wheel JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 478 of 3039

Wheels and Tires - Wheel and Tire

Removal and Installation

Removal

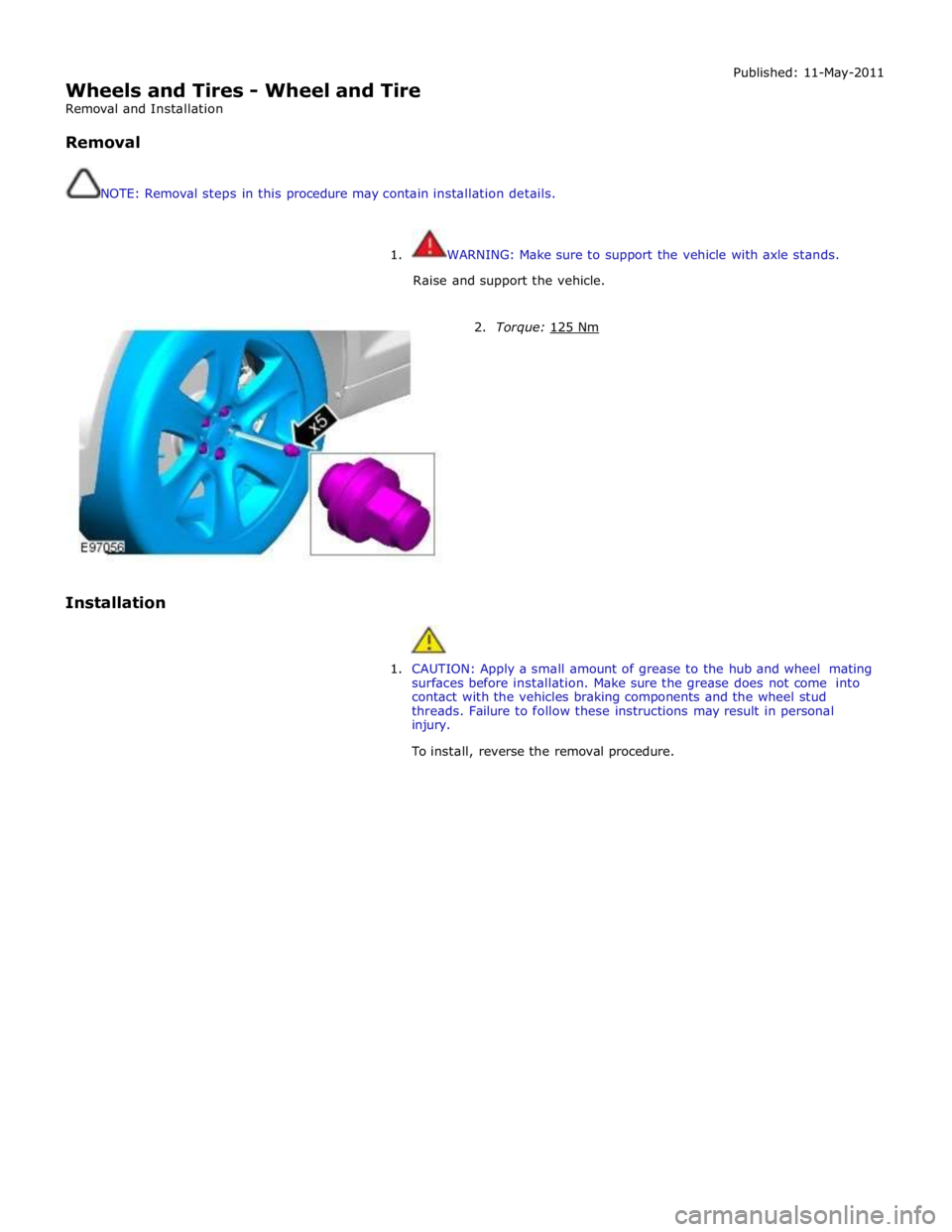

NOTE: Removal steps in this procedure may contain installation details. Published: 11-May-2011

1. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

Installation

2. Torque: 125 Nm

1. CAUTION: Apply a small amount of grease to the hub and wheel mating

surfaces before installation. Make sure the grease does not come into

contact with the vehicles braking components and the wheel stud

threads. Failure to follow these instructions may result in personal

injury.

To install, reverse the removal procedure.

