tow JEEP GRAND CHEROKEE 2023 Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2023Pages: 424, PDF Size: 15.48 MB

Page 290 of 424

288SAFETY

(Continued)

After an accident, if the vehicle will not start after

performing the reset procedure, the vehicle must

be towed to an authorized dealer to be inspected

and to have the Enhanced Accident Response

System reset.

Maintaining Your Air Bag System

Event Data Recorder (EDR)

This vehicle is equipped with an event data

recorder (EDR). The main purpose of an EDR is to

record, in certain crash or near crash-like

situations, such as an air bag deployment or hitting

a road obstacle, data that will assist in

understanding how a vehicle’s systems performed.

The EDR is designed to record data related to

vehicle dynamics and safety systems for a short

period of time, typically 30 seconds or less. The

EDR in this vehicle is designed to record such data

as:

How various systems in your vehicle were oper

-

ating;

Whether or not the driver and passenger safety

belts were buckled/fastened;

How far (if at all) the driver was depressing the

accelerator and/or brake pedal; and,

How fast the vehicle was traveling.

These data can help provide a better

understanding of the circumstances in which

crashes and injuries occur.

WARNING!

Modifications to any part of the air bag system

could cause it to fail when you need it. You

could be injured if the air bag system is not

there to protect you. Do not modify the compo -

nents or wiring, including adding any kind of

badges or stickers to the steering wheel hub

trim cover or the upper passenger side of the

instrument panel. Do not modify the front

fascia/bumper, vehicle body structure, or add

aftermarket side steps or running boards.

It is dangerous to try to repair any part of the

air bag system yourself. Be sure to tell anyone

who works on your vehicle that it has an air

bag system.

Do not attempt to modify any part of your air

bag system. The air bag may inflate acciden -

tally or may not function properly if modifica -

tions are made. Take your vehicle to an

authorized dealer for any air bag system

service. If your seat, including your trim cover

and cushion, needs to be serviced in any way

(including removal or loosening/tightening of

seat attachment bolts), take the vehicle to an

authorized dealer. Only manufacturer

approved seat accessories may be used. If it is

necessary to modify the air bag system for

persons with disabilities, contact an autho -

rized dealer.

WARNING!

23_WL_OM_EN_USC_t.book Page 288

Page 299 of 424

SAFETY297

Six Passenger Second Row Seating:

Seven Passenger Second Row Seating:

If a child restraint installed in the center position

blocks the seat belt webbing or buckle for the

outboard position, do not use that outboard

position. If a child seat in the center position blocks

the outboard LATCH anchors or seat belt, do not

install a child seat in that outboard position.

Always follow the directions of the child restraint

manufacturer when installing your child restraint.

Not all child restraint systems will be installed as

described here.

To Install A LATCH-Compatible Child

Restraint

If the selected seating position has a Switchable

Automatic Locking Retractor (ALR) seat belt, stow

the seat belt, following the instructions below. See

Ú page 298 to check what type of seat belt each

seating position has.

1. Loosen the adjusters on the lower straps and on the tether strap of the child seat so that

you can more easily attach the hooks or

connectors to the vehicle anchorages.

2. Place the child seat between the lower anchorages for that seating position. If the

second row seat can be reclined, you may

recline the seat and/or raise the head restraint

(if adjustable) to get a better fit. If the rear seat

can be moved forward and rearward in the

vehicle, you may wish to move it to its

rear-most position to make room for the child

seat. You may also move the front seat forward

to allow more room for the child seat.

3. Attach the lower hooks or connectors of the child restraint to the lower anchorages in the

selected seating position.

4. If the child restraint has a tether strap, connect it to the top tether anchorage. See

Úpage 300 for directions to attach a tether

anchor. 5. Tighten all of the straps as you push the child

restraint rearward and downward into the

seat. Remove slack in the straps according to

the child restraint manufacturer’s instructions.

6. Test that the child restraint is installed tightly by pulling back and forth on the child seat at

the belt path. It should not move more than

1 inch (25.4 mm) in any direction.

