Engine wiring ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 317 of 6020

3B-56 POWER-ASSISTED STEERING SYSTEM

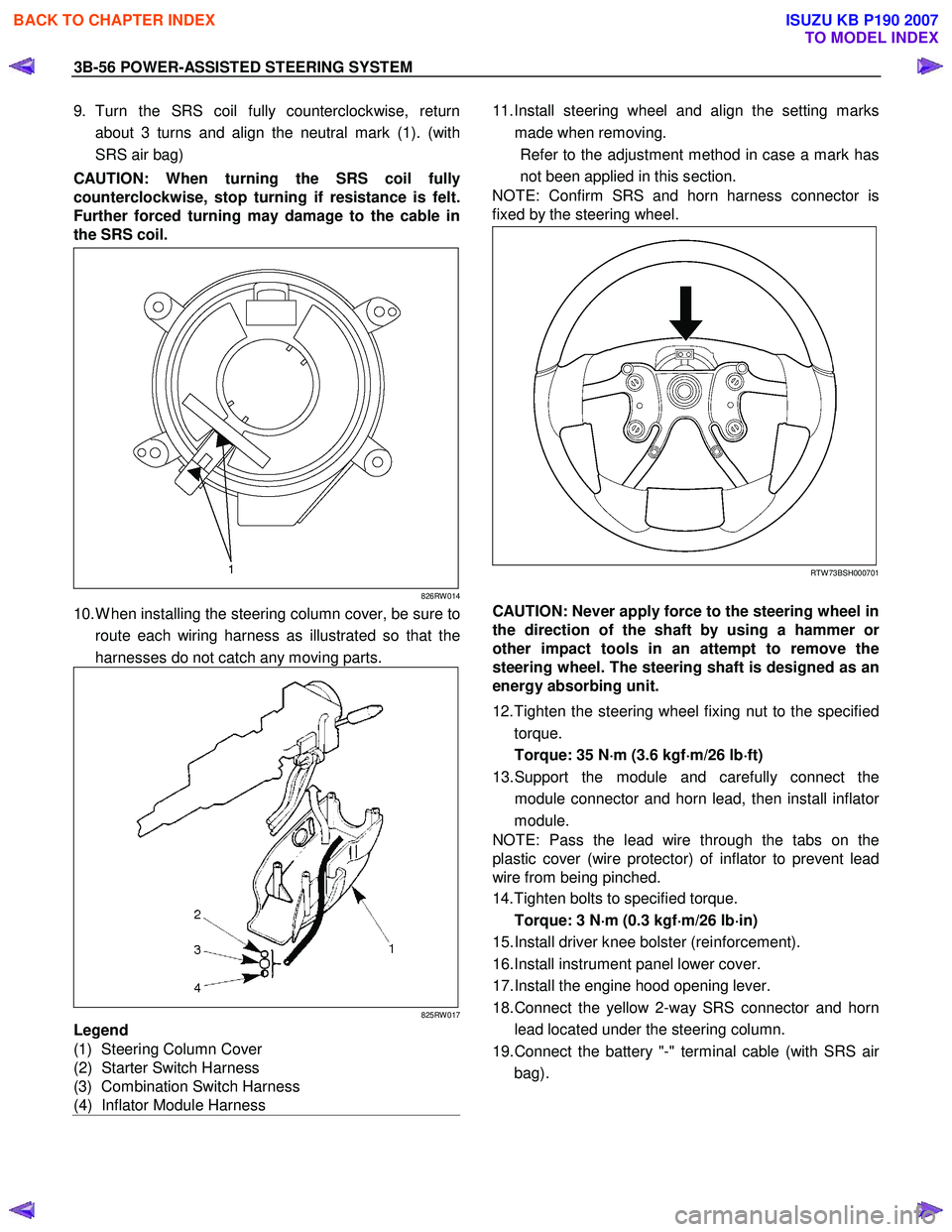

9. Turn the SRS coil fully counterclockwise, return

about 3 turns and align the neutral mark (1). (with

SRS air bag)

CAUTION: When turning the SRS coil fully

counterclockwise, stop turning if resistance is felt.

Further forced turning may damage to the cable in

the SRS coil.

