Vin JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1667 of 2199

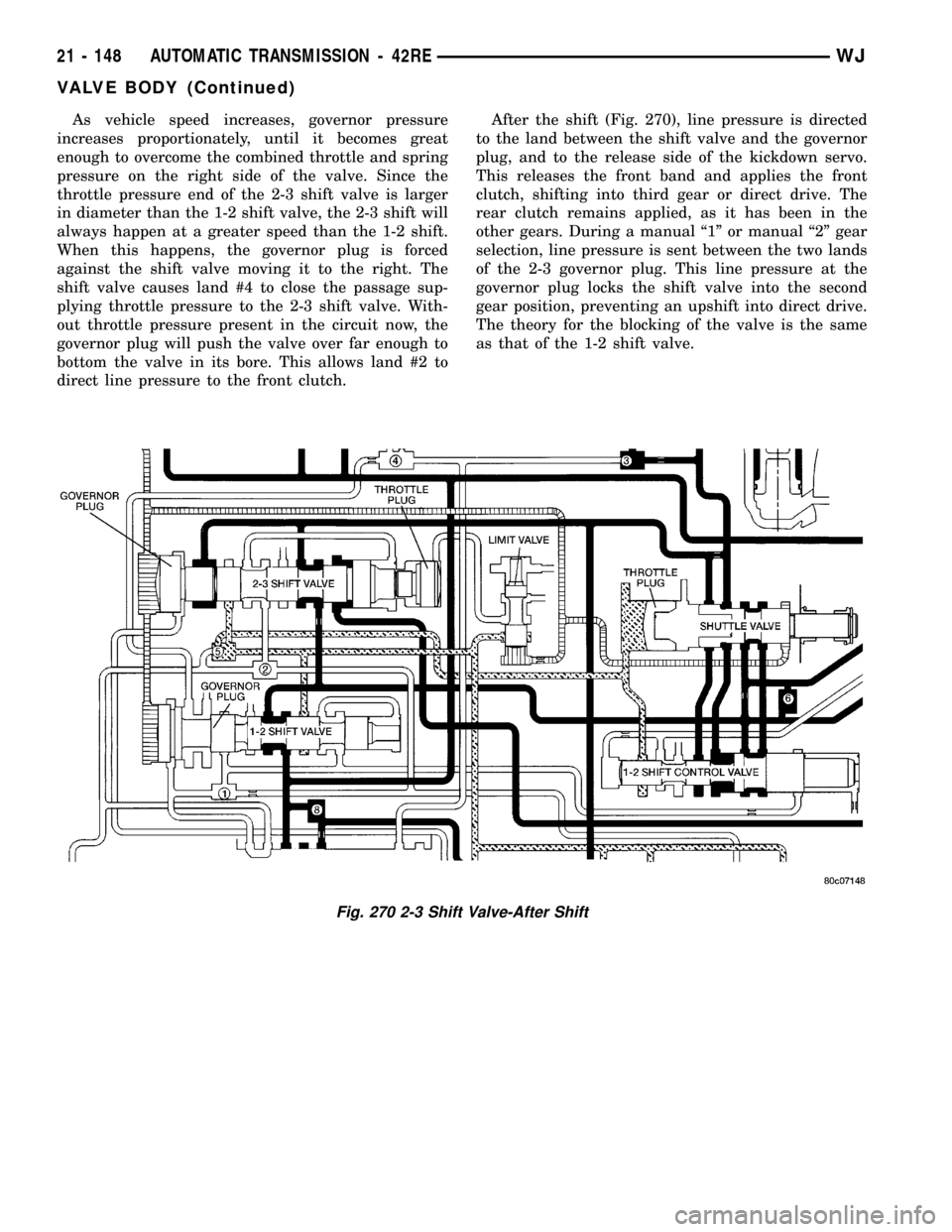

As vehicle speed increases, governor pressure

increases proportionately, until it becomes great

enough to overcome the combined throttle and spring

pressure on the right side of the valve. Since the

throttle pressure end of the 2-3 shift valve is larger

in diameter than the 1-2 shift valve, the 2-3 shift will

always happen at a greater speed than the 1-2 shift.

When this happens, the governor plug is forced

against the shift valve moving it to the right. The

shift valve causes land #4 to close the passage sup-

plying throttle pressure to the 2-3 shift valve. With-

out throttle pressure present in the circuit now, the

governor plug will push the valve over far enough to

bottom the valve in its bore. This allows land #2 to

direct line pressure to the front clutch.After the shift (Fig. 270), line pressure is directed

to the land between the shift valve and the governor

plug, and to the release side of the kickdown servo.

This releases the front band and applies the front

clutch, shifting into third gear or direct drive. The

rear clutch remains applied, as it has been in the

other gears. During a manual ª1º or manual ª2º gear

selection, line pressure is sent between the two lands

of the 2-3 governor plug. This line pressure at the

governor plug locks the shift valve into the second

gear position, preventing an upshift into direct drive.

The theory for the blocking of the valve is the same

as that of the 1-2 shift valve.

Fig. 270 2-3 Shift Valve-After Shift

21 - 148 AUTOMATIC TRANSMISSION - 42REWJ

VALVE BODY (Continued)

