service JEEP GRAND CHEROKEE 2018 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2018, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2018Pages: 368, PDF Size: 5.72 MB

Page 201 of 368

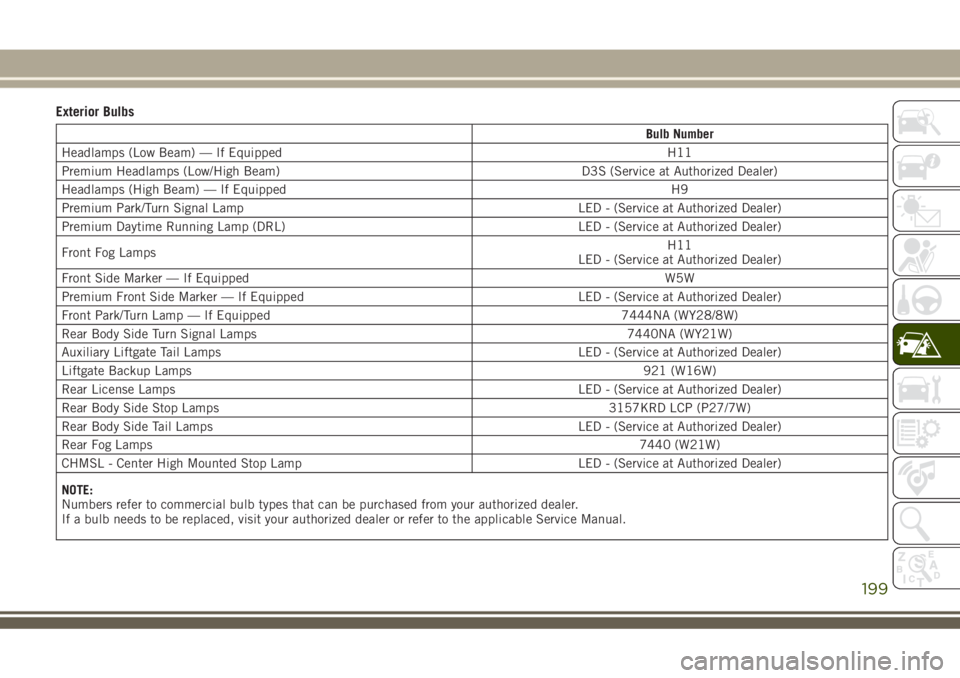

Exterior Bulbs

Bulb Number

Headlamps (Low Beam) — If Equipped H11

Premium Headlamps (Low/High Beam) D3S (Service at Authorized Dealer)

Headlamps (High Beam) — If Equipped H9

Premium Park/Turn Signal Lamp LED - (Service at Authorized Dealer)

Premium Daytime Running Lamp (DRL) LED - (Service at Authorized Dealer)

Front Fog LampsH11

LED - (Service at Authorized Dealer)

Front Side Marker — If EquippedW5W

Premium Front Side Marker — If Equipped LED - (Service at Authorized Dealer)

Front Park/Turn Lamp — If Equipped 7444NA (WY28/8W)

Rear Body Side Turn Signal Lamps 7440NA (WY21W)

Auxiliary Liftgate Tail Lamps LED - (Service at Authorized Dealer)

Liftgate Backup Lamps921 (W16W)

Rear License Lamps LED - (Service at Authorized Dealer)

Rear Body Side Stop Lamps 3157KRD LCP (P27/7W)

Rear Body Side Tail Lamps LED - (Service at Authorized Dealer)

Rear Fog Lamps7440 (W21W)

CHMSL - Center High Mounted Stop Lamp LED - (Service at Authorized Dealer)

NOTE:

Numbers refer to commercial bulb types that can be purchased from your authorized dealer.

If a bulb needs to be replaced, visit your authorized dealer or refer to the applicable Service Manual.

