engine JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1389 of 1803

(3) Remove 4 fuel pump module access plate nuts

(Fig. 3).

(4) While applying heat from a heat gun, carefully

pry up fuel pump module access plate. Take care not

to bend plate.

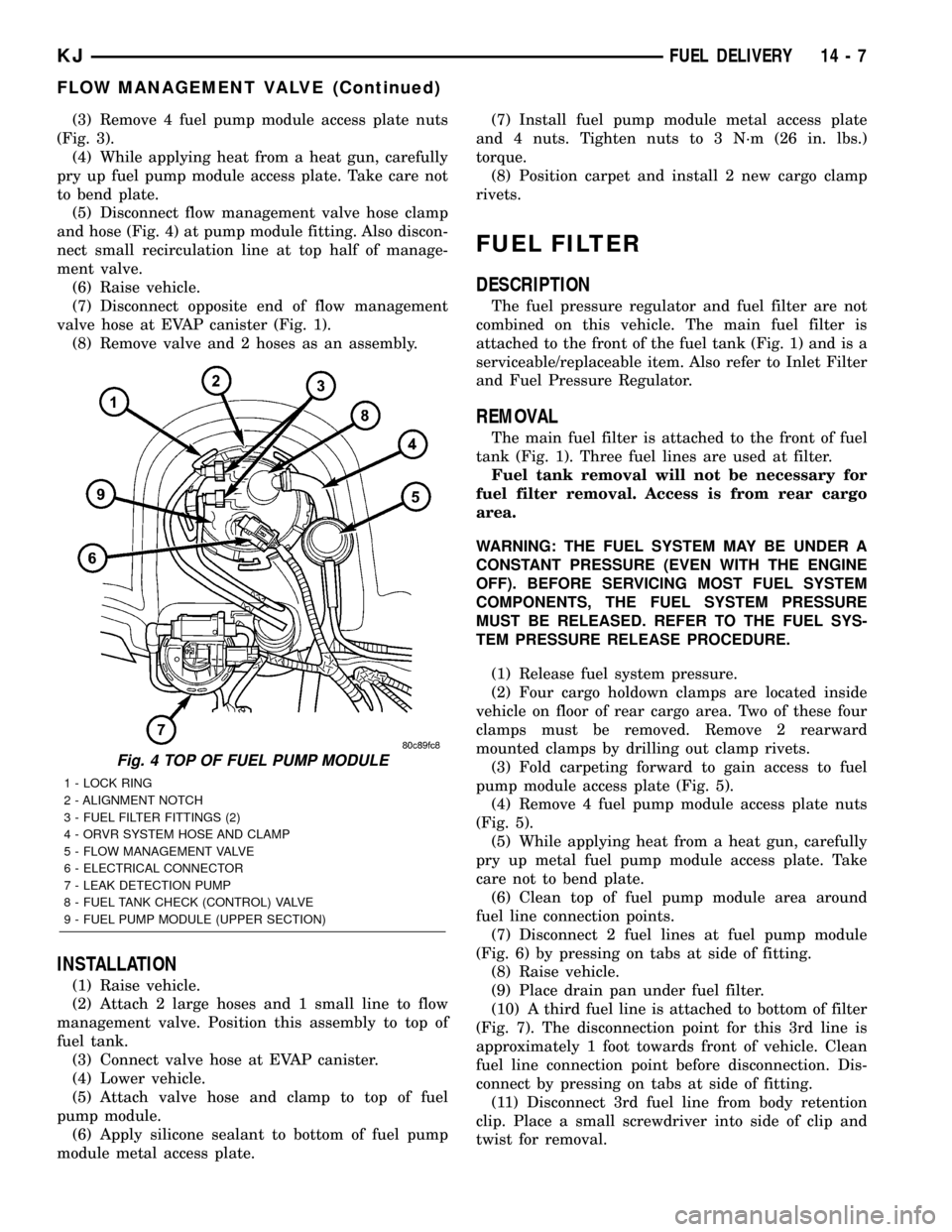

(5) Disconnect flow management valve hose clamp

and hose (Fig. 4) at pump module fitting. Also discon-

nect small recirculation line at top half of manage-

ment valve.

(6) Raise vehicle.

(7) Disconnect opposite end of flow management

valve hose at EVAP canister (Fig. 1).

(8) Remove valve and 2 hoses as an assembly.

INSTALLATION

(1) Raise vehicle.

(2) Attach 2 large hoses and 1 small line to flow

management valve. Position this assembly to top of

fuel tank.

(3) Connect valve hose at EVAP canister.

(4) Lower vehicle.

(5) Attach valve hose and clamp to top of fuel

pump module.

(6) Apply silicone sealant to bottom of fuel pump

module metal access plate.(7) Install fuel pump module metal access plate

and 4 nuts. Tighten nuts to 3 N´m (26 in. lbs.)

torque.

(8) Position carpet and install 2 new cargo clamp

rivets.

FUEL FILTER

DESCRIPTION

The fuel pressure regulator and fuel filter are not

combined on this vehicle. The main fuel filter is

attached to the front of the fuel tank (Fig. 1) and is a

serviceable/replaceable item. Also refer to Inlet Filter

and Fuel Pressure Regulator.

REMOVAL

The main fuel filter is attached to the front of fuel

tank (Fig. 1). Three fuel lines are used at filter.

Fuel tank removal will not be necessary for

fuel filter removal. Access is from rear cargo

area.

WARNING: THE FUEL SYSTEM MAY BE UNDER A

CONSTANT PRESSURE (EVEN WITH THE ENGINE

OFF). BEFORE SERVICING MOST FUEL SYSTEM

COMPONENTS, THE FUEL SYSTEM PRESSURE

MUST BE RELEASED. REFER TO THE FUEL SYS-

TEM PRESSURE RELEASE PROCEDURE.

(1) Release fuel system pressure.

(2) Four cargo holdown clamps are located inside

vehicle on floor of rear cargo area. Two of these four

clamps must be removed. Remove 2 rearward

mounted clamps by drilling out clamp rivets.

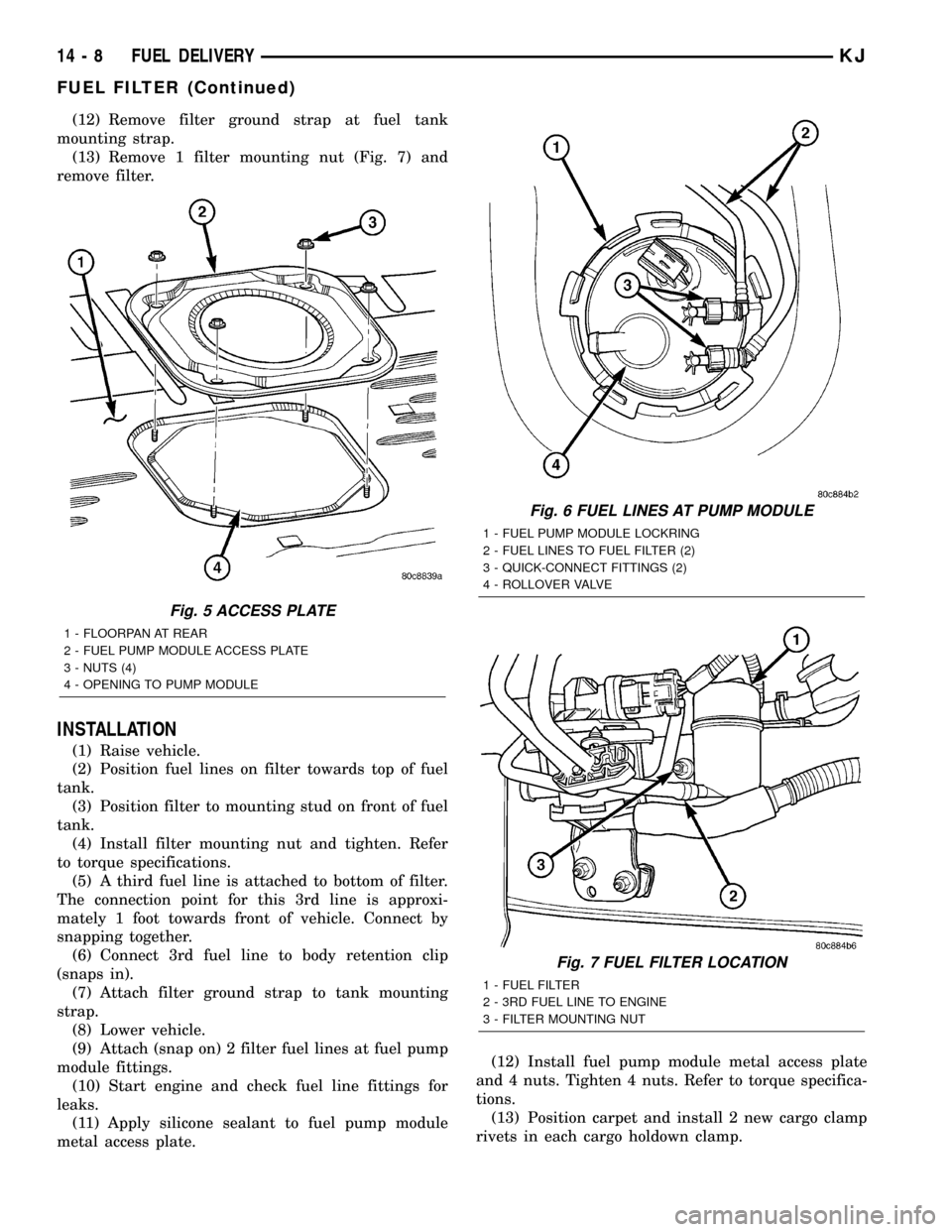

(3) Fold carpeting forward to gain access to fuel

pump module access plate (Fig. 5).

