engine oil ISUZU KB P190 2007 Workshop Manual Online

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 924 of 6020

ENGINE MECHANICAL 6A – 119

Installation

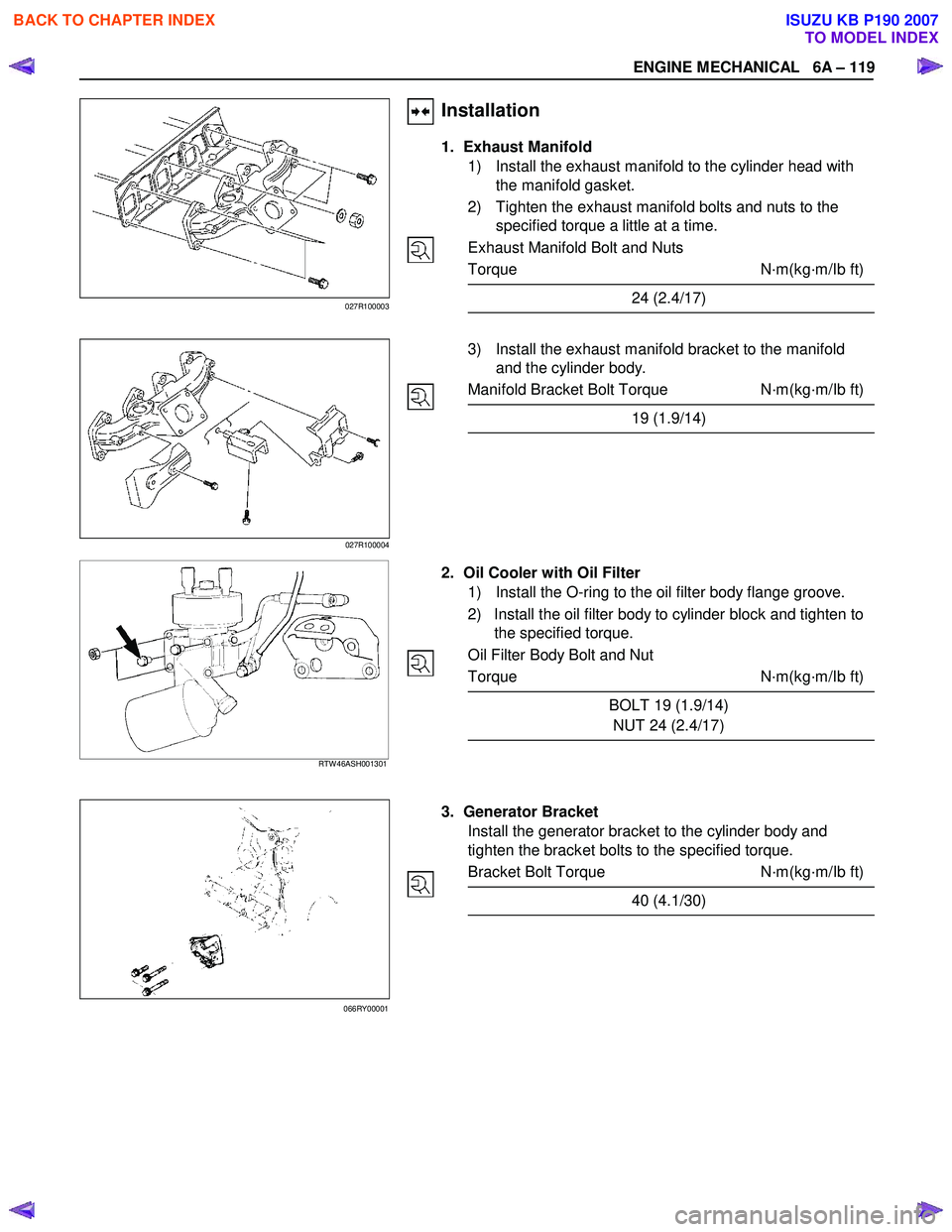

1. Exhaust Manifold

1) Install the exhaust manifold to the cylinder head with the manifold gasket.

2) Tighten the exhaust manifold bolts and nuts to the specified torque a little at a time.

Exhaust Manifold Bolt and Nuts

Torque N·m(kg·m/Ib ft)

24 (2.4/17)

3) Install the exhaust manifold bracket to the manifold

and the cylinder body.

Manifold Bracket Bolt Torque N·m(kg·m/Ib ft)

19 (1.9/14)

RTW 46ASH001301

2. Oil Cooler with Oil Filter

1) Install the O-ring to the oil filter body flange groove.

2) Install the oil filter body to cylinder block and tighten to the specified torque.

Oil Filter Body Bolt and Nut

Torque N·m(kg·m/Ib ft)

BOLT 19 (1.9/14)

NUT 24 (2.4/17)

3. Generator Bracket

Install the generator bracket to the cylinder body and

tighten the bracket bolts to the specified torque.