How To Stow An Unused Switchable-ALR

(ALR) Seat Belt:

When using the LATCH attaching system to install

a child restraint, stow all ALR seat belts that are not

being used by other occupants or being used to

secure child restraints. An unused belt could injure

a child if they play with it and accidentally lock the

seat belt retractor. Before installing a child

restraint using the LATCH system, buckle the seat

belt behind the child restraint and out of the child’s

reach. If the buckled seat belt interferes with the

child restraint installation, instead of buckling it

behind the child restraint, route the seat belt

through the child restraint belt path and then

buckle it. Do not lock the seat belt. Remind all

children in the vehicle that the seat belts are not

toys and that they should not play with them.

WARNING!

This vehicle does not have a center seating

position. Do not use the center lower LATCH

anchorages to install a child seat in the center of

the back seat.

WARNING!

Never use the same lower anchorage to attach

more than one child restraint. For typical

installation instructions, see Ú page 297.

6

23_WL_OM_EN_USC_t.book Page 297

Page 307 of 424

SAFETY305

PERIODIC SAFETY CHECKS YOU SHOULD

M

AKE OUTSIDE THE VEHICLE

Tires

Examine tires for excessive tread wear and uneven

wear patterns. Check for stones, nails, glass, or

other objects lodged in the tread or sidewall.

Inspect the tread for cuts and cracks. Inspect

sidewalls for cuts, cracks, and bulges. Check the

lug nut/bolt torque for tightness. Check the tires

(including spare) for proper cold inflation pressure.

Lights

Have someone observe the operation of brake

lights and exterior lights while you work the

controls. Check turn signal and high beam

indicator lights on the instrument panel.

Door Latches

Check for proper closing, latching, and locking.

Fluid Leaks

Check area under the vehicle after overnight

parking for fuel, coolant, oil, or other fluid leaks.

Also, if gasoline fumes are detected or if fuel or

brake fluid leaks are suspected, the cause should

be located and corrected immediately.

EXHAUST GAS

NEVER place any objects under the floor mat

(e.g., towels, keys, etc.). These objects could

change the position of the floor mat and may

cause interference with the accelerator,

brake, or clutch pedals.

If the vehicle carpet has been removed and

re-installed, always properly attach carpet to

the floor and check the floor mat fasteners are

secure to the vehicle carpet. Fully depress

each pedal to check for interference with the

accelerator, brake, or clutch pedals then

re-install the floor mats.

It is recommended to only use mild soap and

water to clean your floor mats. After cleaning,

always check your floor mat has been properly

installed and is secured to your vehicle using

the floor mat fasteners by lightly pulling mat.

WARNING!

WARNING!

Exhaust gases can injure or kill. They contain

carbon monoxide (CO), which is colorless and

odorless. Breathing it can make you

unconscious and can eventually poison you. To

avoid breathing (CO), follow these safety tips:

Do not run the engine in a closed garage or in

confined areas any longer than needed to

move your vehicle in or out of the area.

If you are required to drive with the trunk/lift -

gate/rear doors open, make sure that all

windows are closed and the climate control

BLOWER switch is set at high speed. DO NOT

use the recirculation mode.

If it is necessary to sit in a parked vehicle with

the engine running, adjust your heating or

cooling controls to force outside air into the

vehicle. Set the blower at high speed.

6

23_WL_OM_EN_USC_t.book Page 305

Page 310 of 424

308IN CASE OF EMERGENCY

(Continued)

ASSIST Call

The ASSIST Button is used to automatically

connect you to any one of the following support

centers:

Roadside Assistance – If you get a flat tire, or

need a tow, just push the ASSIST button and you

will be connected to a representative for assis-

tance. Roadside Assistance will know what

vehicle you’re driving and its location. Additional

fees may apply for roadside assistance.

Vehicle Customer Care – Total support for all

other vehicle issues.

Jeep® Connect Customer Care – Total support

for Radio, Phone and NAV issues.

