recommended oil JEEP GRAND CHEROKEE 2002 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 412 of 2199

INSTALLATION

4.7L High-Output Engine Only

NOTE: The left sensor is identified by an identifica-

tion tag (LEFT). It is also identified by a larger bolt

head. The Powertrain Control Module (PCM) must

have and know the correct sensor left/right posi-

tions. Do not mix the sensor locations.

(1) Thoroughly clean knock sensor mounting holes.

(2) Install sensors (Fig. 22) into cylinder block.

NOTE: Over or under tightening the sensor mount-

ing bolts will affect knock sensor performance, pos-

sibly causing improper spark control. Always use

the specified torque when installing the knock sen-

sors. The torque for the knock senor bolt is rela-

tively light for an 8mm bolt.

NOTE: Note foam strip on bolt threads. This foam is

used only to retain the bolts to sensors for plant

assembly. It is not used as a sealant. Do not apply

any adhesive, sealant or thread locking compound

to these bolts.

(3) Install and tighten mounting bolts.Bolt

torque is critical.Refer to torque specification.

(4) Install intake manifold. Refer to Engine sec-

tion.

(5) Connect knock sensor pigtail wiring harness to

engine wiring harness near right / rear of intake

manifold (Fig. 23).

SPARK PLUG

DESCRIPTION

Both the 4.0L 6-cylinder and the 4.7L V-8 engine

use resistor type spark plugs. Standard 4.7L V-8

engines are equipped with ªfired in suppressor sealº

type spark plugs using a copper core ground elec-

trode. High-Output (H.O.) 4.7L V-8 engines are

equipped with unique plugs using a platinum rivet

located on the tip of the center electrode.

Because of the use of an aluminum cylinder head

on the 4.7L engine, spark plug torque is very critical.

To prevent possible pre-ignition and/or mechanical

engine damage, the correct type/heat range/number

spark plug must be used.Do not substitute any

other spark plug on the 4.7L H.O. engine. Seri-

ous engine damage may occur.

Plugs on both engines have resistance values rang-

ing from 6,000 to 20,000 ohms (when checked with at

least a 1000 volt spark plug tester).Do not use an

ohmmeter to check the resistance values of thespark plugs. Inaccurate readings will result.

Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. A sin-

gle plug displaying an abnormal condition indicates

that a problem exists in the corresponding cylinder.

Replace spark plugs at the intervals recommended in

Group O, Lubrication and Maintenance.

EXCEPT 4.7L H.O. ENGINE :Spark plugs that

have low mileage may be cleaned and reused if not

otherwise defective, carbon or oil fouled. Also refer to

Spark Plug Conditions.4.7L H.O. ENGINE :Never

clean spark plugs on the 4.7L H.O. engine. Damage

to the platinum rivet will result.

CAUTION: EXCEPT 4.7L H.O. ENGINE : Never use a

motorized wire wheel brush to clean the spark

plugs. Metallic deposits will remain on the spark

plug insulator and will cause plug misfire.

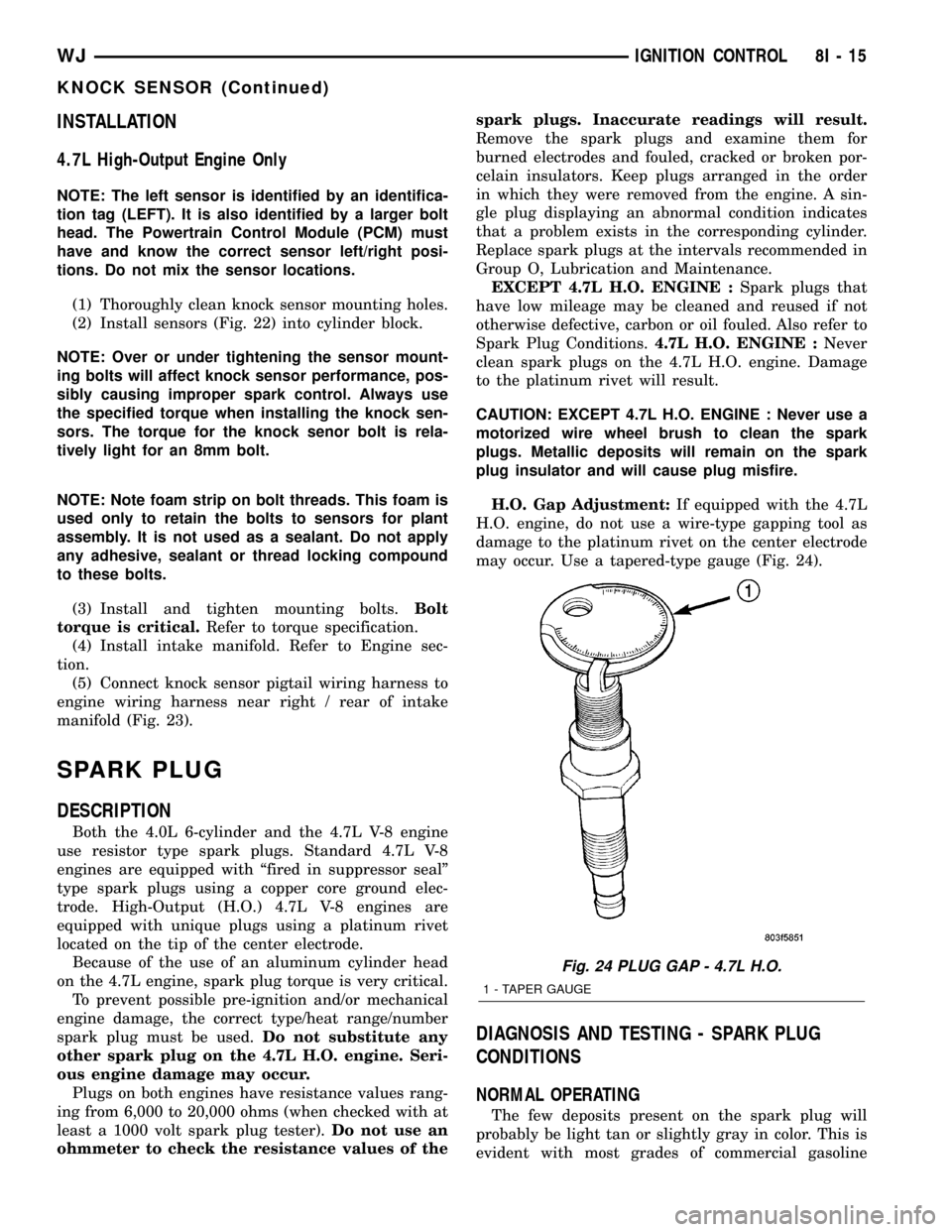

H.O. Gap Adjustment:If equipped with the 4.7L

H.O. engine, do not use a wire-type gapping tool as

damage to the platinum rivet on the center electrode

may occur. Use a tapered-type gauge (Fig. 24).