Bracket Bolt Torque N·m(kg·m/Ib ft)

40 (4.1/30)

027R100003

027R100004

066RY00001

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 925 of 6020

6A – 120 ENGINE MECHANICAL

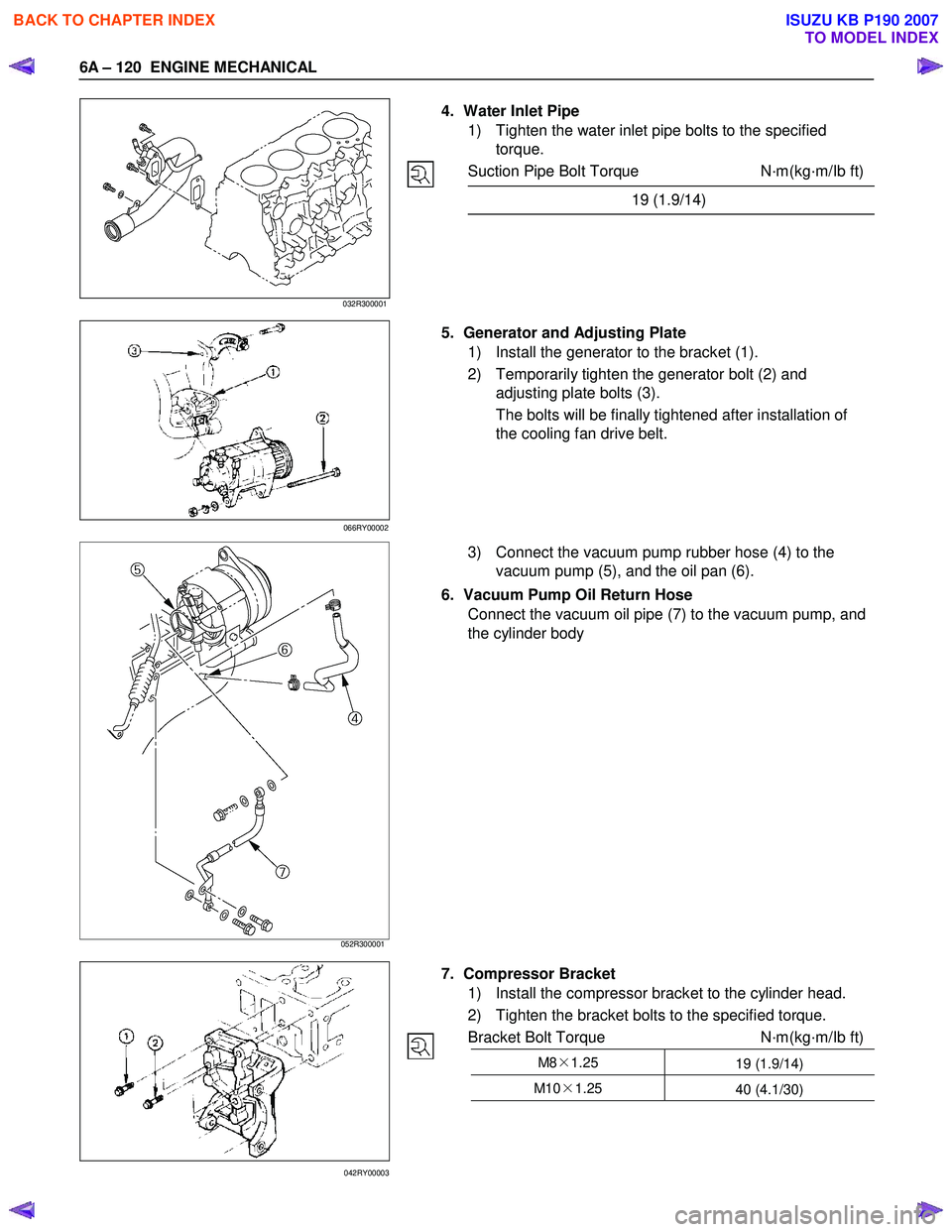

4. Water Inlet Pipe

1) Tighten the water inlet pipe bolts to the specified torque.

Suction Pipe Bolt Torque N·m(kg·m/Ib ft)

19 (1.9/14)

5. Generator and Adjusting Plate

1) Install the generator to the bracket (1).

2) Temporarily tighten the generator bolt (2) and adjusting plate bolts (3).

The bolts will be finally tightened after installation of

the cooling fan drive belt.

3) Connect the vacuum pump rubber hose (4) to the

vacuum pump (5), and the oil pan (6).

6. Vacuum Pump Oil Return Hose Connect the vacuum oil pipe (7) to the vacuum pump, and

the cylinder body

052R300001

7. Compressor Bracket 1) Install the compressor bracket to the cylinder head.

2) Tighten the bracket bolts to the specified torque.

