bolt pattern JEEP LIBERTY 2002 KJ / 1.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 139 of 1803

Condition Possible Causes Correction

Loss Of Lubricant 1. Lubricant level too high. 1. Drain lubricant to the correct

level.

2. Worn axle shaft seals. 2. Replace seals.

3. Cracked differential housing. 3. Repair as necessary.

4. Worn pinion seal. 4. Replace seal.

5. Worn/scored yoke. 5. Replace yoke and seal.

6. Axle cover not properly sealed. 6. Remove, clean, and re-seal

cover.

Axle Overheating 1. Lubricant level low. 1. Fill differential to correct level.

2. Improper grade of lubricant. 2. Fill differential with the correct

fluid type and quantity.

3. Bearing pre-loads too high. 3. Re-adjust bearing pre-loads.

4. Insufficient ring gear backlash. 4. Re-adjust ring gear backlash.

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern. Adjust backlash or

pinion depth.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

3 - 90 REAR AXLE-81/4KJ

REAR AXLE - 8 1/4 (Continued)

Page 141 of 1803

(10) Install axle vent hose.

(11) Install propeller shaft with reference marks.

(12) Install the wheels and tires.

(13) Add gear lubricant to specifications, if neces-

sary.

(14) Remove lifting device from axle and lower the

vehicle.

(15) Tighten the lower control arm bolts to torque

specification.

ADJUSTMENTS

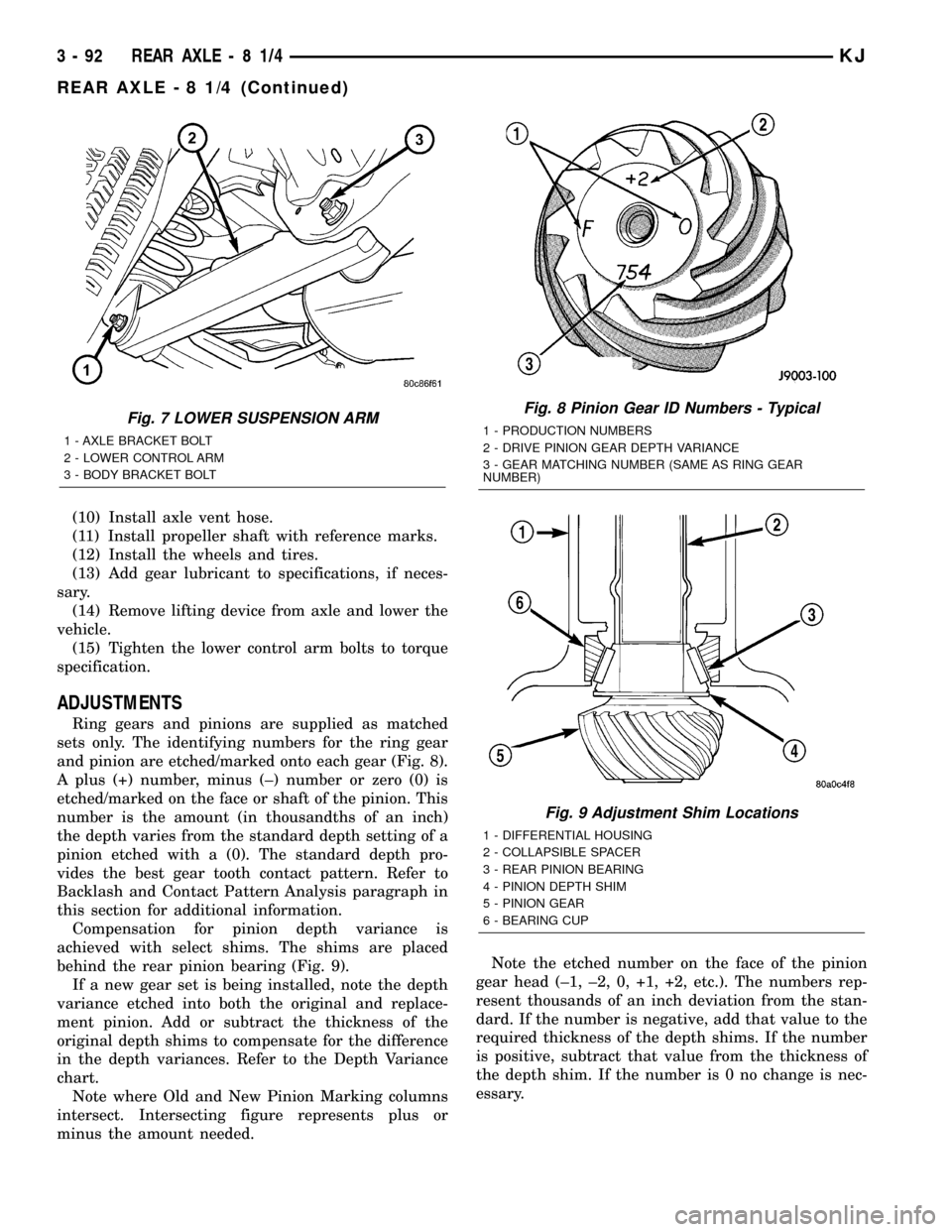

Ring gears and pinions are supplied as matched

sets only. The identifying numbers for the ring gear

and pinion are etched/marked onto each gear (Fig. 8).

A plus (+) number, minus (±) number or zero (0) is

etched/marked on the face or shaft of the pinion. This

number is the amount (in thousandths of an inch)

the depth varies from the standard depth setting of a

pinion etched with a (0). The standard depth pro-

vides the best gear tooth contact pattern. Refer to

Backlash and Contact Pattern Analysis paragraph in

this section for additional information.

Compensation for pinion depth variance is

achieved with select shims. The shims are placed

behind the rear pinion bearing (Fig. 9).

If a new gear set is being installed, note the depth

variance etched into both the original and replace-

ment pinion. Add or subtract the thickness of the

original depth shims to compensate for the difference

in the depth variances. Refer to the Depth Variance

chart.

Note where Old and New Pinion Marking columns

intersect. Intersecting figure represents plus or

minus the amount needed.Note the etched number on the face of the pinion

gear head (±1, ±2, 0, +1, +2, etc.). The numbers rep-

resent thousands of an inch deviation from the stan-

dard. If the number is negative, add that value to the

required thickness of the depth shims. If the number

is positive, subtract that value from the thickness of

the depth shim. If the number is 0 no change is nec-

essary.