SOS Call

1. Push the SOS Call button on the overhead console.

NOTE:In case the SOS Call button is pushed in error,

there will be a 10 second delay before the SOS Call

system initiates a call to a SOS operator. To cancel

the SOS Call connection, push the SOS call button

on the overhead console or press the cancellation

button on the Device Screen. Termination of the

SOS Call will turn off the green LED light on the

overhead console. 2. The LED light located within the ASSIST and

SOS buttons on the overhead console will turn

green once a connection to a SOS operator has

been made.

3. Once a connection between the vehicle and a SOS operator is made, the SOS Call system

may transmit the following important vehicle

information to a SOS operator:

Indication that the occupant placed a SOS

Call

The vehicle brand

The last known GPS coordinates of the

vehicle

4. You should be able to speak with the SOS operator through the vehicle audio system to

determine if additional assistance is needed.

NOTE:Once a connection is made between the vehicle’s

SOS Call system and the SOS operator, the SOS

operator may be able to open a voice connection

with the vehicle to determine if additional assis -

tance is needed. Once the SOS operator opens a

voice connection with the vehicle’s SOS Call

system, the operator should be able to speak with

you or other vehicle occupants and hear sounds

occurring in the vehicle. The vehicle’s SOS Call

system will attempt to remain connected with the

SOS operator until the SOS operator terminates

the connection.

5. The SOS operator may attempt to contact appropriate emergency responders and

provide them with important vehicle

information and GPS coordinates.

WARNING!

ALWAYS obey traffic laws and pay attention to

the road. ALWAYS drive safely with your hands on

the steering wheel. You have full responsibility

and assume all risks related to the use of the

features and applications in this vehicle. Only

use the features and applications when it is safe

to do so. Failure to do so may result in an

accident involving serious injury or death.

WARNING!

If anyone in the vehicle could be in danger

(e.g., fire or smoke is visible, dangerous road

conditions or location), do not wait for voice

contact from an Emergency Services Agent. All

occupants should exit the vehicle immediately

and move to a safe location.

23_WL_OM_EN_USC_t.book Page 308

Page 315 of 424

IN CASE OF EMERGENCY313

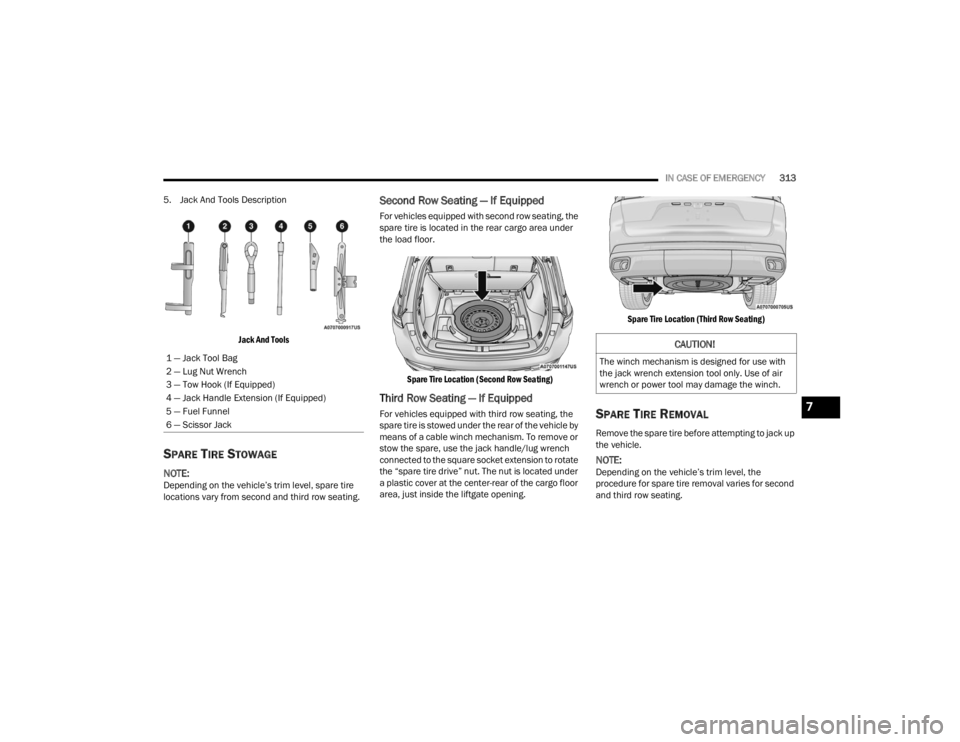

5. Jack And Tools Description

Jack And Tools

SPARE TIRE STOWAGE

NOTE:Depending on the vehicle’s trim level, spare tire

locations vary from second and third row seating.

