left turn JEEP GRAND CHEROKEE 2002 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 373 of 2199

²Passenger Door Module (PDM)- Refer to

Electronic Control Modules for more information.

OPERATION - REAR WINDOW DEFOGGER

The rear window defogger system is controlled by a

momentary switch that is integral to the a/c heater

control located in the center stack area of the instru-

ment panel. A Light-Emitting Diode (LED) in the

switch button will light to indicate when the rear

window defogger system is turned on. The BCM,

which contains the rear window defogger system

timer and control logic, monitors the status of the

defogger switch through a hard-wired input. The

BCM then sends control outputs through a hard

wired circuit to energize or de-energize the defogger

relay.

The electrically heated outside rear view mirror

heating grids are also controlled by the rear window

defogger switch. When the BCM receives an input

from the switch, it sends a defogger switch status

message to the DDM and the PDM over the PCI data

bus. The DDM and PDM respond to the defogger

switch status messages by energizing or de-energiz-

ing the battery current feed to their respective out-

side rear view mirror heating grids.

The rear window defogger system will be automat-

ically turned off after a programmed time interval of

about ten minutes. After the initial time interval has

expired, if the defogger switch is turned on again

during the same ignition cycle, the defogger system

will automatically turn off after about five minutes.

The defogger system will automatically shut off if the

ignition switch is turned to the Off position, or it can

be turned off manually by depressing the rear win-

dow defogger switch again.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the rear window defogger system.

DIAGNOSIS AND TESTING - REAR WINDOW

DEFOGGER SYSTEM

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.For complete circuit diagrams, (Refer to Appropri-

ate Wiring Information). The operation of the electri-

cally heated rear window defogger system can be

confirmed in one of the following manners:

1. Turn the ignition switch to the On position.

While monitoring the instrument panel voltmeter,

depress the rear window defogger switch to the On

position. When the rear window defogger switch is

turned On, a distinct voltmeter needle deflection

should be noted.

2. Turn the ignition switch to the On position.

Depress the rear window defogger switch to the On

position. The rear window defogger operation can be

checked by feeling the rear window or outside rear

view mirror glass. A distinct difference in tempera-

ture between the grid lines and the adjacent clear

glass or the mirror glass can be detected within three

to four minutes of operation.

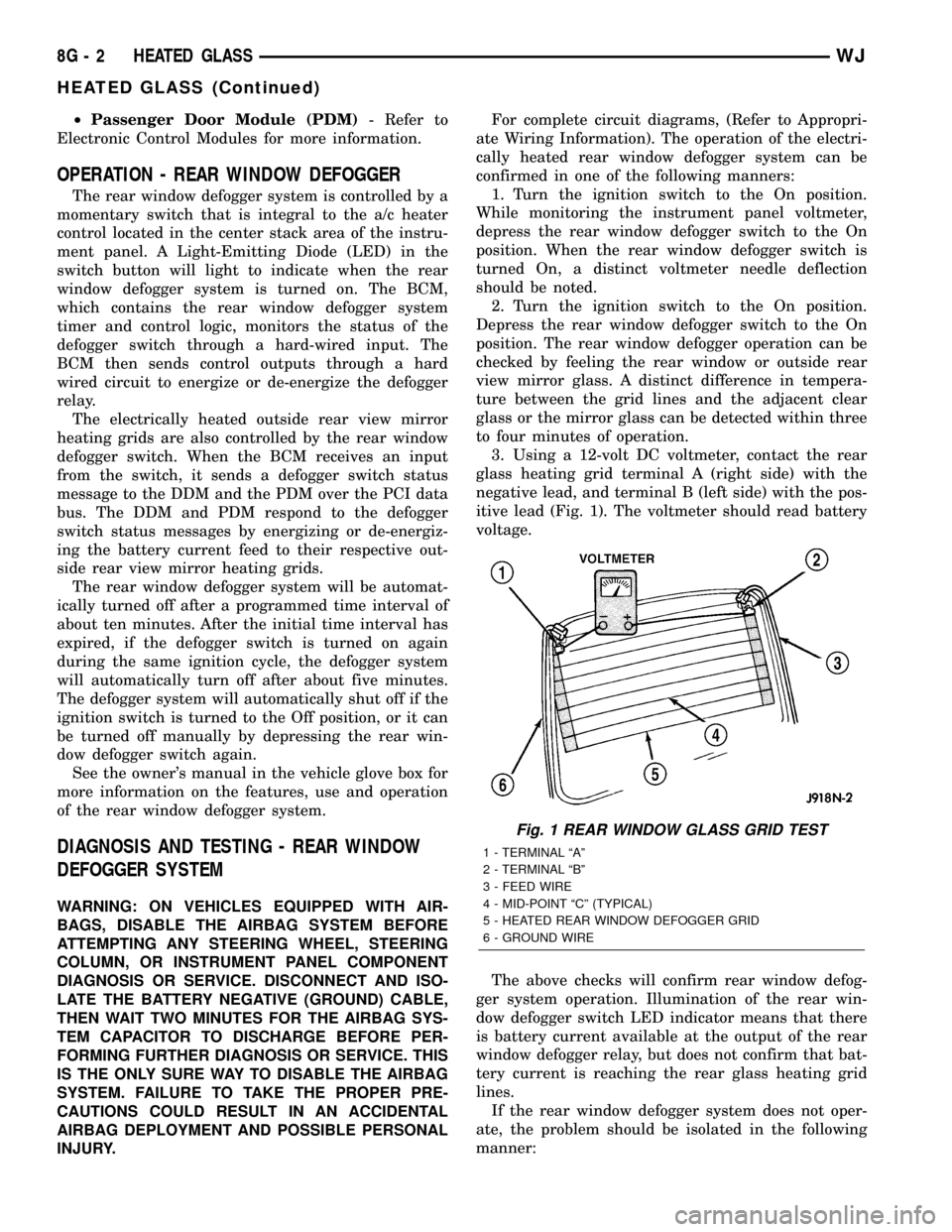

3. Using a 12-volt DC voltmeter, contact the rear

glass heating grid terminal A (right side) with the

negative lead, and terminal B (left side) with the pos-

itive lead (Fig. 1). The voltmeter should read battery

voltage.

The above checks will confirm rear window defog-

ger system operation. Illumination of the rear win-

dow defogger switch LED indicator means that there

is battery current available at the output of the rear

window defogger relay, but does not confirm that bat-

tery current is reaching the rear glass heating grid

lines.

If the rear window defogger system does not oper-

ate, the problem should be isolated in the following

manner:

Fig. 1 REAR WINDOW GLASS GRID TEST

1 - TERMINAL ªAº

2 - TERMINAL ªBº

3 - FEED WIRE

4 - MID-POINT ªCº (TYPICAL)

5 - HEATED REAR WINDOW DEFOGGER GRID

6 - GROUND WIRE

8G - 2 HEATED GLASSWJ

HEATED GLASS (Continued)

Page 374 of 2199

(1) Confirm that the ignition switch is in the On

position.

(2) Ensure that the rear glass heating grid feed

and ground terminals are connected to the glass.

Confirm that the ground wire has continuity to

ground.

(3) Check the fused B(+) fuse in the Power Distri-

bution Center (PDC). The fuse must be tight in its

receptacles and all electrical connections must be

secure.

When the above steps have been completed and the

rear glass heating grid is still inoperative, one or

more of the following is faulty:

²Rear window defogger switch

²Rear window defogger relay

²Body Control Module (BCM)

²Rear window grid lines (all grid lines would

have to be broken or one of the feed wires discon-

nected for the entire system to be inoperative).