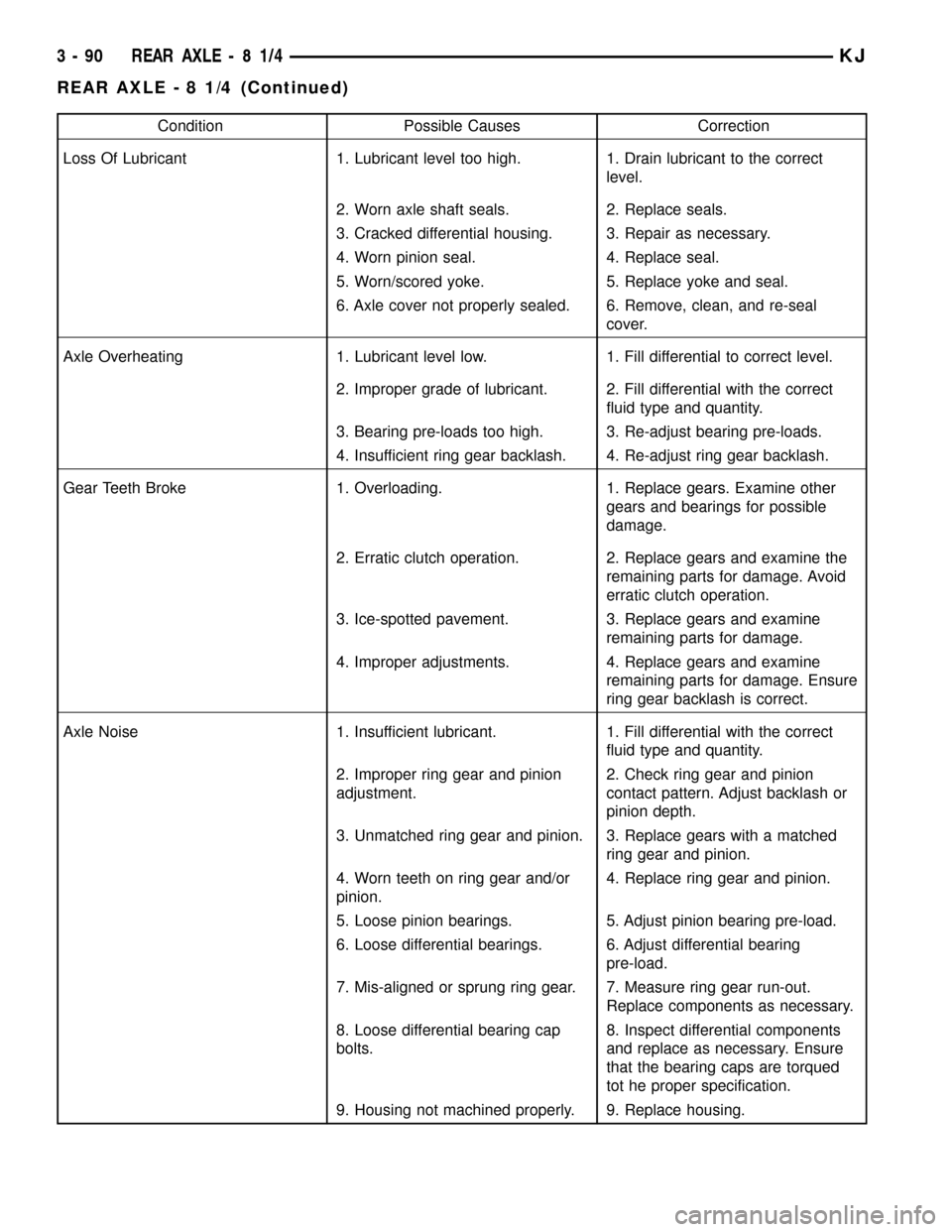

Fig. 7 LOWER SUSPENSION ARM

1 - AXLE BRACKET BOLT

2 - LOWER CONTROL ARM

3 - BODY BRACKET BOLT

Fig. 8 Pinion Gear ID Numbers - Typical

1 - PRODUCTION NUMBERS

2 - DRIVE PINION GEAR DEPTH VARIANCE

3 - GEAR MATCHING NUMBER (SAME AS RING GEAR

NUMBER)

Fig. 9 Adjustment Shim Locations

1 - DIFFERENTIAL HOUSING

2 - COLLAPSIBLE SPACER

3 - REAR PINION BEARING

4 - PINION DEPTH SHIM

5 - PINION GEAR

6 - BEARING CUP

3 - 92 REAR AXLE-81/4KJ

REAR AXLE - 8 1/4 (Continued)

Page 144 of 1803

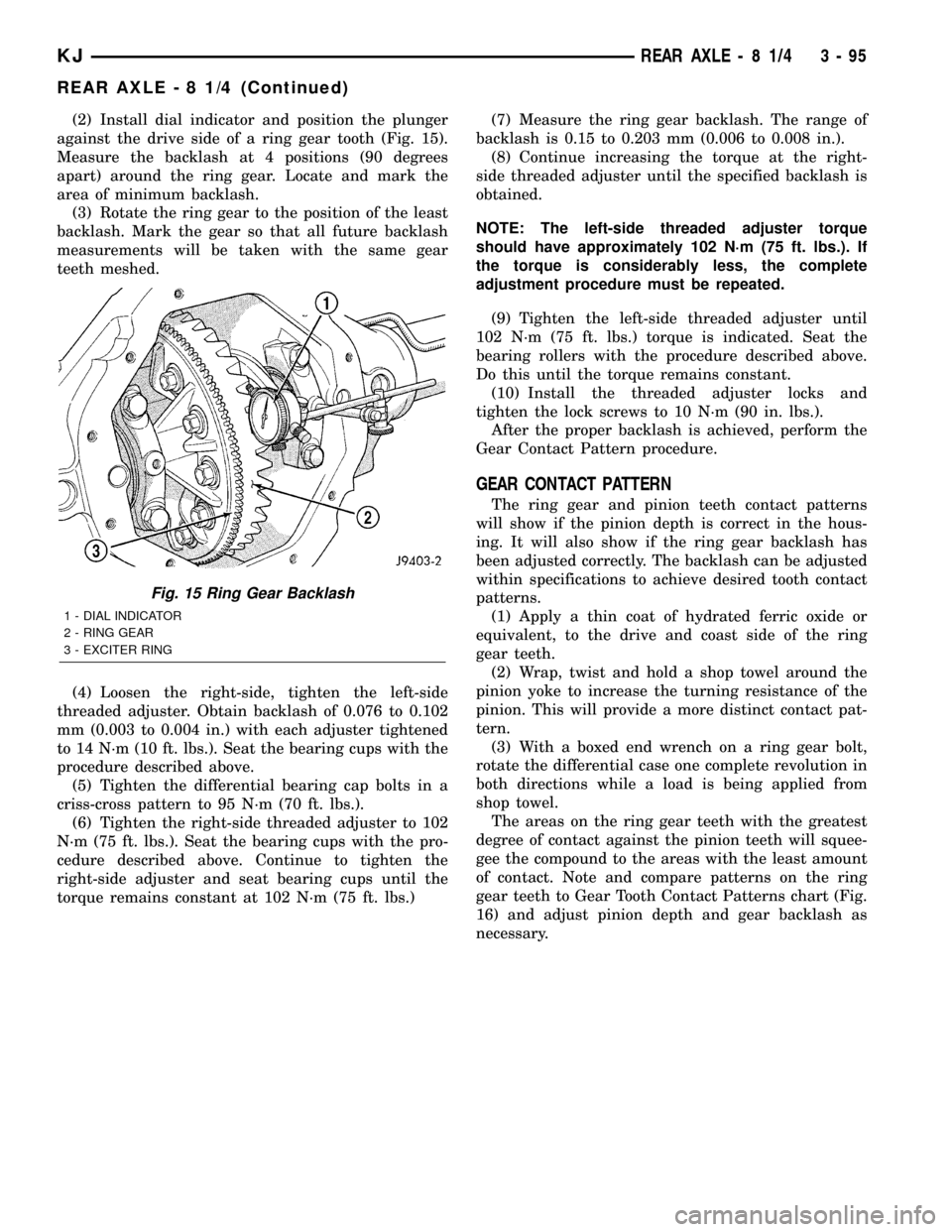

(2) Install dial indicator and position the plunger

against the drive side of a ring gear tooth (Fig. 15).

Measure the backlash at 4 positions (90 degrees

apart) around the ring gear. Locate and mark the

area of minimum backlash.

(3) Rotate the ring gear to the position of the least

backlash. Mark the gear so that all future backlash

measurements will be taken with the same gear

teeth meshed.

(4) Loosen the right-side, tighten the left-side

threaded adjuster. Obtain backlash of 0.076 to 0.102

mm (0.003 to 0.004 in.) with each adjuster tightened

to 14 N´m (10 ft. lbs.). Seat the bearing cups with the

procedure described above.

