engine JAGUAR XJ6 1994 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 2 of 521

Introduction

FOREWORD

This Vehicle Service Manual (VSM) is Dart

-

of a

set of service literature which covers -. diagnosis and rectification of problems associated with all areas of the X300 family of vehicles.

It is designed to be read in conjunction with other manuals, namely the various Unit Service Manuals (USM) (as

applicable to the particular vehicle under diagnosis/ repair) and the X300 Electrical Diagnostic Manual (EDM); see list

below.

It should be noted that its scope is limited to those areas that are unique to the family, e.g. Remove & Refit procedures

for Body Components, Engine, Transmission etcetera, Fuel, Emissions & Engine Management systems, and so on.

Fault Diagnosis and repair procedures (together

with Technical Data, Recommended Lubricants, Capacities etcetera) for major assemblies such as engines, automatic and manual transmissions, are covered in the separate Unit Service

Manuals.

The Unit Service Manuals are notvehicle

-specific, but are designed to be read in conjunction with this VSM, and, where so equipped, with other Jaguar Vehicle Service Manuals for new models launched subsequent to the X300 family.

The X300 Electrical Diagnostic Manual is the final part of the 'set' of service documentation. This manual

is

family-specific, and is designed to aid theTechnician to isolate electrical faults and to correct them. It covers all aspects

of electrical fault diagnosis, including:

OBD

II Codes and emission control system related fault diagnosis / rectification.

Circuit Diagrams

Component (Relays, fuse boxes, control modules etcetera) Location

/ Harness Diagrams I Ground Locations

Connector Locations.

Service Manuals Required

The Manuals required to service the X300 family of vehicles are as follows:

X300 Vehicle Service Manual

X300 Electrical Diagnostic Manual

Unit Service Manuals:

AJ16 Engine Service Manual

VI2 Engine Service Manual ZF AutomaticTransmissions Service Manual (ZF supplies transmissions for 3.2 liter and 4.0 liter normally aspirated

versions) Powertrain Automatic Transmissions Service Manual (The Powertrain name succeeds that of Hydra

-Matic.

Powertrain are suppliers of the 4L 80 E transmission as fitted to 4.0 litre supercharged and 6.0 litre versions)

Each

of the X3Okpecific manuals is divided into Sections which adopt the same title and number where relevant, i.e. Section 5.1 of both the VSM and the EDM cover Fuel, Emission Control & Engine Management System (AJ16). An

over

-all contents list showing each section title and number together with its page-edge locator is given in this section

and in the introduction to the EDM.

The VSM (not applicable to the EDM) also contains Appendices which cover specialized areas such as the current

vehicle specification, routine maintenance schedule etc. These are carried at the rear of this Manual, and have their

own contents page within this section.

INDEX

rapid location of information. The entries are set out as per the following example: @ This manual carries a comprehensive index at the rear, which is designed to save the Technician time by permitting

CLIMATE CONTROL SYSTEMS. Section 14.

See also Electrical Diagnostic Manual

Clutch

Description: Sect. 7.7 - 10

Fault diagnosis: Sect 7.1 - 11

In the example the heading in upper case lettering is to a section title, and it refers to the section number, 14, and also to the EDM as electrical diagnostic information will be found in that manual's section 14. The entry for clutch tells us that the relevant description will be found on page 10 of Section 7.1 of this manual, and

that fault diagnosis procedures start on page 11. In this case there is no reference to the EDM as electrical diagnosis does not apply to this area.

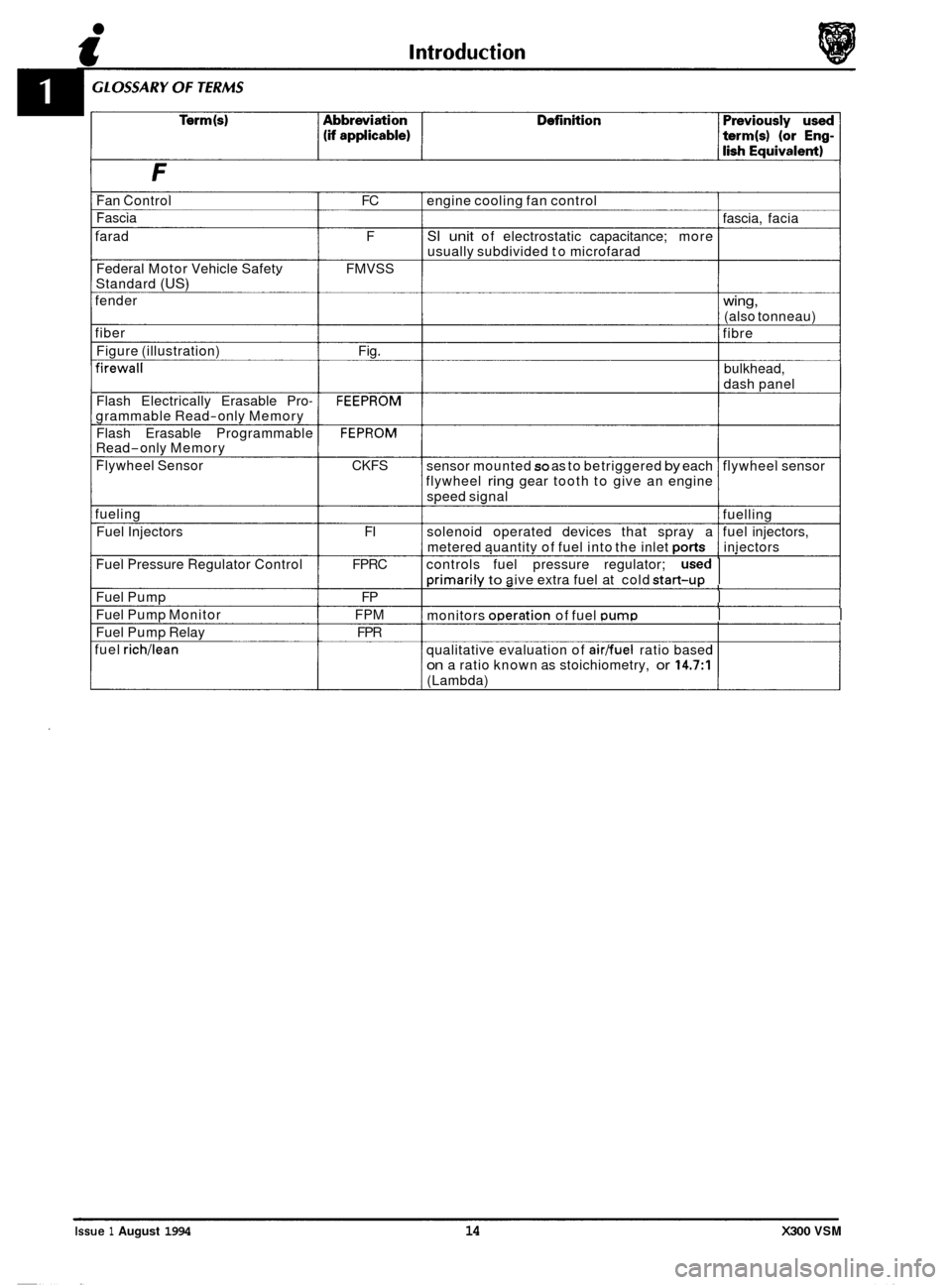

GLOSSARY OF TERMS

This Section contains a Glossary of general and emissions-related terminology (commencing on page 5).