826RW 014

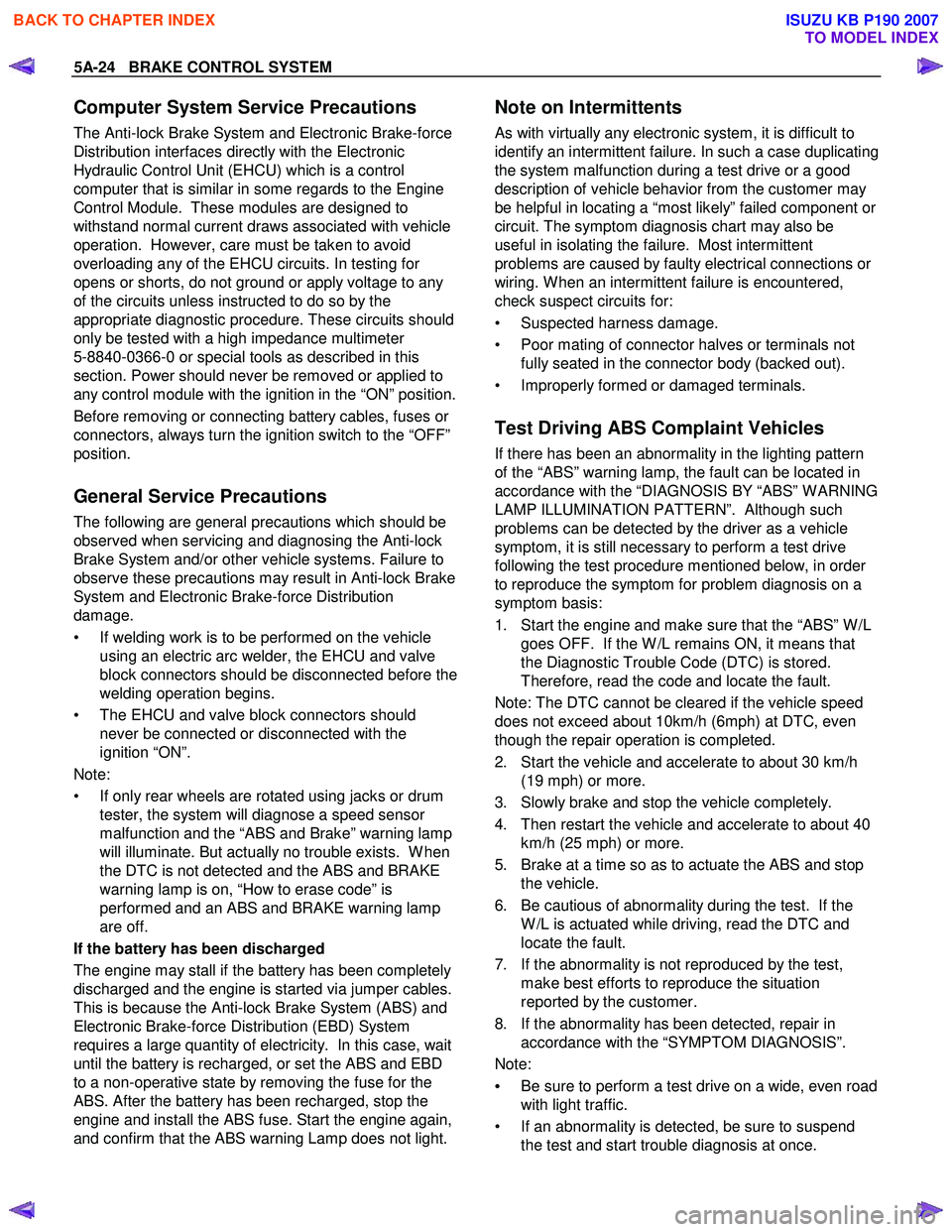

10. W hen installing the steering column cover, be sure to

route each wiring harness as illustrated so that the

harnesses do not catch any moving parts.

825RW 017

Legend

(1) Steering Column Cover

(2) Starter Switch Harness

(3) Combination Switch Harness

(4) Inflator Module Harness

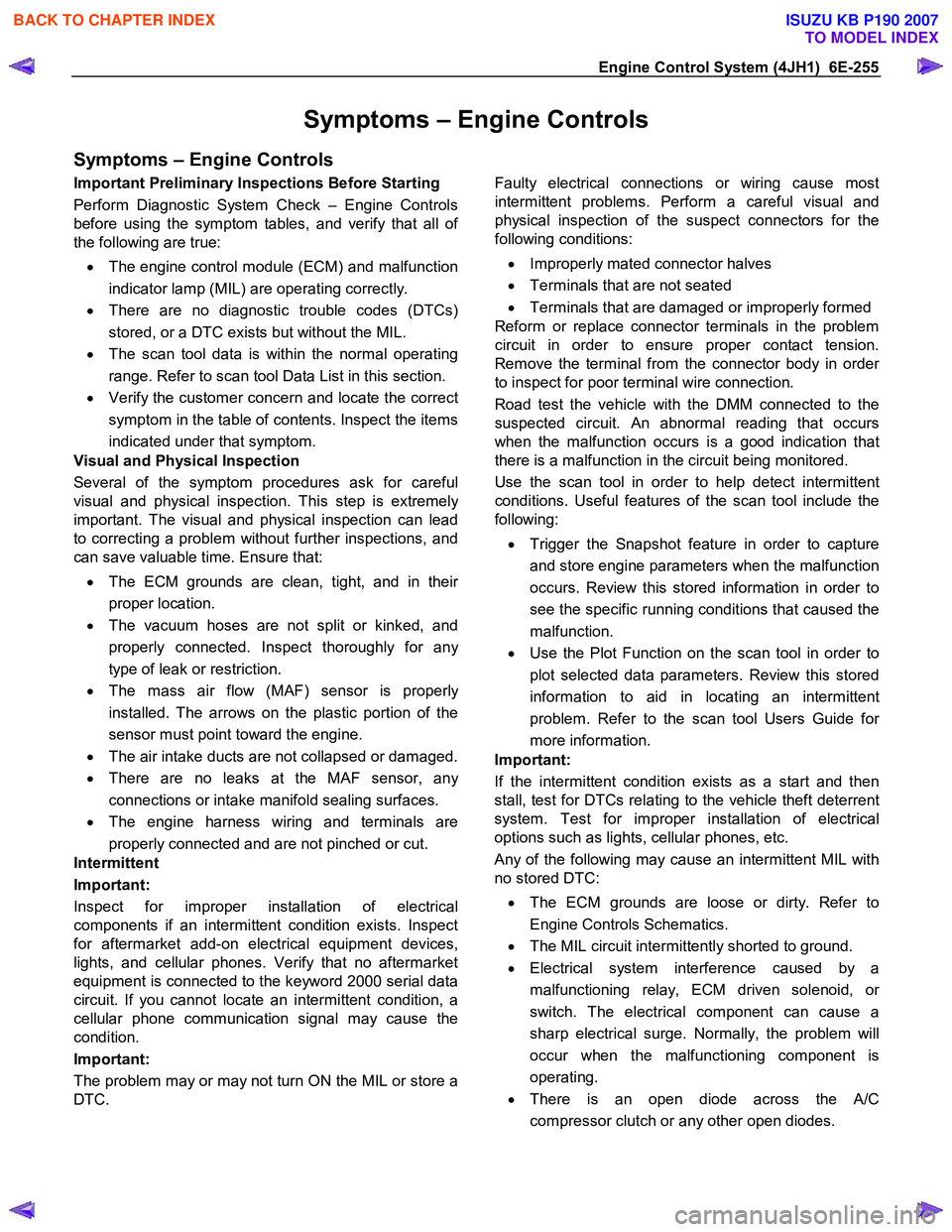

11. Install steering wheel and align the setting marks

made when removing. Refer to the adjustment method in case a mark has

not been applied in this section.