(5) Tighten the differential bearing cap bolts in a

criss-cross pattern to 95 N´m (70 ft. lbs.).

(6) Tighten the right-side threaded adjuster to 102

N´m (75 ft. lbs.). Seat the bearing cups with the pro-

cedure described above. Continue to tighten the

right-side adjuster and seat bearing cups until the

torque remains constant at 102 N´m (75 ft. lbs.)(7) Measure the ring gear backlash. The range of

backlash is 0.15 to 0.203 mm (0.006 to 0.008 in.).

(8) Continue increasing the torque at the right-

side threaded adjuster until the specified backlash is

obtained.

NOTE: The left-side threaded adjuster torque

should have approximately 102 N´m (75 ft. lbs.). If

the torque is considerably less, the complete

adjustment procedure must be repeated.

(9) Tighten the left-side threaded adjuster until

102 N´m (75 ft. lbs.) torque is indicated. Seat the

bearing rollers with the procedure described above.

Do this until the torque remains constant.

(10) Install the threaded adjuster locks and

tighten the lock screws to 10 N´m (90 in. lbs.).

After the proper backlash is achieved, perform the

Gear Contact Pattern procedure.

GEAR CONTACT PATTERN

The ring gear and pinion teeth contact patterns

will show if the pinion depth is correct in the hous-

ing. It will also show if the ring gear backlash has

been adjusted correctly. The backlash can be adjusted

within specifications to achieve desired tooth contact

patterns.

(1) Apply a thin coat of hydrated ferric oxide or

equivalent, to the drive and coast side of the ring

gear teeth.

(2) Wrap, twist and hold a shop towel around the

pinion yoke to increase the turning resistance of the

pinion. This will provide a more distinct contact pat-

tern.

(3) With a boxed end wrench on a ring gear bolt,

rotate the differential case one complete revolution in

both directions while a load is being applied from

shop towel.

The areas on the ring gear teeth with the greatest

degree of contact against the pinion teeth will squee-

gee the compound to the areas with the least amount

of contact. Note and compare patterns on the ring

gear teeth to Gear Tooth Contact Patterns chart (Fig.

16) and adjust pinion depth and gear backlash as

necessary.

Fig. 15 Ring Gear Backlash

1 - DIAL INDICATOR

2 - RING GEAR

3 - EXCITER RING

KJREAR AXLE - 8 1/4 3 - 95

REAR AXLE - 8 1/4 (Continued)

Page 155 of 1803

(6) Install adjuster locks on the bearing caps.

(7) Install axle shafts.

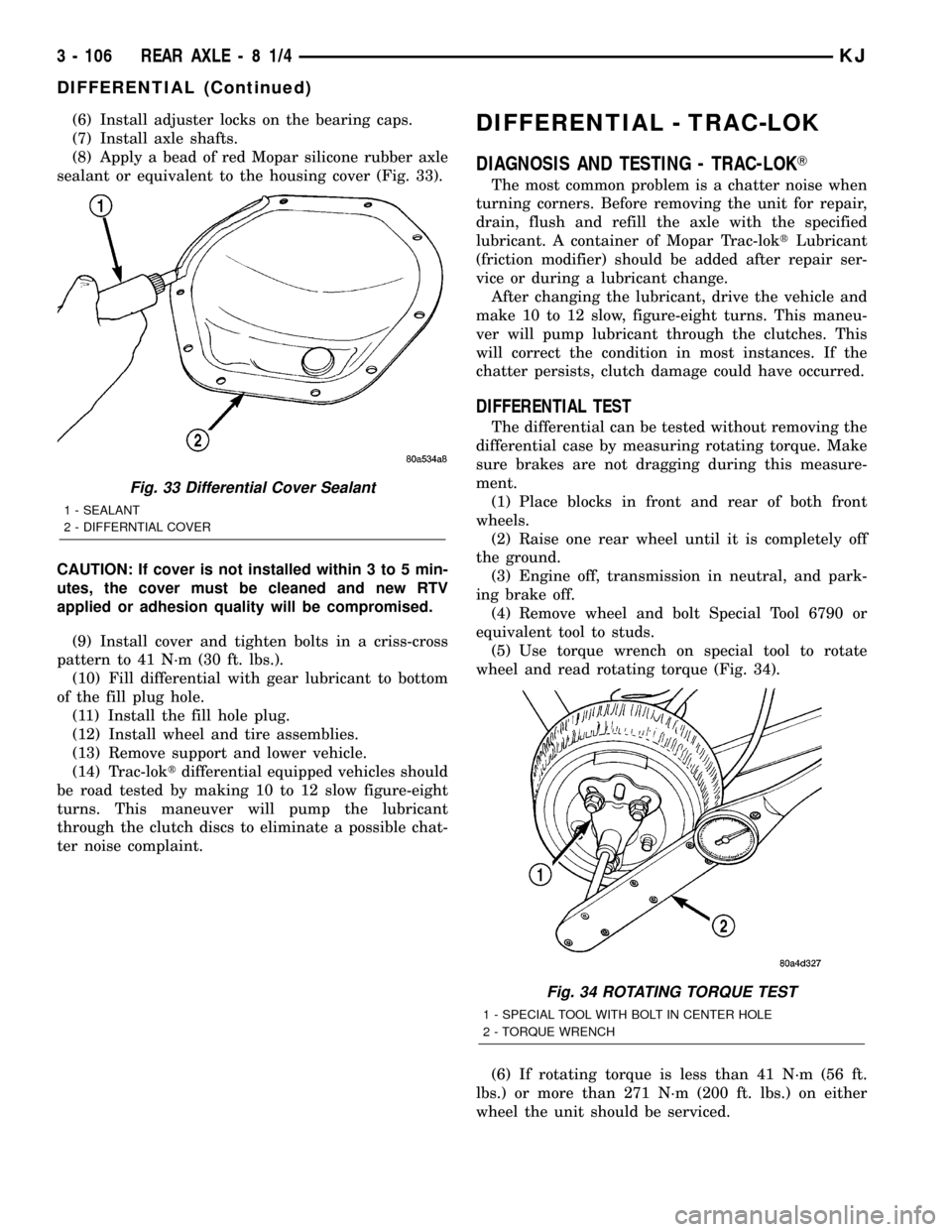

(8) Apply a bead of red Mopar silicone rubber axle

sealant or equivalent to the housing cover (Fig. 33).

CAUTION: If cover is not installed within 3 to 5 min-

utes, the cover must be cleaned and new RTV

applied or adhesion quality will be compromised.

(9) Install cover and tighten bolts in a criss-cross

pattern to 41 N´m (30 ft. lbs.).

(10) Fill differential with gear lubricant to bottom

of the fill plug hole.

(11) Install the fill hole plug.

(12) Install wheel and tire assemblies.

(13) Remove support and lower vehicle.

(14) Trac-loktdifferential equipped vehicles should

be road tested by making 10 to 12 slow figure-eight

turns. This maneuver will pump the lubricant

through the clutch discs to eliminate a possible chat-

ter noise complaint.DIFFERENTIAL - TRAC-LOK

DIAGNOSIS AND TESTING - TRAC-LOKT

The most common problem is a chatter noise when

turning corners. Before removing the unit for repair,

drain, flush and refill the axle with the specified

lubricant. A container of Mopar Trac-loktLubricant

(friction modifier) should be added after repair ser-

vice or during a lubricant change.