199

Page 202 of 368

Bulb Replacement

High Intensity Discharge Headlamps (HID)

— If Equipped

The headlamps are a type of high voltage

discharge tube. High voltage can remain in

the circuit even with the headlamp switch off

and the key removed.Because of this, you

should not attempt to service a headlamp bulb

yourself. If a headlamp bulb fails, take your

vehicle to an authorized dealer for service.

WARNING!

A transient high voltage occurs at the bulb

sockets of High Intensity Discharge (HID)

headlamps when the headlamp switch is

turned ON. It may cause serious electrical

shock or electrocution if not serviced prop-

erly. See your authorized dealer for ser-

vice.NOTE:

On vehicles equipped with High Intensity

Discharge (HID) headlamps, when the head-

lamps are turned on, there is a blue hue to

the lamps. This diminishes and becomes

more white after approximately 10 seconds,

as the system charges.

Halogen Headlamps — If Equipped

NOTE:

Lens fogging can occur under certain atmo-

spheric conditions. This will usually clear as

atmospheric conditions change to allow the

condensation to change back to vapor. Turn-

ing the lamps on will usually accelerate the

clearing process.

1. Open the hood.

2. Access the back of the headlamp.

NOTE:

• The air filter housing must be removed.

• The windshield washer reservoir may

need to be rotated out of the way by

removing the fastener.

• Coolant reservoir (if equipped) will

need to be repositioned by removingthe fasteners, and moving the unit out

of the way.

3. To access the low beam bulb you must

remove the rubber boot seal from back-

side of the lamp housing.

NOTE:

Ensure the rubber boot is properly rein-

stalled to prevent water and moisture from

entering the lamp.

CAUTION!

•Do not contaminate the bulb glass by

touching it with your fingers or by allow-

ing it to contact other oily surfaces.

Shortened bulb life will result.

• Always use the correct bulb size and type

for replacement. An incorrect bulb size

or type may overheat and cause damage

to the lamp, the bulb socket, or the lamp

wiring.

4. Turn the low or high beam bulb one–

quarter turn counterclockwise to remove

from housing.

5. Disconnect the electrical connector and

replace the bulb.IN CASE OF EMERGENCY

200

Page 203 of 368

Front Turn Signal Lamp

The front turn signal lamps are LEDs. See

your authorized dealer for service.

1. Open the hood.

2. Access the back of the headlamp.

NOTE:

• The air filter housing must be removed.

• The windshield washer reservoir may

need to be rotated out of the way by

removing the fastener.

• Coolant reservoir (if equipped) will

need to be repositioned by removing the

fasteners, and moving the unit out of

the way.

3. Turn the turn signal bulb one–quarter turn

counterclockwise to remove from housing.

4. Disconnect the electrical connector and

replace the bulb.CAUTION!

Do not touch the new bulb with your fin-

gers. Oil contamination will severely

shorten bulb life. If the bulb comes in

contact with any oily surface, clean the

bulb with rubbing alcohol.

Front Fog Lamps

Please see your authorized dealer for service.