Second Row Seating — If Equipped

For vehicles equipped with second row seating, the

spare tire is located in the rear cargo area under

the load floor.

Spare Tire Location (Second Row Seating)

Third Row Seating — If Equipped

For vehicles equipped with third row seating, the

spare tire is stowed under the rear of the vehicle by

means of a cable winch mechanism. To remove or

stow the spare, use the jack handle/lug wrench

connected to the square socket extension to rotate

the “spare tire drive” nut. The nut is located under

a plastic cover at the center-rear of the cargo floor

area, just inside the liftgate opening.

Spare Tire Location (Third Row Seating)

SPARE TIRE REMOVAL

Remove the spare tire before attempting to jack up

the vehicle.

NOTE:Depending on the vehicle’s trim level, the

procedure for spare tire removal varies for second

and third row seating.

1 — Jack Tool Bag

2 — Lug Nut Wrench

3 — Tow Hook (If Equipped)

4 — Jack Handle Extension (If Equipped)

5 — Fuel Funnel

6 — Scissor Jack

CAUTION!

The winch mechanism is designed for use with

the jack wrench extension tool only. Use of air

wrench or power tool may damage the winch.

7

23_WL_OM_EN_USC_t.book Page 313

Page 316 of 424

314IN CASE OF EMERGENCY

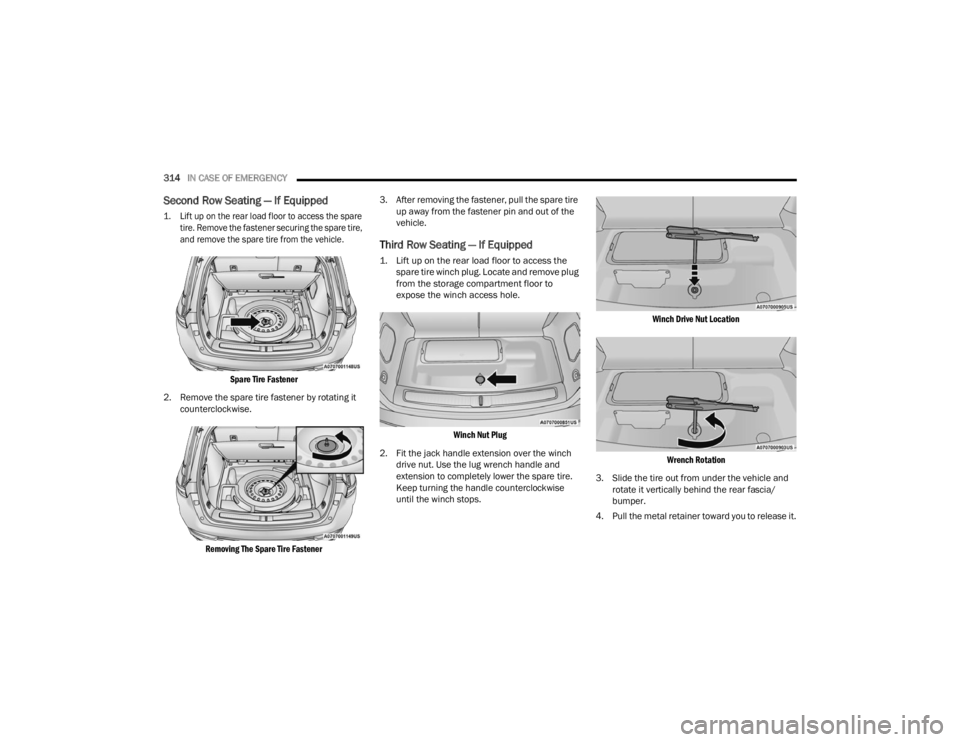

Second Row Seating — If Equipped

1. Lift up on the rear load floor to access the spare

tire. Remove the fastener securing the spare tire,

and remove the spare tire from the vehicle.