DIAGNOSIS AND TESTING - SPARK PLUG

CONDITIONS

NORMAL OPERATING

The few deposits present on the spark plug will

probably be light tan or slightly gray in color. This is

evident with most grades of commercial gasoline

Fig. 24 PLUG GAP - 4.7L H.O.

1 - TAPER GAUGE

WJIGNITION CONTROL 8I - 15

KNOCK SENSOR (Continued)

Page 1252 of 2199

DIAGNOSIS AND TESTINGÐREAR SEAL AREA

LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, distributor seal,

camshaft bore cup plugs, oil galley pipe plugs, oil

filter runoff, and main bearing cap to cylinder

block mating surfaces.

(4) If no leaks are detected, pressurized the crank-

case as outlined in (Refer to 9 - ENGINE/LUBRICA-

TION - DIAGNOSIS AND TESTING)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks or

scratches. The crankshaft seal flange is specially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled. Refer to the service DiagnosisÐMechani-

cal, under the Oil Leak row, for components

inspections on possible causes and corrections.

(7) After the oil leak root cause and appropriate

corrective action have been identified, (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - REMOVAL), for proper replacement

procedures.

STANDARD PROCEDURE

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTV

MopartATF RTV is a specifically designed black

silicone rubber RTV that retains adhesion and seal-

ing properties to seal components exposed to auto-

matic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKER

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of air

when squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobic

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4oz./16 oz. can w/applicator.

WJENGINE - 4.0L 9 - 9

ENGINE - 4.0L (Continued)

Page 1253 of 2199

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier then using precut gaskets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - REPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDUREÐHYDROSTATIC LOCK

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Perform the Fuel Pressure Release Procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).(2) Disconnect the negative cable(s) from the bat-

tery.

(3) Inspect air cleaner, induction system, and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the spark plugs.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (coolant, fuel,

oil, etc.).

(7) Be sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt a small amount of engine oil into the

cylinders to lubricate the walls. This will prevent

damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 41 N´m (30 ft. lbs.) torque.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N´m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil. (Refer to LUBRICATION &

MAINTENANCE - SPECIFICATIONS).

(15) Connect the negative cable(s) to the battery.

(16) Start the engine and check for any leaks.

STANDARD PROCEDURE - CYLINDER BORE

HONING

Before honing, stuff plenty of clean shop towels

under the bores and over the crankshaft to keep

abrasive materials from entering the crankshaft

area.

(1)

Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round, as well as removing light scuff-

ing, scoring and scratches. Usually, a few strokes will

clean up a bore and maintain the required limits.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Using honing

oil C-3501-3880, or a light honing oil, available from

major oil distributors.

9 - 10 ENGINE - 4.0LWJ

ENGINE - 4.0L (Continued)