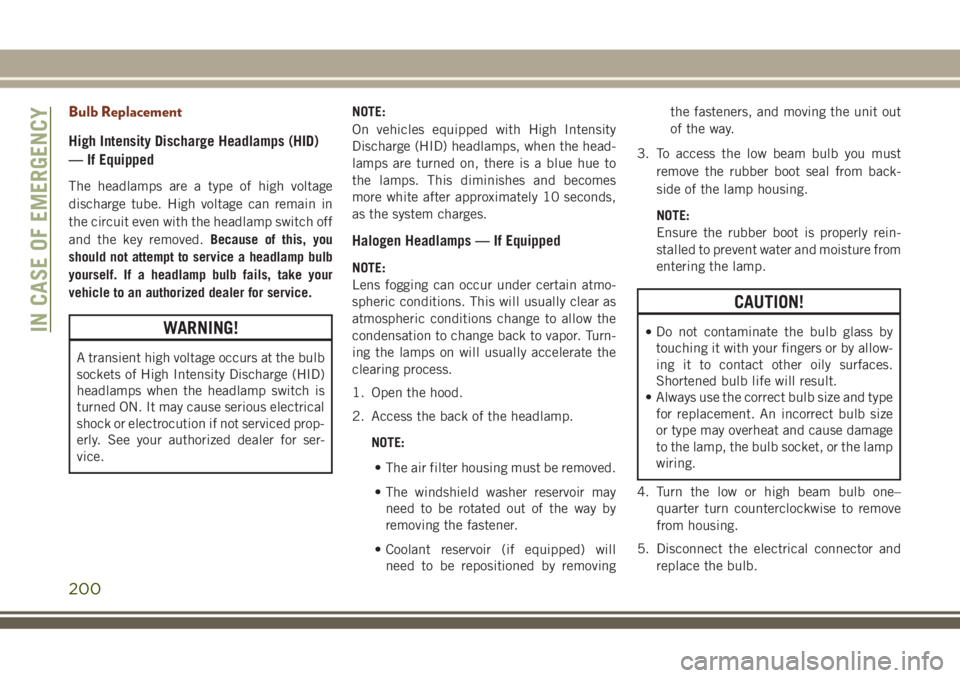

Rear Tail, Stop, and Turn Signal Lamps

1. Raise the liftgate.

2. Remove the two push-pins from the tail

lamp housing.

3. Grasp the tail lamp and pull firmly rear-

ward to disengage the lamp from the ap-

erture panel.

4. Twist socket counter clockwise and re-

move from lamp.

Tail Lamp Push Pins

201

Page 205 of 368

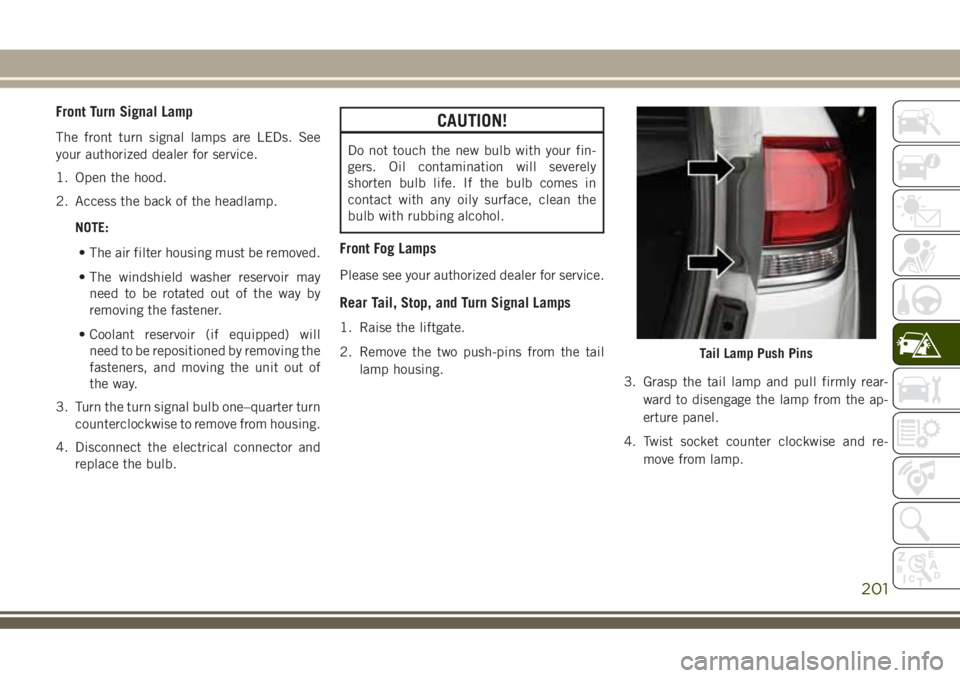

6. Remove/replace bulb(s).

7. Reinstall the socket(s).

8. Reverse process to reinstall the liftgate

trim.

Rear Fascia Mounted Fog Lamp

1. Using a fiber stick or flat blade screw

driver, gently pry between the inboard

edge of the lamp and the fascia.