When the above steps have been completed and the

heated mirror glass heating grid is still inoperative,

one or more of the following is faulty:

²Body Control Module (BCM)

²Programmable Communications Interface (PCI)

data bus

²Driver Door Module (DDM) or Passenger Door

Module (PDM)

²Outside rear view mirror heating grids.

If turning the rear window defogger system on pro-

duces a severe voltmeter deflection, check for a short

circuit between the rear window defogger relay out-

put and the rear glass heating grid.

REAR WINDOW DEFOGGER

GRID

DESCRIPTION

The electrically heated rear window glass is stan-

dard equipment on this model. The liftgate flip-up

glass has two electrically conductive vertical bus bars

and a series of horizontal grid lines made of a silver-

ceramic material, which is baked on and bonded to

the inside surface of the glass. These grid lines and

the bus bars comprise a parallel electrical circuit. A

spade type terminal near the top of each bus bar

accept the connectors from the two coiled liftgate

wire harness take outs.

The grid lines and bus bars are highly resistant to

abrasion. However, it is possible for an open circuit

to occur in an individual grid line, resulting in no

current flow through the line. The grid lines can be

damaged or scraped off with sharp instruments. Care

should be taken when cleaning the glass or removing

foreign materials, decals, or stickers from the glass.Normal glass cleaning solvents or hot water used

with rags or toweling is recommended.

A repair kit is available to repair the grid lines and

bus bars, or to reinstall the heated glass terminals.

(Refer to 8 - ELECTRICAL/HEATED GLASS/REAR

WINDOW DEFOGGER GRID - STANDARD PROCE-

DURE)

OPERATION

The rear glass heating grid is energized and de-en-

ergized by the rear window defogger relay. The Body

Control Module (BCM) monitors the rear window

defogger switch. When the BCM receives an input

from the switch, it energizes or de-energizes the rear

window defogger relay through a hard wired control

output. The rear defogger relay switches fused bat-

tery current to the rear window grid lines through

the bus bars. The grid lines heat the rear window

glass to clear the surface of ice, snow or fog. Protec-

tion for the rear glass heating grid circuit is provided

by a fuse in the Power Distribution Center (PDC).

DIAGNOSIS AND TESTING - REAR WINDOW

DEFOGGER GRID

For complete circuit diagrams, (Refer to Appropri-

ate Wiring Information). To detect breaks in the rear

glass heating grid lines, the following procedure is

required:

(1) Turn the ignition switch to the On position.

Turn the rear window defogger system on. The rear

window defogger switch LED indicator should light.

If OK, go to Step 2. If not OK, (Refer to 8 - ELEC-

TRICAL/HEATED GLASS/REAR WINDOW DEFOG-

GER RELAY - DIAGNOSIS AND TESTING).

(2) Using a 12-volt DC voltmeter, contact the rear

glass heating grid vertical bus bar on the right side

of the vehicle with the negative lead. With the posi-

tive lead, contact the rear glass heating grid vertical

bus bar on the left side of the vehicle. The voltmeter

should read battery voltage. If OK, go to Step 3. If

not OK, repair the open rear window defogger relay

output circuit to the rear window defogger relay as

required.

(3) With the positive voltmeter lead still contacting

the rear glass heating grid vertical bus bar on the

left side of the vehicle, move the negative lead of the

voltmeter to a good body ground point. The voltage

reading should not change. If OK, go to Step 4. If not

OK, repair the ground circuit to ground as required.

(4) Connect the negative lead of the voltmeter to

the right side bus bar and touch each grid line at

midpoint C with the positive lead (Fig. 2). A reading

of approximately six volts indicates a line is good. A

reading of zero volts indicates a break in the grid

line between midpoint C and the left side rear glass

heating grid bus bar. A reading of ten to fourteen

WJHEATED GLASS 8G - 3

HEATED GLASS (Continued)

Page 376 of 2199

not attach the wire harness connectors until the cur-

ing process is complete.

(11) Check the operation of the rear glass heating

grid.

REAR WINDOW DEFOGGER

RELAY

DESCRIPTION

The rear window defogger relay is an electrome-

chanical device that switches fused battery current to

the rear glass heating grid and the Light-Emitting

Diode (LED) indicator of the rear window defogger

switch, when the Body Control Module (BCM) rear

window defogger timer and logic circuitry grounds

the relay coil. The rear window defogger relay is

located in the junction block, under the left end of

the instrument panel in the passenger compartment.

The rear window defogger relay is a International

Standards Organization (ISO) relay. Relays conform-

ing to the ISO specifications have common physical

dimensions, current capacities, terminal patterns,

and terminal functions.

The rear window defogger relay cannot be repaired

or adjusted and, if faulty or damaged, it must be

replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When the elec-

tromagnetic coil is energized, it draws the movable

contact away from the normally closed fixed contact,

and holds it against the other (normally open) fixed

contact.

When the electromagnetic coil is de-energized,

spring pressure returns the movable contact to the

normally closed position. The resistor or diode is con-

nected in parallel with the electromagnetic coil in the

relay, and helps to dissipate voltage spikes that are

produced when the coil is de-energized.