NOTE: Confirm SRS and horn harness connector is

fixed by the steering wheel.

RTW 73BSH000701

CAUTION: Never apply force to the steering wheel in

the direction of the shaft by using a hammer o

r

other impact tools in an attempt to remove the

steering wheel. The steering shaft is designed as an

energy absorbing unit.

12. Tighten the steering wheel fixing nut to the specified torque.

Torque: 35 N ⋅

⋅⋅

⋅

m (3.6 kgf ⋅

⋅⋅

⋅

m/26 lb ⋅

⋅⋅

⋅

ft)

13. Support the module and carefully connect the module connector and horn lead, then install inflato

r

module.

NOTE: Pass the lead wire through the tabs on the

plastic cover (wire protector) of inflator to prevent lead

wire from being pinched.

14. Tighten bolts to specified torque.

Torque: 3 N ⋅

⋅⋅

⋅

m (0.3 kgf ⋅

⋅⋅

⋅

m/26 lb ⋅

⋅⋅

⋅

in)

15. Install driver knee bolster (reinforcement).

16. Install instrument panel lower cover.

17. Install the engine hood opening lever.

18. Connect the yellow 2-way SRS connector and horn lead located under the steering column.

19. Connect the battery "-" terminal cable (with SRS ai

r

bag).

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 617 of 6020

5A-24 BRAKE CONTROL SYSTEM

Computer System Service Precautions

The Anti-lock Brake System and Electronic Brake-force

Distribution interfaces directly with the Electronic

Hydraulic Control Unit (EHCU) which is a control

computer that is similar in some regards to the Engine

Control Module. These modules are designed to

withstand normal current draws associated with vehicle

operation. However, care must be taken to avoid

overloading any of the EHCU circuits. In testing for

opens or shorts, do not ground or apply voltage to any

of the circuits unless instructed to do so by the

appropriate diagnostic procedure. These circuits should

only be tested with a high impedance multimeter

5-8840-0366-0 or special tools as described in this

section. Power should never be removed or applied to

any control module with the ignition in the “ON” position.

Before removing or connecting battery cables, fuses or

connectors, always turn the ignition switch to the “OFF”

position.

General Service Precautions

The following are general precautions which should be

observed when servicing and diagnosing the Anti-lock

Brake System and/or other vehicle systems. Failure to

observe these precautions may result in Anti-lock Brake

System and Electronic Brake-force Distribution

damage.

• If welding work is to be performed on the vehicle using an electric arc welder, the EHCU and valve

block connectors should be disconnected before the

welding operation begins.

• The EHCU and valve block connectors should never be connected or disconnected with the

ignition “ON”.

Note:

• If only rear wheels are rotated using jacks or drum tester, the system will diagnose a speed sensor

malfunction and the “ABS and Brake” warning lamp

will illuminate. But actually no trouble exists. W hen

the DTC is not detected and the ABS and BRAKE

warning lamp is on, “How to erase code” is

performed and an ABS and BRAKE warning lamp

are off.

If the battery has been discharged

The engine may stall if the battery has been completely

discharged and the engine is started via jumper cables.

This is because the Anti-lock Brake System (ABS) and

Electronic Brake-force Distribution (EBD) System

requires a large quantity of electricity. In this case, wait

until the battery is recharged, or set the ABS and EBD

to a non-operative state by removing the fuse for the

ABS. After the battery has been recharged, stop the

engine and install the ABS fuse. Start the engine again,

and confirm that the ABS warning Lamp does not light.

Note on Intermittents

As with virtually any electronic system, it is difficult to

identify an intermittent failure. In such a case duplicating

the system malfunction during a test drive or a good

description of vehicle behavior from the customer may

be helpful in locating a “most likely” failed component or

circuit. The symptom diagnosis chart may also be

useful in isolating the failure. Most intermittent

problems are caused by faulty electrical connections or

wiring. W hen an intermittent failure is encountered,

check suspect circuits for:

• Suspected harness damage.

• Poor mating of connector halves or terminals not fully seated in the connector body (backed out).

• Improperly formed or damaged terminals.

Test Driving ABS Complaint Vehicles

If there has been an abnormality in the lighting pattern

of the “ABS” warning lamp, the fault can be located in

accordance with the “DIAGNOSIS BY “ABS” W ARNING

LAMP ILLUMINATION PATTERN”. Although such

problems can be detected by the driver as a vehicle

symptom, it is still necessary to perform a test drive

following the test procedure mentioned below, in order

to reproduce the symptom for problem diagnosis on a

symptom basis:

1. Start the engine and make sure that the “ABS” W /L

goes OFF. If the W /L remains ON, it means that

the Diagnostic Trouble Code (DTC) is stored.

Therefore, read the code and locate the fault.

Note: The DTC cannot be cleared if the vehicle speed

does not exceed about 10km/h (6mph) at DTC, even

though the repair operation is completed.

2. Start the vehicle and accelerate to about 30 km/h (19 mph) or more.

3. Slowly brake and stop the vehicle completely.

4. Then restart the vehicle and accelerate to about 40 km/h (25 mph) or more.

5. Brake at a time so as to actuate the ABS and stop the vehicle.

6. Be cautious of abnormality during the test. If the W /L is actuated while driving, read the DTC and

locate the fault.

7. If the abnormality is not reproduced by the test, make best efforts to reproduce the situation

reported by the customer.

8. If the abnormality has been detected, repair in accordance with the “SYMPTOM DIAGNOSIS”.

Note:

• Be sure to perform a test drive on a wide, even road

with light traffic.