Page 481 of 3039

Published: 11-May-2011

Vehicle Dynamic Suspension - Vehicle Dynamic Suspension V8 5.0L Petrol/V8 S/C 5.0L Petrol - Overview

Description and Operation

OVERVIEW

Adaptive Dynamics - Supercharged Vehicles from 2010MY

The adaptive dynamics system, is an electronically controlled suspension system which constantly adjusts the damping

characteristics of the suspension dampers in reaction to the existing driving conditions. The adaptive dynamics system is

available on specified models.

The system is controlled by an Adaptive Damping Module (ADM), located beneath the right-hand front seat. The module

receives signals from three dedicated vertical accelerometers; two at the front of the vehicle and one at the rear, which,

together with four suspension height sensors, determine the state of the body and wheel motions. In addition to these inputs,

further signals from other vehicle electronic system components to determine vehicle state and driver inputs are monitored by

the adaptive damping module. These combined signals are used by the adaptive damping module to continuously adjust the

damping characteristics of each of the suspension dampers in reaction to the current driving conditions to give the optimum

body control and vehicle ride.

Page 483 of 3039

7 Rear accelerometer 8 Instrument cluster 9 JaguarDrive selector module 10 ABS (anti-lock brake system) module 11 TCM (transmission control module) 12 ECM (engine control module) 13 RH (right-hand) rear damper 14 RH front damper 15 LH (left-hand) front damper 16 LH rear damper 17 LH rear suspension height sensor 18 RH rear suspension height sensor 19 LH front suspension height sensor 20 RH front accelerometer 21 RH front suspension height sensor 22 Adaptive damping module 23 LH front accelerometer

PRINCIPLES OF OPERATION System Operation

The adaptive damping module uses a combination of information from other system modules and data from the accelerometers

and suspension height sensors to measure the vehicle and suspension states and driver inputs. Using this information, the

adaptive damping module applies algorithms to control the dampers for the current driving conditions.

The adaptive damping module receives signals on the high speed CAN bus from the following system components: Brake Pressure - ABS module. Brake Pressure Quality Factor - ABS module. Car Configuration Parameters - AJB. Center Differential Range Actual - ECM. Engine Speed - ECM. Engine Speed Quality Factor - ECM. Engine Torque Flywheel Actual - ECM. Engine Torque Flywheel Actual Quality Factor - ECM. Gear Position Target - TCM. Lateral Acceleration - ABS module. Power Mode (Ignition Signal) - CJB. Power Mode Quality Factor - CJB. Roll Stability Control Mode - ABS module. Steering Wheel Angle - ABS module. Steering Wheel Angle Speed - ABS module. Steering Wheel Angle Status - ABS module. Terrain Mode Requested - JaguarDrive selector.

Torque Converter Slip - TCM. Vehicle Information Parameters HS - AJB Vehicle Speed - ABS module. Vehicle Speed Quality Factor - ABS module. Front Left Wheel Speed - ABS module. Front Left Wheel Speed Quality Factor - ABS module. Front Right Wheel Speed - ABS module. Front Right Wheel Speed Quality Factor - ABS module. Rear Left Wheel Speed - ABS module. Rear Left Wheel Speed Quality Factor - ABS module. Rear Right Wheel Speed Quality Factor - ABS module. Rear Right Wheel Speed - ABS module. The adaptive damping module also outputs information on the high speed CAN bus for use by other systems as follows: Fault Message - instrument cluster.

Terrain Mode Change Status - JaguarDrive selector.

Terrain Mode - JaguarDrive selector.

The adaptive damping module monitors the input signals and operates the damper solenoids. The input signals are used in

control modes and a force required for each damper for that mode is calculated. An arbitration mode monitors the force

requirements from each mode and apportions a force to a damper. The force is converted to the appropriate current and sent to

the damper.

The control modes are as follows:

Page 484 of 3039

each damper to the appropriate level to maintain a flat and level body.

Roll Rate Control – Uses CAN inputs. Predicts vehicle roll rate due to driver steering inputs 100 times a second and increases damping to reduce roll rate.

Pitch Rate Control – Uses CAN inputs. Predicts vehicle pitch rate due to driver throttle and braking inputs 100 times a second and increases damping to reduce pitch rate.

Bump Rebound Control – Uses suspension height sensor and CAN inputs. Monitors the position of the wheel 500 times a second and increases the damping rate as the damper approaches the end of its travel.

Wheel Hop Control – Uses suspension height sensor and CAN inputs. Monitors the position of the wheel 500 times a second and detects when the wheel is at its natural frequency and increases the dampingto reduce vertical wheel

motion.