Spare Tire Fastener

2. Remove the spare tire fastener by rotating it counterclockwise.

Removing The Spare Tire Fastener

3. After removing the fastener, pull the spare tire

up away from the fastener pin and out of the

vehicle.

Third Row Seating — If Equipped

1. Lift up on the rear load floor to access the spare tire winch plug. Locate and remove plug

from the storage compartment floor to

expose the winch access hole.

Winch Nut Plug

2. Fit the jack handle extension over the winch drive nut. Use the lug wrench handle and

extension to completely lower the spare tire.

Keep turning the handle counterclockwise

until the winch stops.

Winch Drive Nut Location

Wrench Rotation

3. Slide the tire out from under the vehicle and rotate it vertically behind the rear fascia/

bumper.

4. Pull the metal retainer toward you to release it.

23_WL_OM_EN_USC_t.book Page 314

Page 317 of 424

IN CASE OF EMERGENCY315

(Continued)

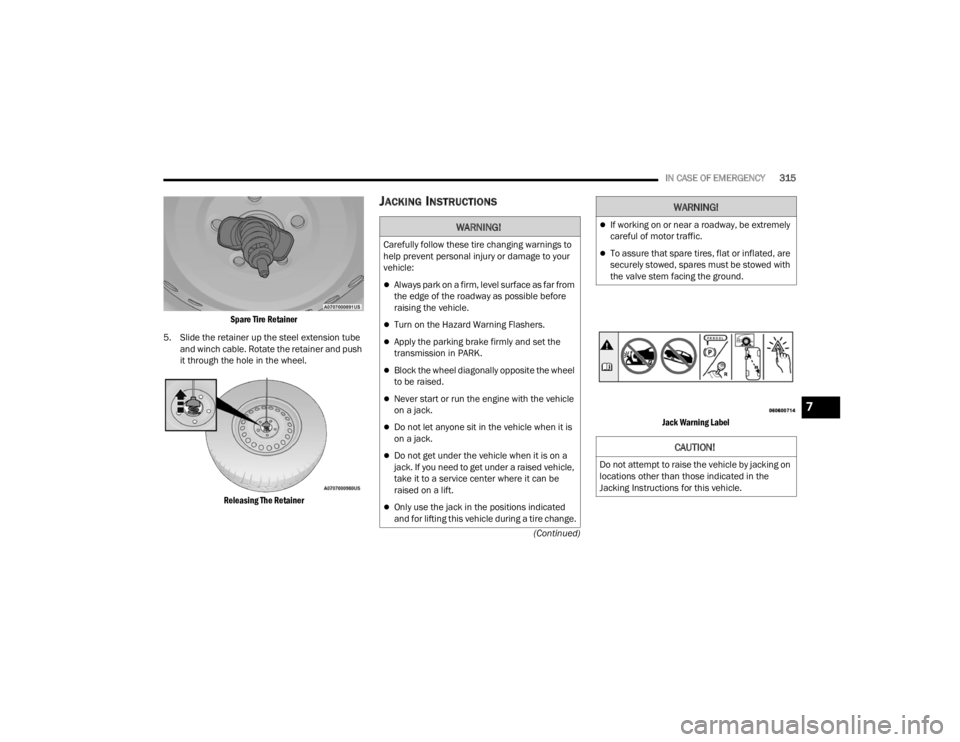

Spare Tire Retainer

5. Slide the retainer up the steel extension tube and winch cable. Rotate the retainer and push

it through the hole in the wheel.

Releasing The Retainer

JACKING INSTRUCTIONS

Jack Warning Label

WARNING!

Carefully follow these tire changing warnings to

help prevent personal injury or damage to your

vehicle:

Always park on a firm, level surface as far from

the edge of the roadway as possible before

raising the vehicle.

Turn on the Hazard Warning Flashers.

Apply the parking brake firmly and set the

transmission in PARK.