2. Remove lamp from fascia opening.

3. Twist socket counter clockwise.

4. Replace bulb.

5. Reinstall the socket.

6. Hook inboard side of the lamp into the

fascia pocket.

7. Rotate lamp forward in car until lamp

snaps back into the opening.

Center High-Mounted Stop Lamp (CHMSL)

The center high mounted stop lamp is an

LED. Service at an authorized dealer.

Rear License Lamp

The rear license lamps are LEDs. See your

authorized dealer for service.

Rear Of Liftgate Tail Lamp

1 — Auxiliary LED Tail Connector – Do

Not Remove

2 — Backup Bulb SocketRear Fog Lamps

Center High-Mounted Stop Lamp

203

Page 206 of 368

FUSES

WARNING!

• When replacing a blown fuse, always use

an appropriate replacement fuse with

the same amp rating as the original fuse.

Never replace a fuse with another fuse of

higher amp rating. Never replace a

blown fuse with metal wires or any other

material. Do not place a fuse inside a

circuit breaker cavity or vice versa. Fail-

ure to use proper fuses may result in

serious personal injury, fire and/or prop-

erty damage.

• Before replacing a fuse, make sure that

the ignition is off and that all the other

services are switched off and/or disen-

gaged.

• If the replaced fuse blows again, contact

an authorized dealer.

• If a general protection fuse for safety

systems (air bag system, braking sys-

WARNING!

tem), power unit systems (engine sys-

tem, transmission system) or steering

system blows, contact an authorized

dealer.

General Information

The fuses protect electrical systems against

excessive current.

When a device does not work, you must check

the fuse element inside the blade fuse for a

break/melt.

Also, please be aware that when using power

outlets for extended periods of time with the

engine off may result in vehicle battery dis-

charge.

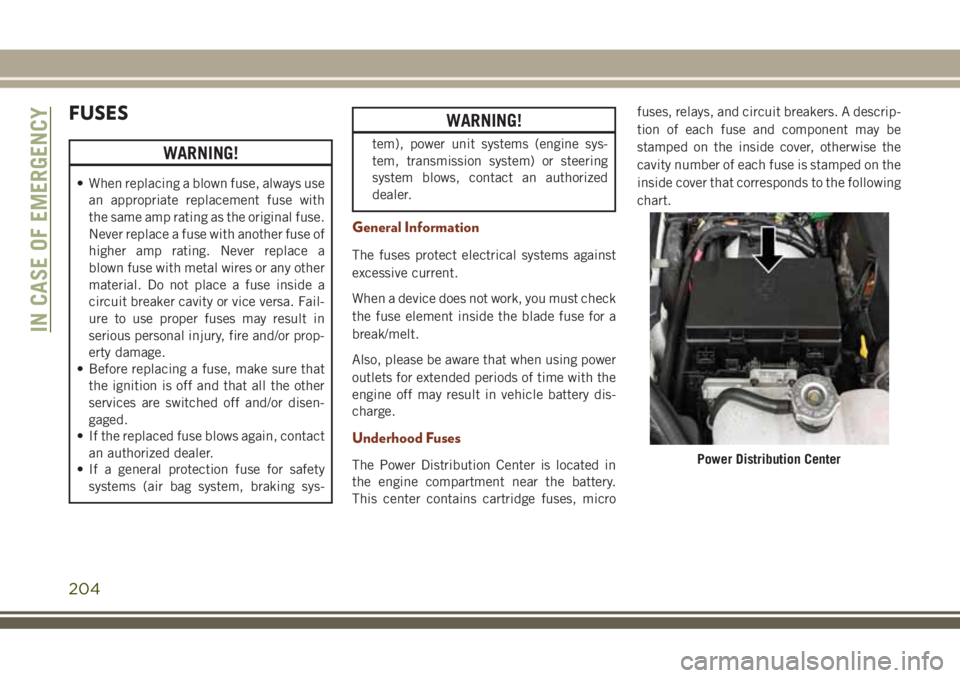

Underhood Fuses

The Power Distribution Center is located in

the engine compartment near the battery.