(4) Remove 4 fuel pump module access plate nuts

(Fig. 5).

(5) While applying heat from a heat gun, carefully

pry up metal fuel pump module access plate. Take

care not to bend plate.

(6) Clean top of fuel pump module area around

fuel line connection points.

(7) Disconnect 2 fuel lines at fuel pump module

(Fig. 6) by pressing on tabs at side of fitting.

(8) Raise vehicle.

(9) Place drain pan under fuel filter.

(10) A third fuel line is attached to bottom of filter

(Fig. 7). The disconnection point for this 3rd line is

approximately 1 foot towards front of vehicle. Clean

fuel line connection point before disconnection. Dis-

connect by pressing on tabs at side of fitting.

(11) Disconnect 3rd fuel line from body retention

clip. Place a small screwdriver into side of clip and

twist for removal.

Fig. 4 TOP OF FUEL PUMP MODULE

1 - LOCK RING

2 - ALIGNMENT NOTCH

3 - FUEL FILTER FITTINGS (2)

4 - ORVR SYSTEM HOSE AND CLAMP

5 - FLOW MANAGEMENT VALVE

6 - ELECTRICAL CONNECTOR

7 - LEAK DETECTION PUMP

8 - FUEL TANK CHECK (CONTROL) VALVE

9 - FUEL PUMP MODULE (UPPER SECTION)

KJFUEL DELIVERY 14 - 7

FLOW MANAGEMENT VALVE (Continued)

Page 1390 of 1803

(12) Remove filter ground strap at fuel tank

mounting strap.

(13) Remove 1 filter mounting nut (Fig. 7) and

remove filter.

INSTALLATION

(1) Raise vehicle.

(2) Position fuel lines on filter towards top of fuel

tank.

(3) Position filter to mounting stud on front of fuel

tank.

(4) Install filter mounting nut and tighten. Refer

to torque specifications.

(5) A third fuel line is attached to bottom of filter.

The connection point for this 3rd line is approxi-

mately 1 foot towards front of vehicle. Connect by

snapping together.

(6) Connect 3rd fuel line to body retention clip

(snaps in).

(7) Attach filter ground strap to tank mounting

strap.

(8) Lower vehicle.

(9) Attach (snap on) 2 filter fuel lines at fuel pump

module fittings.

(10) Start engine and check fuel line fittings for

leaks.

(11) Apply silicone sealant to fuel pump module

metal access plate.(12) Install fuel pump module metal access plate

and 4 nuts. Tighten 4 nuts. Refer to torque specifica-

tions.

(13) Position carpet and install 2 new cargo clamp

rivets in each cargo holdown clamp.

Fig. 5 ACCESS PLATE

1 - FLOORPAN AT REAR

2 - FUEL PUMP MODULE ACCESS PLATE

3 - NUTS (4)

4 - OPENING TO PUMP MODULE

Fig. 6 FUEL LINES AT PUMP MODULE

1 - FUEL PUMP MODULE LOCKRING

2 - FUEL LINES TO FUEL FILTER (2)

3 - QUICK-CONNECT FITTINGS (2)

4 - ROLLOVER VALVE

Fig. 7 FUEL FILTER LOCATION

1 - FUEL FILTER

2 - 3RD FUEL LINE TO ENGINE

3 - FILTER MOUNTING NUT

14 - 8 FUEL DELIVERYKJ

FUEL FILTER (Continued)

Page 1392 of 1803

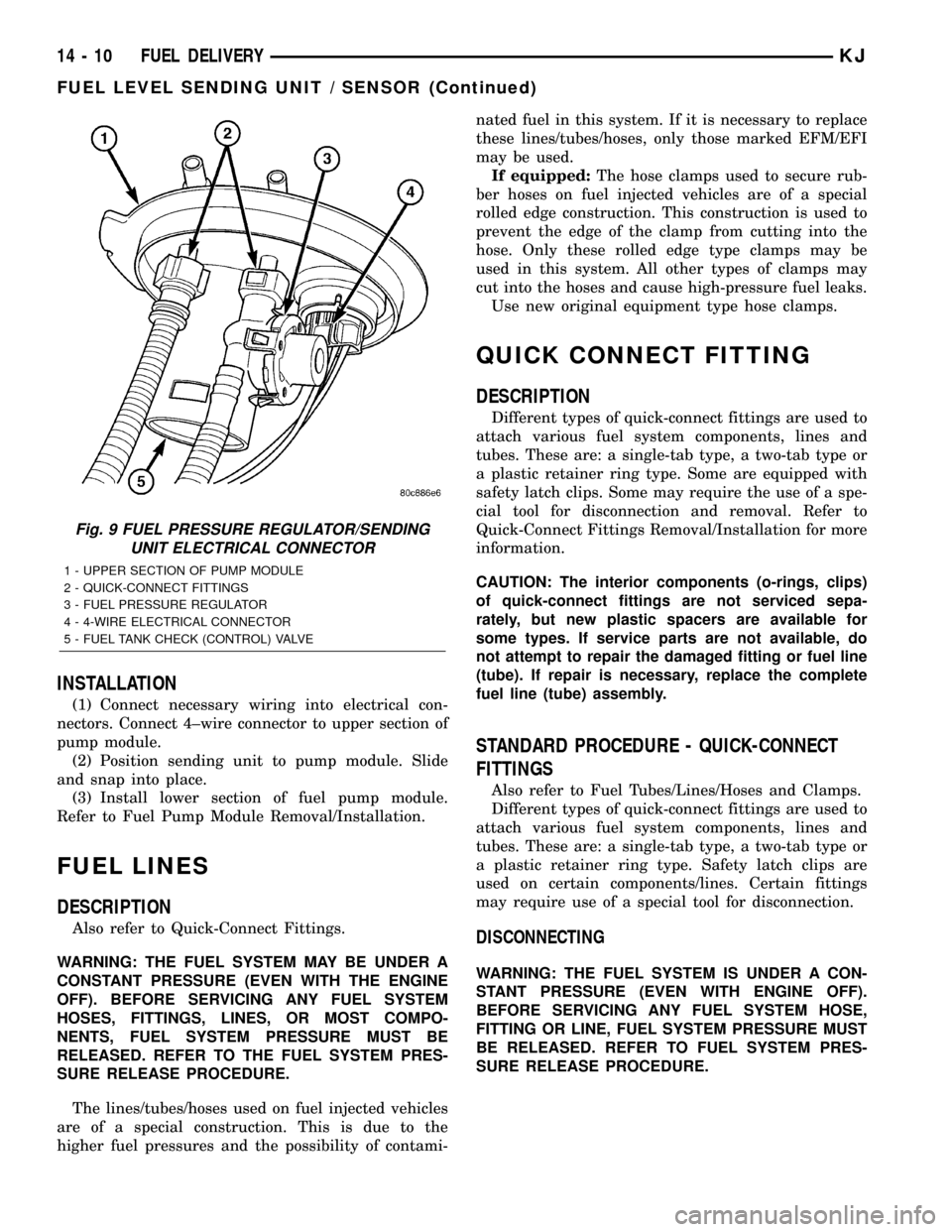

INSTALLATION

(1) Connect necessary wiring into electrical con-

nectors. Connect 4±wire connector to upper section of

pump module.

(2) Position sending unit to pump module. Slide

and snap into place.

(3) Install lower section of fuel pump module.

Refer to Fuel Pump Module Removal/Installation.

FUEL LINES

DESCRIPTION

Also refer to Quick-Connect Fittings.