Block the wheel diagonally opposite the wheel

to be raised.

Never start or run the engine with the vehicle

on a jack.

Do not let anyone sit in the vehicle when it is

on a jack.

Do not get under the vehicle when it is on a

jack. If you need to get under a raised vehicle,

take it to a service center where it can be

raised on a lift.

Only use the jack in the positions indicated

and for lifting this vehicle during a tire change.

If working on or near a roadway, be extremely

careful of motor traffic.

To assure that spare tires, flat or inflated, are

securely stowed, spares must be stowed with

the valve stem facing the ground.

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the

Jacking Instructions for this vehicle.

WARNING!

7

23_WL_OM_EN_USC_t.book Page 315

Page 319 of 424

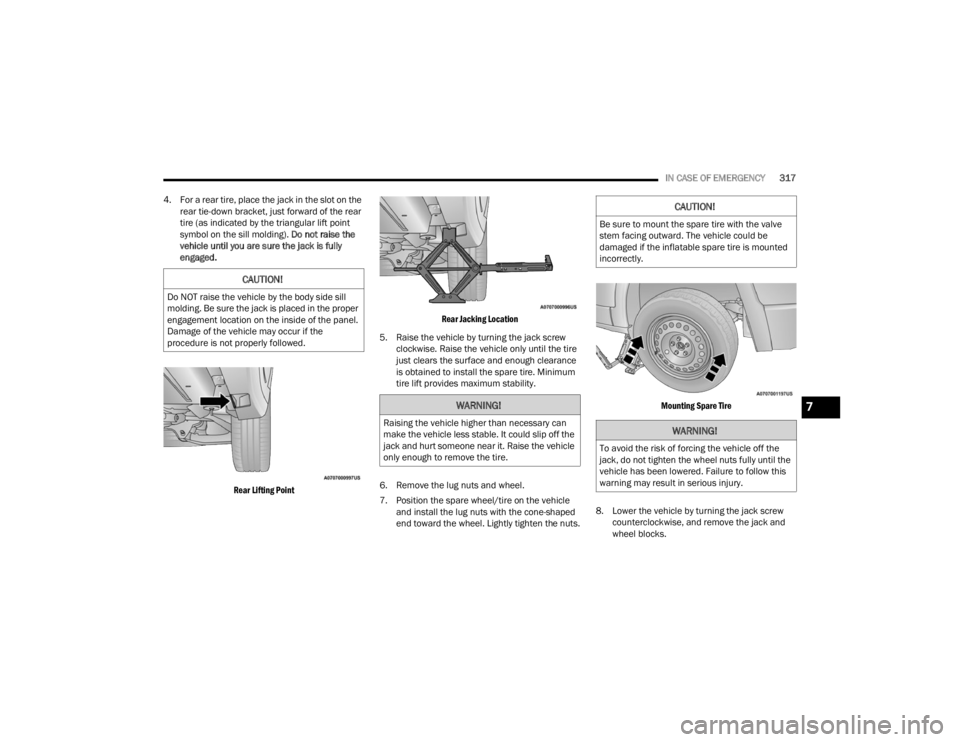

IN CASE OF EMERGENCY317

4. For a rear tire, place the jack in the slot on the rear tie-down bracket, just forward of the rear

tire (as indicated by the triangular lift point

symbol on the sill molding). Do not raise the

vehicle until you are sure the jack is fully

engaged.

Rear Lifting Point Rear Jacking Location

5. Raise the vehicle by turning the jack screw clockwise. Raise the vehicle only until the tire

just clears the surface and enough clearance

is obtained to install the spare tire. Minimum

tire lift provides maximum stability.

6. Remove the lug nuts and wheel.

7. Position the spare wheel/tire on the vehicle and install the lug nuts with the cone-shaped

end toward the wheel. Lightly tighten the nuts.

Mounting Spare Tire

8. Lower the vehicle by turning the jack screw counterclockwise, and remove the jack and

wheel blocks.

CAUTION!

Do NOT raise the vehicle by the body side sill

molding. Be sure the jack is placed in the proper

engagement location on the inside of the panel.

