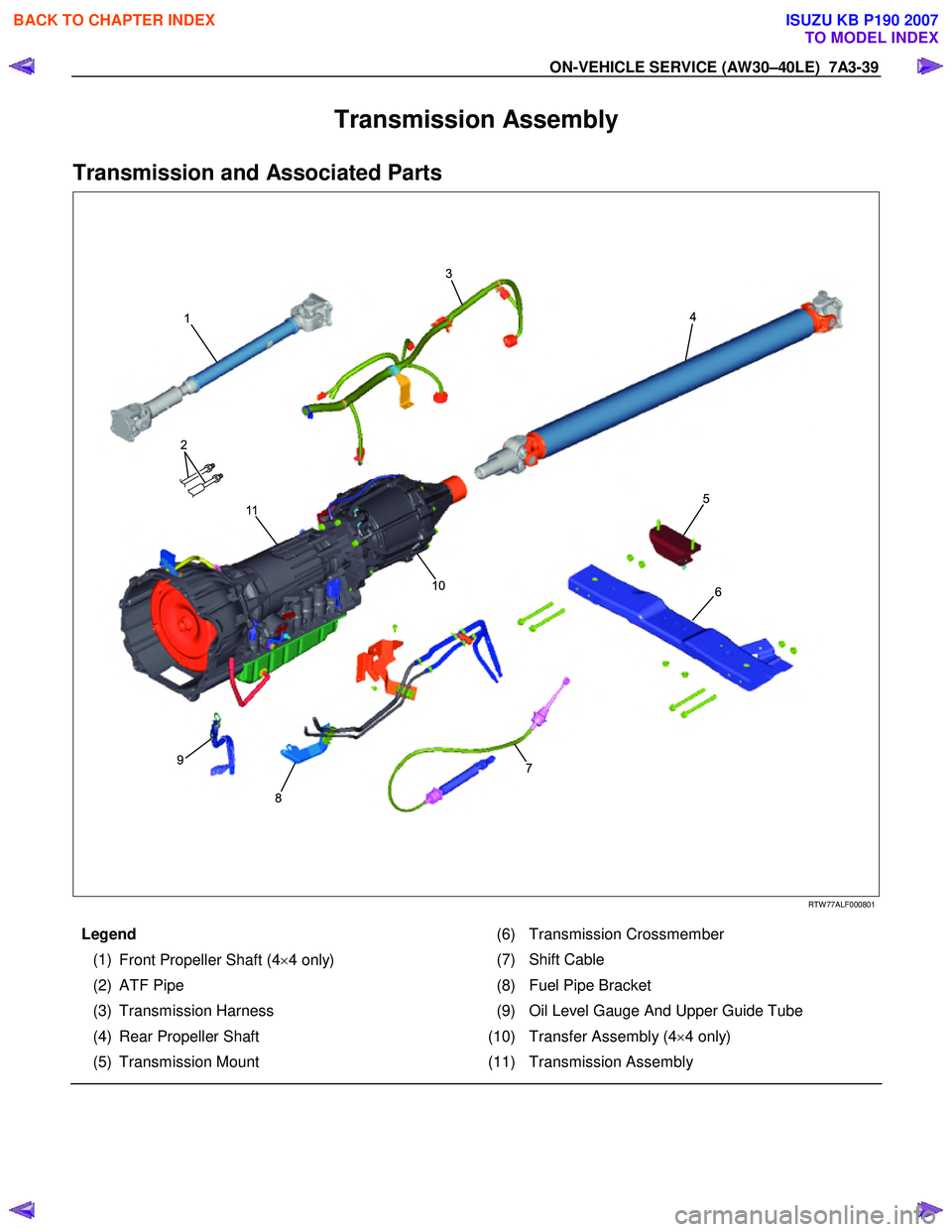

Transmission and Associated Parts

1

3

4

5

6

7

10

11

2

9

8

RTW 77ALF000801

Legend (6) Transmission Crossmember

(1) Front Propeller Shaft (4 ×4 only) (7) Shift Cable

(2) ATF Pipe (8) Fuel Pipe Bracket

(3) Transmission Harness (9) Oil Level Gauge And Upper Guide Tube

(4) Rear Propeller Shaft (10) Transfer Assembly (4×4 only)

