Oil JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 918 of 2490

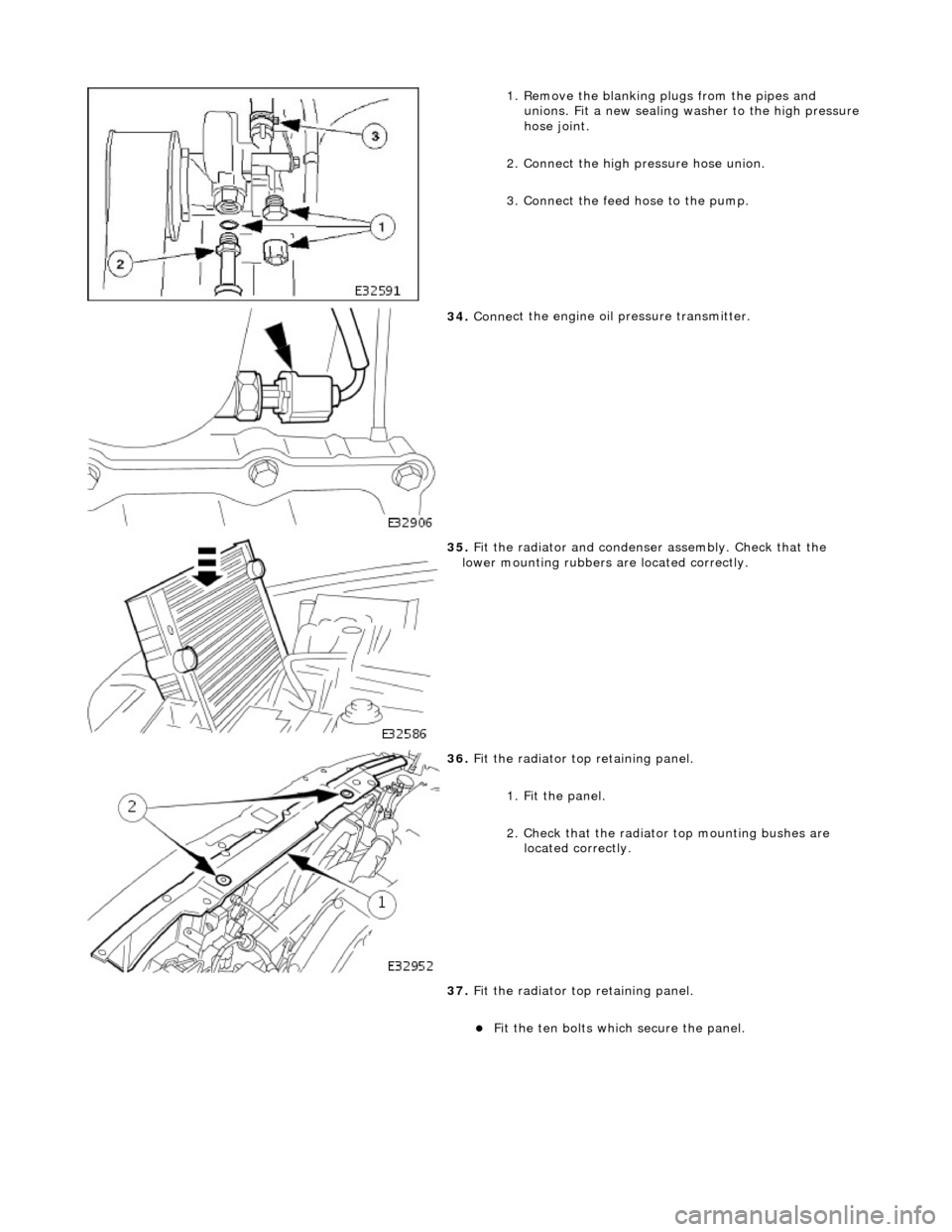

1.

Remove the blanking plugs from the pipes and

unions. Fit a new sealing washer to the high pressure

hose joint.

2. Connect the high pressure hose union.

3. Connect the feed hose to the pump.

34 . Conne

ct the engine oil

pressure transmitter.

35 .

Fit the radiator and

condense

r assembly. Check that the

lower mounting rubbers are located correctly.

36 . Fit the radiator top

retaining panel.

1. Fit the panel.

2. Check that the radiator top mounting bushes are

located correctly.

37. Fit the radiator top retaining panel.

пЃ¬Fit

the ten bolts which secure the panel.