Damage of the vehicle may occur if the

procedure is not properly followed.

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off the

jack and hurt someone near it. Raise the vehicle

only enough to remove the tire.

CAUTION!

Be sure to mount the spare tire with the valve

stem facing outward. The vehicle could be

damaged if the inflatable spare tire is mounted

incorrectly.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until the

vehicle has been lowered. Failure to follow this

warning may result in serious injury.

7

23_WL_OM_EN_USC_t.book Page 317

Page 320 of 424

318IN CASE OF EMERGENCY

9. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for

increased leverage. Tighten the lug nuts in a

star pattern until each nut has been tightened

twice. For correct lug nut torque Úpage 396.

If in doubt about the correct tightness, have

them checked with a torque wrench by an

authorized dealer or at a service station.

Tighten Lug Nuts

10. Lower the jack to the fully closed position.

11. Return the Jack and tools back into the jack storage bin. Reinstall the jack storage cover by

firmly pushing down until the two side clips

lock into position. 12. After 25 miles (40 km), check the lug nut

torque with a torque wrench to ensure that all

lug nuts are properly seated against the wheel.

13. Have the aluminum road wheel and tire repaired as soon as possible and properly

secure the spare tire, jack and tool kit.

NOTE:Do not drive with the spare tire installed for more

than 50 miles (80 km) at a max speed of 50 mph

(80 km/h).

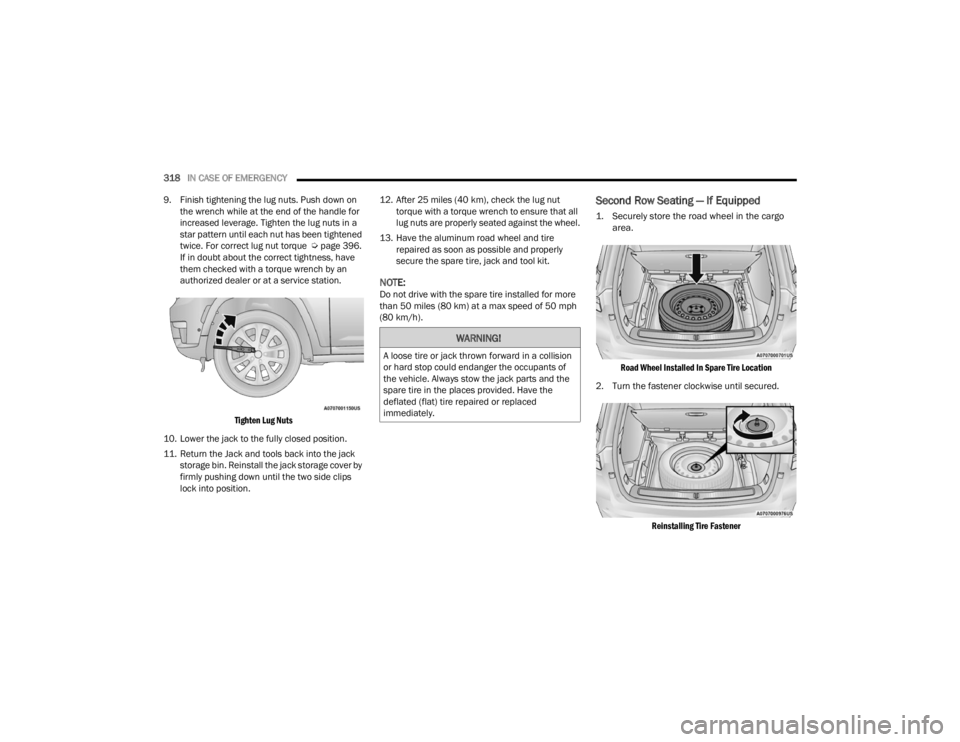

Second Row Seating — If Equipped

1. Securely store the road wheel in the cargo area.

Road Wheel Installed In Spare Tire Location

2. Turn the fastener clockwise until secured.

Reinstalling Tire Fastener

WARNING!