Bracket Bolt Torque N·m(kg·m/Ib ft)

M8×1.25

19 (1.9/14)

M10×1.25

40 (4.1/30)

066RY00002

032R300001

042RY00003

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 926 of 6020

ENGINE MECHANICAL 6A – 121

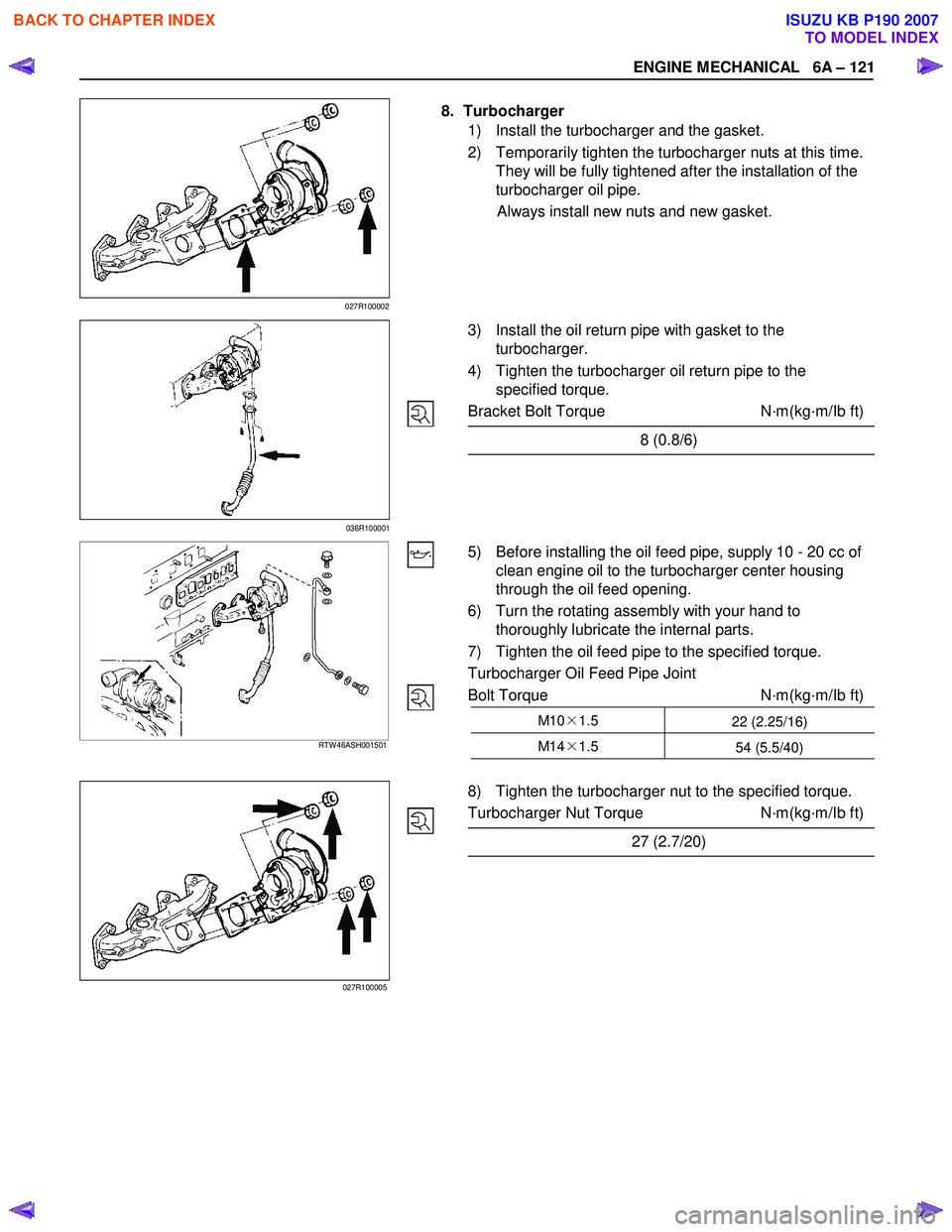

8. Turbocharger

1) Install the turbocharger and the gasket.

2) Temporarily tighten the turbocharger nuts at this time. They will be fully tightened after the installation of the

turbocharger oil pipe.

Always install new nuts and new gasket.

3) Install the oil return pipe with gasket to the

turbocharger.

4) Tighten the turbocharger oil return pipe to the specified torque.

Bracket Bolt Torque N·m(kg·m/Ib ft)

8 (0.8/6)

5) Before installing the oil feed pipe, supply 10 - 20 cc of clean engine oil to the turbocharger center housing

through the oil feed opening.

6) Turn the rotating assembly with your hand to thoroughly lubricate the internal parts.

7) Tighten the oil feed pipe to the specified torque.

Turbocharger Oil Feed Pipe Joint

Bolt Torque N·m(kg·m/Ib ft)

M10×1.5

22 (2.25/16)

M14×1.5

54 (5.5/40)

RTW 46ASH001501

8) Tighten the turbocharger nut to the specified torque.

Turbocharger Nut Torque N·m(kg·m/Ib ft)

27 (2.7/20)

036R100001

027R100005 027R100002

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 927 of 6020

6A – 122 ENGINE MECHANICAL

RTW 46ASH001601

9) Install the water feed adapter (1) with the gaskets to

turbocharger and tighten to the specified torque.

Adapter Torque N·m(kg·m/Ib ft)

39 (4.0/29)

10) Install the water feed pipe with the gaskets and tighten to the specified torque.

W ater Return Pipe Torque N·m(kg·m/Ib ft)

39 (4.0/29)

11) Install the water return pipe with the gaskets and tighten to the specified torque.