X300 VSM 1 Issue 1 August 1994

Page 4 of 521

e-

@

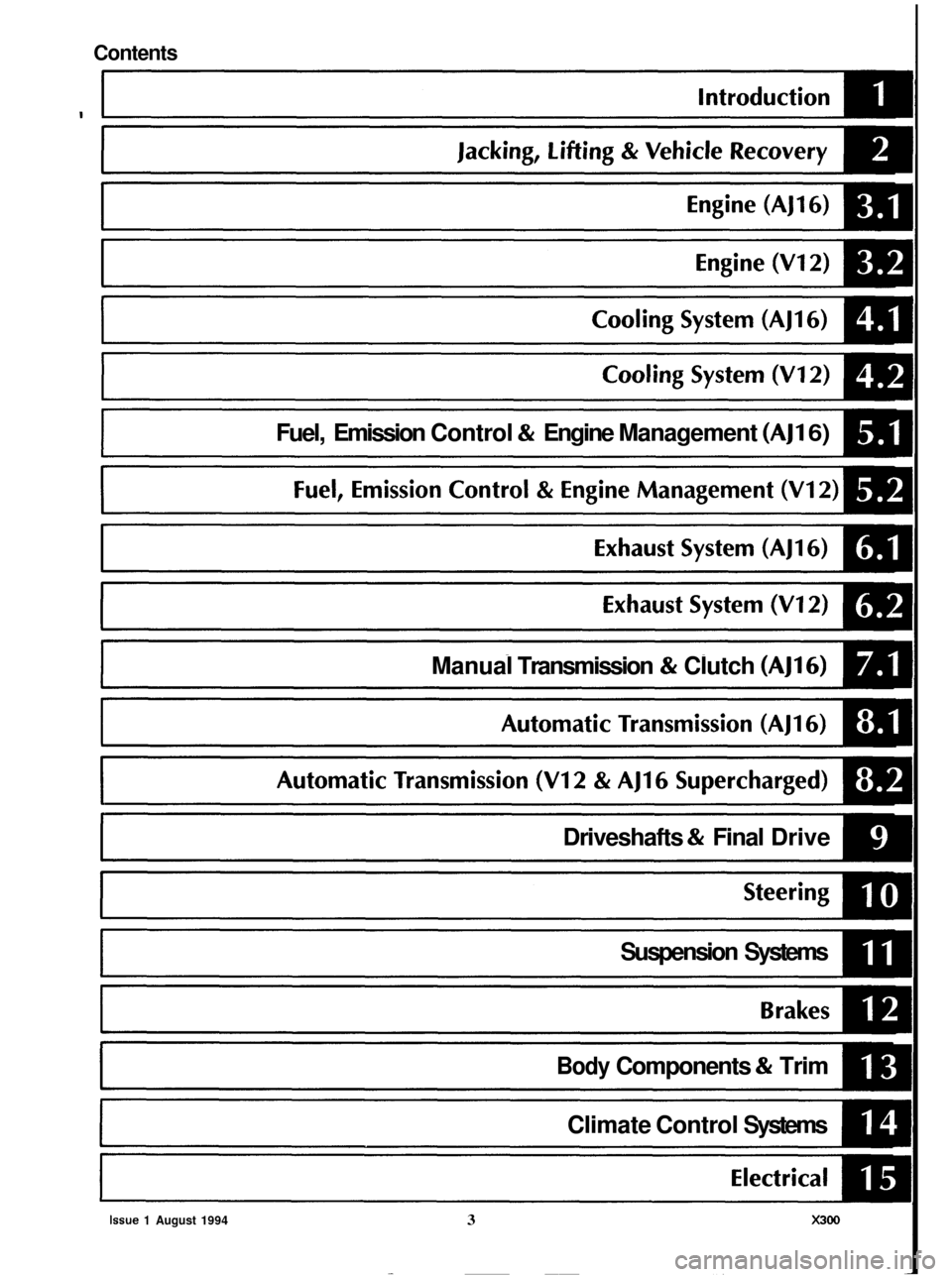

Contents

Fuel, Emission Control & Engine Management (AJI 6)

Manual Transmission & Clutch (AJl6)