A loose tire or jack thrown forward in a collision

or hard stop could endanger the occupants of

the vehicle. Always stow the jack parts and the

spare tire in the places provided. Have the

deflated (flat) tire repaired or replaced

immediately.

23_WL_OM_EN_USC_t.book Page 318

Page 321 of 424

IN CASE OF EMERGENCY319

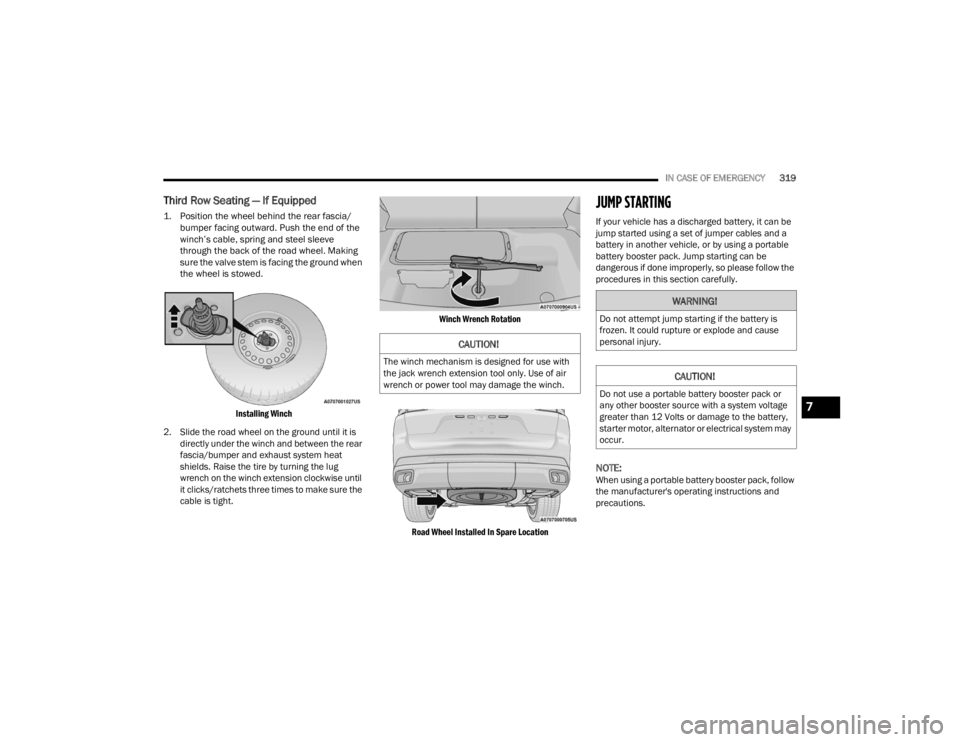

Third Row Seating — If Equipped

1. Position the wheel behind the rear fascia/

bumper facing outward. Push the end of the

winch’s cable, spring and steel sleeve

through the back of the road wheel. Making

sure the valve stem is facing the ground when

the wheel is stowed.

Installing Winch

2. Slide the road wheel on the ground until it is directly under the winch and between the rear

fascia/bumper and exhaust system heat

shields. Raise the tire by turning the lug

wrench on the winch extension clockwise until

it clicks/ratchets three times to make sure the

cable is tight.

Winch Wrench Rotation

Road Wheel Installed In Spare Location

JUMP STARTING

If your vehicle has a discharged battery, it can be

jump started using a set of jumper cables and a

battery in another vehicle, or by using a portable

battery booster pack. Jump starting can be

dangerous if done improperly, so please follow the

procedures in this section carefully.

NOTE:When using a portable battery booster pack, follow

the manufacturer's operating instructions and

precautions.

CAUTION!

The winch mechanism is designed for use with

the jack wrench extension tool only. Use of air

wrench or power tool may damage the winch.

WARNING!

Do not attempt jump starting if the battery is

frozen. It could rupture or explode and cause

personal injury.

CAUTION!

Do not use a portable battery booster pack or

any other booster source with a system voltage

greater than 12 Volts or damage to the battery,

starter motor, alternator or electrical system may

occur.

7

23_WL_OM_EN_USC_t.book Page 319