(5) Transmission Mount (11) Transmission Assembly

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4126 of 6020

ON-VEHICLE SERVICE (AW30–40LE) 7A3-41

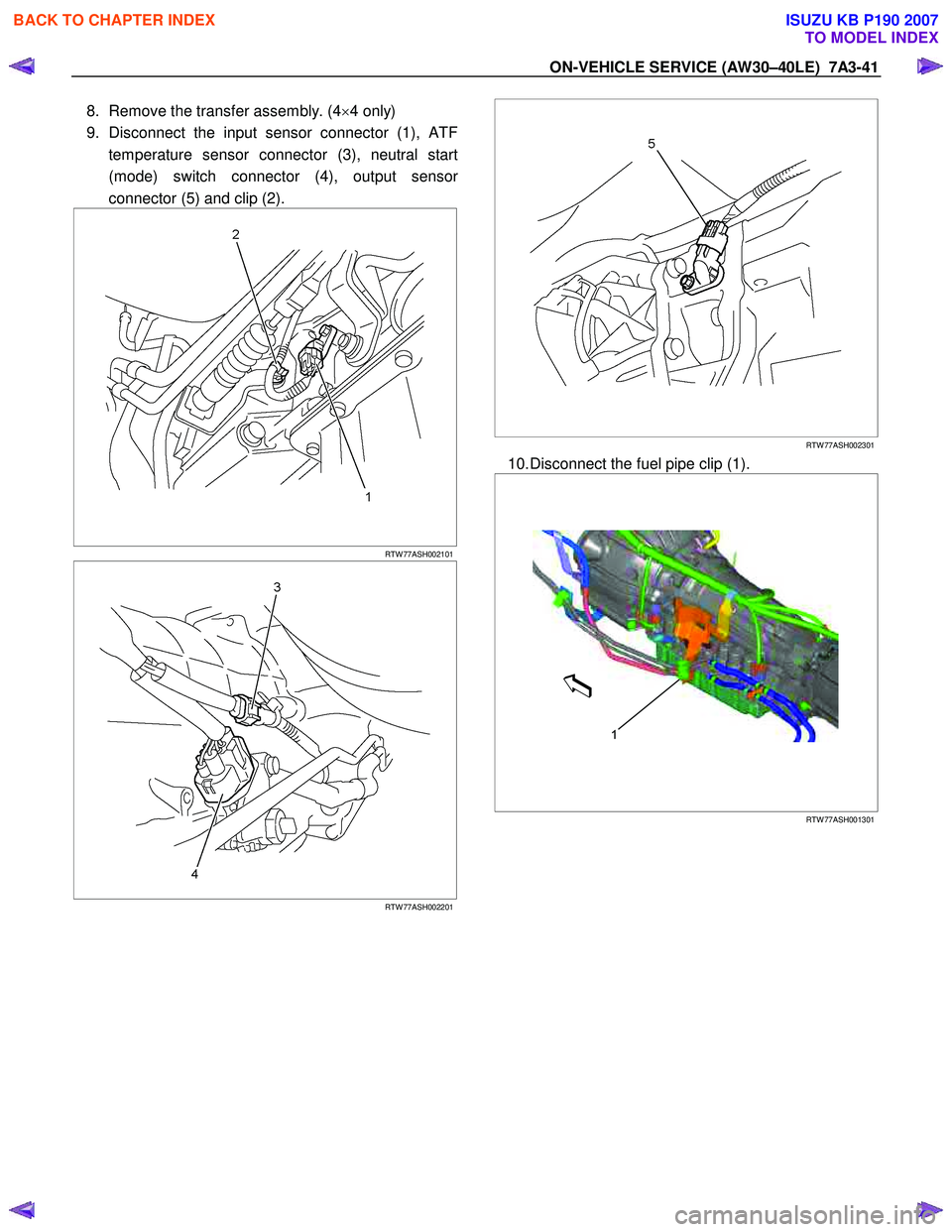

8. Remove the transfer assembly. (4×4 only)

9. Disconnect the input sensor connector (1), ATF temperature sensor connector (3), neutral start

(mode) switch connector (4), output senso

r

connector (5) and clip (2).