WARNING: THE FUEL SYSTEM MAY BE UNDER A

CONSTANT PRESSURE (EVEN WITH THE ENGINE

OFF). BEFORE SERVICING ANY FUEL SYSTEM

HOSES, FITTINGS, LINES, OR MOST COMPO-

NENTS, FUEL SYSTEM PRESSURE MUST BE

RELEASED. REFER TO THE FUEL SYSTEM PRES-

SURE RELEASE PROCEDURE.

The lines/tubes/hoses used on fuel injected vehicles

are of a special construction. This is due to the

higher fuel pressures and the possibility of contami-nated fuel in this system. If it is necessary to replace

these lines/tubes/hoses, only those marked EFM/EFI

may be used.

If equipped:The hose clamps used to secure rub-

ber hoses on fuel injected vehicles are of a special

rolled edge construction. This construction is used to

prevent the edge of the clamp from cutting into the

hose. Only these rolled edge type clamps may be

used in this system. All other types of clamps may

cut into the hoses and cause high-pressure fuel leaks.

Use new original equipment type hose clamps.

QUICK CONNECT FITTING

DESCRIPTION

Different types of quick-connect fittings are used to

attach various fuel system components, lines and

tubes. These are: a single-tab type, a two-tab type or

a plastic retainer ring type. Some are equipped with

safety latch clips. Some may require the use of a spe-

cial tool for disconnection and removal. Refer to

Quick-Connect Fittings Removal/Installation for more

information.

CAUTION: The interior components (o-rings, clips)

of quick-connect fittings are not serviced sepa-

rately, but new plastic spacers are available for

some types. If service parts are not available, do

not attempt to repair the damaged fitting or fuel line

(tube). If repair is necessary, replace the complete

fuel line (tube) assembly.

STANDARD PROCEDURE - QUICK-CONNECT

FITTINGS

Also refer to Fuel Tubes/Lines/Hoses and Clamps.

Different types of quick-connect fittings are used to

attach various fuel system components, lines and

tubes. These are: a single-tab type, a two-tab type or

a plastic retainer ring type. Safety latch clips are

used on certain components/lines. Certain fittings

may require use of a special tool for disconnection.

DISCONNECTING

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSE,

FITTING OR LINE, FUEL SYSTEM PRESSURE MUST

BE RELEASED. REFER TO FUEL SYSTEM PRES-

SURE RELEASE PROCEDURE.

Fig. 9 FUEL PRESSURE REGULATOR/SENDING

UNIT ELECTRICAL CONNECTOR

1 - UPPER SECTION OF PUMP MODULE

2 - QUICK-CONNECT FITTINGS

3 - FUEL PRESSURE REGULATOR

4 - 4-WIRE ELECTRICAL CONNECTOR

5 - FUEL TANK CHECK (CONTROL) VALVE

14 - 10 FUEL DELIVERYKJ

FUEL LEVEL SENDING UNIT / SENSOR (Continued)

Page 1395 of 1803

(b) After disconnection, plastic retainer ring will

remain with quick-connect fitting connector body.

(c) Inspect fitting connector body, plastic retainer

ring and fuel system component for damage.

Replace as necessary.

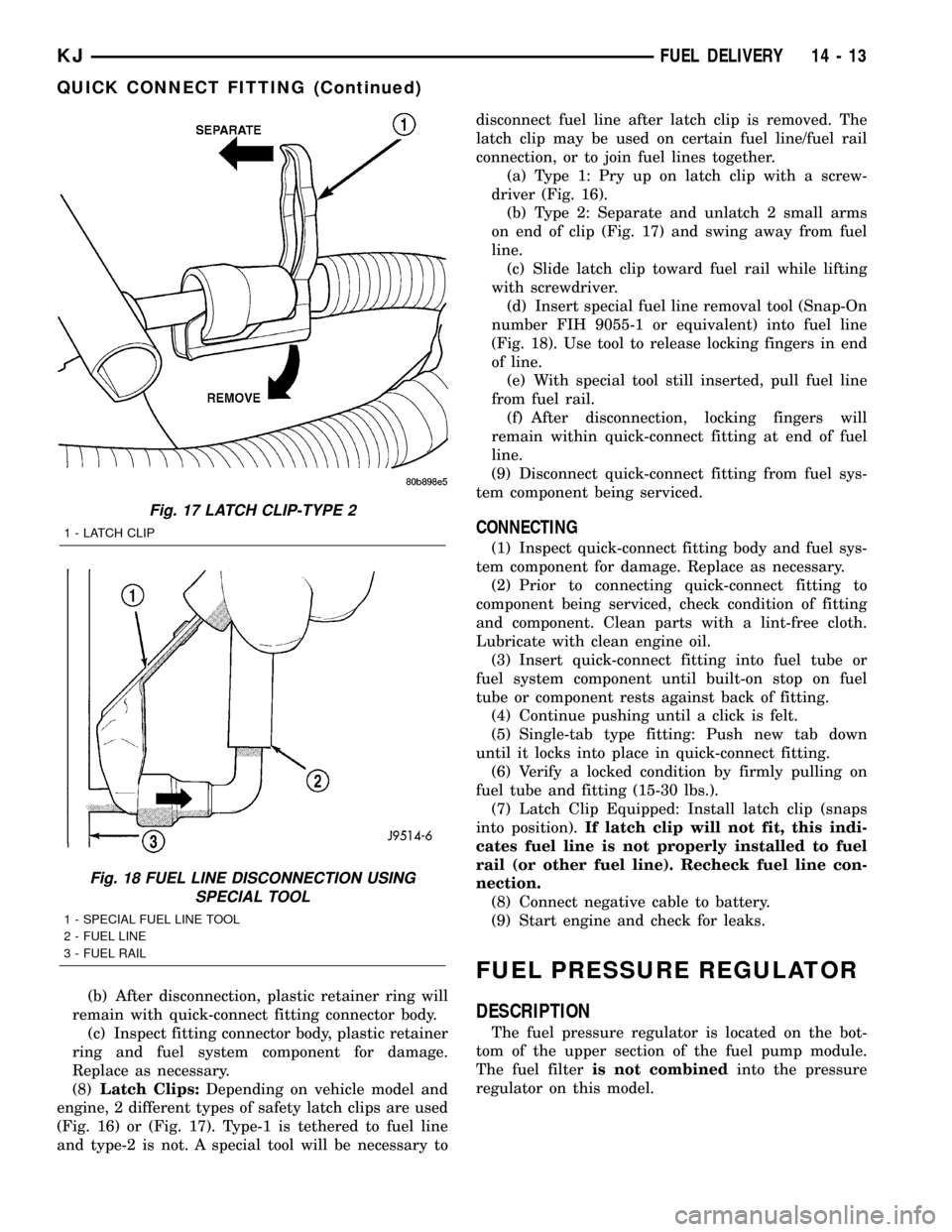

(8)Latch Clips:Depending on vehicle model and

engine, 2 different types of safety latch clips are used

(Fig. 16) or (Fig. 17). Type-1 is tethered to fuel line

and type-2 is not. A special tool will be necessary todisconnect fuel line after latch clip is removed. The

latch clip may be used on certain fuel line/fuel rail

connection, or to join fuel lines together.

(a) Type 1: Pry up on latch clip with a screw-

driver (Fig. 16).

(b) Type 2: Separate and unlatch 2 small arms

on end of clip (Fig. 17) and swing away from fuel

line.

(c) Slide latch clip toward fuel rail while lifting

with screwdriver.

(d) Insert special fuel line removal tool (Snap-On

number FIH 9055-1 or equivalent) into fuel line

(Fig. 18). Use tool to release locking fingers in end

of line.

(e) With special tool still inserted, pull fuel line

from fuel rail.

(f) After disconnection, locking fingers will

remain within quick-connect fitting at end of fuel

line.

(9) Disconnect quick-connect fitting from fuel sys-

tem component being serviced.

CONNECTING

(1) Inspect quick-connect fitting body and fuel sys-

tem component for damage. Replace as necessary.

(2) Prior to connecting quick-connect fitting to

component being serviced, check condition of fitting

and component. Clean parts with a lint-free cloth.

Lubricate with clean engine oil.

(3) Insert quick-connect fitting into fuel tube or

fuel system component until built-on stop on fuel

tube or component rests against back of fitting.

(4) Continue pushing until a click is felt.

(5) Single-tab type fitting: Push new tab down

until it locks into place in quick-connect fitting.

(6) Verify a locked condition by firmly pulling on

fuel tube and fitting (15-30 lbs.).

(7) Latch Clip Equipped: Install latch clip (snaps

into position).If latch clip will not fit, this indi-

cates fuel line is not properly installed to fuel

rail (or other fuel line). Recheck fuel line con-

nection.

(8) Connect negative cable to battery.

(9) Start engine and check for leaks.