After changing the lubricant, drive the vehicle and

make 10 to 12 slow, figure-eight turns. This maneu-

ver will pump lubricant through the clutches. This

will correct the condition in most instances. If the

chatter persists, clutch damage could have occurred.

DIFFERENTIAL TEST

The differential can be tested without removing the

differential case by measuring rotating torque. Make

sure brakes are not dragging during this measure-

ment.

(1) Place blocks in front and rear of both front

wheels.

(2) Raise one rear wheel until it is completely off

the ground.

(3) Engine off, transmission in neutral, and park-

ing brake off.

(4) Remove wheel and bolt Special Tool 6790 or

equivalent tool to studs.

(5) Use torque wrench on special tool to rotate

wheel and read rotating torque (Fig. 34).

(6) If rotating torque is less than 41 N´m (56 ft.

lbs.) or more than 271 N´m (200 ft. lbs.) on either

wheel the unit should be serviced.

Fig. 33 Differential Cover Sealant

1 - SEALANT

2 - DIFFERNTIAL COVER

Fig. 34 ROTATING TORQUE TEST

1 - SPECIAL TOOL WITH BOLT IN CENTER HOLE

2 - TORQUE WRENCH

3 - 106 REAR AXLE-81/4KJ

DIFFERENTIAL (Continued)

Page 364 of 1803

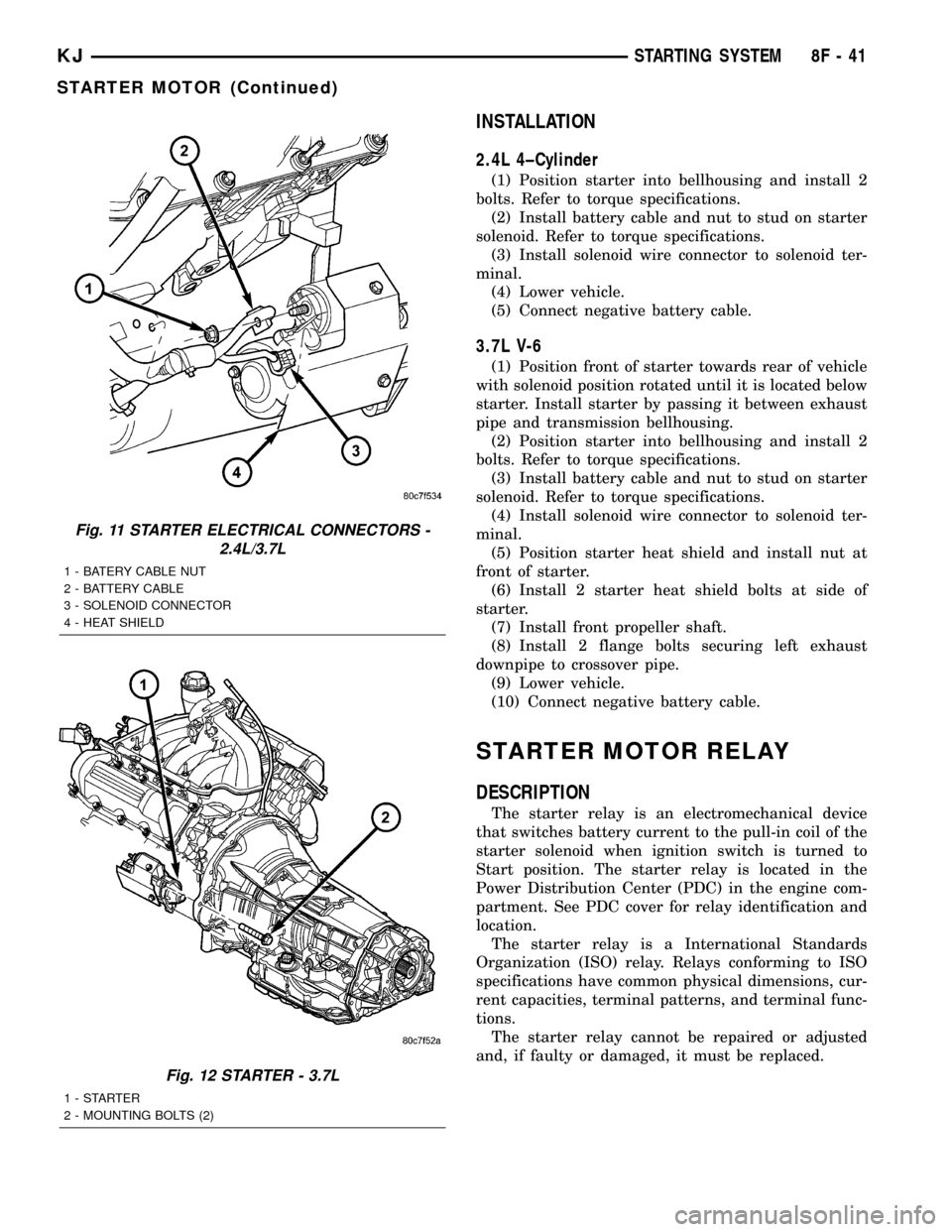

INSTALLATION

2.4L 4±Cylinder

(1) Position starter into bellhousing and install 2

bolts. Refer to torque specifications.

(2) Install battery cable and nut to stud on starter

solenoid. Refer to torque specifications.

(3) Install solenoid wire connector to solenoid ter-

minal.

(4) Lower vehicle.

(5) Connect negative battery cable.