Page 1274 of 2199

REMOVAL

REMOVAL - CAMSHAFT BEARINGS

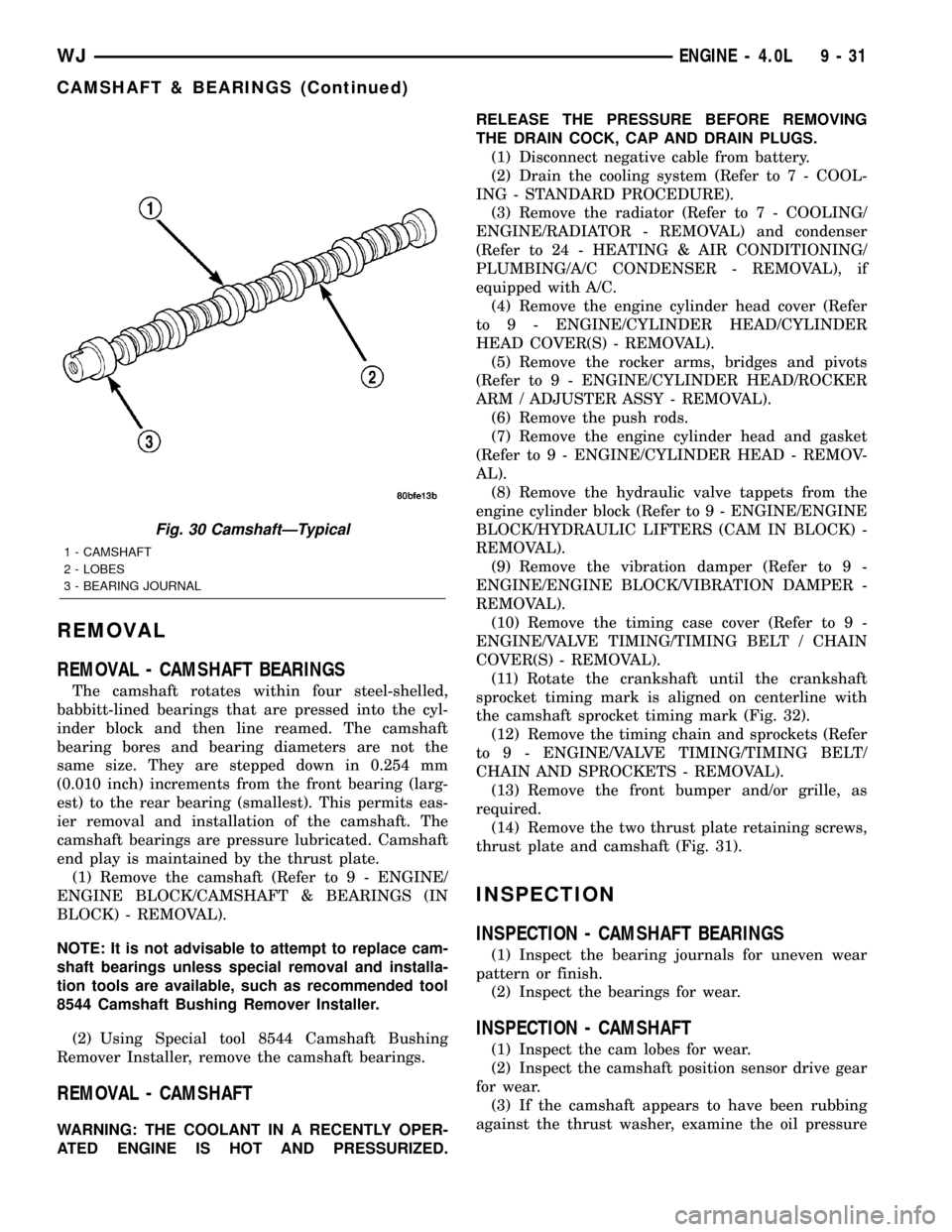

The camshaft rotates within four steel-shelled,

babbitt-lined bearings that are pressed into the cyl-

inder block and then line reamed. The camshaft

bearing bores and bearing diameters are not the

same size. They are stepped down in 0.254 mm

(0.010 inch) increments from the front bearing (larg-

est) to the rear bearing (smallest). This permits eas-

ier removal and installation of the camshaft. The

camshaft bearings are pressure lubricated. Camshaft

end play is maintained by the thrust plate.

(1) Remove the camshaft (Refer to 9 - ENGINE/

ENGINE BLOCK/CAMSHAFT & BEARINGS (IN

BLOCK) - REMOVAL).

NOTE: It is not advisable to attempt to replace cam-

shaft bearings unless special removal and installa-

tion tools are available, such as recommended tool

8544 Camshaft Bushing Remover Installer.

(2) Using Special tool 8544 Camshaft Bushing

Remover Installer, remove the camshaft bearings.

REMOVAL - CAMSHAFT

WARNING: THE COOLANT IN A RECENTLY OPER-

ATED ENGINE IS HOT AND PRESSURIZED.RELEASE THE PRESSURE BEFORE REMOVING

THE DRAIN COCK, CAP AND DRAIN PLUGS.

(1) Disconnect negative cable from battery.

(2) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(3) Remove the radiator (Refer to 7 - COOLING/

ENGINE/RADIATOR - REMOVAL) and condenser

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C CONDENSER - REMOVAL), if

equipped with A/C.

(4) Remove the engine cylinder head cover (Refer

to 9 - ENGINE/CYLINDER HEAD/CYLINDER

HEAD COVER(S) - REMOVAL).

(5) Remove the rocker arms, bridges and pivots

(Refer to 9 - ENGINE/CYLINDER HEAD/ROCKER

ARM / ADJUSTER ASSY - REMOVAL).

(6) Remove the push rods.

(7) Remove the engine cylinder head and gasket

(Refer to 9 - ENGINE/CYLINDER HEAD - REMOV-

AL).

(8) Remove the hydraulic valve tappets from the

engine cylinder block (Refer to 9 - ENGINE/ENGINE

BLOCK/HYDRAULIC LIFTERS (CAM IN BLOCK) -

REMOVAL).

(9) Remove the vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(10) Remove the timing case cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