• If an abnormality is detected, be sure to suspend the test and start trouble diagnosis at once.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1191 of 6020

Engine Control System (4JH1) 6E-157

DTC P0500 (Symptom Code 1, A) (Flash Code 24)

Circuit Description

The vehicle speed sensor (VSS) is used by the engine

control module (ECM) and speedometer, which

generates a speed signal from the transmission output

shaft. The VSS has the following circuits.

• Ignition voltage feed circuit

• VSS signal circuit

• VSS low reference circuit

The VSS uses a hall effect element. It interacts with the

magnetic field created by the rotating magnet and

outputs square wave pulse signal. The 12 volts

operating supply from the Meter fuse (except 2W D with

A/T) or Back Up fuse (2W D with A/T). The ECM

calculates the vehicle speed by the VSS. If the vehicle

is 2W D with automatic transmission, VSS signals are

sent from the transmission control module (TCM). If the

ECM detects VSS signals are generated with high

frequencies, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC

• The ECM detects that the vehicle speed is highe

r

than 200 km/h (125 MPH) for 5 seconds.

(Symptom Code 1)

•

The ECM detects that the vehicle speed senso

r

signal frequency is too high for 0.6 seconds.

(Symptom Code A)

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM uses a vehicle speed substitution of 5

km/h (3 MPH) for engine control.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• Electrical or magnetic interference may affect

intermittent condition.

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

DTC P0500 (Symptom Code 1, A) (Flash Code 24)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Chart for 2WD with A/T

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Inspect all of the circuits going to the automatic transmission (A/T) vehicle speed sensor (VSS)

for the following: • Routed too closely to fuel injection solenoid

wiring or components

• Routed too closely to after-market add-on

electrical equipment

• Routed too closely to solenoids, relays, and

motors

2. If you find incorrect routing, correct the harness routing.

Did you find and correct the condition?

Go to Step 7 Go to Step 3

3 1. Turn OFF the ignition. 2. Disconnect the A/T VSS harness connector.

3. Inspect for an intermittent and for poor connections at the harness connector of the A/T

VSS (pins 1, 2 and 3 of E-30 connector).

4. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 7 Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1192 of 6020

6E-158 Engine Control System (4JH1)

Step Action Value(s) Yes No

4 1. Turn OFF the ignition.

2. Disconnect the engine control module (ECM) harness connector.

3. Inspect for an intermittent and for a poor connection on A/T VSS circuit at the harness

connector of the ECM (pin 68 of C-56 connector).

4. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 7 Go to Step 5

5 1. Remove the A/T VSS. Refer to A/T Speed Sensor Replacement in automatic transmission

section.

2. Visually inspect the A/T VSS for the following conditions: • Physical damage

• Being loose

• Improper installation

3. The following conditions may cause this DTC to set: • Electromagnetic interference in the A/T

VSS circuits

4. Repair or replace as necessary.

Did you find and correct the condition?

Go to Step 7 Go to Step 6

6 Replace the A/T VSS. Refer to A/T Speed Sensor Replacement in automatic transmission section

Did you complete the replacement?

Go to Step 7

7 1. Reconnect all previously disconnected harness

connector(s).

2. Clear the DTCs with the scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Drive the vehicle.

5. Observe the Vehicle Speed parameter with the scan tool.

Does the Vehicle Speed parameter indicate correct

vehicle speed?

Go to Step 8 Go to Step 2

8 Observe the DTC Information with the scan tool. Are there any DTCs that you have not diagnosed? Go to Diagnostic

Trouble Code (DTC) List System OK

Chart for except 2WD with A/T

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Inspect all of the circuits going to the vehicle speed sensor (VSS) for the following: • Routed too closely to fuel injection solenoid

wiring or components

• Routed too closely to after-market add-on

electrical equipment

• Routed too closely to solenoids, relays, and

motors

2. If you find incorrect routing, correct the harness routing.

Did you find and correct the condition?

Go to Step 7 Go to Step 3

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1289 of 6020

Engine Control System (4JH1) 6E-255

Symptoms – Engine Controls

Symptoms – Engine Controls

Important Preliminary Inspections Before Starting

Perform Diagnostic System Check – Engine Controls

before using the symptom tables, and verify that all o

f

the following are true:

• The engine control module (ECM) and malfunction

indicator lamp (MIL) are operating correctly.

• There are no diagnostic trouble codes (DTCs)

stored, or a DTC exists but without the MIL.

• The scan tool data is within the normal operating

range. Refer to scan tool Data List in this section.

• Verify the customer concern and locate the correct

symptom in the table of contents. Inspect the items

indicated under that symptom.

Visual and Physical Inspection

Several of the symptom procedures ask for careful

visual and physical inspection. This step is extremel

y

important. The visual and physical inspection can lead

to correcting a problem without further inspections, and

can save valuable time. Ensure that:

• The ECM grounds are clean, tight, and in thei

r

proper location.

• The vacuum hoses are not split or kinked, and

properly connected. Inspect thoroughly for an

y

type of leak or restriction.

• The mass air flow (MAF) sensor is properl

y

installed. The arrows on the plastic portion of the

sensor must point toward the engine.

• The air intake ducts are not collapsed or damaged.

• There are no leaks at the MAF sensor, an

y

connections or intake manifold sealing surfaces.

• The engine harness wiring and terminals are

properly connected and are not pinched or cut.

Intermittent

Important:

Inspect for improper installation of electrical

components if an intermittent condition exists. Inspect

for aftermarket add-on electrical equipment devices,

lights, and cellular phones. Verify that no aftermarket

equipment is connected to the keyword 2000 serial data

circuit. If you cannot locate an intermittent condition, a

cellular phone communication signal may cause the

condition.

Important:

The problem may or may not turn ON the MIL or store a

DTC.