Driveshafts & Final Drive

Suspension Systems

Body Components & Trim

Climate Control Systems

Issue 1 August 1994 3 x300

- - ~~

Page 8 of 521

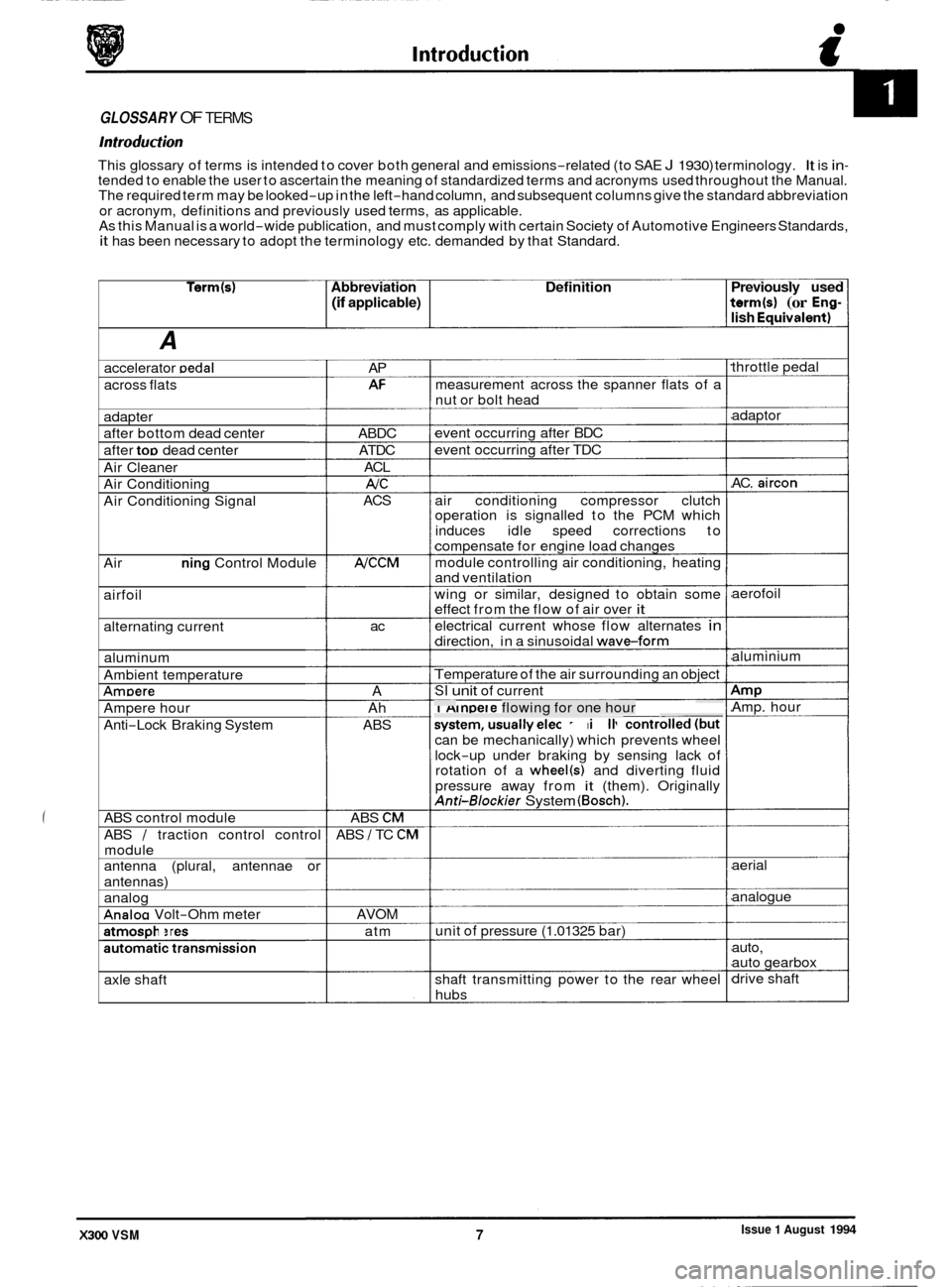

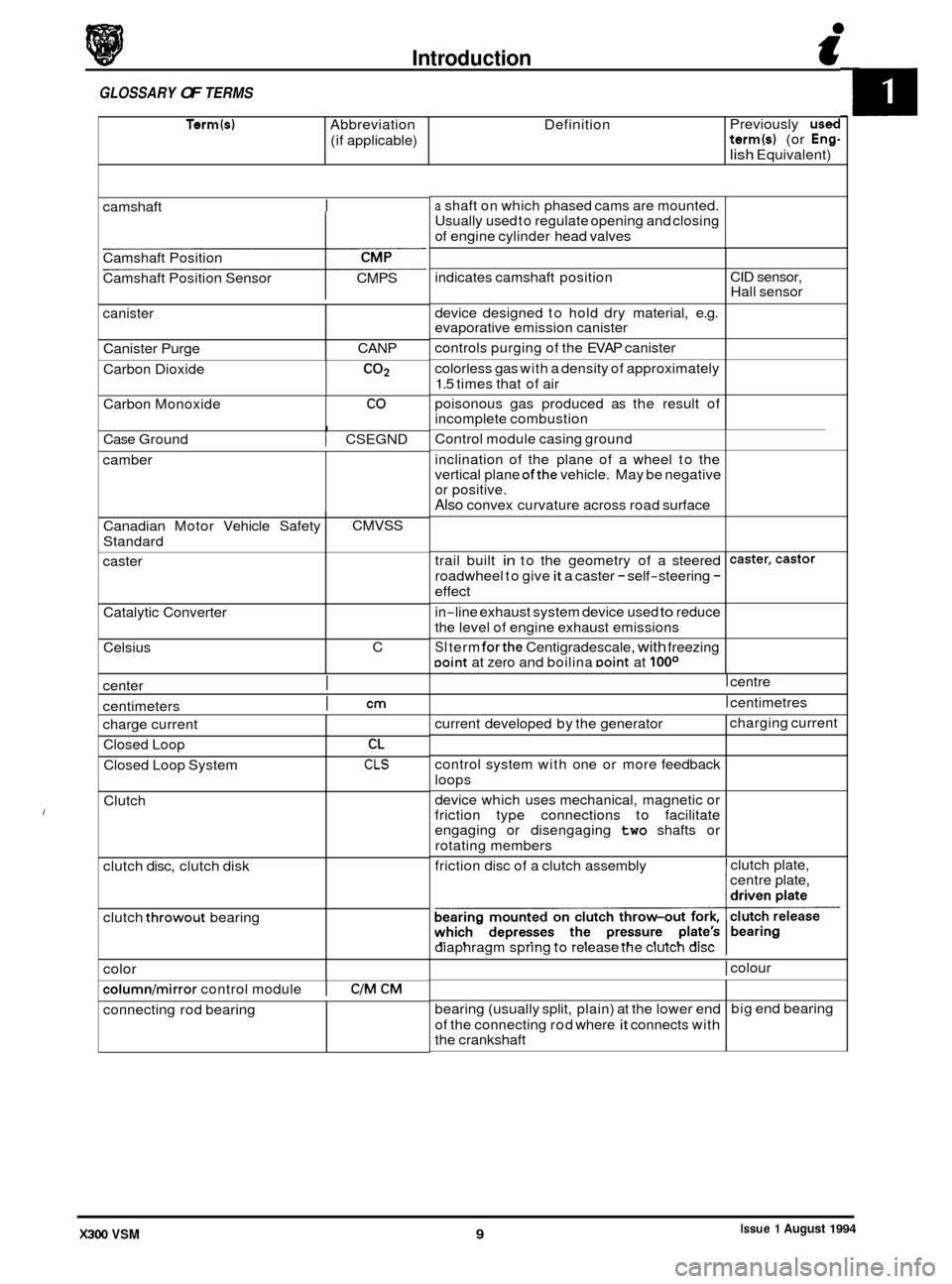

GLOSSARY OF TERMS

Introduction

This glossary of terms is intended to cover both general and emissions-related (to SAE J 1930) terminology. It is in- tended to enable the user to ascertain the meaning of standardized terms and acronyms used throughout the Manual.

The required term may be looked-up in the left-hand column, and subsequent columns give the standard abbreviation

or acronym, definitions and previously used terms, as applicable.

As this Manual is a world

-wide publication, and must comply with certain Society of Automotive Engineers Standards, it has been necessary to adopt the terminology etc. demanded by that Standard.