Under normal road conditions when the vehicle is stationary with the engine running, the dampers are set to the firm condition

to reduce power consumption.

The adaptive damping module receives its power supply via a relay and fuse in the CJB. The relay remains energized for a period of time after the ignition is off. This allows the adaptive damping module to record and store any DTC (diagnostic

trouble code) relating to adaptive dynamics system faults.

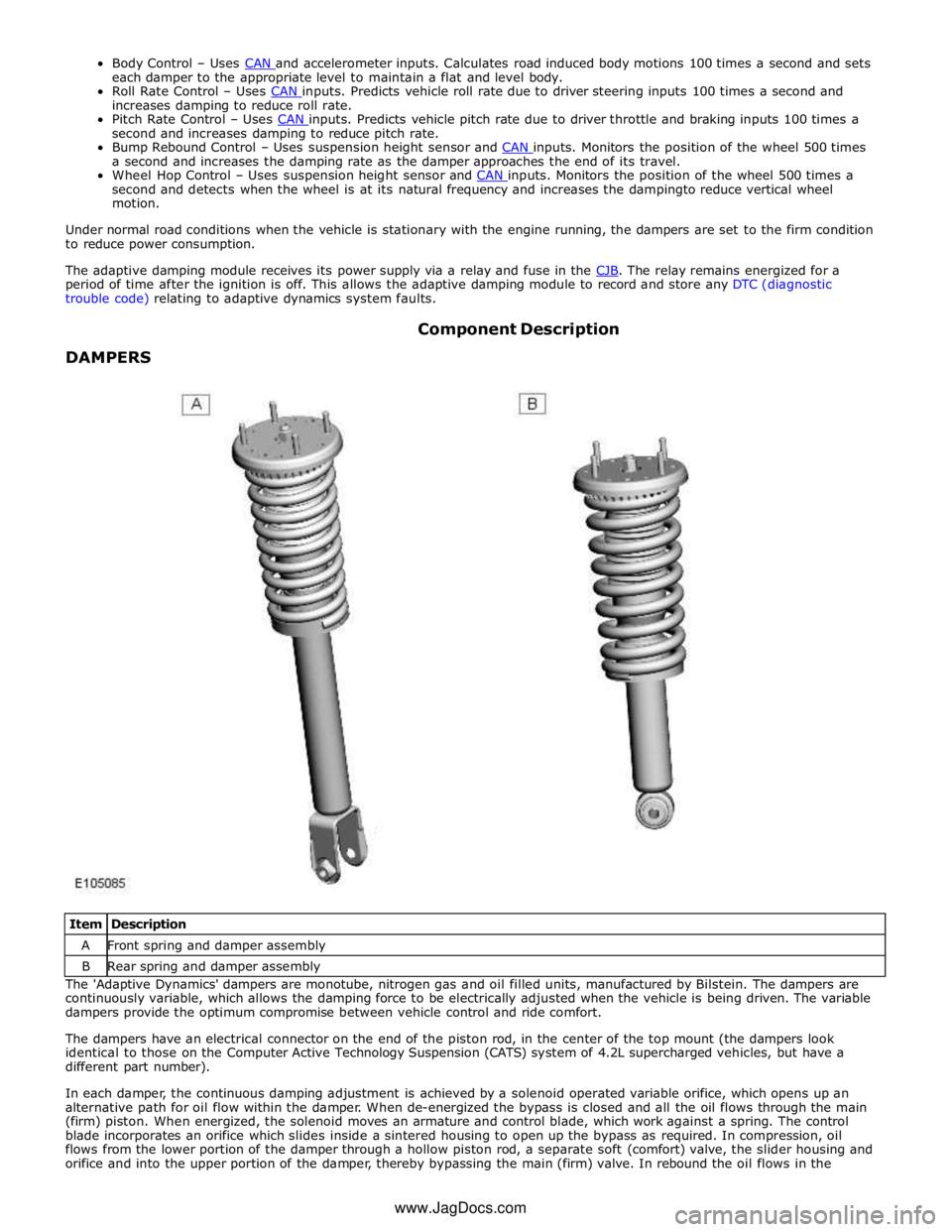

DAMPERS Component Description

Item Description A Front spring and damper assembly B Rear spring and damper assembly The 'Adaptive Dynamics' dampers are monotube, nitrogen gas and oil filled units, manufactured by Bilstein. The dampers are

continuously variable, which allows the damping force to be electrically adjusted when the vehicle is being driven. The variable

dampers provide the optimum compromise between vehicle control and ride comfort.