Page 919 of 2490

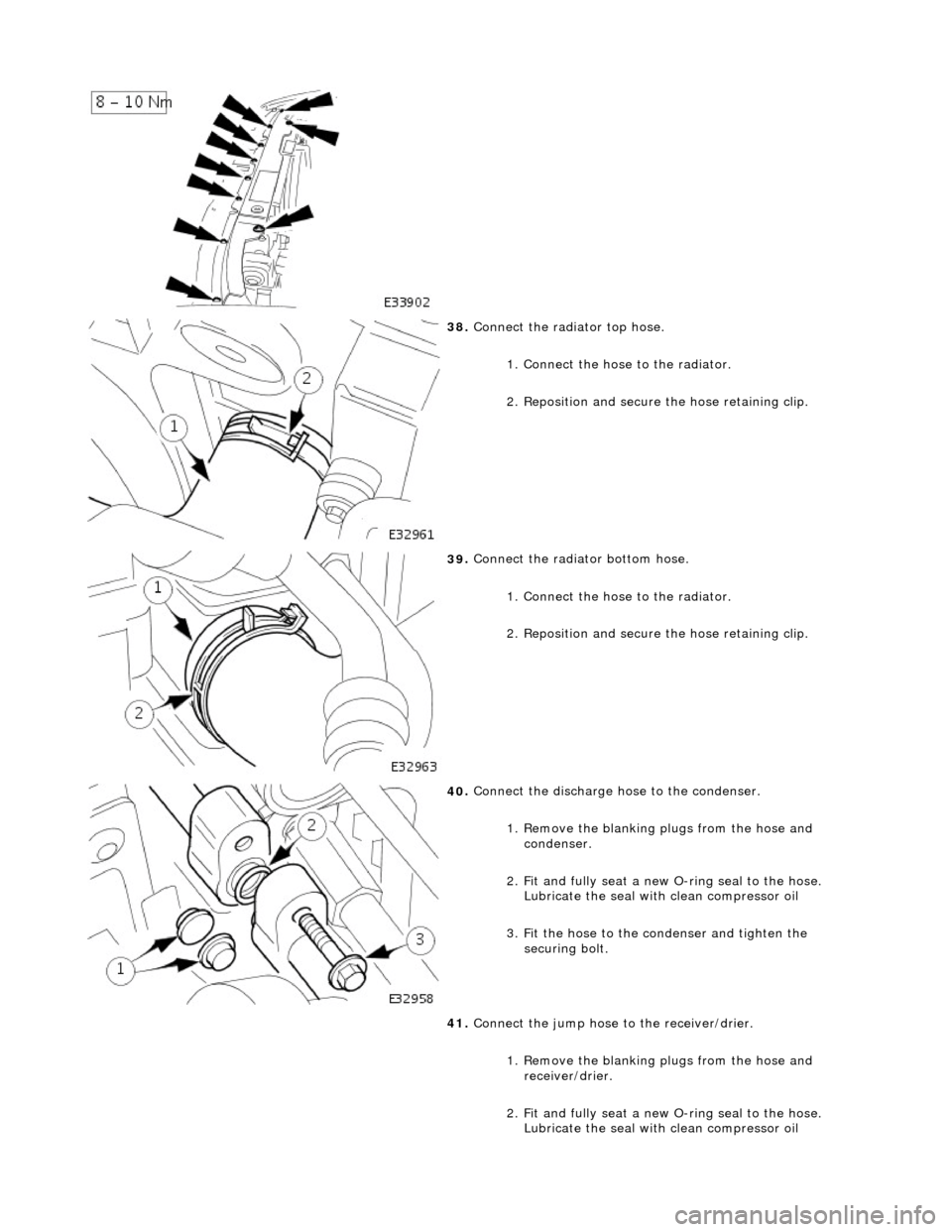

38

.

Connect the radiator top hose.

1. Connect the hose to the radiator.

2. Reposition and secure the hose retaining clip.

39

.

Connect the radiator bottom hose.

1. Connect the hose to the radiator.

2. Reposition and secure the hose retaining clip.

40

.

Connect the discharge hose to the condenser.