RTW 77ASH002101

RTW 77ASH002201

RTW 77ASH002301

10. Disconnect the fuel pipe clip (1).

1

RTW 77ASH001301

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4127 of 6020

7A3-42 ON-VEHICLE SERVICE (AW30–40LE)

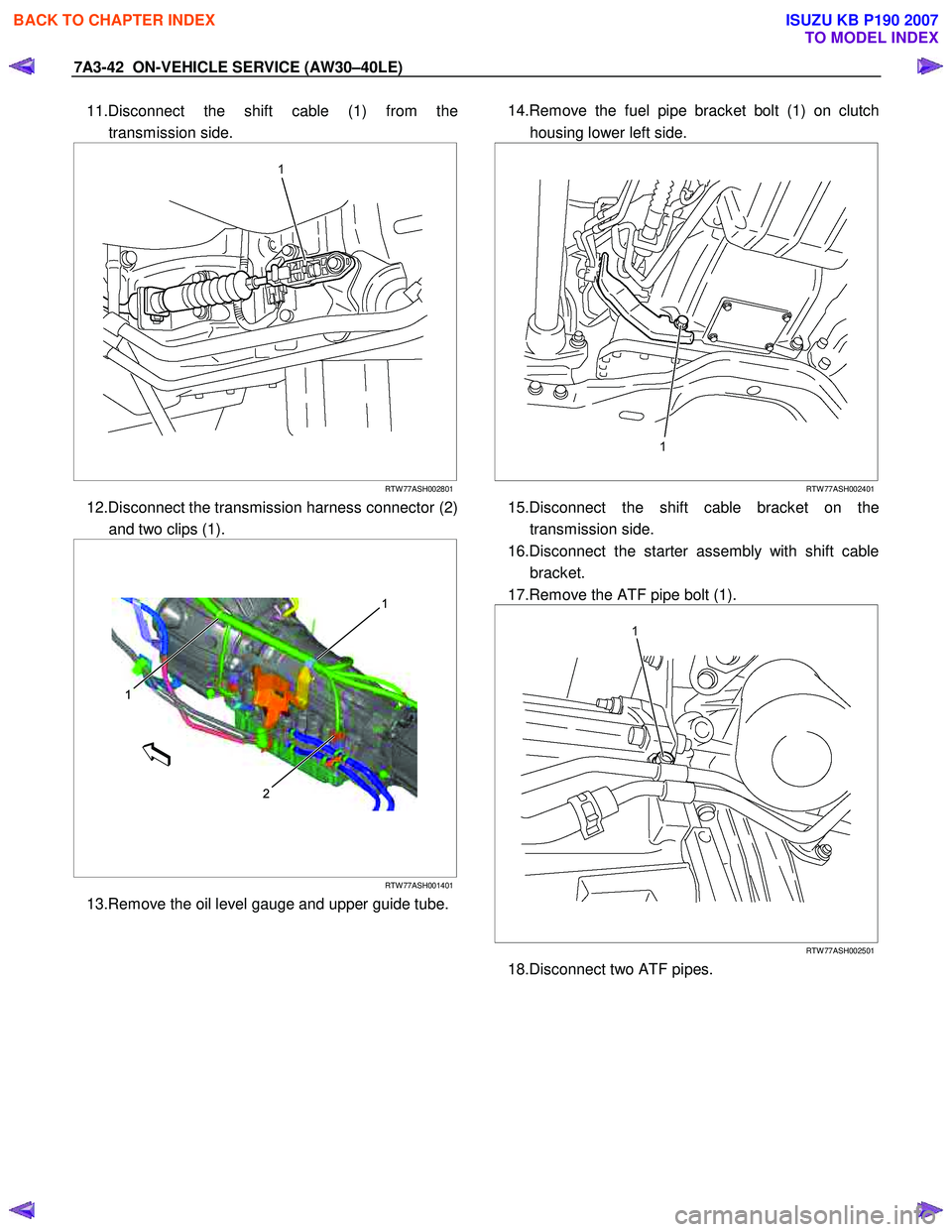

11.Disconnect the shift cable (1) from the

transmission side.

RTW 77ASH002801

12.Disconnect the transmission harness connector (2)

and two clips (1).

2

1

1

RTW 77ASH001401

13.Remove the oil level gauge and upper guide tube.

14.Remove the fuel pipe bracket bolt (1) on clutch

housing lower left side.