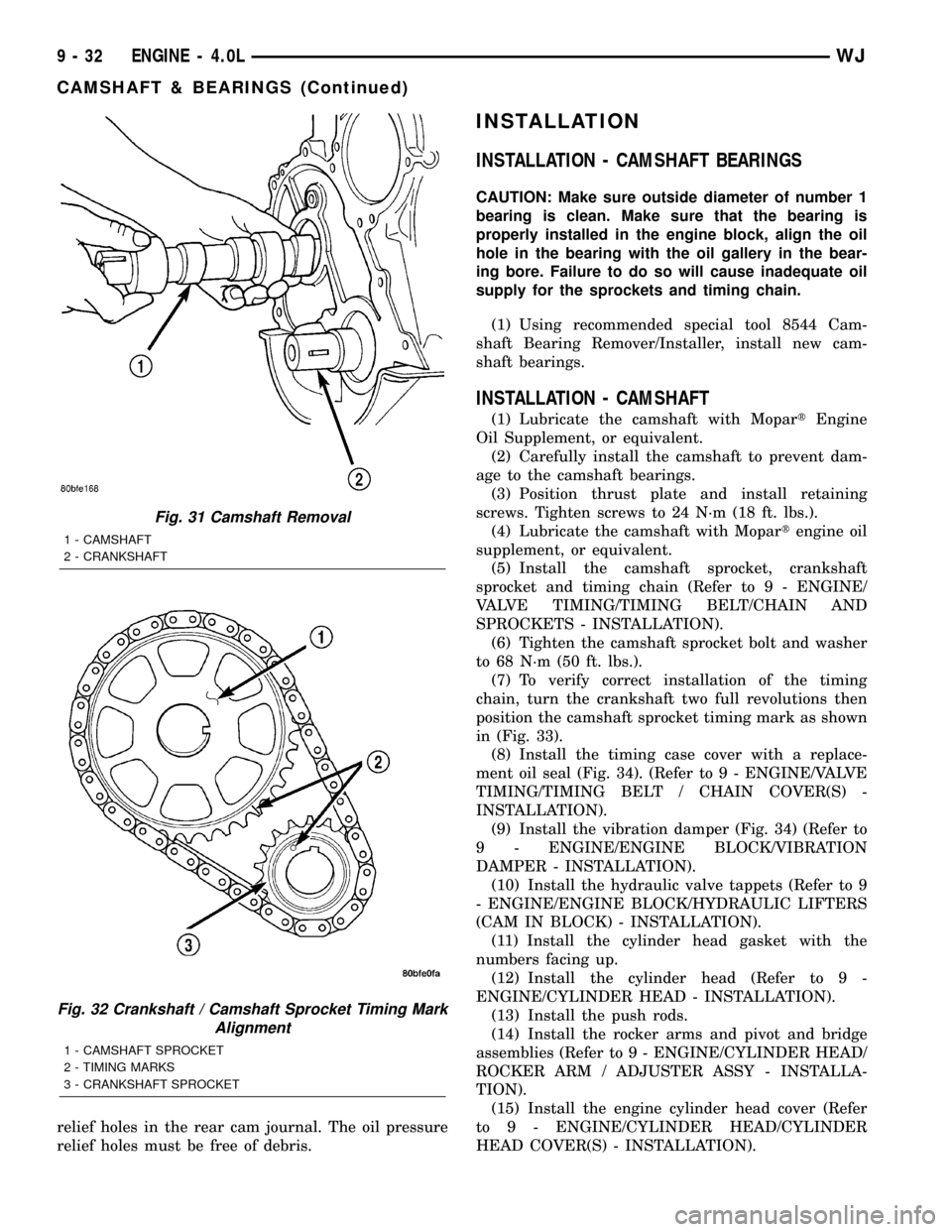

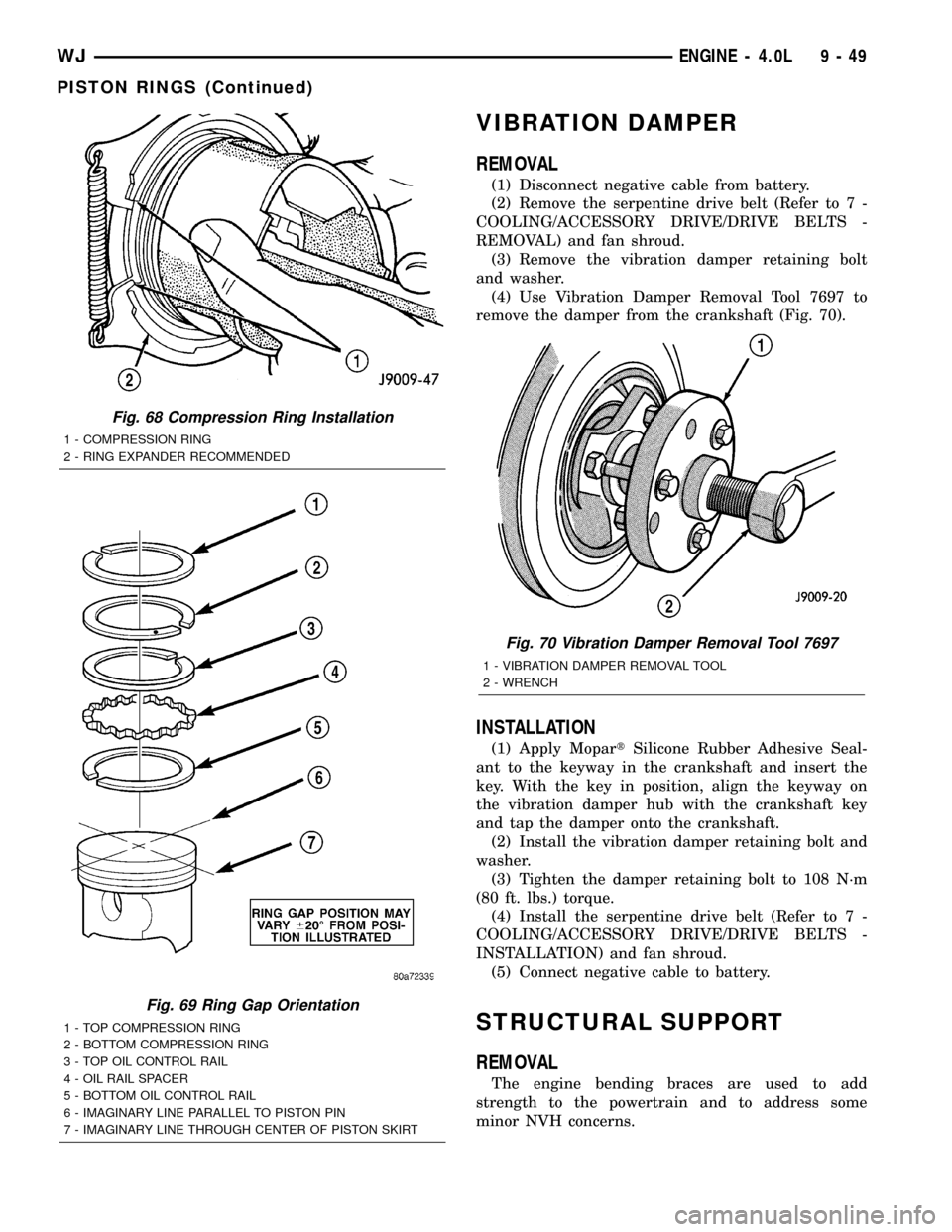

(11) Rotate the crankshaft until the crankshaft

sprocket timing mark is aligned on centerline with

the camshaft sprocket timing mark (Fig. 32).

(12) Remove the timing chain and sprockets (Refer

to 9 - ENGINE/VALVE TIMING/TIMING BELT/

CHAIN AND SPROCKETS - REMOVAL).

(13) Remove the front bumper and/or grille, as

required.

(14) Remove the two thrust plate retaining screws,

thrust plate and camshaft (Fig. 31).

INSPECTION

INSPECTION - CAMSHAFT BEARINGS

(1) Inspect the bearing journals for uneven wear

pattern or finish.

(2) Inspect the bearings for wear.

INSPECTION - CAMSHAFT

(1) Inspect the cam lobes for wear.

(2) Inspect the camshaft position sensor drive gear

for wear.

(3) If the camshaft appears to have been rubbing

against the thrust washer, examine the oil pressure

Fig. 30 CamshaftÐTypical

1 - CAMSHAFT

2 - LOBES

3 - BEARING JOURNAL

WJENGINE - 4.0L 9 - 31

CAMSHAFT & BEARINGS (Continued)

Page 1275 of 2199

relief holes in the rear cam journal. The oil pressure

relief holes must be free of debris.