FUEL PRESSURE REGULATOR

DESCRIPTION

The fuel pressure regulator is located on the bot-

tom of the upper section of the fuel pump module.

The fuel filteris not combinedinto the pressure

regulator on this model.

Fig. 17 LATCH CLIP-TYPE 2

1 - LATCH CLIP

Fig. 18 FUEL LINE DISCONNECTION USING

SPECIAL TOOL

1 - SPECIAL FUEL LINE TOOL

2 - FUEL LINE

3 - FUEL RAIL

KJFUEL DELIVERY 14 - 13

QUICK CONNECT FITTING (Continued)

Page 1396 of 1803

OPERATION

The fuel pressure regulator is a mechanical device

that is not controlled by engine vacuum or the Pow-

ertrain Control Module (PCM).

The regulator is calibrated to maintain fuel system

operating pressure of approximately 339 kPa +/- 34

kPa (49.2 psi +/- 5 psi) at the fuel injectors. It con-

tains a diaphragm, calibrated springs and a fuel

return valve.

The main fuel filteris not combinedwithin the

fuel pressure regulator as in other Jeeptmodels.

Three different fuel filters are used: 1. a serviceable,

separate, externally mounted, main fuel filter; 2. a

non-serviceable primary filter located on the bottom

of the electric fuel pump; 3. a non-serviceable second-

ary filter attached to the side of the fuel pump mod-

ule.

Fuel Flow:Fuel migrates into the fuel pump mod-

ule reservoir through a one-way check valve located

on the bottom of the module. This check valve pre-

vents the reservoir from running empty such as

when going up or down hills with a low amount of

fuel in the tank. A primary fuel filter (sock) is located

at the bottom of the electric fuel pump. Fuel is drawn

in through this filter, and up to the electric fuel

pump. High pressure fuel (unregulated) is supplied

from the electric fuel pump through a high-pressure

line to one of 3 fittings on the main fuel filter. If fuel

pressure at the pressure regulator exceeds approxi-

mately 49 psi, an internal diaphragm within the reg-

ulator closes, and excess fuel is routed through a

second fitting on the main fuel filter, and back into

the fuel tank (the fuel pressure regulator is installed

into the return side of the system). Pressure regu-

lated fuel is then delivered from the third fitting on

the fuel filter, up to and through the fuel rail, and on

to the fuel injectors.

A secondary fuel filter is attached to the side of the

fuel pump module. High-pressure from the electric

fuel pump causes a siphoning action across a passage

connected to this filter, and fuel is drawn into the

fuel pump module reservoir. This is used to help keep

the module reservoir full of fuel.

The fuel pressure regulator also acts as a check

valve to maintain some fuel pressure when the

engine is not operating. This will help to start the

engine. A second check valve is located at the outlet

of the fuel pump module housing.Refer to Fuel

Pump - Description and Operation for more

information. Also refer to the Fuel Pressure

Leak Down Test, and the Fuel Pump Pressure

Tests.

A separate fuel return line from the engine is not

used with this system.

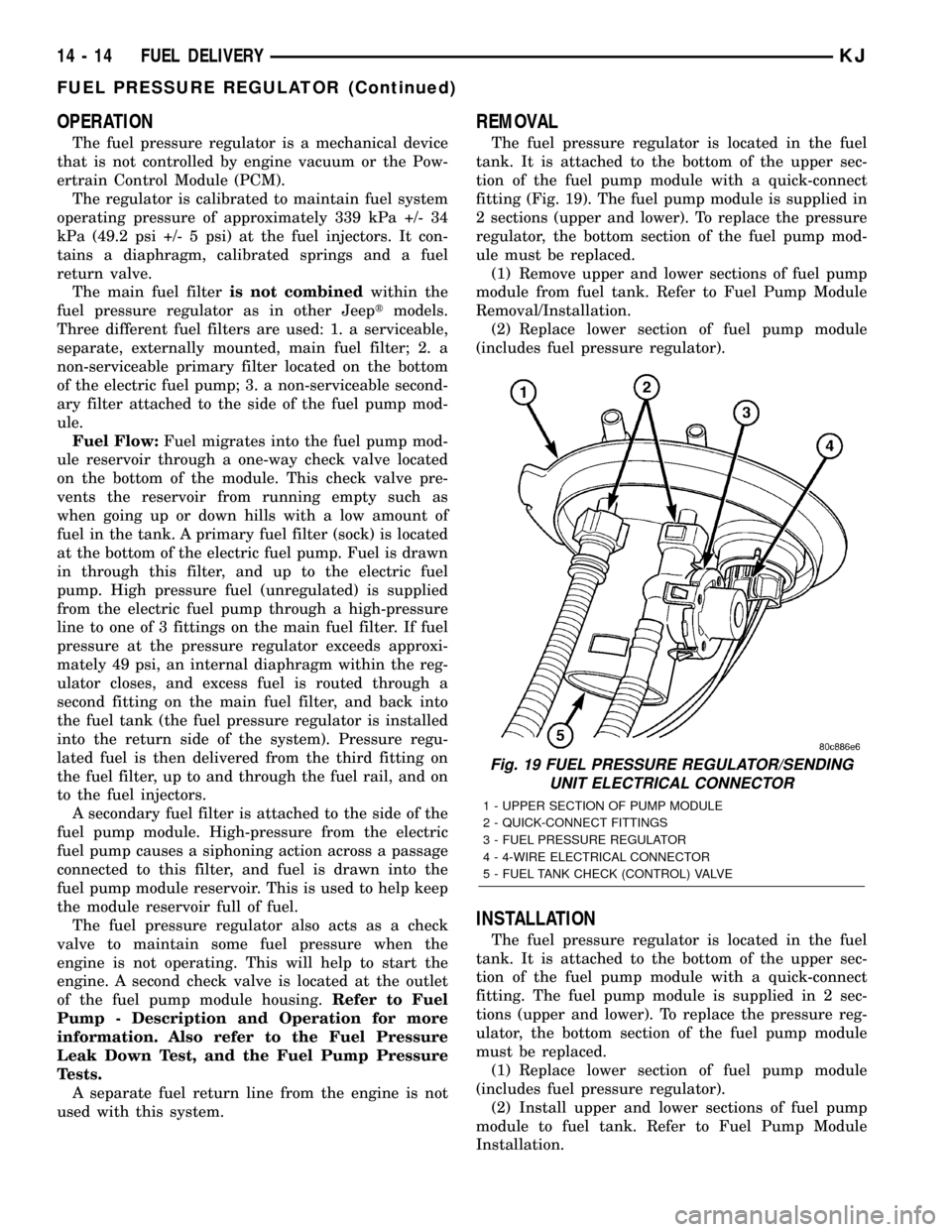

REMOVAL

The fuel pressure regulator is located in the fuel

tank. It is attached to the bottom of the upper sec-

tion of the fuel pump module with a quick-connect

fitting (Fig. 19). The fuel pump module is supplied in

2 sections (upper and lower). To replace the pressure

regulator, the bottom section of the fuel pump mod-

ule must be replaced.

(1) Remove upper and lower sections of fuel pump

module from fuel tank. Refer to Fuel Pump Module

Removal/Installation.

(2) Replace lower section of fuel pump module

(includes fuel pressure regulator).

INSTALLATION

The fuel pressure regulator is located in the fuel

tank. It is attached to the bottom of the upper sec-

tion of the fuel pump module with a quick-connect

fitting. The fuel pump module is supplied in 2 sec-

tions (upper and lower). To replace the pressure reg-

ulator, the bottom section of the fuel pump module

must be replaced.

(1) Replace lower section of fuel pump module

(includes fuel pressure regulator).

(2) Install upper and lower sections of fuel pump

module to fuel tank. Refer to Fuel Pump Module

Installation.

Fig. 19 FUEL PRESSURE REGULATOR/SENDING

UNIT ELECTRICAL CONNECTOR

1 - UPPER SECTION OF PUMP MODULE

2 - QUICK-CONNECT FITTINGS

3 - FUEL PRESSURE REGULATOR

4 - 4-WIRE ELECTRICAL CONNECTOR

5 - FUEL TANK CHECK (CONTROL) VALVE

14 - 14 FUEL DELIVERYKJ

FUEL PRESSURE REGULATOR (Continued)

Page 1397 of 1803

FUEL PUMP

DESCRIPTION

The electric fuel pump is located inside of the fuel

pump module. A 12 volt, permanent magnet, electric

motor powers the fuel pump. The electric fuel pump

is not a separate, serviceable component.

OPERATION

Voltage to operate the electric pump is supplied

through the fuel pump relay.

Fuel is drawn in through a filter at the bottom of

the module and pushed through the electric motor

gearset to the pump outlet.