Page 1668 of 2199

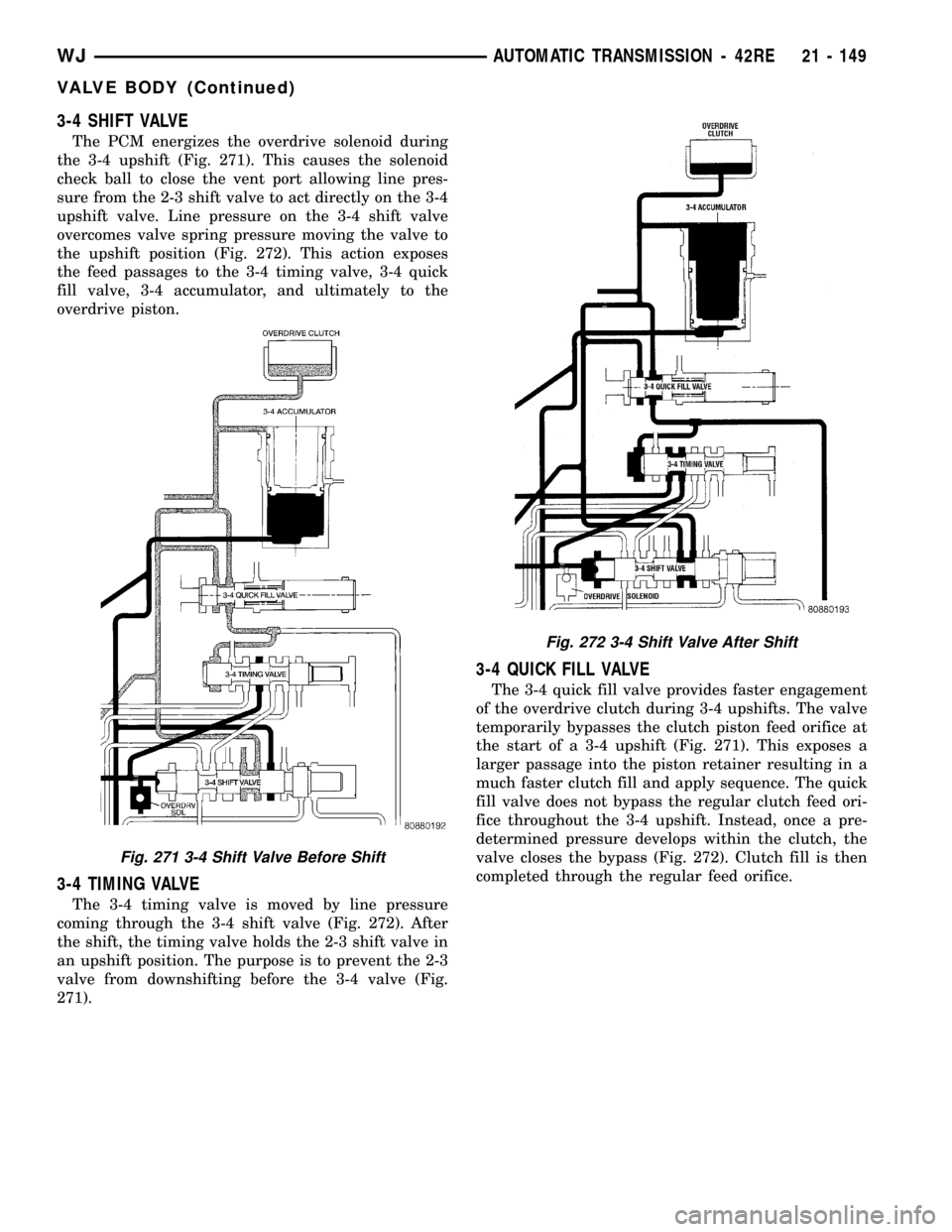

3-4 SHIFT VALVE

The PCM energizes the overdrive solenoid during

the 3-4 upshift (Fig. 271). This causes the solenoid

check ball to close the vent port allowing line pres-

sure from the 2-3 shift valve to act directly on the 3-4

upshift valve. Line pressure on the 3-4 shift valve

overcomes valve spring pressure moving the valve to

the upshift position (Fig. 272). This action exposes

the feed passages to the 3-4 timing valve, 3-4 quick

fill valve, 3-4 accumulator, and ultimately to the

overdrive piston.

3-4 TIMING VALVE

The 3-4 timing valve is moved by line pressure

coming through the 3-4 shift valve (Fig. 272). After

the shift, the timing valve holds the 2-3 shift valve in

an upshift position. The purpose is to prevent the 2-3

valve from downshifting before the 3-4 valve (Fig.

271).

3-4 QUICK FILL VALVE

The 3-4 quick fill valve provides faster engagement

of the overdrive clutch during 3-4 upshifts. The valve

temporarily bypasses the clutch piston feed orifice at

the start of a 3-4 upshift (Fig. 271). This exposes a

larger passage into the piston retainer resulting in a

much faster clutch fill and apply sequence. The quick

fill valve does not bypass the regular clutch feed ori-

fice throughout the 3-4 upshift. Instead, once a pre-

determined pressure develops within the clutch, the

valve closes the bypass (Fig. 272). Clutch fill is then

completed through the regular feed orifice.

Fig. 271 3-4 Shift Valve Before Shift

Fig. 272 3-4 Shift Valve After Shift

WJAUTOMATIC TRANSMISSION - 42RE 21 - 149

VALVE BODY (Continued)

Page 1669 of 2199

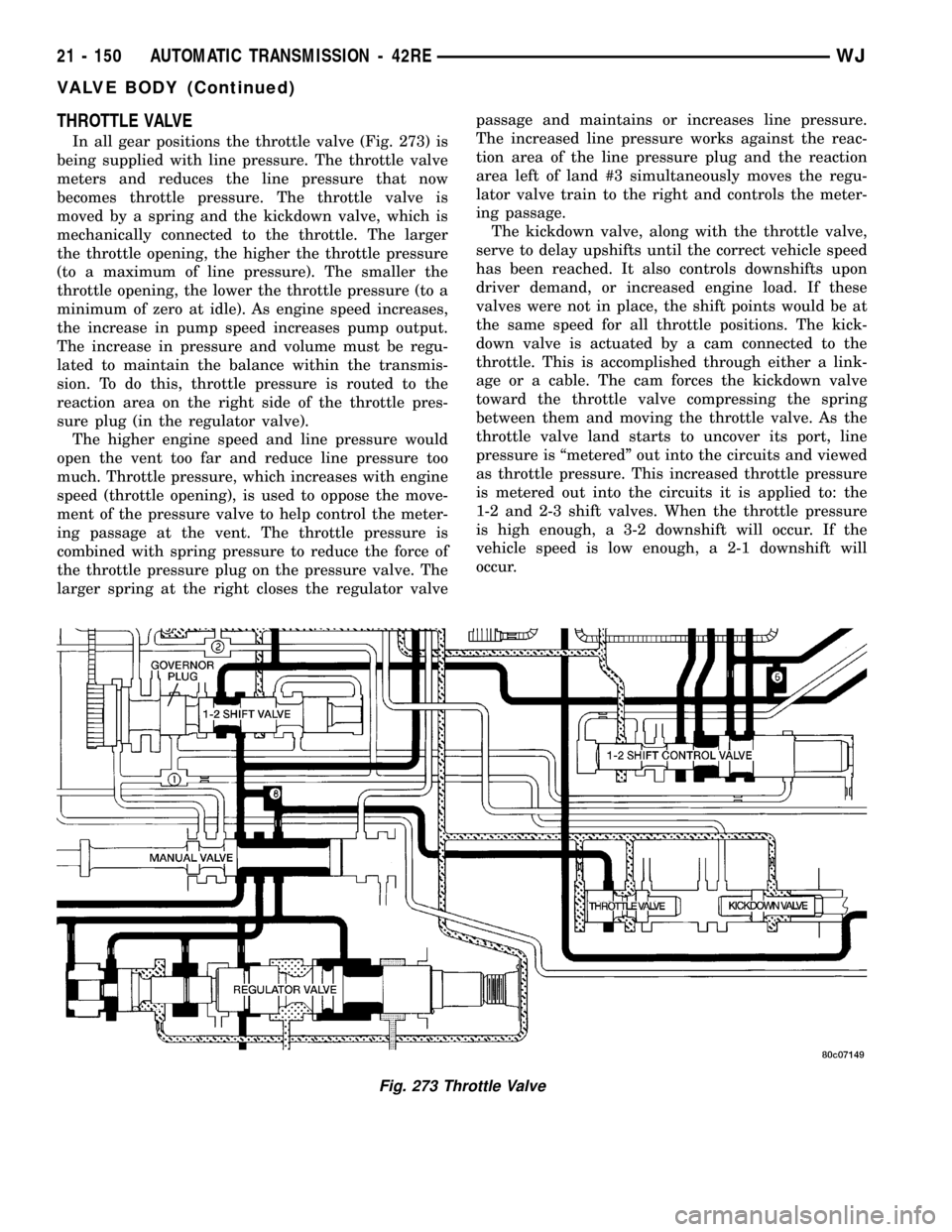

THROTTLE VALVE

In all gear positions the throttle valve (Fig. 273) is

being supplied with line pressure. The throttle valve

meters and reduces the line pressure that now

becomes throttle pressure. The throttle valve is

moved by a spring and the kickdown valve, which is

mechanically connected to the throttle. The larger

the throttle opening, the higher the throttle pressure

(to a maximum of line pressure). The smaller the

throttle opening, the lower the throttle pressure (to a

minimum of zero at idle). As engine speed increases,

the increase in pump speed increases pump output.