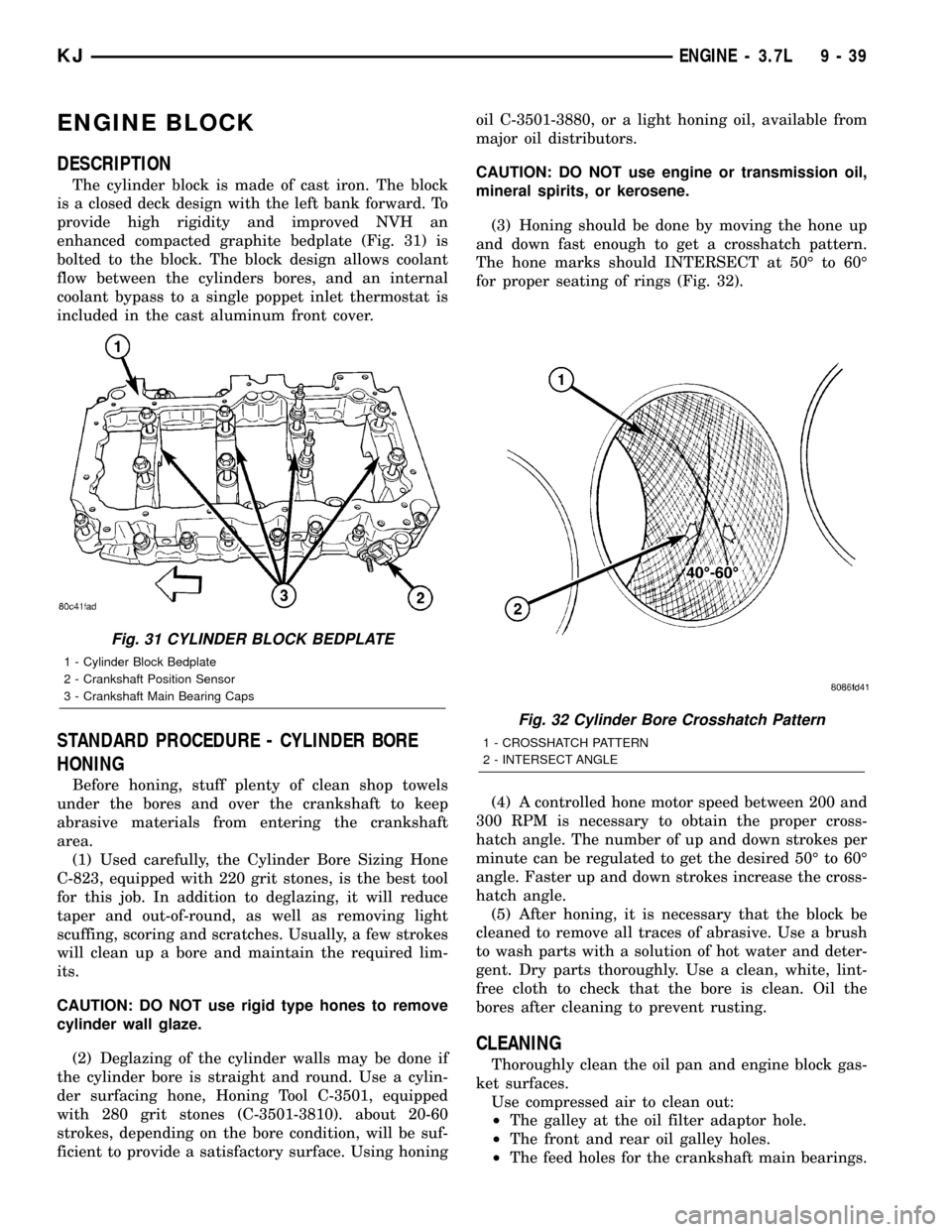

3.7L V-6

(1) Position front of starter towards rear of vehicle

with solenoid position rotated until it is located below

starter. Install starter by passing it between exhaust

pipe and transmission bellhousing.

(2) Position starter into bellhousing and install 2

bolts. Refer to torque specifications.

(3) Install battery cable and nut to stud on starter

solenoid. Refer to torque specifications.

(4) Install solenoid wire connector to solenoid ter-

minal.

(5) Position starter heat shield and install nut at

front of starter.

(6) Install 2 starter heat shield bolts at side of

starter.

(7) Install front propeller shaft.

(8) Install 2 flange bolts securing left exhaust

downpipe to crossover pipe.

(9) Lower vehicle.

(10) Connect negative battery cable.

STARTER MOTOR RELAY

DESCRIPTION

The starter relay is an electromechanical device

that switches battery current to the pull-in coil of the

starter solenoid when ignition switch is turned to

Start position. The starter relay is located in the

Power Distribution Center (PDC) in the engine com-

partment. See PDC cover for relay identification and

location.

The starter relay is a International Standards

Organization (ISO) relay. Relays conforming to ISO

specifications have common physical dimensions, cur-

rent capacities, terminal patterns, and terminal func-

tions.

The starter relay cannot be repaired or adjusted

and, if faulty or damaged, it must be replaced.

Fig. 11 STARTER ELECTRICAL CONNECTORS -

2.4L/3.7L

1 - BATERY CABLE NUT

2 - BATTERY CABLE

3 - SOLENOID CONNECTOR

4 - HEAT SHIELD

Fig. 12 STARTER - 3.7L

1-STARTER

2 - MOUNTING BOLTS (2)

KJSTARTING SYSTEM 8F - 41

STARTER MOTOR (Continued)

Page 1254 of 1803

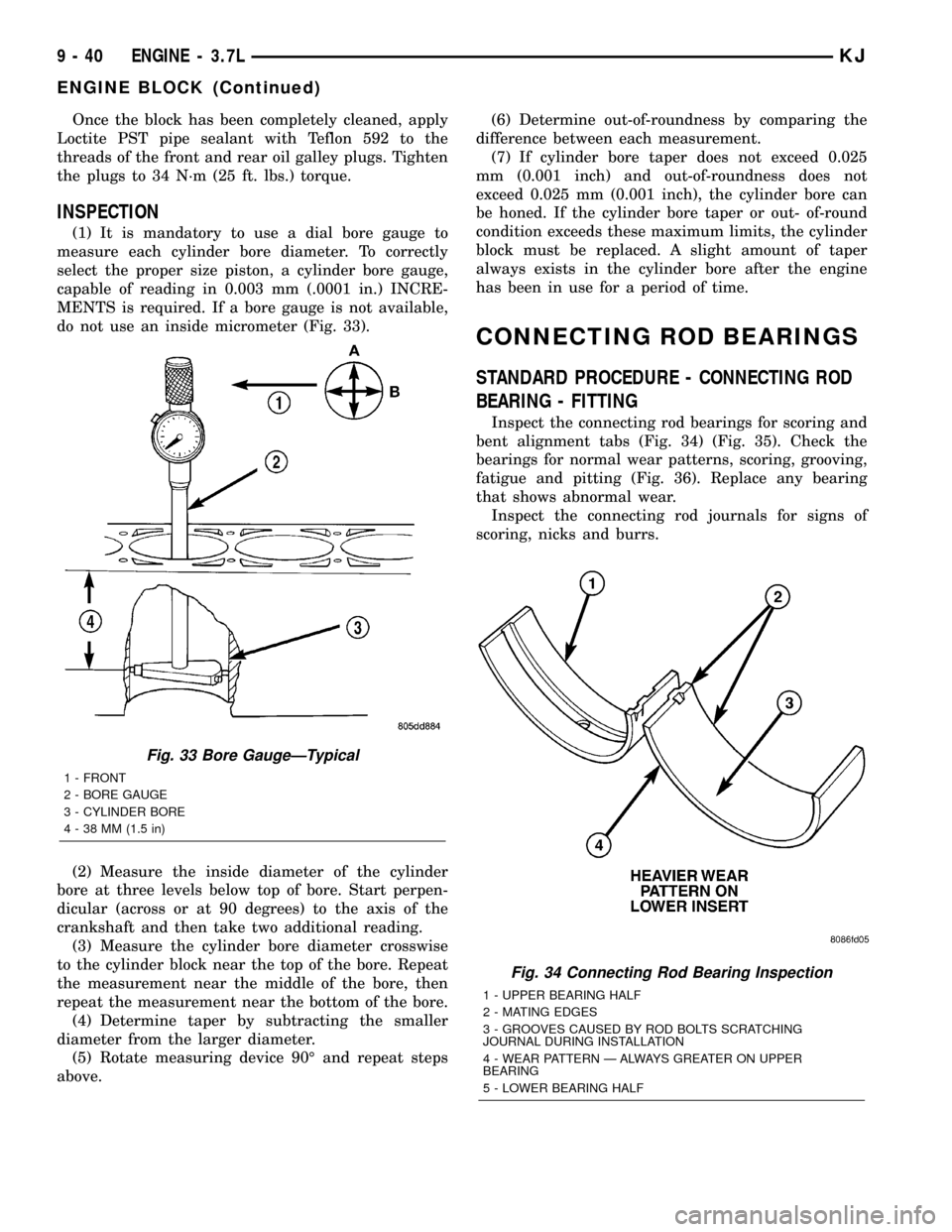

ENGINE BLOCK

DESCRIPTION

The cylinder block is made of cast iron. The block

is a closed deck design with the left bank forward. To

provide high rigidity and improved NVH an

enhanced compacted graphite bedplate (Fig. 31) is

bolted to the block. The block design allows coolant

flow between the cylinders bores, and an internal

coolant bypass to a single poppet inlet thermostat is

included in the cast aluminum front cover.