Term(s) Abbreviation Definition Previously used

(if applicable) term(s) (or Eng- lish Eauivalent)

A

throttle pedal

accelerator Dedal AP

AI= measurement across the spanner flats of a

across flats

nut or bolt head

adaptor

AC.

aircon

adapter

after bottom dead center

after

too dead center event

occurring after BDC

event occurring after TDC

ABDC

ATDC ACL

AIC

ACS

Air

Cleaner

Air Conditioning

Air Conditioning Signal air conditioning

compressor clutch

operation is signalled to the PCM which

induces idle speed corrections to

compensate for engine load changes

module controlling air conditioning, heating

and ventilation

wing or similar, designed to obtain some

effect from the flow of air over

it

electrical current whose flow alternates in

direction, in a sinusoidal waveform

NCCM Air Conditioning Control Module

airfoil aerofoil

alternating current ac

aluminium

aluminum

Ambient temperature Temperature

of the air surrounding an object

SI unit of current AmDere A Amp Amp. hour -~ 1 Ampere flowing for one hour

system, usually ele&o&ally controlled (but ~- __. .. . Ampere hour

Anti

-Lock Braking System Ah

ABS can be mechanically) which prevents wheel

lock

-up under braking by sensing lack of

rotation of a wheel(s) and diverting fluid

pressure away from

it (them). Originally Anti-Blockier System (Bosch).

ABS control module

ABS

/ traction control control

module ABS

CM

ABS I TC CM

aerial

antenna (plural, antennae or

antennas)

analog

Analoa Volt-Ohm meter analogue

AVOM unit of pressure

(1.01325 bar)

atmospheres

automatic transmission atm

auto,

auto gearbox

drive shaft

axle shaft shaft

transmitting power to the rear wheel

hubs

.-

Issue 1 August 1994 X300 VSM 7

Page 9 of 521

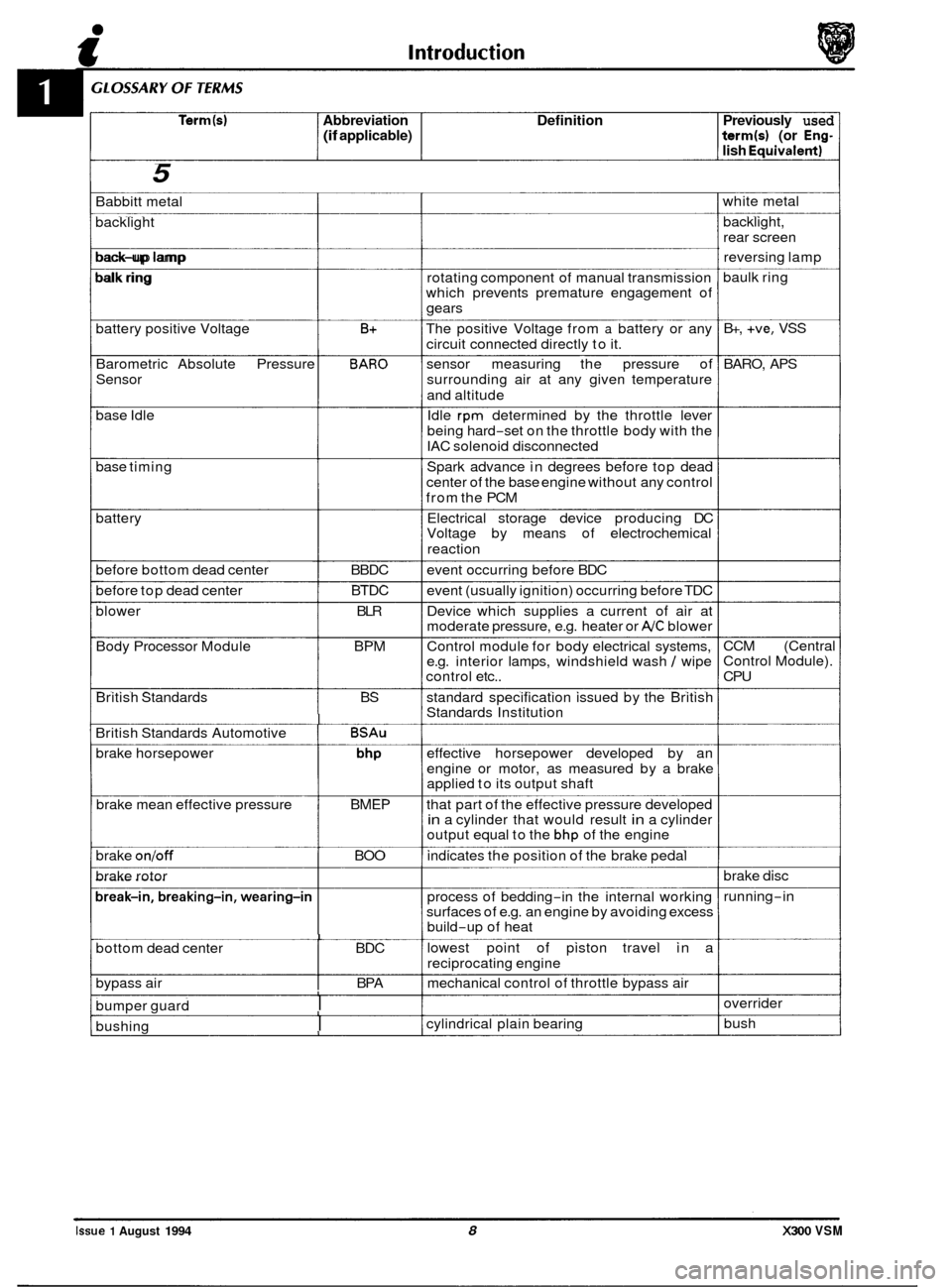

Terrn(s1 Abbreviation Definition Previously used (if applicable) term(s) (or Eng- lish Eauivalentl

5

Babbitt metal

backlight

back

-up lamp

balk ring

t

battery positive Voltage B+

Barometric Absolute Pressure BARO

Sensor

base Idle

base timing

battery

before bottom dead center BBDC

before top dead center BTDC

blower BLR

Body Processor Module BPM

British Standards BS

I British Standards Automotive BSAu

brake horsepower

brake mean effective pressure BMEP

brake

ontoff BOO

brake rotor

I bottom dead center BDC

bypass air BPA

bumper guard

I

bushing I

rotating component of manual transmission

which prevents premature engagement of

gears

The positive Voltage from

a battery or any

circuit connected directly to it.

sensor measuring the pressure of

surrounding air at any given temperature

and altitude

Idle

rpm determined by the throttle lever

being hard

-set on the throttle body with the

IAC solenoid disconnected

Spark advance in degrees before top dead

center of the base engine without any control

from the PCM

Electrical storage device producing DC

Voltage by means of electrochemical

reaction

event occurring before BDC

event (usually ignition) occurring before TDC

Device which supplies a current of air at

moderate pressure, e.g. heater or

AJC blower

Control module for body electrical systems,

e.g. interior lamps, windshield wash wipe

control etc..

standard specification issued by the British

Standards Institution

effective horsepower developed by an

engine or motor, as measured by a brake

applied to its output shaft

that part of the effective pressure developed

in a cylinder that would result in a cylinder

output equal to the bhp of the engine

indicates the position of the brake pedal

process of bedding

-in the internal working

surfaces of e.g. an engine by avoiding excess

build

-up of heat

lowest point of piston travel in a

reciprocating engine

mechanical control of throttle bypass air

cylindrical plain bearing white

metal

backlight,

rear screen reversing lamp

baulk ring

B+,

+ve, VSS

BARO, APS

CCM (Central

Control Module).