W ater Return Torque N·m(kg·m/Ib ft)

39 (4.0/29)

12) Clamp the water feed pipe to the oil return pipe of the turbocharger.

Fixing Bolt (3) Torque N·m(kg·m/Ib ft)

8 (0.8/6)

13) Install the hoses for the water feed and return.

9. Catalytic Converter

Install the catalytic converter with gasket and tighten the

nut to the specified torque.

Catalytic converter Nut Torque N·m(kg·m/Ib ft)

27 (2.7/20)

Do not install the catalytic converter, if drop down it.

10. Heat Protector Install the heat protector and tighten the bolt to the

specified torque.

Heat Protector Bolt Torque N·m(kg·m/Ib ft)

9 (0.9/6.5 Ib in)

033R300002

11. Cooling Fan Pulley

1) Install the cooling fan pulley to the water pump.

2) Tighten the cooling fan pulley nuts to the specified torque.

Pulley Nut Torque N·m(kg·m/Ib ft)

8 (0.8/6)

12. Oil Cooler Water Pipe

13. Fuel Leak Off Pipe

14. Oil Pressure Warning Switch

027R100007

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 929 of 6020

6A – 124 ENGINE MECHANICAL

20. Power Steering Oil Pump Bracket

Oil Pump Braket Nut and Bolt Torque N·m(kg·m/Ib ft)

1M10 ×1.25

37 (3.8/28)

2

3M8×1.25

18 (1.8/13) (Bolt ID:8)

040R300005

21. Fuel Injection Pipe with Clip

1) Temporarily tighten the injection pipe sleeve nut.

2) Set the clip in the illustrated position. Note:

Make absolutely sure that the clip is correctly

positioned.

An improperly positioned clip will result in injection

pipe breakage and fuel pulsing noise.

3) Tighten the injection pipe sleeve nut to the specified torque.

Torque

Injection Pump Side (4JA1TC/4JH1TC) N·m(kg·m/Ib ft)

40 (4.1/30)

Injection Pipe Sleeve Nuts N·m(kg·m/Ib ft)

29 (3.0/22)

Injection Pipe Clip Nuts N·m(kg·m/Ib ft)

8 (0.8/6)

22. Fuel Filter Bracket (Except EURO III model)

Install the fuel filter bracket and tighten fixing bolts to the

specified torque.

Fuel Filter Bracket Bolt Torque N·m(kg·m/Ib ft)

21 (2.1/15)

23. Fuel Filter Assembly (Except EURO III model)

Install the fuel filter assembly and tighten fixing bolts to the

specified torque.

Fuel Filter Assembly Bolt Torque N·m(kg·m/Ib ft)

21 (2.1/15)

24. Oil Level Gauge

Install the oil level gauge and tighten fixing bolts to the

specified torque.

Oil Level Gauge Bolt Torque N·m(kg·m/Ib ft)

M8 19 (1.9/14)

M6 8 (0.8/6)