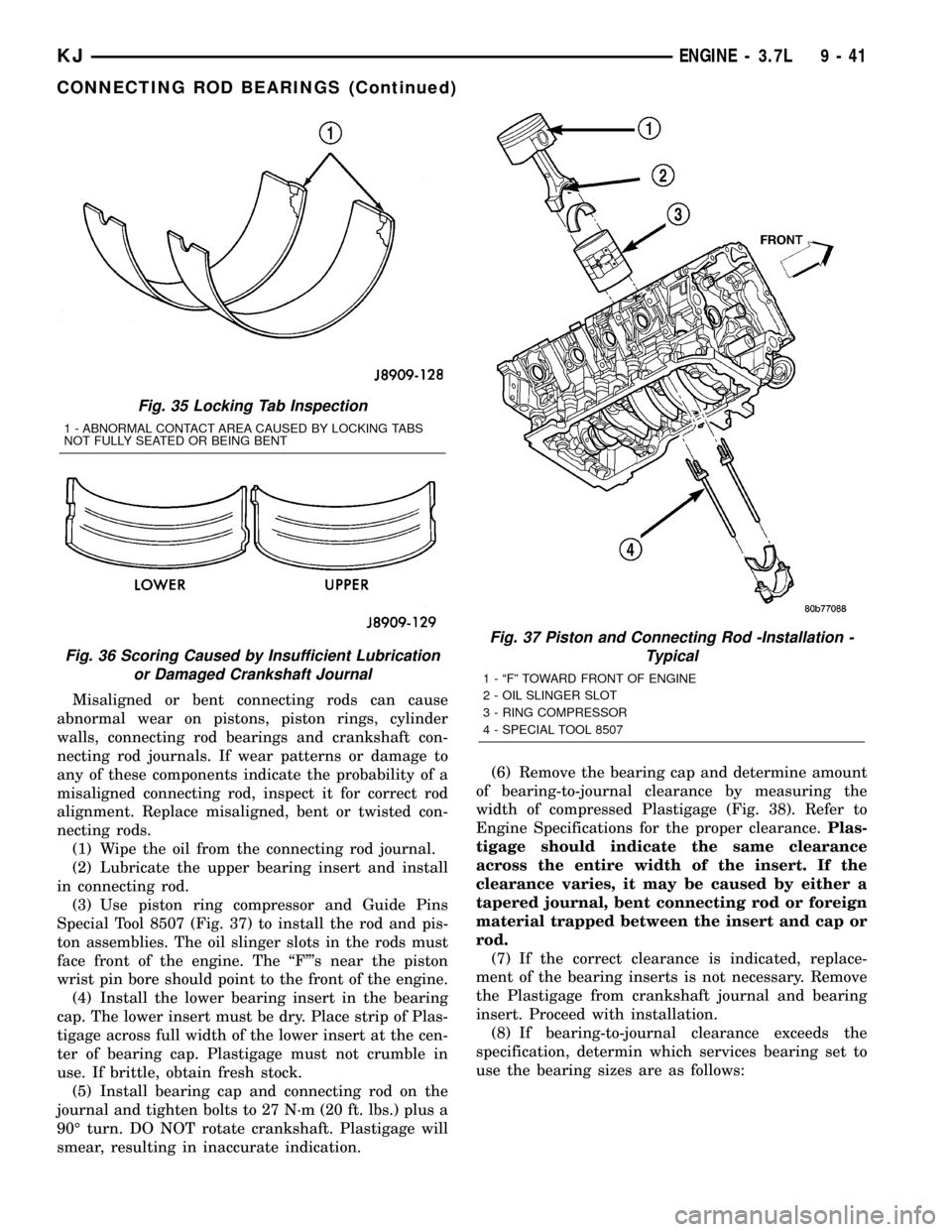

STANDARD PROCEDURE - CYLINDER BORE

HONING

Before honing, stuff plenty of clean shop towels

under the bores and over the crankshaft to keep

abrasive materials from entering the crankshaft

area.

(1) Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round, as well as removing light

scuffing, scoring and scratches. Usually, a few strokes

will clean up a bore and maintain the required lim-

its.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Using honingoil C-3501-3880, or a light honing oil, available from

major oil distributors.

CAUTION: DO NOT use engine or transmission oil,

mineral spirits, or kerosene.

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.

The hone marks should INTERSECT at 50É to 60É

for proper seating of rings (Fig. 32).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 50É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

CLEANING

Thoroughly clean the oil pan and engine block gas-

ket surfaces.

Use compressed air to clean out:

²The galley at the oil filter adaptor hole.

²The front and rear oil galley holes.

²The feed holes for the crankshaft main bearings.

Fig. 31 CYLINDER BLOCK BEDPLATE

1 - Cylinder Block Bedplate

2 - Crankshaft Position Sensor

3 - Crankshaft Main Bearing Caps

Fig. 32 Cylinder Bore Crosshatch Pattern

1 - CROSSHATCH PATTERN

2 - INTERSECT ANGLE

KJENGINE - 3.7L 9 - 39

Page 1255 of 1803

Once the block has been completely cleaned, apply

Loctite PST pipe sealant with Teflon 592 to the

threads of the front and rear oil galley plugs. Tighten

the plugs to 34 N´m (25 ft. lbs.) torque.

INSPECTION

(1) It is mandatory to use a dial bore gauge to

measure each cylinder bore diameter. To correctly

select the proper size piston, a cylinder bore gauge,

capable of reading in 0.003 mm (.0001 in.) INCRE-

MENTS is required. If a bore gauge is not available,

do not use an inside micrometer (Fig. 33).

(2) Measure the inside diameter of the cylinder

bore at three levels below top of bore. Start perpen-

dicular (across or at 90 degrees) to the axis of the

crankshaft and then take two additional reading.

(3) Measure the cylinder bore diameter crosswise

to the cylinder block near the top of the bore. Repeat

the measurement near the middle of the bore, then

repeat the measurement near the bottom of the bore.

(4) Determine taper by subtracting the smaller

diameter from the larger diameter.

(5) Rotate measuring device 90É and repeat steps

above.(6) Determine out-of-roundness by comparing the

difference between each measurement.

(7) If cylinder bore taper does not exceed 0.025

mm (0.001 inch) and out-of-roundness does not

exceed 0.025 mm (0.001 inch), the cylinder bore can

be honed. If the cylinder bore taper or out- of-round

condition exceeds these maximum limits, the cylinder

block must be replaced. A slight amount of taper

always exists in the cylinder bore after the engine

has been in use for a period of time.

CONNECTING ROD BEARINGS

STANDARD PROCEDURE - CONNECTING ROD

BEARING - FITTING

Inspect the connecting rod bearings for scoring and

bent alignment tabs (Fig. 34) (Fig. 35). Check the

bearings for normal wear patterns, scoring, grooving,

fatigue and pitting (Fig. 36). Replace any bearing

that shows abnormal wear.

Inspect the connecting rod journals for signs of

scoring, nicks and burrs.

Fig. 33 Bore GaugeÐTypical

1 - FRONT

2 - BORE GAUGE

3 - CYLINDER BORE

4 - 38 MM (1.5 in)

Fig. 34 Connecting Rod Bearing Inspection

1 - UPPER BEARING HALF

2 - MATING EDGES

3 - GROOVES CAUSED BY ROD BOLTS SCRATCHING

JOURNAL DURING INSTALLATION

4 - WEAR PATTERN Ð ALWAYS GREATER ON UPPER

BEARING

5 - LOWER BEARING HALF

9 - 40 ENGINE - 3.7LKJ

ENGINE BLOCK (Continued)

Page 1256 of 1803

Misaligned or bent connecting rods can cause

abnormal wear on pistons, piston rings, cylinder

walls, connecting rod bearings and crankshaft con-

necting rod journals. If wear patterns or damage to

any of these components indicate the probability of a

misaligned connecting rod, inspect it for correct rod

alignment. Replace misaligned, bent or twisted con-

necting rods.