INSTALLATION

INSTALLATION - CAMSHAFT BEARINGS

CAUTION: Make sure outside diameter of number 1

bearing is clean. Make sure that the bearing is

properly installed in the engine block, align the oil

hole in the bearing with the oil gallery in the bear-

ing bore. Failure to do so will cause inadequate oil

supply for the sprockets and timing chain.

(1) Using recommended special tool 8544 Cam-

shaft Bearing Remover/Installer, install new cam-

shaft bearings.

INSTALLATION - CAMSHAFT

(1) Lubricate the camshaft with MopartEngine

Oil Supplement, or equivalent.

(2) Carefully install the camshaft to prevent dam-

age to the camshaft bearings.

(3) Position thrust plate and install retaining

screws. Tighten screws to 24 N´m (18 ft. lbs.).

(4) Lubricate the camshaft with Mopartengine oil

supplement, or equivalent.

(5) Install the camshaft sprocket, crankshaft

sprocket and timing chain (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION).

(6) Tighten the camshaft sprocket bolt and washer

to 68 N´m (50 ft. lbs.).

(7) To verify correct installation of the timing

chain, turn the crankshaft two full revolutions then

position the camshaft sprocket timing mark as shown

in (Fig. 33).

(8) Install the timing case cover with a replace-

ment oil seal (Fig. 34). (Refer to 9 - ENGINE/VALVE

TIMING/TIMING BELT / CHAIN COVER(S) -

INSTALLATION).

(9) Install the vibration damper (Fig. 34) (Refer to

9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - INSTALLATION).

(10) Install the hydraulic valve tappets (Refer to 9

- ENGINE/ENGINE BLOCK/HYDRAULIC LIFTERS

(CAM IN BLOCK) - INSTALLATION).

(11) Install the cylinder head gasket with the

numbers facing up.

(12) Install the cylinder head (Refer to 9 -

ENGINE/CYLINDER HEAD - INSTALLATION).

(13) Install the push rods.

(14) Install the rocker arms and pivot and bridge

assemblies (Refer to 9 - ENGINE/CYLINDER HEAD/

ROCKER ARM / ADJUSTER ASSY - INSTALLA-

TION).

(15) Install the engine cylinder head cover (Refer

to 9 - ENGINE/CYLINDER HEAD/CYLINDER

HEAD COVER(S) - INSTALLATION).

Fig. 31 Camshaft Removal

1 - CAMSHAFT

2 - CRANKSHAFT

Fig. 32 Crankshaft / Camshaft Sprocket Timing Mark

Alignment

1 - CAMSHAFT SPROCKET

2 - TIMING MARKS

3 - CRANKSHAFT SPROCKET

9 - 32 ENGINE - 4.0LWJ

CAMSHAFT & BEARINGS (Continued)

Page 1292 of 2199

VIBRATION DAMPER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the serpentine drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL) and fan shroud.

(3) Remove the vibration damper retaining bolt

and washer.

(4) Use Vibration Damper Removal Tool 7697 to

remove the damper from the crankshaft (Fig. 70).

INSTALLATION

(1) Apply MopartSilicone Rubber Adhesive Seal-

ant to the keyway in the crankshaft and insert the

key. With the key in position, align the keyway on

the vibration damper hub with the crankshaft key

and tap the damper onto the crankshaft.

(2) Install the vibration damper retaining bolt and

washer.

(3) Tighten the damper retaining bolt to 108 N´m

(80 ft. lbs.) torque.

(4) Install the serpentine drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION) and fan shroud.

(5) Connect negative cable to battery.

STRUCTURAL SUPPORT

REMOVAL

The engine bending braces are used to add

strength to the powertrain and to address some

minor NVH concerns.