The dampers have an electrical connector on the end of the piston rod, in the center of the top mount (the dampers look

identical to those on the Computer Active Technology Suspension (CATS) system of 4.2L supercharged vehicles, but have a

different part number).

In each damper, the continuous damping adjustment is achieved by a solenoid operated variable orifice, which opens up an

alternative path for oil flow within the damper. When de-energized the bypass is closed and all the oil flows through the main

(firm) piston. When energized, the solenoid moves an armature and control blade, which work against a spring. The control

blade incorporates an orifice which slides inside a sintered housing to open up the bypass as required. In compression, oil

flows from the lower portion of the damper through a hollow piston rod, a separate soft (comfort) valve, the slider housing and

orifice and into the upper portion of the damper, thereby bypassing the main (firm) valve. In rebound the oil flows in the www.JagDocs.com

Page 486 of 3039

2 Main piston 3 Tube 4 Bypass valve (closed) 5 Piston and rod assembly ACCELEROMETERS

Three accelerometers are used in the adaptive dynamics system. The accelerometers are located as follows:

One each on the rear edge of the radiator support panel.

One in the luggage compartment, in the rear LH corner adjacent to the rear lamp assembly.

The accelerometers measure acceleration in the vertical plane and output a corresponding analogue signal to the adaptive

damping module. The algorithms in the adaptive damping module calculate the heave, pitch and roll motions of the vehicle,

which are used by the module to control road induced body modes.

Each accelerometer is connected to the adaptive damping module via three wires, which supply ground, 5 V supply and signal

return.

The sensing element comprises a single parallel plate capacitor, one plate of which moves relative to the other dependant on

the force (acceleration) applied. This causes the capacitance to change as a function of applied acceleration. This capacitance

is compared with a fixed reference capacitor in a bridge circuit and the signal is processed by means of a dedicated integrated

circuit to generate an output voltage that varies as a function of applied acceleration. The sensors output a signal voltage of

approximately 1 V/g ± 0.05 V/g.

SUSPENSION HEIGHT SENSORS

Four suspension height sensors are used in the adaptive dynamics system, two for the front suspension and two for the rear

suspension. A front suspension height sensor is attached to each side of the front subframes and connected by a sensor arm

and sensor link to the related lower lateral arm of the front suspension. A rear suspension height sensor is attached to each

side of the rear subframe and connected by a sensor arm and sensor link to the related upper control arm of the rear

suspension. On each suspension height sensor, the sensor arm and sensor link convert linear movement of the suspension into

rotary movement of the sensor shaft.

The sensors are also used for the static dynamic headlamp leveling system on vehicles fitted with xenon headlamps.

The suspension height sensors measure suspension displacement at each corner of the vehicle and output a corresponding

analogue signal to the adaptive damping module. The algorithms in the adaptive damping module calculate the position,

velocity and frequency content of the signals and use the results for wheel control.

Each suspension height sensor is connected to the adaptive damping module via three wires, which supply ground, 5 V supply

Page 495 of 3039

Published: 11-May-2011

Ride and Handling Optimization - Ride and Handling Optimization - System

Operation and Component Description

Description and Operation

JAGUARDRIVE CONTROL OPERATION

Engine Management System System Operation

The Engine Management System (EMS) varies the accelerator pedal maps to change the amount of torque per percentage of

pedal travel. The EMS can also change the accelerator pedal response to control the allowed torque change relative to the

speed of pedal travel.

Each driving mode uses a combination of operating parameters for each sub-system. Changing between driving modes initiates

a different set of operating characteristics, which will be noticeable to the driver. The driver will notice differences in engine

response when, for example, the accelerator pedal is held in a constant position and the driving mode is changed from Winter

to Dynamic, the driver will notice the torque and engine speed increase. Similarly, if the mode is changed from Normal or

Dynamic to Winter the driver will notice a reduction in torque and engine speed.

NOTE: The change in torque and engine speed can take approximately 30 seconds and care must be taken not to confuse

the JaguarDrive Control system operation with an EMS fault.

Transmission Control

The TCM (transmission control module) changes the shift maps for the JaguarDrive Control mode selected. This changes the

shift points providing early or late upshifts and downshifts. For example, on slippery surfaces in Winter mode the transmission

will select 2nd gear for starting from a standstill on a flat surface to minimize wheel slip.