RTW 77ASH002401

15.Disconnect the shift cable bracket on the

transmission side.

16.Disconnect the starter assembly with shift cable bracket.

17.Remove the ATF pipe bolt (1).

RTW 77ASH002501

18.Disconnect two ATF pipes.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4128 of 6020

ON-VEHICLE SERVICE (AW30–40LE) 7A3-43

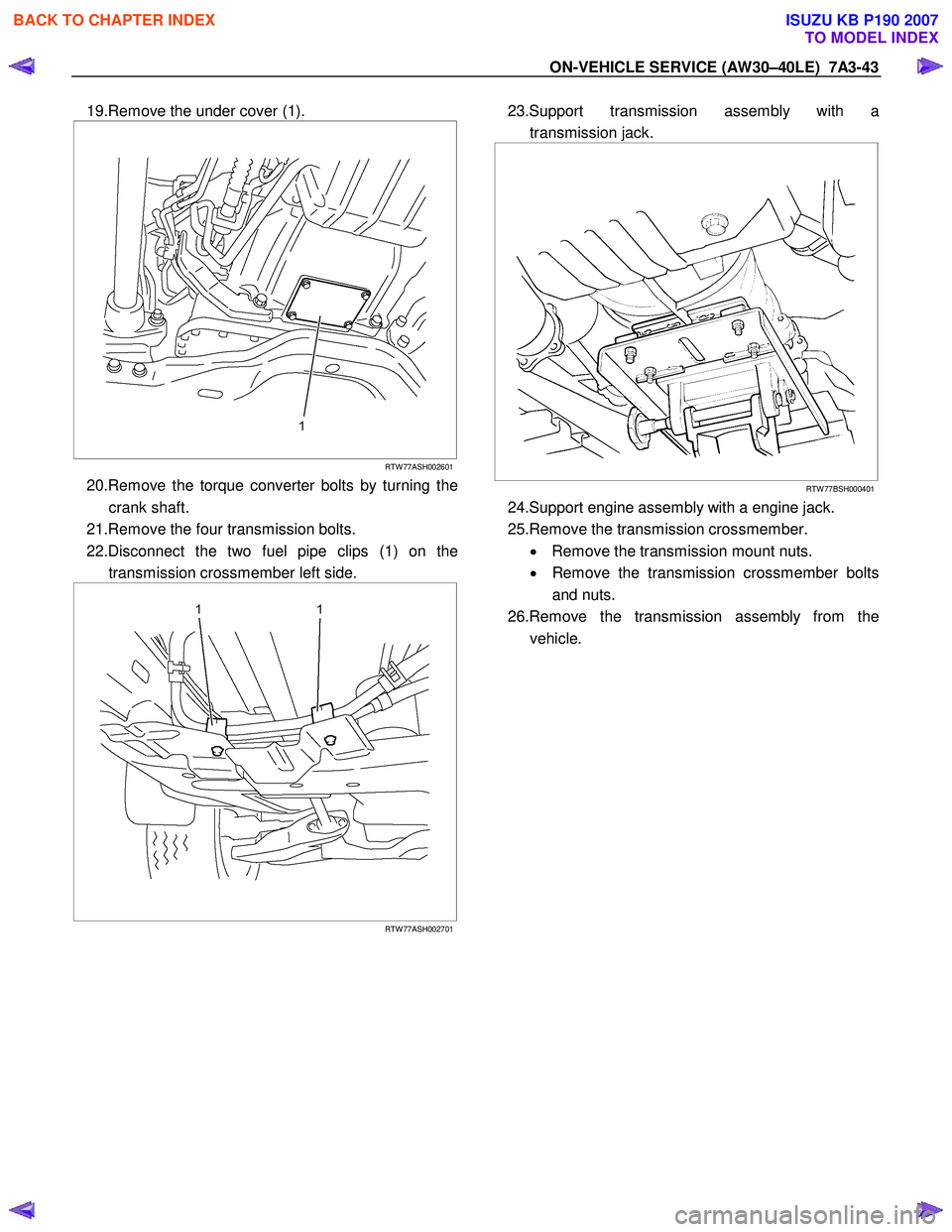

19.Remove the under cover (1).

RTW 77ASH002601

20.Remove the torque converter bolts by turning the

crank shaft.

21.Remove the four transmission bolts.