This center contains cartridge fuses, microfuses, relays, and circuit breakers. A descrip-

tion of each fuse and component may be

stamped on the inside cover, otherwise the

cavity number of each fuse is stamped on the

inside cover that corresponds to the following

chart.Power Distribution Center

IN CASE OF EMERGENCY

204

Page 211 of 368

CAUTION!

• When replacing a blown fuse, it is impor-

tant to use only a fuse having the correct

amperage rating. The use of a fuse with

a rating other than indicated may result

in a dangerous electrical system over-

load. If a properly rated fuse continues

to blow, it indicates a problem in the

circuit that must be corrected.

JACKING AND TIRE

CHANGING

Run Flat Tires — SRT Models

SRT models are equipped with “run flat”

tires. Run flat tires allow the vehicle to be

driven approximately 50 miles (80 km) at

55 mph (88 km/h). Tire service should be

obtained to avoid prolonged run flat feature

usage.

WARNING!

Do not exceed 50 mph (80 km/h) if the

“Tire Pressure Monitoring Telltale Light” is

illuminated. Vehicle handling and braking

may be reduced. You could have a collision

and be severely or fatally injured.

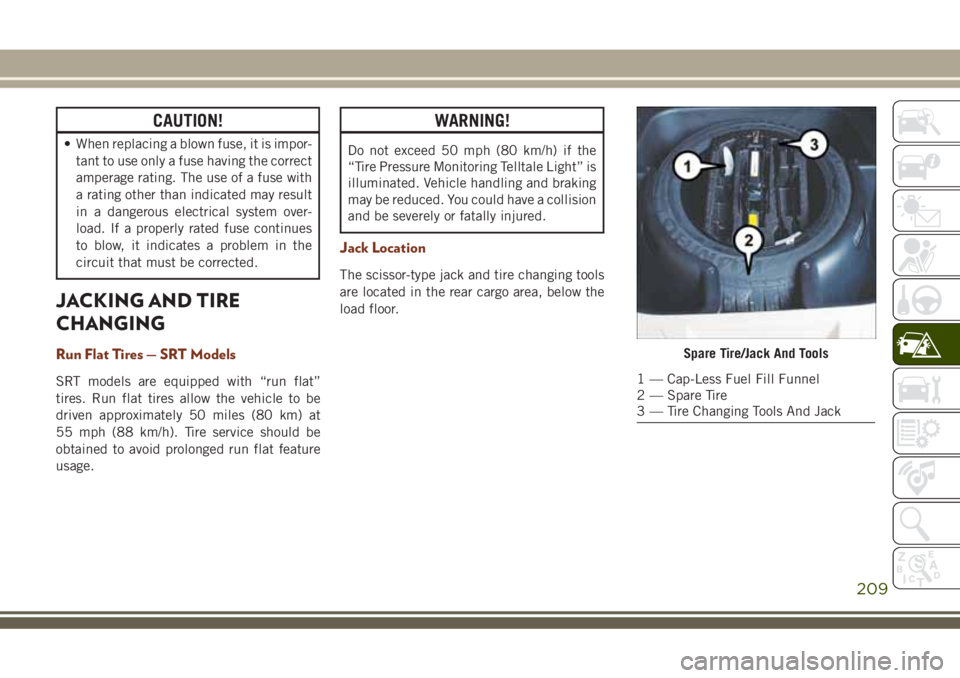

Jack Location

The scissor-type jack and tire changing tools

are located in the rear cargo area, below the

load floor.

Spare Tire/Jack And Tools

1 — Cap-Less Fuel Fill Funnel

2 — Spare Tire

3 — Tire Changing Tools And Jack

209

Page 213 of 368

WARNING!

raised vehicle, take it to a service center

where it can be raised on a lift.

• Only use the jack in the positions indi-

cated and for lifting this vehicle during a

tire change.

• If working on or near a roadway, be

extremely careful of motor traffic.