Anti-lock Braking System Control

The ABS (anti-lock brake system) module controls several vehicle functions and adjusts the operating parameters of these

functions to optimize the selected JaguarDrive Control mode. Traction control uses different slip/acceleration thresholds to

improve traction and vehicle composure. For example, the system sensitivity is increased on slippery surfaces to reduce wheel

spin.

If TracDSC is selected or DSC is switched off, then subsequently the JaguarDrive Control mode is changed, DSC is automatically

switched back on (or to TracDSC for Dynamic mode).

The stability control uses different threshold values for the selected mode, reducing the requirement for the driver to change

the DSC system mode for optimum performance in various driving scenarios.

Incorrect Mode Usage

Selection of an inappropriate mode is discouraged in the following ways:

The active mode icon is continually displayed in the instrument cluster message center

In any special mode, when the ignition has been in the off position continuously for more than 6 hours, the JaguarDrive

Control system defaults to the special modes off (DSC on).

Selection of an inappropriate mode for the conditions will not endanger the driver or immediately cause damage to the vehicle.

Continued use of an inappropriate mode may reduce the life of some components. The driver may notice a different vehicle

response, with the engine and transmission responses being different than in the special modes off.

Driver Information

The instrument cluster contains a message center, which displays vehicle information to the driver. The message center

contains the JaguarDrive Control mode icons, which display the currently selected mode. If no symbol is displayed, no special

mode is selected and the system is in special modes off.

Any required changes to the subsystems are also passed to the driver in the form of warning illumination in the instrument

cluster or appropriate messages in the message center, DSC off for example.

In Dynamic mode when the transmission is in manual mode, the gear information is displayed in amber when the appropriate

engine speed is reached for optimum sporty change point.

DIAGNOSTICS

JaguarDrive Control relies on the correct functionality of the sub-systems. If one of the sub-systems develops a fault, the

JaguarDrive Control system will not function, even though the fault is not in the JaguarDrive Control system.

The JaguarDrive Selector module and rotary control should only be investigated if there are no apparent faults in any of the

sub-systems. If a fault in a sub-system is subsequently corrected, the JaguarDrive Control system will function normally after

an ignition on and off cycle.

Page 499 of 3039

Driveline System - General Information - Driveline System

Diagnosis and Testing

Principle of Operation Published: 11-May-2011

For a detailed description of driveline operation, refer to the relevant Description and Operation section in the workshop

manual. REFER to:

Driveshaft (205-01 Driveshaft, Description and Operation), Driveshaft (205-01 Driveshaft, Description and Operation), Driveshaft (205-01 Driveshaft, Description and Operation), Rear Drive Axle and Differential (205-02, Description and Operation),

Rear Drive Axle and Differential (205-02, Description and Operation),

Rear Drive Axle and Differential (205-02, Description and Operation),

Rear Drive Halfshafts (205-05 Rear Drive Halfshafts, Description and Operation), Rear Drive Halfshafts (205-05 Rear Drive Halfshafts, Description and Operation), Rear Drive Halfshafts (205-05 Rear Drive Halfshafts, Description and Operation).

Inspection and Verification

CAUTION: Only serviceable items can be renewed or adjusted. Failure to follow this instruction may result in the warranty

of the component being rejected.

Certain driveline trouble symptoms are also common to the engine, transmission, wheel bearings, tires, and other parts of the

vehicle. For this reason, make sure that the cause of the trouble is in the driveline before adjusting, repairing, or installing any

new components. For additional information, refer to Workshop Manual section 100-04 Noise, Vibration and Harshness.

1. Verify the customer concern by carrying out a road test of the vehicle.

2. Visually inspect for obvious signs of mechanical damage and system integrity.

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the concern is not visually evident, verify the symptom and refer to the Symptom Chart.