22.Disconnect the two fuel pipe clips (1) on the transmission crossmember left side.

RTW 77ASH002701

23.Support transmission assembly with a

transmission jack.

RTW 77BSH000401

24.Support engine assembly with a engine jack.

25.Remove the transmission crossmember. • Remove the transmission mount nuts.

• Remove the transmission crossmember bolts

and nuts.

26.Remove the transmission assembly from the vehicle.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4130 of 6020

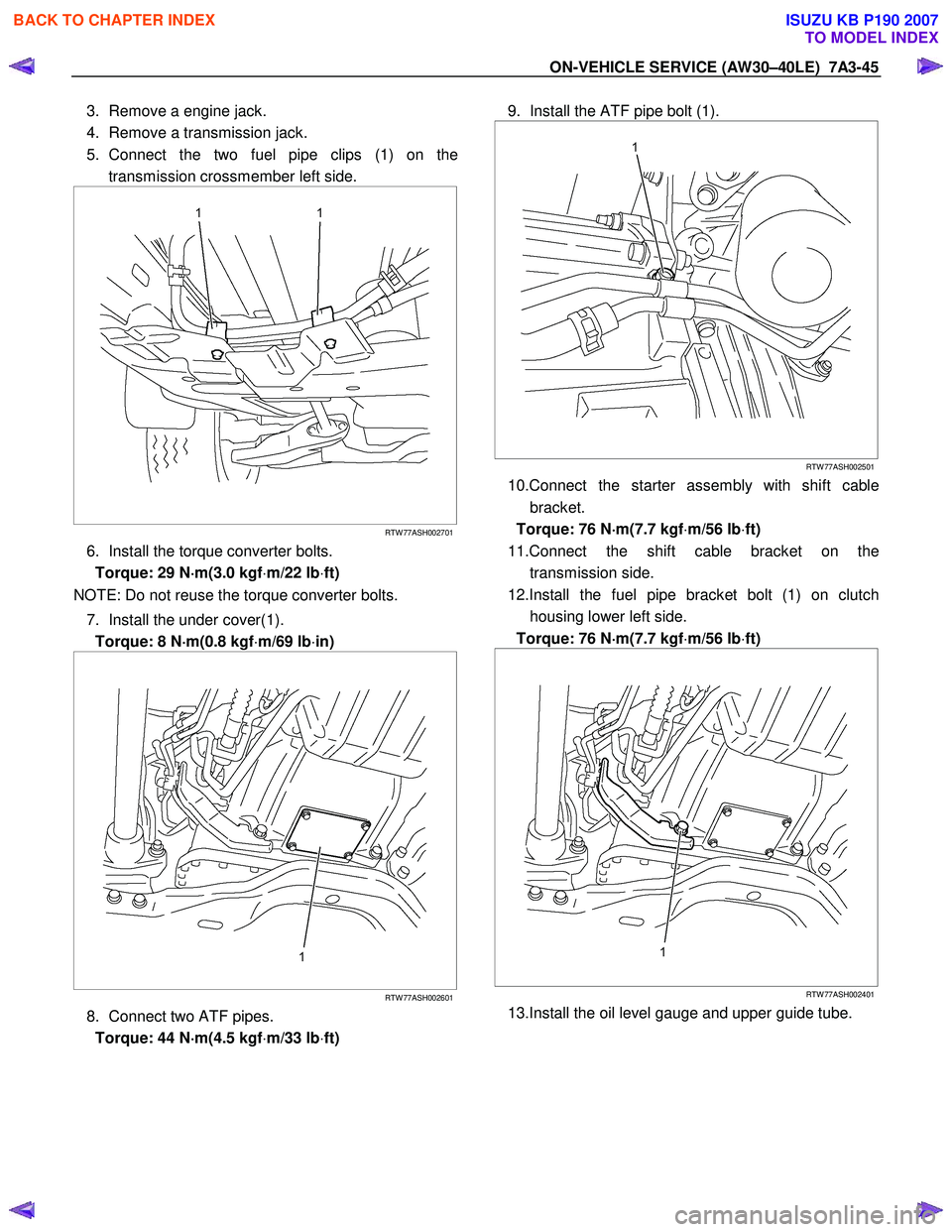

ON-VEHICLE SERVICE (AW30–40LE) 7A3-45

3. Remove a engine jack.

4. Remove a transmission jack.

5. Connect the two fuel pipe clips (1) on the transmission crossmember left side.

RTW 77ASH002701

6. Install the torque converter bolts.

Torque: 29 N ⋅

⋅⋅

⋅

m(3.0 kgf ⋅m/22 lb ⋅ft)

NOTE: Do not reuse the torque converter bolts.