CPU

brake disc

running

-in

overrider bush

Issue 1 August 1994 8 X300 VSM

Page 10 of 521

Introduction i

Term(s) Abbreviation Definition

(if applicable)

GLOSSARY OF TERMS

Previously used term(s) (or Eng-

lish Equivalent)

indicates camshaft position

device designed to hold dry material, e.g.

evaporative emission canister

controls purging of the EVAP canister

colorless gas with a density of approximately

1.5 times that of air

poisonous gas produced as the result of

incomplete combustion

camshaft

I

CID

sensor,

Hall sensor

Camshaft

Position

Camshaft Position Sensor CMPS

canister

Canister Purge CANP

Carbon Dioxide

CO2

I Case Ground I CSEGND

Carbon

Monoxide

camber

CO

Canadian Motor Vehicle Safety

Standard

caster

Catalytic Converter

Celsius

center

I

CMVSS

C

centimeters

I cm

trail built in to the geometry of a steered

roadwheel to give

it a caster - self-steering -

effect

caster,castor

color

columnlmirror control module I C/M CM

charge current

Closed Loop

Closed Loop System

Clutch

clutch disc, clutch disk

clutch

throwout bearing

connecting rod bearing

CL

CLS

a shaft on which phased cams are mounted.

Usually used to regulate opening and closing

of engine cylinder head valves

current developed by the generator

control system with one or more feedback

loops

device which uses mechanical, magnetic or

friction type connections to facilitate

engaging or disengaging

two shafts or

rotating members charging

current

Control

module casing ground

inclination of the plane of a wheel to the

vertical plane

ofthe vehicle. May be negative

or positive.

Also convex curvature across road surface

bearing (usually split, plain) at the lower end

of the connecting rod where

it connects with

the crankshaft big

end bearing

in

-line exhaust

system device used to reduce

the level of engine exhaust emissions

SI term forthe Centigradescale, with freezing Doint at zero and boilina Doint at looo

I centre

I centimetres

friction disc of a clutch assembly clutch

plate,

centre plate,

diaphragm spring to release the clutch disc

I colour

Issue 1 August 1994 X300 VSM 9

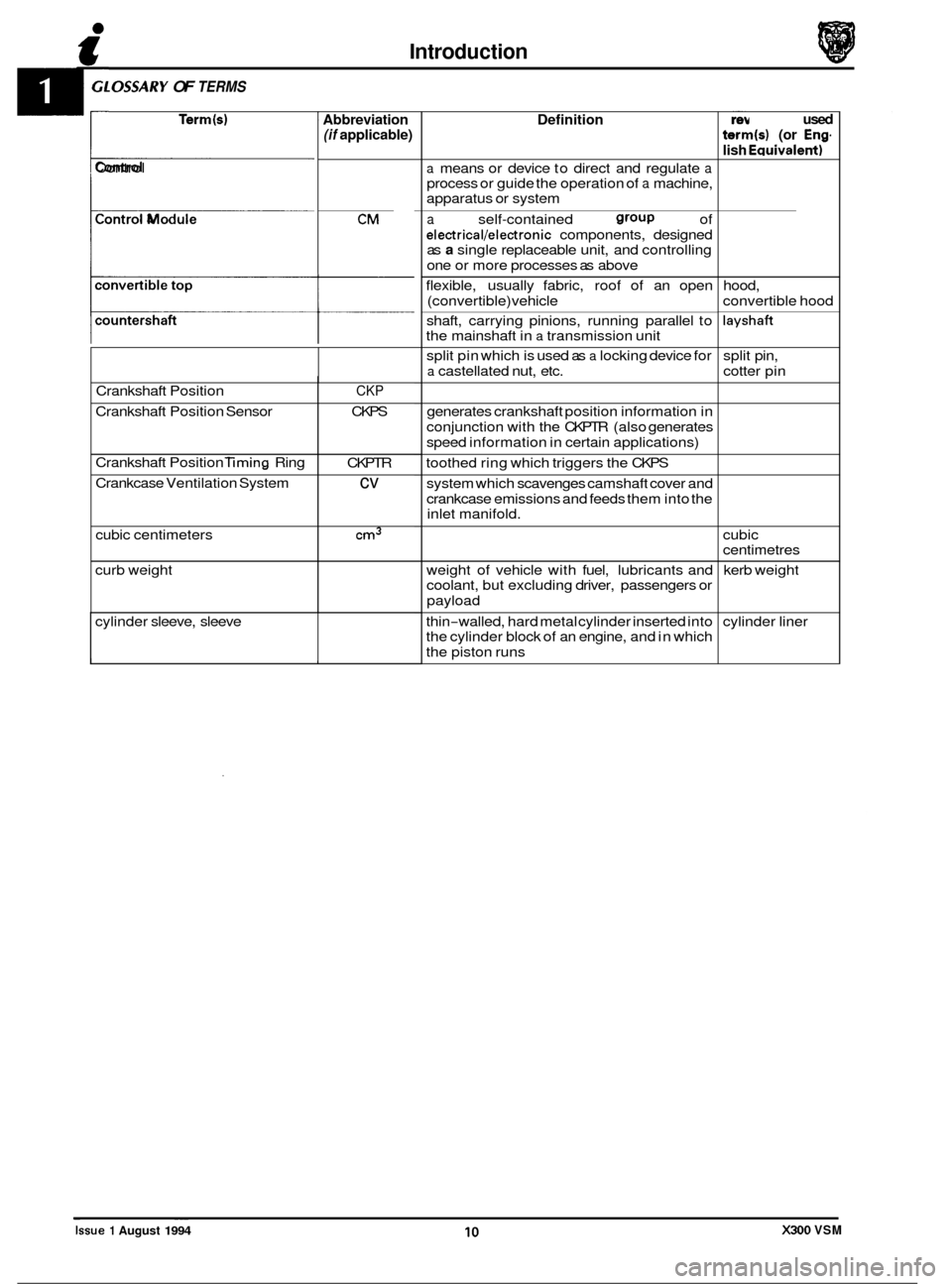

Page 11 of 521

Introduction

.OSSARY OF TERMS

Term(s)