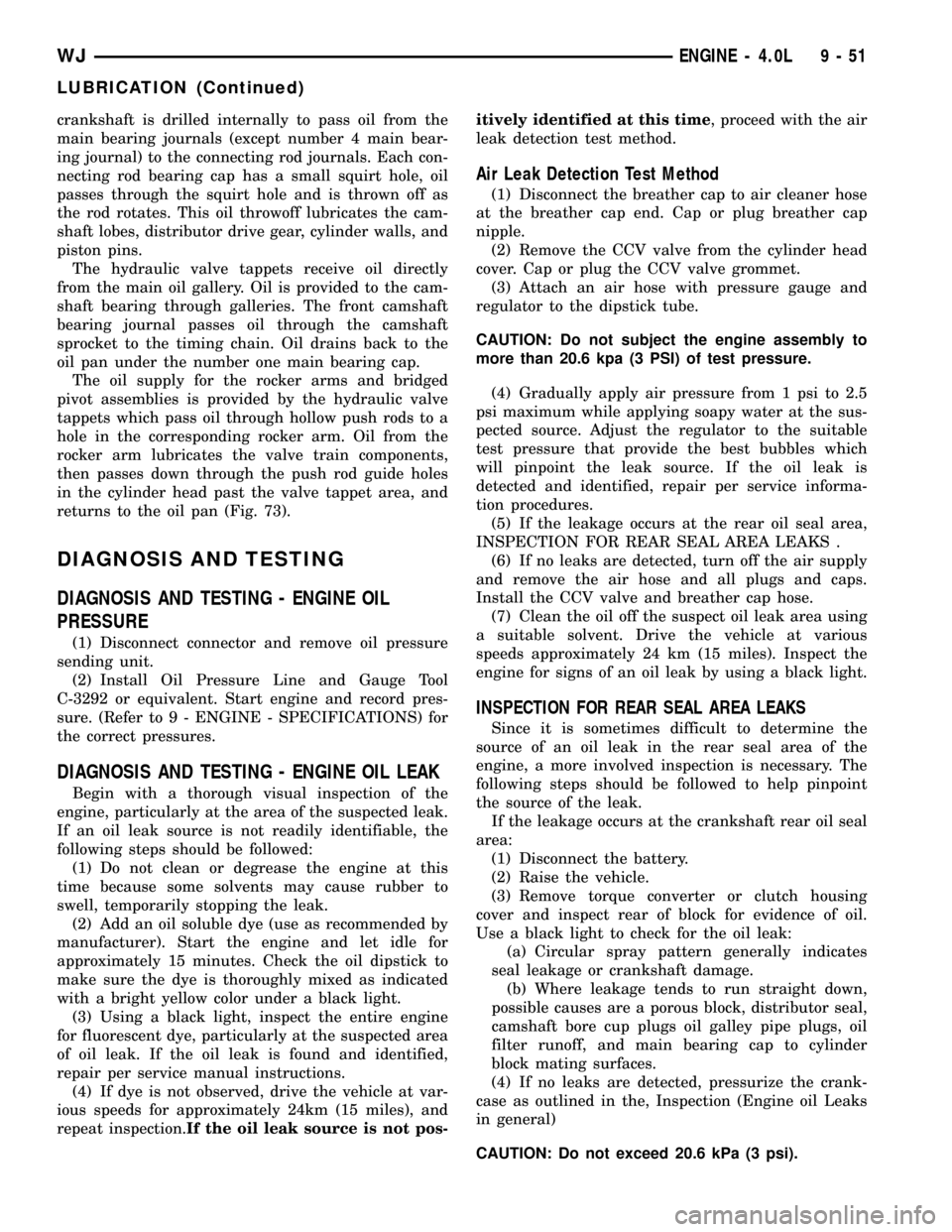

Fig. 68 Compression Ring Installation

1 - COMPRESSION RING

2 - RING EXPANDER RECOMMENDED

Fig. 69 Ring Gap Orientation

1 - TOP COMPRESSION RING

2 - BOTTOM COMPRESSION RING

3 - TOP OIL CONTROL RAIL

4 - OIL RAIL SPACER

5 - BOTTOM OIL CONTROL RAIL

6 - IMAGINARY LINE PARALLEL TO PISTON PIN

7 - IMAGINARY LINE THROUGH CENTER OF PISTON SKIRT

Fig. 70 Vibration Damper Removal Tool 7697

1 - VIBRATION DAMPER REMOVAL TOOL

2 - WRENCH

WJENGINE - 4.0L 9 - 49

PISTON RINGS (Continued)

Page 1294 of 2199

crankshaft is drilled internally to pass oil from the

main bearing journals (except number 4 main bear-

ing journal) to the connecting rod journals. Each con-

necting rod bearing cap has a small squirt hole, oil

passes through the squirt hole and is thrown off as

the rod rotates. This oil throwoff lubricates the cam-

shaft lobes, distributor drive gear, cylinder walls, and

piston pins.

The hydraulic valve tappets receive oil directly

from the main oil gallery. Oil is provided to the cam-

shaft bearing through galleries. The front camshaft

bearing journal passes oil through the camshaft

sprocket to the timing chain. Oil drains back to the

oil pan under the number one main bearing cap.

The oil supply for the rocker arms and bridged

pivot assemblies is provided by the hydraulic valve

tappets which pass oil through hollow push rods to a

hole in the corresponding rocker arm. Oil from the

rocker arm lubricates the valve train components,

then passes down through the push rod guide holes

in the cylinder head past the valve tappet area, and

returns to the oil pan (Fig. 73).

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE OIL

PRESSURE

(1) Disconnect connector and remove oil pressure

sending unit.

(2) Install Oil Pressure Line and Gauge Tool

C-3292 or equivalent. Start engine and record pres-

sure. (Refer to 9 - ENGINE - SPECIFICATIONS) for

the correct pressures.

DIAGNOSIS AND TESTING - ENGINE OIL LEAK

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat inspection.If the oil leak source is not pos-itively identified at this time, proceed with the air

leak detection test method.

Air Leak Detection Test Method

(1) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(2) Remove the CCV valve from the cylinder head

cover. Cap or plug the CCV valve grommet.

(3) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(4) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service informa-

tion procedures.

(5) If the leakage occurs at the rear oil seal area,

INSPECTION FOR REAR SEAL AREA LEAKS .

(6) If no leaks are detected, turn off the air supply

and remove the air hose and all plugs and caps.

Install the CCV valve and breather cap hose.

(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, distributor seal,

camshaft bore cup plugs oil galley pipe plugs, oil

filter runoff, and main bearing cap to cylinder

block mating surfaces.

(4) If no leaks are detected, pressurize the crank-

case as outlined in the, Inspection (Engine oil Leaks

in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

WJENGINE - 4.0L 9 - 51

LUBRICATION (Continued)

Page 1313 of 2199

STANDARD PROCEDURE

STANDARD PROCEDURE - REPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTV

MopartATF RTV is a specifically designed black

silicone rubber RTV that retains adhesion and seal-

ing properties to seal components exposed to auto-

matic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKER

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of airwhen squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobic

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4oz./16 oz. can w/applicator.

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier then using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - ENGINE GASKET

SURFACE PREPARATION

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

Neveruse the following to clean gasket surfaces:

²Metal scraper

9 - 70 ENGINE - 4.7LWJ

ENGINE - 4.7L (Continued)

