maintenance schedule JEEP WRANGLER 2015 JK / 3.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2015, Model line: WRANGLER, Model: JEEP WRANGLER 2015 JK / 3.GPages: 695, PDF Size: 20.64 MB

Page 594 of 695

Engine Air Cleaner Filter Inspection and

Replacement — Gasoline Engine

Follow the recommended maintenance intervals as

shown in the Maintenance Schedule.

Engine Air Cleaner Filter Removal

1. Remove the bolts from the air cleaner intake tube.

2. Remove air hose and loosen clean air hose clamp then

release the spring clips on the air intake cover.

Air Cleaner Filter Cover

1—SpringClips

2—AirHose3 — Clean Air Hose Clamp4 — Clean Air Intake Tube Bolts5 — Air Cleaner Filter Cover6—CleanAirIntakeTube

592 MAINTAINING YOUR VEHICLE

Page 603 of 695

7. Install the A/C air filter with the air filter position

indicators pointing in the same direction as removal.

CAUTION!

The A/C air filter is identified with an arrow to

indicate airflow direction through the filter. Failure

to properly install the filter will result in the need to

replace it more often.

8. Close A/C Air Filter access doors and secure retaining

tabs.

9. Rotate the glove compartment door back into position.

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

Body Lubrication

Locks and all body pivot points, including such items as

seat tracks, door hinge pivot points and rollers, liftgate,

tailgate, decklid, sliding doors and hood hinges, should

be lubricated periodically with a lithium based grease,

such as MOPAR® Spray White Lube to assure quiet, easy

Air Filter Access Door Open

1—AirConditioningFilterAccessDoor2 — Air Conditioning Air Filter

7

MAINTAINING YOUR VEHICLE 601

Page 614 of 695

Engine Coolant Checks

Check the engine coolant (antifreeze) protection every 12

months (before the onset of freezing weather, where

applicable). If the engine coolant (antifreeze) is dirty or

rusty in appearance, the system should be drained,

flushed and refilled with fresh engine coolant (anti-

freeze). Check the front of the A/C condenser (if

equipped) or radiator for any accumulation of bugs,

leaves, etc. If dirty, clean by gently spraying water from a

garden hose vertically down the face of the A/C con-

denser (if equipped) or the back of the radiator core.

Check the engine cooling system hoses for brittle rubber,

cracking, tears, cuts, and tightness of the connection at

the coolant recovery bottle and radiator. Inspect the

entire system for leaks.

With the engine at normal operating temperature (but

not running), check the cooling system pressure cap for

proper vacuum sealing by draining a small amount of

engine coolant (antifreeze) from the radiator drain cock.

If the cap is sealing properly, the engine coolant (anti-

freeze) will begin to drain from the coolant recovery

bottle. DO NOT REMOVE THE COOLANT PRESSURE

CAP WHEN THE COOLING SYSTEM IS HOT.

Cooling System — Drain, Flush And Refill

NOTE:Some vehicles require special tools to add coolant

properly. Failure to fill these systems properly could lead

to severe internal engine damage. If any coolant is

needed to be added to the system please contact your

local authorized dealer.

If the engine coolant (antifreeze) is dirty or contains visible

sediment, have an authorized dealer clean and flush with

OAT coolant (antifreeze) (conforming to MS-12106).

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

612 MAINTAINING YOUR VEHICLE

Page 619 of 695

If an examination of your engine compartment shows no

evidence of radiator or hose leaks, the vehicle may be

safely driven. The vapor will soon dissipate.

•Do not overfill the coolant expansion bottle.

•Check the coolant freeze point in the radiator and in

the coolant expansion bottle. If engine coolant (anti-

freeze) needs to be added, the contents of the coolant

expansion bottle must also be protected against freez-

ing.

•If frequent engine coolant (antifreeze) additions are

required, the cooling system should be pressure tested

for leaks.

•Maintain engine coolant (antifreeze) concentration

at a minimum of 50% OAT coolant (conforming to

MS-12106) and distilled water for proper corrosion

protection of your engine which contains aluminum

components.

•Make sure that the coolant expansion bottle overflow

hoses are not kinked or obstructed.

•Keep the front of the radiator clean. If your vehicle is

equipped with air conditioning, keep the front of the

condenser clean.

•Do not change the thermostat for Summer or Winter

operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory engine coolant (antifreeze)

performance, poor gas mileage, and increased emis-

sions.

Brake System

In order to assure brake system performance, all brake

system components should be inspected periodically.

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

7

MAINTAINING YOUR VEHICLE 617

Page 624 of 695

NOTE:

•The holes in the dipstick will be full of fluid if the

actual level is at or above the hole.

•If it is necessary to check the transmission below the

operating temperature, the fluid level should be

between the two COLD (lower) holes on the dipstick

with the fluid at approximately 80° F (27° C). If the

fluid level is correctly established at 80° F (27° C), it

should be between the HOT (upper) reference holes

when the transmission reaches 180° F (82° C). Re-

member it is best to check the level at the normal

operating temperature.