• To assure that spare tires, flat or in-

flated, are securely stowed, spares must

be stowed with the valve stem facing the

ground.

• The jack should be used on level firm

ground wherever possible.

• It is recommended that the wheels of

the vehicle be chocked, and that no

person should be remain in a vehicle

that is being jacked.

• No person should place any portion of

their body under a vehicle that is sup-

ported by a jack.

CAUTION!

Do not attempt to raise the vehicle by

jacking on locations other than those indi-

cated in the Jacking Instructions for this

vehicle.

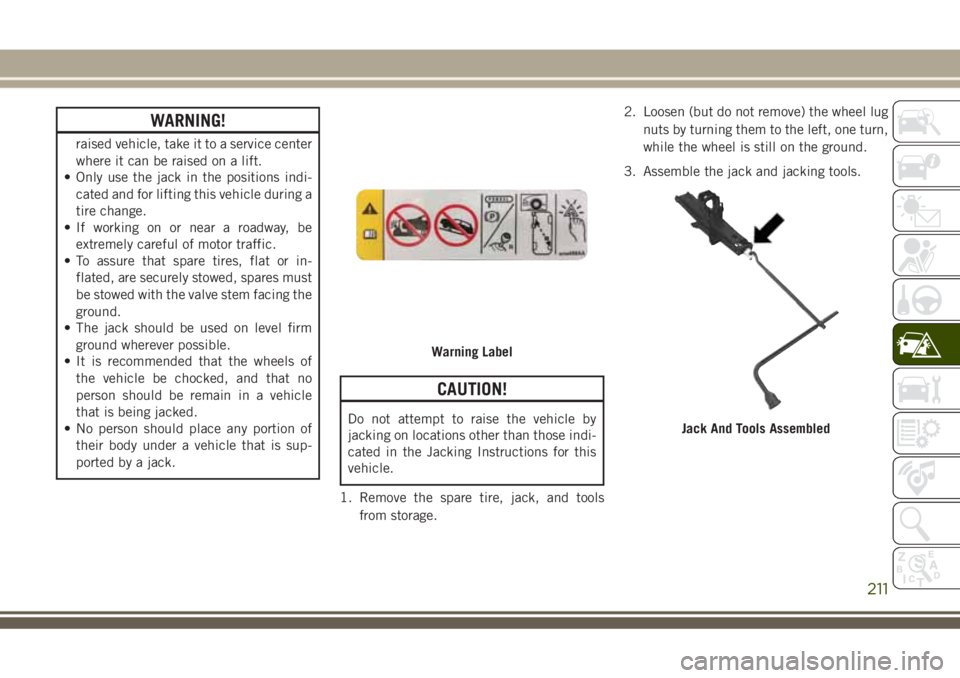

1. Remove the spare tire, jack, and tools

from storage.2. Loosen (but do not remove) the wheel lug

nuts by turning them to the left, one turn,

while the wheel is still on the ground.