1. Remove the blanking plugs from the hose and condenser.

2. Fit and fully seat a new O-ring seal to the hose.

Lubricate the seal with clean compressor oil

3. Fit the hose to the condenser and tighten the securing bolt.

41. Connect the jump hose to the receiver/drier.

1. Remove the blanking plugs from the hose and receiver/drier.

2. Fit and fully seat a new O-ring seal to the hose.

Lubricate the seal with clean compressor oil

Page 920 of 2490

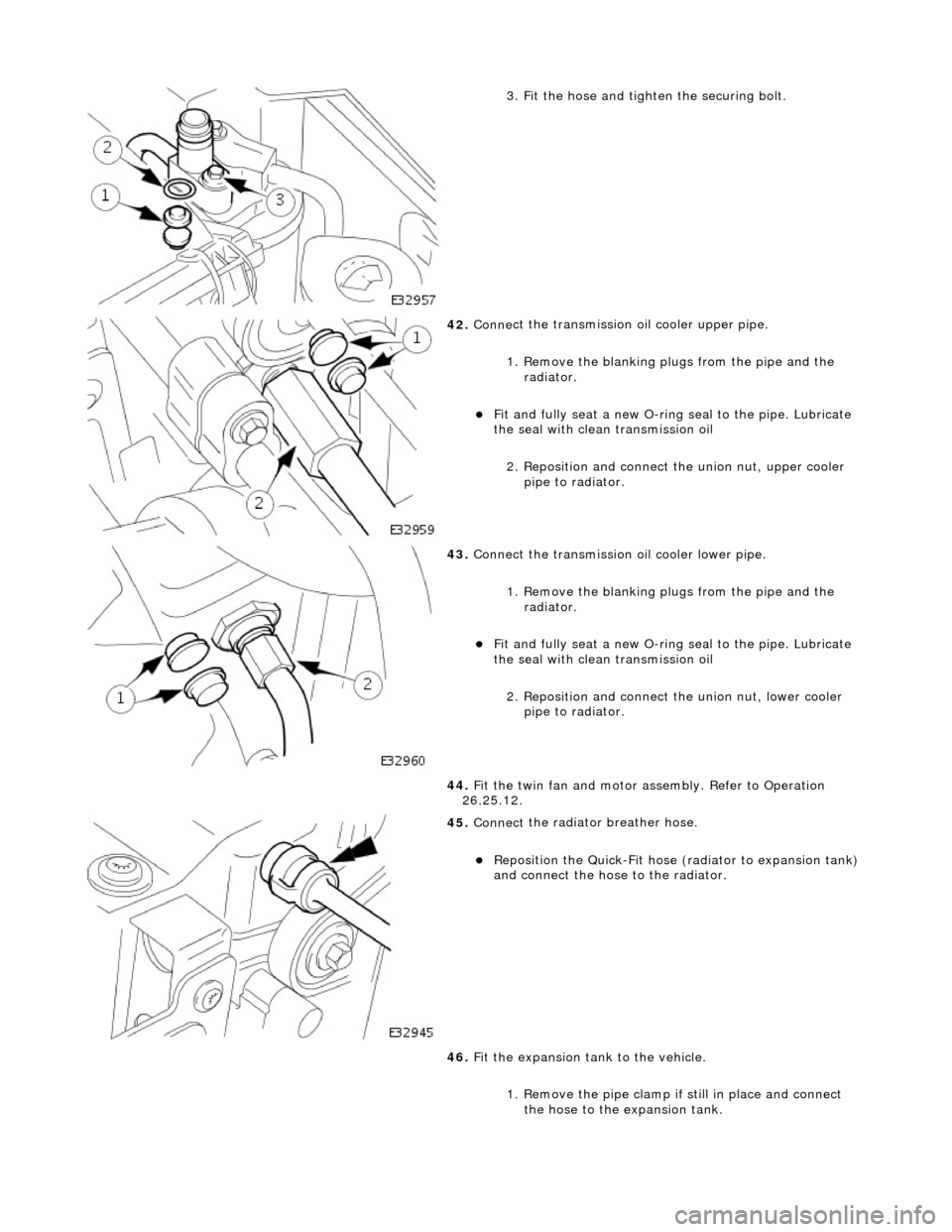

3.

Fit the hose and tighten the securing bolt.

42 . Conne

ct the transmission

oil cooler upper pipe.

1. Remove the blanking plugs from the pipe and the radiator.

пЃ¬Fit and

fully seat a new O-ring

seal to the pipe. Lubricate

the seal with clean transmission oil

2. Reposition and connect the union nut, upper cooler pipe to radiator.

43 . Conne

ct the transmission oil cooler lower pipe.

1. Remove the blanking plugs from the pipe and the radiator.

пЃ¬Fit and

fully seat a new O-ring

seal to the pipe. Lubricate

the seal with clean transmission oil

2. Reposition and connect the union nut, lower cooler

pipe to radiator.

44. Fit the twin fan and motor assembly. Refer to Operation

26.25.12.

45 . Connect

the radiator breather hose.

пЃ¬Re

po

sition the Quick-Fit hose (radiator to expansion tank)

and connect the hose to the radiator.

46. Fit the expansion tank to the vehicle.

1. Remove the pipe clamp if still in place and connect

the hose to the expansion tank.