Crankshaft Position

Crankshaft Position Sensor

Crankshaft Position

liming Ring

Crankcase Ventilation System

cubic centimeters

curb weight

4 Control

CKP

CKPS

CKPTR

cv

cm3

Control Module

P

T Abbreviation (if applicable)

CM

cylinder sleeve, sleeve

I I

Definition

a means or device to direct and regulate a process or guide the operation of a machine,

apparatus or system

a self-contained group of

electrical/electronic components, designed

as a single replaceable unit, and controlling

one or more processes as above

flexible, usually fabric, roof of an open

(convertible) vehicle

shaft, carrying pinions, running parallel to

the mainshaft in

a transmission unit

split pin which is used as

a locking device for

a castellated nut, etc.

generates crankshaft position information in

conjunction with the CKPTR (also generates

speed information in certain applications)

toothed ring which triggers the CKPS

system which scavenges camshaft cover and

crankcase emissions and feeds them into the

inlet manifold.

weight of vehicle with fuel, lubricants and

coolant, but excluding driver, passengers or

payload

thin

-walled, hard metal cylinder inserted into

the cylinder block of an engine, and in which

the piston runs

Previously used

term(s) (or Eng.

lish Eauivalent)

hood,

convertible hood

layshaft

split pin,

cotter pin

cubic

centimetres kerb weight

cylinder liner ~ ~~

Issue 1 August 1994 10 X300 VSM

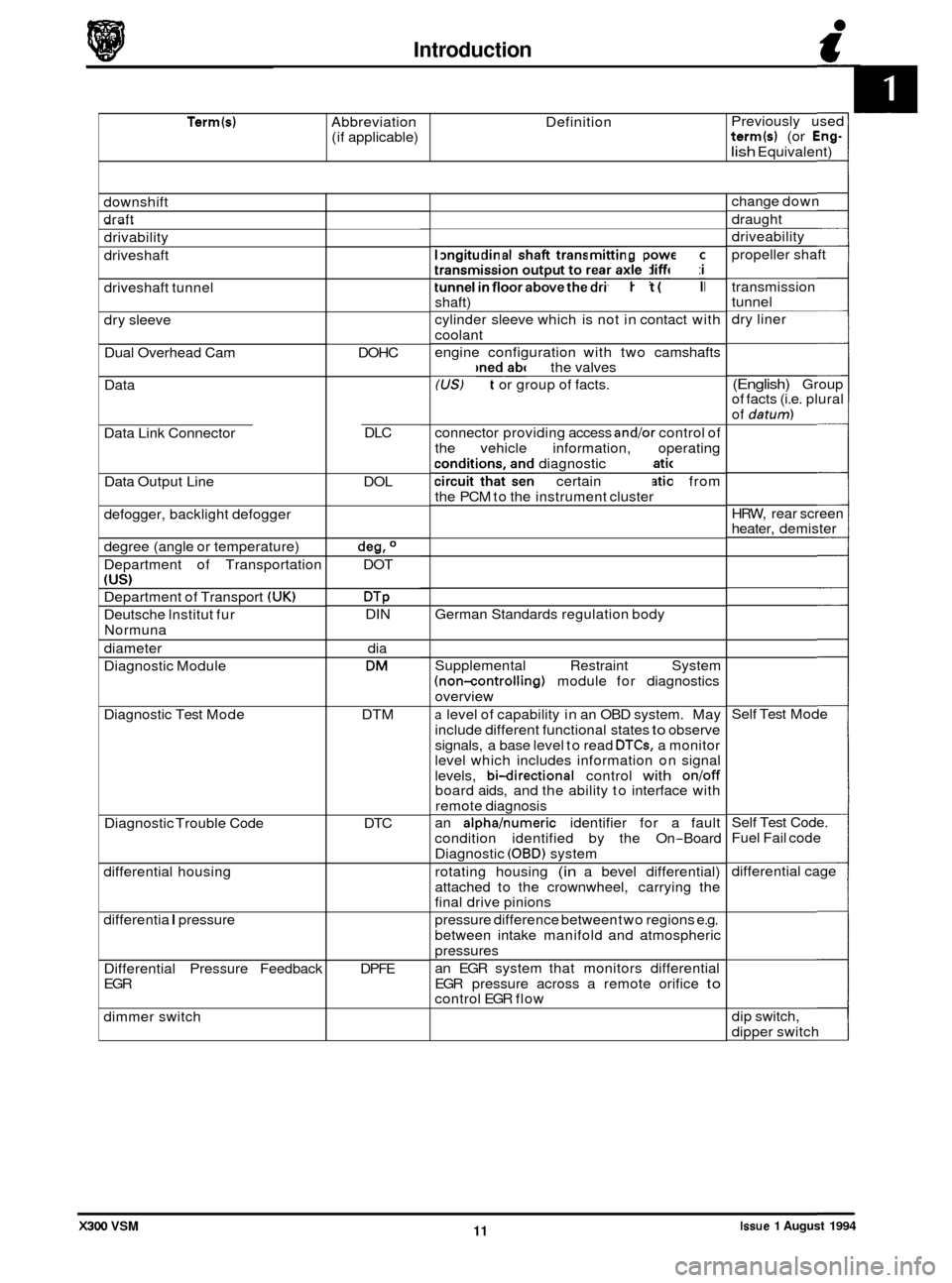

Page 12 of 521

Introduction

Term(s) Abbreviation Definition

(if applicable) Previously

used term(s) (or Eng-

lish Equivalent)

downshift

draft _.

drivability

driveshaft

driveshaft tunnel

dry sleeve

Dual Overhead Cam

Data

Data Link Connector

Data Output Line

defogger, backlight defogger

degree (angle or temperature)

Department of Transportation

(US)

Department of Transport (UK)

Deutsche lnstitut fur

Normuna

diameter

Diagnostic Module

Diagnostic Test Mode

Diagnostic Trouble Code

differential housing

differentia

I pressure

Differential Pressure Feedback

EGR

dimmer switch DOHC

DLC

DOL

deg, O

DOT

DTP DIN dia

DM

DTM

DTC

DPFE longitudinal

shaft transmitting power from

transmission output to rear axle differential

tunnel

in floor above the driveshaft (propeller

shaft)

cylinder sleeve which is not in contact with

coolant

engine configuration with two camshafts

positioned above the valves

(US) Fact or group of facts.

connector providing access

andlor control of

the vehicle information, operating

conditions, and diagnostic information

circuit that sends certain information from

the PCM to the instrument cluster

German Standards regulation body

Supplemental Restraint System

(non-controlling) module for diagnostics

overview

a level of capability in an OBD system. May

include different functional states

to observe

signals, a base level to read

DTCs, a monitor

level which includes information on signal

levels,

bi-directional control with onloff board aids, and the ability to interface with

remote diagnosis

an

alphahumeric identifier for a fault

condition identified by the On

-Board

Diagnostic

(OBD) system

rotating housing

(in a bevel differential)

attached to the crownwheel, carrying the

final drive pinions

pressure difference between two regions e.g.

between intake manifold and atmospheric

pressures

an EGR system that monitors differential

EGR pressure across a remote orifice

to control EGR flow change

down

draught

driveability

propeller shaft

transmission

tunnel

dry liner

(English) Group

of facts (i.e. plural

of

datum)

HRW, rear screen

heater, demister

Self Test Mode

Self Test Code.