DIAGNOSIS AND TESTING - REAR WINDOW

DEFOGGER RELAY

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

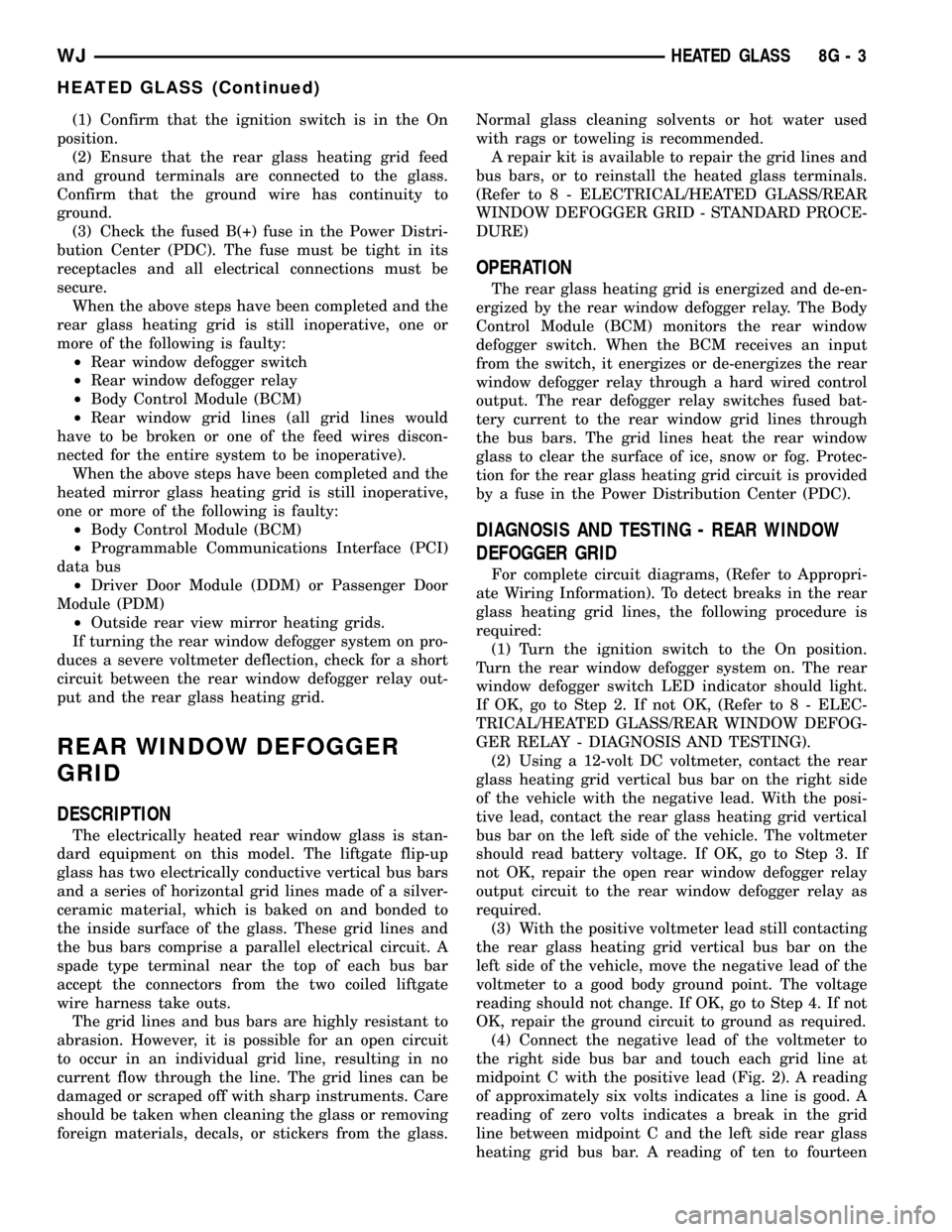

RELAY TEST

The rear window defogger relay (Fig. 4) is located

in the junction block, under the left end of the instru-

ment panel in the passenger compartment. Remove

the rear window defogger relay from the junction

block to perform the following tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 10 ohms. If OK, go to Step

3. If not OK, replace the faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, refer to theRelay Circuit Test.If

not OK, replace the faulty relay.

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair the open

fused B(+) circuit to the Power Distribution Center

(PDC) fuse as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

Fig. 4 REAR WINDOW DEFOGGER RELAY

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

WJHEATED GLASS 8G - 5

REAR WINDOW DEFOGGER GRID (Continued)

Page 383 of 2199

OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run) fuse in the junction block. If OK, go to

Step 3. If not OK, repair the open fused ignition

switch output (run) circuit to the ignition switch as

required.

(3) Disconnect and isolate the battery negative

cable. Remove the lower center bezel from the instru-

ment panel and disconnect the instrument panel wire

harness connectors from both heated seat switch con-

nector receptacles. Check for continuity between the

ground circuit cavity of the instrument panel wire

harness connector for the inoperative heated seat

switch(es) and a good ground. There should be conti-

nuity. If OK, go to Step 4. If not OK, repair the open

ground circuit to ground as required.

(4) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (run) cir-

cuit cavity of the instrument panel wire harness con-

nector for the inoperative heated seat switch(es). If

OK, turn the ignition switch to the Off position, dis-

connect and isolate the battery negative cable, and go

to Step 5. If not OK, repair the open fused ignition

switch output (run) circuit to the junction block fuse

as required.