431RY00013

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 931 of 6020

6A – 126 ENGINE MECHANICAL

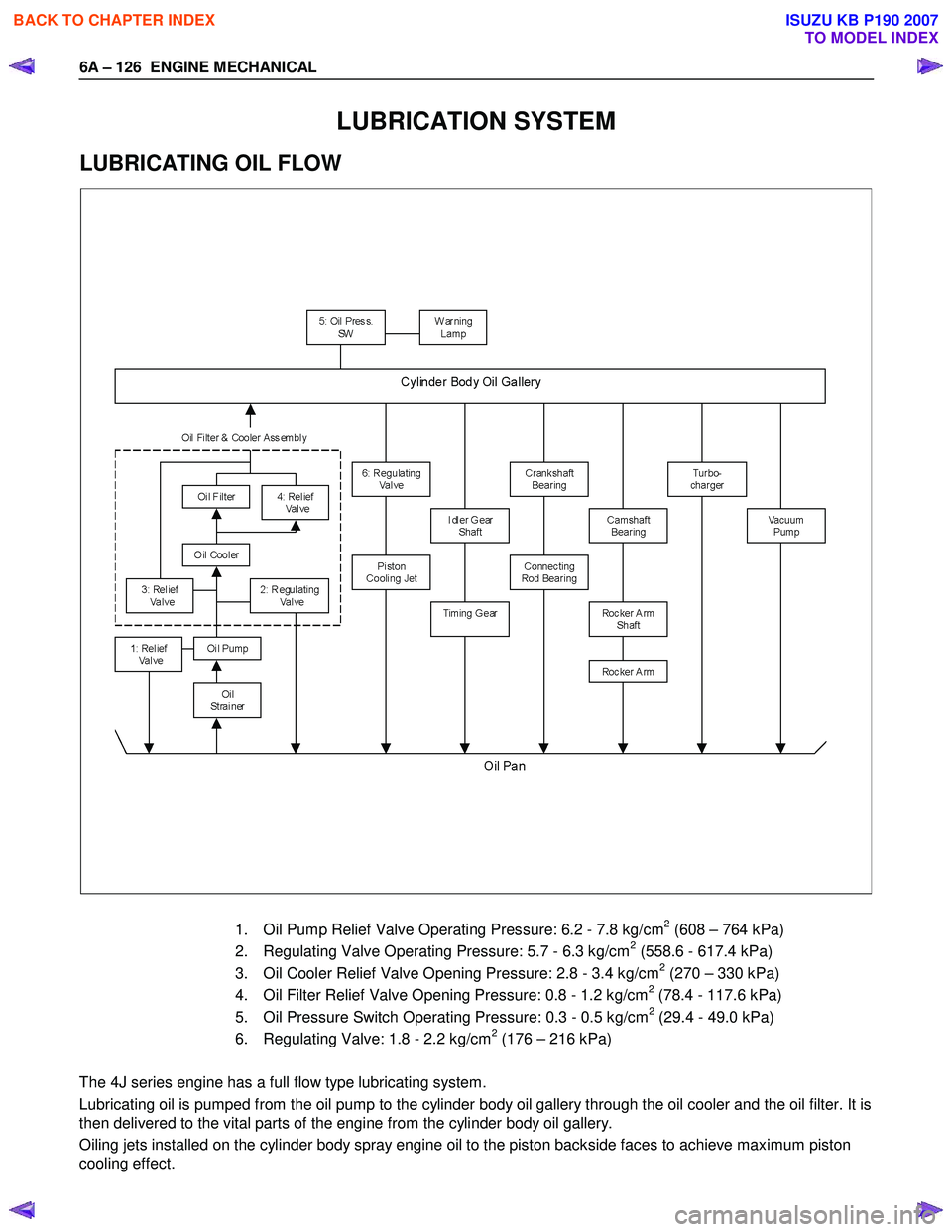

LUBRICATION SYSTEM

LUBRICATING OIL FLOW

1. Oil Pump Relief Valve Operating Pressure: 6.2 - 7.8 kg/cm

2 (608 – 764 kPa)

2. Regulating Valve Operating Pressure: 5.7 - 6.3 kg/cm2 (558.6 - 617.4 kPa)

3. Oil Cooler Relief Valve Opening Pressure: 2.8 - 3.4 kg/cm2 (270 – 330 kPa)

4. Oil Filter Relief Valve Opening Pressure: 0.8 - 1.2 kg/cm2 (78.4 - 117.6 kPa)

5. Oil Pressure Switch Operating Pressure: 0.3 - 0.5 kg/cm2 (29.4 - 49.0 kPa)

6. Regulating Valve: 1.8 - 2.2 kg/cm2 (176 – 216 kPa)

The 4J series engine has a full flow type lubricating system.

Lubricating oil is pumped from the oil pump to the cylinder body oil gallery through the oil cooler and the oil filter. It is

then delivered to the vital parts of the engine from the cylinder body oil gallery.

Oiling jets installed on the cylinder body spray engine oil to the piston backside faces to achieve maximum piston