7. Install the under cover(1). Torque: 8 N ⋅

⋅⋅

⋅

m(0.8 kgf ⋅m/69 lb ⋅in)

RTW 77ASH002601

8. Connect two ATF pipes.

Torque: 44 N ⋅

⋅⋅

⋅

m(4.5 kgf ⋅m/33 lb ⋅ft)

9. Install the ATF pipe bolt (1).

RTW 77ASH002501

10.Connect the starter assembly with shift cable

bracket.

Torque: 76 N ⋅

⋅⋅

⋅

m(7.7 kgf ⋅m/56 lb ⋅ft)

11.Connect the shift cable bracket on the transmission side.

12.Install the fuel pipe bracket bolt (1) on clutch housing lower left side.

Torque: 76 N ⋅

⋅⋅

⋅

m(7.7 kgf ⋅m/56 lb ⋅ft)

RTW 77ASH002401

13.Install the oil level gauge and upper guide tube.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4131 of 6020

7A3-46 ON-VEHICLE SERVICE (AW30–40LE)

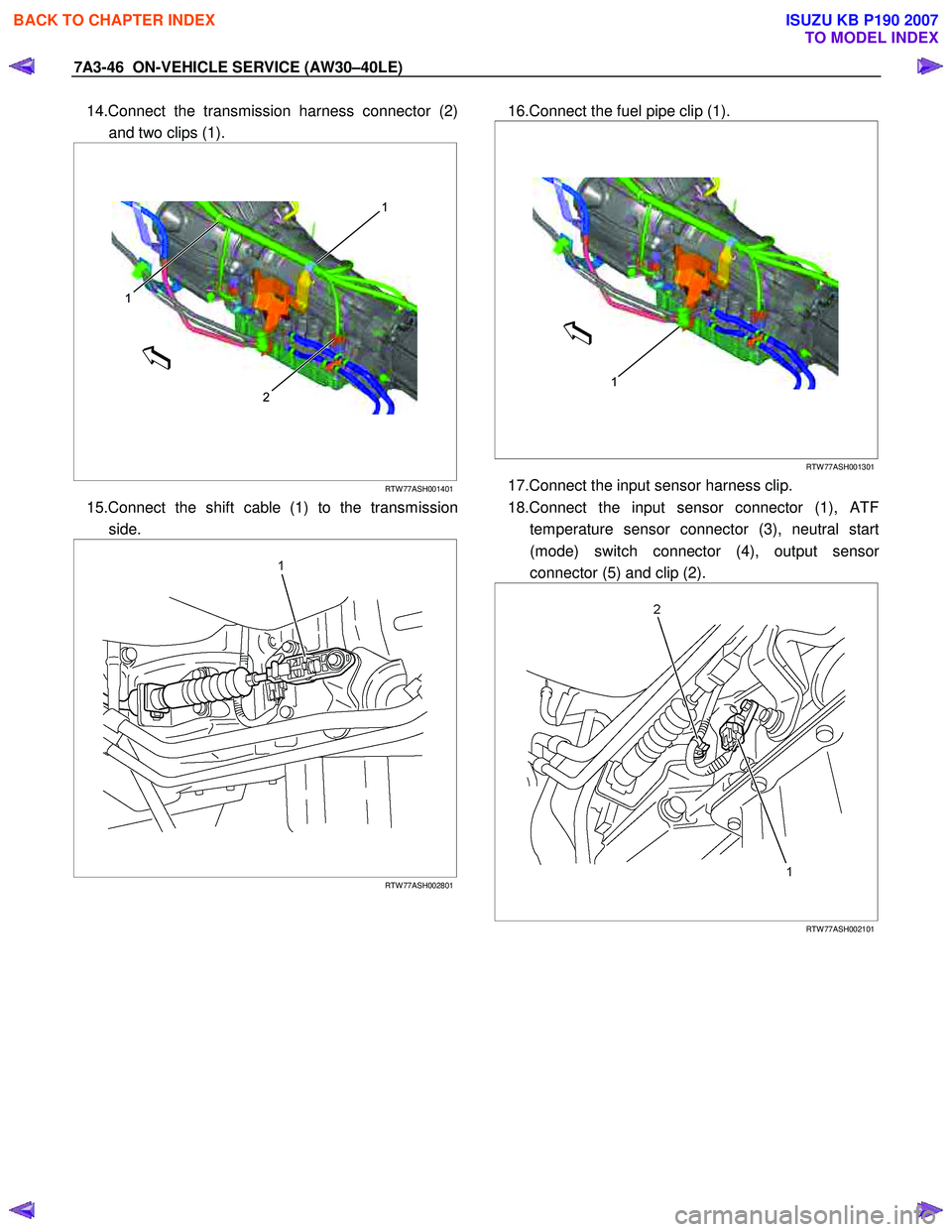

14.Connect the transmission harness connector (2)

and two clips (1).

2

1

1

RTW 77ASH001401

15.Connect the shift cable (1) to the transmission

side.

RTW 77ASH002801

16.Connect the fuel pipe clip (1).

1

RTW 77ASH001301

17.Connect the input sensor harness clip.

18.Connect the input sensor connector (1), ATF temperature sensor connector (3), neutral start

(mode) switch connector (4), output senso

r

connector (5) and clip (2).