The increase in pressure and volume must be regu-

lated to maintain the balance within the transmis-

sion. To do this, throttle pressure is routed to the

reaction area on the right side of the throttle pres-

sure plug (in the regulator valve).

The higher engine speed and line pressure would

open the vent too far and reduce line pressure too

much. Throttle pressure, which increases with engine

speed (throttle opening), is used to oppose the move-

ment of the pressure valve to help control the meter-

ing passage at the vent. The throttle pressure is

combined with spring pressure to reduce the force of

the throttle pressure plug on the pressure valve. The

larger spring at the right closes the regulator valvepassage and maintains or increases line pressure.

The increased line pressure works against the reac-

tion area of the line pressure plug and the reaction

area left of land #3 simultaneously moves the regu-

lator valve train to the right and controls the meter-

ing passage.

The kickdown valve, along with the throttle valve,

serve to delay upshifts until the correct vehicle speed

has been reached. It also controls downshifts upon

driver demand, or increased engine load. If these

valves were not in place, the shift points would be at

the same speed for all throttle positions. The kick-

down valve is actuated by a cam connected to the

throttle. This is accomplished through either a link-

age or a cable. The cam forces the kickdown valve

toward the throttle valve compressing the spring

between them and moving the throttle valve. As the

throttle valve land starts to uncover its port, line

pressure is ªmeteredº out into the circuits and viewed

as throttle pressure. This increased throttle pressure

is metered out into the circuits it is applied to: the

1-2 and 2-3 shift valves. When the throttle pressure

is high enough, a 3-2 downshift will occur. If the

vehicle speed is low enough, a 2-1 downshift will

occur.

Fig. 273 Throttle Valve

21 - 150 AUTOMATIC TRANSMISSION - 42REWJ

VALVE BODY (Continued)

Page 1672 of 2199

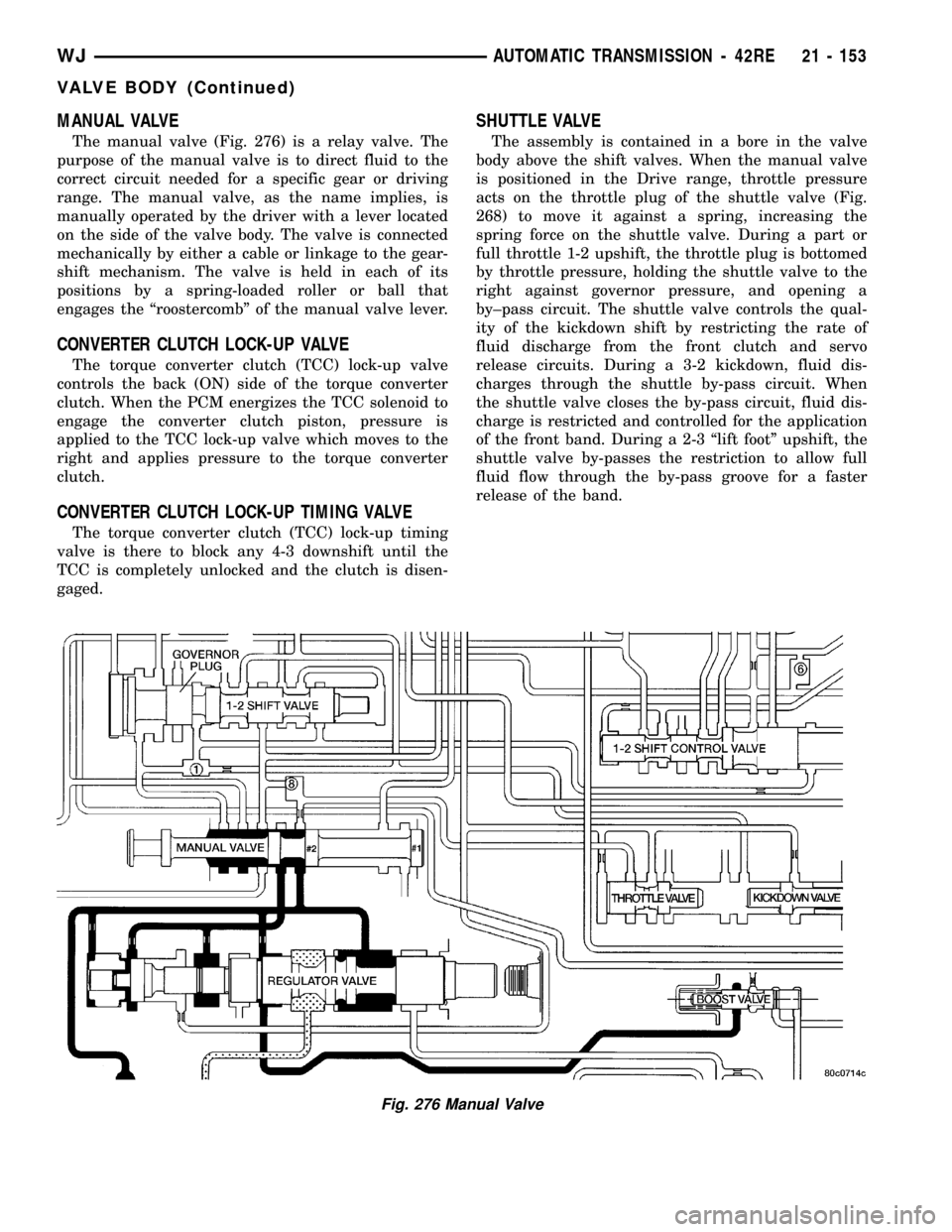

MANUAL VALVE

The manual valve (Fig. 276) is a relay valve. The

purpose of the manual valve is to direct fluid to the

correct circuit needed for a specific gear or driving

range. The manual valve, as the name implies, is

manually operated by the driver with a lever located

on the side of the valve body. The valve is connected

mechanically by either a cable or linkage to the gear-

shift mechanism. The valve is held in each of its

positions by a spring-loaded roller or ball that

engages the ªroostercombº of the manual valve lever.

CONVERTER CLUTCH LOCK-UP VALVE

The torque converter clutch (TCC) lock-up valve

controls the back (ON) side of the torque converter

clutch. When the PCM energizes the TCC solenoid to

engage the converter clutch piston, pressure is

applied to the TCC lock-up valve which moves to the

right and applies pressure to the torque converter

clutch.

CONVERTER CLUTCH LOCK-UP TIMING VALVE

The torque converter clutch (TCC) lock-up timing

valve is there to block any 4-3 downshift until the

TCC is completely unlocked and the clutch is disen-

gaged.

SHUTTLE VALVE

The assembly is contained in a bore in the valve

body above the shift valves. When the manual valve

is positioned in the Drive range, throttle pressure

acts on the throttle plug of the shuttle valve (Fig.

268) to move it against a spring, increasing the

spring force on the shuttle valve. During a part or

full throttle 1-2 upshift, the throttle plug is bottomed

by throttle pressure, holding the shuttle valve to the

right against governor pressure, and opening a

by±pass circuit. The shuttle valve controls the qual-

ity of the kickdown shift by restricting the rate of

fluid discharge from the front clutch and servo

release circuits. During a 3-2 kickdown, fluid dis-

charges through the shuttle by-pass circuit. When

the shuttle valve closes the by-pass circuit, fluid dis-

charge is restricted and controlled for the application

of the front band. During a 2-3 ªlift footº upshift, the

shuttle valve by-passes the restriction to allow full

fluid flow through the by-pass groove for a faster

release of the band.