cooling effect.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 932 of 6020

ENGINE MECHANICAL 6A – 127

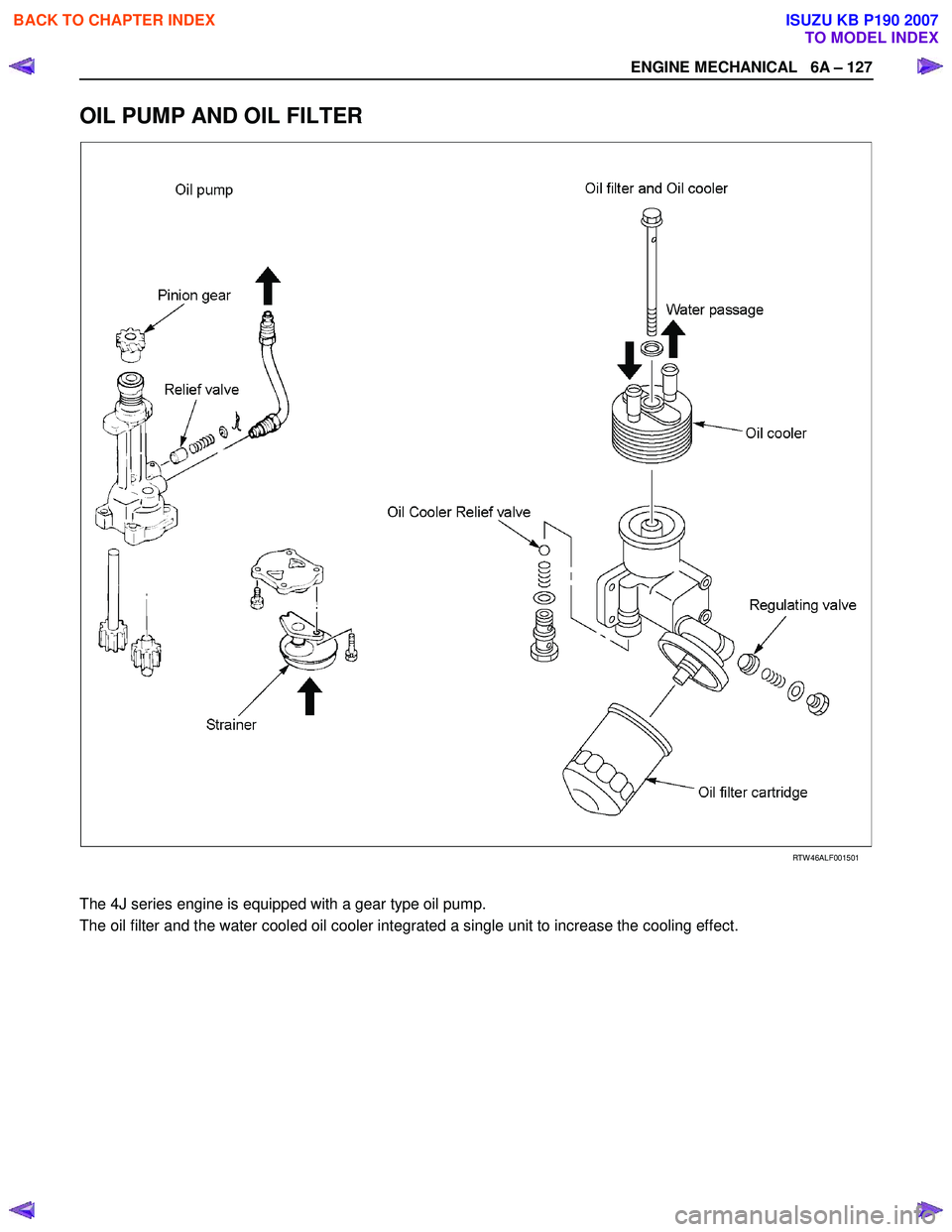

OIL PUMP AND OIL FILTER

RTW 46ALF001501

The 4J series engine is equipped with a gear type oil pump.

The oil filter and the water cooled oil cooler integrated a single unit to increase the cooling effect.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 933 of 6020

6A – 128 ENGINE MECHANICAL

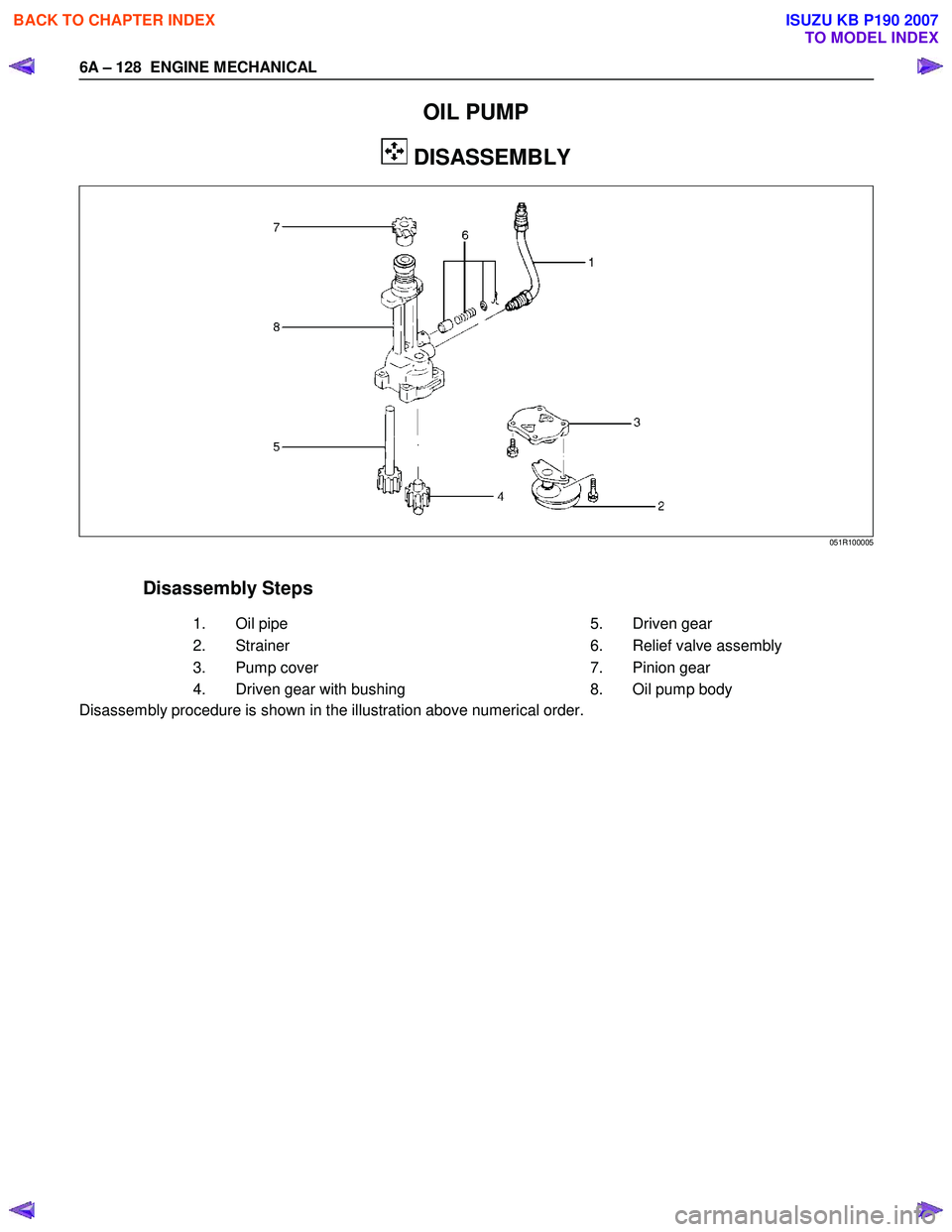

OIL PUMP

DISASSEMBLY

Disassembly Steps

1.