Page 922 of 2490

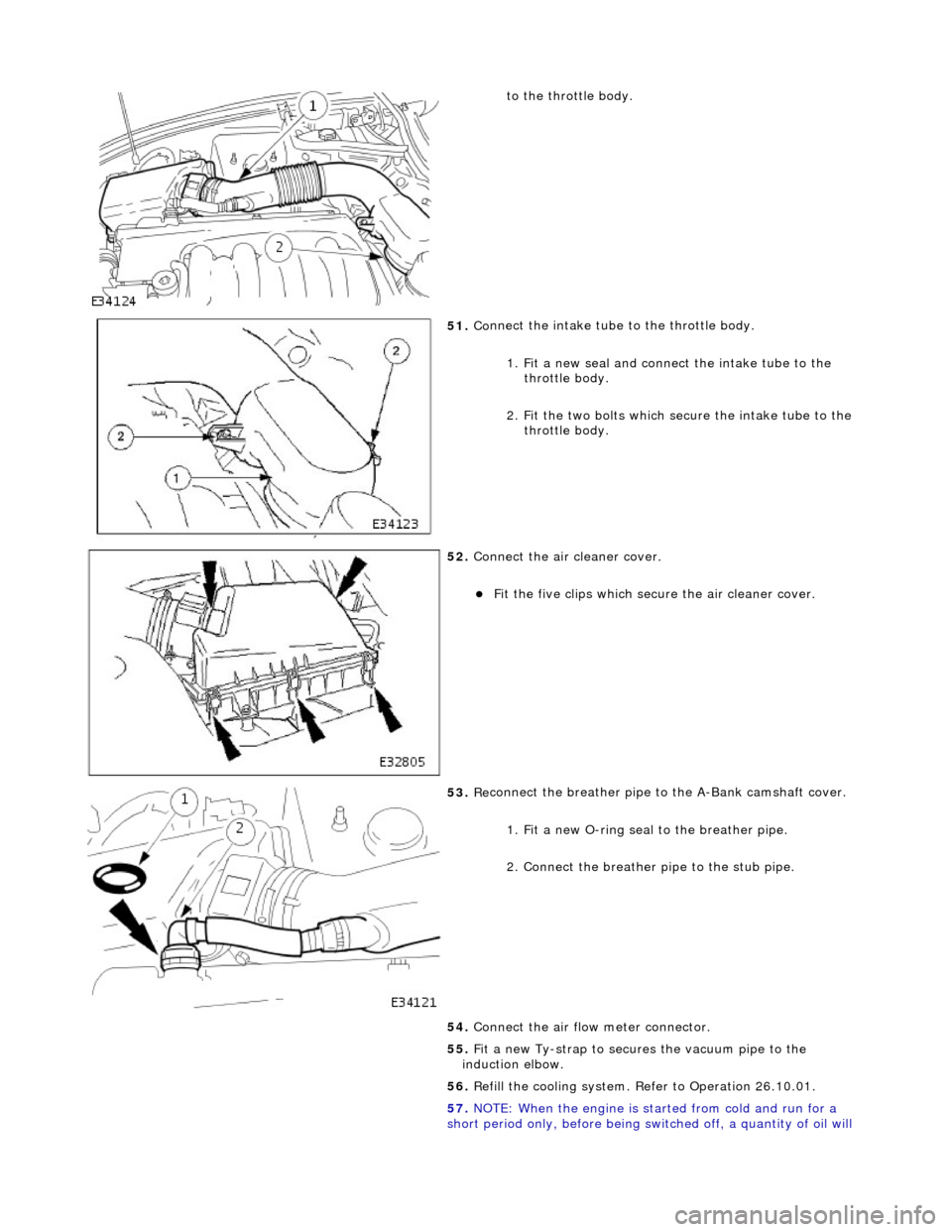

to th

e throttle body.

51 . Co

nnect the intake tube to the throttle body.

1. Fit a new seal and connect the intake tube to the throttle body.

2. Fit the two bolts which secure the intake tube to the throttle body.

52 . Conne

ct the air cleaner cover.

пЃ¬F

it

the five clips which secu

re the air cleaner cover.

53 . Re

connect the breather pipe to the A-Bank camshaft cover.

1. Fit a new O-ring seal to the breather pipe.

2. Connect the breather pipe to the stub pipe.

54. Connect the air flow meter connector.

55. Fit a new Ty-strap to secures the vacuum pipe to the

induction elbow.

56. Refill the cooling system. Refer to Operation 26.10.01.

57. NOTE: When the engine is star ted from cold and run for a

short period only, before being swit ched off, a quantity of oil will

Page 923 of 2490

be 'hun

g up' within the engine because it is not up to operating

temperature.

Should the oil level subsequently be topped-up, the level could

become too high, causing oil burning.

Typically, 0.875L is hung up.

Refill the engine with the correct specification engine oil.

58. Refill the automatic transmission. Refer to Section 307-01A,

Operation 44.24. 02.

59. Refill and bleed the power stee ring system. Refer to Section

211-02 General Procedures.

60. Repressurise the air conditioni ng system. Refer to Operation

82.30.30 and note all Wa rnings and Cautions.