Fig. 276 Manual Valve

WJAUTOMATIC TRANSMISSION - 42RE 21 - 153

VALVE BODY (Continued)

Page 1673 of 2199

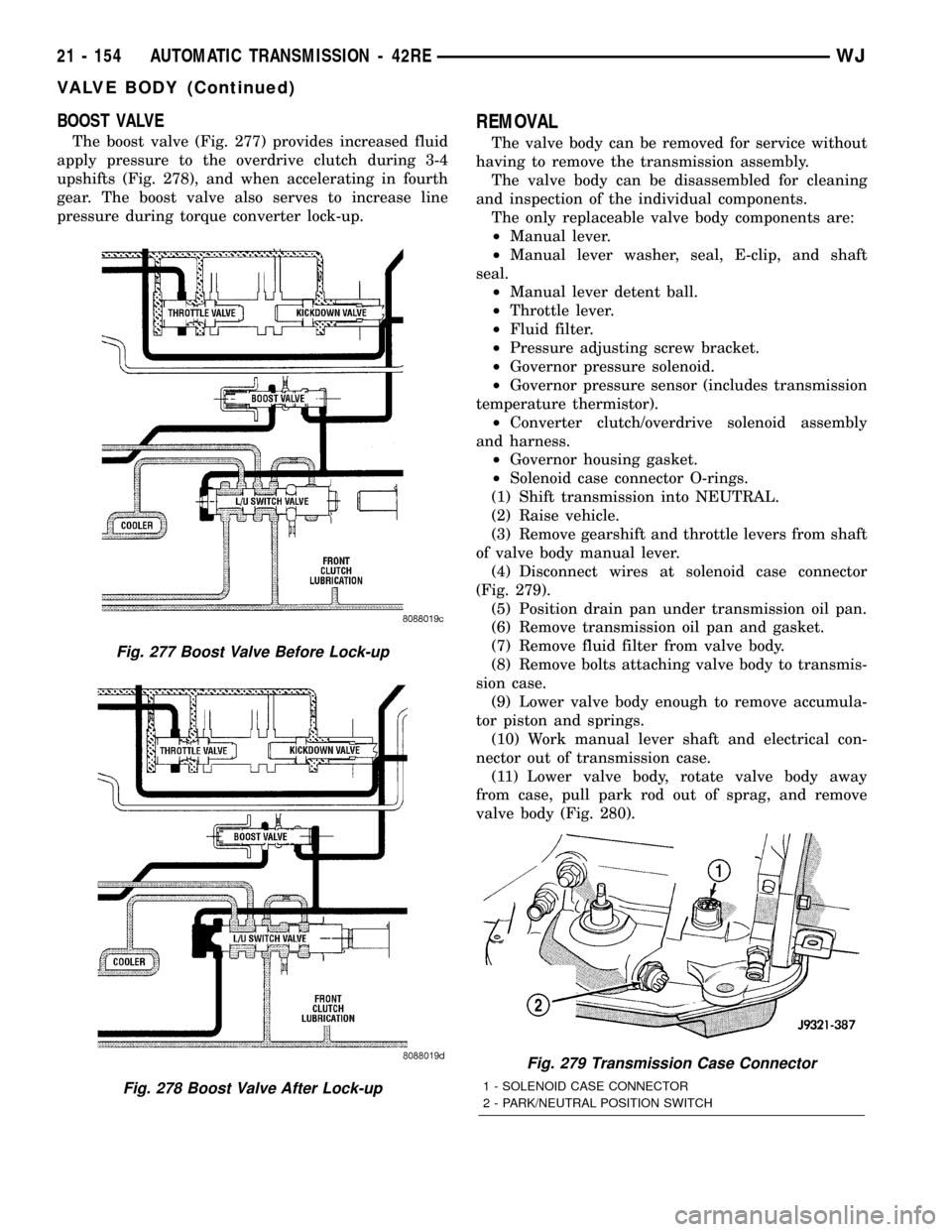

BOOST VALVE

The boost valve (Fig. 277) provides increased fluid

apply pressure to the overdrive clutch during 3-4

upshifts (Fig. 278), and when accelerating in fourth

gear. The boost valve also serves to increase line

pressure during torque converter lock-up.

REMOVAL

The valve body can be removed for service without

having to remove the transmission assembly.

The valve body can be disassembled for cleaning

and inspection of the individual components.

The only replaceable valve body components are:

²Manual lever.

²Manual lever washer, seal, E-clip, and shaft

seal.

²Manual lever detent ball.

²Throttle lever.

²Fluid filter.

²Pressure adjusting screw bracket.

²Governor pressure solenoid.

²Governor pressure sensor (includes transmission

temperature thermistor).

²Converter clutch/overdrive solenoid assembly

and harness.

²Governor housing gasket.

²Solenoid case connector O-rings.

(1) Shift transmission into NEUTRAL.

(2) Raise vehicle.

(3) Remove gearshift and throttle levers from shaft

of valve body manual lever.

(4) Disconnect wires at solenoid case connector

(Fig. 279).

(5) Position drain pan under transmission oil pan.

(6) Remove transmission oil pan and gasket.

(7) Remove fluid filter from valve body.

(8) Remove bolts attaching valve body to transmis-

sion case.

(9) Lower valve body enough to remove accumula-

tor piston and springs.

(10) Work manual lever shaft and electrical con-

nector out of transmission case.

(11) Lower valve body, rotate valve body away

from case, pull park rod out of sprag, and remove

valve body (Fig. 280).

Fig. 277 Boost Valve Before Lock-up

Fig. 278 Boost Valve After Lock-up

Fig. 279 Transmission Case Connector

1 - SOLENOID CASE CONNECTOR

2 - PARK/NEUTRAL POSITION SWITCH

21 - 154 AUTOMATIC TRANSMISSION - 42REWJ

VALVE BODY (Continued)