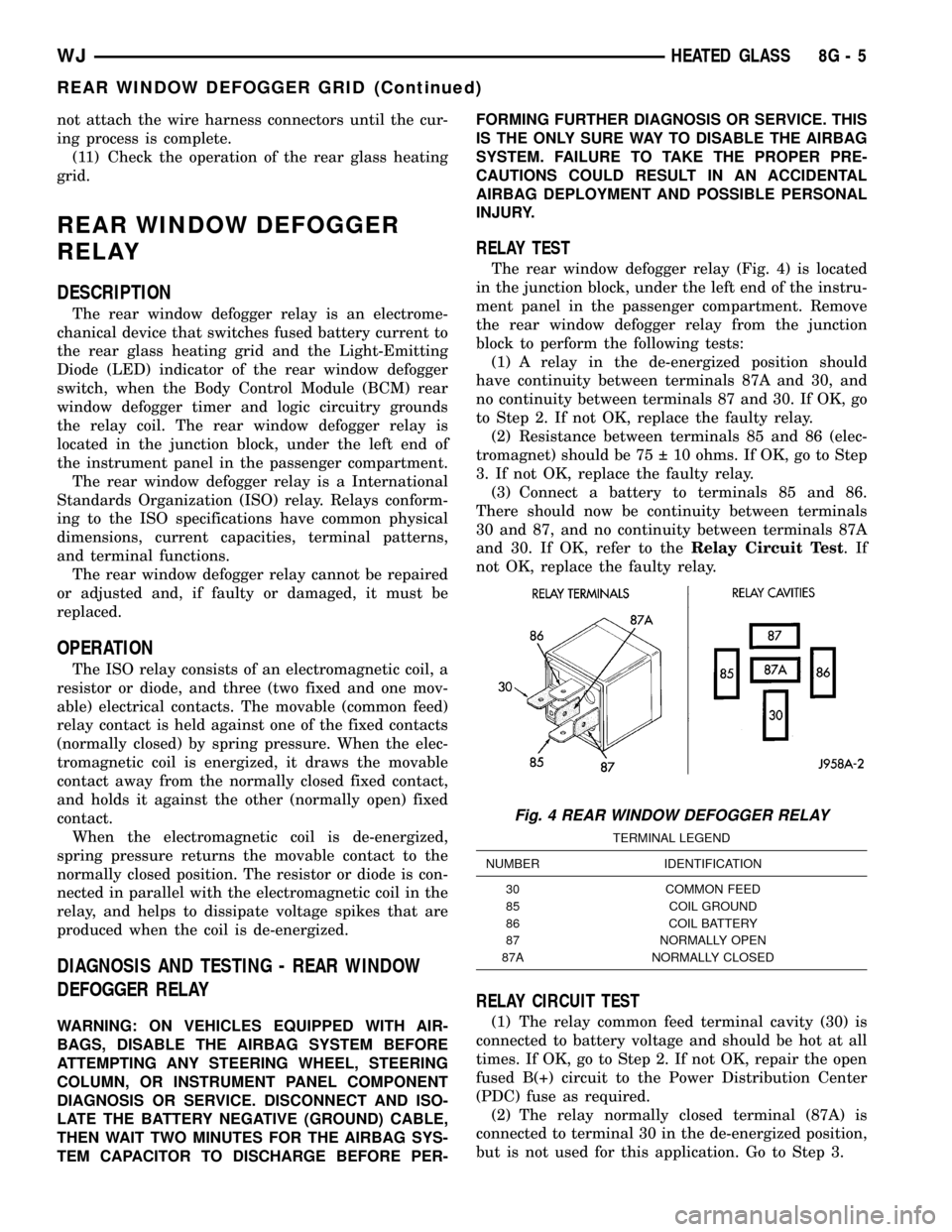

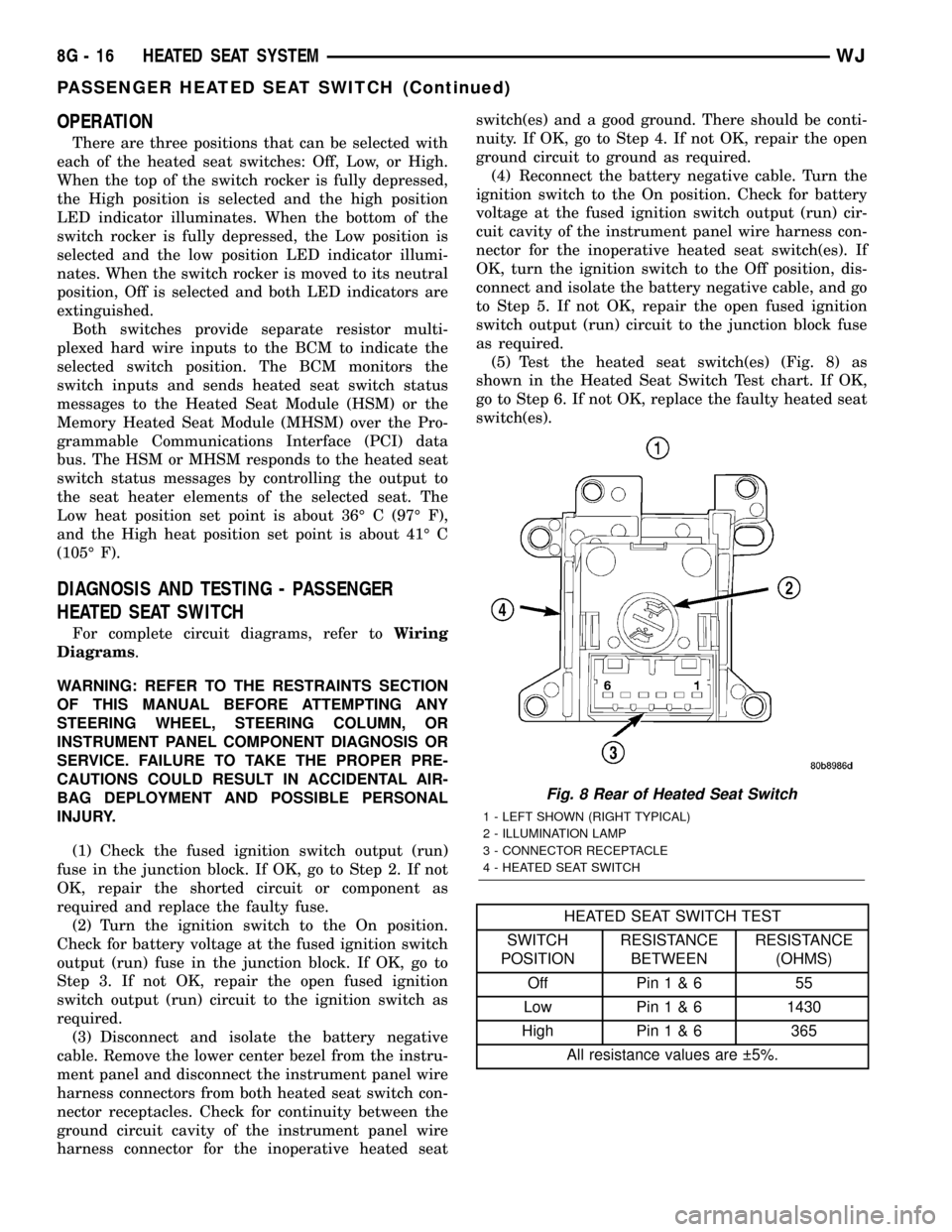

(5) Test the heated seat switch(es) (Fig. 3) as

shown in the Heated Seat Switch Test chart. If OK,

go to Step 6. If not OK, replace the faulty heated seat

switch(es).

HEATED SEAT SWITCH TEST

SWITCH

POSITIONRESISTANCE

BETWEENRESISTANCE

(OHMS)

Off Pin1&6 55

Low Pin1&61430

High Pin1&6 365

All resistance values are 5%.

(6) Disconnect the 22-way instrument panel wire

harness connector from the Body Control Module

(BCM) connector receptacle. Check for continuity

between the seat heater switch sensor ground circuit

cavity of the instrument panel wire harness connec-

tor for the inoperative heated seat switch(es) and a

good ground. There should be no continuity. If OK, go

to Step 7. If not OK, repair the shorted seat heater

switch sensor ground circuit as required.

(7) Check for continuity between the seat heater

switch sensor ground circuit cavities of the instru-

ment panel wire harness connector for the in opera-

tive heated seat switch(es) and the 22-way

instrument panel wire harness connector for theBCM. There should be continuity. If OK, go to Step 8.

If not OK, repair the open seat heater switch sensor

ground circuit as required.

(8) Check for continuity between the seat heater

switch mux circuit cavity of the instrument panel

wire harness connector for the inoperative heated

seat switch and a good ground. There should be no

continuity. If OK, go to Step 9. If not OK, repair the

shorted seat heater switch mux circuit as required.

(9) Check for continuity between the seat heater

switch mux circuit cavity of the instrument panel

wire harness connector for the inoperative heated

seat switch and the 22-way instrument panel wire

harness connector for the BCM. There should be con-

tinuity. If OK, use a DRBtscan tool and the proper

Diagnostic Procedures manual to test the BCM. If

not OK, repair the open seat heater switch mux cir-

cuit as required.

REMOVAL

WARNING: REFER TO THE RESTRAINTS SECTION

OF THIS MANUAL BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

Fig. 3 Rear of Heated Seat Switch

1 - LEFT SHOWN (RIGHT TYPICAL)

2 - ILLUMINATION LAMP

3 - CONNECTOR RECEPTACLE

4 - HEATED SEAT SWITCH

8G - 12 HEATED SEAT SYSTEMWJ

DRIVER HEATED SEAT SWITCH (Continued)

Page 387 of 2199

OPERATION

There are three positions that can be selected with

each of the heated seat switches: Off, Low, or High.

When the top of the switch rocker is fully depressed,

the High position is selected and the high position

LED indicator illuminates. When the bottom of the

switch rocker is fully depressed, the Low position is

selected and the low position LED indicator illumi-

nates. When the switch rocker is moved to its neutral

position, Off is selected and both LED indicators are

extinguished.

Both switches provide separate resistor multi-

plexed hard wire inputs to the BCM to indicate the

selected switch position. The BCM monitors the

switch inputs and sends heated seat switch status

messages to the Heated Seat Module (HSM) or the

Memory Heated Seat Module (MHSM) over the Pro-

grammable Communications Interface (PCI) data

bus. The HSM or MHSM responds to the heated seat

switch status messages by controlling the output to

the seat heater elements of the selected seat. The

Low heat position set point is about 36É C (97É F),

and the High heat position set point is about 41É C

(105É F).

DIAGNOSIS AND TESTING - PASSENGER

HEATED SEAT SWITCH

For complete circuit diagrams, refer toWiring

Diagrams.

WARNING: REFER TO THE RESTRAINTS SECTION

OF THIS MANUAL BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check the fused ignition switch output (run)

fuse in the junction block. If OK, go to Step 2. If not

OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run) fuse in the junction block. If OK, go to

Step 3. If not OK, repair the open fused ignition

switch output (run) circuit to the ignition switch as

required.

(3) Disconnect and isolate the battery negative

cable. Remove the lower center bezel from the instru-

ment panel and disconnect the instrument panel wire

harness connectors from both heated seat switch con-

nector receptacles. Check for continuity between the

ground circuit cavity of the instrument panel wire

harness connector for the inoperative heated seatswitch(es) and a good ground. There should be conti-

nuity. If OK, go to Step 4. If not OK, repair the open

ground circuit to ground as required.

(4) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (run) cir-

cuit cavity of the instrument panel wire harness con-

nector for the inoperative heated seat switch(es). If

OK, turn the ignition switch to the Off position, dis-

connect and isolate the battery negative cable, and go

to Step 5. If not OK, repair the open fused ignition

switch output (run) circuit to the junction block fuse

as required.

(5) Test the heated seat switch(es) (Fig. 8) as

shown in the Heated Seat Switch Test chart. If OK,

go to Step 6. If not OK, replace the faulty heated seat

switch(es).