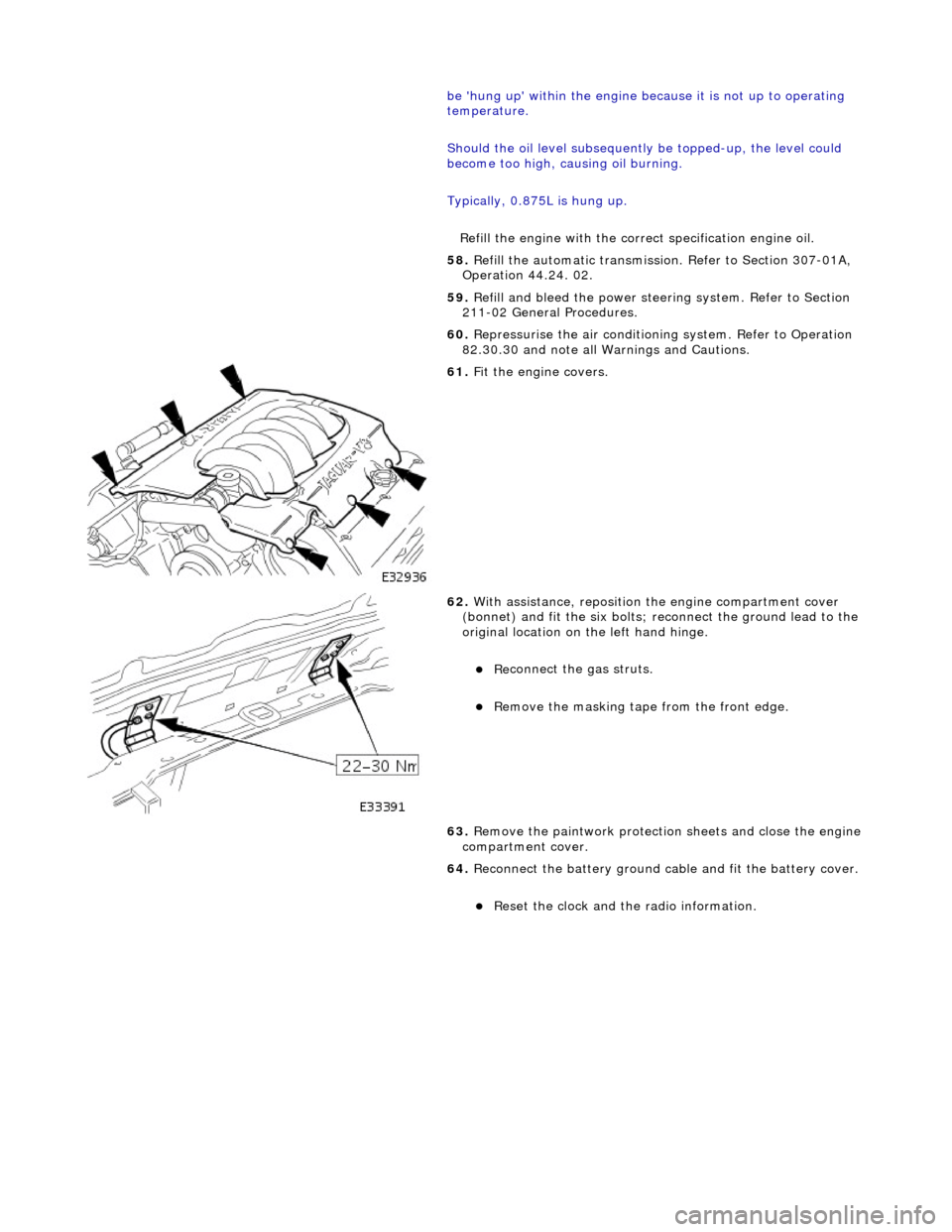

61

.

Fit the engine covers.

62

.

With assistance, reposition the engine compartment cover

(bonnet) and fit the si x bolts; reconnect the ground lead to the

original location on the left hand hinge.

пЃ¬Re

connect the gas struts.

пЃ¬R

emove the masking tape from the front edge.

63. Remove the paintwork protection sheets and close the engine

compartment cover.

64. Reconnect the battery ground cable and fit the battery cover.

пЃ¬Re

set the clock and the radio information.

Page 929 of 2490

The cooling

pack incorporates the radiator a

ssembly with integral transmission oil cool er (located in the radiator outlet tank),

an air conditioning condenser, and the cooling fans and cowl assembly.

The cooling pack on supercharged vehicles is the same as described above, but with the addition of a charge air cooler

coolant radiator located in front of the condenser.

Radiator Mounti

ng/Retention

T

he radiator is mounted on four rubber mounts, one on each

end of the upper and lower horizontal face. The two lower

mountings are supported on two isolated brackets mounted on the body; the lower cradle assembly has subsequently been

deleted.

A closing panel made from polypropylene, which retains the radiat or assembly, fits over the top of the radiator and is bolted

to the vehicle top panel.