Page 1676 of 2199

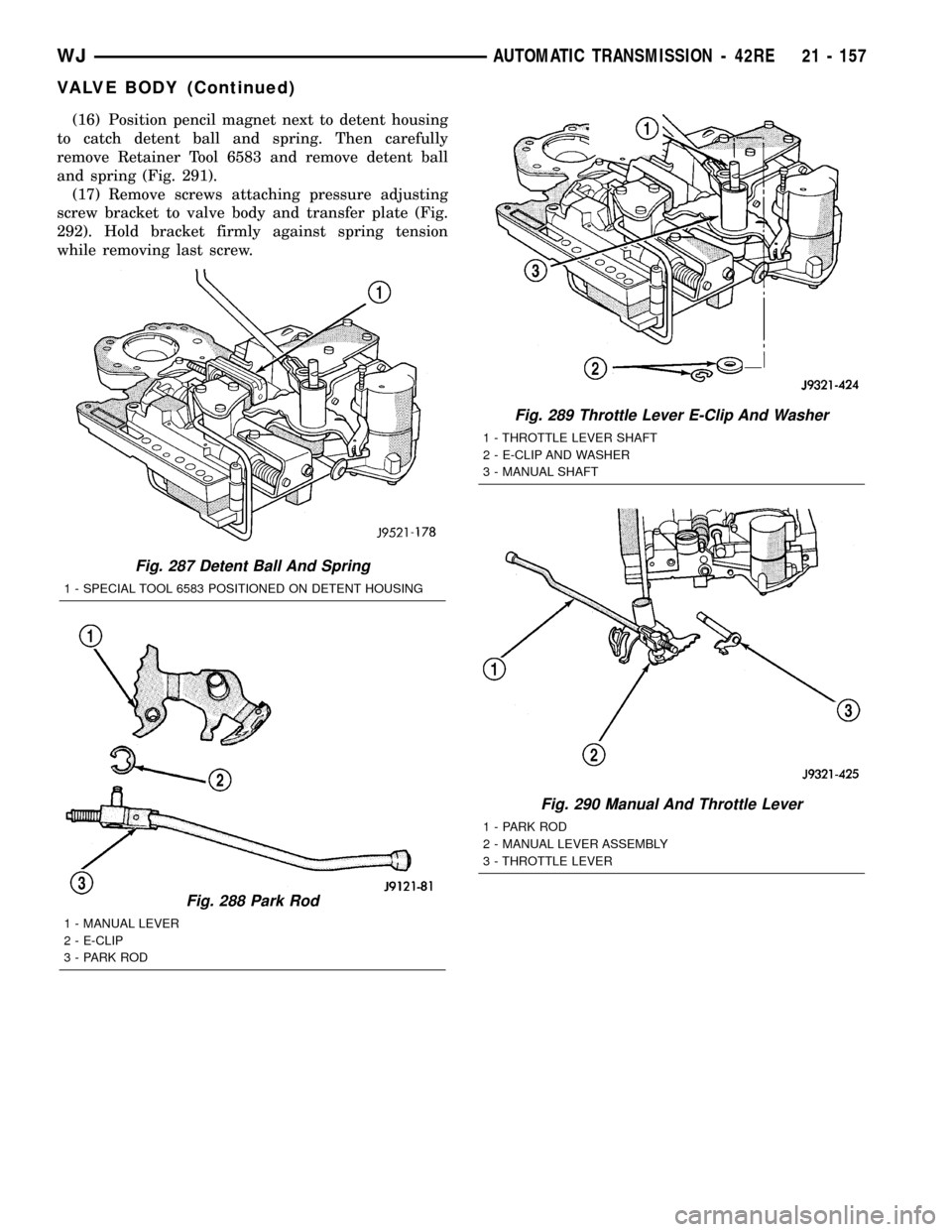

(16) Position pencil magnet next to detent housing

to catch detent ball and spring. Then carefully

remove Retainer Tool 6583 and remove detent ball

and spring (Fig. 291).

(17) Remove screws attaching pressure adjusting

screw bracket to valve body and transfer plate (Fig.

292). Hold bracket firmly against spring tension

while removing last screw.

Fig. 287 Detent Ball And Spring

1 - SPECIAL TOOL 6583 POSITIONED ON DETENT HOUSING

Fig. 288 Park Rod

1 - MANUAL LEVER

2 - E-CLIP

3 - PARK ROD

Fig. 289 Throttle Lever E-Clip And Washer

1 - THROTTLE LEVER SHAFT

2 - E-CLIP AND WASHER

3 - MANUAL SHAFT

Fig. 290 Manual And Throttle Lever

1 - PARK ROD

2 - MANUAL LEVER ASSEMBLY

3 - THROTTLE LEVER

WJAUTOMATIC TRANSMISSION - 42RE 21 - 157

VALVE BODY (Continued)

Page 1698 of 2199

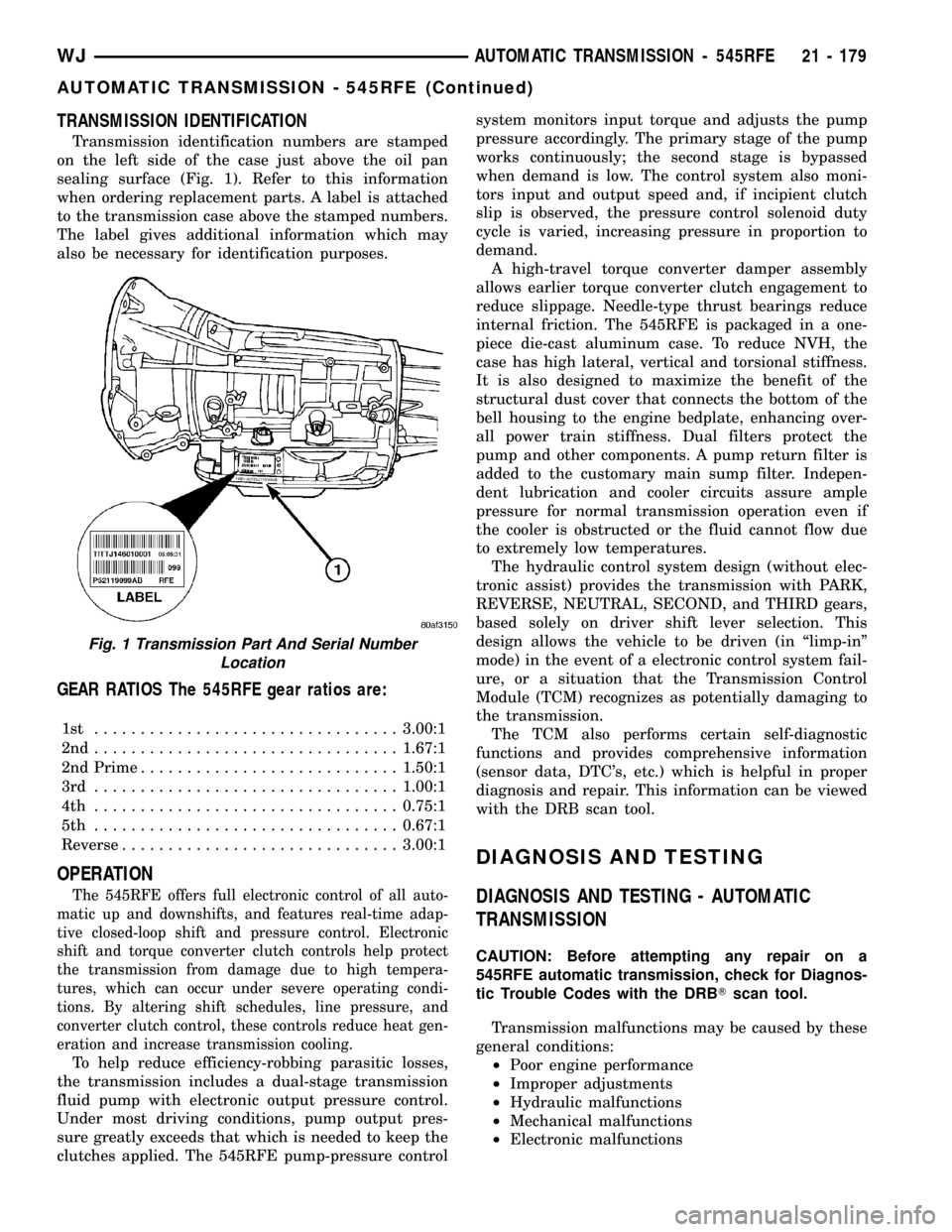

TRANSMISSION IDENTIFICATION

Transmission identification numbers are stamped

on the left side of the case just above the oil pan

sealing surface (Fig. 1). Refer to this information

when ordering replacement parts. A label is attached

to the transmission case above the stamped numbers.