HEATED SEAT SWITCH TEST

SWITCH

POSITIONRESISTANCE

BETWEENRESISTANCE

(OHMS)

Off Pin1&6 55

Low Pin1&61430

High Pin1&6 365

All resistance values are 5%.

Fig. 8 Rear of Heated Seat Switch

1 - LEFT SHOWN (RIGHT TYPICAL)

2 - ILLUMINATION LAMP

3 - CONNECTOR RECEPTACLE

4 - HEATED SEAT SWITCH

8G - 16 HEATED SEAT SYSTEMWJ

PASSENGER HEATED SEAT SWITCH (Continued)

Page 411 of 2199

The voltage signal produced by the knock sensor

increases with the amplitude of vibration. The PCM

receives the knock sensor voltage signal as an input.

If the signal rises above a predetermined level, the

PCM will store that value in memory and retard

ignition timing to reduce engine knock. If the knock

sensor voltage exceeds a preset value, the PCM

retards ignition timing for all cylinders. It is not a

selective cylinder retard.

The PCM ignores knock sensor input during engine

idle conditions. Once the engine speed exceeds a

specified value, knock retard is allowed.

Knock retard uses its own short term and long

term memory program.

Long term memory stores previous detonation

information in its battery-backed RAM. The maxi-

mum authority that long term memory has over tim-

ing retard can be calibrated.

Short term memory is allowed to retard timing up

to a preset amount under all operating conditions (as

long as rpm is above the minimum rpm) except at

Wide Open Throttle (WOT). The PCM, using short

term memory, can respond quickly to retard timing

when engine knock is detected. Short term memory

is lost any time the ignition key is turned off.

NOTE: Over or under tightening the sensor mount-

ing bolts will affect knock sensor performance, pos-

sibly causing improper spark control. Always use

the specified torque when installing the knock sen-

sors.

REMOVAL

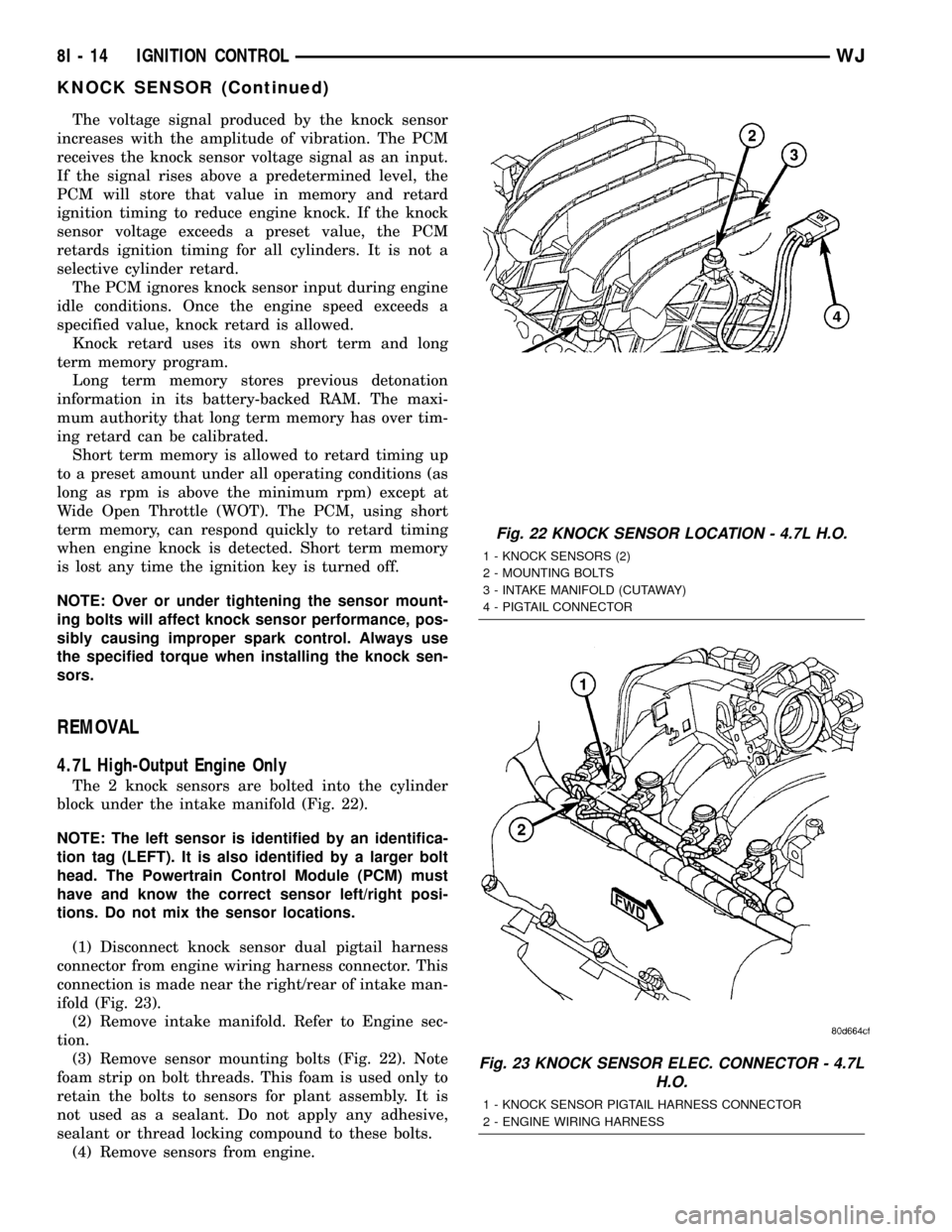

4.7L High-Output Engine Only

The 2 knock sensors are bolted into the cylinder

block under the intake manifold (Fig. 22).

NOTE: The left sensor is identified by an identifica-

tion tag (LEFT). It is also identified by a larger bolt

head. The Powertrain Control Module (PCM) must

have and know the correct sensor left/right posi-

tions. Do not mix the sensor locations.

(1) Disconnect knock sensor dual pigtail harness

connector from engine wiring harness connector. This

connection is made near the right/rear of intake man-

ifold (Fig. 23).

(2) Remove intake manifold. Refer to Engine sec-

tion.

(3) Remove sensor mounting bolts (Fig. 22). Note

foam strip on bolt threads. This foam is used only to

retain the bolts to sensors for plant assembly. It is

not used as a sealant. Do not apply any adhesive,

sealant or thread locking compound to these bolts.

(4) Remove sensors from engine.

Fig. 22 KNOCK SENSOR LOCATION - 4.7L H.O.

1 - KNOCK SENSORS (2)

2 - MOUNTING BOLTS

3 - INTAKE MANIFOLD (CUTAWAY)

4 - PIGTAIL CONNECTOR

Fig. 23 KNOCK SENSOR ELEC. CONNECTOR - 4.7L

H.O.