Oil pipe 5.

Driven gear

2.

Strainer 6. Relief valve assembly

3. Pump cover 7. Pinion gear

4. Driven gear with bushing 8. Oil pump body

Disassembly procedure is shown in the illustration above numerical order.

051R100005

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 934 of 6020

ENGINE MECHANICAL 6A – 129

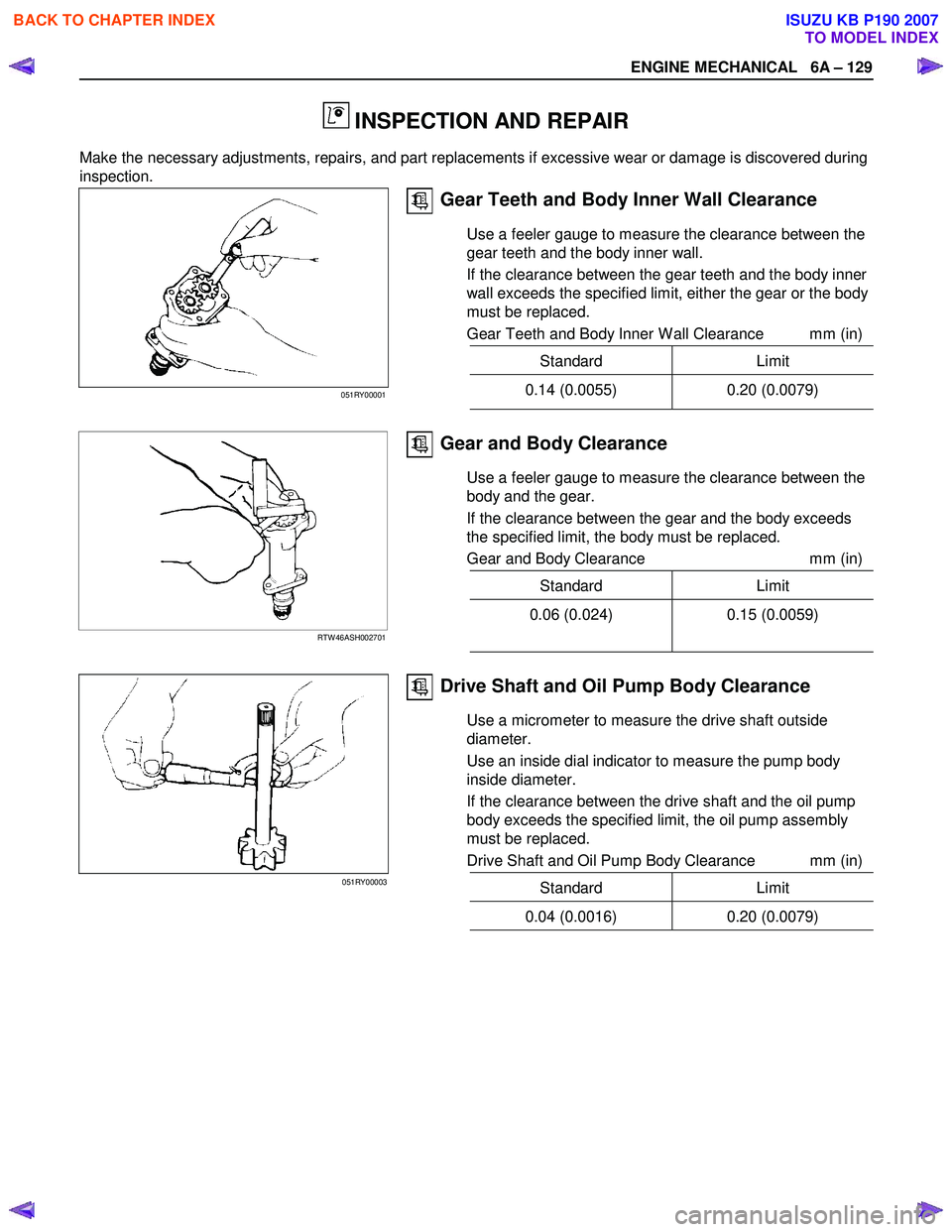

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is discovered during

inspection.

Gear Teeth and Body Inner Wall Clearance

Use a feeler gauge to measure the clearance between the

gear teeth and the body inner wall.

If the clearance between the gear teeth and the body inner

wall exceeds the specified limit, either the gear or the body

must be replaced.