Identify the Condition

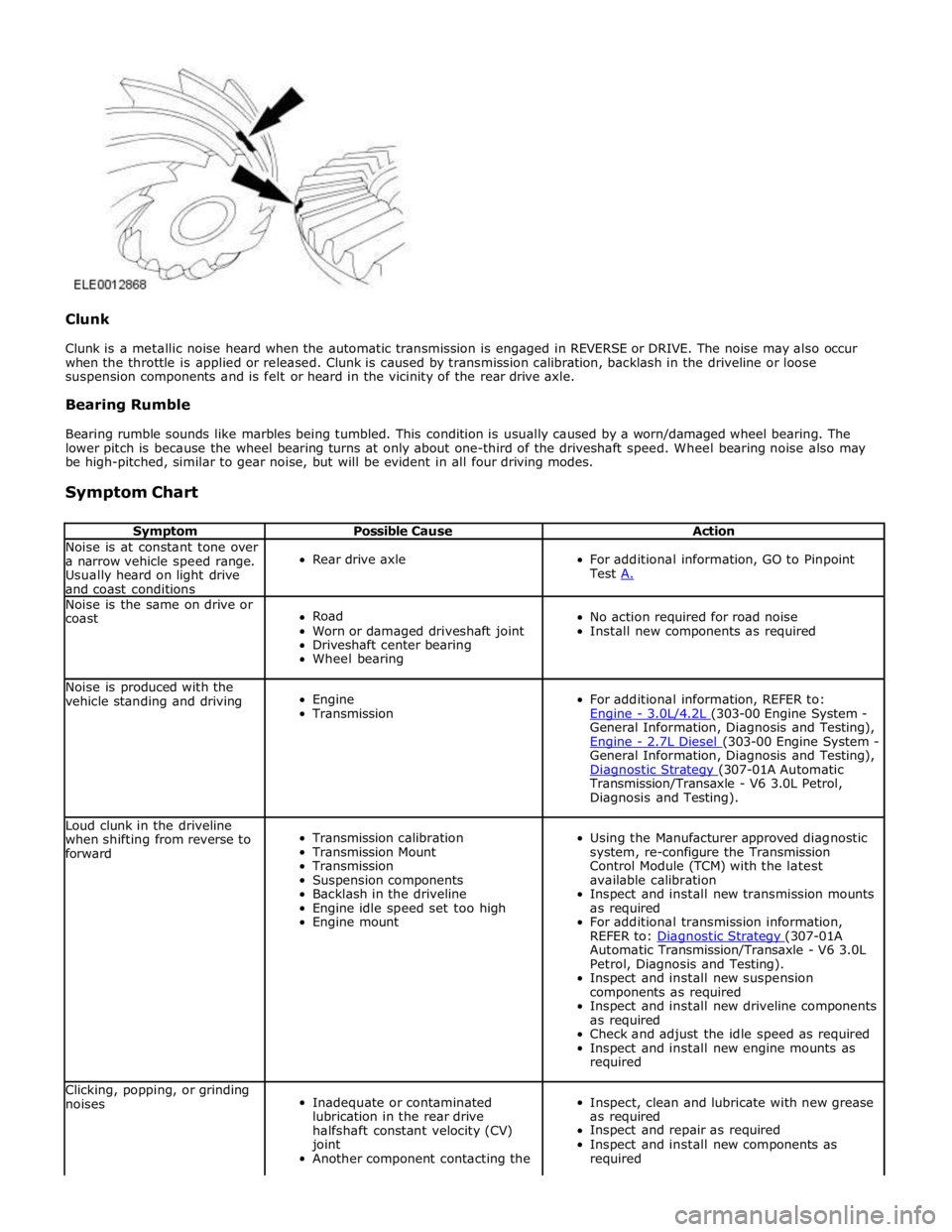

Gear Howl and Whine

Howling or whining of the ring gear and pinion is due to an incorrect gear pattern, gear damage or incorrect bearing preload.

Bearing Whine

Bearing whine is a high-pitched sound similar to a whistle. It is usually caused by worn/damaged pinion bearings, which are

operating at driveshaft speed. Bearing noise occurs at all driving speeds. This distinguishes it from gear whine which is speed

dependent.

As noted, pinion bearings make a high-pitched, whistling noise, usually at all speeds. If however there is only one pinion

bearing that is worn/damaged, the noise may vary in different driving phases.

A wheel bearing noise can be mistaken for a pinion bearing noise.

Chuckle

Chuckle that occurs on the coast driving phase is usually caused by excessive clearance between the differential gear hub and

the differential case bore. www.JagDocs.com

Page 501 of 3039

Clunk

Clunk is a metallic noise heard when the automatic transmission is engaged in REVERSE or DRIVE. The noise may also occur

when the throttle is applied or released. Clunk is caused by transmission calibration, backlash in the driveline or loose

suspension components and is felt or heard in the vicinity of the rear drive axle.

Bearing Rumble

Bearing rumble sounds like marbles being tumbled. This condition is usually caused by a worn/damaged wheel bearing. The

lower pitch is because the wheel bearing turns at only about one-third of the driveshaft speed. Wheel bearing noise also may

be high-pitched, similar to gear noise, but will be evident in all four driving modes.