3. Assemble the jack and jacking tools.

Warning Label

Jack And Tools Assembled

211

Page 215 of 368

6. Raise the vehicle by turning the jack

screw clockwise. Raise the vehicle only

until the tire just clears the surface and

enough clearance is obtained to install

the spare tire. Minimum tire lift provides

maximum stability.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

7. Remove the lug nuts and wheel.

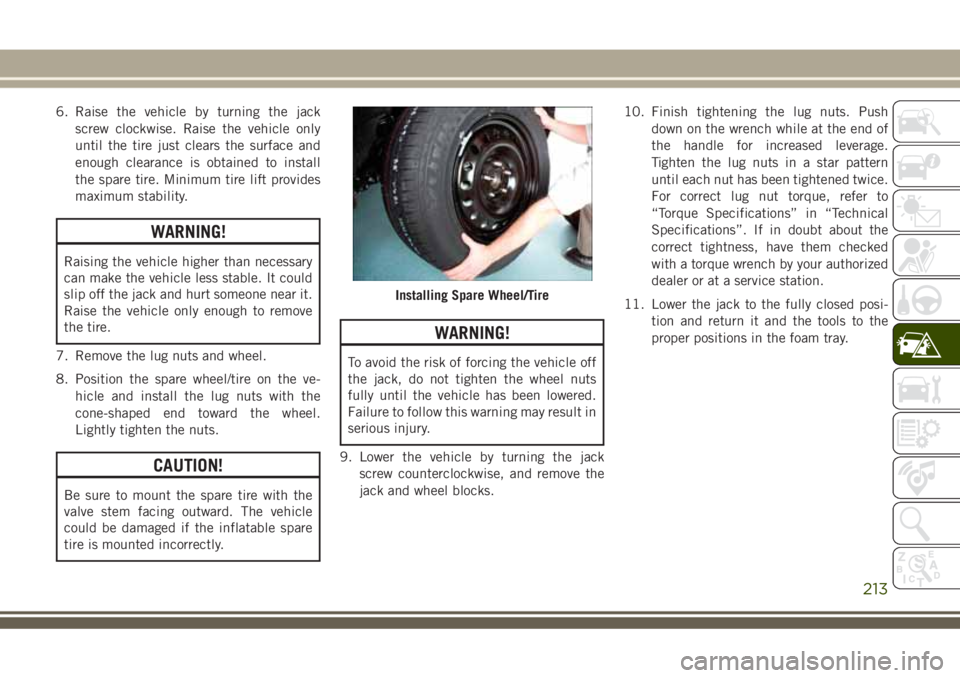

8. Position the spare wheel/tire on the ve-

hicle and install the lug nuts with the

cone-shaped end toward the wheel.

Lightly tighten the nuts.

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle

could be damaged if the inflatable spare

tire is mounted incorrectly.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

9. Lower the vehicle by turning the jack

screw counterclockwise, and remove the

jack and wheel blocks.10. Finish tightening the lug nuts. Push

down on the wrench while at the end of

the handle for increased leverage.

Tighten the lug nuts in a star pattern

until each nut has been tightened twice.

For correct lug nut torque, refer to

“Torque Specifications” in “Technical

Specifications”. If in doubt about the

correct tightness, have them checked

with a torque wrench by your authorized

dealer or at a service station.

11. Lower the jack to the fully closed posi-

tion and return it and the tools to the

proper positions in the foam tray.

Installing Spare Wheel/Tire

213

Page 223 of 368

CAUTION!

Driving with a hot cooling system could

damage your vehicle. If the temperature

gauge reads HOT (H), pull over and stop

the vehicle. Idle the vehicle with the air

conditioner turned off until the pointer

drops back into the normal range. If the

pointer remains on HOT (H), and you hear

continuous chimes, turn the engine off

immediately and call for service.

MANUAL PARK RELEASE

WARNING!

Always secure your vehicle by fully apply-

ing the parking brake before activating the

Manual Park Release. In addition, you

should be seated in the driver’s seat with

your foot firmly on the brake pedal when

activating the Manual Park Release. Acti-

vating the Manual Park Release will allow

your vehicle to roll away if it is not secured

by the parking brake, or by proper connec-

tion to a tow vehicle. Activating the

WARNING!

Manual Park Release on an unsecured

vehicle could lead to serious injury or

death for those in or around the vehicle.

In order to move the vehicle in cases where

the transmission will not shift out of PARK

(such as a dead battery), a Manual Park

Release is available.