Page 1314 of 2199

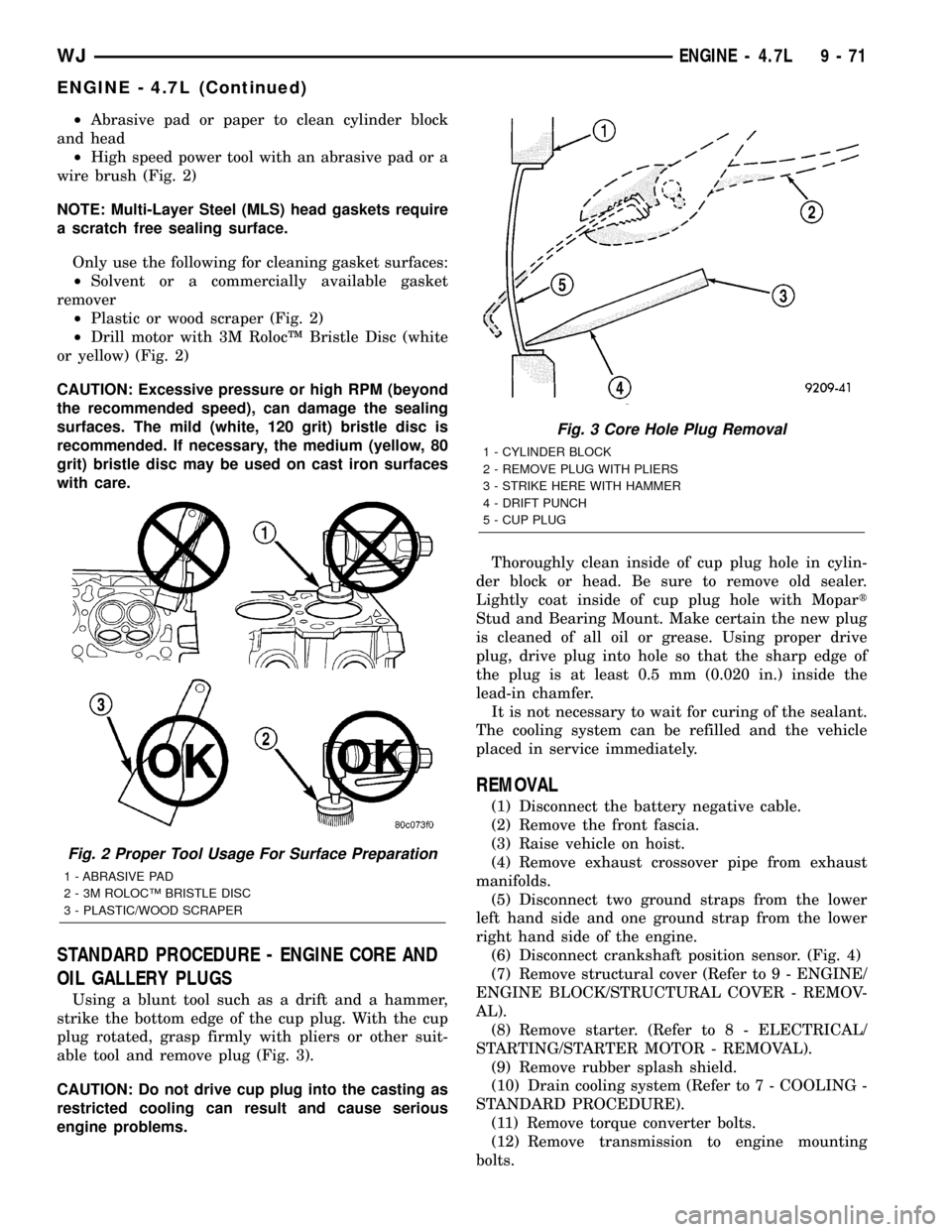

²Abrasive pad or paper to clean cylinder block

and head

²High speed power tool with an abrasive pad or a

wire brush (Fig. 2)

NOTE: Multi-Layer Steel (MLS) head gaskets require

a scratch free sealing surface.

Only use the following for cleaning gasket surfaces:

²Solvent or a commercially available gasket

remover

²Plastic or wood scraper (Fig. 2)

²Drill motor with 3M RolocŸ Bristle Disc (white

or yellow) (Fig. 2)

CAUTION: Excessive pressure or high RPM (beyond

the recommended speed), can damage the sealing

surfaces. The mild (white, 120 grit) bristle disc is

recommended. If necessary, the medium (yellow, 80

grit) bristle disc may be used on cast iron surfaces

with care.

STANDARD PROCEDURE - ENGINE CORE AND

OIL GALLERY PLUGS

Using a blunt tool such as a drift and a hammer,

strike the bottom edge of the cup plug. With the cup

plug rotated, grasp firmly with pliers or other suit-

able tool and remove plug (Fig. 3).

CAUTION: Do not drive cup plug into the casting as

restricted cooling can result and cause serious

engine problems.Thoroughly clean inside of cup plug hole in cylin-

der block or head. Be sure to remove old sealer.

Lightly coat inside of cup plug hole with Mopart

Stud and Bearing Mount. Make certain the new plug

is cleaned of all oil or grease. Using proper drive

plug, drive plug into hole so that the sharp edge of

the plug is at least 0.5 mm (0.020 in.) inside the

lead-in chamfer.

It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle

placed in service immediately.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove the front fascia.

(3) Raise vehicle on hoist.

(4) Remove exhaust crossover pipe from exhaust

manifolds.

(5) Disconnect two ground straps from the lower

left hand side and one ground strap from the lower

right hand side of the engine.

(6) Disconnect crankshaft position sensor. (Fig. 4)

(7) Remove structural cover (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER - REMOV-

AL).

(8) Remove starter. (Refer to 8 - ELECTRICAL/

STARTING/STARTER MOTOR - REMOVAL).

(9) Remove rubber splash shield.

(10) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(11) Remove torque converter bolts.

(12) Remove transmission to engine mounting

bolts.

Fig. 2 Proper Tool Usage For Surface Preparation

1 - ABRASIVE PAD

2 - 3M ROLOCŸ BRISTLE DISC

3 - PLASTIC/WOOD SCRAPER

Fig. 3 Core Hole Plug Removal

1 - CYLINDER BLOCK

2 - REMOVE PLUG WITH PLIERS

3 - STRIKE HERE WITH HAMMER

4 - DRIFT PUNCH

5 - CUP PLUG

WJENGINE - 4.7L 9 - 71

ENGINE - 4.7L (Continued)