1 - KNOCK SENSOR PIGTAIL HARNESS CONNECTOR

2 - ENGINE WIRING HARNESS

8I - 14 IGNITION CONTROLWJ

KNOCK SENSOR (Continued)

Page 418 of 2199

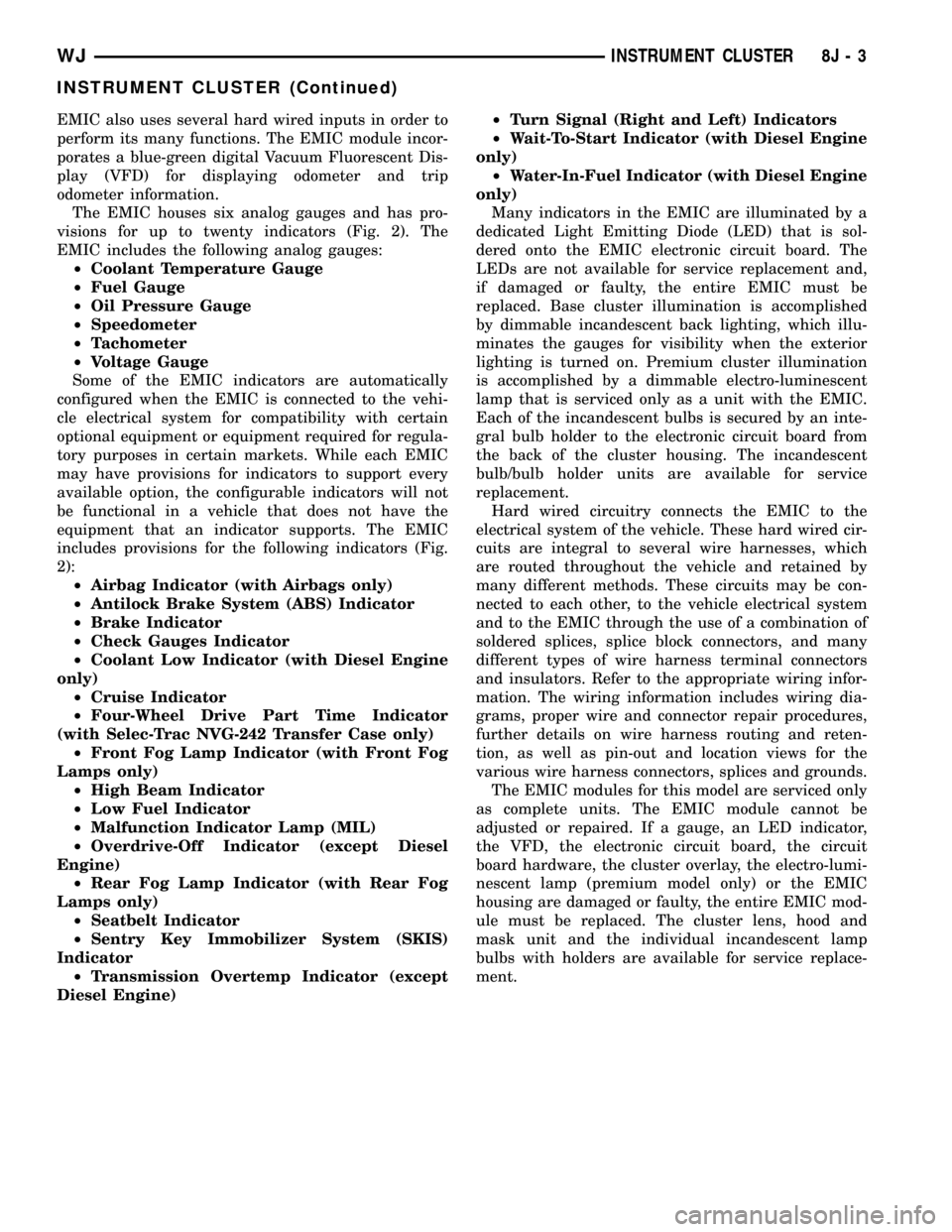

EMIC also uses several hard wired inputs in order to

perform its many functions. The EMIC module incor-

porates a blue-green digital Vacuum Fluorescent Dis-

play (VFD) for displaying odometer and trip

odometer information.

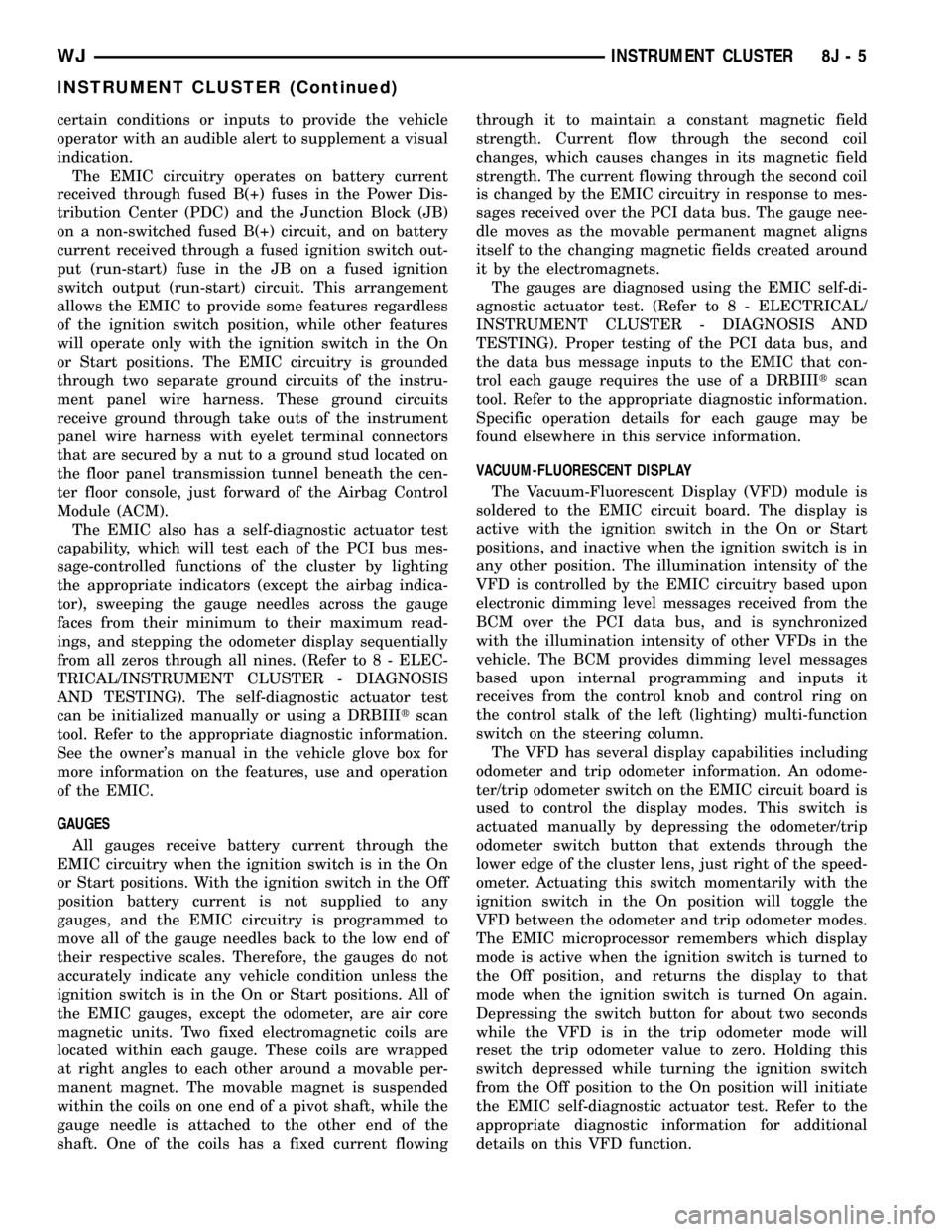

The EMIC houses six analog gauges and has pro-

visions for up to twenty indicators (Fig. 2). The

EMIC includes the following analog gauges:

²Coolant Temperature Gauge

²Fuel Gauge

²Oil Pressure Gauge

²Speedometer

²Tachometer

²Voltage Gauge

Some of the EMIC indicators are automatically

configured when the EMIC is connected to the vehi-

cle electrical system for compatibility with certain

optional equipment or equipment required for regula-

tory purposes in certain markets. While each EMIC

may have provisions for indicators to support every

available option, the configurable indicators will not

be functional in a vehicle that does not have the

equipment that an indicator supports. The EMIC

includes provisions for the following indicators (Fig.