Fuel Fail code

differential cage

dip switch,

dipper switch

Issue 1 August 1994 11 X300 VSM

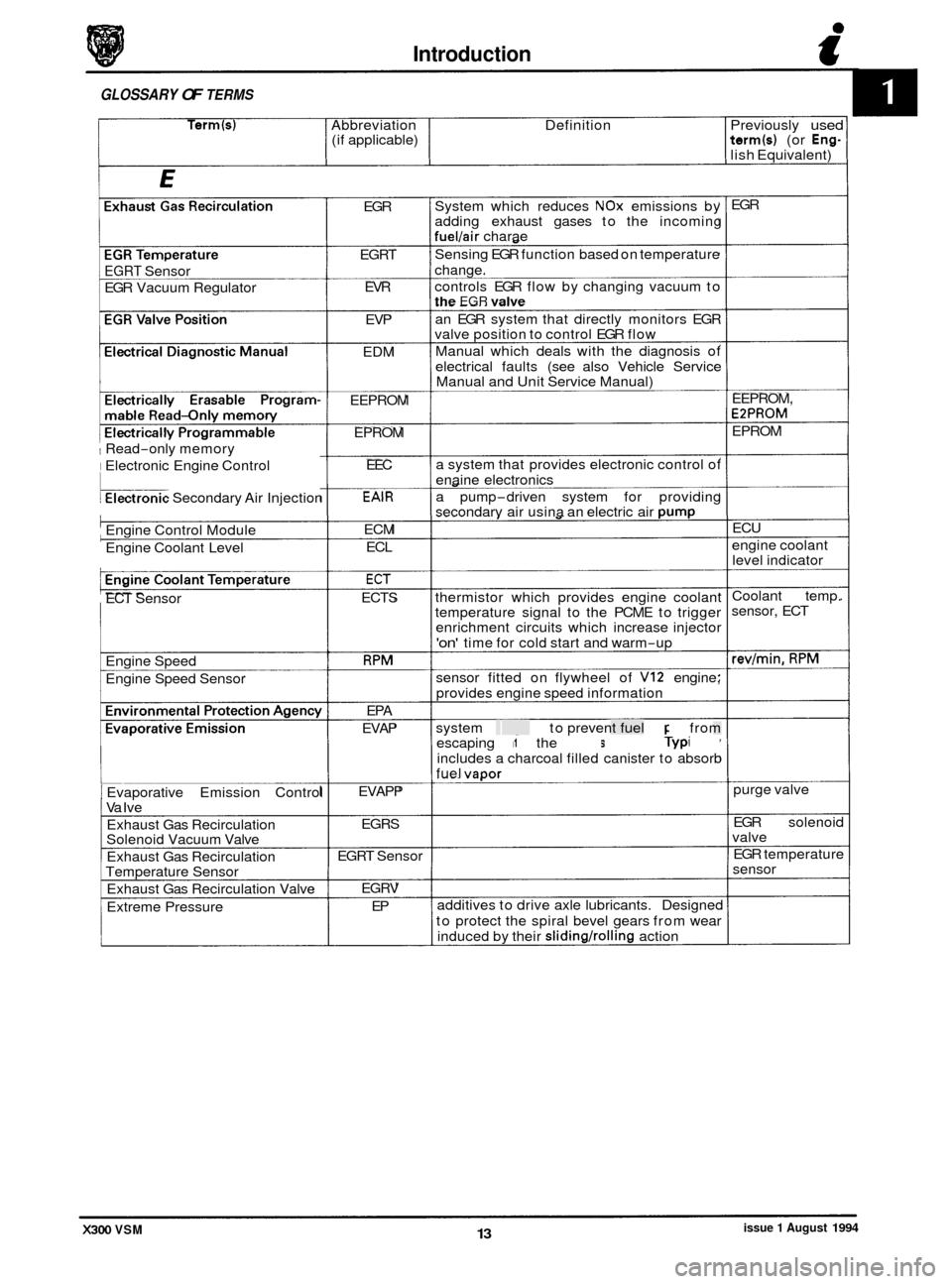

Page 14 of 521

Introduction c

GLOSSARY OF TERMS

Term(s) Abbreviation Definition Previously used (if applicable) term(s) (or Eng- lish Equivalent)

0

EGRT Sensor

EGR Vacuum Regulator

1 Read-only memory

I Electronic Engine Control

kronic Secondary Air Injection

Engine Control Module

Engine Coolant Level

ECT Sensor

Engine Speed

Engine Speed Sensor

1 Evaporative Emission Control

Va Ive

Exhaust Gas Recirculation

Solenoid Vacuum Valve

Exhaust Gas Recirculation

Temperature Sensor

Exhaust Gas Recirculation Valve

Extreme Pressure EGR

EGRT EVR

EVP

EDM

EEPROM EPROM EEC

EAlR

ECM ECL

ECT

ECTS

RPM

EPA

EVAP

EVAPP EGRS

EGRT Sensor

EGRV EP System

which reduces

NOx emissions by

adding exhaust gases to the incoming

fuel/air charae

Sensing EGR function based on temperature

change.

controls EGR flow by changing vacuum to

the EGR valve

an EGR system that directly monitors EGR

valve position to control EGR flow

Manual which deals with the diagnosis of

electrical faults (see also Vehicle Service

Manual and Unit Service Manual)

a system that provides electronic control of

enaine electronics

a pump

-driven system for providing

secondarv air usina an electric air Dump

thermistor which provides engine coolant

temperature signal to the PCME to trigger

enrichment circuits which increase injector

'on' time for cold start and warm-up

sensor fitted on flywheel of

VI2 engine;

provides engine speed information

system designed to prevent fuel vapor from

escaping into the atmosphere. Typically

includes a charcoal filled canister to absorb

fuel

vaoor

additives to drive axle lubricants. Designed

to protect the spiral bevel gears from wear

induced by their

slidingholling action EGR

EEPROM,

EPPROM

EPROM ECU

engine coolant level indicator

Coolant temp.

sensor, ECT

revlmin. RPM

purge valve

EGR solenoid

valve

EGR temperature

sensor

X300 VSM issue 1 August 1994 13

Page 15 of 521

Fan Control FC

Fascia

farad F

I Federal Motor Vehicle Safetv I FMVSS

Standard (US)

fender

fiber

Figure (illustration) Fig.