Check Valve Operation:The bottom section of

the fuel pump module contains a one-way check

valve to prevent fuel flow back into the tank and to

maintain fuel supply line pressure (engine warm)

when pump is not operational. It is also used to keep

the fuel supply line full of gasoline when pump is not

operational. After the vehicle has cooled down, fuel

pressure may drop to 0 psi (cold fluid contracts), but

liquid gasoline will remain in fuel supply line

between the check valve and fuel injectors.Fuel

pressure that has dropped to 0 psi on a cooled

down vehicle (engine off) is a normal condition.

Refer to the Fuel Pressure Leak Down Test for more

information.

The electric fuel pump is not a separate, service-

able component.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - FUEL PUMP

CAPACITY TEST

Before performing this test, verify fuel pump

pressure. Refer to Fuel Pump Pressure Test.

Use this test in conjunction with the Fuel Pres-

sure Leak Down Test.

(1) Release fuel system pressure. Refer to Fuel

Pressure Release Procedure.

(2) Disconnect fuel supply line at fuel rail. Refer to

Quick-Connect Fittings. Some engines may require

air cleaner housing removal before line disconnection.

(3) Obtain correct Fuel Line Pressure Test Adapter

Tool Hose. Tool number 6539 is used for 5/16º fuel

lines and tool number 6631 is used for 3/8º fuel lines.

(4) Connect correct Fuel Line Pressure Test

Adapter Tool Hose into disconnected fuel supply line.

Insert other end of Adaptor Tool Hose into a gradu-

ated container.

(5) Remove fuel fill cap.(6) To activate fuel pump and pressurize system,

obtain DRBtscan tool and actuate ASD Fuel System

Test.

(7) A good fuel pump will deliver at least 1/10 liter

of fuel in 7 seconds. Do not operate fuel pump for

longer than 7 seconds with fuel line disconnected as

fuel pump module reservoir may run empty.

(a) If capacity is lower than specification, but

fuel pump can be heard operating through fuel fill

cap opening, check for a kinked/damaged fuel sup-

ply line somewhere between fuel rail and fuel

pump module.

(b) If line is not kinked/damaged, and fuel pres-

sure is OK, but capacity is low, replace fuel filter.

Refer to Fuel Filter Removal/Installation for addi-

tional information.

(c) If both fuel pressure and capacity are low,

replace bottom section of fuel pump module. Refer

to Fuel Pump Module Removal/Installation.

DIAGNOSIS AND TESTING - FUEL PUMP

PRESSURE TEST

Use this test in conjunction with the Fuel Pump

Capacity Test, Fuel Pressure Leak Down Test and

Fuel Pump Amperage Test found elsewhere in this

group.

Check Valve Operation:The bottom section of

the fuel pump module contains a one-way check

valve to prevent fuel flow back into the tank and to

maintain fuel supply line pressure (engine warm)

when pump is not operational. It is also used to keep

the fuel supply line full of gasoline when pump is not

operational. After the vehicle has cooled down, fuel

pressure may drop to 0 psi (cold fluid contracts), but

liquid gasoline will remain in fuel supply line

between the check valve and fuel injectors.Fuel

pressure that has dropped to 0 psi on a cooled

down vehicle (engine off) is a normal condition.

When the electric fuel pump is activated, fuel pres-

sure shouldimmediately(1±2 seconds) rise to spec-

ification.

The fuel system is equipped with a separate fuel

pump module mounted, fuel pressure regulator. The

fuel filter is remotely mounted. The fuel pressure

regulator is not controlled by engine vacuum.

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT FUEL PRESSURE EVEN WITH THE ENGINE

OFF. BEFORE DISCONNECTING FUEL LINE AT

FUEL RAIL, THIS PRESSURE MUST BE RELEASED.

REFER TO THE FUEL SYSTEM PRESSURE

RELEASE PROCEDURE.

KJFUEL DELIVERY 14 - 15

Page 1398 of 1803

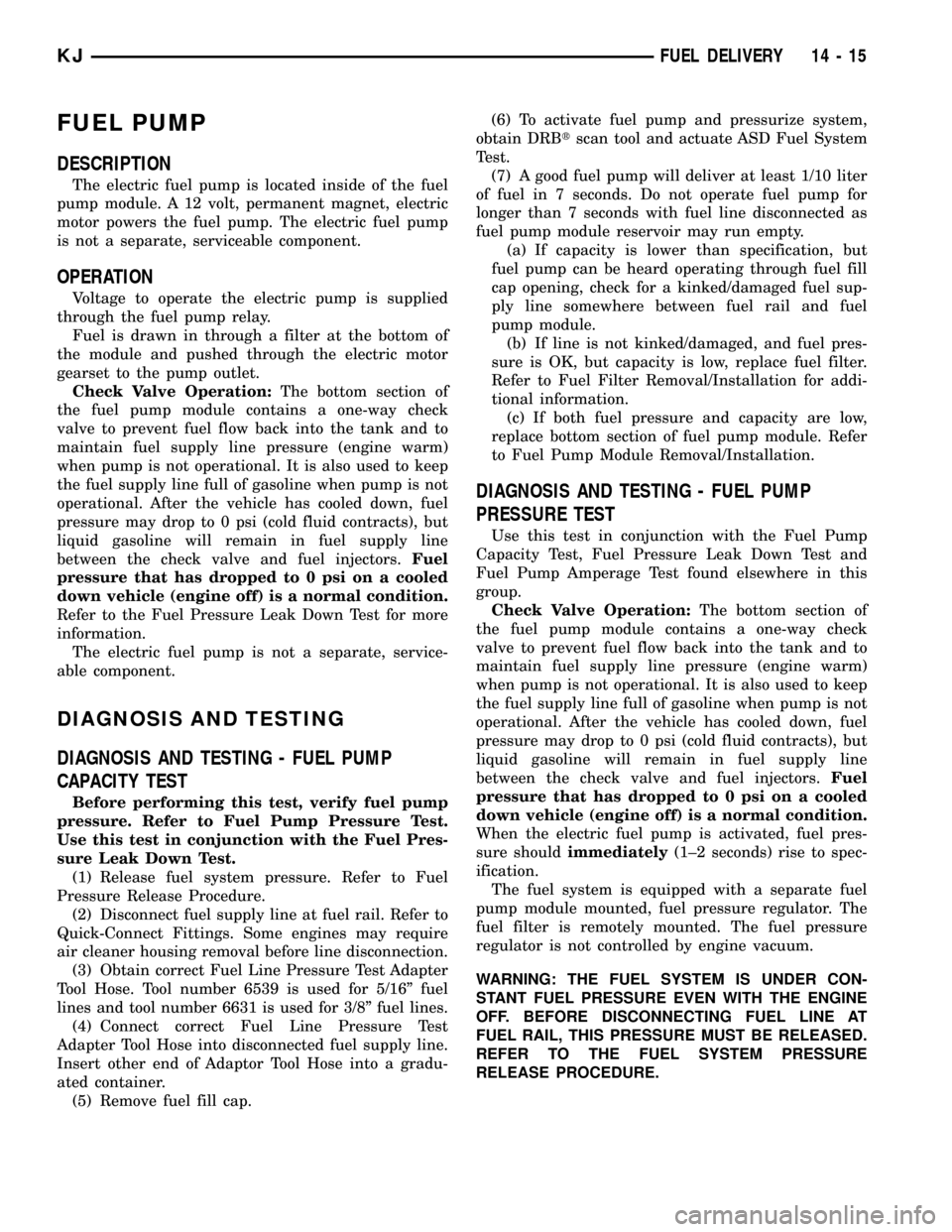

(1) Remove protective cap at fuel rail test port.

Connect the 0±414 kPa (0-60 psi) fuel pressure gauge

(from gauge set 5069) to test port pressure fitting on

fuel rail (Fig. 20).The DRBtIII Scan Tool along

with the PEP module, the 500 psi pressure

transducer, and the transducer-to-test port

adapter may also be used in place of the fuel

pressure gauge.

(2) Start and warm engine and note pressure

gauge reading. Fuel pressure should be 339 kPa 34

kPa (49.2 psi 5 psi) at idle.

(3) If engine runs, but pressure is below 44.2 psi,

check for a kinked fuel supply line somewhere

between fuel rail and fuel pump module. If line is not

kinked, but specifications for either the Fuel Pump

Capacity, Fuel Pump Amperage or Fuel Pressure

Leak Down Tests were not met, replace lower section

of fuel pump module. Refer to Fuel Pump Module

Removal/Installation.

(4) If operating pressure is above 54.2 psi, electric

fuel pump is OK, but fuel pressure regulator is defec-

tive. Replace lower section of fuel pump module.