Faulty electrical connections or wiring cause most

intermittent problems. Perform a careful visual and

physical inspection of the suspect connectors for the

following conditions:

• Improperly mated connector halves

• Terminals that are not seated

• Terminals that are damaged or improperly formed

Reform or replace connector terminals in the problem

circuit in order to ensure proper contact tension.

Remove the terminal from the connector body in orde

r

to inspect for poor terminal wire connection.

Road test the vehicle with the DMM connected to the

suspected circuit. An abnormal reading that occurs

when the malfunction occurs is a good indication that

there is a malfunction in the circuit being monitored.

Use the scan tool in order to help detect intermittent

conditions. Useful features of the scan tool include the

following:

• Trigger the Snapshot feature in order to capture

and store engine parameters when the malfunction

occurs. Review this stored information in order to

see the specific running conditions that caused the

malfunction.

• Use the Plot Function on the scan tool in order to

plot selected data parameters. Review this stored

information to aid in locating an intermittent

problem. Refer to the scan tool Users Guide fo

r

more information.

Important:

If the intermittent condition exists as a start and then

stall, test for DTCs relating to the vehicle theft deterrent

system. Test for improper installation of electrical

options such as lights, cellular phones, etc.

Any of the following may cause an intermittent MIL with

no stored DTC:

• The ECM grounds are loose or dirty. Refer to

Engine Controls Schematics.

• The MIL circuit intermittently shorted to ground.

• Electrical system interference caused by a

malfunctioning relay, ECM driven solenoid, o

r

switch. The electrical component can cause a

sharp electrical surge. Normally, the problem will

occur when the malfunctioning component is

operating.

• There is an open diode across the A/C

compressor clutch or any other open diodes.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1290 of 6020

6E-256 Engine Control System (4JH1)

Important:

The following symptom tables contain groups o

f

possible causes for each symptom. The order of these

procedures is not important. If the scan tool readings do

not indicate the problems, then proceed in a logical

order, easiest to check or most likely to cause first. In

order to determine if a specific vehicle is using a

particular system or component, refer to Engine

Controls Schematics for an application.

Use the following tables when diagnosing a symptom

complaint:

• Intermittent Conditions

• Hard Start

• Rough, Unstable, or Incorrect Idle and Stalling

• Cuts Out, Misses

• Surge/Chuggles

• Lack of Power, Sluggishness, or Sponginess

• Hesitation, Sag, Stumble

• Fuel Knock/Combustion Noise

• Poor Fuel Economy

• Excessive Smoke (Black Smoke)

• Excessive Smoke (W hite Smoke)

Intermittent Conditions

Checks Action

DEFINITION:The problem is not currently present but is indicated in DTC History.

OR

There is a customer complaint, but the symptom cannot currently be duplicated, if the problem is not DTC related.

Preliminary Checks • Refer to Symptoms – Engine Controls before starting.

Harness/Connector Many intermittent open or shorted circuits are affected by harness/connector

movement that is caused by vibration, engine torque, bumps/rough pavement, etc.

Test for this type of condition by performing the applicable procedure from the

following list:

• Move related connectors and wiring while monitoring the appropriate scan tool data.

• Move related connectors and wiring with the component commanded ON, and OFF,

with the scan tool. Observe the component operation.

• W ith the engine running, move related connectors and wiring while monitoring

engine operation.

If harness or connector movement affects the data displayed, component/system

operation, or engine operation, inspect and repair the harness/connections as

necessary.

Refer to Electrical Connections or W iring.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1291 of 6020