firewall

Flash Electrically Erasable Pro- FEEPROM grammable Read-only Memory

Flash Erasable Programmable

FEPROM Read-only Memory

Flywheel Sensor CKFS

fueling Fuel Injectors FI

Fuel Pressure Regulator Control FPRC

Fuel Pump FP

Fuel Pump Monitor FPM

Fuel Pump Relay FPR

fuel

rich/lean

engine cooling fan control

SI unit of electrostatic capacitance; more

usually subdivided to microfarad fascia,

facia

wing,

(also tonneau)

fibre

bulkhead,

dash panel

sensor mounted

so as to be triggered by each flywheel sensor

flywheel ring gear tooth to give an engine

speed signal

fuelling

iniectors

solenoid operated

devices that spray a fuel injectors,

metered auantitv of fuel into the inlet

~0rt.s

Drimarilv to aive extra fuel at cold start-uo used I

controls fuel pressure regulator;

I I

monitors oDeration of fuel DumD I I

qualitative evaluation of airbuel ratio based on a ratio known as stoichiometry, or 14.7:l

(Lambda)

Issue 1 August 1994 14 X300 VSM

0

0

Page 20 of 521

- .. I lish Equivalent)

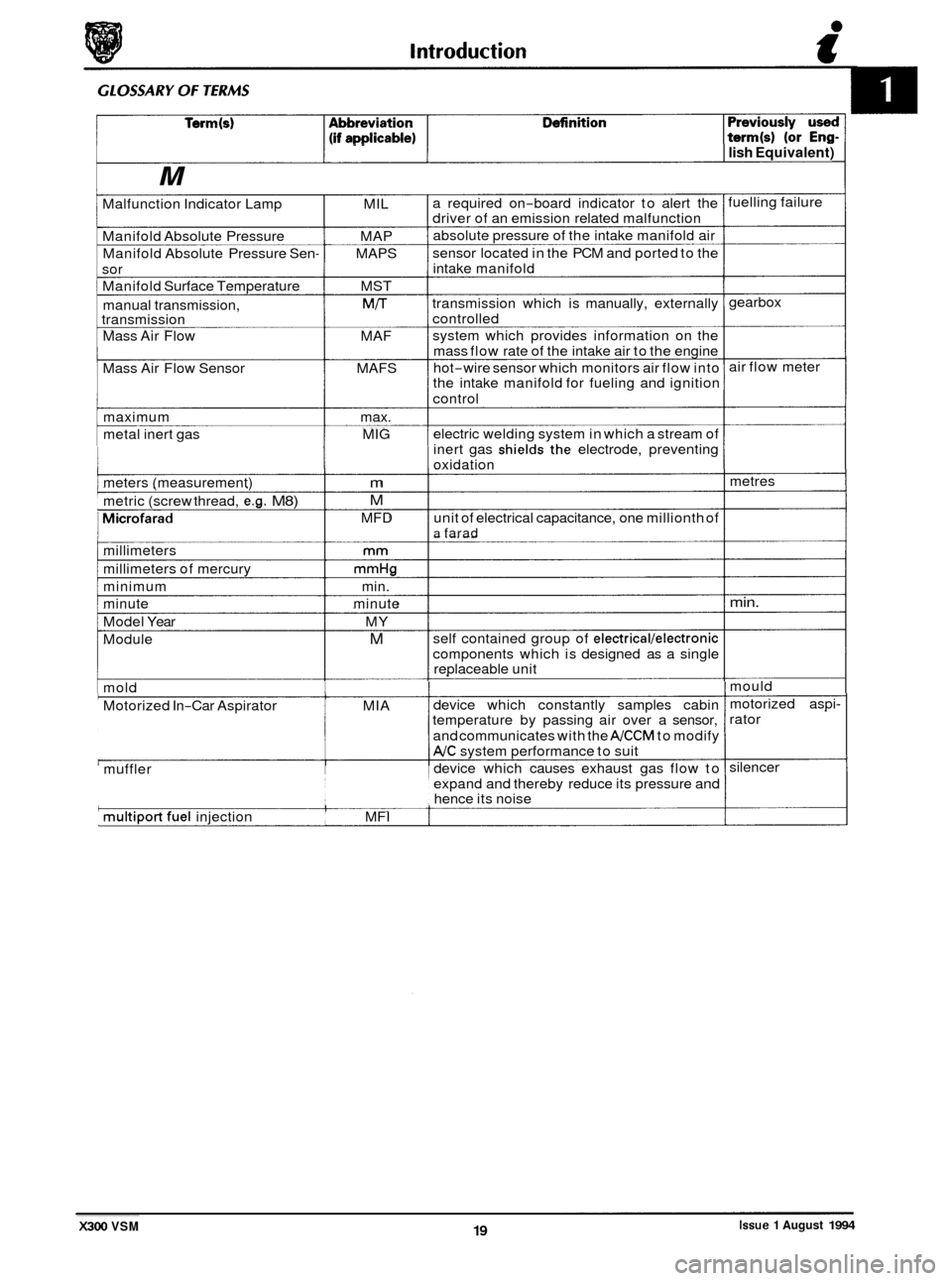

M

Malfunction Indicator Lamp MIL

Manifold Absolute Pressure MAP

Manifold Absolute Pressure Sen

- MAPS

sor

Manifold Surface Temperature MST

manual transmission,

M/T transmission

Mass Air Flow MAF

Mass Air Flow Sensor MAFS

maximum max.

metal inert gas MIG ~

meters (measurement) m

metric

(screw thread, e.g. M8) M

MFD I Microfarad

millimeters mm

millimeters

of mercury mmHg

minimum min.

minute minute

Model Year MY

Module

M

mold

Motorized In

-Car Aspirator MIA

muffler

multiport fuel injection MFI a required

on

-board indicator to alert the

driver of an emission related malfunction

absolute pressure of the intake manifold air

sensor located in the PCM and ported to the

intake manifold

transmission which is manually, externally

controlled

system which provides information on the

mass flow rate of the intake air to the engine

hot

-wire sensor which monitors air flow into

the intake manifold for fueling and ignition

control

electric welding system in which a stream of

inert gas

shielbs~the electrode, preventing

oxidation

unit of electrical capacitance, one millionth of

a farad

self contained group of electrical/electronic

components which is designed as a single

replaceable unit

device which constantly samples cabin

temperature by passing air over a sensor,

and communicates with the

NCCM to modify

NC system performance to suit

device which causes exhaust gas flow to

expand and thereby reduce its pressure and

hence its noise fuelling failure

gearbox

air flow meter

metres

min.

mould

motorized aspi

-

rator

silencer ~~

X300 VSM 19 Issue 1 August 1994