Refer to Fuel Pump Module Removal/Installation.

(5) Install protective cap to fuel rail test port.

DIAGNOSIS AND TESTING - FUEL PUMP

AMPERAGE TEST

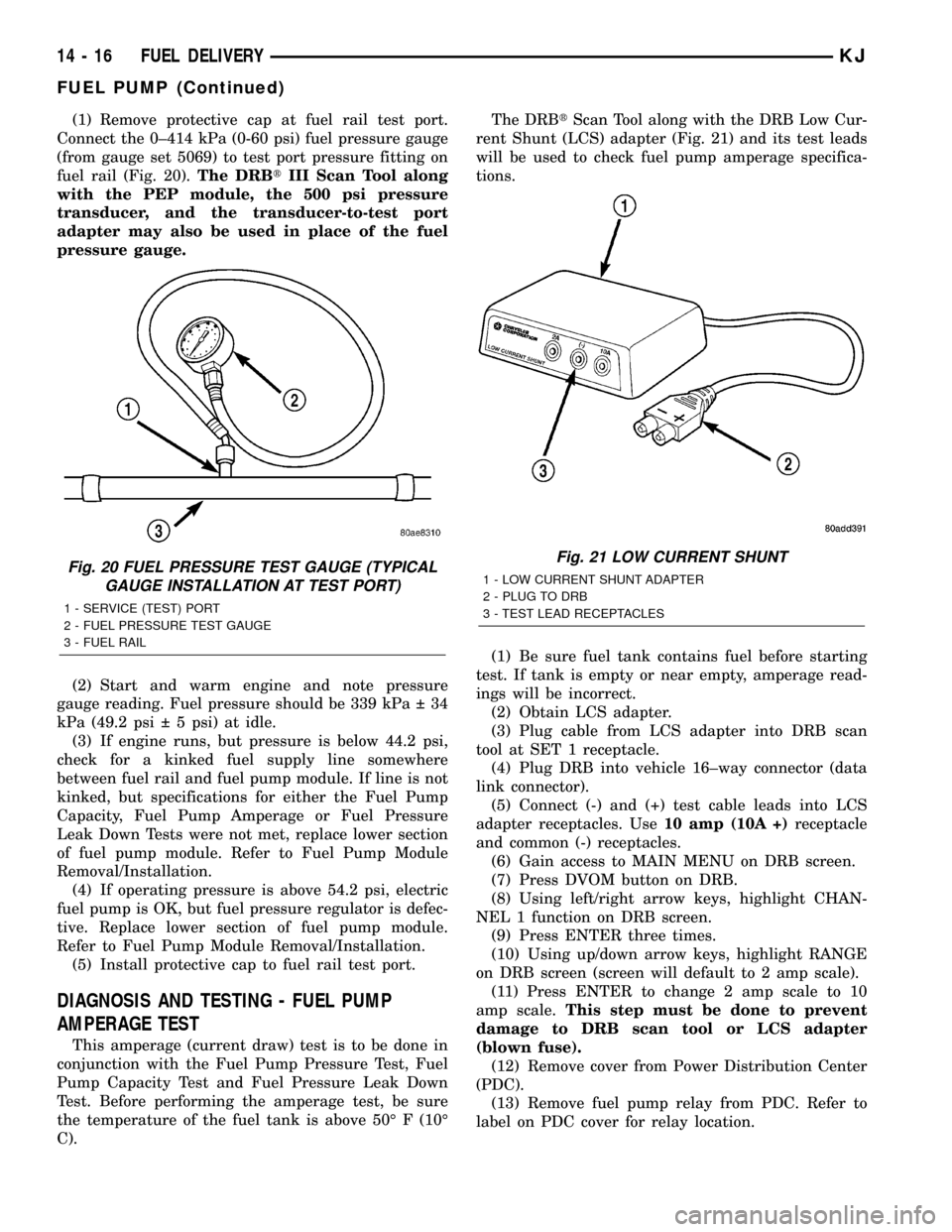

This amperage (current draw) test is to be done in

conjunction with the Fuel Pump Pressure Test, Fuel

Pump Capacity Test and Fuel Pressure Leak Down

Test. Before performing the amperage test, be sure

the temperature of the fuel tank is above 50É F (10É

C).The DRBtScan Tool along with the DRB Low Cur-

rent Shunt (LCS) adapter (Fig. 21) and its test leads

will be used to check fuel pump amperage specifica-

tions.

(1) Be sure fuel tank contains fuel before starting

test. If tank is empty or near empty, amperage read-

ings will be incorrect.

(2) Obtain LCS adapter.

(3) Plug cable from LCS adapter into DRB scan

tool at SET 1 receptacle.

(4) Plug DRB into vehicle 16±way connector (data

link connector).

(5) Connect (-) and (+) test cable leads into LCS

adapter receptacles. Use10 amp (10A +)receptacle

and common (-) receptacles.

(6) Gain access to MAIN MENU on DRB screen.

(7) Press DVOM button on DRB.

(8) Using left/right arrow keys, highlight CHAN-

NEL 1 function on DRB screen.

(9) Press ENTER three times.

(10) Using up/down arrow keys, highlight RANGE

on DRB screen (screen will default to 2 amp scale).

(11) Press ENTER to change 2 amp scale to 10

amp scale.This step must be done to prevent

damage to DRB scan tool or LCS adapter

(blown fuse).

(12) Remove cover from Power Distribution Center

(PDC).

(13) Remove fuel pump relay from PDC. Refer to

label on PDC cover for relay location.

Fig. 20 FUEL PRESSURE TEST GAUGE (TYPICAL

GAUGE INSTALLATION AT TEST PORT)

1 - SERVICE (TEST) PORT

2 - FUEL PRESSURE TEST GAUGE

3 - FUEL RAIL

Fig. 21 LOW CURRENT SHUNT

1 - LOW CURRENT SHUNT ADAPTER

2 - PLUG TO DRB

3 - TEST LEAD RECEPTACLES

14 - 16 FUEL DELIVERYKJ

FUEL PUMP (Continued)

Page 1399 of 1803

WARNING: BEFORE PROCEEDING TO NEXT STEP,

NOTE THE FUEL PUMP WILL BE ACTIVATED AND

SYSTEM PRESSURE WILL BE PRESENT. THIS WILL

OCCUR AFTER CONNECTING TEST LEADS FROM

LCS ADAPTER INTO FUEL PUMP RELAY CAVITIES.

THE FUEL PUMP WILL OPERATE EVEN WITH IGNI-

TION KEY IN OFF POSITION. BEFORE ATTACHING

TEST LEADS, BE SURE ALL FUEL LINES AND

FUEL SYSTEM COMPONENTS ARE CONNECTED.

CAUTION: To prevent possible damage to the vehi-

cle electrical system and LCS adapter, the test

leads must be connected into relay cavities exactly

as shown in following steps.