RTW 77ASH002101

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4337 of 6020

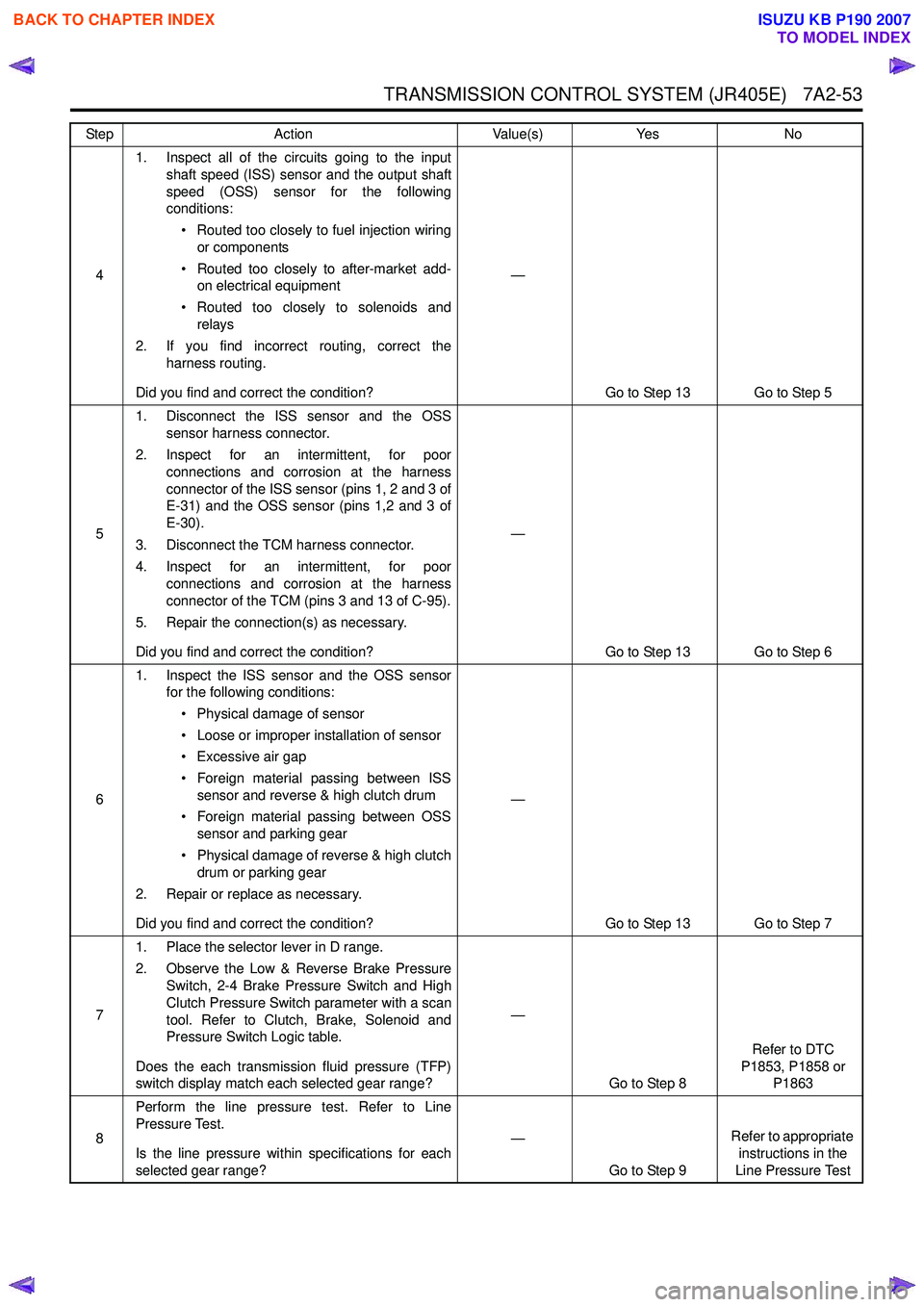

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-53

41. Inspect all of the circuits going to the input

shaft speed (ISS) sensor and the output shaft

speed (OSS) sensor for the following

conditions:

• Routed too closely to fuel injection wiring or components

• Routed too closely to after-market add- on electrical equipment

• Routed too closely to solenoids and relays

2. If you find incorrect routing, correct the harness routing.

Did you find and correct the condition? —

Go to Step 13 Go to Step 5

5 1. Disconnect the ISS sensor and the OSS

sensor harness connector.

2. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the ISS sensor (pins 1, 2 and 3 of

E-31) and the OSS sensor (pins 1,2 and 3 of

E-30).

3. Disconnect the TCM harness connector.

4. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the TCM (pins 3 and 13 of C-95).

5. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 13 Go to Step 6

6 1. Inspect the ISS sensor and the OSS sensor

for the following conditions:

• Physical damage of sensor

• Loose or improper installation of sensor

• Excessive air gap

• Foreign material passing between ISS sensor and reverse & high clutch drum

• Foreign material passing between OSS sensor and parking gear

• Physical damage of reverse & high clutch drum or parking gear

2. Repair or replace as necessary.

Did you find and correct the condition? —

Go to Step 13 Go to Step 7

7 1. Place the selector lever in D range.

2. Observe the Low & Reverse Brake Pressure Switch, 2-4 Brake Pressure Switch and High

Clutch Pressure Switch parameter with a scan

tool. Refer to Clutch, Brake, Solenoid and

Pressure Switch Logic table.