Follow these steps to use the Manual Park

Release:

1. Firmly apply the parking brake.

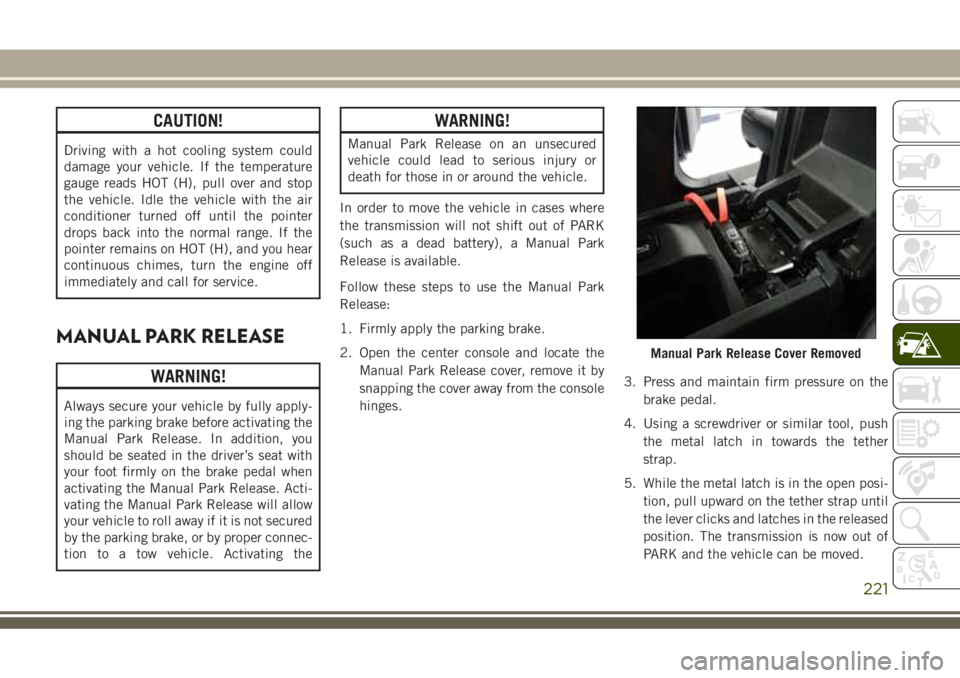

2. Open the center console and locate the

Manual Park Release cover, remove it by

snapping the cover away from the console

hinges.3. Press and maintain firm pressure on the

brake pedal.

4. Using a screwdriver or similar tool, push

the metal latch in towards the tether

strap.

5. While the metal latch is in the open posi-

tion, pull upward on the tether strap until

the lever clicks and latches in the released

position. The transmission is now out of

PARK and the vehicle can be moved.

Manual Park Release Cover Removed

221

Page 225 of 368

WARNING!

of the axle and tires. A tire could explode

and injure someone. Do not spin your

vehicle's wheels faster than 30 mph

(48 km/h) or for longer than 30 seconds

continuously without stopping when you

are stuck and do not let anyone near a

spinning wheel, no matter what the speed.

CAUTION!

• Racing the engine or spinning the

wheels may lead to transmission over-

heating and failure. Allow the engine to

idle with the transmission in NEUTRAL

for at least one minute after every five

rocking-motion cycles. This will mini-

mize overheating and reduce the risk of

transmission failure during prolonged

efforts to free a stuck vehicle.

CAUTION!

• When “rocking” a stuck vehicle by shift-

ing between DRIVE and REVERSE, do

not spin the wheels faster than 15 mph

(24 km/h), or drivetrain damage may

result.

• Revving the engine or spinning the

wheels too fast may lead to transmission

overheating and failure. It can also dam-

age the tires. Do not spin the wheels

above 30 mph (48 km/h) while in gear

(no transmission shifting occurring).

TOWING A DISABLED

VEHICLE

This section describes procedures for towing

a disabled vehicle using a commercial towing

service. If the transmission and drivetrain areoperable, disabled vehicles may also be

towed as described under “Recreational Tow-

ing” in the “Starting And Operating” section.

NOTE:

Vehicles equipped with Quadra-Lift must be

placed in Transport mode, before tying them

down (from the body) on a trailer or flatbed

truck. Refer to the section on Quadra-Lift for

more information. If the vehicle cannot be

placed in Transport mode (for example, en-

gine will not run), tie-downs must be fastened

to the axles (not to the body). Failure to follow

these instructions may cause fault codes to

be set and/or cause loss of proper tie-down

tension.

223