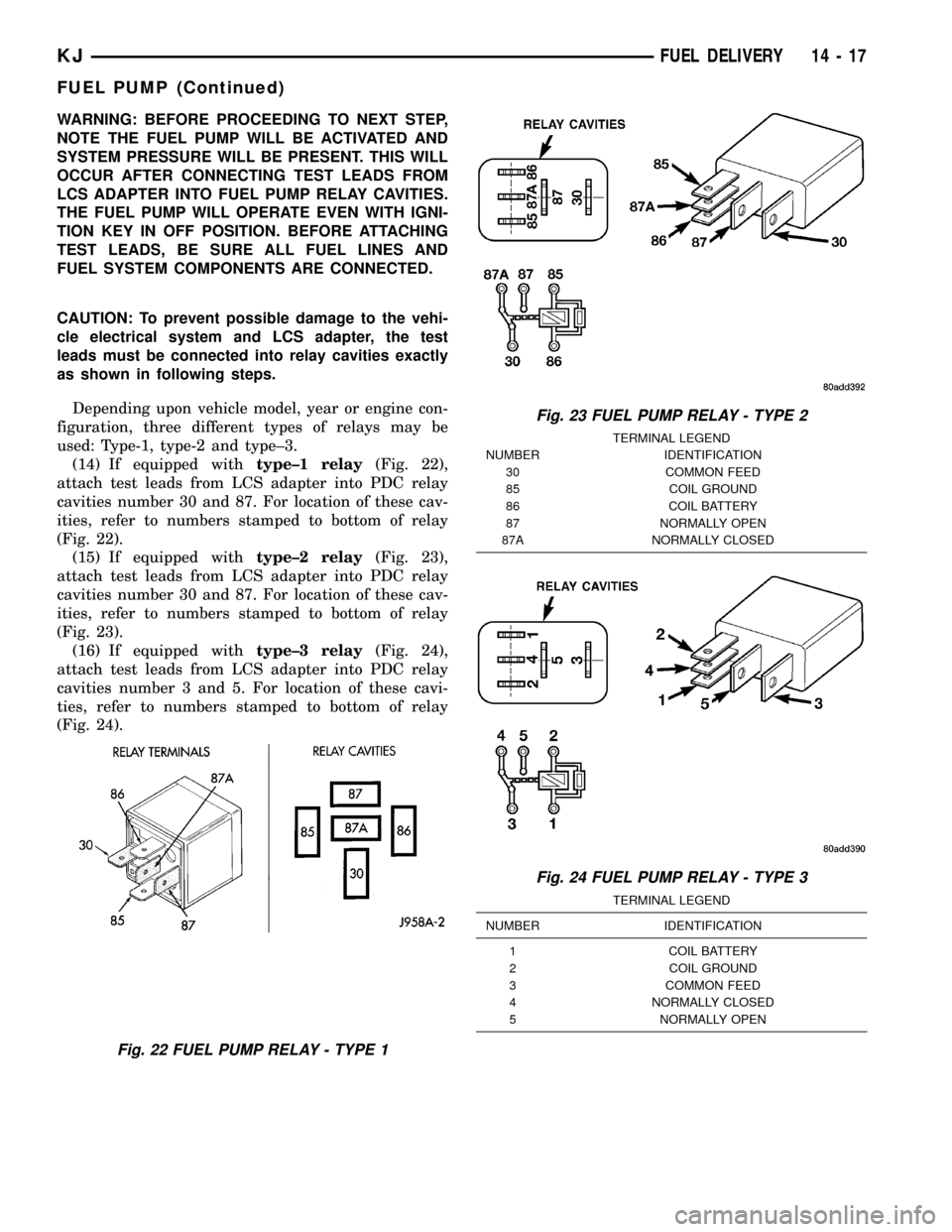

Depending upon vehicle model, year or engine con-

figuration, three different types of relays may be

used: Type-1, type-2 and type±3.

(14) If equipped withtype±1 relay(Fig. 22),

attach test leads from LCS adapter into PDC relay

cavities number 30 and 87. For location of these cav-

ities, refer to numbers stamped to bottom of relay

(Fig. 22).

(15) If equipped withtype±2 relay(Fig. 23),

attach test leads from LCS adapter into PDC relay

cavities number 30 and 87. For location of these cav-

ities, refer to numbers stamped to bottom of relay

(Fig. 23).

(16) If equipped withtype±3 relay(Fig. 24),

attach test leads from LCS adapter into PDC relay

cavities number 3 and 5. For location of these cavi-

ties, refer to numbers stamped to bottom of relay

(Fig. 24).

Fig. 22 FUEL PUMP RELAY - TYPE 1

Fig. 23 FUEL PUMP RELAY - TYPE 2

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

Fig. 24 FUEL PUMP RELAY - TYPE 3

TERMINAL LEGEND

NUMBER IDENTIFICATION

1 COIL BATTERY

2 COIL GROUND

3 COMMON FEED

4 NORMALLY CLOSED

5 NORMALLY OPEN

KJFUEL DELIVERY 14 - 17

FUEL PUMP (Continued)

Page 1400 of 1803

(17) When LCS adapter test leads are attached

into relay cavities, fuel pumpwill be activated.

Determine fuel pump amperage on DRB screen.

Amperage should be below 10.0 amps. If amperage is

below 10.0 amps, and specifications for the Fuel

Pump Pressure, Fuel Pump Capacity and Fuel Pres-

sure Leak Down tests were met, the fuel pump mod-

ule is OK.

(18) If amperage is more than 10.0 amps, replace

fuel pump module assembly. The electric fuel pump

is not serviced separately.

(19) Disconnect test leads from relay cavities

immediately after testing.

FUEL PUMP MODULE

DESCRIPTION

The fuel pump module assembly is located in the

fuel tank (Fig. 1). The assembly is divided into 2±sec-

tions, upper and lower. The lower section is locked to

the bottom of the fuel tank. The complete assembly

contains the following components:

²A fuel pressure regulator

²A separate fuel pick-up, or inlet filter

²An electric fuel pump

²A lockring to retain upper section of pump mod-

ule to tank

²A rollover valve

²A vent fitting for ORVR system

²A soft gasket between tank flange and module

²A fuel gauge sending unit (fuel level sensor)

²Two fuel line connections (supply and return)

The fuel gauge sending unit may be serviced sepa-

rately. If the electrical fuel pump, primary inlet filter

or fuel pressure regulator require service, the lower

section of the fuel pump module must be replaced.

OPERATION

Refer to Fuel Pump, Inlet Filter, Fuel Pressure

Regulator and Fuel Gauge Sending Unit.

REMOVAL

The fuel pump module is divided into 2 sections,

upper and lower. To service the check (control) valve,

replace only the upper section. To service the fuel

gauge sending unit, remove the upper section. To ser-

vice the electric fuel pump, fuel pressure regulator or

primary inlet filter, remove both sections and replace

lower section.

Fuel tank removal will not be necessary for

fuel pump module removal. Access is from rear

cargo area.

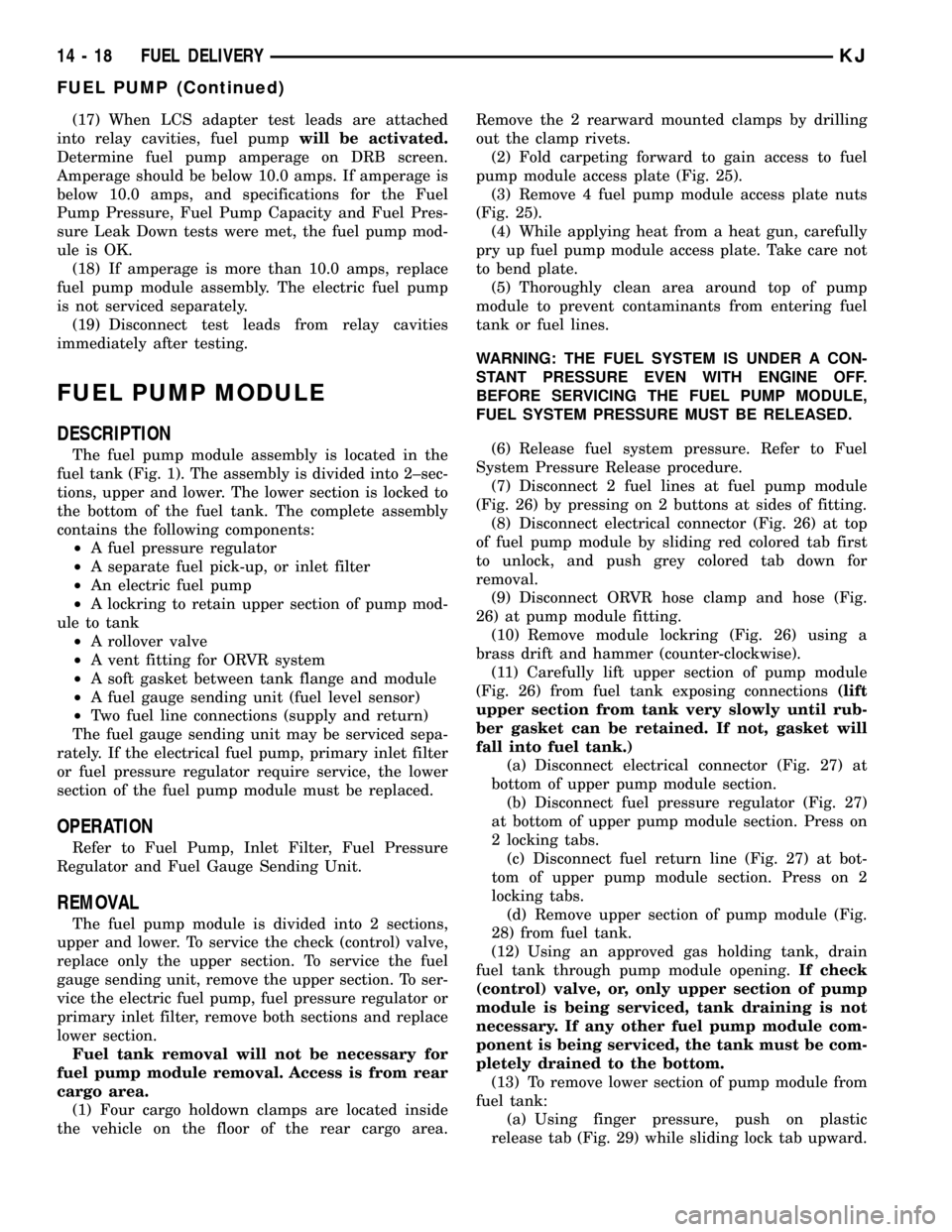

(1) Four cargo holdown clamps are located inside

the vehicle on the floor of the rear cargo area.Remove the 2 rearward mounted clamps by drilling

out the clamp rivets.