Does the each transmission fluid pressure (TFP)

switch display match each selected gear range? —

Go to Step 8 Refer to DTC

P1853, P1858 or P1863

8 Perform the line pressure test. Refer to Line

Pressure Test.

Is the line pressure within specifications for each

selected gear range? —

Go to Step 9 Refer to appropriate

instructions in the

Line Pressure Test

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4381 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-97

Faulty Operation in Stopping Vehicle moves in P range or parking is not disengaged in other than Prange G1

Large creeping force G2

Small creeping force G3

Large noise during idle with vehicle stop G4

Faulty Lock Up Judder Occurs at Lock Up H1

Large Shock at Lock Up H2

Lock Up Point is High or Low H3

No Lock Up No Lock Up I1

Transmission Fluid Leak Transmission fluid leaks from breather J1

Transmission fluid leaks between engine and converter housing J2

Transmission fluid leaks between converter housing and transmission

case J3

Transmission fluid leaks between transmission case and extension

housing J4

Transmission fluid leaks from oil pan J5

Transmission fluid leaks from manual shaft oil seal J6

Transmission fluid leaks from oil cooler pipe joint J7

Others Transmission overheat Z1

Mode lamp (power drive or 3rd start) does not turn On Z2

Mode lamp (power drive or 3rd start) does not turn Off Z3

A/T oil temperature lamp turns On Z4

Selector lever feeling is faulty Z5

Poor fuel consumption Z6

Shift indicator is faulty Z7

Abnormal smell Z8

Transmission fluid quantity is low or high Z9

Transmission fluid quantity is low or high Z10

Abnormal transmission fluid pressure Z11

Diagnostic Category

Category No.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007