The label gives additional information which may

also be necessary for identification purposes.

GEAR RATIOS The 545RFE gear ratios are:

1st .................................3.00:1

2nd.................................1.67:1

2nd Prime............................1.50:1

3rd .................................1.00:1

4th .................................0.75:1

5th .................................0.67:1

Reverse..............................3.00:1

OPERATION

The 545RFE offers full electronic control of all auto-

matic up and downshifts, and features real-time adap-

tive closed-loop shift and pressure control. Electronic

shift and torque converter clutch controls help protect

the transmission from damage due to high tempera-

tures, which can occur under severe operating condi-

tions. By altering shift schedules, line pressure, and

converter clutch control, these controls reduce heat gen-

eration and increase transmission cooling.

To help reduce efficiency-robbing parasitic losses,

the transmission includes a dual-stage transmission

fluid pump with electronic output pressure control.

Under most driving conditions, pump output pres-

sure greatly exceeds that which is needed to keep the

clutches applied. The 545RFE pump-pressure controlsystem monitors input torque and adjusts the pump

pressure accordingly. The primary stage of the pump

works continuously; the second stage is bypassed

when demand is low. The control system also moni-

tors input and output speed and, if incipient clutch

slip is observed, the pressure control solenoid duty

cycle is varied, increasing pressure in proportion to

demand.

A high-travel torque converter damper assembly

allows earlier torque converter clutch engagement to

reduce slippage. Needle-type thrust bearings reduce

internal friction. The 545RFE is packaged in a one-

piece die-cast aluminum case. To reduce NVH, the

case has high lateral, vertical and torsional stiffness.

It is also designed to maximize the benefit of the

structural dust cover that connects the bottom of the

bell housing to the engine bedplate, enhancing over-

all power train stiffness. Dual filters protect the

pump and other components. A pump return filter is

added to the customary main sump filter. Indepen-

dent lubrication and cooler circuits assure ample

pressure for normal transmission operation even if

the cooler is obstructed or the fluid cannot flow due

to extremely low temperatures.

The hydraulic control system design (without elec-

tronic assist) provides the transmission with PARK,

REVERSE, NEUTRAL, SECOND, and THIRD gears,

based solely on driver shift lever selection. This

design allows the vehicle to be driven (in ªlimp-inº

mode) in the event of a electronic control system fail-

ure, or a situation that the Transmission Control

Module (TCM) recognizes as potentially damaging to

the transmission.

The TCM also performs certain self-diagnostic

functions and provides comprehensive information

(sensor data, DTC's, etc.) which is helpful in proper

diagnosis and repair. This information can be viewed

with the DRB scan tool.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION

CAUTION: Before attempting any repair on a

545RFE automatic transmission, check for Diagnos-

tic Trouble Codes with the DRBTscan tool.

Transmission malfunctions may be caused by these

general conditions:

²Poor engine performance

²Improper adjustments

²Hydraulic malfunctions

²Mechanical malfunctions

²Electronic malfunctions

Fig. 1 Transmission Part And Serial Number

Location

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 179

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1701 of 2199

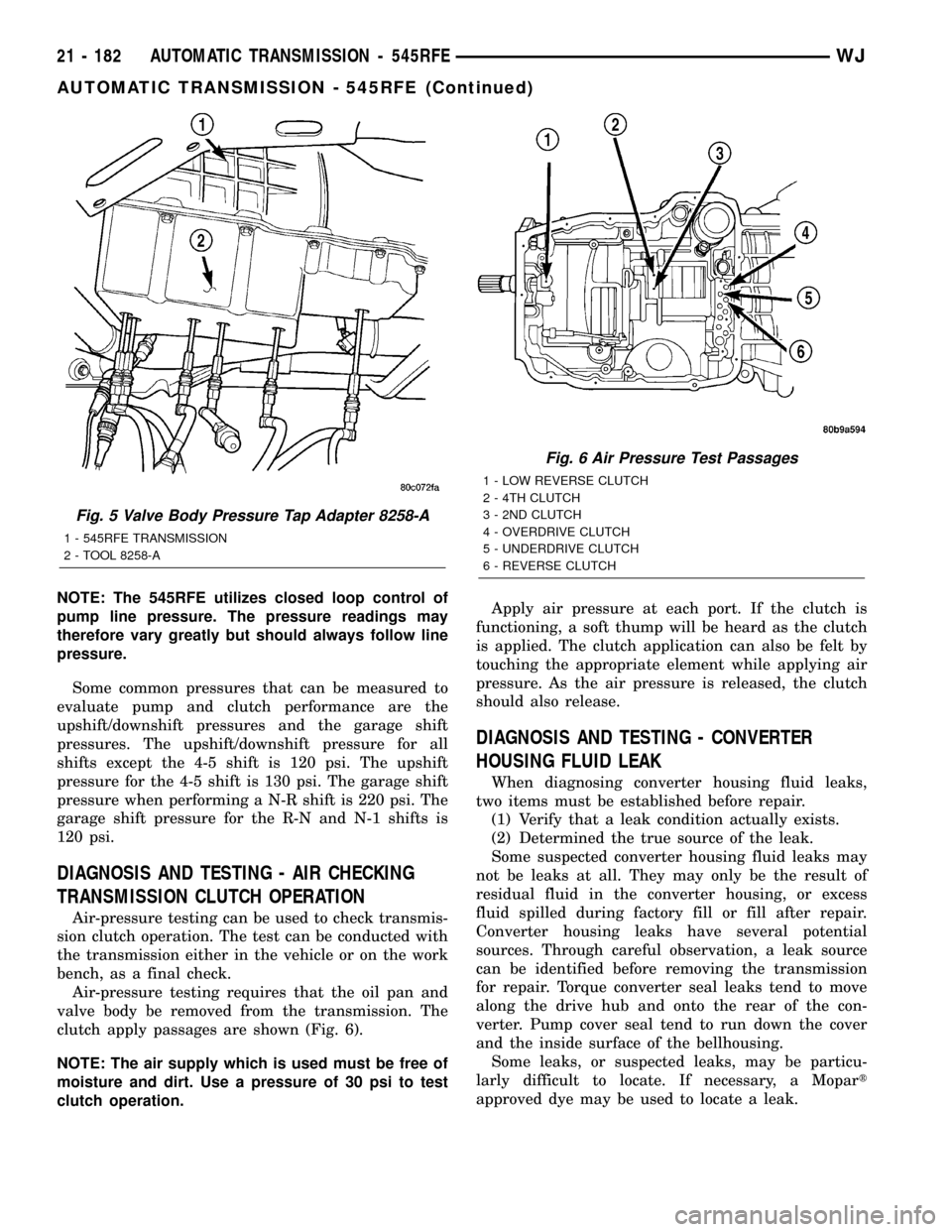

NOTE: The 545RFE utilizes closed loop control of

pump line pressure. The pressure readings may

therefore vary greatly but should always follow line

pressure.

Some common pressures that can be measured to

evaluate pump and clutch performance are the

upshift/downshift pressures and the garage shift

pressures. The upshift/downshift pressure for all

shifts except the 4-5 shift is 120 psi. The upshift

pressure for the 4-5 shift is 130 psi. The garage shift

pressure when performing a N-R shift is 220 psi. The

garage shift pressure for the R-N and N-1 shifts is

120 psi.