(1) Wipe the oil from the connecting rod journal.

(2) Lubricate the upper bearing insert and install

in connecting rod.

(3) Use piston ring compressor and Guide Pins

Special Tool 8507 (Fig. 37) to install the rod and pis-

ton assemblies. The oil slinger slots in the rods must

face front of the engine. The ªFº's near the piston

wrist pin bore should point to the front of the engine.

(4) Install the lower bearing insert in the bearing

cap. The lower insert must be dry. Place strip of Plas-

tigage across full width of the lower insert at the cen-

ter of bearing cap. Plastigage must not crumble in

use. If brittle, obtain fresh stock.

(5) Install bearing cap and connecting rod on the

journal and tighten bolts to 27 N´m (20 ft. lbs.) plus a

90É turn. DO NOT rotate crankshaft. Plastigage will

smear, resulting in inaccurate indication.(6) Remove the bearing cap and determine amount

of bearing-to-journal clearance by measuring the

width of compressed Plastigage (Fig. 38). Refer to

Engine Specifications for the proper clearance.Plas-

tigage should indicate the same clearance

across the entire width of the insert. If the

clearance varies, it may be caused by either a

tapered journal, bent connecting rod or foreign

material trapped between the insert and cap or

rod.

(7) If the correct clearance is indicated, replace-

ment of the bearing inserts is not necessary. Remove

the Plastigage from crankshaft journal and bearing

insert. Proceed with installation.

(8) If bearing-to-journal clearance exceeds the

specification, determin which services bearing set to

use the bearing sizes are as follows:

Fig. 35 Locking Tab Inspection

1 - ABNORMAL CONTACT AREA CAUSED BY LOCKING TABS

NOT FULLY SEATED OR BEING BENT

Fig. 36 Scoring Caused by Insufficient Lubrication

or Damaged Crankshaft Journal

Fig. 37 Piston and Connecting Rod -Installation -

Typical

1 - ªFº TOWARD FRONT OF ENGINE

2 - OIL SLINGER SLOT

3 - RING COMPRESSOR

4 - SPECIAL TOOL 8507

KJENGINE - 3.7L 9 - 41

CONNECTING ROD BEARINGS (Continued)

Page 1264 of 1803

FLEX PLATE

REMOVAL

(1) Remove the transmission.

(2) Remove the bolts and flexplate.

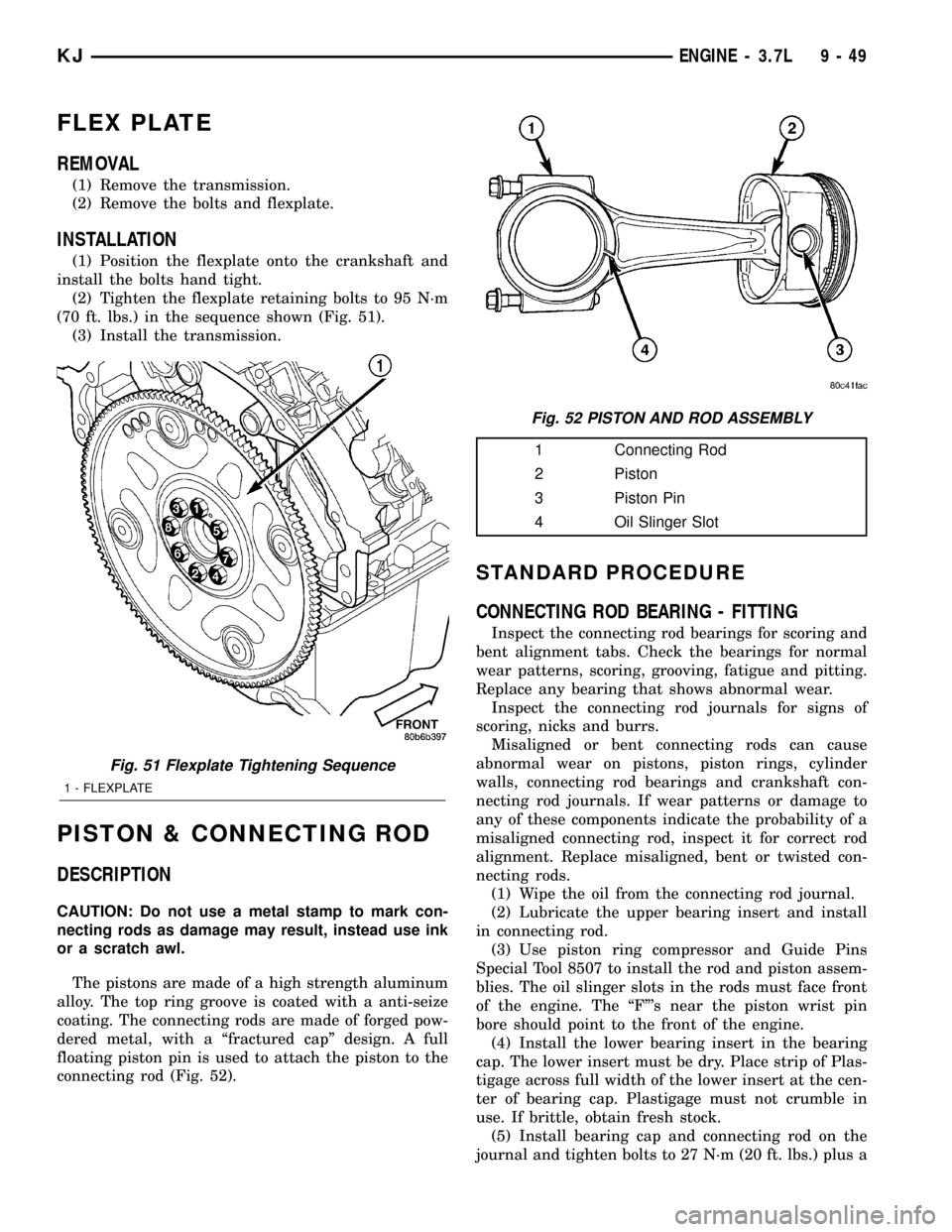

INSTALLATION

(1) Position the flexplate onto the crankshaft and

install the bolts hand tight.

(2) Tighten the flexplate retaining bolts to 95 N´m

(70 ft. lbs.) in the sequence shown (Fig. 51).

(3) Install the transmission.

PISTON & CONNECTING ROD

DESCRIPTION

CAUTION: Do not use a metal stamp to mark con-

necting rods as damage may result, instead use ink

or a scratch awl.

The pistons are made of a high strength aluminum

alloy. The top ring groove is coated with a anti-seize

coating. The connecting rods are made of forged pow-

dered metal, with a ªfractured capº design. A full

floating piston pin is used to attach the piston to the

connecting rod (Fig. 52).

1 Connecting Rod

2 Piston

3 Piston Pin

4 Oil Slinger Slot

STANDARD PROCEDURE

CONNECTING ROD BEARING - FITTING

Inspect the connecting rod bearings for scoring and

bent alignment tabs. Check the bearings for normal

wear patterns, scoring, grooving, fatigue and pitting.

Replace any bearing that shows abnormal wear.

Inspect the connecting rod journals for signs of

scoring, nicks and burrs.

Misaligned or bent connecting rods can cause

abnormal wear on pistons, piston rings, cylinder

walls, connecting rod bearings and crankshaft con-

necting rod journals. If wear patterns or damage to

any of these components indicate the probability of a

misaligned connecting rod, inspect it for correct rod

alignment. Replace misaligned, bent or twisted con-

necting rods.

(1) Wipe the oil from the connecting rod journal.