Coolant Hoses - Engine

Page 935 of 2490

Pinpoint test

A: P0116, P0125

Connector

loose or corroded

*

D

TC P0118 ECT circuit high input

Sensor short

Harness open circui

t

Harness short

Connector loose or corroded

*

*

*

*

GO to Pinpoint

Test C

*

D

TC P1474 Intercooler coolant pump relay malfunction

Intercooler pump relay

failure

Intercooler pump relay to ECM drive circuit

fault Intercooler pump relay coil ground circuit

fault Harness fault

Connector loose or corroded

Connector pins(s) bent or tracking between

connections ECM power supply fault

*

*

*

*

*

*

*

GO to Pinpoint

Test D

*

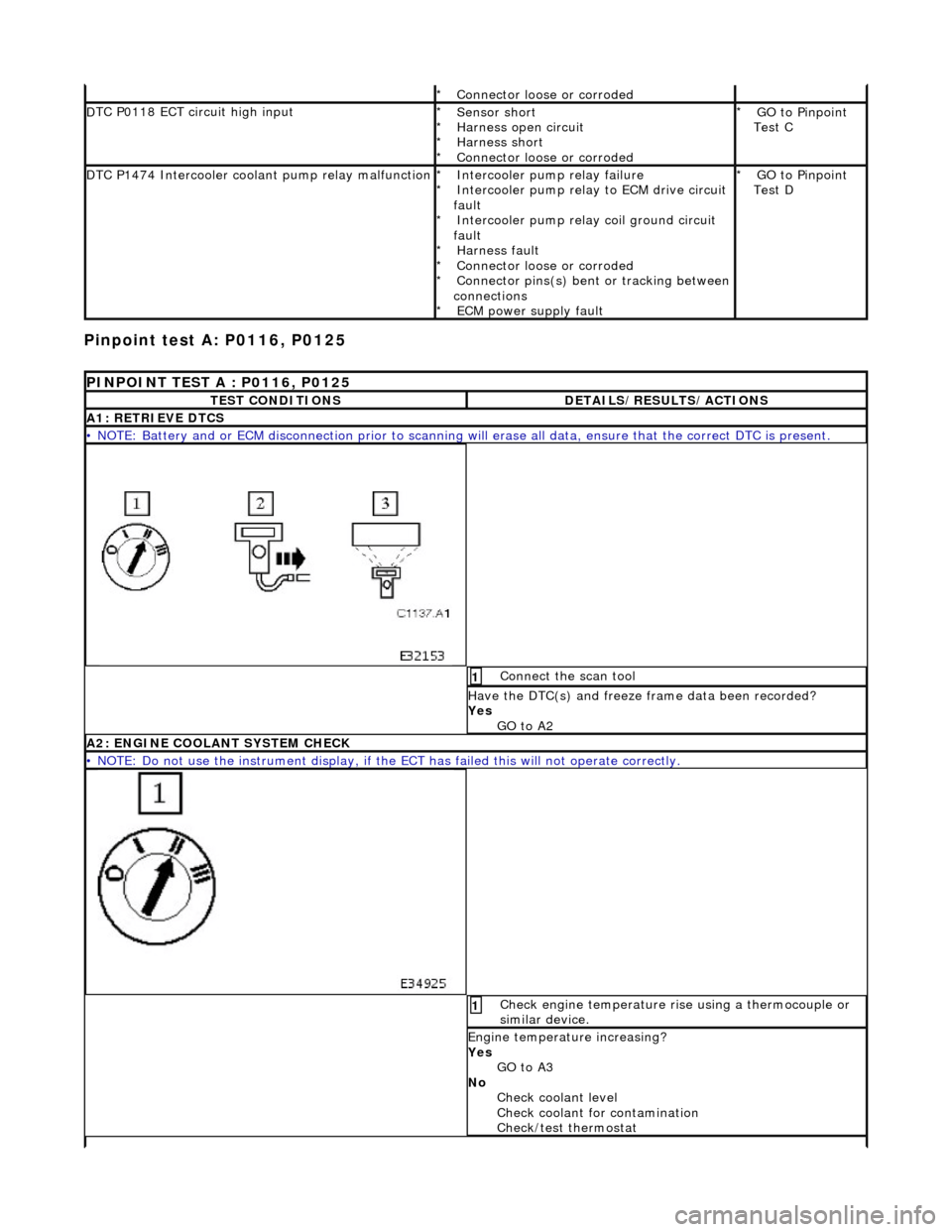

P

INPOINT TEST A : P0116, P0125

T

EST CONDITIONS

D

ETAILS/RESULTS/ACTIONS

A1

: RETRIEVE DTCS

•

NOTE: Battery and or ECM disconnection prior to scanning wi

ll erase all data, ensure that the correct DTC is present.

Conne

ct the scan tool

1

Have the DTC(s) and fr

eeze

frame data been recorded?

Yes GO to A2

A2: ENGINE

COOLANT SYSTEM CHECK

•

NOTE: Do not use the instrument display, if th

e ECT has failed this will not operate correctly.

Chec

k engine temperature rise using a thermocouple or

similar device.

1

Engine

temperature increasing?

Yes GO to A3

No Check coolant level

Check coolant for contamination

Check/test thermostat

Page 950 of 2490

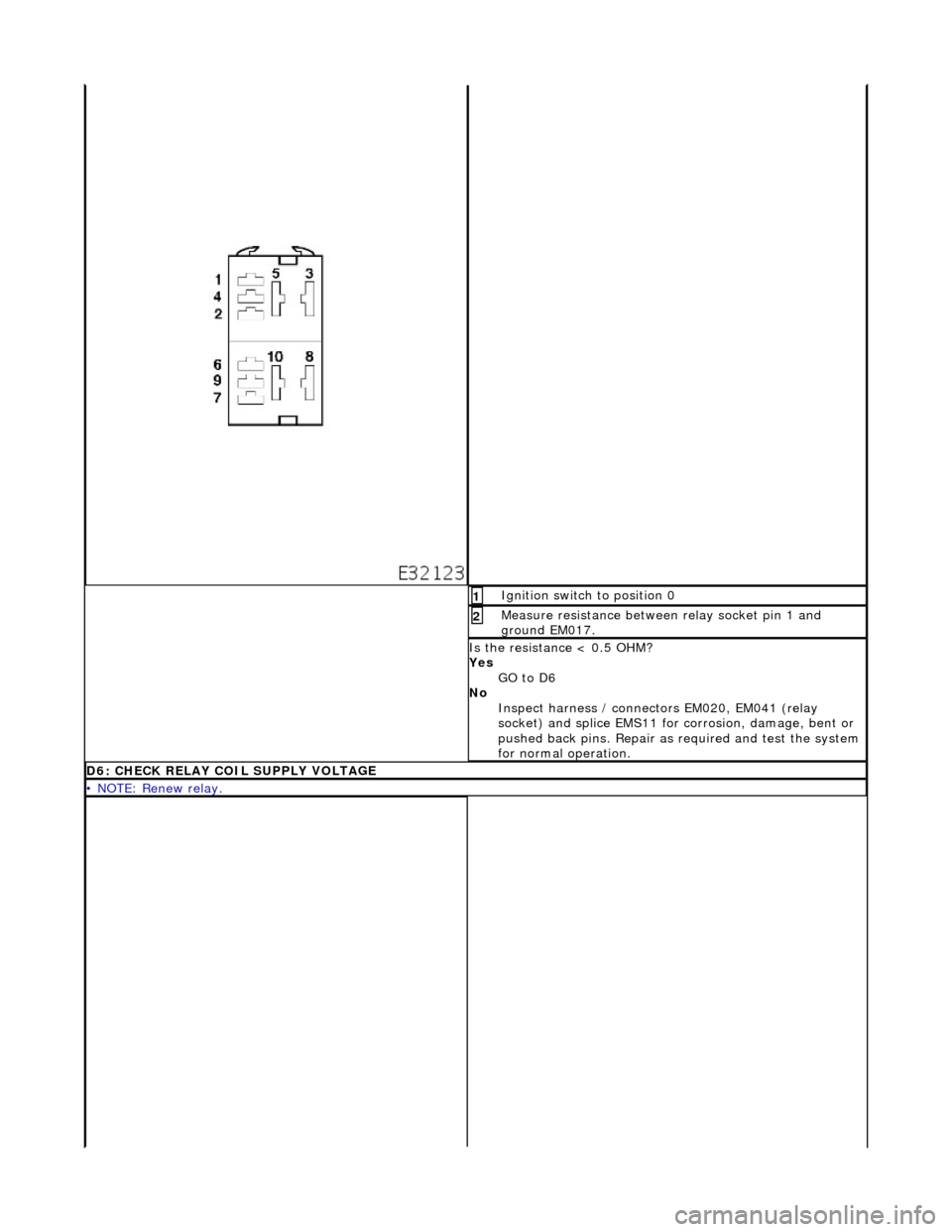

Ig

nition switch to position 0

1

Meas

ure re

sistance between relay socket pin 1 and

ground EM017.