DIAGNOSIS AND TESTING - AIR CHECKING

TRANSMISSION CLUTCH OPERATION

Air-pressure testing can be used to check transmis-

sion clutch operation. The test can be conducted with

the transmission either in the vehicle or on the work

bench, as a final check.

Air-pressure testing requires that the oil pan and

valve body be removed from the transmission. The

clutch apply passages are shown (Fig. 6).

NOTE: The air supply which is used must be free of

moisture and dirt. Use a pressure of 30 psi to test

clutch operation.Apply air pressure at each port. If the clutch is

functioning, a soft thump will be heard as the clutch

is applied. The clutch application can also be felt by

touching the appropriate element while applying air

pressure. As the air pressure is released, the clutch

should also release.

DIAGNOSIS AND TESTING - CONVERTER

HOUSING FLUID LEAK

When diagnosing converter housing fluid leaks,

two items must be established before repair.

(1) Verify that a leak condition actually exists.

(2) Determined the true source of the leak.

Some suspected converter housing fluid leaks may

not be leaks at all. They may only be the result of

residual fluid in the converter housing, or excess

fluid spilled during factory fill or fill after repair.

Converter housing leaks have several potential

sources. Through careful observation, a leak source

can be identified before removing the transmission

for repair. Torque converter seal leaks tend to move

along the drive hub and onto the rear of the con-

verter. Pump cover seal tend to run down the cover

and the inside surface of the bellhousing.

Some leaks, or suspected leaks, may be particu-

larly difficult to locate. If necessary, a Mopart

approved dye may be used to locate a leak.

Fig. 5 Valve Body Pressure Tap Adapter 8258-A

1 - 545RFE TRANSMISSION

2 - TOOL 8258-A

Fig. 6 Air Pressure Test Passages

1 - LOW REVERSE CLUTCH

2 - 4TH CLUTCH

3 - 2ND CLUTCH

4 - OVERDRIVE CLUTCH

5 - UNDERDRIVE CLUTCH

6 - REVERSE CLUTCH

21 - 182 AUTOMATIC TRANSMISSION - 545RFEWJ

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1748 of 2199

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transmssion has too much fluid, the

geartrain churns up foam and cause the same condi-

tions which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can inter-

fere with normal valve, clutch, and accumulator opera-

tion. Foaming can also result in fluid escaping from the

transmission vent where it may be mistaken for a leak.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

The transmission has a dipstick to check oil level.

It is located on the right side of the engine. Be sure

to wipe all dirt from dipstick handle before removing.

The torque converter fills in both the P (PARK)

and N (NEUTRAL) positions. Place the selector lever

in P (PARK) to be sure that the fluid level check is

accurate.The engine should be running at idle

speed for at least one minute, with the vehicle

on level ground.At normal operating temperature(approximately 82 C. or 180 F.), the fluid level is cor-

rect if it is in the HOT region (cross-hatched area) on

the oil level indicator. The fluid level will be approx-

imately at the upper COLD hole of the dipstick at

70É F fluid temperature.

NOTE: Engine and Transmission should be at nor-

mal operating temperature before performing this

procedure.

(1) Start engine and apply parking brake.

(2) Shift the transmission into DRIVE for approxi-

mately 2 seconds.

(3) Shift the transmission into REVERSE for

approximately 2 seconds.

(4) Shift the transmission into PARK.

(5)

Hook up DRBtscan tool and select transmission.

(6) Select sensors.

(7) Read the transmission temperature value.

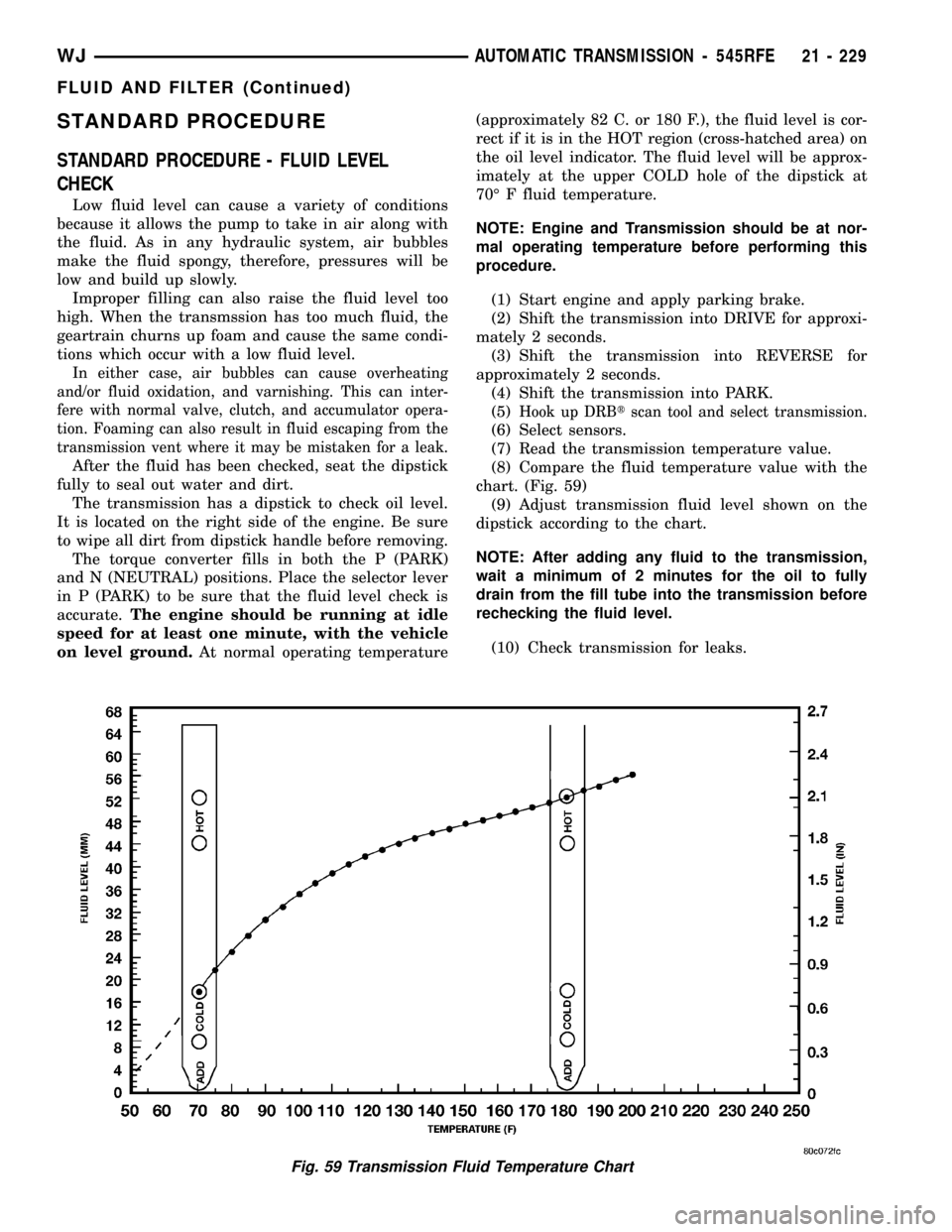

(8) Compare the fluid temperature value with the

chart. (Fig. 59)

(9) Adjust transmission fluid level shown on the

dipstick according to the chart.