Engine Control System (4JH1) 6E-257

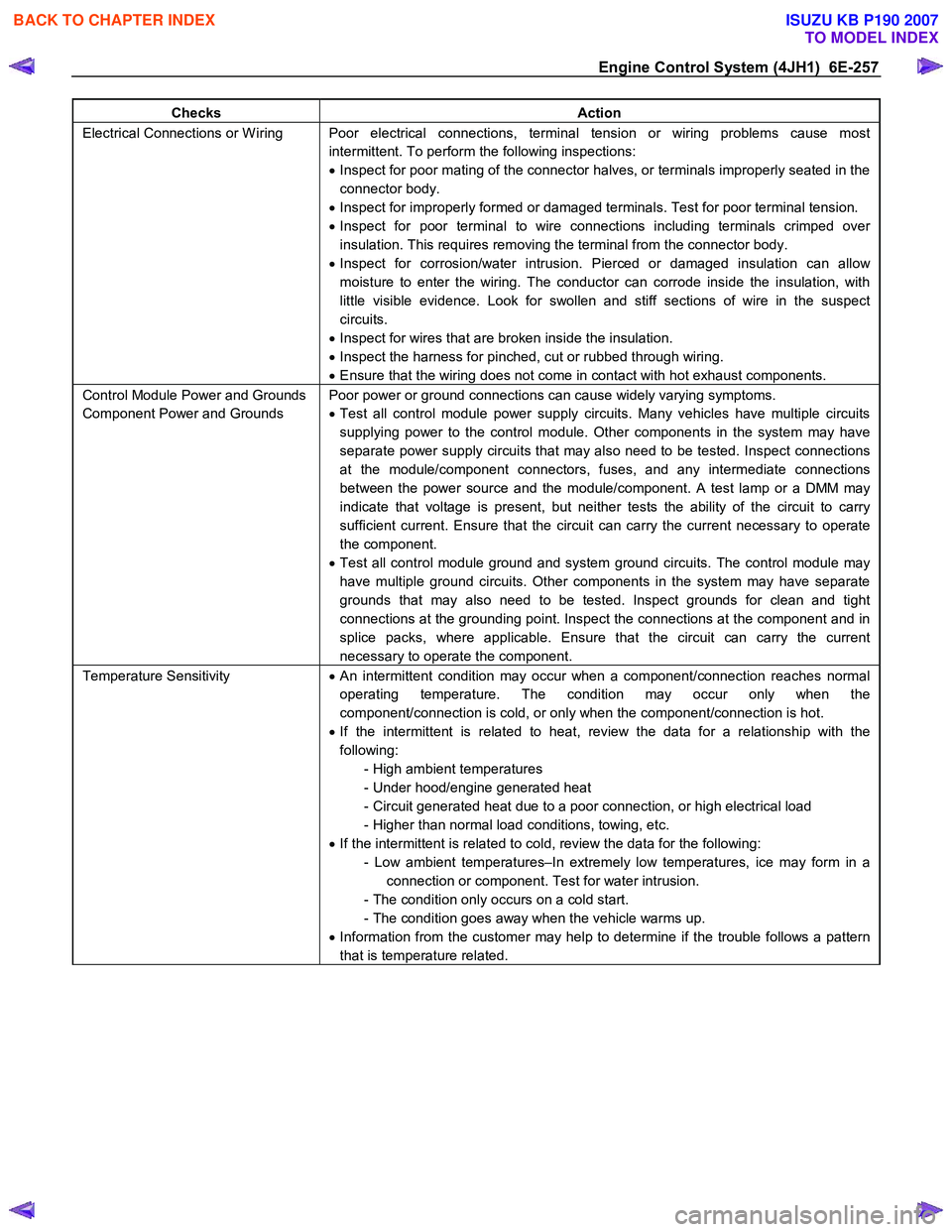

Checks Action

Electrical Connections or W iring Poor electrical connections, terminal tension or wiring problems cause most intermittent. To perform the following inspections:

• Inspect for poor mating of the connector halves, or terminals improperly seated in the

connector body.

• Inspect for improperly formed or damaged terminals. Test for poor terminal tension.

• Inspect for poor terminal to wire connections including terminals crimped over

insulation. This requires removing the terminal from the connector body.

• Inspect for corrosion/water intrusion. Pierced or damaged insulation can allow

moisture to enter the wiring. The conductor can corrode inside the insulation, with

little visible evidence. Look for swollen and stiff sections of wire in the suspect

circuits.

• Inspect for wires that are broken inside the insulation.

• Inspect the harness for pinched, cut or rubbed through wiring.

• Ensure that the wiring does not come in contact with hot exhaust components.

Control Module Power and Grounds

Component Power and Grounds Poor power or ground connections can cause widely varying symptoms.

• Test all control module power supply circuits. Many vehicles have multiple circuits

supplying power to the control module. Other components in the system may have

separate power supply circuits that may also need to be tested. Inspect connections

at the module/component connectors, fuses, and any intermediate connections

between the power source and the module/component. A test lamp or a DMM may

indicate that voltage is present, but neither tests the ability of the circuit to carry

sufficient current. Ensure that the circuit can carry the current necessary to operate

the component.

• Test all control module ground and system ground circuits. The control module may

have multiple ground circuits. Other components in the system may have separate

grounds that may also need to be tested. Inspect grounds for clean and tight

connections at the grounding point. Inspect the connections at the component and in

splice packs, where applicable. Ensure that the circuit can carry the current

necessary to operate the component.

Temperature Sensitivity • An intermittent condition may occur when a component/connection reaches normal

operating temperature. The condition may occur only when the

component/connection is cold, or only when the component/connection is hot.

• If the intermittent is related to heat, review the data for a relationship with the

following: - High ambient temperatures

- Under hood/engine generated heat

- Circuit generated heat due to a poor connection, or high electrical load

- Higher than normal load conditions, towing, etc.

• If the intermittent is related to cold, review the data for the following:

- Low ambient temperatures–In extremely low temperatures, ice may form in a connection or component. Test for water intrusion.

- The condition only occurs on a cold start.

- The condition goes away when the vehicle warms up.

• Information from the customer may help to determine if the trouble follows a pattern

that is temperature related.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1296 of 6020

6E-262 Engine Control System (4JH1)

Checks Action

Additional Checks •

Electromagnetic interference (EMI) on the reference circuit can cause an engine miss

condition. The scan tool can usually detect EMI by monitoring the engine speed. A

sudden increase in speed with little change in actual engine speed change indicates that

EMI is present. If a problem exists, check routing of high voltage components, such as

fuel injection solenoid valve wiring, near the sensor circuits.

• Inspect for faulty engine mounts.

• Inspect faulty crank pulley.

• Inspect faulty generator & A/C compressor.

• Inspect the generator output voltage. Repair if less than 9 volts or more than 16 volts.

• Inspect the EGR system operating correctly.

• Inspect the A/C operation.

Cut Out, Misses

Checks Action

DEFINITION:A constant jerking that follows the engine speed, usually more pronounced as the engine load increase. The

exhaust has a steady spitting sound at idle, low speed, or hard acceleration for the fuel starvation that can cause the engine to

cut-out.

Preliminary Check • Diagnostic System Check - Engine Controls.

• Inspect that the harness connectors are correctly connected.

• Inspect the engine control module (ECM) and fuel injection pump control unit (PCU)

grounds for being clean, tight, and in their proper locations.

• Inspect the scan tool Data List in this section.

• Inspect the Service Bulletins for ECM software updates.

Sensor Checks Inspect the engine control sensors for the following conditions. Refer to the scan tool

Data List in this section.

• Use the scan tool to observe the Accelerator Pedal Position. Accelerator Pedal

Position indicating angle parameter should change linearly from 0% to 100%

according to the accelerator pedal operation.