2):

²Airbag Indicator (with Airbags only)

²Antilock Brake System (ABS) Indicator

²Brake Indicator

²Check Gauges Indicator

²Coolant Low Indicator (with Diesel Engine

only)

²Cruise Indicator

²Four-Wheel Drive Part Time Indicator

(with Selec-Trac NVG-242 Transfer Case only)

²Front Fog Lamp Indicator (with Front Fog

Lamps only)

²High Beam Indicator

²Low Fuel Indicator

²Malfunction Indicator Lamp (MIL)

²Overdrive-Off Indicator (except Diesel

Engine)

²Rear Fog Lamp Indicator (with Rear Fog

Lamps only)

²Seatbelt Indicator

²Sentry Key Immobilizer System (SKIS)

Indicator

²Transmission Overtemp Indicator (except

Diesel Engine)²Turn Signal (Right and Left) Indicators

²Wait-To-Start Indicator (with Diesel Engine

only)

²Water-In-Fuel Indicator (with Diesel Engine

only)

Many indicators in the EMIC are illuminated by a

dedicated Light Emitting Diode (LED) that is sol-

dered onto the EMIC electronic circuit board. The

LEDs are not available for service replacement and,

if damaged or faulty, the entire EMIC must be

replaced. Base cluster illumination is accomplished

by dimmable incandescent back lighting, which illu-

minates the gauges for visibility when the exterior

lighting is turned on. Premium cluster illumination

is accomplished by a dimmable electro-luminescent

lamp that is serviced only as a unit with the EMIC.

Each of the incandescent bulbs is secured by an inte-

gral bulb holder to the electronic circuit board from

the back of the cluster housing. The incandescent

bulb/bulb holder units are available for service

replacement.

Hard wired circuitry connects the EMIC to the

electrical system of the vehicle. These hard wired cir-

cuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained by

many different methods. These circuits may be con-

nected to each other, to the vehicle electrical system

and to the EMIC through the use of a combination of

soldered splices, splice block connectors, and many

different types of wire harness terminal connectors

and insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

The EMIC modules for this model are serviced only

as complete units. The EMIC module cannot be

adjusted or repaired. If a gauge, an LED indicator,

the VFD, the electronic circuit board, the circuit

board hardware, the cluster overlay, the electro-lumi-

nescent lamp (premium model only) or the EMIC

housing are damaged or faulty, the entire EMIC mod-

ule must be replaced. The cluster lens, hood and

mask unit and the individual incandescent lamp

bulbs with holders are available for service replace-

ment.

WJINSTRUMENT CLUSTER 8J - 3

INSTRUMENT CLUSTER (Continued)

Page 419 of 2199

OPERATION

The ElectroMechanical Instrument Cluster (EMIC)

is designed to allow the vehicle operator to monitor

the conditions of many of the vehicle components and

operating systems. The gauges and indicators in the

EMIC provide valuable information about the various

standard and optional powertrains, fuel and emis-

sions systems, cooling systems, lighting systems,

safety systems and many other convenience items.

The EMIC is installed in the instrument panel so

that all of these monitors can be easily viewed by the

vehicle operator when driving, while still allowing

relative ease of access for service. The microproces-

sor-based EMIC hardware and software uses various

inputs to control the gauges and indicators visible on

the face of the cluster. Some of these inputs are hard

wired, but most are in the form of electronic mes-

sages that are transmitted by other electronic mod-ules over the Programmable Communications

Interface (PCI) data bus network. (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/COMMUNICATION - OPERATION).

The EMIC microprocessor smooths the input data

using algorithms to provide gauge readings that are

accurate, stable and responsive to operating condi-

tions. These algorithms are designed to provide

gauge readings during normal operation that are con-

sistent with customer expectations. However, when

abnormal conditions exist, such as low or high bat-

tery voltage, low oil pressure or high coolant temper-

ature, the algorithm can drive the gauge pointer to

an extreme position and the microprocessor turns on

the Check Gauges indicator to provide a distinct

visual indication of a problem to the vehicle operator.

The instrument cluster circuitry also sends electronic

chime tone request messages over the PCI data bus

to the Body Control Module (BCM) when it monitors

Fig. 2 EMIC Gauges & Indicators

1 - BRAKE INDICATOR 15 - TRANSMISSION OVERTEMP INDICATOR

2 - REAR FOG LAMP INDICATOR 16 - PART TIME 4WD INDICATOR

3 - WATER-IN-FUEL INDICATOR 17 - CHECK GAUGES INDICATOR

4 - VOLTAGE GAUGE 18 - ENGINE TEMPERATURE GAUGE

5 - LEFT TURN INDICATOR 19 - ODOMETER/TRIP ODOMETER SWITCH BUTTON

6 - TACHOMETER 20 - ODOMETER/TRIP ODOMETER DISPLAY

7 - HIGH BEAM INDICATOR 21 - WAIT-TO-START INDICATOR

8 - AIRBAG INDICATOR 22 - OVERDRIVE-OFF INDICATOR

9 - SPEEDOMETER 23 - SEATBELT INDICATOR

10 - RIGHT TURN INDICATOR 24 - ABS INDICATOR

11 - OIL PRESSURE GAUGE 25 - FUEL GAUGE

12 - SKIS INDICATOR 26 - FRONT FOG LAMP INDICATOR

13 - MALFUNCTION INDICATOR LAMP (MIL) 27 - LOW FUEL INDICATOR

14 - CRUISE INDICATOR 28 - COOLANT LOW INDICATOR

8J - 4 INSTRUMENT CLUSTERWJ

INSTRUMENT CLUSTER (Continued)

Page 420 of 2199

certain conditions or inputs to provide the vehicle

operator with an audible alert to supplement a visual

indication.

The EMIC circuitry operates on battery current

received through fused B(+) fuses in the Power Dis-

tribution Center (PDC) and the Junction Block (JB)

on a non-switched fused B(+) circuit, and on battery

current received through a fused ignition switch out-

put (run-start) fuse in the JB on a fused ignition

switch output (run-start) circuit. This arrangement

allows the EMIC to provide some features regardless

of the ignition switch position, while other features

will operate only with the ignition switch in the On

or Start positions. The EMIC circuitry is grounded

through two separate ground circuits of the instru-

ment panel wire harness. These ground circuits

receive ground through take outs of the instrument

panel wire harness with eyelet terminal connectors

that are secured by a nut to a ground stud located on

the floor panel transmission tunnel beneath the cen-

ter floor console, just forward of the Airbag Control

Module (ACM).

The EMIC also has a self-diagnostic actuator test

capability, which will test each of the PCI bus mes-

sage-controlled functions of the cluster by lighting

the appropriate indicators (except the airbag indica-

tor), sweeping the gauge needles across the gauge

faces from their minimum to their maximum read-

ings, and stepping the odometer display sequentially

from all zeros through all nines. (Refer to 8 - ELEC-

TRICAL/INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING). The self-diagnostic actuator test

can be initialized manually or using a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the EMIC.