(2) Fold carpeting forward to gain access to fuel

pump module access plate (Fig. 25).

(3) Remove 4 fuel pump module access plate nuts

(Fig. 25).

(4) While applying heat from a heat gun, carefully

pry up fuel pump module access plate. Take care not

to bend plate.

(5) Thoroughly clean area around top of pump

module to prevent contaminants from entering fuel

tank or fuel lines.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE EVEN WITH ENGINE OFF.

BEFORE SERVICING THE FUEL PUMP MODULE,

FUEL SYSTEM PRESSURE MUST BE RELEASED.

(6) Release fuel system pressure. Refer to Fuel

System Pressure Release procedure.

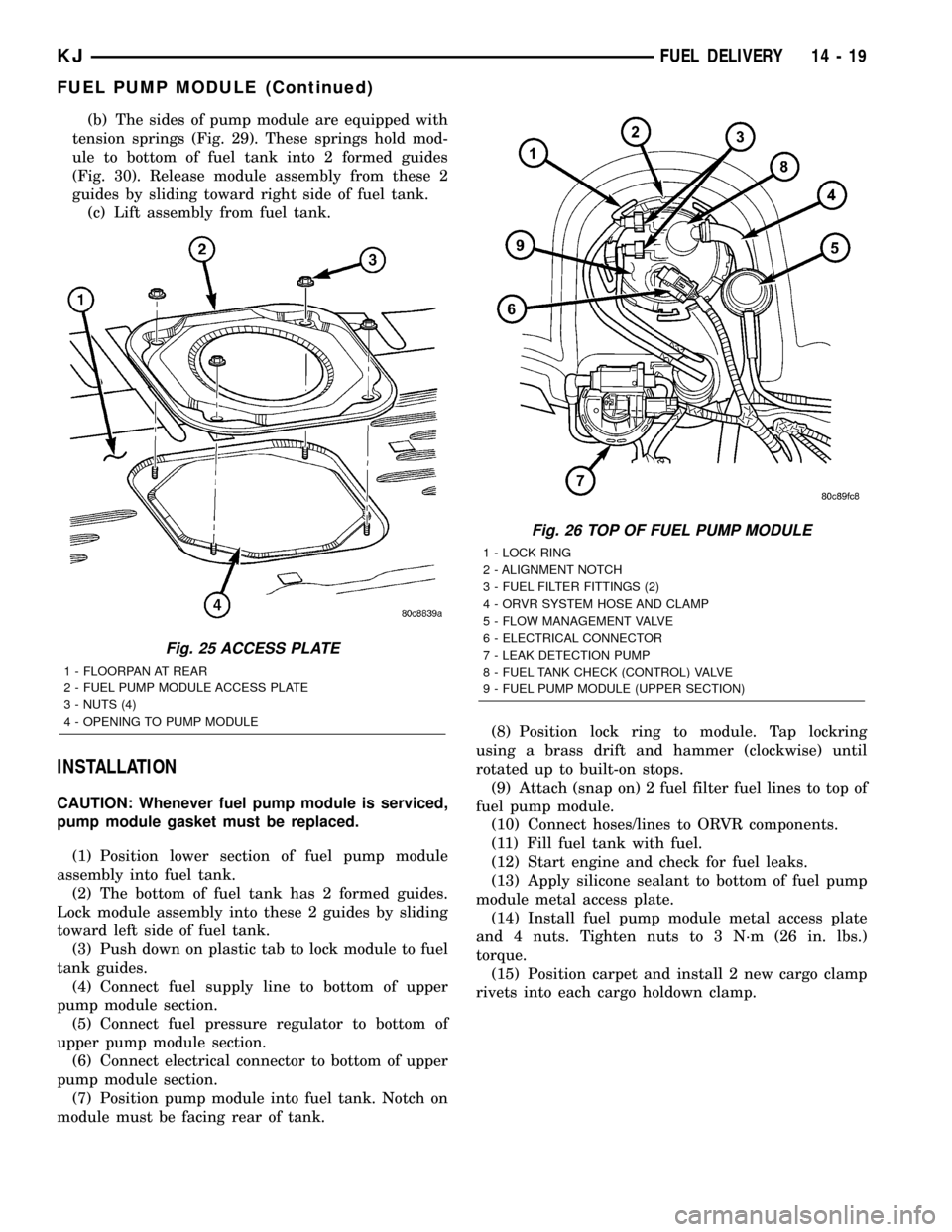

(7) Disconnect 2 fuel lines at fuel pump module

(Fig. 26) by pressing on 2 buttons at sides of fitting.

(8) Disconnect electrical connector (Fig. 26) at top

of fuel pump module by sliding red colored tab first

to unlock, and push grey colored tab down for

removal.

(9) Disconnect ORVR hose clamp and hose (Fig.

26) at pump module fitting.

(10) Remove module lockring (Fig. 26) using a

brass drift and hammer (counter-clockwise).

(11) Carefully lift upper section of pump module

(Fig. 26) from fuel tank exposing connections(lift

upper section from tank very slowly until rub-

ber gasket can be retained. If not, gasket will

fall into fuel tank.)

(a) Disconnect electrical connector (Fig. 27) at

bottom of upper pump module section.

(b) Disconnect fuel pressure regulator (Fig. 27)

at bottom of upper pump module section. Press on

2 locking tabs.

(c) Disconnect fuel return line (Fig. 27) at bot-

tom of upper pump module section. Press on 2

locking tabs.

(d) Remove upper section of pump module (Fig.

28) from fuel tank.

(12) Using an approved gas holding tank, drain

fuel tank through pump module opening.If check

(control) valve, or, only upper section of pump

module is being serviced, tank draining is not

necessary. If any other fuel pump module com-

ponent is being serviced, the tank must be com-

pletely drained to the bottom.

(13) To remove lower section of pump module from

fuel tank:

(a) Using finger pressure, push on plastic

release tab (Fig. 29) while sliding lock tab upward.

14 - 18 FUEL DELIVERYKJ

FUEL PUMP (Continued)

Page 1401 of 1803

(b) The sides of pump module are equipped with

tension springs (Fig. 29). These springs hold mod-

ule to bottom of fuel tank into 2 formed guides

(Fig. 30). Release module assembly from these 2

guides by sliding toward right side of fuel tank.

(c) Lift assembly from fuel tank.

INSTALLATION

CAUTION: Whenever fuel pump module is serviced,

pump module gasket must be replaced.

(1) Position lower section of fuel pump module

assembly into fuel tank.

(2) The bottom of fuel tank has 2 formed guides.

Lock module assembly into these 2 guides by sliding

toward left side of fuel tank.

(3) Push down on plastic tab to lock module to fuel

tank guides.

(4) Connect fuel supply line to bottom of upper

pump module section.

(5) Connect fuel pressure regulator to bottom of

upper pump module section.

(6) Connect electrical connector to bottom of upper

pump module section.

(7) Position pump module into fuel tank. Notch on

module must be facing rear of tank.(8) Position lock ring to module. Tap lockring

using a brass drift and hammer (clockwise) until

rotated up to built-on stops.

(9) Attach (snap on) 2 fuel filter fuel lines to top of

fuel pump module.

(10) Connect hoses/lines to ORVR components.

(11) Fill fuel tank with fuel.

(12) Start engine and check for fuel leaks.

(13) Apply silicone sealant to bottom of fuel pump

module metal access plate.

(14) Install fuel pump module metal access plate

and 4 nuts. Tighten nuts to 3 N´m (26 in. lbs.)

torque.

(15) Position carpet and install 2 new cargo clamp

rivets into each cargo holdown clamp.

Fig. 25 ACCESS PLATE

1 - FLOORPAN AT REAR

2 - FUEL PUMP MODULE ACCESS PLATE

3 - NUTS (4)

4 - OPENING TO PUMP MODULE

Fig. 26 TOP OF FUEL PUMP MODULE

1 - LOCK RING

2 - ALIGNMENT NOTCH

3 - FUEL FILTER FITTINGS (2)

4 - ORVR SYSTEM HOSE AND CLAMP

5 - FLOW MANAGEMENT VALVE

6 - ELECTRICAL CONNECTOR

7 - LEAK DETECTION PUMP

8 - FUEL TANK CHECK (CONTROL) VALVE

9 - FUEL PUMP MODULE (UPPER SECTION)

KJFUEL DELIVERY 14 - 19

FUEL PUMP MODULE (Continued)