CAUTION!

If the fluid temperature is below 50°F (10°C) it may

not register on the dipstick. Do not add fluid until

(Continued)

CAUTION!(Continued)

the temperature is elevated enough to produce an

accurate reading. Run the engine at idle, in PARK, to

warm the fluid.

8. Reinstall the engine cover and snap it down securely

onto the four mounting studs.

9. Check for leaks. Release the parking brake.

NOTE:To prevent dirt and water from entering the

transmission after checking or replenishing fluid, make

sure that the dipstick cap is properly reseated. It is

normal for the dipstick cap to spring back slightly from

its fully seated position, as long as its seal remains

engaged in the dipstick tube.

Fluid And Filter Changes

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

622 MAINTAINING YOUR VEHICLE

Page 625 of 695

In addition, change the fluid and filter if the fluid

becomes contaminated (with water, etc.), or if the trans-

mission is disassembled for any reason.

Clutch Hydraulic System (Manual Transmission) —

If Equipped

The clutch hydraulic system is fed by a segregated

volume of fluid within the brake system master cylinder

reservoir. In the event of leakage or wear, use only the

manufacturer’s recommended brake fluid. Refer to “Flu-

ids, Lubricants, and Genuine Parts” in “Maintaining Your

Vehicle” for further information.

Manual Transmission — If Equipped

Selection Of Lubricant

Use only manufacturer’s recommended manual trans-

mission fluid. Refer to “Fluids, Lubricants, and Genuine

Parts” in “Maintaining Your Vehicle” for further informa-

tion.

Fluid Level Check

Check the fluid level by removing the fill plug. The fluid

level should be between the bottom of the fill hole and a

point not more than 3/16 in (4.76 mm) below the bottom

of the hole.

Add fluid, if necessary, to maintain the proper level.

Frequency Of Fluid Change

Under normal operating conditions, the fluid installed at

the factory will give satisfactory lubrication for the life of

the vehicle. If the fluid becomes contaminated with

water, it should be changed immediately. Otherwise,

change the fluid as recommended in the Maintenance

Schedule. Refer to the “Maintenance Schedule” for the

proper maintenance intervals.

7

MAINTAINING YOUR VEHICLE 623

Page 653 of 695

MAINTENANCE SCHEDULES

CONTENTS

!MAINTENANCE SCHEDULE.............652▫Maintenance Chart.....................654

8

MAINTENANCE

SCHEDULES

Page 654 of 695

MAINTENANCE SCHEDULE

Your vehicle is equipped with an automatic oil change

indicator system. The oil change indicator system will

remind you that it is time to take your vehicle in for

scheduled maintenance.

Based on engine operation conditions, the oil change

indicator message will illuminate. This means that service

is required for your vehicle. Operating conditions such as

frequent short-trips, trailer tow, extremely hot or cold

ambient temperatures, and E85 fuel usage will influence

when the “Change Oil” or “Oil Change Required” message

is displayed. Severe Operating Conditions can cause the

change oil message to illuminate as early as 3,500 miles

(5,600 km) since last reset. Have your vehicle serviced as

soon as possible, within the next 500 miles (805 km).

On Electronic Vehicle Information Center (EVIC) equipped

vehicles, “Oil Change Required” will be displayed in the

EVIC and a single chime will sound, indicating that an oil

change is necessary.

On Non-EVIC equipped vehicles, “Change Oil” will flash

in the instrument cluster odometer and a single chime

will sound, indicating that an oil change is necessary.

Your authorized dealer will reset the oil change indicator

message after completing the scheduled oil change. If a

scheduled oil change is performed by someone other

than your authorized dealer, the message can be reset by

referring to the steps described under “Instrument Clus-

ter Descriptions” or “Electronic Vehicle Information Cen-

ter (EVIC)” in “Understanding Your Instrument Panel”

for further information.

NOTE:Under no circumstances should oil change inter-

vals exceed 10,000 miles (16,000 km) or twelve months,

whichever comes first.

Severe Duty All Models

Change Engine Oil at 4000 miles (6,500 km) if the vehicle

is operated in a dusty and off road environment. This

type of vehicle use is considered Severe Duty

8

MAINTENANCE

SCHEDULES

652 MAINTENANCE SCHEDULES

Page 655 of 695

Once A Month Or Before A Long Trip:

•Check engine oil level

•Check windshield washer fluid level

•Check the tire inflation pressures and look for unusual

wear or damage

•Check the fluid levels of the coolant reservoir, brake

master cylinder, power steering and automatic trans-

mission, and fill as needed

•Check function of all interior and exterior lights

Required Maintenance Intervals.

Refer to the maintenance schedules on the following

page for the required maintenance intervals.

At Every Oil Change Interval As Indicated By Oil

Change Indicator System:

•Change oil and filter

At Every Oil Change Interval As Indicated By Oil

Change Indicator System:

•Rotate the tires.Rotate at the first sign of irregu-

lar wear, even if it occurs before the oil indicator

system turns on.