Gear Teeth and Body Inner W all Clearance mm (in)

Standard Limit

051RY00001 0.14 (0.0055) 0.20 (0.0079)

Gear and Body Clearance

Use a feeler gauge to measure the clearance between the

body and the gear.

If the clearance between the gear and the body exceeds

the specified limit, the body must be replaced.

Gear and Body Clearance mm (in)

Standard Limit

RTW 46ASH002701

0.06 (0.024) 0.15 (0.0059)

Drive Shaft and Oil Pump Body Clearance

Use a micrometer to measure the drive shaft outside

diameter.

Use an inside dial indicator to measure the pump body

inside diameter.

If the clearance between the drive shaft and the oil pump

body exceeds the specified limit, the oil pump assembly

must be replaced.

Drive Shaft and Oil Pump Body Clearance mm (in)

Standard Limit

0.04 (0.0016) 0.20 (0.0079)

051RY00003

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 935 of 6020

6A – 130 ENGINE MECHANICAL

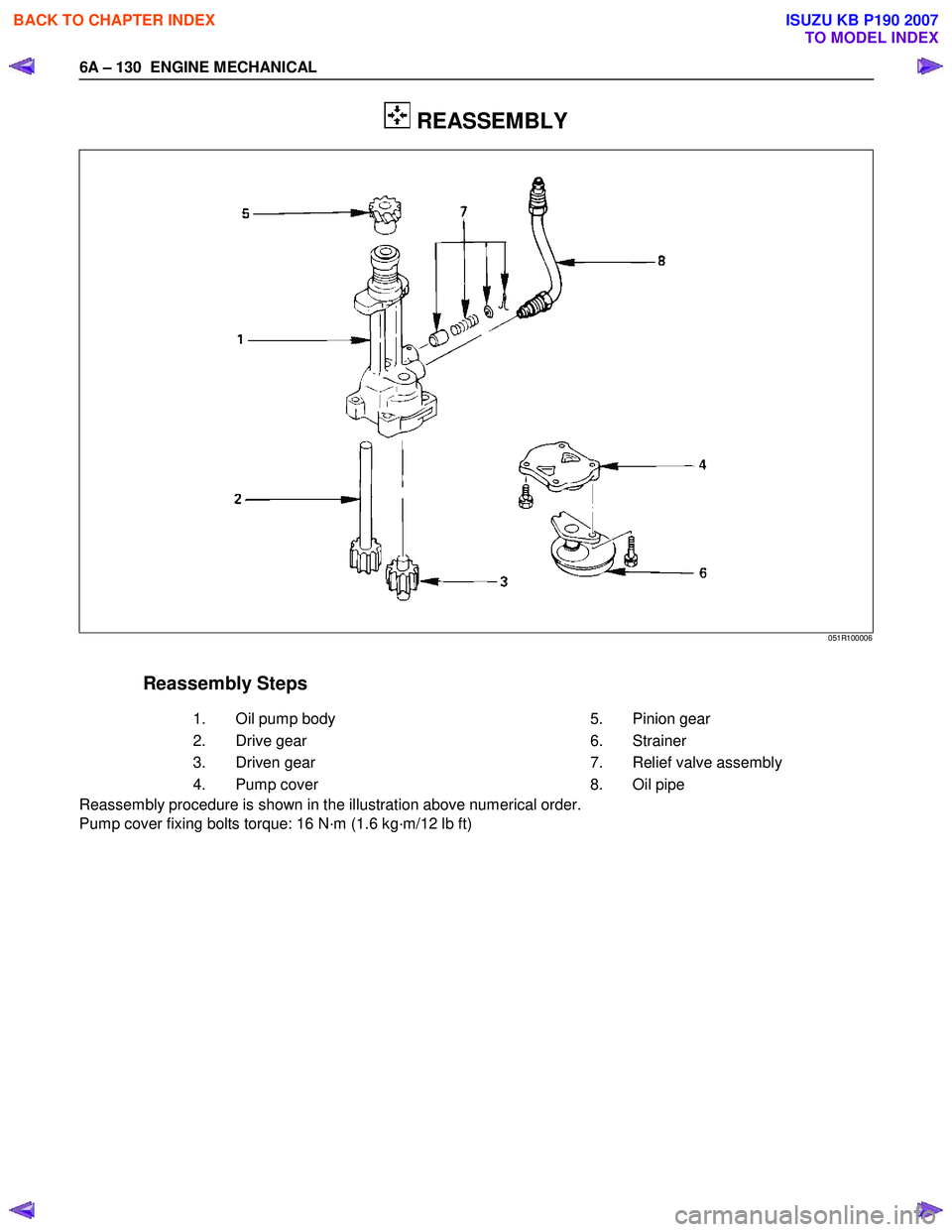

REASSEMBLY

Reassembly Steps

1.

Oil pump body 5.

Pinion gear

2.

Drive gear 6. Strainer

3. Driven gear 7. Relief valve assembly

4. Pump cover 8.

Oil pipe

Reassembly procedure is shown in the illustration above numerical order.

Pump cover fixing bolts torque: 16 N·m (1.6 kg·m/12 lb ft)

051R100006

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007