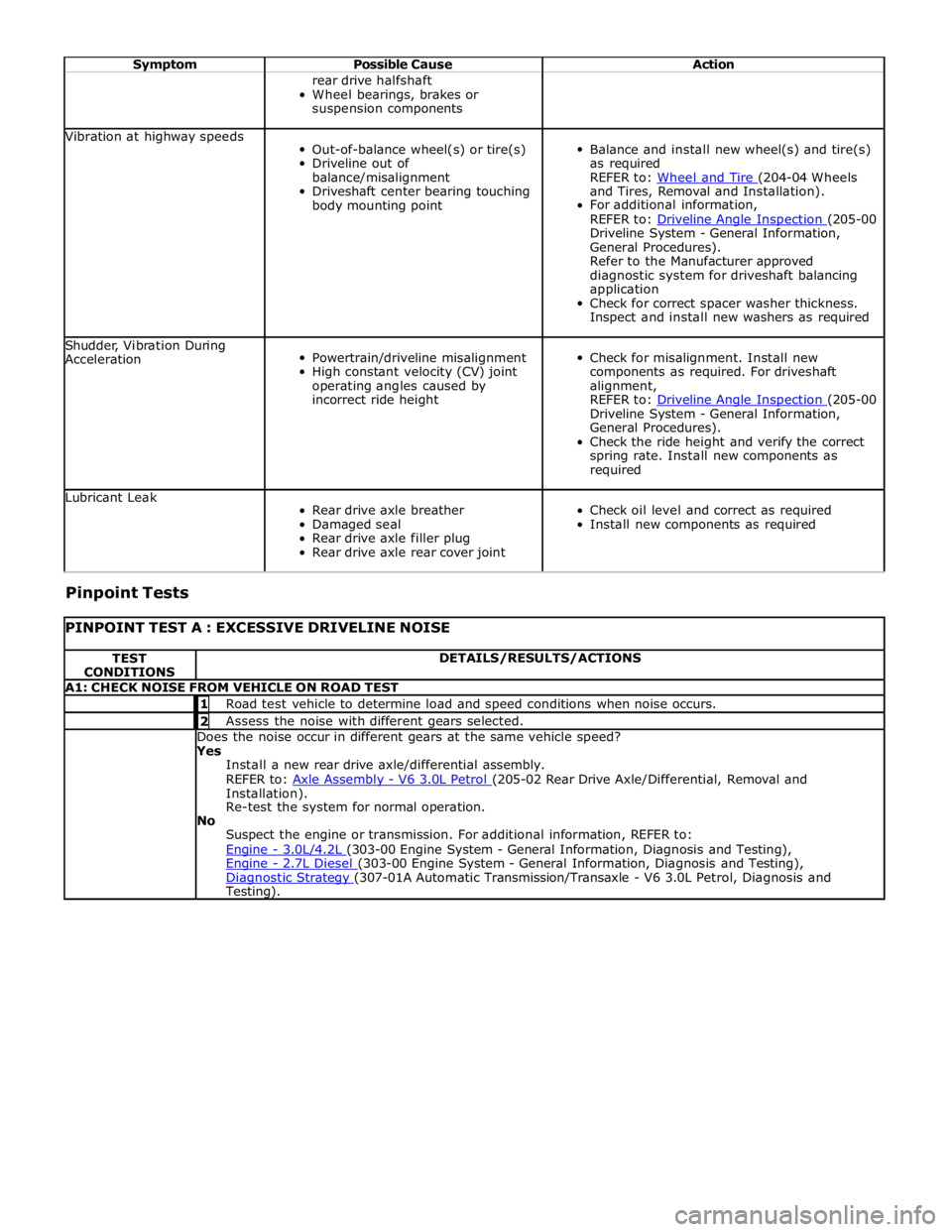

Symptom Chart

Symptom Possible Cause Action Noise is at constant tone over

a narrow vehicle speed range.