2

I s

the resistance < 0.5 OHM?

Yes GO to D6

No Inspect harness / connec tors EM020, EM041 (relay

socket) and splice EMS11 for corrosion, damage, bent or

pushed back pins. Repair as required and test the system

for normal operation.

D6: CHECK

RELAY COIL SUPPLY VOLTAGE

• NO

TE: Renew relay.

Page 973 of 2490

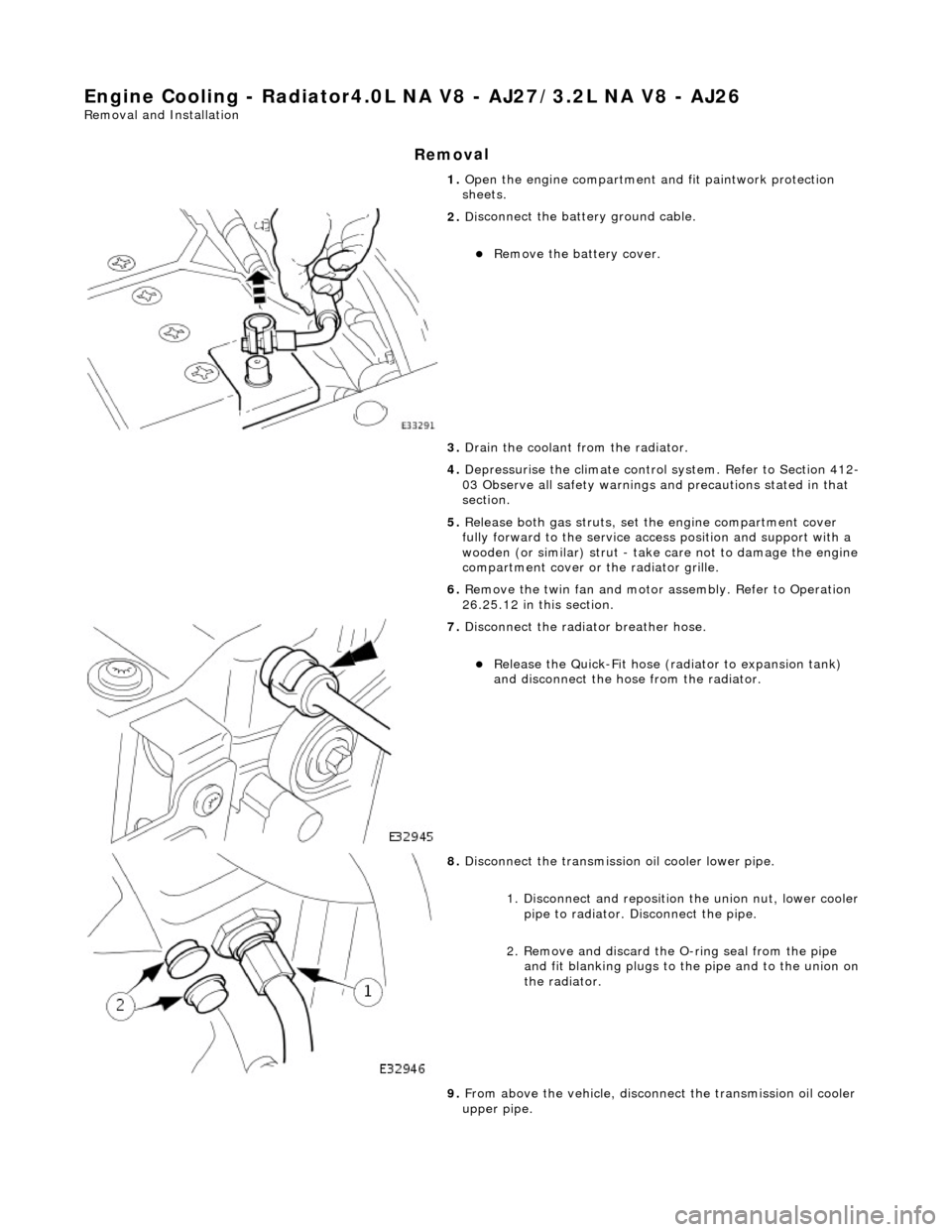

Engine Cooling - Radiator4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

Re

moval and Installation

Remov

al

1.

O

pen the engine compartment and fit paintwork protection

sheets.

2. Di

sconnect the batt

ery ground cable.

пЃ¬R

emove the battery cover.

3. Drain the coolant from the radiator.

4. Depressurise the climate control system. Refer to Section 412-

03 Observe all safety warnings and precautions stated in that

section.