NOTE: After adding any fluid to the transmission,

wait a minimum of 2 minutes for the oil to fully

drain from the fill tube into the transmission before

rechecking the fluid level.

(10) Check transmission for leaks.

Fig. 59 Transmission Fluid Temperature Chart

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 229

FLUID AND FILTER (Continued)

Page 1751 of 2199

(3) Install nuts to hold seal plate to floor pan.

Tighten nuts to 7 N´m (65 in.lbs.).

(4) Install the shift cable to the shifter assembly

bracket. Push cable into the bracket until secure.

(5) Place the floor shifter lever in PARK position.

(6) Loosen the adjustment screw on the shift cable.

(7) Snap the shift cable onto the shift lever pin.

(8) Raise the vehicle.

(9) Install the shift cable to the shift cable support

bracket.

(10) Shift the transmission into PARK. PARK is

the rearmost detent position on the transmission

manual shift lever.

(11) Snap the shift cable onto the transmission

manual shift lever.

(12) Lower vehicle.

(13) Verify that the shift lever is in the PARK posi-

tion.

(14) Tighten the adjustment screw to 7 N´m (65

in.lbs.).

(15) Verify correct shifter operation.

(16) Install any console parts removed for access to

shift lever assembly and shift cable. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE - INSTALLA-

TION)

ADJUSTMENTS - GEARSHIFT CABLE

Check adjustment by starting the engine in PARK

and NEUTRAL. Adjustment is CORRECT if the

engine starts only in these positions. Adjustment is

INCORRECT if the engine starts in one but not both

positions. If the engine starts in any position other

than PARK or NEUTRAL, or if the engine will not

start at all, the park/neutral position switch or TRS

may be faulty.

(1) Shift transmission into PARK.

(2) Remove floor console as necessary for access to

the shift cable adjustment. (Refer to 23 - BODY/IN-

TERIOR/FLOOR CONSOLE - REMOVAL)

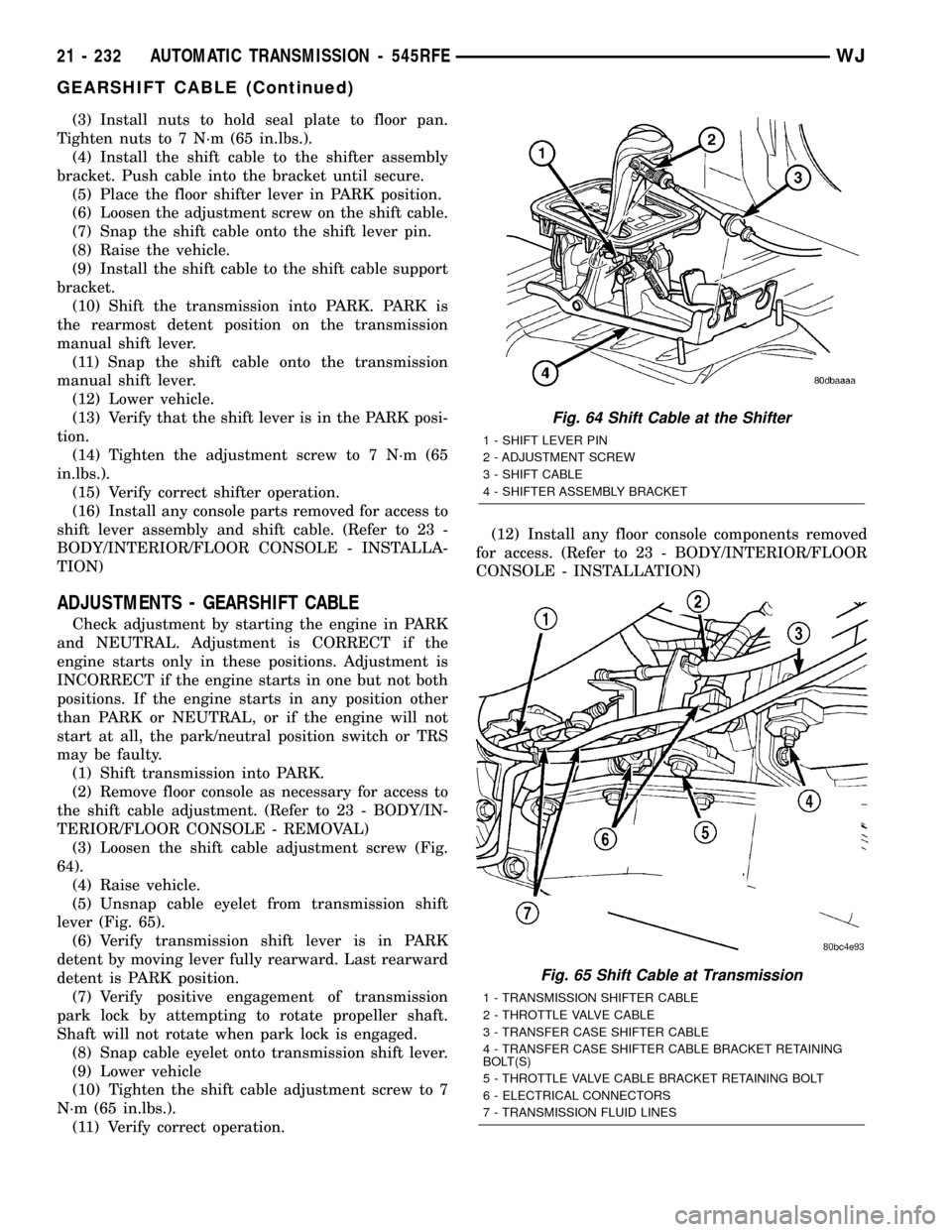

(3) Loosen the shift cable adjustment screw (Fig.

64).

(4) Raise vehicle.

(5) Unsnap cable eyelet from transmission shift

lever (Fig. 65).

(6) Verify transmission shift lever is in PARK

detent by moving lever fully rearward. Last rearward

detent is PARK position.

(7) Verify positive engagement of transmission

park lock by attempting to rotate propeller shaft.

Shaft will not rotate when park lock is engaged.

(8) Snap cable eyelet onto transmission shift lever.

(9) Lower vehicle

(10) Tighten the shift cable adjustment screw to 7

N´m (65 in.lbs.).

(11) Verify correct operation.(12) Install any floor console components removed

for access. (Refer to 23 - BODY/INTERIOR/FLOOR

CONSOLE - INSTALLATION)

Fig. 64 Shift Cable at the Shifter

1 - SHIFT LEVER PIN

2 - ADJUSTMENT SCREW

3 - SHIFT CABLE

4 - SHIFTER ASSEMBLY BRACKET

Fig. 65 Shift Cable at Transmission

1 - TRANSMISSION SHIFTER CABLE

2 - THROTTLE VALVE CABLE

3 - TRANSFER CASE SHIFTER CABLE

4 - TRANSFER CASE SHIFTER CABLE BRACKET RETAINING

BOLT(S)

5 - THROTTLE VALVE CABLE BRACKET RETAINING BOLT

6 - ELECTRICAL CONNECTORS

7 - TRANSMISSION FLUID LINES

21 - 232 AUTOMATIC TRANSMISSION - 545RFEWJ

GEARSHIFT CABLE (Continued)