Usually heard on light drive

and coast conditions

Rear drive axle

For additional information, GO to Pinpoint

Test A. Noise is the same on drive or

coast

Road

Worn or damaged driveshaft joint

Driveshaft center bearing

Wheel bearing

No action required for road noise

Install new components as required Noise is produced with the

vehicle standing and driving

Engine

Transmission

For additional information, REFER to:

Engine - 3.0L/4.2L (303-00 Engine System - General Information, Diagnosis and Testing),

Engine - 2.7L Diesel (303-00 Engine System - General Information, Diagnosis and Testing),

Diagnostic Strategy (307-01A Automatic Transmission/Transaxle - V6 3.0L Petrol,

Diagnosis and Testing). Loud clunk in the driveline

when shifting from reverse to

forward

Transmission calibration

Transmission Mount

Transmission

Suspension components

Backlash in the driveline

Engine idle speed set too high

Engine mount

Using the Manufacturer approved diagnostic

system, re-configure the Transmission

Control Module (TCM) with the latest

available calibration

Inspect and install new transmission mounts

as required

For additional transmission information,

REFER to: Diagnostic Strategy (307-01A Automatic Transmission/Transaxle - V6 3.0L

Petrol, Diagnosis and Testing).

Inspect and install new suspension

components as required

Inspect and install new driveline components

as required

Check and adjust the idle speed as required

Inspect and install new engine mounts as

required Clicking, popping, or grinding

noises

Inadequate or contaminated

lubrication in the rear drive

halfshaft constant velocity (CV)

joint

Another component contacting the

Inspect, clean and lubricate with new grease

as required

Inspect and repair as required

Inspect and install new components as

required

Page 502 of 3039

Symptom Possible Cause Action rear drive halfshaft

Wheel bearings, brakes or

suspension components Vibration at highway speeds

Out-of-balance wheel(s) or tire(s)

Driveline out of

balance/misalignment

Driveshaft center bearing touching

body mounting point

Balance and install new wheel(s) and tire(s)

as required

REFER to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

For additional information,

REFER to: Driveline Angle Inspection (205-00 Driveline System - General Information,

General Procedures).

Refer to the Manufacturer approved

diagnostic system for driveshaft balancing

application

Check for correct spacer washer thickness.

Inspect and install new washers as required Shudder, Vibration During

Acceleration

Powertrain/driveline misalignment

High constant velocity (CV) joint

operating angles caused by

incorrect ride height

Check for misalignment. Install new

components as required. For driveshaft

alignment,

REFER to: Driveline Angle Inspection (205-00 Driveline System - General Information,

General Procedures).

Check the ride height and verify the correct

spring rate. Install new components as

required Lubricant Leak

Rear drive axle breather

Damaged seal

Rear drive axle filler plug

Rear drive axle rear cover joint

Check oil level and correct as required

Install new components as required Pinpoint Tests

PINPOINT TEST A : EXCESSIVE DRIVELINE NOISE TEST

CONDITIONS DETAILS/RESULTS/ACTIONS A1: CHECK NOISE FROM VEHICLE ON ROAD TEST 1 Road test vehicle to determine load and speed conditions when noise occurs. 2 Assess the noise with different gears selected. Does the noise occur in different gears at the same vehicle speed? Yes

Install a new rear drive axle/differential assembly.

REFER to: Axle Assembly - V6 3.0L Petrol (205-02 Rear Drive Axle/Differential, Removal and Installation).

Re-test the system for normal operation.

No

Suspect the engine or transmission. For additional information, REFER to:

Engine - 3.0L/4.2L (303-00 Engine System - General Information, Diagnosis and Testing), Engine - 2.7L Diesel (303-00 Engine System - General Information, Diagnosis and Testing), Diagnostic Strategy (307-01A Automatic Transmission/Transaxle - V6 3.0L Petrol, Diagnosis and Testing).

Page 532 of 3039

6 Oil temperature sensor 7 High speed CAN from suspension control module 8 CJB (central junction box)

System Operation

ELECTRONIC

DIFFERENTIAL

-

5.0L

SUPERCHARGER

VEHICLES

FROM

2010MY

The

multi-plate

clutch

prevents

excessive

differential

slip and

therefore

maximizes

the

traction

performance

of

the

vehicle.

This

is

fundamentally

different

from

'braked'

traction

control

systems,

which

can

only

counteract

differential

slip when it

occurs.

A

certain

amount

of

differential

slip is

required

to

allow

the

vehicle

to

turn

corners

and

to

remain

stable

under

control

of

the

ABS

(anti-lock

brake

system).

The

system

is

completely

automatic and

does

not

require

any

special

driver

input.

The

multi-plate

clutch

actively

controls

the

torque

flow

through

the

differential

and

optimizes

the

torque

distribution in

the

driveline.

The

clutch

biases

the

torque

from

the

differential

to

the

wheel

with the

higher

grip

and prevents

the

wheel

with the

lower

grip

from

spinning.

www.JagDocs.com