• Inspect the crankshaft position (CKP) sensor is tight and the flywheel circumference

is not damaged.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1297 of 6020

Engine Control System (4JH1) 6E-263

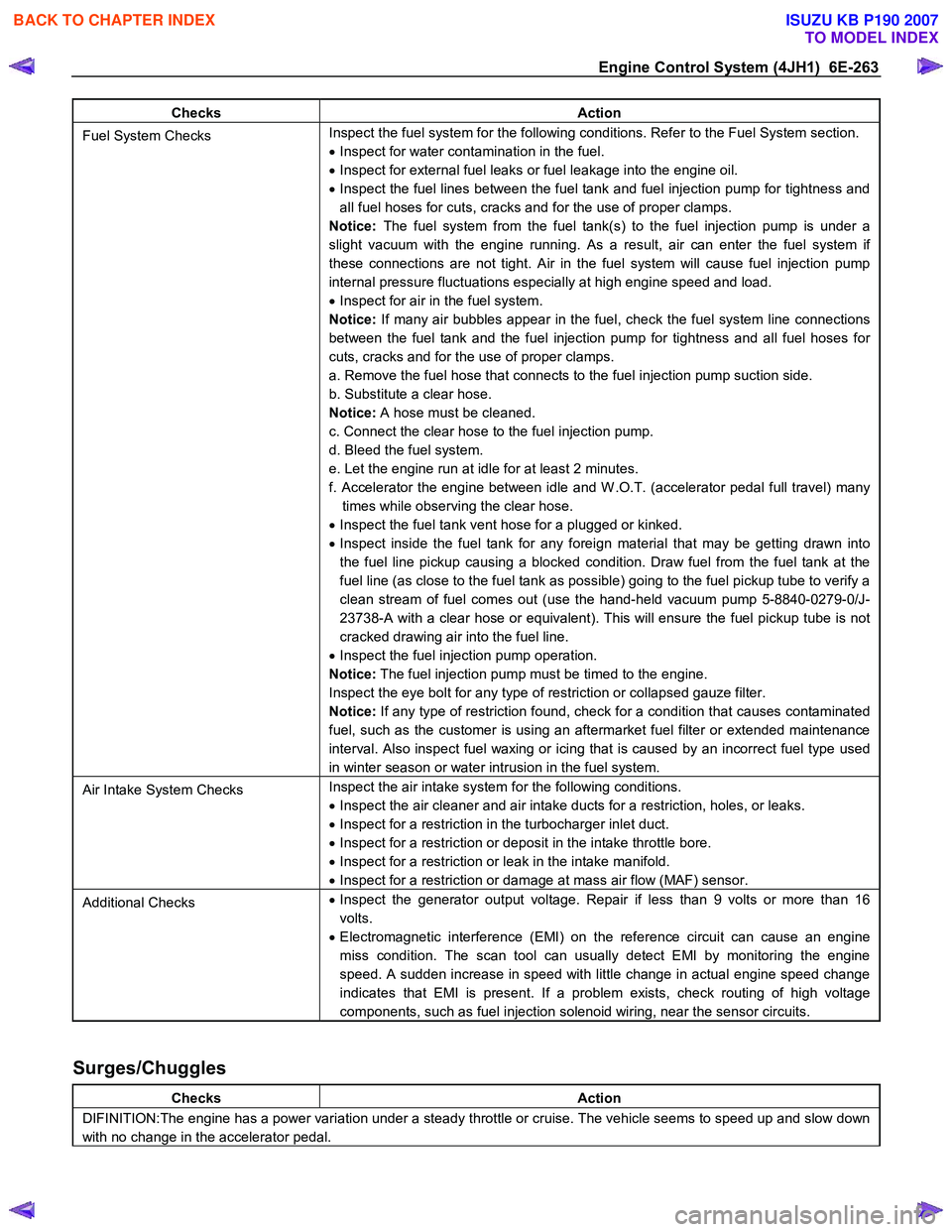

Checks Action

Fuel System Checks Inspect the fuel system for the following conditions. Refer to the Fuel System section.

• Inspect for water contamination in the fuel.

• Inspect for external fuel leaks or fuel leakage into the engine oil.

• Inspect the fuel lines between the fuel tank and fuel injection pump for tightness and

all fuel hoses for cuts, cracks and for the use of proper clamps.

Notice: The fuel system from the fuel tank(s) to the fuel injection pump is under a

slight vacuum with the engine running. As a result, air can enter the fuel system if

these connections are not tight. Air in the fuel system will cause fuel injection pump

internal pressure fluctuations especially at high engine speed and load.

• Inspect for air in the fuel system.

Notice: If many air bubbles appear in the fuel, check the fuel system line connections

between the fuel tank and the fuel injection pump for tightness and all fuel hoses for

cuts, cracks and for the use of proper clamps.

a. Remove the fuel hose that connects to the fuel injection pump suction side.

b. Substitute a clear hose.

Notice: A hose must be cleaned.

c. Connect the clear hose to the fuel injection pump.

d. Bleed the fuel system.

e. Let the engine run at idle for at least 2 minutes.

f. Accelerator the engine between idle and W .O.T. (accelerator pedal full travel) many times while observing the clear hose.

• Inspect the fuel tank vent hose for a plugged or kinked.

• Inspect inside the fuel tank for any foreign material that may be getting drawn into

the fuel line pickup causing a blocked condition. Draw fuel from the fuel tank at the

fuel line (as close to the fuel tank as possible) going to the fuel pickup tube to verify a

clean stream of fuel comes out (use the hand-held vacuum pump 5-8840-0279-0/J-

23738-A with a clear hose or equivalent). This will ensure the fuel pickup tube is not

cracked drawing air into the fuel line.

• Inspect the fuel injection pump operation.

Notice: The fuel injection pump must be timed to the engine.

Inspect the eye bolt for any type of restriction or collapsed gauze filter.

Notice: If any type of restriction found, check for a condition that causes contaminated

fuel, such as the customer is using an aftermarket fuel filter or extended maintenance

interval. Also inspect fuel waxing or icing that is caused by an incorrect fuel type used

in winter season or water intrusion in the fuel system.

Air Intake System Checks Inspect the air intake system for the following conditions.

• Inspect the air cleaner and air intake ducts for a restriction, holes, or leaks.

• Inspect for a restriction in the turbocharger inlet duct.