GAUGES

All gauges receive battery current through the

EMIC circuitry when the ignition switch is in the On

or Start positions. With the ignition switch in the Off

position battery current is not supplied to any

gauges, and the EMIC circuitry is programmed to

move all of the gauge needles back to the low end of

their respective scales. Therefore, the gauges do not

accurately indicate any vehicle condition unless the

ignition switch is in the On or Start positions. All of

the EMIC gauges, except the odometer, are air core

magnetic units. Two fixed electromagnetic coils are

located within each gauge. These coils are wrapped

at right angles to each other around a movable per-

manent magnet. The movable magnet is suspended

within the coils on one end of a pivot shaft, while the

gauge needle is attached to the other end of the

shaft. One of the coils has a fixed current flowingthrough it to maintain a constant magnetic field

strength. Current flow through the second coil

changes, which causes changes in its magnetic field

strength. The current flowing through the second coil

is changed by the EMIC circuitry in response to mes-

sages received over the PCI data bus. The gauge nee-

dle moves as the movable permanent magnet aligns

itself to the changing magnetic fields created around

it by the electromagnets.

The gauges are diagnosed using the EMIC self-di-

agnostic actuator test. (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). Proper testing of the PCI data bus, and

the data bus message inputs to the EMIC that con-

trol each gauge requires the use of a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

Specific operation details for each gauge may be

found elsewhere in this service information.

VACUUM-FLUORESCENT DISPLAY

The Vacuum-Fluorescent Display (VFD) module is

soldered to the EMIC circuit board. The display is

active with the ignition switch in the On or Start

positions, and inactive when the ignition switch is in

any other position. The illumination intensity of the

VFD is controlled by the EMIC circuitry based upon

electronic dimming level messages received from the

BCM over the PCI data bus, and is synchronized

with the illumination intensity of other VFDs in the

vehicle. The BCM provides dimming level messages

based upon internal programming and inputs it

receives from the control knob and control ring on

the control stalk of the left (lighting) multi-function

switch on the steering column.

The VFD has several display capabilities including

odometer and trip odometer information. An odome-

ter/trip odometer switch on the EMIC circuit board is

used to control the display modes. This switch is

actuated manually by depressing the odometer/trip

odometer switch button that extends through the

lower edge of the cluster lens, just right of the speed-

ometer. Actuating this switch momentarily with the

ignition switch in the On position will toggle the

VFD between the odometer and trip odometer modes.

The EMIC microprocessor remembers which display

mode is active when the ignition switch is turned to

the Off position, and returns the display to that

mode when the ignition switch is turned On again.

Depressing the switch button for about two seconds

while the VFD is in the trip odometer mode will

reset the trip odometer value to zero. Holding this

switch depressed while turning the ignition switch

from the Off position to the On position will initiate

the EMIC self-diagnostic actuator test. Refer to the

appropriate diagnostic information for additional

details on this VFD function.

WJINSTRUMENT CLUSTER 8J - 5

INSTRUMENT CLUSTER (Continued)

Page 421 of 2199

The VFD is diagnosed using the EMIC self-diag-

nostic actuator test. (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND

TESTING). Proper testing of the PCI data bus and

the data bus message inputs to the EMIC that con-

trol the VFD functions requires the use of a DRBIIIt

scan tool. Refer to the appropriate diagnostic infor-

mation. Specific operation details for the odometer

and trip odometer functions of the VFD may be found

elsewhere in this service information.

INDICATORS

Indicators are located in various positions within

the EMIC and are all connected to the EMIC circuit

board. The turn signal indicators are hard wired. The

brake indicator is controlled by PCI data bus mes-

sages from the Controller Antilock Brake (CAB) as

well as by hard wired park brake switch and brake

fluid level switch inputs to the EMIC. The Malfunc-

tion Indicator Lamp (MIL) is normally controlled by

PCI data bus messages from the Powertrain Control

Module (PCM); however, if the EMIC loses PCI data

bus communication, the EMIC circuitry will automat-

ically turn the MIL on until PCI data bus communi-

cation is restored. The EMIC uses PCI data bus

messages from the Airbag Control Module (ACM), the

BCM, the PCM, the CAB, the Sentry Key Immobi-

lizer Module (SKIM), and the Transmission Control

Module (TCM) to control all of the remaining indica-

tors.

The various indicators are controlled by different

strategies; some receive fused ignition switch output

from the EMIC circuitry and have a switched ground,

others are grounded through the EMIC circuitry and

have a switched battery feed, while still others are

completely controlled by the EMIC microprocessor

based upon various hard wired and electronic mes-

sage inputs. Some indicators are illuminated at a

fixed intensity, while the illumination intensity of

others is synchronized with that of the EMIC general

illumination lamps.

The hard wired indicators are diagnosed using con-

ventional diagnostic methods. The EMIC and PCI

bus message controlled indicators are diagnosed

using the EMIC self-diagnostic actuator test. (Refer

to 8 - ELECTRICAL/INSTRUMENT CLUSTER -

DIAGNOSIS AND TESTING). Proper testing of the

PCI data bus and the electronic data bus message

inputs to the EMIC that control each indicator

require the use of a DRBIIItscan tool. Refer to the

appropriate diagnostic information. Specific details of

the operation for each indicator may be found else-

where in this service information.CLUSTER ILLUMINATION

Two types of general cluster illumination are avail-

able in this model. Base versions of the EMIC have

several incandescent illumination lamps, while pre-

mium versions of the EMIC have a single electro-lu-

minescent lamp. Both types of lamps provide cluster

back lighting whenever the exterior lighting is

turned On with the control knob on the left (lighting)

multi-function switch control stalk. The illumination

intensity of these lamps is adjusted by the EMIC

microprocessor based upon electronic dimming level

messages received from the Body Control Module

(BCM) over the PCI data bus. The BCM provides

electronic dimming level messages to the EMIC

based upon internal programming and inputs it

receives when the control ring on the left (lighting)

multi-function switch control stalk is rotated (down

to dim, up to brighten) to one of six available minor

detent positions.

The incandescent illumination lamps receive bat-

tery current at all times, while the ground for these

lamps is controlled by a 12-volt Pulse Width Modu-

lated (PWM) output of the EMIC electronic circuitry.

The illumination intensity of these bulbs and of the

vacuum-fluorescent electronic display are controlled

by the instrument cluster microprocessor based upon

dimming level messages received from the Body Con-

trol Module (BCM) over the PCI data bus. The BCM

uses inputs from the headlamp and panel dimmer

switches within the left (lighting) multi-function

switch control stalk and internal programming to

decide what dimming level message is required. The

BCM then sends the proper dimming level messages

to the EMIC over the PCI data bus.

The electro-luminescent lamp unit consists of lay-

ers of phosphor, carbon, idium tin oxide, and dielec-

tric applied by a silk-screen process between two

polyester membranes and includes a short pigtail

wire and connector. The lamp pigtail wire is con-

nected to a small connector receptacle on the EMIC

circuit board through a small clearance hole in the

cluster housing rear cover. The EMIC electronic cir-

cuitry also uses a PWM strategy to control the illu-

mination intensity of this lamp; however, the EMIC

powers this lamp with an Alternating Current (AC)

rated at 80 volts rms (root mean squared) and 415

Hertz, which excites the phosphor particles causing

them to luminesce.

The BCM also has several hard wired panel lamp

driver outputs and sends the proper panel lamps

dimming level messages over the PCI data bus to

coordinate the illumination intensity of all of the

instrument panel lighting and the VFDs of other

electronic modules on the PCI data bus. Vehicles

equipped with the Auto Headlamps option have an

automatic parade mode. In this mode, the BCM uses

8J - 6 INSTRUMENT CLUSTERWJ

INSTRUMENT CLUSTER (Continued)