Page 1327 of 2199

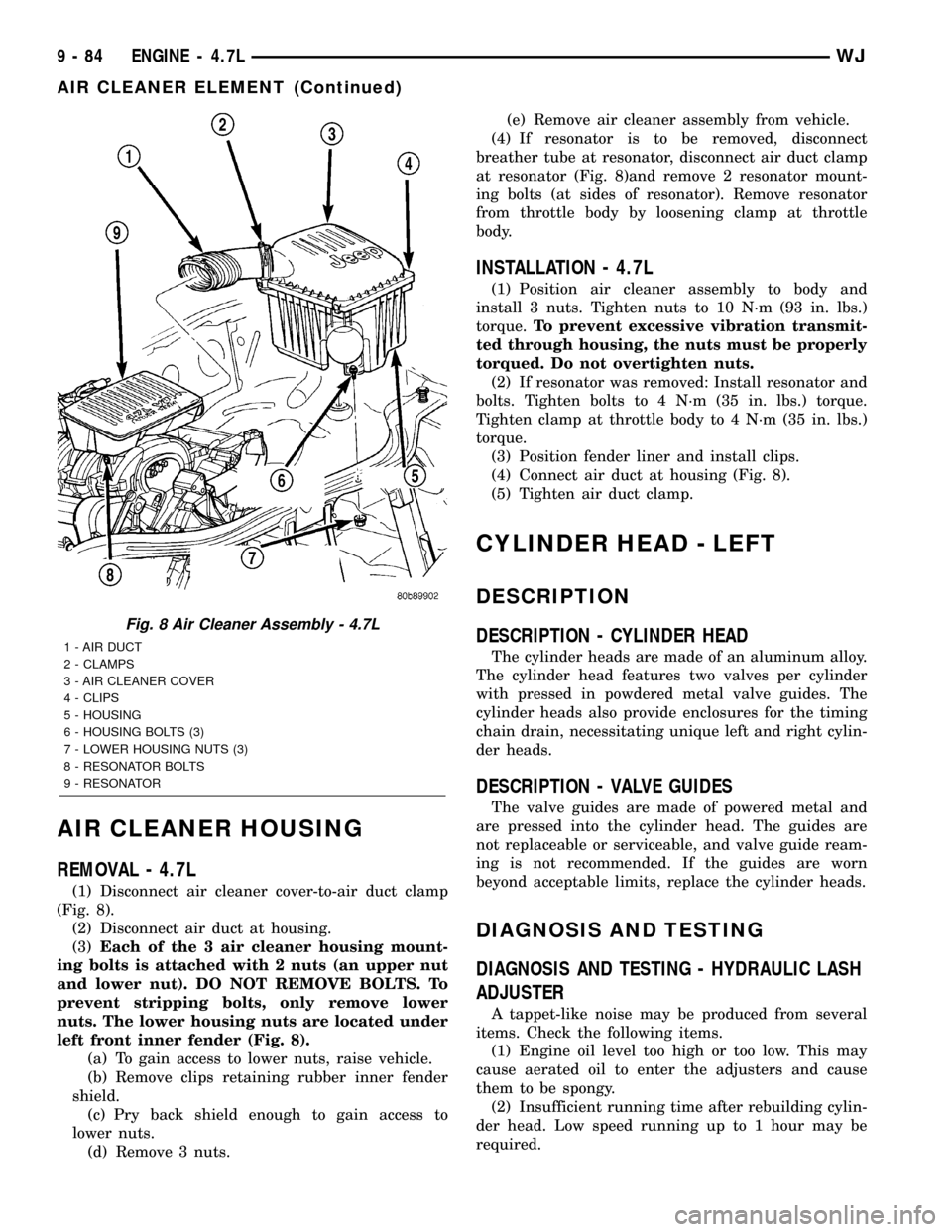

AIR CLEANER HOUSING

REMOVAL - 4.7L

(1) Disconnect air cleaner cover-to-air duct clamp

(Fig. 8).

(2) Disconnect air duct at housing.

(3)Each of the 3 air cleaner housing mount-

ing bolts is attached with 2 nuts (an upper nut

and lower nut). DO NOT REMOVE BOLTS. To

prevent stripping bolts, only remove lower

nuts. The lower housing nuts are located under

left front inner fender (Fig. 8).

(a) To gain access to lower nuts, raise vehicle.

(b) Remove clips retaining rubber inner fender

shield.

(c) Pry back shield enough to gain access to

lower nuts.

(d) Remove 3 nuts.(e) Remove air cleaner assembly from vehicle.

(4) If resonator is to be removed, disconnect

breather tube at resonator, disconnect air duct clamp

at resonator (Fig. 8)and remove 2 resonator mount-

ing bolts (at sides of resonator). Remove resonator

from throttle body by loosening clamp at throttle

body.

INSTALLATION - 4.7L

(1) Position air cleaner assembly to body and

install 3 nuts. Tighten nuts to 10 N´m (93 in. lbs.)

torque.To prevent excessive vibration transmit-

ted through housing, the nuts must be properly

torqued. Do not overtighten nuts.

(2) If resonator was removed: Install resonator and

bolts. Tighten bolts to 4 N´m (35 in. lbs.) torque.

Tighten clamp at throttle body to 4 N´m (35 in. lbs.)

torque.

(3) Position fender liner and install clips.

(4) Connect air duct at housing (Fig. 8).

(5) Tighten air duct clamp.

CYLINDER HEAD - LEFT

DESCRIPTION

DESCRIPTION - CYLINDER HEAD

The cylinder heads are made of an aluminum alloy.

The cylinder head features two valves per cylinder

with pressed in powdered metal valve guides. The

cylinder heads also provide enclosures for the timing

chain drain, necessitating unique left and right cylin-

der heads.

DESCRIPTION - VALVE GUIDES

The valve guides are made of powered metal and

are pressed into the cylinder head. The guides are

not replaceable or serviceable, and valve guide ream-

ing is not recommended. If the guides are worn

beyond acceptable limits, replace the cylinder heads.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - HYDRAULIC LASH

ADJUSTER

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

Fig. 8 Air Cleaner Assembly - 4.7L

1 - AIR DUCT

2 - CLAMPS

3 - AIR CLEANER COVER

4 - CLIPS

5 - HOUSING

6 - HOUSING BOLTS (3)

7 - LOWER HOUSING NUTS (3)

8 - RESONATOR BOLTS

9 - RESONATOR

9 - 84 ENGINE - 4.7LWJ

AIR CLEANER ELEMENT (Continued)