5. Release both gas struts, set the engine compartment cover

fully forward to the service acce ss position and support with a

wooden (or similar) strut - take care not to damage the engine

compartment cover or the radiator grille.

6. Remove the twin fan and motor assembly. Refer to Operation

26.25.12 in this section.

7. D

isconnect the radiator breather hose.

пЃ¬R

elease the Quick-Fit hose (radiator to expansion tank)

and disconnect the hose from the radiator.

8. Di

sconnect the transmission oil cooler lower pipe.

1. Disconnect and reposition the union nut, lower cooler pipe to radiator. Di sconnect the pipe.

2. Remove and discard the O- ring seal from the pipe

and fit blanking plugs to the pipe and to the union on

the radiator.

9. From above the vehicle, disconne ct the transmission oil cooler

upper pipe.

Page 976 of 2490

In

stallation

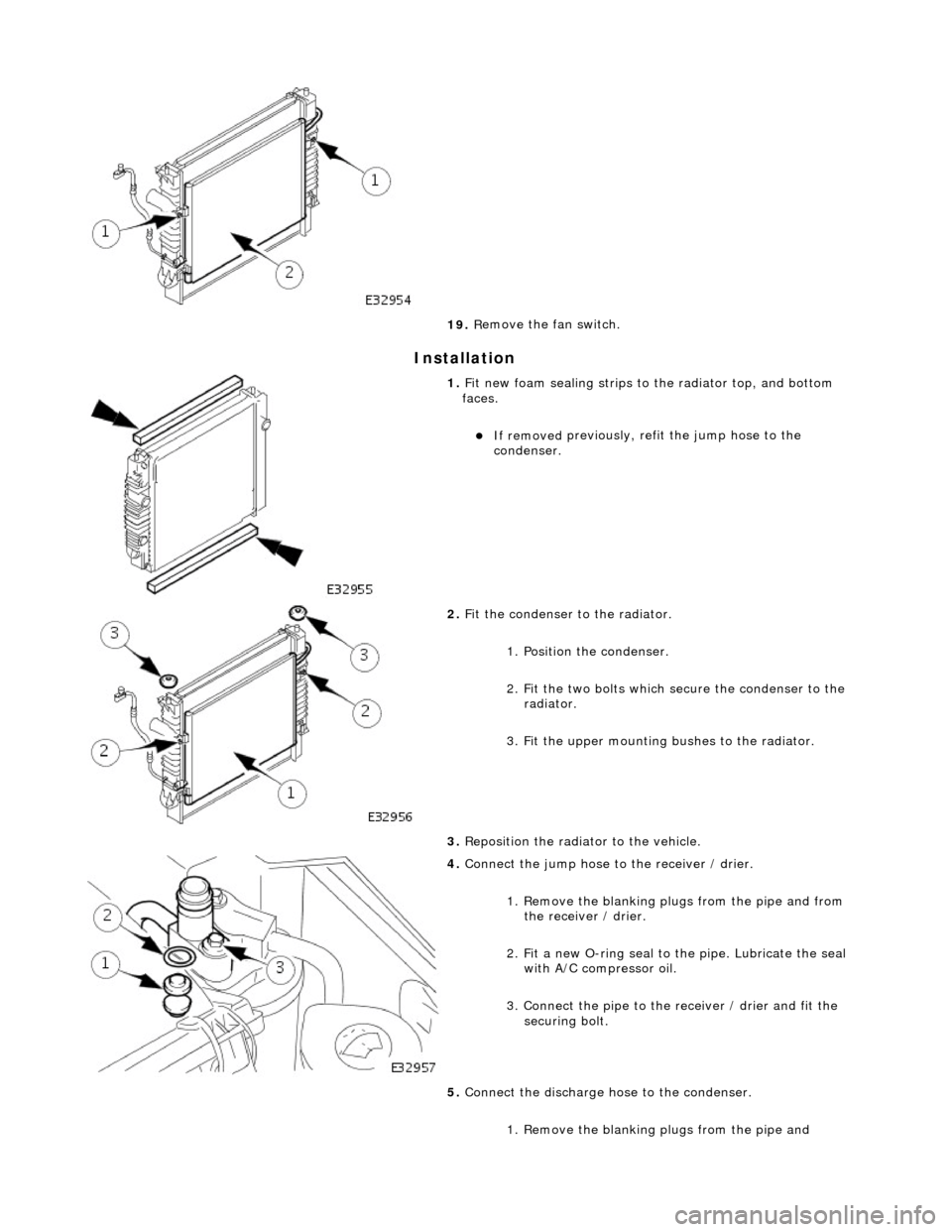

19

. R

emove the fan switch.

1. Fi

t new foam sealing strips to

the radiator top, and bottom

faces.

пЃ¬If removed

previously, refit the jump hose to the

condenser.

2. Fit t

he condenser to the radiator.

1. Position the condenser.

2. Fit the two bolts which secure the condenser to the radiator.

3. Fit the upper mounting bushes to the radiator.

3. Reposition the radiator to the vehicle.

4. Conne ct

the jump hose to

the receiver / drier.

1. Remove the blanking plugs from the pipe and from the receiver / drier.

2. Fit a new O-ring seal to the pipe. Lubricate the seal with A/C compressor oil.

3. Connect the pipe to the receiver / drier and fit the

securing bolt.

5. Connect the discharge hose to the condenser.

1. Remove the blanking plugs from the pipe and