• Inspect for a restriction or deposit in the intake throttle bore.

• Inspect for a restriction or leak in the intake manifold.

• Inspect for a restriction or damage at mass air flow (MAF) sensor.

Additional Checks •

Inspect the generator output voltage. Repair if less than 9 volts or more than 16

volts.

• Electromagnetic interference (EMI) on the reference circuit can cause an engine

miss condition. The scan tool can usually detect EMI by monitoring the engine

speed. A sudden increase in speed with little change in actual engine speed change

indicates that EMI is present. If a problem exists, check routing of high voltage

components, such as fuel injection solenoid wiring, near the sensor circuits.

Surges/Chuggles

Checks Action

DIFINITION:The engine has a power variation under a steady throttle or cruise. The vehicle seems to speed up and slow down

with no change in the accelerator pedal.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1371 of 6020

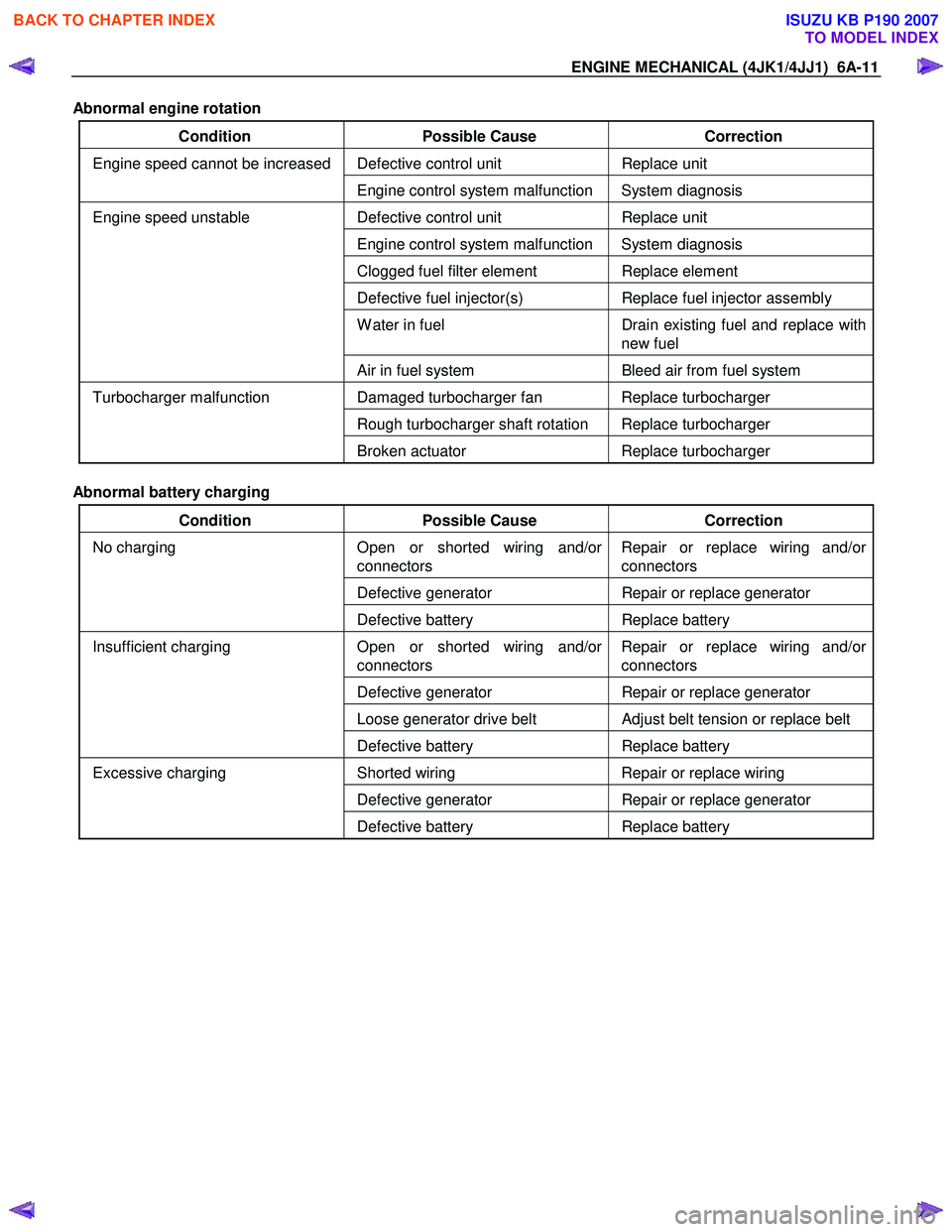

ENGINE MECHANICAL (4JK1/4JJ1) 6A-11

Abnormal engine rotation

Condition Possible Cause Correction

Defective control unit Replace unit Engine speed cannot be increased

Engine control system malfunction System diagnosis

Defective control unit Replace unit

Engine control system malfunction System diagnosis

Clogged fuel filter element Replace element

Defective fuel injector(s) Replace fuel injector assembly

W ater in fuel Drain existing fuel and replace with

new fuel

Engine speed unstable

Air in fuel system Bleed air from fuel system

Damaged turbocharger fan Replace turbocharger

Rough turbocharger shaft rotation Replace turbocharger

Turbocharger malfunction

Broken actuator Replace turbocharger

Abnormal battery charging

Condition Possible Cause Correction

Open or shorted wiring and/or

connectors Repair or replace wiring and/or

connectors

Defective generator Repair or replace generator

No charging

Defective battery Replace battery

Open or shorted wiring and/or

connectors Repair or replace wiring and/or

connectors

Defective generator Repair or replace generator

Loose generator drive belt Adjust belt tension or replace belt

Insufficient charging

Defective battery Replace battery

Shorted wiring Repair or replace wiring

Defective generator Repair or replace generator

Excessive charging

Defective battery Replace battery

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007