(2) Lubricate the upper bearing insert and install

in connecting rod.

(3) Use piston ring compressor and Guide Pins

Special Tool 8507 to install the rod and piston assem-

blies. The oil slinger slots in the rods must face front

of the engine. The ªFº's near the piston wrist pin

bore should point to the front of the engine.

(4) Install the lower bearing insert in the bearing

cap. The lower insert must be dry. Place strip of Plas-

tigage across full width of the lower insert at the cen-

ter of bearing cap. Plastigage must not crumble in

use. If brittle, obtain fresh stock.

(5) Install bearing cap and connecting rod on the

journal and tighten bolts to 27 N´m (20 ft. lbs.) plus a

Fig. 51 Flexplate Tightening Sequence

1 - FLEXPLATE

Fig. 52 PISTON AND ROD ASSEMBLY

KJENGINE - 3.7L 9 - 49

Page 1462 of 1803

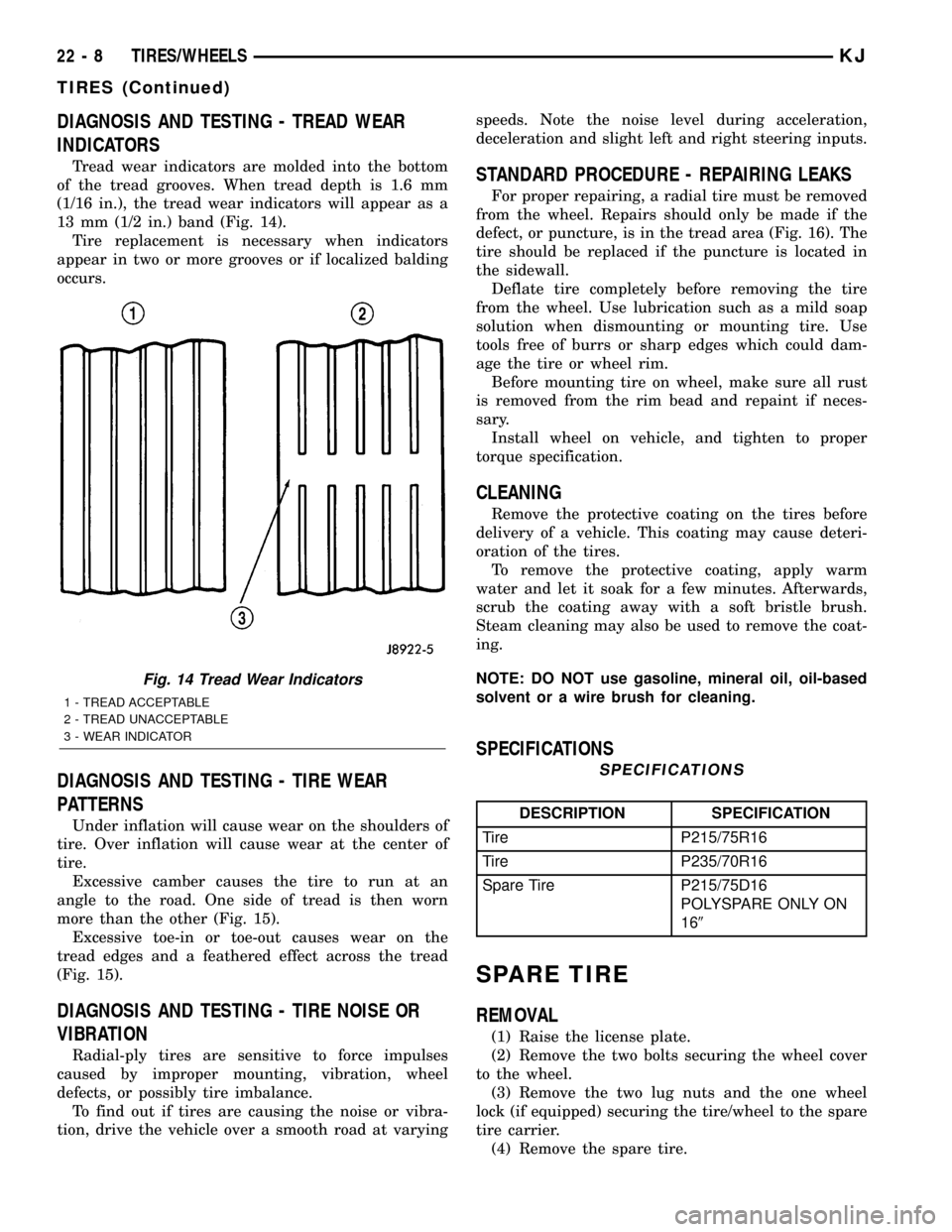

DIAGNOSIS AND TESTING - TREAD WEAR

INDICATORS

Tread wear indicators are molded into the bottom

of the tread grooves. When tread depth is 1.6 mm

(1/16 in.), the tread wear indicators will appear as a

13 mm (1/2 in.) band (Fig. 14).

Tire replacement is necessary when indicators

appear in two or more grooves or if localized balding

occurs.

DIAGNOSIS AND TESTING - TIRE WEAR

PATTERNS

Under inflation will cause wear on the shoulders of

tire. Over inflation will cause wear at the center of

tire.

Excessive camber causes the tire to run at an

angle to the road. One side of tread is then worn

more than the other (Fig. 15).

Excessive toe-in or toe-out causes wear on the

tread edges and a feathered effect across the tread

(Fig. 15).

DIAGNOSIS AND TESTING - TIRE NOISE OR

VIBRATION

Radial-ply tires are sensitive to force impulses

caused by improper mounting, vibration, wheel

defects, or possibly tire imbalance.

To find out if tires are causing the noise or vibra-

tion, drive the vehicle over a smooth road at varyingspeeds. Note the noise level during acceleration,

deceleration and slight left and right steering inputs.

STANDARD PROCEDURE - REPAIRING LEAKS

For proper repairing, a radial tire must be removed

from the wheel. Repairs should only be made if the

defect, or puncture, is in the tread area (Fig. 16). The

tire should be replaced if the puncture is located in

the sidewall.

Deflate tire completely before removing the tire

from the wheel. Use lubrication such as a mild soap

solution when dismounting or mounting tire. Use

tools free of burrs or sharp edges which could dam-

age the tire or wheel rim.

Before mounting tire on wheel, make sure all rust

is removed from the rim bead and repaint if neces-

sary.

Install wheel on vehicle, and tighten to proper

torque specification.

CLEANING

Remove the protective coating on the tires before

delivery of a vehicle. This coating may cause deteri-

oration of the tires.

To remove the protective coating, apply warm

water and let it soak for a few minutes. Afterwards,

scrub the coating away with a soft bristle brush.

Steam cleaning may also be used to remove the coat-

ing.

NOTE: DO NOT use gasoline, mineral oil, oil-based

solvent or a wire brush for cleaning.

SPECIFICATIONS

SPECIFICATIONS

DESCRIPTION SPECIFICATION

Tire P215/75R16

Tire P235/70R16

Spare Tire P215/75D16

POLYSPARE ONLY ON

169

SPARE TIRE

REMOVAL

(1) Raise the license plate.

(2) Remove the two bolts securing the wheel cover

to the wheel.

(3) Remove the two lug nuts and the one wheel

lock (if equipped) securing the tire/wheel to the spare

tire carrier.

(4) Remove the spare tire.

Fig. 14 Tread Wear Indicators

1 - TREAD ACCEPTABLE

2 - TREAD UNACCEPTABLE

3 - WEAR INDICATOR

22 - 8 TIRES/WHEELSKJ

TIRES (Continued)