•Inspect battery and clean and tighten terminals as

required

•Inspect automatic transmission fluid if equipped

with dipstick

•Inspect brake pads, shoes, rotors, drums, hoses

and park brake

•Inspect engine cooling system protection and hoses

•Inspect exhaust system

•Inspect engine air cleaner if using in dusty or

off-road conditions

•Inspect all door latches for presence of grease,

reapply if necessary.

8

MAINTENANCE

SCHEDULES

MAINTENANCE SCHEDULES 653

Page 656 of 695

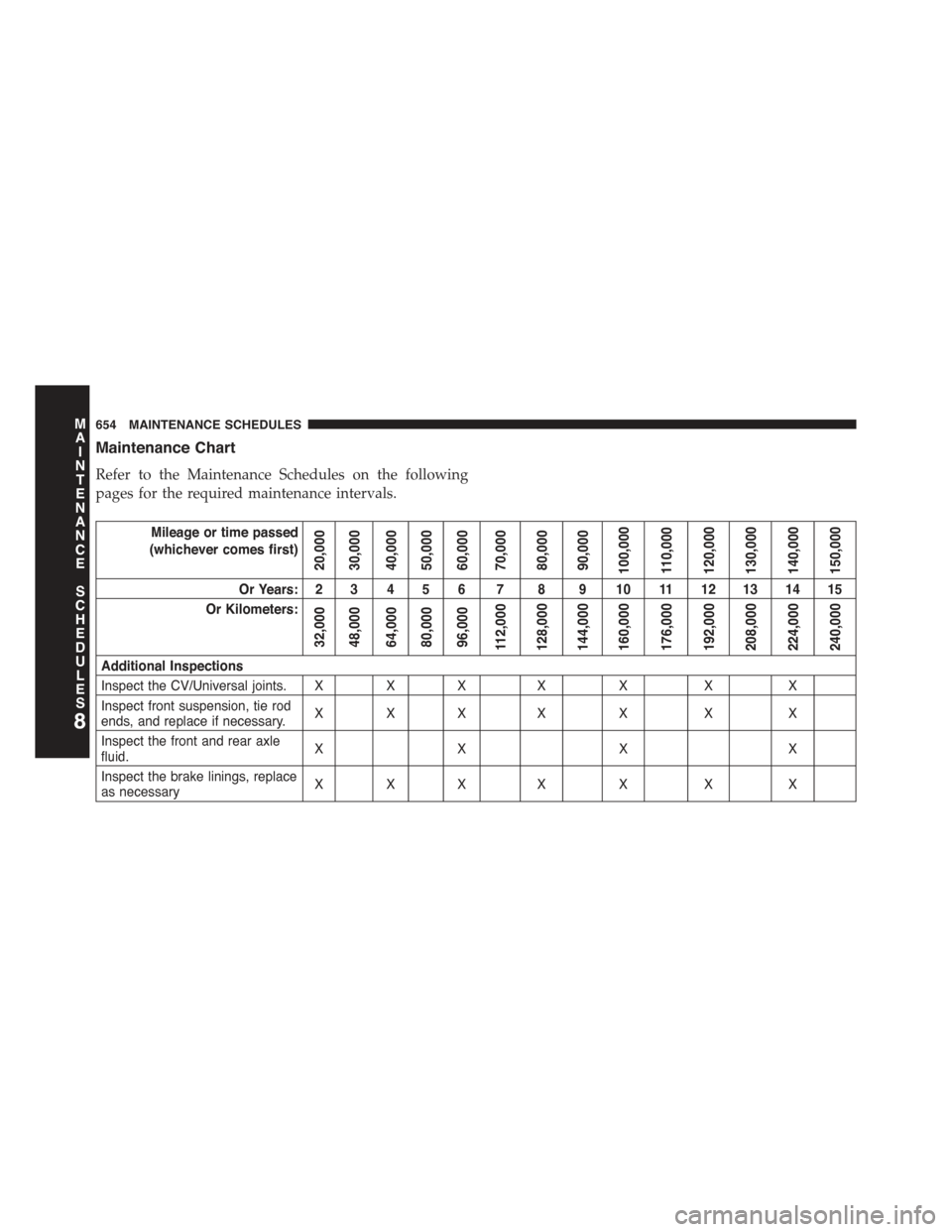

Maintenance Chart

Refer to the Maintenance Schedules on the following

pages for the required maintenance intervals.

Mileage or time passed

(whichever comes first)

20,00030,00040,00050,00060,00070,00080,00090,000100,000110,000120,000130,000140,000150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,00048,00064,00080,00096,000112,000128,000144,000160,000176,000192,000208,000224,000240,000

Additional Inspections

Inspect the CV/Universal joints. X X XXXXX

Inspect front suspension, tie rodends, and replace if necessary.XXX X X X X

Inspect the front and rear axlefluid.XX X X

Inspect the brake linings, replaceas necessaryXXX X X X X

8

MAINTENANCE

SCHEDULES

654 MAINTENANCE SCHEDULES